CN114810028A - A kind of underground in-situ pyrolysis mining technology of huge thick coal seam - Google Patents

A kind of underground in-situ pyrolysis mining technology of huge thick coal seamDownload PDFInfo

- Publication number

- CN114810028A CN114810028ACN202210500511.4ACN202210500511ACN114810028ACN 114810028 ACN114810028 ACN 114810028ACN 202210500511 ACN202210500511 ACN 202210500511ACN 114810028 ACN114810028 ACN 114810028A

- Authority

- CN

- China

- Prior art keywords

- pyrolysis

- well

- coal seam

- coal

- mining

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B43/00—Methods or apparatus for obtaining oil, gas, water, soluble or meltable materials or a slurry of minerals from wells

- E21B43/295—Gasification of minerals, e.g. for producing mixtures of combustible gases

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B43/00—Methods or apparatus for obtaining oil, gas, water, soluble or meltable materials or a slurry of minerals from wells

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B43/00—Methods or apparatus for obtaining oil, gas, water, soluble or meltable materials or a slurry of minerals from wells

- E21B43/006—Production of coal-bed methane

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B43/00—Methods or apparatus for obtaining oil, gas, water, soluble or meltable materials or a slurry of minerals from wells

- E21B43/30—Specific pattern of wells, e.g. optimising the spacing of wells

Landscapes

- Engineering & Computer Science (AREA)

- Geology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Mining & Mineral Resources (AREA)

- Environmental & Geological Engineering (AREA)

- Fluid Mechanics (AREA)

- Physics & Mathematics (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Production Of Liquid Hydrocarbon Mixture For Refining Petroleum (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及巨厚煤层热解开采技术领域,具体为一种巨厚煤层的地下原位热解开采工艺。The invention relates to the technical field of pyrolysis mining of huge thick coal seams, in particular to an underground in-situ pyrolysis mining technology of huge thick coal seams.

背景技术Background technique

目前厚煤层的开采,通过分层和大采高放顶煤结合的办法,可以开采一些厚度达到四十米左右的煤层,但这要求煤层上部水系不发育以及有良好的隔水层,同时需要保留足够的煤柱支撑来减少或延迟顶板坍塌,这种赋存条件的煤层比较少见,而且所开采的煤层越厚,地表塌陷现象也越严重,对于易自燃厚煤层的开采,不仅开采出来的煤在地表堆放时易自燃,而且由于顶板塌陷导致水及空气进入煤层也易导致煤在地层的燃烧,所以现在巨厚煤层(单层大于30米)的开采,存在着采收率低、开采成本高、对环境和生态影响较大等问题,无法进行大规模经济、高效、环保的开采。At present, in the mining of thick coal seams, some coal seams with a thickness of about 40 meters can be mined through the combination of stratification and large mining height top coal caving. Retain enough coal pillar support to reduce or delay the collapse of the roof. The coal seam with this occurrence condition is relatively rare, and the thicker the coal seam mined, the more serious the surface collapse phenomenon. For the mining of thick coal seams that are prone to spontaneous combustion, not only the mined Coal is easy to spontaneously ignite when stacked on the surface, and water and air entering the coal seam due to the collapse of the roof can also easily lead to coal burning in the formation. Therefore, the mining of extremely thick coal seams (single layer greater than 30 meters) has low recovery rate and mining. Due to the problems of high cost and great impact on the environment and ecology, large-scale economical, efficient and environmentally friendly mining cannot be carried out.

公开号为AU2019438341B2的澳洲发明专利提供了A method for the radialmining of opencast end slope remnant coal,comprising:arrangement of L-shapedmain caverns(6,13)or a U-shaped main cavern(11)and radial mining.Branchcaverns(4,9,10)are formed by excavation from the L-shaped main caverns(6,13)or the U-shaped main cavern(11)to a direction perpendicular to or obliquewith respect to the main caverns(6,11,13).A coal mining system and atransportation system of the mining method are both remotely controlled.Anexcavator(1)excavates coal and a belt conveyor(2)conveys the coal.Theventilation of the main caverns(6,11,13)of the mining method is implementedin an exhaust manner,and the ventilation of the branch caverns(4,9,10)isimplemented in a forced manner.The length of the branch caverns(4,9,10)of themining method does not exceed the maximum operation and control distance of aremote control system,and the length of the main caverns(6,11,13)needs toensure that all end slope remnant coal is excavated in the case that thelength of the branch caverns(4,9,10)does not exceed the maximum operation andcontrol distance of the remote control system。The Australian invention patent publication number AU2019438341B2 provides a method for the radialmining of opencast end slope remnant coal,comprising:arrangement of L-shaped main caverns(6,13)or a U-shaped main cavern(11)and radial mining.Branchcaverns (4,9,10)are formed by excavation from the L-shaped main caverns(6,13) or the U-shaped main cavern(11) to a direction perpendicular to or oblique with respect to the main caverns(6,11, 13). A coal mining system and atransportation system of the mining method are both remotely controlled. Anexcavator(1)excavates coal and a belt conveyor(2)conveys the coal.Theventilation of the main caverns(6,11,13)of the The mining method is implemented in an exhaust manner, and the ventilation of the branch caverns(4,9,10) is implemented in a forced manner. The length of the branch caverns(4,9,10) of the mining method does not exceed the maximum operation and control distance of aremote control system, and the length of the main caverns(6,11,13) needs to ensure that all end slope remnant coal is excavated in the case that the length of the branch caverns(4,9,10) does not exceed the maximum operation and control distance of the remote control system.

公开号为CN103726846A中国发明专利中提出了一种上行分层开采特厚煤层的工艺,其过程是首先对厚煤层进行合理划分,然后分别对下分层工作面进行开采与充填,然后对充填效果及顶板运移进行分析,最后逐步向上开采各分层,直至完成所有分层的充填开采。The Chinese invention patent with publication number CN103726846A proposes a process for upward layered mining of extra-thick coal seams. The process is to first divide the thick coal seam reasonably, and then separately mine and fill the lower layered working face, and then adjust the filling effect. And the roof migration is analyzed, and finally each layer is gradually mined upward until the filling and mining of all layers is completed.

上述开采方法均为于井工开采领域,是煤的物理开采方式,都对煤层的储层特性及地质条件有一定的选择,要求煤层具备能够形成再生煤体的条件,煤层不易自燃,瓦斯含量不大,同时要求施工机械要能够应对复杂的冒落及复杂的工程施工要求等,目前来看,厚煤层的开采,主要存在以下几个方面的制约,一是开采过程中煤的开采回收率较低,包括分层及放煤的损失以及区段煤柱的损失;二是开采过程中存在的安全环保问题,包括瓦斯防治及煤自燃的问题;亦需要解决地层塌陷引发的透水及水体污染问题;三是开采的经济性问题,由于以上这些问题的制约,使得一些地区的厚煤层开采工作难以开展。The above mining methods are all in the field of well mining, which is the physical mining method of coal, and all have certain choices for the reservoir characteristics and geological conditions of the coal seam. At the same time, construction machinery is required to be able to cope with complex caving and complex engineering construction requirements. At present, the mining of thick coal seams is mainly restricted by the following aspects. First, the recovery rate of coal in the mining process It is relatively low, including the loss of stratification and coal caving and the loss of coal pillars in sections; the second is the safety and environmental protection problems existing in the mining process, including gas prevention and coal spontaneous combustion problems; it is also necessary to solve the permeation and water pollution caused by stratum collapse. The third is the economic problem of mining. Due to the constraints of the above problems, it is difficult to carry out the mining of thick coal seams in some areas.

发明内容SUMMARY OF THE INVENTION

针对上述存在的技术不足,本发明的目的是提供一种巨厚煤层的地下原位热解开采工艺,解决用井工开采方法开采巨厚煤层存在的回采率低、开采效益差、煤炭自燃及瓦斯突出风险高、透水及地表塌陷的问题,特别是能够解决厚度超过30米以上巨厚煤层条件下煤的安全、高效、高采出率开采问题。In view of the above-mentioned technical deficiencies, the purpose of the present invention is to provide a kind of underground in-situ pyrolysis mining technology of huge thick coal seam, which solves the problems of low recovery rate, poor mining efficiency, spontaneous combustion of coal and low mining efficiency in mining huge thick coal seams with well mining method. It can solve the problems of high risk of gas outburst, water penetration and surface subsidence, especially the problem of safe, efficient and high recovery rate mining of coal under the condition of thick coal seam exceeding 30 meters.

为解决上述技术问题,本发明采用如下技术方案:In order to solve the above-mentioned technical problems, the present invention adopts the following technical solutions:

本发明提供一种巨厚煤层的地下原位热解开采工艺,包括以下具体步骤:The invention provides an underground in-situ pyrolysis mining process of a huge thick coal seam, comprising the following specific steps:

步骤一、对目标采煤区进行地质评估:通过评估来确定该区块煤层是否适合采用地下原位热解工艺进行开采,评估出该区块巨厚煤层适合热解法开发,进入下一步骤;

步骤二、热解单元建设:以地面钻井的方式构建煤层热解热量输入及产品产出通道,这些井网以反五点法部署,注入井及生产井均以垂直或接近垂直的角度穿过煤层,当其中一口井作为注入井时,其周围与其相邻的井则作为生产井,这一组井即构成了一个热解单元,相邻两个热解单元共有相邻井,通过多个热解单元的有序启动、运行来实现区块的热解开采;煤层的热解开采是通过在煤层部署热载体注入井及煤气、煤焦油生产井,由热载体将煤层发生低温热解需要的热量带入,煤层发生热解反应,形成低温热解煤气以及煤焦油并以气态方式由生产井产出来实现的。

步骤三、煤层水的排采:煤层中都含有多少不等的水分,特别巨厚煤层,一般都为低变质煤,含水量较大,为了有效地实施煤层热解,必须在热解前将其中的游离水分排出。采取整体排水的工作流程,即区块内所有的井组在完井后都开始排水作业,排水采用目前油田机械式采油所使用设备来进行,在排水过程中,如果煤层含有煤层气,则同时对煤层气进行回收利用,在区块排水过程中,较高部位煤层的水分下降较快,当井内水位低于煤层底部时,则认为这口井的排水工作结束,其它水位未降至煤层底部的井则继续排水,当大部分井的排水工作结束时,在区块煤层构造较低部位适当保留一些井继续充当排水井的角色,保证区块生产井内水面始终低于煤层底部;

步骤四、煤层热解:首先拆除排水设备,给井组安装热解配套设施,包括用于热载体注入及热解气态产品产出的隔热管的下入安装、井底测温仪及专用井口的安装、地面热载体加热器、热载体加压泵及产出品处理系统的安装调试,以及相关管网、储罐及配套设施的建设,当热解单元启动热解流程时,经过加压的热载体气体经过地面加热器的加热后由注入井注入煤层,可根据煤层厚度及煤层渗透率来确定热载体气体注入量,煤层较厚及煤层渗透率较高时采用较高的注入速率,反之采用较低的注入速率,注入速率随着热解过程的进行在不断调整,开始的时候较小一些,随着热解通道的逐步形成以及热解面的不断扩大而逐渐加大,其后当热解产品产率下降时,注入速率下调,直到热解完成,一般情况下,热解过程中热载体注入量按每米煤层厚度每小时50~150立方米(标准状态下体积)来调整,当热载体气体由注入井注入时,生产井井口阀门处于关闭状态,随着热载体气体的持续注入,注入井井口压力不断上升,同时生产井井口压力也会上升,当注入井井口压力上升到地层压力的65-75%时,将生产井中压力上升较少的井的阀门依次打开开始生产,随着生产的进行,这些井的产量逐步增加,井口压力也逐步上升,同时要检测产出井产品的井口温度,通过对井口生产压力、产量及温度的监控来动态调整生产井生产阀门开启量,来达到各口井比较平衡的生产参数,最终实现煤层较高的热解率及利用率,当煤层参数相异性较大时,会发生煤层热解反应不均衡的情况,这时需要调整区域内生产井与注入井的搭配关系及相关生产参数,当区块内注入气体的量与产出气体的量基本相同且组分一致时,完成区块的煤的热解开采。Step 4. Coal seam pyrolysis: First, remove the drainage equipment and install pyrolysis supporting facilities for the well group, including the installation of heat insulation pipes for heat carrier injection and pyrolysis gaseous product output, bottom hole thermometers and special The installation of the wellhead, the installation and commissioning of the surface heat carrier heater, the heat carrier pressurization pump and the output product processing system, as well as the construction of the related pipeline network, storage tank and supporting facilities, when the pyrolysis unit starts the pyrolysis process, it will be pressurized. The heat carrier gas is heated by the ground heater and injected into the coal seam from the injection well. The heat carrier gas injection amount can be determined according to the thickness of the coal seam and the permeability of the coal seam. On the contrary, a lower injection rate is used, and the injection rate is constantly adjusted with the progress of the pyrolysis process. It is relatively small at the beginning, and gradually increases with the gradual formation of the pyrolysis channel and the continuous expansion of the pyrolysis surface. When the yield of pyrolysis products decreases, the injection rate is lowered until the pyrolysis is completed. In general, the injection amount of heat carrier during the pyrolysis process is adjusted by 50 to 150 cubic meters per hour per meter of coal seam thickness (volume in standard state). , when the heat carrier gas is injected from the injection well, the wellhead valve of the production well is closed. With the continuous injection of the heat carrier gas, the wellhead pressure of the injection well continues to rise, and the wellhead pressure of the production well also rises. When the wellhead pressure of the injection well rises When the formation pressure reaches 65-75% of the formation pressure, the valves of the wells with less pressure rise in the production wells are opened in turn to start production. The wellhead temperature of the well product, through the monitoring of the wellhead production pressure, output and temperature to dynamically adjust the production valve opening amount of the production well, to achieve a relatively balanced production parameter for each well, and finally achieve a higher coal seam pyrolysis rate and utilization rate , when the dissimilarity of coal seam parameters is large, the unbalanced coal seam pyrolysis reaction will occur. At this time, it is necessary to adjust the matching relationship between production wells and injection wells in the area and related production parameters. When the amount of outgoing gas is basically the same and the composition is the same, the coal pyrolysis mining of the block is completed.

优选的,所述步骤一中,该工艺优先应用于单层厚度超过20米的厚煤层,评估要求煤层有完整致密的顶底板隔层,与水系没有直接沟通,一般要求与水系的距离大于50米,保证在煤层热解时水系的水不会有明显的侵入,同时通过勘探准确了解煤层的倾角、走向及断层情况,并对煤层进行渗透率、煤层气项目测试并对煤样进行理化分析,作为布井及工程设计的依据。Preferably, in the first step, the process is preferentially applied to thick coal seams with a single layer thickness of more than 20 meters. The evaluation requires the coal seam to have complete and dense roof and floor interlayers, and there is no direct communication with the water system. Generally, the distance from the water system is required to be greater than 50 meters. To ensure that the water in the water system will not have obvious invasion during the coal seam pyrolysis, and at the same time accurately understand the dip angle, trend and fault conditions of the coal seam through exploration, and conduct the permeability and coalbed methane project tests of the coal seam and physical and chemical analysis of coal samples. , as the basis for well layout and engineering design.

优选的,所述步骤二中,注入井与生产井的井距不超过一百米,其具体井距主要由煤层厚度及煤层渗透率来确定,煤层较厚或煤层渗透率较低采用小的井距,反之则采用较大井距。Preferably, in the second step, the well spacing between the injection well and the production well is no more than 100 meters, and the specific well spacing is mainly determined by the thickness of the coal seam and the permeability of the coal seam. Well spacing, and vice versa, use a larger well spacing.

优选的,如权利要求1所述的一种巨厚煤层的地下原位热解开采工艺,其特征在于,所述步骤二中,注入井及生产井生产套管均采用耐温耐蚀钢材,并设置热膨胀补偿短节。Preferably, the underground in-situ pyrolysis mining process of a huge thick coal seam as claimed in

优选的,所述步骤二中,为了保证热解产率及煤层利用率,在生产过程中注入井与生产井的角色可以互换。Preferably, in the second step, in order to ensure the pyrolysis yield and coal seam utilization rate, the roles of the injection well and the production well can be interchanged during the production process.

优选的,所述步骤二中,根据煤层地质情况,井网方案也可以是四点法、反九点法方案,使得井网的设置能够有利热解的均匀、可控进行即可。Preferably, in the second step, according to the geological conditions of the coal seam, the well pattern scheme may also be a four-point method or an inverse nine-point method, so that the setting of the well pattern can facilitate the uniform and controllable pyrolysis.

优选的,所述步骤三中,如果煤层比较致密,则首先需要对煤层进行压裂改造,保证井组内各口井之间的联通要求,然后进行排水作业,排出压裂液及煤层自由水。Preferably, in the third step, if the coal seam is relatively tight, fracturing the coal seam needs to be carried out first to ensure the communication requirements between the wells in the well group, and then the drainage operation is carried out to discharge the fracturing fluid and the free water of the coal seam. .

优选的,所述步骤四中,为保证加热强度,在注入井井筒内设置加热器作为主加热器或辅助加热器。Preferably, in the fourth step, in order to ensure the heating intensity, a heater is provided in the wellbore of the injection well as a main heater or an auxiliary heater.

优选的,所述步骤四中,热载体气体在注入井井底温度不低于600℃,所述热载体气体可以是天然气、二氧化碳、氮气中任一种或者天然气、二氧化碳、氮气的混合体,也可以是区块内生产出的煤层热解气。Preferably, in the step 4, the temperature of the heat carrier gas at the bottom of the injection well is not lower than 600°C, and the heat carrier gas can be any one of natural gas, carbon dioxide, nitrogen, or a mixture of natural gas, carbon dioxide, and nitrogen, It can also be the coal seam pyrolysis gas produced in the block.

本发明的有益效果在于:The beneficial effects of the present invention are:

一、能够实现目前井工技术难以开采或无法开采的巨厚煤层的开发利用:采用热解工艺开采巨厚煤层,煤层越厚越有利于工艺的经济性,煤层中的瓦斯作为优质资源亦同时被采出,这些巨量资源的有效开发利用,能够缓解煤炭资源存量压力;1. It can realize the development and utilization of huge and thick coal seams that are difficult or impossible to mine by current well technology: the use of pyrolysis technology to mine huge thick coal seams, the thicker the coal seam, the more economical the process is. After being mined, the effective development and utilization of these huge resources can relieve the pressure on the coal resource stock;

二、实现了煤炭低碳洁净化开采的发展要求:低变质煤化学活性大,挥发分高,焦油含量较高,通过热解得到优质的混合煤气及焦油产品,避免了这些低变质煤在开采出地面后在运输、储存、使用方面的问题,且在煤层的热解开采过程当中,由于煤在热解后只是轻质组分及煤焦油的析出,煤层基本形态构架还存在,只是孔隙度增加,避免造成透水及地表塌陷以及由此引发的一系列问题;2. Realize the development requirements of low-carbon and clean coal mining: low-metamorphic coal has high chemical activity, high volatile content and high tar content, and high-quality mixed gas and tar products are obtained through pyrolysis, which avoids the mining of these low-metamorphic coals. Problems in transportation, storage and use after leaving the ground, and in the process of pyrolysis and mining of coal seams, since coal only precipitates light components and coal tar after pyrolysis, the basic morphological framework of coal seams still exists, only the porosity increase to avoid water penetration and surface subsidence and a series of problems arising therefrom;

三、资源利用率高:当巨厚煤层经过热解开采后,原煤层基本上以半焦的形式存在于原位,煤层能够进行进一步的井工开采或进行进一步的地下化学合成利用,如果进行进一步的井工开采,由于煤层轻质组分已被提取,避免自燃及瓦斯突出的问题,煤的强度变大,有利于煤炭的开采,而且产出品价值有明显提升,如果进行进一步的煤层化学加工或合成,由于煤层强度及孔隙度明显增加,且煤的性状更加稳定和一致,有利于相关反应的进行。3. High resource utilization rate: When the huge thick coal seam is mined by pyrolysis, the original coal seam basically exists in the form of semi-coke, and the coal seam can be further exploited by well mining or further underground chemical synthesis and utilization. In further well mining, since the light components of the coal seam have been extracted, the problems of spontaneous combustion and gas outburst are avoided, and the strength of the coal increases, which is conducive to the mining of coal, and the value of the output products is significantly improved. If further coal seam chemical Processing or synthesis, because the coal seam strength and porosity are significantly increased, and the coal properties are more stable and consistent, which is conducive to the progress of related reactions.

附图说明Description of drawings

为了更清楚地说明本发明实施例或现有技术中的技术方案,下面将对实施例或现有技术描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图仅仅是本发明的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to explain the embodiments of the present invention or the technical solutions in the prior art more clearly, the following briefly introduces the accompanying drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained according to these drawings without creative efforts.

图1为本发明实施例提供的一种巨厚煤层的地下原位热解开采工艺的井网布置图