CN114907033B - A system and method for producing cement clinker and co-producing liquid CO2 by oxy-fuel combustion - Google Patents

A system and method for producing cement clinker and co-producing liquid CO2 by oxy-fuel combustionDownload PDFInfo

- Publication number

- CN114907033B CN114907033BCN202210774521.7ACN202210774521ACN114907033BCN 114907033 BCN114907033 BCN 114907033BCN 202210774521 ACN202210774521 ACN 202210774521ACN 114907033 BCN114907033 BCN 114907033B

- Authority

- CN

- China

- Prior art keywords

- flue gas

- oxygen

- coal

- combustion

- furnace

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B7/00—Hydraulic cements

- C04B7/36—Manufacture of hydraulic cements in general

- C04B7/43—Heat treatment, e.g. precalcining, burning, melting; Cooling

- C04B7/44—Burning; Melting

- C04B7/4407—Treatment or selection of the fuel therefor, e.g. use of hazardous waste as secondary fuel ; Use of particular energy sources, e.g. waste hot gases from other processes

- C—CHEMISTRY; METALLURGY

- C01—INORGANIC CHEMISTRY

- C01B—NON-METALLIC ELEMENTS; COMPOUNDS THEREOF; METALLOIDS OR COMPOUNDS THEREOF NOT COVERED BY SUBCLASS C01C

- C01B32/00—Carbon; Compounds thereof

- C01B32/50—Carbon dioxide

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B7/00—Hydraulic cements

- C04B7/36—Manufacture of hydraulic cements in general

- C04B7/43—Heat treatment, e.g. precalcining, burning, melting; Cooling

- C04B7/44—Burning; Melting

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B7/00—Hydraulic cements

- C04B7/36—Manufacture of hydraulic cements in general

- C04B7/43—Heat treatment, e.g. precalcining, burning, melting; Cooling

- C04B7/44—Burning; Melting

- C04B7/4407—Treatment or selection of the fuel therefor, e.g. use of hazardous waste as secondary fuel ; Use of particular energy sources, e.g. waste hot gases from other processes

- C04B7/4446—Treatment or selection of the fuel therefor, e.g. use of hazardous waste as secondary fuel ; Use of particular energy sources, e.g. waste hot gases from other processes the fuel being treated in a separate gasifying or decomposing chamber, e.g. a separate combustion chamber

- C—CHEMISTRY; METALLURGY

- C04—CEMENTS; CONCRETE; ARTIFICIAL STONE; CERAMICS; REFRACTORIES

- C04B—LIME, MAGNESIA; SLAG; CEMENTS; COMPOSITIONS THEREOF, e.g. MORTARS, CONCRETE OR LIKE BUILDING MATERIALS; ARTIFICIAL STONE; CERAMICS; REFRACTORIES; TREATMENT OF NATURAL STONE

- C04B7/00—Hydraulic cements

- C04B7/36—Manufacture of hydraulic cements in general

- C04B7/43—Heat treatment, e.g. precalcining, burning, melting; Cooling

- C04B7/44—Burning; Melting

- C04B7/4476—Selection of the kiln atmosphere

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P40/00—Technologies relating to the processing of minerals

- Y02P40/10—Production of cement, e.g. improving or optimising the production methods; Cement grinding

- Y02P40/18—Carbon capture and storage [CCS]

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Ceramic Engineering (AREA)

- Organic Chemistry (AREA)

- Structural Engineering (AREA)

- Materials Engineering (AREA)

- Physics & Mathematics (AREA)

- Thermal Sciences (AREA)

- Combustion & Propulsion (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Inorganic Chemistry (AREA)

- Curing Cements, Concrete, And Artificial Stone (AREA)

- Treating Waste Gases (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及水泥烧成技术领域,特别是涉及一种全氧燃烧生产水泥熟料联产液态CO2的系统及方法。The invention relates to the technical field of cement firing, in particular to a system and method for producing cement clinker and co-producing liquidCO2 through oxy-fuel combustion.

背景技术Background technique

化石能源作为全球最主要的能源来源,其消耗过程所带来的巨大CO2排放成为温室效应的重要排放源。我国富煤贫油少气的现状,决定了煤炭在我国一次能源的结构中的比例短期内难以改变。近年来,我国碳排放总量超过美国,成为世界上最大的二氧化碳排放国,碳减排形势非常的严峻。Fossil energy is the most important energy source in the world, and the huge CO2 emission brought by its consumption process has become an important emission source of the greenhouse effect. my country's current situation of rich coal, poor oil and little gas determines that the proportion of coal in my country's primary energy structure is difficult to change in the short term. In recent years, my country's total carbon emissions have surpassed that of the United States, becoming the world's largest carbon dioxide emitter, and the situation of carbon emission reduction is very severe.

全氧燃烧是在现有的工业窑炉系统的基础上,用高纯度的氧代替助燃空气,同时采用烟气循环调节炉膛的介质流量和传热特性,可获得高达80%体积浓度的CO2烟气,从而以较小的代价捕集提纯后实现CO2的永久封存或者资源化利用,实现大规模化工业CO2的富集和减排。已有的分析表明,和其他碳捕获方式相比,全氧燃烧技术在投资成本、运行成本、CO2减排成本、大型化和与现有技术的兼容度等方面都具有优越性。Oxygen combustion is based on the existing industrial kiln system, using high-purity oxygen to replace the combustion-supporting air, and at the same time using flue gas circulation to adjust the medium flow and heat transfer characteristics of the furnace, and can obtain CO2 with a volume concentration of up to 80% The flue gas can be captured and purified at a relatively low cost to achieve permanent sequestration or resource utilization of CO2 , and realize the enrichment and emission reduction of CO2 in large-scale chemical industries. Existing analysis shows that compared with other carbon capture methods, oxyfuel combustion technology has advantages in terms of investment cost, operating cost, CO2 emission reduction cost, large scale and compatibility with existing technologies.

现有的全氧燃烧器多用于浮法玻璃窑、玻纤窑、轧钢加热炉、锻造炉、热处理炉等,燃料主要为天然气。燃煤型全氧燃烧器在工业上应用较少,中国专利公开号CN101825278A提出了一种富氧燃烧器,及美国专利US20110126780A1提出了一种全氧燃烧锅炉煤粉燃烧器,这两个专利主要针对于燃煤发电锅炉的全氧燃烧。对于水泥工业窑炉,由于在生产布置、反应条件上与玻璃、火电窑炉等有较大差异,同时还需要对冷却机以及系统用风等进行特殊设计,目前水泥行业尚未有纯氧燃烧技术投运的实际案例。Existing oxy-fuel burners are mostly used in float glass kilns, glass fiber kilns, steel rolling heating furnaces, forging furnaces, heat treatment furnaces, etc., and the fuel is mainly natural gas. Coal-fired oxy-fuel burners are rarely used in industry. Chinese Patent Publication No. CN101825278A proposes an oxygen-enriched burner, and US Patent US20110126780A1 proposes a pulverized coal burner for oxy-fuel boilers. These two patents mainly Oxy-fuel combustion for coal-fired power boilers. For cement industrial kilns, due to the large differences in production layout and reaction conditions with glass and thermal power kilns, and the need for special designs for coolers and system wind, there is no pure oxygen combustion technology in the cement industry at present. The actual case of putting into operation.

水泥生产过程会产生大量的二氧化碳,据统计,生产1t水泥会排放0.6~0.7t二氧化碳。The cement production process will produce a large amount of carbon dioxide. According to statistics, the production of 1 ton of cement will emit 0.6 to 0.7 tons of carbon dioxide.

水泥窑废气中二氧化碳主要来源于以下两个方面:Carbon dioxide in cement kiln exhaust gas mainly comes from the following two aspects:

1、燃料燃烧烟气中生成的二氧化碳,占比约40%;1. The carbon dioxide generated in the flue gas of fuel combustion accounts for about 40%;

2、原料中碳酸盐分解产生的二氧化碳,占比约60%。2. The carbon dioxide produced by the decomposition of carbonate in raw materials accounts for about 60%.

碳捕集与封存技术是目前水泥行业减少二氧化碳排放最可行的新技术,其中全氧燃烧技术在碳捕集与封存技术中发展前景较好。Carbon capture and storage technology is currently the most feasible new technology for reducing carbon dioxide emissions in the cement industry, among which oxyfuel combustion technology has a better development prospect in carbon capture and storage technology.

全氧燃烧是指用工业氧气代替空气来燃烧燃料,可以使燃料燃烧更加完全,全氧燃烧相比空气燃烧有如下诸多优点:Oxygen combustion refers to the use of industrial oxygen instead of air to burn fuel, which can make the fuel burn more completely. Compared with air combustion, oxyfuel combustion has the following advantages:

1)全氧燃烧过程与空气燃烧相比,空气中约79%的氮气不再参与燃烧,可以提高火焰温度;1) Compared with the air combustion process, about 79% of the nitrogen in the air no longer participates in the combustion, which can increase the flame temperature;

2)烟气中氮气含量少,燃烧产物为三原子产物,三原子物质的传热效果高于双原子的物质,提高了加热效率;2) The nitrogen content in the flue gas is low, and the combustion products are triatomic products. The heat transfer effect of triatomic substances is higher than that of diatomic substances, which improves the heating efficiency;

3)氮气不再参与排烟,可以大幅减少烟气量,减少排烟热损失。3) Nitrogen no longer participates in the exhaust, which can greatly reduce the amount of flue gas and reduce the heat loss of exhaust.

目前,全氧燃烧技术在浮法玻璃、玻纤窑上应用广泛,在水泥行业的应用还处于研发阶段,水泥行业主要是在分解炉以及回转窑内采用全氧燃烧技术。At present, oxy-fuel combustion technology is widely used in float glass and glass fiber kilns, and its application in the cement industry is still in the research and development stage. The cement industry mainly uses oxy-fuel combustion technology in calciners and rotary kilns.

在高氧气浓度水泥窑炉全氧燃烧过程中需要将氧气和循环烟气引入窑炉替代空气作为燃烧气体,但是氧气和循环烟气如何注入水泥窑炉是一个关键技术难点。在传统的全氧燃烧系统中,一般将氧气和循环烟气进行混合,混合后的气体通过管路进行输运注入水泥窑炉。然而在高氧气浓度全氧燃烧系统中,如果仍然采用将氧气和循环烟气先混合,混合后的气体通过管路输运送再注入水泥窑炉的供风方式,会存在严重的安全问题。因为在烟气循环系统中,即使设置布袋除尘器对循环烟气进行除尘处理,烟气中仍然携带少量粒径微小的含碳颗粒,如果高浓度工业氧气(体积分数约80%~95%)和循环烟气按照常规方法直接进行混合和运输,循环烟气中携带的少量含碳颗粒遇到纯氧后易于发生着火并燃烧,一旦混合气在管道中发生燃烧,将是重大安全事故,不但危及设备本体,同时也对运行人员的安全造成威胁。中国专利公开号CN105650628A提出了一种循环流化床富氧燃烧装置及其富氧燃烧供风方法,其氧气和循环烟气在进入炉体之前不进行混合,在各自管路中分别输送,在炉体不同高度的多个部位供风,解决了氧气输送混合过程中的安全问题。然而,该专利的供风方式仅针对循环流化床,对水泥窑炉全氧燃烧并不适用。In the oxy-fuel combustion process of high oxygen concentration cement kiln, oxygen and circulating flue gas need to be introduced into the kiln to replace air as combustion gas, but how to inject oxygen and circulating flue gas into the cement kiln is a key technical difficulty. In the traditional oxy-fuel combustion system, oxygen and circulating flue gas are generally mixed, and the mixed gas is transported through pipelines and injected into the cement kiln. However, in the high oxygen concentration oxy-fuel combustion system, if the air supply method of mixing oxygen and circulating flue gas is still used, the mixed gas is transported through pipelines and then injected into the cement kiln, there will be serious safety problems. Because in the flue gas circulation system, even if a bag filter is installed to remove dust from the circulating flue gas, the flue gas still carries a small amount of carbon-containing particles with a small particle size. and the circulating flue gas are directly mixed and transported according to conventional methods. A small amount of carbon-containing particles carried in the circulating flue gas are easy to catch fire and burn when they encounter pure oxygen. Once the mixed gas burns in the pipeline, it will be a major safety accident, not only It endangers the equipment body and also poses a threat to the safety of operating personnel. Chinese Patent Publication No. CN105650628A proposes a circulating fluidized bed oxygen-enriched combustion device and its oxygen-enriched combustion air supply method. The oxygen and circulating flue gas are not mixed before entering the furnace body, and are transported separately in their respective pipelines. Air is supplied from multiple parts at different heights of the furnace body, which solves the safety problem in the process of oxygen delivery and mixing. However, the air supply method of this patent is only for the circulating fluidized bed, and it is not suitable for the oxy-fuel combustion of the cement kiln.

另外,由于水泥分解炉内燃料燃烧和生料分解过程耦合进行,分解炉炉膛内燃烧温度相对较低,一般为900~1100℃,如果出烧成系统的中低温循环烟气(一般为400℃以下)直接进入分解炉,分解炉内燃烧区温度势必很难维持在煤粉的着火温度以上,将导致分解炉内火焰不稳定,甚至熄火。因此,氧气和循环烟气引入水泥分解炉之前先进行升温非常必要。在富氧富碳下,由于燃料理论燃烧温度大幅度提升,燃烧装置的安全性和污染物排放也面临很大挑战,主要存在的问题有:1)燃烧装置内容易出现爆燃、燃烧不稳定及炉壁烧蚀的问题;2)当富氧状态下火焰温度上升时易引起燃烧过程NOX排放升高,加大了后续废气处理系统烟气脱硝的负荷。In addition, due to the coupled process of fuel combustion and raw meal decomposition in the cement calciner, the combustion temperature in the calciner furnace is relatively low, generally 900-1100°C. (below) directly into the calciner, the temperature of the combustion zone in the calciner is bound to be difficult to maintain above the ignition temperature of the pulverized coal, which will lead to unstable flames in the calciner, or even flameout. Therefore, it is very necessary to raise the temperature before introducing oxygen and circulating flue gas into the cement decomposition furnace. Under oxygen-enriched and carbon-enriched conditions, due to the substantial increase in the theoretical combustion temperature of the fuel, the safety of the combustion device and the emission of pollutants are also facing great challenges. The main problems are: 1) Deflagration, unstable combustion and The problem of furnace wall ablation; 2) When the flame temperature rises in the oxygen-enriched state, it is easy to cause the NOX emission in the combustion process to increase, which increases the load of the flue gas denitrification of the subsequent exhaust gas treatment system.

因此,开发一种技术可靠、运行成本低、不影响现有生产运行工况的水泥窑炉局部全氧燃烧烟气碳捕集技术是水泥行业碳减排更实际可行的方法。但目前仍存在如下问题:Therefore, developing a local oxy-combustion flue gas carbon capture technology for cement kilns that has reliable technology, low operating costs, and does not affect the existing production and operation conditions is a more practical and feasible method for carbon emission reduction in the cement industry. But there are still the following problems:

1)当全氧燃烧碳富集系统处于点火阶段时,需使用空气燃烧工况点火升温以减少工业氧气消耗;或者异常工况下需暂停富二氧化碳烟气输出时,面临将运行状态从局部全氧燃烧快速切换至空气燃烧状态的问题;1) When the oxy-fuel combustion carbon enrichment system is in the ignition stage, it is necessary to use air combustion conditions to ignite and heat up to reduce industrial oxygen consumption; or when it is necessary to suspend the output of carbon dioxide-rich flue gas under abnormal conditions, it is faced with changing the operating state from partial to full The problem of rapid switching from oxygen combustion to air combustion state;

2)局部全氧燃烧碳富集子系统与水泥生产主系统的工艺相容性差,彼此相互干扰;2) The process compatibility between the local oxy-fuel combustion carbon enrichment subsystem and the main cement production system is poor, and they interfere with each other;

3)中低温循环烟气与工业氧气混合输送方式导致内部残余碳粒着火燃烧引起管道安全问题;3) The medium and low temperature circulating flue gas mixed with industrial oxygen causes the internal residual carbon particles to ignite and burn, causing pipeline safety problems;

4)生料分解吸热和燃烧放热过程耦合,中低温循环烟气直接入分解炉,会导致燃料难以起燃,火焰不稳定,燃烧过程容易熄火的问题;4) The heat absorption and heat release process of raw material decomposition is coupled, and the medium and low temperature circulating flue gas directly enters the calciner, which will cause the fuel to be difficult to ignite, the flame is unstable, and the combustion process is easy to extinguish;

5)中低温循环烟气直接入分解炉,由于工况风量少,会导致分解炉生料难以被风托起进而引起塌料的问题。5) The medium and low temperature circulating flue gas directly enters the calciner. Due to the small air volume in the working condition, it will make it difficult for the raw material in the calciner to be lifted by the wind and cause the problem of material collapse.

此外,二氧化碳作为一种可以利用的宝贵资源,在化学工业、食品工业、机械加工、石油开采等诸多领域大量应用,回收利用是减排二氧化碳的一种重要方法。因此。提供一种在生产水泥熟料时联产液态CO2产品的系统,减少水泥生产过程碳排放,且不影响水泥生产线产量、质量;同时CO2产品的生产成本低、回收率高、产品纯度高且质量稳定,是本领域技术人员亟待解决的问题。In addition, carbon dioxide, as a valuable resource that can be used, is widely used in many fields such as chemical industry, food industry, mechanical processing, oil exploration, etc. Recycling is an important method to reduce carbon dioxide emission. therefore. Provide a system for co-producing liquid CO2 products during the production of cement clinker, which reduces carbon emissions in the cement production process without affecting the output and quality of the cement production line; at the same time, the production cost of CO2 products is low, the recovery rate is high, and the product purity is high And stable quality is a problem to be solved urgently by those skilled in the art.

发明内容Contents of the invention

本发明为解决现有技术存在的问题,提供了一种全氧燃烧生产水泥熟料联产液态CO2的系统及方法,该系统主要由水泥煅烧主系统、全氧燃烧子系统和CO2捕集提纯系统组成,在生产水泥熟料的过程中,采用子系统全氧燃烧富集烟气中CO2,再经过CO2捕集提纯系统制备液态CO2,可实现水泥生产过程中碳减排和低成本在线制备CO2产品,具有良好的社会经济效益。In order to solve the problems existing in the prior art, the present invention provides a system and method forproducing cement clinker co-production liquid CO2 through oxy-fuel combustion. It is composed of a purification system. In the process of producing cement clinker, the subsystem adopts full oxygen combustion to enrich CO2 in the flue gas, and then prepares liquid CO2 through the CO2 capture and purification system, which can realize carbon emission reduction in the cement production process And low-cost on-line preparation ofCO2 products, has good social and economic benefits.

本发明是这样实现的,一种全氧燃烧生产水泥熟料联产液态CO2的系统,由水泥煅烧主系统、全氧燃烧子系统和CO2捕集提纯系统组成;The present invention is achieved in this way, a system for the production of cement clinker co-production liquidCO by oxy-fuel combustion, which is composed of a cement calcining main system, a oxy-fuel combustion subsystem anda CO capture and purification system;

所述全氧燃烧子系统由子预热器单元、自富集炉、烟气预热单元、文丘里喉管、子高温风机、冷却器、子收尘器、中温循环风机、中温循环烟气供应管路、低温循环风机、低温循环烟气供应管路、燃料供应管路和工业氧气供应管路组成;The oxy-fuel combustion subsystem is supplied by a sub-preheater unit, a self-enrichment furnace, a flue gas preheating unit, a venturi throat, a sub-high temperature fan, a cooler, a sub-dust collector, a medium-temperature circulating fan, and a medium-temperature circulating flue gas Pipeline, low-temperature circulation fan, low-temperature circulation flue gas supply pipeline, fuel supply pipeline and industrial oxygen supply pipeline;

所述子预热器单元的倒数第二级子旋风筒下料管与所述自富集炉的生料喂料管连接,所述子预热器单元的末级子旋风筒下料管与水泥煅烧主系统的窑尾烟室连接,所述子预热器单元的顶部出口风管上依次设置所述子高温风机、冷却器、子收尘器和子排风机;所述中温循环风机设置在中温循环烟气供应管路上,所述中温循环烟气供应管路一端与子高温风机和冷却器之间的管路连接,另一端与烟气预热单元连接;所述低温循环风机设置在低温循环烟气供应管路上,所述低温循环烟气供应管路一端与子收尘器气体出口的管路连接,另一端与燃料供应管路连接;The penultimate sub-cyclone feeding pipe of the sub-preheater unit is connected to the raw material feeding pipe of the self-enrichment furnace, and the last-stage sub-cyclone feeding pipe of the sub-preheater unit is connected to the The kiln tail smoke chamber of the cement calcining main system is connected, and the sub-high temperature fan, cooler, sub-dust collector and sub-exhaust fan are arranged in sequence on the top outlet air duct of the sub-preheater unit; On the medium-temperature circulating flue gas supply pipeline, one end of the medium-temperature circulating flue gas supply pipeline is connected to the pipeline between the high-temperature fan and the cooler, and the other end is connected to the flue gas preheating unit; the low-temperature circulating fan is set at a low temperature On the circulating flue gas supply pipeline, one end of the low-temperature circulating flue gas supply pipeline is connected to the gas outlet pipeline of the sub-dust collector, and the other end is connected to the fuel supply pipeline;

所述烟气预热单元用于通过燃料将低温循环烟气和中温循环烟气进行预加热至900℃以上;所述烟气预热单元的底部烟气出口与所述文丘里喉管的底部进口连接,所述文丘里喉管的顶部出口与所述自富集炉的柱体底部连接,所述自富集炉的顶部出口与末级子旋风筒进口连接;The flue gas preheating unit is used to preheat the low-temperature circulating flue gas and the medium-temperature circulating flue gas to above 900°C with fuel; the flue gas outlet at the bottom of the flue gas preheating unit is connected to the bottom of the Venturi throat The inlet is connected, the top outlet of the Venturi throat is connected to the bottom of the column of the self-enrichment furnace, and the top outlet of the self-enrichment furnace is connected to the inlet of the final sub-cyclone;

所述燃料供应管路分别与烟气预热单元、文丘里喉管上部的喷煤管连接,所述工业氧气供应管路分别与烟气预热单元、文丘里喉管下部的氧气管连接;The fuel supply pipeline is respectively connected with the flue gas preheating unit and the coal injection pipe at the upper part of the Venturi throat, and the industrial oxygen supply pipeline is respectively connected with the flue gas preheating unit and the oxygen pipe at the lower part of the Venturi throat;

所述CO2捕集提纯系统包括依次连接设置在子排风机出口管路上的分水罐、干燥床、吸附床、制冷机和精馏塔,所述精馏塔的顶部气体出口依次连接冷凝器和气液分离器,所述气液分离器的液体出口与精馏塔连接,所述精馏塔的底部液体出口连接再沸器入口,所述再沸器的气体出口与精馏塔连接,所述再沸器的液体出口与液态CO2储罐连接。The CO captureand purification system includes sequentially connecting a water separation tank, a drying bed, an adsorption bed, a refrigerator and a rectification tower arranged on the outlet pipeline of the sub-exhaust fan, and the top gas outlet of the rectification tower is connected to the condenser in sequence and a gas-liquid separator, the liquid outlet of the gas-liquid separator is connected with the rectification tower, the bottom liquid outlet of the rectification tower is connected with the reboiler inlet, and the gas outlet of the reboiler is connected with the rectification tower, the The liquid outlet of the reboiler is connected to the liquidCO storage tank.

水泥生料分一部分至全氧燃烧子系统进行预热、分解,分解后的生料回到水泥煅烧主系统的回转窑煅烧生产水泥熟料。全氧燃烧子系统设置预热炉和自富集炉,燃料为煤粉,助燃空气为工业氧气,燃烧烟气和生料分解产生的CO2形成浓度至80%以上的富CO2烟气。富CO2烟气在CO2捕集提纯系统依次进行脱水干燥、脱硫脱硝、冷凝精馏后制备出CO2质量分数至99%以上的液态CO2产品。Part of the cement raw meal is sent to the oxy-fuel combustion subsystem for preheating and decomposition, and the decomposed raw meal is returned to the rotary kiln of the main cement calcination system for calcination to produce cement clinker. The oxy-fuel combustion subsystem is equipped with a preheating furnace and a self-enriching furnace. The fuel is pulverized coal, and the combustion air is industrial oxygen. The CO2 generated by the combustion flue gas and the decomposition of raw meal forms a CO2 rich flue gas with a concentration of more than 80%. TheCO2- rich flue gas is sequentially dehydrated and dried, desulfurized and denitrified, and condensed and rectified in theCO2 capture and purification system to prepare a liquidCO2 product with aCO2 mass fraction of more than 99%.

优选的,所述烟气预热单元包括燃烧器和预热炉,所述燃烧器安装在预热炉的顶部,燃烧器的头部伸入预热炉内,所述燃烧器包括由内至外依次同轴套装的油管、内一次风管、煤管和外一次风管,使燃烧器内由内至外依次形成中心油枪通道、内一次风通道、煤粉通道和外一次风通道;所述内一次风管和外一次风管的尾部均与工业氧气供应管路连接,所述煤管的尾部与燃料供应管路连接;Preferably, the flue gas preheating unit includes a burner and a preheating furnace, the burner is installed on the top of the preheating furnace, the head of the burner extends into the preheating furnace, and the burner includes The oil pipe, the inner primary air pipe, the coal pipe and the outer primary air pipe are coaxially set on the outside in turn, so that the central oil gun channel, the inner primary air channel, the coal powder channel and the outer primary air channel are formed in the burner from the inside to the outside; Both the tails of the inner primary air pipe and the outer primary air pipe are connected to the industrial oxygen supply pipeline, and the tails of the coal pipe are connected to the fuel supply pipeline;

所述油管、煤管和外一次风管的头部端口对齐,形成燃烧器的头部;所述内一次风管的头部与燃烧器的头部之间留有距离H0,使内一次风通道和煤粉通道在燃烧器的头部形成风煤预混通道;所述内一次风通道和煤粉通道之间设置有可沿燃烧器轴向前后移动的风煤预混调节环,使所述风煤预混通道的长度可在0~H0之间调节;The head ports of the oil pipe, coal pipe and the outer primary air pipe are aligned to form the head of the burner; a distance H0 is left between the head of the inner primary air pipe and the head of the burner, so that the inner primary air The channel and the pulverized coal channel form an air-coal premixing channel at the head of the burner; an air-coal premixing adjustment ring that can move back and forth along the axial direction of the burner is arranged between the inner primary air channel and the pulverized coal channel, so that all The length of the air-coal premixing channel can be adjusted between 0 and H0;

所述预热炉从上至下由旋流室、变径段和炉膛组成,所述旋流室为蜗壳式结构,使从旋流室进口进入的烟气为蜗壳式切向旋流进入;The preheating furnace is composed of a swirl chamber, a variable diameter section and a furnace from top to bottom. The swirl chamber is a volute structure, so that the flue gas entering from the inlet of the swirl chamber is a volute tangential swirl flow Enter;

在所述预热炉内形成位于炉膛中心的富燃料区、位于富燃料区外部的富氧区、和位于富氧区与炉壁之间的富碳区。A fuel-rich area located at the center of the furnace, an oxygen-enriched area located outside the fuel-enriched area, and a carbon-enriched area located between the oxygen-enriched area and the furnace wall are formed in the preheating furnace.

进一步优选的,所述风煤预混调节环设置在内一次风管的内侧璧上。Further preferably, the air-coal premixing adjusting ring is arranged on the inner wall of the inner primary air pipe.

进一步优选的,所述内一次风通道的进口及外一次风通道的出口处均设置有旋流器。Further preferably, swirlers are provided at the inlet of the inner primary air channel and the outlet of the outer primary air channel.

进一步优选的,所述外一次风通道外设有耐火材料层。Further preferably, a refractory material layer is arranged on the outside of the outer primary air passage.

进一步优选的,在与所述内一次风管、外一次风管、文丘里喉管下部的氧气管连接的工业氧气供应管路上分别设置有流量控制器。Further preferably, flow controllers are respectively arranged on the industrial oxygen supply pipelines connected to the inner primary air pipe, the outer primary air pipe, and the oxygen pipe at the lower part of the Venturi throat.

进一步优选的,所述旋流室的顶盖中心设置有燃烧器安装孔,所述燃烧器的头部通过燃烧器安装孔伸入至旋流室内。Further preferably, a burner installation hole is provided at the center of the top cover of the swirl chamber, and the head of the burner extends into the swirl chamber through the burner installation hole.

进一步优选的,所述变径段的内直径从上至下逐渐变大。Further preferably, the inner diameter of the diameter reducing section gradually increases from top to bottom.

优选的,所述中温循环风机入口处的中温循环烟气供应管路上设置有中温循环风阀门,所述低温循环风机入口处的低温循环烟气供应管路上设置有低温循环风阀门。Preferably, a medium-temperature circulating air valve is provided on the medium-temperature circulating flue gas supply pipeline at the entrance of the medium-temperature circulating fan, and a low-temperature circulating air valve is provided on the low-temperature circulating flue gas supply pipeline at the entrance of the low-temperature circulating fan.

优选的,所述文丘里喉管从下至上分为下收缩段,喉区高速段和上扩张段,所述下收缩段插入所述氧气管,所述氧气管向下倾斜插入至靠近文丘里喉管轴向中心,氧气管与水平方向夹角为30~60°,使工业氧气与循环烟气混合均匀;所述上扩张段插入有所述喷煤管,所述喷煤管插入至靠近上扩张段内壁,使循环烟气和煤粉在上扩张段外侧形成的涡流低压区处混合;所述氧气管和喷煤管的数量分别为2~4支,沿圆周对称布置。Preferably, the Venturi throat is divided into a lower constriction section, a high-speed throat section and an upper expansion section from bottom to top, the lower constriction section is inserted into the oxygen tube, and the oxygen tube is inserted obliquely downwards close to the Venturi The axial center of the throat pipe, the angle between the oxygen pipe and the horizontal direction is 30-60°, so that the industrial oxygen and the circulating flue gas can be mixed evenly; the coal injection pipe is inserted into the upper expansion section, and the coal injection pipe is inserted close to The inner wall of the upper expansion section allows the circulating flue gas and coal powder to mix at the vortex low-pressure area formed outside the upper expansion section; the number of the oxygen pipes and coal injection pipes are 2-4 respectively, arranged symmetrically along the circumference.

优选的,所述生料喂料管设置在所述自富集炉的柱体底部。Preferably, the raw material feeding pipe is arranged at the bottom of the column of the self-enrichment furnace.

优选的,所述分水罐出口和干燥床入口之间的管路上依次设置有压缩机组和稳压罐。Preferably, a compressor unit and a surge tank are sequentially arranged on the pipeline between the outlet of the water separation tank and the inlet of the drying bed.

一种全氧燃烧生产水泥熟料联产液态CO2的方法,所述方法采用水泥煅烧主系统和全氧燃烧子系统并联运行进行空气燃烧和局部全氧燃烧,在预热预分解环节,生料流动路径为并联无交叉;在熟料煅烧环节,经过水泥煅烧主系统和全氧燃烧子系统分解后的两股生料共同进入回转窑煅烧,制备水泥熟料;A method for producing cement clinker with co-production of liquidCO2 by oxy-fuel combustion, the method adopts the parallel operation of the cement calcining main system and the oxy-fuel combustion sub-system to carry out air combustion and local oxy-fuel combustion, and in the preheating and pre-decomposition link, the production The material flow path is parallel without intersection; in the clinker calcination link, the two strands of raw material decomposed by the cement calcination main system and the oxy-combustion subsystem enter the rotary kiln for calcination to prepare cement clinker;

在全氧燃烧子系统中,生料喂入子预热器单元,经过子预热器单元预热后喂入自富集炉预分解,然后进入回转窑煅烧;出自富集炉的烟气在子高温风机抽风下经过子预热器单元进行热交换,部分烟气作为中温循环烟气返回预热炉;剩余烟气再经冷却、收尘后,一部分用作低温循环烟气,剩余部分为富CO2烟气进入CO2捕集提纯系统,经过脱水干燥、脱硫脱硝、冷凝精馏后,制备出CO2质量分数至99%以上的液态CO2产品。In the oxy-fuel combustion subsystem, the raw meal is fed into the sub-preheater unit, preheated by the sub-preheater unit, fed into the self-enrichment furnace for pre-decomposition, and then enters the rotary kiln for calcination; the flue gas from the enrichment furnace is The sub-high temperature fan passes through the sub-preheater unit for heat exchange, and part of the flue gas returns to the preheating furnace as medium-temperature circulating flue gas; after cooling and dust collection, part of the remaining flue gas is used as low-temperature circulating flue gas, and the rest is TheCO2- rich flue gas enters theCO2 capture and purification system, and after dehydration and drying, desulfurization and denitrification, condensation and rectification, a liquidCO2 product with aCO2 mass fraction of more than 99% is prepared.

优选的,在所述自富集炉预分解生料采用两次全氧燃烧碳富集的方式进行生料分解,具体步骤如下:Preferably, the self-enrichment furnace predecomposes the raw meal by adopting two oxy-combustion carbon enrichment methods to decompose the raw meal, and the specific steps are as follows:

步骤一:从子收尘器气体出口的管路取低温循环烟气,低温循环烟气携带煤粉进入燃烧器的煤粉通道;工业氧气分两股分别进入燃烧器的内一次风通道和外一次风通道,内一次风通道的工业氧气旋流进入,外一次风通道内的工业氧气旋流喷出,工业氧气供应的量满足预热炉内煤粉燃烧所需的氧气量,使煤粉喷出后在预热炉内燃烧稳定;Step 1: Take low-temperature circulating flue gas from the gas outlet pipeline of the sub-dust collector, and the low-temperature circulating flue gas carries coal powder into the coal powder channel of the burner; industrial oxygen enters the inner primary air channel and the outer primary air channel of the burner respectively in two streams. In the primary air channel, the industrial oxygen swirls in the inner primary air channel, and the industrial oxygen swirls in the outer primary air channel. After spraying, it burns stably in the preheating furnace;

从子高温风机和冷却器之间的管路取中温循环烟气,将中温循环烟气切向旋流引入预热炉的旋流室,在顶部旋流室的离心力下贴壁向下运动;煤粉和工业氧气从燃烧器喷出后在预热炉内着火燃烧,使预热炉内空间形成位于炉膛中心的富燃料区、位于富燃料区外部的富氧区、和位于富氧区与炉壁之间的富碳区;煤粉燃烧热量将中、低温循环烟气温度提升至900℃以上;Take the medium-temperature circulating flue gas from the pipeline between the high-temperature fan and the cooler, introduce the medium-temperature circulating flue gas into the swirl chamber of the preheating furnace in a tangential swirl, and move downward against the wall under the centrifugal force of the top swirl chamber; After the pulverized coal and industrial oxygen are ejected from the burner, they are ignited and burned in the preheating furnace, so that the space in the preheating furnace forms a fuel-rich area located in the center of the furnace, an oxygen-enriched area located outside the fuel-enriched area, and an oxygen-enriched area between the oxygen-enriched area and the The carbon-rich area between the furnace walls; the heat of pulverized coal combustion raises the temperature of the medium and low temperature circulating flue gas to above 900°C;

步骤二:出烟气预热单元的900℃以上高温循环烟气反向向上运动;Step 2: The high-temperature circulating flue gas above 900°C of the flue gas preheating unit moves upward in reverse;

步骤三:高温循环烟气进入文丘里喉管,在文丘里喉管进口喷入工业氧气,使中心区氧浓度升高至30%以上;在文丘里喉管出口喷入煤粉,出口气体形成射流,在射流作用下使文丘里喉管上部外侧形成涡流低压区;Step 3: The high-temperature circulating flue gas enters the Venturi throat, and industrial oxygen is injected into the inlet of the Venturi throat to increase the oxygen concentration in the central area to more than 30%; the pulverized coal is injected into the outlet of the Venturi throat, and the outlet gas forms Jet flow, under the action of jet flow, forms a vortex low-pressure area on the outer side of the upper part of the Venturi throat;

步骤四:煤粉随循环烟气进入自富集炉燃烧放热,在自富集炉的生料喂料管喂入生料,使生料在自富集炉内完成分解,并释放CO2,出自富集炉烟气干基CO2浓度达80%以上,温度为850~1000℃。Step 4: The pulverized coal enters the self-enrichment furnace to burn and release heat with the circulating flue gas, and feeds raw meal into the raw meal feeding pipe of the self-enrichment furnace, so that the raw meal is decomposed in the self-enrichment furnace and releases CO2 , the dry basisCO2 concentration of flue gas from the enrichment furnace is over 80%, and the temperature is 850-1000°C.

进一步优选的,所述煤粉细度控制80um筛余低于20%;所述工业氧气的氧气浓度不低于80%;所述低温循环烟气的温度低于150℃,CO2浓度高于60%,O2浓度低于10%;所述中温循环烟气的温度低于400℃,CO2浓度高于60%,O2浓度低于10%。Further preferably, the pulverized coal fineness is controlled to be less than 20% at 80um sieve; the oxygen concentration of the industrial oxygen is not lower than 80%; the temperature of the low-temperature circulating flue gas is lower than 150°C, andthe CO concentration is higher than 60%, the O2 concentration is lower than 10%; the temperature of the medium-temperature circulating flue gas is lower than 400°C, the CO2 concentration is higher than 60%, and the O2 concentration is lower than 10%.

进一步优选的,根据煤粉的燃烧特性,通过调节风煤预混调节环来调节风煤预混通道的长度,和/或通过调节进入内一次风通道和外一次风通道的工业氧气量,强化煤粉的着火与火焰稳定性,使煤粉喷出后在预热炉内燃烧稳定。Further preferably, according to the combustion characteristics of pulverized coal, the length of the air-coal premixing channel is adjusted by adjusting the air-coal premixing adjustment ring, and/or the industrial oxygen quantity entering the inner primary air channel and the outer primary air channel is adjusted to strengthen The ignition and flame stability of pulverized coal make the pulverized coal burn stably in the preheating furnace after being sprayed out.

进一步优选的,所述步骤三中,所述文丘里喉管的喉区高速段的截面平均风速为25~50m/s,上扩张段的出口截面平均风速为5~15m/s,喉区高速段风速为上扩张段出口风速的2倍以上。Further preferably, in the step 3, the average wind speed of the cross-section of the high-speed section in the throat area of the Venturi throat is 25-50 m/s, the average wind speed of the outlet section of the upper expansion section is 5-15 m/s, and the high-speed section in the throat area is 5-15 m/s. The wind speed of the section is more than 2 times of the outlet wind speed of the upper expansion section.

优选的,制备液态CO2产品的具过程如下:富CO2烟气先经过分水罐进行初步脱水,分水后的烟气进入压缩机组加压,经过稳压罐后进入干燥床进行脱水干燥;干燥后的烟气进入吸附床脱除SOX和NOX杂质;出吸附床的富二氧化碳烟气进入制冷机制冷,之后进入精馏塔;在精馏塔内,轻组分杂质和少量二氧化碳在精馏塔顶部析出,析出的混合气经过冷凝器处理将二氧化碳再次凝结为液态,经过气液分离器后,液态二氧化碳返回精馏塔,剩余气体为排出系统;精馏塔底部的液态二氧化碳进入再沸器,将溶解在二氧化碳中的杂质返回精馏塔,出再沸器的液态二氧化碳输送至液态CO2储罐。Preferably, the specific process for preparing liquidCO2 products is as follows: theCO2- rich flue gas first passes through the water separation tank for preliminary dehydration, the water-divided flue gas enters the compressor unit for pressurization, and then enters the drying bed for dehydration and drying after passing through the surge tank ; the dried flue gas enters the adsorption bed to remove SOX and NOX impurities; the carbon dioxide-rich flue gas out of the adsorption bed enters the refrigerator for refrigeration, and then enters the rectification tower; in the rectification tower, light component impurities and a small amount of carbon dioxide It is precipitated at the top of the rectification tower, and the precipitated mixed gas is processed by a condenser to condense carbon dioxide into a liquid state again. After passing through the gas-liquid separator, the liquid carbon dioxide returns to the rectification tower, and the remaining gas is discharged from the system; the liquid carbon dioxide at the bottom of the rectification tower enters The reboiler returns the impurities dissolved in the carbon dioxide to the rectification column, and the liquid carbon dioxide out of the reboiler is sent to the liquidCO2 storage tank.

本发明具有的优点和积极效果是:The advantages and positive effects that the present invention has are:

1、本发明的采用水泥煅烧主系统和全氧燃烧子系统并联运行进行空气燃烧和局部全氧燃烧,在烧成窑尾预热预分解环节,采用主系统和子系统并联运行,在熟料煅烧环节,采用主系统和子系统产生的煅烧生料同时喂入回转窑生产水泥熟料,减少了主系统与子系统之间的相互干扰;全氧燃烧子系统采用分级取循环风,从子高温风机与冷却器之间取中温循环风(150~400℃)直接入预热炉,从子收尘器之后取低温循环风(低于150℃)用作煤粉输送风,在确保煤粉输送安全的同时提升了热量回收,降低了能耗,并实现了碳富集;富CO2烟气同时进入CO2捕集提纯系统,经过脱水干燥、脱硫脱硝、冷凝精馏后,制备出CO2质量分数至99%以上的液态CO2产品,实现了水泥生产过程中碳减排和低成本在线制备液态CO2产品,具有良好的社会经济效益。1. The present invention adopts the parallel operation of the cement calcination main system and the oxy-fuel combustion subsystem to carry out air combustion and partial oxy-fuel combustion. In the preheating and pre-decomposition link at the end of the kiln, the main system and the subsystem operate in parallel, and the clinker calcination In the link, the calcined raw meal produced by the main system and the subsystem is fed into the rotary kiln to produce cement clinker at the same time, which reduces the mutual interference between the main system and the subsystem; Take medium-temperature circulating air (150-400°C) directly into the preheating furnace between the cooler and the cooler, and take low-temperature circulating air (below 150°C) from the sub-dust collector as coal powder conveying air to ensure the safety of coal powder conveying At the same time, it improves heat recovery, reduces energy consumption, and realizes carbon enrichment; CO2 rich flue gas enters the CO2 capture and purification system at the same time, and after dehydration and drying, desulfurization and denitrification, condensation and rectification, CO2 quality The liquidCO2 product with a fraction of more than 99% realizes carbon emission reduction in the cement production process and low-cost online preparation of the liquidCO2 product, and has good social and economic benefits.

2、本发明在全氧燃烧子系统中,将生料预分解分为串联运行的一次燃烧区和二次燃烧区进行,在燃烧器和预热炉所在的一次燃烧区,一次燃烧区不喂入生料,煤粉通过低温循环烟气输送,工业氧气分两股在煤粉通道内外侧供风,中温循环烟气从预热炉旋流室贴壁供风,实现预热炉内煤粉火焰稳定、预热炉炉壁不烧蚀、低NOX排放以及煤粉的充分燃尽,在预热炉内将中、低温循环烟气升温至900℃以上;在文丘里喉管和自富集炉所在的二次燃烧区,二次燃烧区带料运行,将高温循环烟气引入二次燃烧区底部,并喷入工业氧气和煤粉,进行生料分解,通过设置的文丘里喉管形成射流进行托料,解决了生料塌料和煤粉局部爆燃引起炉壁高温结皮问题,又抑制了煤粉燃烧NOX释放,使出自富集炉时烟气温度为850~1000℃,干基CO2浓度至80%以上,实现生料充分分解。2. In the oxy-fuel combustion subsystem of the present invention, the raw material is pre-decomposed into a primary combustion zone and a secondary combustion zone running in series. In the primary combustion zone where the burner and the preheating furnace are located, the primary combustion zone does not feed The raw meal is fed into the raw meal, and the pulverized coal is transported through the low-temperature circulating flue gas. The industrial oxygen is divided into two streams to supply air on the inside and outside of the pulverized coal channel, and the medium-temperature circulating flue gas is supplied from the wall of the preheating furnace swirl chamber to realize the pulverized coal in the preheating furnace. The flame is stable, the furnace wall of the preheating furnace is not ablated, the emission of NOX is low, and the pulverized coal is fully burnt out. The secondary combustion area where the collection furnace is located, the secondary combustion area runs with materials, introduces high-temperature circulating flue gas into the bottom of the secondary combustion area, and injects industrial oxygen and coal powder to decompose the raw material, and passes through the set Venturi throat The formation of a jet for material support solves the problem of high-temperature crusting on the furnace wall caused by raw material slumping and partial deflagration of coal powder, and inhibits the release of NOX from coal combustion, so that the flue gas temperature when it comes out of the enrichment furnace is 850-1000 ° C. The dry baseCO2 concentration is above 80% to achieve full decomposition of raw meal.

3、本发明提供的燃烧器,工业氧气与煤粉、循环烟气在输送过程中不接触,且煤粉输送的送煤风采用小于150℃的低温循环烟气,避免循环烟气中未燃尽的碳粒自燃,解决了全氧燃烧子系统工业氧气、煤粉混合输送引起自燃的安全问题。3. In the burner provided by the present invention, industrial oxygen does not contact with pulverized coal and circulating flue gas during the transportation process, and the coal feeding air for pulverized coal transportation adopts low-temperature circulating flue gas less than 150°C to avoid unburned gas in the circulating flue gas. The exhausted carbon particles are spontaneously ignited, which solves the safety problem of spontaneous combustion caused by the mixed transportation of industrial oxygen and coal powder in the oxy-fuel combustion subsystem.

4、本发明提供的燃烧器,在内一次风通道和煤粉通道之间增加可沿燃烧器轴向前后移动的风煤预混调节环,可灵活调节风煤预混通道的长度,使得可根据煤粉的燃烧特性,调节工业氧气与煤粉在燃烧器内是否进行预混合,避免引起火焰不稳定甚至熄火问题,强化煤的着火与火焰稳定性;或避免火焰燃烧速度过快出现火焰回火至预混合区烧坏燃烧器头部问题,防止了煤粉爆燃和回火,在不回火前提下,强化了煤粉的着火与火焰稳定性。4. In the burner provided by the present invention, an air-coal premixing adjustment ring that can move back and forth along the axial direction of the burner is added between the inner primary air channel and the pulverized coal channel, so that the length of the air-coal premixing channel can be flexibly adjusted, so that it can be According to the combustion characteristics of pulverized coal, adjust whether industrial oxygen and pulverized coal are pre-mixed in the burner to avoid the problem of unstable flame or even flameout, and strengthen the ignition and flame stability of coal; or avoid flame back when the flame burns too fast. The problem of burning out the head of the burner in the pre-mixing area prevents the deflagration and tempering of the pulverized coal, and strengthens the ignition and flame stability of the pulverized coal without tempering.

5、本发明提供的燃烧器,还可根据煤粉的燃烧特性,调节进入内一次风通道和外一次风通道的工业氧气量,防止了煤粉爆燃和回火,强化了煤粉的着火与火焰稳定性;且外一次风为高速旋流风,进一步强化了火焰稳定性。5. The burner provided by the present invention can also adjust the amount of industrial oxygen entering the inner primary air passage and the outer primary air passage according to the combustion characteristics of the pulverized coal, preventing deflagration and tempering of the pulverized coal, and strengthening the ignition and combustion of the pulverized coal. Flame stability; and the external primary wind is a high-speed swirling wind, which further strengthens the flame stability.

6、本发明提供的预热炉,中温循环烟气(150~400℃)从预热炉顶部旋流室进入,在旋流室内贴壁旋转向下流动,由于中温循环烟气温度相对较低,且氧含量低,使得在炉壁和火焰之前形成一道低温保护气膜,有效保护了预热炉壁面耐火材料,防止被火焰烧蚀。6. In the preheating furnace provided by the present invention, the medium-temperature circulating flue gas (150-400°C) enters from the swirl chamber at the top of the preheating furnace, and flows downward in the swirling chamber, because the temperature of the medium-temperature circulating flue gas is relatively low , and the oxygen content is low, so that a low-temperature protective gas film is formed in front of the furnace wall and the flame, which effectively protects the refractory material on the wall of the preheating furnace and prevents it from being ablated by the flame.

7、本发明提供的文丘里喉管,煤粉位于文丘里喉管上扩张区,工业氧气引入文丘里喉管下收缩区,工业氧气与循环烟气通过文丘里喉管混合均匀后再与煤粉接触,防止因自富集炉内局部氧浓度高引起煤粉爆燃,导致自富集炉壁面结皮;文丘里喉管出口气体形成射流,使得在射流作用下上扩张段外侧形成涡流低压区,循环烟气和煤粉在该区域返混,外侧循环烟气氧浓度相对低,抑制了煤粉燃烧NOX释放。7. In the Venturi throat provided by the present invention, the pulverized coal is located in the upper expansion area of the Venturi throat, the industrial oxygen is introduced into the lower contraction area of the Venturi throat, and the industrial oxygen and circulating flue gas are mixed evenly through the Venturi throat and then mixed with coal Powder contact, to prevent coal powder deflagration due to high local oxygen concentration in the self-enrichment furnace, resulting in crusting on the wall of the self-enrichment furnace; the gas at the outlet of the Venturi throat forms a jet, which makes a vortex low-pressure area formed outside the upper expansion section under the action of the jet , the circulating flue gas and pulverized coal are back-mixed in this area, and the oxygen concentration of the outer circulating flue gas is relatively low, which inhibits the release of NOX from pulverized coal combustion.

附图说明Description of drawings

为了更清楚地说明本发明具体实施方式的技术方案,下面将对具体实施方式描述中所需要使用的附图作简单的介绍,显而易见地,下面描述中的附图是本发明的一些具体实施方式,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to more clearly illustrate the technical solutions of specific embodiments of the present invention, the accompanying drawings that need to be used in the description of specific embodiments will be briefly introduced below. Obviously, the accompanying drawings in the following description are some specific embodiments of the present invention. , for those skilled in the art, other drawings can also be obtained according to these drawings on the premise of not paying creative work.

图1是本发明实施例提供的全氧燃烧生产水泥熟料联产液态CO2的系统的工艺流程图;Fig. 1 is the process flow diagram of the system for the production of cement clinker co-production liquidCO by oxy-fuel combustion provided by the embodiment of the present invention;

图2是本发明实施例提供的全氧燃烧子系统的工艺流程图;Fig. 2 is a process flow chart of the oxy-fuel combustion subsystem provided by the embodiment of the present invention;

图3是本发明实施例提供的烟气预热单元的结构示意图;Fig. 3 is a schematic structural diagram of a flue gas preheating unit provided by an embodiment of the present invention;

图4是本发明实施例提供的预热炉的结构示意图;Fig. 4 is the structural representation of the preheating furnace that the embodiment of the present invention provides;

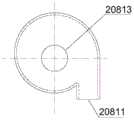

图5是本发明实施例提供的旋流室的结构示意图;Fig. 5 is a schematic structural diagram of a cyclone chamber provided by an embodiment of the present invention;

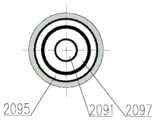

图6是本发明实施例提供的燃烧器的结构示意图一;Fig. 6 is a structural schematic diagram 1 of a burner provided by an embodiment of the present invention;

图7是图6的A-A剖面的结构示意图;Fig. 7 is the structural representation of the A-A section of Fig. 6;

图8是本发明实施例提供的燃烧器的结构示意图二;Fig. 8 is a structural schematic diagram II of the burner provided by the embodiment of the present invention;

图9是图8的B-B剖面的结构示意图;Fig. 9 is a schematic structural view of the B-B section of Fig. 8;

图10是本发明实施例提供的文丘里喉管的结构示意图;Fig. 10 is a schematic structural diagram of a Venturi throat provided by an embodiment of the present invention;

图11是本发明实施例提供的文丘里喉管的俯视图。Fig. 11 is a top view of the Venturi throat provided by the embodiment of the present invention.

其中:g1-工业氧气;g2-中温循环烟气;g3-低温循环烟气;g4-富CO2烟气;g5-精馏塔放空气;F-煤粉;A-富燃料区;B-富氧区;C-富碳区;H-风煤预混区长度;M-生料;K-水泥熟料;W-分离水;Among them: g1-industrial oxygen; g2-medium temperature circulating flue gas; g3-low temperature circulating flue gas; g4-CO2 rich flue gas; Oxygen-enriched area; C-carbon-enriched area; H-wind-coal premixing area length; M-raw meal; K-cement clinker; W-separated water;

1-水泥煅烧主系统;101-第一级主旋风筒;102-第二级主旋风筒;103-第三级主旋风筒;104-第四级主旋风筒;105-第五级主旋风筒;106-主分解炉;107-窑尾烟室;108-回转窑;109-冷却机;110-窑头燃烧器;111-三次风管;112-主高温风机;113-拉链机;114-熟料储存库;1-Cement calcining main system; 101-First stage main cyclone; 102-Second stage main cyclone; 103-Third stage main cyclone; 104-Fourth stage main cyclone; 105-Fifth stage main cyclone barrel; 106-main decomposition furnace; 107-kiln tail smoke chamber; 108-rotary kiln; 109-cooler; 110-kiln head burner; 111-tertiary air duct; - clinker storage;

2-全氧燃烧子系统;2- Oxygen combustion subsystem;

201-第一级子旋风筒;202-第二级子旋风筒;203-第三级子旋风筒;204-第四级子旋风筒;205-第五级子旋风筒;201-first-level sub-cyclone; 202-second-level sub-cyclone; 203-third-level sub-cyclone; 204-fourth-level sub-cyclone; 205-fifth-level sub-cyclone;

206-自富集炉;2061-生料喂料管;206-self-enrichment furnace; 2061-raw material feeding pipe;

207-文丘里喉管;2071-下收缩段;2072-喉区高速段;2073-上扩张段;2074-氧气管;2075-喷煤管;207-Venturi throat; 2071-lower contraction section; 2072-high-speed throat section; 2073-upper expansion section; 2074-oxygen pipe; 2075-coal injection pipe;

208-预热炉;2081-旋流室;2082-变径段;2083-炉膛;20811-旋流室进口;20812-旋流室顶盖;20813-燃烧器安装孔;208-preheating furnace; 2081-swirl chamber; 2082-reducing section; 2083-furnace; 20811-swirl chamber inlet; 20812-swirl chamber top cover; 20813-burner installation hole;

209-燃烧器;2091-中心油枪通道;2092-内一次风旋流器;2093-内一次风通道;2094-煤粉通道;2095-外一次风通道;2096-外一次风旋流器;2097-风煤预混通道;2098-风煤预混调节环;2099-耐火材料层;209-burner; 2091-central oil gun channel; 2092-inner primary air cyclone; 2093-inner primary air channel; 2094-coal powder channel; 2095-outer primary air channel; 2096-outer primary air cyclone; 2097-wind coal premixing channel; 2098-wind coal premixing adjustment ring; 2099-refractory material layer;

210-子高温风机;211-中温循环风机;212-中温循环风阀门;213-冷却器;214-子收尘器;215-子排风机;216-低温循环风机;217-低温循环风阀门;218-煤粉仓;219-内一次风流量控制器;220-外一次风流量控制器;221-二次风流量控制器;210-sub-high temperature fan; 211-medium temperature circulating fan; 212-medium temperature circulating air valve; 213-cooler; 214-sub dust collector; 215-sub exhaust fan; 216-low temperature circulating fan; 217-low temperature circulating air valve; 218-coal powder bin; 219-inner primary air flow controller; 220-outer primary air flow controller; 221-secondary air flow controller;

3-CO2捕集提纯系统;301-分水罐;302-压缩机组;303-稳压罐;304-干燥床;305-吸附床;306-制冷机;307-精馏塔;308-冷凝器;309-气液分离器;310-再沸器;311-液态CO2储罐。3-CO2 capture and purification system; 301-water separation tank; 302-compressor unit; 303-surge tank; 304-drying bed; 305-adsorption bed; 306-refrigerator; device; 309-gas-liquid separator; 310-reboiler; 311-liquid CO2 storage tank.

具体实施方式Detailed ways

下面将结合附图对本发明的技术方案进行清楚、完整地描述,显然,所描述的实施例是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The technical solutions of the present invention will be clearly and completely described below in conjunction with the accompanying drawings. Apparently, the described embodiments are some of the embodiments of the present invention, but not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

在本发明的描述中,需要说明的是,术语“中心”、“上”、“下”、“左”、“右”、“竖直”、“水平”、“内”、“外”等指示的方位或位置关系为基于附图所示的方位或位置关系,仅是为了便于描述本发明和简化描述,而不是指示或暗示所指的装置或元件必须具有特定的方位、以特定的方位构造和操作,因此不能理解为对本发明的限制。此外,术语“第一”、“第二”、“第三”仅用于描述目的,而不能理解为指示或暗示相对重要性。In the description of the present invention, it should be noted that the terms "center", "upper", "lower", "left", "right", "vertical", "horizontal", "inner", "outer" etc. The indicated orientation or positional relationship is based on the orientation or positional relationship shown in the drawings, and is only for the convenience of describing the present invention and simplifying the description, rather than indicating or implying that the referred device or element must have a specific orientation, or in a specific orientation. construction and operation, therefore, should not be construed as limiting the invention. In addition, the terms "first", "second", and "third" are used for descriptive purposes only, and should not be construed as indicating or implying relative importance.

在本发明的描述中,需要说明的是,除非另有明确的规定和限定,术语“安装”、“相连”、“连接”应做广义理解,例如,可以是固定连接,也可以是可拆卸连接,或一体地连接;可以是机械连接,也可以是电连接;可以是直接相连,也可以通过中间媒介间接相连,可以是两个元件内部的连通。对于本领域的普通技术人员而言,可以具体情况理解上述术语在本发明中的具体含义。In the description of the present invention, it should be noted that unless otherwise specified and limited, the terms "installation", "connection" and "connection" should be understood in a broad sense, for example, it can be a fixed connection or a detachable connection. Connected, or integrally connected; it may be mechanically connected or electrically connected; it may be directly connected or indirectly connected through an intermediary, and it may be the internal communication of two components. Those of ordinary skill in the art can understand the specific meanings of the above terms in the present invention in specific situations.

实施例Example

请参阅图1~图11,本实施例提供一种全氧燃烧生产水泥熟料联产液态CO2的系统,由水泥煅烧主系统1、全氧燃烧子系统2和CO2捕集提纯系统3组成,水泥煅烧主系统1和全氧燃烧子系统2两个系统的预热器单元可采用二至七级预热器,本实施例以五级预热器为例进行说明。Please refer to Figures 1 to 11.This embodiment provides a system for the production of cement clinker and co-production of liquid CO2 by oxy-fuel combustion, which consists of a main cement calcination system 1, an oxy-

所述水泥煅烧主系统1包括主预热器单元、主分解炉106、窑尾烟室107、回转窑108、冷却机109、窑头燃烧器110、三次风管111、主高温风机112、拉链机113和熟料储存库114,主预热器单元为五级旋风预热器,主预热器单元的顶部出口风管上依次设置主高温风机、主收尘器、主排风机和烟囱。入水泥煅烧主系统1的生料通过管道喂入第二级主旋风筒102出口风管中进行气固换热,在气流带动下进入第一级主旋风筒101;在第一级主旋风筒101内经过气固分离后,物料从第一级主旋风筒101的下料管喂入第三级主旋风筒103的出口风管。按上述方式,依次进入第二级主旋风筒102、第三级主旋风筒103、第四级主旋风筒104。经第四级主旋风筒104气固分离后的生料进入主分解炉106,在主分解炉106内完成生料分解(生料中碳酸钙分解为氧化钙),分解后的生料随气流进入第五级主旋风筒105,经气固分离后,生料喂入窑尾烟室107。The cement calcining main system 1 includes a main preheater unit, a

见图2,所述全氧燃烧子系统2由子预热器单元、自富集炉206、烟气预热单元、文丘里喉管207、子高温风机210、冷却器213、子收尘器214、中温循环风机211、中温循环烟气供应管路、低温循环风机216、低温循环烟气供应管路、燃料供应管路和工业氧气供应管路组成,所述子预热器单元也为五级旋风预热器。所述子预热器单元的第四级子旋风筒204下料管与所述自富集炉206的生料喂料管2061连接,所述自富集炉206的顶部出口与第五级子旋风筒205进口连接,所述子预热器单元的第五级子旋风筒205下料管与水泥煅烧主系统1的窑尾烟室107连接。入全氧燃烧子系统2的生料通过管道喂入第二级子旋风筒202出口风管中进行气固换热,在气流带动下进入第一级子旋风筒201;在第一级子旋风筒201内经过气固分离后,物料从第一级子旋风筒201的下料管喂入第三级子旋风筒203的出口风管。按上述方式,依次进入第二级子旋风筒202、第三级子旋风筒203、第四级子旋风筒204。经第四级子旋风筒204气固分离后的生料进入自富集炉206,在自富集炉206内完成生料分解,分解后的生料随气流进入第五级子旋风筒205,经气固分离后,生料喂入窑尾烟室107。As shown in Figure 2, the oxy-

水泥煅烧主系统1的生料和全氧燃烧子系统2的生料共同进入窑尾烟室107,在回转窑108内煅烧为水泥熟料,高温熟料在冷却机109冷却后,经过拉链机113输送至熟料储存库114。The raw meal of the cement calcining main system 1 and the raw meal of the oxy-

所述子预热器单元的顶部出口风管上依次设置所述子高温风机210、冷却器213、子收尘器214和子排风机215;所述中温循环风机211设置在中温循环烟气供应管路上,所述中温循环烟气供应管路一端与子高温风机210和冷却器213之间的管路连接,另一端与烟气预热单元连接,所述中温循环风机211入口处的中温循环烟气供应管路上设置有中温循环风阀门212;所述低温循环风机216设置在低温循环烟气供应管路上,所述低温循环烟气供应管路一端与子收尘器214气体出口的管路连接,另一端与燃料供应管路连接,所述低温循环风机216入口处的低温循环烟气供应管路上设置有低温循环风阀门217;所述烟气预热单元的底部烟气出口与所述文丘里喉管207的底部进口连接,所述文丘里喉管207的顶部出口与所述自富集炉206的柱体底部连接;所述燃料供应管路分别与烟气预热单元、文丘里喉管207上部的喷煤管2075连接,所述工业氧气供应管路分别与烟气预热单元、文丘里喉管207下部的氧气管2074连接。The

出自富集炉206的烟气在子高温风机210抽风下经过子预热器单元进行热交换,部分烟气作为中温循环风返回预热炉208;剩余烟气再经冷却器213冷却、收尘后,一部分用作低温循环风,剩余部分为富CO2烟气进入CO2捕集提纯系统3。The flue gas from the

见图1,所述CO2捕集提纯系统3包括依次连接设置在子排风机215出口管路上的分水罐301、压缩机组302、稳压罐303、干燥床304、吸附床305、制冷机306和精馏塔307,所述精馏塔307的顶部气体出口依次连接冷凝器308和气液分离器309,所述气液分离器309的液体出口与精馏塔307连接,所述精馏塔307的底部液体出口连接再沸器310入口,所述再沸器310的气体出口与精馏塔307连接,所述再沸器310的液体出口与液态CO2储罐311连接。As shown in Fig. 1, the CO2 capture and purification system 3 includes a

低温循环烟气g3的温度低于150℃,其成分主要为CO2,CO2浓度(均指体积分数)高于60%,O2浓度低于10%;中温循环烟气g2的温度低于400℃,其成分主要为CO2,CO2浓度高于60%,O2浓度低于10%。所用的燃料为煤粉F,细度控制80um筛余低于20%。燃烧所用氧化剂为工业氧气g1,工业氧气g1浓度不低于80%。The temperature of the low-temperature circulating flue gas g3 is lower than 150°C, and its composition is mainly CO2 , the concentration of CO2 (both refers to the volume fraction) is higher than 60%, and the concentration of O2 is lower than 10%; the temperature of the medium-temperature circulating flue gas g2 is lower than 400°C, its composition is mainly CO2 , the CO2 concentration is higher than 60%, and the O2 concentration is lower than 10%. The fuel used is pulverized coal F, and the fineness control 80um sieve is less than 20%. The oxidant used for combustion is industrial oxygen g1, and the concentration of industrial oxygen g1 is not less than 80%.

见图3,所述烟气预热单元用于通过燃料将低温循环烟气g3和中温循环烟气g2进行预加热至900℃以上;所述烟气预热单元包括燃烧器209和预热炉208,燃烧器209安装在预热炉208的顶部,燃烧器209的头部伸入预热炉208内,预热炉208用于将中温循环烟气g2、低温循环烟气g3加热。As shown in Fig. 3, the flue gas preheating unit is used to preheat the low-temperature circulating flue gas g3 and the medium-temperature circulating flue gas g2 to above 900°C with fuel; the flue gas preheating unit includes a

燃烧器209为圆柱形结构,见图6,包括由内至外依次同轴套装的油管、内一次风管、煤管和外一次风管,内部共形成有四个通道,从内到外分别为中心油枪通道2091、内一次风通道2093,煤粉通道2094和外一次风通道2095。所述油管、煤管和外一次风管的头部端口对齐,形成燃烧器209的头部;所述内一次风管的头部与燃烧器209的头部之间留有距离H0,使内一次风通道2093和煤粉通道2094在燃烧器209的头部形成风煤预混通道2097;所述内一次风通道2093和煤粉通道2094之间设置有可沿燃烧器209轴向前后移动的风煤预混调节环2098,使所述风煤预混通道2097的长度可在0~H0之间调节。本实施例的风煤预混调节环2098设置在内一次风管的内侧璧上。The

见图4和图5,预热炉208从上至下由旋流室2081、变径段2082和炉膛2083组成。旋流室2081为蜗壳式结构,使从旋流室进口20811进入的烟气为蜗壳式切向旋流进入。在旋流室顶盖20812中心设燃烧器安装孔20813,燃烧器209通过燃烧器安装孔20813安装在预热炉208的顶部,且燃烧器209的头部伸入至旋流室2081内。燃烧器209的外一次风通道2095外设耐火材料层2099,用于隔热,防止因预热炉208内火焰辐射传热到燃烧器209,使燃烧器209内部温度过高及工业氧气g1在燃烧器209内输送过程中氧化壁面钢材。旋流室2081截面周长小于炉膛2083周长,变径段2082的内直径从上至下逐渐变大,加快了循环烟气旋流运行对炉壁圆周方向的全覆盖。Referring to Fig. 4 and Fig. 5, the preheating

见图10和图11,所述炉膛2083的底部出口通过管道与所述文丘里喉管207的底部连接,所述文丘里喉管207的顶部与所述自富集炉206的柱体底部连接;所述自富集炉206的柱体底部设置所述生料喂料管2061。所述文丘里喉管207从下至上分为下收缩段2071,喉区高速段2072和上扩张段2073,所述下收缩段2071插入所述氧气管2074,所述氧气管2074向下倾斜插入至靠近文丘里喉管207轴向中心,氧气管2074与水平方向夹角为30~60°,使工业氧气g1与循环烟气混合均匀,本实施例的插入深度为300~1000mm;所述上扩张段2073插入所述喷煤管2075,所述喷煤管2075水平插入至靠近上扩张段2073内壁,使循环烟气和煤粉在上扩张段2073外侧形成的涡流低压区处混合,本实施例的插入深度为100~500mm;所述氧气管2074和喷煤管2075的数量分别为2~4支,沿圆周对称布置。本实施例中,氧气管2074和喷煤管2075均设置2支,4支管在周向均匀布设。10 and 11, the outlet at the bottom of the

在全氧燃烧子系统2中,所述燃料供应管路分为两路,分别与煤管、文丘里喉管207上部的喷煤管2075连接;所述低温循环烟气供应管路与燃料供应管路连接;所述中温循环烟气供应管路与所述旋流室2081的进口连接;所述工业氧气g1供应管路分为三路,分别与外一次风管、内一次风管、文丘里喉管207下部的氧气管2074连接,在与所述外一次风管、内一次风管、文丘里喉管207下部的氧气管2074连接的工业氧气g1供应管路上分别设置有流量控制器。燃料供应管路内通入煤粉F,工业氧气g1供应管路内通入工业氧气g1,低温循环烟气供应管路内通入低温循环烟气g3,中温循环烟气供应管路内通入中温循环烟气g2。In the

由于风煤预混调节环2098的位置可以沿着燃烧器209轴向前后移动,使风煤预混通道2097的长度可以在0~H0之前调节。设风煤预混调节环2098头部距离燃烧器209头部的距离为H,当H大于0时,内一次风通道2093内的内一次风(即工业氧气g1)与煤粉通道2094内的送煤风(即低温循环烟气g3)在风煤预混通道2097(即预混合区)内预混合为一股,通过风煤预混通道2097后喷出燃烧器209。风煤预混通道2097的长度越大,预混合程度越强,煤粉F与工业氧气g1的接触更均匀。Since the position of the air-coal

见图6和图7,当燃料为难燃煤质(例如无烟煤)时,如果没有风煤预混通道2097,煤粉与工业氧气g1从燃烧器209两个通道独立的喷出,由于送煤风为低温循环烟气g3,可能会导致煤粉燃烧过程中供氧不足,引起火焰不稳定甚至熄火问题。通过调节在内一次风通道2093和煤粉通道2094之间增加的风煤预混调节环2098,将工业氧气g1与煤粉F在燃烧器209内进行预混合,使煤粉F喷出之前与工业氧气g1可以提前接触,可强化煤的着火与火焰稳定性。内一次风进入风煤预混通道2097时为旋流,煤粉通道2094为直流,在风煤预混通道2097,内一次风在旋流离心力作用下与送煤风产生碰撞,提升了工业氧气g1和煤粉F的预混合效果。See Fig. 6 and Fig. 7, when the fuel is difficult-to-combustible coal (such as anthracite), if there is no air-

对于中等易燃性的煤,可通过风煤预混调节环2098灵活调节预混合区的长度H,进而在不回火前提下,强化煤的着火与火焰稳定性。For coal with medium flammability, the length H of the premixing zone can be flexibly adjusted through the air-coal

见图8和图9,对于易燃煤质,若工业氧气g1与煤粉F在燃烧器209内提前预混合,会存在火焰燃烧速度过快,出现火焰回火至预混合区,进而烧坏燃烧器209头部的问题。此时,通过调节风煤预混调节环2098位置可以解决回火问题,即将风煤预混调节环2098插入深度至燃烧器209出口,使预混合区消失,燃烧器209出口有四个通道,工业氧气g1和煤粉F在燃烧器209内无预混合,从各自通道喷出,由于煤粉F与工业氧气g1在喷出之前相互隔离,火焰无法回火至燃烧器209通道内,该状态为非预混模式燃烧,适用于易着火燃烧的煤质,可防止烧坏燃烧器209头部。See Figure 8 and Figure 9, for combustible coal, if industrial oxygen g1 and pulverized coal F are pre-mixed in the

此外,内一次风通道2093的工业氧气流量可通过内一次风流量控制器219调节,当煤质易燃时,减少内一次风通道2093的工业氧气流量,减少与煤粉预混合的工业氧气g1,降低内一次风出口中氧浓度,防止煤粉爆燃和回火。当煤质难燃时,增加内一次风通道2093的工业氧气g1流量,强化煤粉着火的火焰稳定性。In addition, the industrial oxygen flow rate of the inner

一种全氧燃烧生产水泥熟料联产液态CO2的方法,所述方法采用水泥煅烧主系统1和全氧燃烧子系统2并联运行进行空气燃烧和局部全氧燃烧,在预热预分解环节,生料流动路径为并联无交叉;在熟料煅烧环节,经过水泥煅烧主系统1和全氧燃烧子系统2分解后的两股生料共同进入回转窑108煅烧,制备水泥熟料;A method for producing cement clinker and co-producing liquid CO by oxy-fuel combustion. The method uses cement calcining main system 1 and oxy-fuel

在全氧燃烧子系统2中,生料喂入子预热器单元,经过子预热器单元预热后喂入自富集炉206预分解,然后进入回转窑108煅烧;出自富集炉206的烟气在子高温风机210抽风下经过子预热器单元进行热交换,出子预热器单元的部分烟气作为中温循环烟气g2返回预热炉208,剩余烟气再经冷却器213冷却、子收尘器214收尘后,一部分用作低温循环烟气g3,剩余部分为富二氧化碳烟气经子排风机215进入CO2捕集提纯系统3,经过脱水干燥、脱硫脱硝、冷凝精馏后,制备出CO2质量分数至99%以上的液态CO2产品。In the oxy-

在所述全氧燃烧子系统2采用两次全氧燃烧串联的方式进行煤粉燃烧和生料分解,具体步骤如下:In the oxy-

步骤一:从子收尘器214气体出口的管路取低温循环烟气g3,低温循环烟气g3携带煤粉F进入燃烧器209的煤粉通道2094;工业氧气g1分两股分别进入燃烧器209的内一次风通道2093和外一次风通道2095,内一次风通道2093的工业氧气g1旋流进入,外一次风通道2095内的工业氧气g1旋流喷出,工业氧气g1供应的量满足预热炉208内煤粉燃烧所需的氧气量,使煤粉喷出后在预热炉208内燃烧稳定。Step 1: Take the low-temperature circulating flue gas g3 from the gas outlet pipeline of the

步骤二:从子高温风机210和冷却器213之间的管路取中温循环烟气g2,将中温循环烟气g2切向旋流引入预热炉208的旋流室2081,在顶部旋流室2081的离心力下贴壁向下运动;煤粉和工业氧气g1从燃烧器209喷出后在预热炉208内着火燃烧,使预热炉208内空间形成位于炉膛2083中心的富燃料区A、位于富燃料区外部的富氧区B、和位于富氧区与炉壁之间的富碳区C;煤粉燃烧热量将中、低温循环烟气温度提升至900℃以上。Step 2: Take the medium-temperature circulating flue gas g2 from the pipeline between the

步骤三:出预热炉208的900℃以上高温循环烟气反向向上运动。Step 3: The high-temperature circulating flue gas above 900° C. exiting the preheating

步骤四:高温循环烟气进入文丘里喉管207,在文丘里喉管207进口的下收缩段2071喷入工业氧气g1,使中心区氧浓度升高至30%以上;在文丘里喉管207出口的上扩张段2073喷入煤粉,出口气体形成射流,使得在射流作用下上扩张段2073外侧形成涡流低压区。Step 4: The high-temperature circulating flue gas enters the

步骤五:煤粉随循环烟气进入自富集炉206燃烧放热,在自富集炉206柱体底部的生料喂料管2061喂入生料,使生料在自富集炉206内完成分解,并释放CO2,出自富集炉206烟气干基CO2浓度达80%以上,温度为850~1000℃。Step 5: The pulverized coal enters the self-

整个水泥烧成过程中,水泥生料分为2部分,第1部分喂入水泥煅烧主系统1的主预热器单元,经过预热后进入主分解炉106分解,然后进入回转窑108煅烧;第2部分喂入全氧燃烧子系统2的子预热器单元,经过预热后喂入自富集炉206分解,然后进入回转窑108煅烧。煤粉分为3部分,第1部分通过窑头燃烧器110喂入回转窑108,用于煅烧水泥熟料;第2部分喂入主分解炉106,用于生料分解;第3部分再分为2组,一组喂入全氧燃烧子系统2的烟气预热单元,用于循环烟气升温;另一组喂入全氧燃烧子系统2的自富集炉206,用于生料分解。During the entire cement firing process, the cement raw meal is divided into two parts. The first part is fed into the main preheater unit of the cement calcining main system 1, and after preheating, enters the

全氧燃烧子系统2中,燃烧器209中心的中心油枪通道2091用于预热炉208的点火。内一次风通道2093和外一次风通道2095两个通道供入工业氧气g1,工业氧气供应的量满足预热炉208内煤粉燃烧所需的氧气量。内一次风通道2093的进口处设置内一次风旋流器2092,使进入内一次风通道2093进口的工业氧气g1在内一次风旋流器2092的作用下向下旋转流动;外一次风通道2095位于煤粉通道2094的外部,外一次风通道2095的出口处设置外一次风旋流器2096,使外一次风通道2095内的工业氧气g1在外一次风旋流器2096的作用下高速旋流喷出,可强化预热炉208内火焰的稳定性。In the

从子高温风机210出口管道取风,150~400℃的中温循环烟气g2从旋流室进口20811进入,沿壁面旋转向下流动。由于以工业氧气g1为氧化剂,氧含量相对空气提高较多,对应的火焰温度相对较高,高温区可达到1300℃以上,当火焰接触到预热炉208侧壁时,容易导致炉壁面耐火材料烧损。而将中温循环烟气g2旋流进入预热炉208,由于温度相对较低,且氧含量低,使得相当于在炉壁和火焰之前形成一道低温保护气膜,有效保护预热炉208壁面耐火材料被火焰烧蚀。The wind is taken from the outlet pipe of the high-

从子收尘器214后取风,将150℃以下的低温循环烟气g3作为煤粉输送用风,低温循环烟气CO2浓度不低于60%,煤粉通过低温循环烟气g3喂入燃烧器209的煤粉通道2094;工业氧气g1分为两股进入燃烧器209,其中一股旋流进入燃烧器209的内一次风通道2093,并通过内一次风流量控制器219控制工业氧气流量,另一股进入燃烧器209的外一次风通道2095,并通过外一次风流量控制器220控制工业氧气流量,工业氧气g1供应的量满足预热炉208内煤粉燃烧所需的氧气量,使煤粉喷出后在预热炉208内燃烧稳定;中温循环烟气g2从预热炉208的旋流室进口20811切向旋流进入,在顶部旋流室2081的离心力下贴壁向下运动;使预热炉208内空间形成位于炉膛2083中心的富燃料区A、位于富燃料区外部的富氧区B、和位于富氧区与炉壁之间的富碳区C;煤粉F和工业氧气g1(氧浓度不低于80%)从燃烧器209喷出后在预热炉208内着火燃烧,为一次燃烧,通过调控喂煤量,煤粉燃烧热量使出预热炉208的烟气从预热炉208底部流出,温度为900℃以上,烟气中CO2浓度大于60%。该供风方式的优势为:1)煤粉F与工业氧气g1在输送过程中不进行混合,且采用低温循环烟气g3输送煤粉,解决了全氧燃烧子系统2工业氧气g1、煤粉F混合输送引起自燃的安全问题;2)中温循环烟气g2直接进入预热炉208,并贴壁向下运动,在煤粉燃烧火焰和壁面之前起到保护气膜的作用,可防止高温火焰烧损壁面。The wind is taken from the back of the

通过本发明提供的烟气预热单元的供风方式,即:低温循环烟气g3作为送煤风输送煤粉;中温循环烟气g2从预热炉208旋流室2081贴壁供风;工业氧气g1中两股,在煤粉通道2094内侧作为内一次风供风并根据煤粉的燃烧特性确定是否与煤粉提前预混,在煤粉通道2094外侧高速旋流喷出作为外一次风。使得可在预热炉208内空间建立三个区域,即富燃料区A,位于炉膛2083中心;富氧区B,位于富燃料区外部;富碳区C,位于富燃料区与炉壁之间。该分区燃烧方法的优势为:1、富燃料区内过氧系数小于1,为还原气氛,可抑制NOx的生成;2、富碳区主要为CO2,气体温度相对低,可保护炉壁面,防止火焰烧炉壁。Through the air supply mode of the flue gas preheating unit provided by the present invention, that is: the low-temperature circulating flue gas g3 is used as coal supply air to transport coal powder; the medium-temperature circulating flue gas g2 is supplied with air from the preheating

出预热炉208的高温循环烟气通过管道后方向变为垂直向上运动,进入文丘里喉管207,在文丘里喉管207进口的下收缩段2071喷入工业氧气g1,使中心区氧浓度升高至30%以上,喉区高速段2072截面平均风速为25~50m/s,上扩张段2073出口截面平均风速为5~15m/s,喉区高速段2072风速是上扩张段2073出口风速的2倍以上。高温循环烟气继续向上运动,文丘里喉管207出口气体形成射流,在上扩张段2073通过喷煤管2075喷入煤粉,在射流作用下,上扩张段2073外侧形成涡流低压区,循环烟气和煤粉在该区域返混,外侧循环烟气氧浓度相对低,抑制了煤粉燃烧NOX释放。The high-temperature circulating flue gas exiting the preheating

从喷煤管2075喷入的煤粉随循环烟气向上运动在自富集炉206中燃烧,为二次燃烧。生料从自富集炉206柱体底部喂料,生料喂料管2061位于喷煤管2075高度以上。在自富集炉206内实现生料充分分解,并释放CO2,出自富集炉206烟气温度为850~1000℃,出自富集炉206烟气干基CO2浓度至80%以上。The pulverized coal injected from the

出自富集炉206的烟气在子高温风机210抽风下经过子预热器单元进行热交换,部分烟气作为中温循环烟气g2返回预热炉208;剩余烟气再经冷却器213冷却、收尘后,一部分用作低温循环烟气g3,剩余部分为富CO2烟气进入CO2捕集提纯系统3进行提纯。The flue gas from the

二氧化碳的临界温度为31.4℃,临界压力为7.28MPa,常压沸点为-78.4℃。富CO2烟气中的杂质主要有N2、O2、CO、H2O、SOX、NOX等。其中,沸点高的重组分杂质,如H2O、SOX、NOX等,在液化分离时可以溶解在液态二氧化碳中,需在液化精馏之前加以脱除。进入CO2捕集提纯系统3的富二氧化碳烟气含有N2、O2、SOX、NOX、水蒸气等组分需进行脱除。The critical temperature of carbon dioxide is 31.4°C, the critical pressure is 7.28MPa, and the boiling point at normal pressure is -78.4°C. The impurities in CO2 rich flue gas mainly include N2 , O2 , CO, H2 O, SOX , NOX and so on. Among them, heavy component impurities with high boiling points, such as H2 O, SOX , NOX, etc., can be dissolved in liquid carbon dioxide during liquefaction and separation, and need to be removed before liquefaction and rectification. The carbon dioxide-rich flue gas entering the CO2 capture purification system 3 contains N2 , O2 , SOX , NOX , water vapor and other components that need to be removed.

本实施例中,富CO2烟气先经过分水罐301进行初步脱水,分水后的烟气进入压缩机组302加压,经过稳压罐303后进入干燥床304进行脱水干燥,干燥后的烟气进入吸附床305脱除SOX和NOX杂质。吸附床305内装载吸附剂,吸附剂的填量根据烟气中杂质的多少而不同,不同吸附剂之间用筛网隔离。烟气经过吸附床305时,杂质被吸附剂吸收,当吸附量达到饱和后,吸附剂需进行再生处理。吸附床305的个数为2个或多个,当一个吸附床305处于吸附工作状态时,另一个吸附床305为再生状态,这样可以保证生产过程连续进行。In this embodiment, the CO2- enriched flue gas first passes through the

出吸附床305的富二氧化碳烟气进入制冷机306制冷,制冷机306为螺杆式或活塞式制冷机,有电动机驱动,制冷剂为液氨或氟利昂。烟气制冷后由气态冷凝为液态,进入精馏塔307。精馏塔307的结构为填料塔,内装波纹板或丝网承载填料。由于轻组分杂质的沸点比二氧化碳低,轻组分杂质N2、O2、CO和少量二氧化碳等在精馏塔307顶部析出,析出的混合气经过冷凝器308处理将二氧化碳再次凝结为液态,经过气液分离器309后,液态二氧化碳返回精馏塔307,剩余气体为精馏塔放空气g5排出系统。精馏塔307塔底装有再沸器310,再沸器310利用加热把溶解在二氧化碳中的杂质赶出,通过塔内的填料层进行气液传质,逐步把轻组分杂质集中到塔顶,连续排出塔外。出再沸器310的液态二氧化碳通过管道输送至液态CO2储罐311,纯度为99%以上。The carbon dioxide-rich flue gas exiting the

综上,本发明采用水泥煅烧主系统1和全氧燃烧子系统2并联运行进行空气燃烧和局部全氧燃烧,在烧成窑尾预热预分解环节,主系统和子系统并联运行;在回转窑中,主系统和子系统产生的煅烧生料同时喂入窑内生产水泥熟料;减少了主系统与子系统之间的相互干扰,例如相互窜风、压力波动干扰等。其次,在进行局部全氧燃烧时,全氧燃烧子系统2中,将生料分解分为一次燃烧区和二次燃烧区串联运行,煤粉通过低温循环烟气输送,一次燃烧区不喂入生料,工业氧气分两股在煤粉通道内外侧供风,中温循环烟气从预热炉旋流室进口送入预热炉,在预热炉内将中、低温循环烟气升温至900℃以上,实现预热炉内煤粉火焰稳定、预热炉炉壁不烧蚀、低NOX排放以及煤粉的充分燃尽,可解决中低温循环烟气直接入分解炉时燃料难以起燃,火焰不稳定,燃烧过程易熄火问题,同时避免了混合输送引起自燃着火的安全问题;二次燃烧区带料运行,将高温循环烟气引入二次燃烧区,并喷入工业氧气和煤粉,进行生料分解,并通过设置的文丘里喉管射流进行托料,解决了生料塌料和煤粉局部爆燃引起炉壁高温结皮问题,又抑制了煤粉燃烧NOX释放;使出自富集炉烟气温度为850~1000℃,干基CO2浓度至80%以上,实现生料充分分解。再次,在进行局部全氧燃烧时,全氧燃烧子系统2分级取循环风,从子高温风机与冷却器之间取中温循环风(150~400℃)直接入预热炉,从子收尘器之后取低温循环风(低于150℃)用作煤粉输送风,在确保煤粉输送安全的同时提升了热量回收,降低能耗,并实现了碳富集。最后,富CO2烟气同时进入CO2捕集提纯系统3,经过脱水干燥、脱硫脱硝、冷凝精馏后,制备出CO2质量分数至99%以上的液态CO2产品,实现了水泥生产过程中碳减排和低成本在线制备液态CO2产品,具有良好的社会经济效益。In summary, the present invention adopts the parallel operation of cement calcining main system 1 and oxy-

最后应说明的是:以上各实施例仅用以说明本发明的技术方案,而非对其限制;尽管参照前述各实施例对本发明进行了详细的说明,本领域的普通技术人员应当理解:其依然可以对前述各实施例所记载的技术方案进行修改,或者对其中部分或者全部技术特征进行等同替换;而这些修改或者替换,并不使相应技术方案的本质脱离本发明各实施例技术方案的范围。Finally, it should be noted that: the above embodiments are only used to illustrate the technical solutions of the present invention, rather than limiting them; although the present invention has been described in detail with reference to the foregoing embodiments, those of ordinary skill in the art should understand that: It is still possible to modify the technical solutions described in the foregoing embodiments, or perform equivalent replacements for some or all of the technical features; and these modifications or replacements do not make the essence of the corresponding technical solutions deviate from the technical solutions of the various embodiments of the present invention. scope.

Claims (15)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210774521.7ACN114907033B (en) | 2022-07-01 | 2022-07-01 | A system and method for producing cement clinker and co-producing liquid CO2 by oxy-fuel combustion |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210774521.7ACN114907033B (en) | 2022-07-01 | 2022-07-01 | A system and method for producing cement clinker and co-producing liquid CO2 by oxy-fuel combustion |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114907033A CN114907033A (en) | 2022-08-16 |

| CN114907033Btrue CN114907033B (en) | 2023-04-14 |

Family

ID=82773018

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210774521.7AActiveCN114907033B (en) | 2022-07-01 | 2022-07-01 | A system and method for producing cement clinker and co-producing liquid CO2 by oxy-fuel combustion |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114907033B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115745438B (en)* | 2022-11-07 | 2023-09-01 | 天津水泥工业设计研究院有限公司 | System and method for purifying carbon by coupling total oxygen combustion of cement kiln with low energy consumption |

| CN115682747A (en)* | 2022-11-14 | 2023-02-03 | 南京凯盛国际工程有限公司 | Carbon dioxide enrichment system of gradient combustion off-line decomposing furnace and process principle thereof |

| CN116196734A (en)* | 2023-02-21 | 2023-06-02 | 中建材玻璃新材料研究院集团有限公司 | A cement full-oxygen combustion coupled flue gas carbon dioxide capture and purification device |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101792276B (en)* | 2010-02-25 | 2011-12-21 | 东南大学 | Method for producing partial full-oxygen type cement suitable for separation and collection of CO2 |

| CN112654828B (en)* | 2019-08-12 | 2022-07-22 | 天津水泥工业设计研究院有限公司 | Cement predecomposition kiln system and method for preparing cement clinker |

| CN112393596B (en)* | 2019-08-12 | 2025-02-21 | 天津水泥工业设计研究院有限公司 | Cement kiln system transformed from online calciner and method for preparing cement clinker |

| CN113237337B (en)* | 2021-04-08 | 2022-03-29 | 华南理工大学 | Cement production carbon capture device and process for waste co-processing |

- 2022

- 2022-07-01CNCN202210774521.7Apatent/CN114907033B/enactiveActive

Also Published As

| Publication number | Publication date |

|---|---|

| CN114907033A (en) | 2022-08-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN114907033B (en) | A system and method for producing cement clinker and co-producing liquid CO2 by oxy-fuel combustion | |

| CN105020700A (en) | Layer combustion boiler combination denitration device and method | |

| CN102628589B (en) | Combustion method and device for pulverized coal at high temperature and low NOx | |

| CN102012019A (en) | Multi-coal low-nitrogen direct-flow pulverized coal combustion device and its nozzle control method | |

| CN103104910B (en) | A kind of micro-oxygen-enriched combusting W flame boiler and CO 2emission-reducing system | |

| CN101280920B (en) | Fluidization-suspension combined combustion boiler | |

| CN103697465A (en) | Boiler capable of achieving reignition of exhaust gas coal powder and reducing NOx by using high-temperature flue gas | |

| CN115127358A (en) | Cement burning system and method capable of realizing local oxy-fuel combustion carbon enrichment | |

| CN110117011A (en) | A kind of method that physical method prepares active carbon | |

| CN108240619A (en) | A kind of flue gas recirculation system using hi-temp hi-effective cyclone separator | |

| CN105605560B (en) | Micro- discharge pulverized coal combustion system | |

| CN115597375A (en) | A deep self-denitration cement clinker calcination system and process with an online reduction furnace | |

| CN114907034B (en) | A cement burning system and method that can realize rapid switching operation of air combustion and partial oxygen combustion | |

| CN107044633A (en) | Vertical pulverized-coal fired boiler | |

| CN115164592B (en) | A system and method for enriching CO2 by secondary full oxygen combustion in a decomposition furnace | |

| CN104048502B (en) | A kind of burning-aid method of cement rotary kiln burner oxygen-enriching device | |

| CN115095856B (en) | Oxygen-enriched carbon-enriched pulverized coal combustion device and air supply method thereof | |

| CN102563635B (en) | Pulverized coal flame preheating combustion device | |

| CN108592013B (en) | Boiler system and method of operating the same | |

| CN103196137A (en) | Multi-burner pulverized coal combustion device | |

| CN212640307U (en) | Device with light-burned magnesium oxide preparation and carbon dioxide collection functions | |

| CN102297422B (en) | Burn-out wind combustion device and method with low NOx emission | |

| CN202229177U (en) | Ember-burning air combustion device with low NOx emission | |

| CN202002085U (en) | Multi-coal low-nitrogen direct-current coal powder burning device | |

| CN203881120U (en) | Oxygen enrichment device for combustor of rotary cement kiln |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |