CN114878416A - Selection method and evaluation method of rational injection water source for offshore water injection development oil field - Google Patents

Selection method and evaluation method of rational injection water source for offshore water injection development oil fieldDownload PDFInfo

- Publication number

- CN114878416A CN114878416ACN202210390519.XACN202210390519ACN114878416ACN 114878416 ACN114878416 ACN 114878416ACN 202210390519 ACN202210390519 ACN 202210390519ACN 114878416 ACN114878416 ACN 114878416A

- Authority

- CN

- China

- Prior art keywords

- water

- oil

- salinity

- experiment

- injection

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N13/00—Investigating surface or boundary effects, e.g. wetting power; Investigating diffusion effects; Analysing materials by determining surface, boundary, or diffusion effects

- G01N13/04—Investigating osmotic effects

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N15/00—Investigating characteristics of particles; Investigating permeability, pore-volume or surface-area of porous materials

- G01N15/08—Investigating permeability, pore-volume, or surface area of porous materials

- G01N15/082—Investigating permeability by forcing a fluid through a sample

- G01N15/0826—Investigating permeability by forcing a fluid through a sample and measuring fluid flow rate, i.e. permeation rate or pressure change

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02A—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE

- Y02A10/00—TECHNOLOGIES FOR ADAPTATION TO CLIMATE CHANGE at coastal zones; at river basins

- Y02A10/40—Controlling or monitoring, e.g. of flood or hurricane; Forecasting, e.g. risk assessment or mapping

Landscapes

- Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- General Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Fluid Mechanics (AREA)

- Dispersion Chemistry (AREA)

- Investigation Of Foundation Soil And Reinforcement Of Foundation Soil By Compacting Or Drainage (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及海上注水开发油田储层水敏伤害评价领域,尤其涉及一种海上注水开发油田合理注入水源选择方法及评价方法。The invention relates to the field of water-sensitive damage evaluation of oilfield reservoirs by offshore waterflooding, in particular to a method for selecting a rational injection water source for offshore waterflooding and developing oilfields and an evaluation method.

背景技术Background technique

水敏感性导致储层中粘土膨胀或微粒运移,从而引起储层渗流能力降低。储层水敏伤害严重影响注水开发油田的开发效果,因此,储层水敏伤害评价对注水开发油田至关重要,能够有效指导注入水与储层的配伍性认识和合理注入水源的选择。目前,行业中常用的储层水敏伤害评价方法来自行业标准《储层敏感性流动实验评价方法(SY/T 5358-2010)》,其方法是选择地层水、1/2矿化度地层水和蒸馏水逐次进行单相水驱渗透率测试,获得水敏伤害程度参数进行水敏伤害评价。海上注水开发油田所用的注入水源矿化度普遍高于地层水,且注水开发油田储层普遍存在油水两相流动,因此,水敏伤害程度参数难以有效评价海上注水开发油田的储层水敏伤害,需要建立一种能够表征油水两相流动、注入水矿化度升高或降低的水敏伤害评价方法进行海上注水开发油田的储层水敏伤害评价及注入水源选择方法。Water sensitivity leads to clay swelling or particle migration in the reservoir, resulting in a reduction in the reservoir's seepage capacity. Reservoir water-sensitive damage seriously affects the development effect of water-flooding oilfields. Therefore, reservoir water-sensitive damage evaluation is very important for water-flooding oilfields, which can effectively guide the understanding of the compatibility of injected water and reservoirs and the selection of rational injection water sources. At present, the commonly used reservoir water-sensitive damage evaluation method in the industry comes from the industry standard "Reservoir Sensitivity Flow Experiment Evaluation Method (SY/T 5358-2010)", the method is to select formation water, 1/2 salinity formation water The single-phase water flooding permeability test was carried out successively with distilled water, and the water-sensitive damage degree parameter was obtained for water-sensitive damage evaluation. The salinity of the injected water source used in offshore waterflooding development oilfields is generally higher than that of formation water, and oil-water two-phase flow generally exists in the reservoirs of waterflooding development oilfields. Therefore, the water-sensitive damage degree parameter is difficult to effectively evaluate the water-sensitive damage of reservoirs in offshore waterflooding development oilfields. , it is necessary to establish a water-sensitive damage evaluation method that can characterize the oil-water two-phase flow and increase or decrease the salinity of injected water for reservoir water-sensitive damage evaluation and injection water source selection in offshore waterflooding oilfields.

发明内容SUMMARY OF THE INVENTION

本发明针对行业中常用的储层水敏伤害评价方法难以有效评价海上注水开发油田水敏伤害程度的问题,建立一种适合海上注水开发油田的储层水敏伤害评价方法,量化海上注水开发油田不同注入水源对储层的伤害程度,指导合理注入水源的选择,实现表征合理、可靠性强、操作性强的海上注水开发油田合理注入水源选择方法及评价方法。Aiming at the problem that the water-sensitive damage evaluation method of reservoirs commonly used in the industry is difficult to effectively evaluate the degree of water-sensitive damage of oilfields developed by offshore waterflooding, the invention establishes a water-sensitive damage evaluation method of reservoirs suitable for oilfields developed by offshore waterflooding, and quantifies the water-sensitive damages of oilfields developed by offshore waterflooding. The damage degree of different injection water sources to the reservoir guides the selection of reasonable injection water sources, and realizes the selection and evaluation methods of reasonable injection water sources for offshore water injection development oilfields with reasonable characterization, strong reliability and strong operability.

本发明所采用的技术方案是:The technical scheme adopted in the present invention is:

提供一种海上注水开发油田合理注入水源选择方法,包括以下步骤:Provided is a method for selecting a rational injection water source for an offshore water injection development oil field, comprising the following steps:

S1、根据矿场所取地层水离子成分分析结果配制0-3倍的矿化度地层水,进行驱替实验,所用原油为地层原油;岩心选择同一口井位置、岩性、储层物性相近的两块或者多块平行岩样,并对平行岩样进行常规物性测试;S1. Prepare formation water with a salinity of 0-3 times according to the analysis results of the ion composition of the formation water at the mine site, and carry out the displacement experiment. The crude oil used is the formation crude oil; the core is selected from the same well location, lithology, and reservoir physical properties. Two or more parallel rock samples, and perform routine physical property tests on the parallel rock samples;

S2、对同一块岩样依次进行1-3倍或1-0倍的矿化度地层水的水驱油实验,同一块岩样做完一种矿化度地层水的水驱油实验后,直接重新饱和油到初始束缚水饱和度后进行老化,然后再进行下一种矿化度地层水的水驱油实验;S2. Carry out the water flooding experiment of formation water with a salinity of 1-3 times or 1-0 times in turn on the same rock sample. The oil is directly re-saturated to the initial irreducible water saturation and then aged, and then the water flooding experiment of the formation water with the next salinity is carried out;

S3、基于油水两相渗流理论和Li-Horne模型,建立考虑驱替压差与可动油饱和度影响的油水两相渗流模型进而推导获得表征储层中油水两相渗流能力的评价因子计算模型其中,a1为考虑驱替压差的毛管压力相关系数;b1为考虑驱替压差的重力相关系数;R为岩心驱替/自吸实验中某一驱替/自吸速度对应的原油采收率;Me为有效流度;Swi为初始含水饱和度;Sor为残余油饱和度;Δp为驱替压差;S3. Based on the oil-water two-phase seepage theory and Li-Horne model, establish an oil-water two-phase seepage model considering the influence of displacement pressure difference and movable oil saturation Then, the calculation model of the evaluation factor to characterize the oil-water two-phase seepage ability in the reservoir is derived. Among them, a1 is the capillary pressure correlation coefficient considering the displacement pressure difference; b1 is the gravity correlation coefficient considering the displacement pressure difference; R is the crude oil corresponding to a certain displacement/self-priming speed in the core displacement/self-priming experiment recovery factor;Me is the effective mobility; Swiis the initial water saturation;Sor is the residual oil saturation; Δp is the displacement pressure difference;

S4、记录不同矿化度注入水驱油实验过程中的驱替时间、驱替压差、产油量、产水量,利用S3中的油水两相渗流模型拟合不同矿化度注入水驱油实验对应的单位压差产油速度与原油采收率倒数之间的关系,获得相应的拟合参数;S4. Record the displacement time, displacement pressure difference, oil production, and water production during the experiment of water flooding with different salinities, and use the oil-water two-phase seepage model in S3 to fit the water flooding with different salinities. The relationship between the oil production rate per unit pressure difference and the inverse of the crude oil recovery factor corresponding to the experiment, and the corresponding fitting parameters are obtained;

S5、根据步骤S4中拟合参数和步骤S1中岩心常规物性测试结果,利用步骤S3中评价因子计算模型计算不同矿化度注入水驱油实验对应的储层中油水两相渗流能力的评价因子;S5. According to the fitting parameters in step S4 and the conventional physical property test results of the core in step S1, use the evaluation factor calculation model in step S3 to calculate the evaluation factor of the oil-water two-phase seepage capability in the reservoir corresponding to the water-flooding experiment with different salinities ;

S6、根据计算的评价因子评价不同矿化度注入水对储层的伤害程度,进而选择合适的地层水矿化度倍数对应的注入水源进行注水开发。S6. Evaluate the damage degree of the injected water with different salinity to the reservoir according to the calculated evaluation factor, and then select the injection water source corresponding to the appropriate formation water salinity multiple for water injection development.

接上述技术方案,对同一块岩样进行注入水矿化度升高或降低的水驱油实验。Following the above technical scheme, water flooding experiments in which the salinity of injected water is increased or decreased are carried out on the same rock sample.

接上述技术方案,选用两块平行岩样进行驱替实验,对其中一块平行岩样依次进行地层水、2倍矿化度地层水和3倍矿化度地层水的水驱油实验,对另一个平行岩样依次进行地层水、1/2倍矿化度地层水和蒸馏水的水驱油实验。In connection with the above technical scheme, two parallel rock samples were selected for the displacement experiment, and one of the parallel rock samples was subjected to the water flooding experiment of formation water, 2 times the salinity formation water and 3 times the salinity formation water in turn, and the other A parallel rock sample was subjected to water flooding experiments with formation water, 1/2 times salinity formation water and distilled water in sequence.

接上述技术方案,常规物性测试包括测试平行岩样的长度、直径、孔隙度、渗透率。Following the above technical solutions, conventional physical property testing includes testing the length, diameter, porosity and permeability of parallel rock samples.

本发明还提供一种海上注水开发油田储层水敏伤害评价方法,其特征在于,包括以下步骤:The present invention also provides a method for evaluating water-sensitive damage of oilfield reservoirs by offshore water flooding, which is characterized by comprising the following steps:

S1、根据矿场所取地层水离子成分分析结果配制3倍矿化度地层水、2倍矿化度地层水、地层水、1/2倍矿化度地层水和蒸馏水,驱替实验所用原油为地层原油,岩心选择同一口井位置、岩性、储层物性相近的2块平行岩样,并进行常规物性测试;S1. Prepare formation water with 3 times salinity, formation water with 2 times salinity, formation water, 1/2 times salinity formation water and distilled water according to the ion composition analysis results of formation water taken from the mine site. The crude oil used in the displacement experiment is: For formation crude oil, two parallel rock samples with similar well location, lithology and reservoir physical properties are selected as cores, and conventional physical property tests are carried out;

S2、对其中一个平行岩样依次进行地层水、2倍矿化度地层水和3倍矿化度地层水的水驱油实验,对另一个平行岩样依次进行地层水、1/2倍矿化度地层水和蒸馏水的水驱油实验,同一块岩样做完一种矿化度注入水驱油实验后,直接重新饱和油到初始束缚水饱和度后进行老化,然后再做下一种矿化度注入水驱油实验;S2. Carry out the water flooding experiment of formation water, formation water with 2 times salinity and formation water with 3 times salinity successively on one of the parallel rock samples, and carry out the formation water, 1/2 times the mineralization water, and other parallel rock samples in turn. For the water flooding experiment of chemical-degree formation water and distilled water, after the same rock sample has completed a water-flooding experiment with a salinity degree, the oil is directly re-saturated to the initial irreducible water saturation and then aged, and then the next one is performed. salinity injection water flooding experiment;

S3、基于油水两相渗流理论和Li-Horne模型,建立考虑驱替压差与可动油饱和度影响的油水两相渗流模型进而推导获得表征储层中油水两相渗流能力的评价因子计算模型其中,a1为考虑驱替压差的毛管压力相关系数;b1为考虑驱替压差的重力相关系数;R为岩心驱替/自吸实验中某一驱替/自吸速度对应的原油采收率;Me为有效流度;Swi为初始含水饱和度;Sor为残余油饱和度;Δp为驱替压差;S3. Based on the oil-water two-phase seepage theory and Li-Horne model, establish an oil-water two-phase seepage model considering the influence of displacement pressure difference and movable oil saturation Then, the calculation model of the evaluation factor to characterize the oil-water two-phase seepage ability in the reservoir is derived. Among them, a1 is the capillary pressure correlation coefficient considering the displacement pressure difference; b1 is the gravity correlation coefficient considering the displacement pressure difference; R is the crude oil corresponding to a certain displacement/self-priming speed in the core displacement/self-priming experiment recovery factor;Me is the effective mobility; Swiis the initial water saturation;Sor is the residual oil saturation; Δp is the displacement pressure difference;

S4、记录不同矿化度注入水驱油实验过程中的驱替时间、驱替压差、产油量、产水量,利用S3中的油水两相渗流模型拟合不同矿化度注入水驱油实验对应的单位压差产油速度与原油采收率倒数之间的关系,获得相应的拟合参数;S4. Record the displacement time, displacement pressure difference, oil production, and water production during the experiment of water flooding with different salinities, and use the oil-water two-phase seepage model in S3 to fit the water flooding with different salinities. The relationship between the oil production rate per unit pressure difference and the inverse of the crude oil recovery factor corresponding to the experiment, and the corresponding fitting parameters are obtained;

S5、根据步骤S4中拟合参数和步骤S1中岩心常规物性测试结果,利用步骤S3中评价因子计算模型计算不同矿化度注入水驱油实验对应的储层渗流能力的评价因子;S5, according to the fitting parameters in step S4 and the test results of conventional core physical properties in step S1, using the evaluation factor calculation model in step S3 to calculate the evaluation factor of the reservoir seepage capacity corresponding to the injection water flooding experiment with different salinity;

S6、根据计算的评价因子评价不同矿化度注入水对储层的伤害程度。S6. Evaluate the degree of damage to the reservoir caused by injected water with different salinity according to the calculated evaluation factor.

接上述技术方案,在步骤S2中,对两块平行岩样分别进行注入水矿化度升高和降低的水驱油实验。In connection with the above technical solution, in step S2, water flooding experiments in which the salinity of injected water is increased and decreased respectively are performed on two parallel rock samples.

接上述技术方案,常规物性测试包括测试平行岩样的长度、直径、孔隙度、渗透率。Following the above technical solutions, conventional physical property testing includes testing the length, diameter, porosity and permeability of parallel rock samples.

本发明产生的有益效果是:本发明基于油水两相渗流理论和Li-Horne模型,建立考虑驱替压差与可动油饱和度影响的油水两相渗流模型,通过分析不同矿化度注入水的水驱油实验结果,结合岩心常规物性参数计算获得相应的储层渗流能力评价因子参数,量化不同矿化度注入水对储层的水敏伤害程度,有效指导海上注水开发油田合理注入水源选择。本发明解决了现有方法无法评价海上注水开发油田所用的注入水源矿化度普遍高于地层水和储层中油水两相渗流能力表征的问题,为海上注水开发油田合理注入水源的选择提供了简便、快捷、准确的评价方法及水上油田的注入水源选择方法。The beneficial effects produced by the present invention are: based on the oil-water two-phase seepage theory and the Li-Horne model, the present invention establishes an oil-water two-phase seepage model considering the influence of displacement pressure difference and movable oil saturation, and injects water by analyzing different salinities. According to the results of water-flooding experiments, the corresponding reservoir seepage capacity evaluation factor parameters are calculated in combination with the conventional physical parameters of the core, and the water-sensitive damage degree of the injected water with different salinity to the reservoir can be quantified, which can effectively guide the selection of reasonable injection water sources for offshore waterflooding development oilfields. . The invention solves the problem that the salinity of the injection water source used in the offshore water flooding development oilfield cannot be evaluated by the existing method is generally higher than that of the formation water and the oil-water two-phase seepage capability in the reservoir, and provides a reasonable choice for the selection of the injection water source for the offshore water flooding development oilfield. Simple, fast and accurate evaluation method and selection method of injection water source for floating oilfields.

附图说明Description of drawings

下面将结合附图及实施例对本发明作进一步说明,附图中:The present invention will be further described below in conjunction with the accompanying drawings and embodiments, in which:

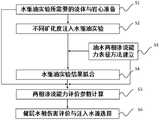

图1是本发明实施例海上注水开发油田合理注入水源选择方法的结构示意图;1 is a schematic structural diagram of a method for selecting a rational injection water source for offshore water injection development oilfields according to an embodiment of the present invention;

图2为本发明的一具体实例中水驱油实验装置;Fig. 2 is a water flooding experimental device in a specific example of the present invention;

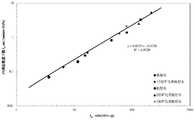

图3为本发明的一具体实例中平行样品2_砂砾岩的地层水驱油实验的单位压差产油速度与原油采收率倒数之间的关系图;3 is a graph of the relationship between the oil production rate per unit pressure difference and the inverse of crude oil recovery in the formation water flooding experiment of parallel sample 2-glutenite in a specific example of the present invention;

图4为本发明的一具体实例中储层渗流能力评价因子与5%原油采收率下的单位压差产油速度之间的关系图;4 is a graph showing the relationship between the evaluation factor of reservoir seepage capability and the oil production rate per unit pressure difference under 5% crude oil recovery factor in a specific example of the present invention;

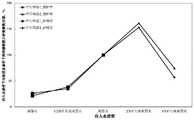

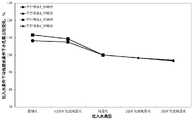

图5为本发明的一具体实例中不同矿化度注入水驱油实验对应的储层渗流能力评价因子变化图;Fig. 5 is a variation diagram of reservoir seepage capability evaluation factors corresponding to different salinity injection water flooding experiments in a specific example of the present invention;

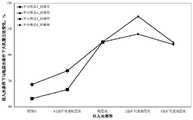

图6a为本发明的一具体实例中砂砾岩样品不同矿化度单相水驱实验对应的大孔隙占比变化图;Fig. 6a is a graph showing the change in the proportion of macropores corresponding to a single-phase water flooding experiment of glutenite samples with different salinities in a specific example of the present invention;

图6b为本发明的一具体实例中砂砾岩样品不同矿化度单相水驱实验对应的中孔隙占比变化图;Fig. 6b is a graph showing the change of the proportion of mesopores corresponding to the single-phase water flooding experiment of glutenite samples with different salinities in a specific example of the present invention;

图6c为本发明的一具体实例中砂砾岩样品不同矿化度单相水驱实验对应的小孔隙占比变化图;Fig. 6c is a graph showing the change in the proportion of small pores corresponding to a single-phase water flooding experiment of glutenite samples with different salinities in a specific example of the present invention;

图7为本发明的一具体实例中砂砾岩样品不同矿化度单相水驱实验对应的水测渗透率变化图。FIG. 7 is a graph showing the variation of water permeability corresponding to a single-phase water flooding experiment of glutenite samples with different salinities in a specific example of the present invention.

具体实施方式Detailed ways

为了使本发明的目的、技术方案及优点更加清楚明白,以下结合附图及实施例,对本发明进行进一步详细说明。应当理解,此处所描述的具体实施例仅用以解释本发明,并不用于限定本发明。In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings and embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

如图1所示,本发明实施例海上注水开发油田合理注入水源选择方法,包括以下步骤:As shown in Figure 1, the method for selecting a rational injection water source for an offshore water injection development oil field according to the embodiment of the present invention includes the following steps:

S1、根据矿场所取地层水离子成分分析结果配制0-3倍的矿化度地层水,进行驱替实验,所用原油为地层原油;岩心选择同一口井位置、岩性、储层物性相近的两块或者多块平行岩样,并对平行岩样进行常规物性测试;S1. Prepare formation water with a salinity of 0-3 times according to the analysis results of the ion composition of the formation water at the mine site, and carry out the displacement experiment. The crude oil used is the formation crude oil; the core is selected from the same well location, lithology, and reservoir physical properties. Two or more parallel rock samples, and perform routine physical property tests on the parallel rock samples;

S2、对同一块岩样依次进行1-3倍或1-0倍的矿化度地层水的水驱油实验,同一块岩样做完一种矿化度地层水的水驱油实验后,直接重新饱和油到初始束缚水饱和度后进行老化,然后再进行下一种矿化度地层水的水驱油实验;S2. Carry out the water flooding experiment of formation water with a salinity of 1-3 times or 1-0 times in turn on the same rock sample. The oil is directly re-saturated to the initial irreducible water saturation and then aged, and then the water flooding experiment of the formation water with the next salinity is carried out;

S3、基于油水两相渗流理论和Li-Horne模型,建立考虑驱替压差与可动油饱和度影响的油水两相渗流模型进而推导获得表征储层中油水两相渗流能力的评价因子计算模型其中,a1为考虑驱替压差的毛管压力相关系数;b1为考虑驱替压差的重力相关系数;R为岩心驱替/自吸实验中某一驱替/自吸速度对应的原油采收率;Me为有效流度;Swi为初始含水饱和度;Sor为残余油饱和度;Δp为驱替压差;S3. Based on the oil-water two-phase seepage theory and Li-Horne model, establish an oil-water two-phase seepage model considering the influence of displacement pressure difference and movable oil saturation Then, the calculation model of the evaluation factor to characterize the oil-water two-phase seepage ability in the reservoir is derived. Among them, a1 is the capillary pressure correlation coefficient considering the displacement pressure difference; b1 is the gravity correlation coefficient considering the displacement pressure difference; R is the crude oil corresponding to a certain displacement/self-priming speed in the core displacement/self-priming experiment recovery factor;Me is the effective mobility; Swiis the initial water saturation;Sor is the residual oil saturation; Δp is the displacement pressure difference;

S4、记录不同矿化度注入水驱油实验过程中的驱替时间、驱替压差、产油量、产水量,利用S3中的油水两相渗流模型拟合不同矿化度注入水驱油实验对应的单位压差产油速度与原油采收率倒数之间的关系,获得相应的拟合参数;S4. Record the displacement time, displacement pressure difference, oil production, and water production during the experiment of water flooding with different salinities, and use the oil-water two-phase seepage model in S3 to fit the water flooding with different salinities. The relationship between the oil production rate per unit pressure difference and the inverse of the crude oil recovery factor corresponding to the experiment, and the corresponding fitting parameters are obtained;

S5、根据步骤S4中拟合参数和步骤S1中岩心常规物性测试结果,利用步骤S3中评价因子计算模型计算不同矿化度注入水驱油实验对应的储层中油水两相渗流能力的评价因子;S5. According to the fitting parameters in step S4 and the conventional physical property test results of the core in step S1, use the evaluation factor calculation model in step S3 to calculate the evaluation factor of the oil-water two-phase seepage capability in the reservoir corresponding to the water-flooding experiment with different salinities ;

S6、根据计算的评价因子评价不同矿化度注入水对储层的伤害程度,进而选择合适的地层水矿化度倍数对应的注入水源进行注水开发。S6. Evaluate the damage degree of the injected water with different salinity to the reservoir according to the calculated evaluation factor, and then select the injection water source corresponding to the appropriate formation water salinity multiple for water injection development.

进一步地,可以对两块平行岩样分别进行注入水矿化度升高和降低的水驱油实验。如对其中一个平行岩样依次进行地层水、2倍矿化度地层水和3倍矿化度地层水的水驱油实验,对另一个平行岩样依次进行地层水、1/2倍矿化度地层水和蒸馏水的水驱油实验,同一块岩样做完一种矿化度注入水驱油实验后,直接重新饱和油到初始束缚水饱和度后进行老化,然后再做下一种矿化度注入水驱油实验Further, water flooding experiments with increased and decreased salinity of injected water can be performed on two parallel rock samples respectively. For example, the water flooding experiment of formation water, formation water with 2 times salinity and formation water with 3 times salinity is carried out on one of the parallel rock samples in turn, and formation water, 1/2 times mineralization is carried out on the other parallel rock sample in turn. For the water flooding experiment of formation water and distilled water with high degree of water, after the same rock sample has completed a water flooding experiment of a salinity degree, the oil is directly re-saturated to the initial irreducible water saturation and then aged, and then the next mineral Chemical injection water flooding experiment

其中,基于油水两相渗流理论和Li-Horne模型的评价不同矿化度水驱油实验的理论模型推导如下:Among them, the theoretical model for evaluating different salinity water flooding experiments based on oil-water two-phase seepage theory and Li-Horne model is deduced as follows:

假定自吸过程发生在垂直放置的岩样中,润湿相与非润湿相的渗流速度方程如下:Assuming that the self-absorption process occurs in a vertically placed rock sample, the seepage velocity equations of the wetting and non-wetting phases are as follows:

根据毛管压力的定义,润湿相的压力方程为pw=pnw-Pc,代入方程(1a),得:According to the definition of capillary pressure, the pressure equation of the wetting phase is pw =pnw -Pc , and into equation (1a), we get:

其中,in,

方程(1b)可以变形为:Equation (1b) can be transformed into:

其中,in,

在同向渗吸过程中,vw=vnw。方程(3)可以简化为:During co-imbibition, vw =vnw . Equation (3) can be simplified to:

把方程(4)代入(2),可得:Substituting equation (4) into (2), we get:

定义并且在活塞式渗吸过程中,成立。方程(5)可变形为:definition And in the process of piston imbibition, established. Equation (5) can be transformed into:

假设在多孔介质中Swi均匀分布,则润湿相的渗吸总量可由如下方程计算:Assuming a uniform distribution ofSwi in the porous medium, the total amount of imbibition in the wetting phase can be calculated by the following equation:

Nwt=Axφ(Swf-Swi) (7)Nwt =Axφ(Swf -Swi ) (7)

润湿相的渗吸速度qw=Avw,方程(6)可以如下表述:The imbibition velocity qw =Avw of the wetting phase, equation (6) can be expressed as follows:

定义和以便与其它任何含水饱和度下的毛管压力和有效流度区分。将方程(7)代入方程(8)后,可以得到如下方程:definition and in order to distinguish it from capillary pressure and effective mobility at any other water saturation. After substituting equation (7) into equation (8), the following equation can be obtained:

其中,in,

在驱替过程中,进入岩心水的速度等于驱替出岩心油的速度,即qw=qo。方程(9)可变为:During the displacement process, the velocity of water entering the core is equal to the velocity of displacing the core oil, that is, qw =qo . Equation (9) can be transformed into:

考虑驱替压差的影响,方程(10)可变形为:Considering the effect of displacement pressure difference, equation (10) can be transformed into:

其中,Jo=qo/△p,a1=a0/△p,b1=b0/△p。Among them, Jo =qo /Δp, a1 =a0 /Δp, b1 =b0 /Δp.

定义两相渗流能力评价参数如下:The two-phase seepage capacity evaluation parameters are defined as follows:

则,方程(11)可变形为:Then, equation (11) can be transformed into:

符号注释:vw和vnw分别表示润湿相和非润湿相的渗流速度;kw和knw为润湿相和非润湿相的有效渗透率;μw和μnw、ρw和ρnw分别为润湿相和非润湿相的粘度、密度;pw和pnw代表距离为x时润湿相和非润湿相的压力;g为重力加速度;Pc为毛管压力;Me为有效流度;Mw为湿相流度;Mnw为非湿相流度;Δρ为润湿相与非润湿相的密度差;A为岩心横截面积;L为岩心长度;φ为岩心孔隙度;Swf为某一时刻的含水(或润湿相)饱和度;Swi为初始含水(或润湿相)饱和度;Sor为残余油饱和度;qw为润湿相的渗吸速度;qo为驱替实验在Swf下的产油量;a0为毛管压力相关系数;b0为重力相关系数;a1为考虑驱替压差的毛管压力相关系数;b1为考虑驱替压差的重力相关系数;R为岩心驱替/自吸实验中某一驱替/自吸速度对应的原油采收率;pc*为在Swf下的毛管压力;Me*为Swf下的两相全流度;Ip为两相渗流能力评价参数;Δp为驱替压差;Jo为驱替实验在Swf下单位压差下的产油速度;Nwt是润湿相的渗吸总量;Vp为孔隙体积。Symbol notes: vw and vnw represent the seepage velocity of the wetting and non-wetting phases, respectively; kw and knw are the effective permeability of the wetting and non-wetting phases; μw and μnw , ρw and ρnw are the viscosity and density of the wetting and non-wetting phases, respectively; pw and pnw represent the pressures of the wetting and non-wetting phases when the distance is x; g is the acceleration of gravity; Pc is the capillary pressure; Me is the effective mobility; Mw is the wet phase mobility; Mnw is the non-wet phase mobility; Δρ is the density difference between the wetting phase and the non-wetting phase; A is the core cross-sectional area; L is the core length; φ is the core porosity; Swf is the water (or wet phase) saturation at a certain time; Swi is the initial water (or wet phase) saturation; Sor is the residual oil saturation; qw is the wet phase qo is the oil production of the displacement experiment under Swf ; a0 is the capillary pressure correlation coefficient; b0 is the gravity correlation coefficient; a1 is the capillary pressure correlation coefficient considering the displacement pressure difference; b1 is the gravity correlation coefficient considering the displacement pressure difference; R is the oil recovery rate corresponding to a certain displacement/self-absorption rate in the core flooding/self-absorption experiment; pc* is the capillary pressure under Swf ; Me* is the two-phase full mobility at Swf ; Ip is the evaluation parameter of the two-phase seepage capacity; Δp is the displacement pressure difference; Jo is the oil production rate of the displacement experiment under the unit pressure difference under Swf ; Nwt is the total amount of imbibition of the wetting phase;Vp is the pore volume.

利用方程(11)中的油水两相渗流模型拟合不同矿化度注入水驱油实验对应的单位压差产油速度与原油采收率倒数之间的关系(数据如下表1所示),获得相应的拟合参数,见图3,拟合效果很好。The oil-water two-phase seepage model in equation (11) was used to fit the relationship between the oil production rate per unit pressure difference and the reciprocal of the crude oil recovery factor corresponding to different salinity injection water flooding experiments (data shown in Table 1 below), The corresponding fitting parameters are obtained, as shown in Figure 3, and the fitting effect is very good.

表1:平行样品2_砂砾岩的地层水驱油实验数据Table 1: Experimental data of formation water flooding of parallel sample 2_ glutenite

通过拟合不同岩性的4块岩样不同矿化度注入水驱油实验结果,利用方程(12),结合岩心物性参数计算获得对应的两相渗流能力评价参数(如下表2所示),图4为油水两相渗流能力评价因子与5%原油采收率下的单位压差产油速度之间的关系图,两者具有很好的线性关系,说明两相渗流能力评价参数能够很好的表征油水两相在细砂岩和砂砾岩储层中的渗流能力。By fitting four rock samples with different lithologies and different salinities of water-flooding experiment results, using equation (12), combined with core physical parameters, the corresponding two-phase seepage capacity evaluation parameters (as shown in Table 2 below) are obtained. Figure 4 shows the relationship between the oil-water two-phase seepage capacity evaluation factor and the oil production rate per unit pressure difference under 5% oil recovery factor. The two have a good linear relationship, indicating that the two-phase seepage capacity evaluation parameters can be very good. Characterization of seepage capacity of oil-water two-phase in fine sandstone and glutenite reservoirs.

根据上述获得的不同矿化度注入水驱油实验对应的油水两相渗流能力评价因子,计算得到不同矿化度注入水与地层水条件下油水两相渗流能力的差异,如下表2及见图5所示。2倍矿化度地层水与储层的配伍性最好,注入水为3倍矿化度地层水时两相渗流能力评价参数较注入水为2倍矿化度地层水时出现了下降。According to the evaluation factors of oil-water two-phase seepage ability corresponding to different salinity injection water flooding experiments obtained above, the difference in oil-water two-phase seepage ability under different salinity injection water and formation water conditions is calculated, as shown in Table 2 and Fig. 5 shown. The 2 times salinity formation water has the best compatibility with the reservoir. When the injected water is 3 times the salinity formation water, the two-phase seepage capacity evaluation parameter is lower than that when the injected water is 2 times the salinity formation water.

表2:不同矿化度注入水驱油实验对应的油水两相渗流能力评价参数Table 2: Evaluation parameters of oil-water two-phase seepage capacity corresponding to different salinity injection water flooding experiments

本发明另一实施例海上注水开发油田储层水敏伤害评价方法,包括以下步骤:Another embodiment of the present invention includes the following steps:

S1、根据矿场所取地层水离子成分分析结果配制3倍矿化度地层水、2倍矿化度地层水、地层水、1/2倍矿化度地层水和蒸馏水,驱替实验所用原油为地层原油,岩心选择同一口井位置、岩性、储层物性相近的2块平行岩样,分别是平行岩样1和平行岩样2,并进行常规物性测试(长度、直径、孔隙度、渗透率等)。其中,在步骤S1中,主要是准备不同矿化度注入水驱油实验所需要的流体与岩心资料。S1. Prepare formation water with 3 times salinity, formation water with 2 times salinity, formation water, 1/2 times salinity formation water and distilled water according to the ion composition analysis results of formation water taken from the mine site. The crude oil used in the displacement experiment is: For formation crude oil, two parallel rock samples with similar well location, lithology, and reservoir physical properties are selected as cores, namely

S2、对平行岩样1依次进行地层水、2倍矿化度地层水和3倍矿化度地层水的水驱油实验,对平行岩样2依次进行地层水、1/2倍矿化度地层水和蒸馏水的水驱油实验,同一块岩样做完一种矿化度注入水驱油实验后,直接重新饱和油到初始束缚水饱和度后进行老化,然后再做下一种矿化度注入水驱油实验。其中,在步骤S2中,对两块平行岩样分别进行注入水矿化度升高和降低的水驱油实验。S2. Carry out the water flooding experiment of formation water, 2 times salinity formation water and 3 times salinity formation water in sequence for

S3、基于油水两相渗流理论和Li-Horne模型,建立考虑驱替压差与可动油饱和度影响的油水两相渗流模型,进而推导获得表征储层中油水两相渗流能力的评价参数计算模型。其中,在步骤S3中,主要针对储层中油水两相渗流特征,建立评价不同矿化度注入水驱油实验对应的油水两相渗流能力表征方法。S3. Based on the oil-water two-phase seepage theory and the Li-Horne model, establish an oil-water two-phase seepage model considering the influence of displacement pressure difference and movable oil saturation, and then derive the evaluation parameters that characterize the oil-water two-phase seepage capacity in the reservoir. Model. Among them, in step S3, mainly aiming at the characteristics of oil-water two-phase seepage in the reservoir, a method for evaluating oil-water two-phase seepage capability corresponding to different salinity injection water flooding experiments is established.

S4、记录不同矿化度注入水驱油实验过程中的驱替时间、驱替压差、产油量、产水量,利用S3中的油水两相渗流模型拟合不同矿化度注入水驱油实验对应的单位压差产油速度与采出程度倒数之间的关系,获得相应的拟合参数。S4. Record the displacement time, displacement pressure difference, oil production, and water production during the experiment of water flooding with different salinities, and use the oil-water two-phase seepage model in S3 to fit the water flooding with different salinities. The relationship between the oil production rate per unit pressure difference and the reciprocal of the recovery degree corresponding to the experiment was obtained, and the corresponding fitting parameters were obtained.

S5、根据S4中拟合参数和S1中岩心常规物性测试结果,利用S3中储层渗流能力评价因子计算模型,获得不同矿化度注入水驱油实验对应的储层渗流能力评价因子参数,评价不同矿化度注入水对储层的伤害程度,指导海上注水开发油田合理注入水源选择。其中,在步骤S4、S5中,利用S3中的理论方法评价S2中的水驱油实验结果,获得不同矿化度注入水驱油实验对应的储层渗流能力评价因子;S5. According to the fitting parameters in S4 and the conventional physical property test results of the core in S1, and using the reservoir seepage capacity evaluation factor calculation model in S3, obtain the reservoir seepage capacity evaluation factor parameters corresponding to different salinity injection water flooding experiments, and evaluate The degree of damage to reservoirs caused by injected water with different salinities guides the rational selection of injection water sources for offshore waterflooding development oilfields. Wherein, in steps S4 and S5, the theoretical method in S3 is used to evaluate the results of the water flooding experiment in S2, and the reservoir seepage capacity evaluation factors corresponding to the water flooding experiments with different salinities are obtained;

S6、根据计算的评价因子评价注入水矿化度升高和降低对储层的水敏伤害程度,从而指导海上注水开发油田合理注入水源选择。S6. Evaluate the increase of the salinity of the injected water and the reduction of the degree of water-sensitive damage to the reservoir according to the calculated evaluation factor, so as to guide the rational selection of the injection water source for the offshore water-flooding development oilfield.

本发明的海上注水开发油田储层水敏伤害评价方法,有效解决了行业中常用的储层水敏伤害评价方法与海上注水开发油田所用的注入水源矿化度普遍高于地层水和注水开发油田储层普遍存在油水两相流动的情况不符导致注入水与储层的配伍性难以准确量化的难题。为海上注水开发油田储层水敏伤害评价提供一种表征合理、可靠性强、操作性强的方法,有效指导海上注水开发油田合理注入水源的选择,为海上注水开发油田合理、高效开发提供了有利的支持和保障。The method for evaluating water-sensitive damage to reservoirs in offshore water-flooding development oilfields of the present invention effectively solves the problems commonly used in the industry for evaluating water-susceptibility damage to reservoirs and that the salinity of injected water sources used in offshore water-flooding oilfields is generally higher than that of formation water and water-flooding oilfields. The inconsistency of oil-water two-phase flow in reservoirs generally makes it difficult to accurately quantify the compatibility of injected water with the reservoir. It provides a method with reasonable representation, strong reliability and strong operability for the evaluation of reservoir water-sensitive damage in offshore waterflooding development oilfields, effectively guides the selection of reasonable injection water sources for offshore waterflooding development oilfields, and provides a rational and efficient development method for offshore waterflooding development oilfields. Favorable support and assurance.

为了进一步证实评价结果的可靠性,本发明优选实施例选择砂砾岩平行样品3、4、5、6进行不同矿化度水驱的核磁共振实验(如下表3所示),实验结果见图6a、6b、6c。对比3倍矿化度地层水和2倍矿化度地层水的核磁共振实验结果,一部分大孔转化为中孔导致油水两相渗流能力下降,主要原因是3倍矿化度地层水中用于中和黏土矿物中的负电荷和作为交换阳离子后剩余的Ca2+、Mg2+较多,其与储层中的SO42-、CO32-反应生成沉淀或难溶物质堵塞大孔喉。砂砾岩平行样品3、4、5、6在不同矿化度单相水驱渗透率测试结果见下表3及图7,水测渗透率随注入水矿化度增加而增加,说明水测渗透率难以有效表征储层微观孔喉变化对渗流能力的影响,这一结果也进一步证实了建立的储层水敏伤害评价方法的优越性。In order to further confirm the reliability of the evaluation results, in the preferred embodiment of the present invention,

表3:砂砾岩平行样品不同矿化度单相水驱的核磁共振实验数据与水测渗透率数据Table 3: NMR experimental data and water permeability data of single-phase water flooding with different salinity of parallel samples of glutenite

通过以上评价结果,结合可作为油田注入水源的水分析结果,选择与两倍矿化度地层水相近的水源作为油田注入水源能够有效降低储层水敏伤害,提高油田注水开发效果。Based on the above evaluation results, combined with the water analysis results that can be used as the oilfield injection water source, selecting a water source similar to the formation water with twice the salinity as the oilfield injection water source can effectively reduce the water-sensitive damage of the reservoir and improve the oilfield water injection development effect.

应当理解的是,对本领域普通技术人员来说,可以根据上述说明加以改进或变换,而所有这些改进和变换都应属于本发明所附权利要求的保护范围。It should be understood that, for those skilled in the art, improvements or changes can be made according to the above description, and all these improvements and changes should fall within the protection scope of the appended claims of the present invention.

Claims (7)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210390519.XACN114878416B (en) | 2022-04-14 | 2022-04-14 | Selection and evaluation methods of reasonable injection water sources for offshore water injection development of oil fields |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210390519.XACN114878416B (en) | 2022-04-14 | 2022-04-14 | Selection and evaluation methods of reasonable injection water sources for offshore water injection development of oil fields |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114878416Atrue CN114878416A (en) | 2022-08-09 |

| CN114878416B CN114878416B (en) | 2024-05-14 |

Family

ID=82669409

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210390519.XAActiveCN114878416B (en) | 2022-04-14 | 2022-04-14 | Selection and evaluation methods of reasonable injection water sources for offshore water injection development of oil fields |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114878416B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118730844A (en)* | 2023-03-29 | 2024-10-01 | 中国石油天然气股份有限公司 | Improved method, device, electronic equipment and medium for oilfield injection water index control |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103926186A (en)* | 2014-04-28 | 2014-07-16 | 西安石油大学 | Method for quantitatively evaluating influence of water injection on distribution of pore throats |

| CN106522931A (en)* | 2015-09-14 | 2017-03-22 | 中国石油化工股份有限公司 | Injected water damage evaluation method under simulated stratum condition |

| CN107121370A (en)* | 2017-03-29 | 2017-09-01 | 西南石油大学 | Fine and close oil reservoir Water trapping damages experimental evaluation method |

| CN107907654A (en)* | 2017-11-07 | 2018-04-13 | 北京拓普莱博油气田开发技术研究院 | A kind of method and device of the definite LIMESTONE RESERVOIR injection optimal salinity of water |

| WO2021180189A1 (en)* | 2020-03-13 | 2021-09-16 | 重庆科技学院 | Multi-element thermal fluid thermal recovery oil reservoir numerical simulation method |

- 2022

- 2022-04-14CNCN202210390519.XApatent/CN114878416B/enactiveActive

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103926186A (en)* | 2014-04-28 | 2014-07-16 | 西安石油大学 | Method for quantitatively evaluating influence of water injection on distribution of pore throats |

| CN106522931A (en)* | 2015-09-14 | 2017-03-22 | 中国石油化工股份有限公司 | Injected water damage evaluation method under simulated stratum condition |

| CN107121370A (en)* | 2017-03-29 | 2017-09-01 | 西南石油大学 | Fine and close oil reservoir Water trapping damages experimental evaluation method |

| CN107907654A (en)* | 2017-11-07 | 2018-04-13 | 北京拓普莱博油气田开发技术研究院 | A kind of method and device of the definite LIMESTONE RESERVOIR injection optimal salinity of water |

| WO2021180189A1 (en)* | 2020-03-13 | 2021-09-16 | 重庆科技学院 | Multi-element thermal fluid thermal recovery oil reservoir numerical simulation method |

Non-Patent Citations (2)

| Title |

|---|

| 孙雷;魏瑾;李浩;雷昊;罗军;: "WS17-2低渗砂砾岩油藏注水/注气长岩心驱替效果评价及方案优选", 油气藏评价与开发, no. 06, 26 December 2017 (2017-12-26)* |

| 张亚蒲;杨正明;侯海涛;朱光亚;: "中东H油田不同注入水对储层渗流能力的影响", 油气地质与采收率, no. 02, 25 March 2017 (2017-03-25)* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118730844A (en)* | 2023-03-29 | 2024-10-01 | 中国石油天然气股份有限公司 | Improved method, device, electronic equipment and medium for oilfield injection water index control |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114878416B (en) | 2024-05-14 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Lufeng et al. | Evaluation of permeability damage caused by drilling and fracturing fluids in tight low permeability sandstone reservoirs | |

| Zhou et al. | Interrelationship of wettability, initial water saturation, aging time, and oil recovery by spontaneous imbibition and waterflooding | |

| Lian et al. | The characteristics of relative permeability curves in naturally fractured carbonate reservoirs | |

| Liang et al. | Impacts of low harm fracturing fluid on fossil hydrogen energy production in tight reservoirs | |

| CN110261274B (en) | Evaluation method for static contribution rate of spontaneous imbibition effect on water flooding oil displacement efficiency | |

| CN105651665B (en) | A kind of drilling and completing fluids influence evaluation method to rock core grease permeability | |

| CN109612906A (en) | A method for optimal water flooding speed in dynamic water flooding in tight oil reservoirs | |

| CN110879196B (en) | Oil-water phase permeability testing method for oil-rich condensate gas reservoir | |

| CN113484216B (en) | Method for evaluating water phase flowback rate and reasonable flowback pressure difference of tight sandstone gas reservoir | |

| Busch et al. | Determining CO2/brine relative permeability and capillary threshold pressures for reservoir rocks and caprocks: Recommendations for development of standard laboratory protocols | |

| CN110646332A (en) | Determination method of movable water saturation in gas-water interbedded gas reservoirs under high temperature and high pressure conditions | |

| CN110309611B (en) | Gas-water two-phase seepage rule prediction method and system based on gas-water thickness distribution | |

| Xu et al. | Reducing residual oil saturation: underlying mechanism of imbibition in oil recovery enhancement of tight reservoir | |

| CN113406307A (en) | Conversion method of resistivity index and relative permeability of argillaceous sandstone reservoir | |

| CN104389592B (en) | Oil loss evaluation experiment test method for water flooded layer of bottom water condensate gas reservoir with oil rim | |

| CN116044389A (en) | Determination method for reasonable production pressure difference of early failure exploitation of tight shale oil reservoir | |

| CN114878416A (en) | Selection method and evaluation method of rational injection water source for offshore water injection development oil field | |

| Zhang et al. | An integrated method to evaluate formation damage resulting from water and alkali sensitivity in dongping bedrock reservoir | |

| Qi et al. | Mathematical model for prediction of dynamic reserves loss due to water invasion in water-drive gas reservoir | |

| CN118049226A (en) | Evaluation method for flow capacity of heterogeneous shale oil reservoir | |

| CN114397228B (en) | Method for evaluating long-term migration performance of polymer for oil displacement in stratum | |

| Zhang et al. | Experimental Investigation of Seepage Mechanism on Oil‐Water Two‐Phase Displacement in Fractured Tight Reservoir | |

| He et al. | Research progress on the method of determining gas–water relative permeability curve in unconventional reservoirs | |

| CN116877047A (en) | Method for measuring oil-water relative permeability curve of low-permeability core under low-speed flow condition | |

| Moghadasi et al. | Use of X-Ray Saturation Measurements in Flowthrough Investigations for the Characterization of Two-and Three-Phase Relative Permeability of Carbonate Rock |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |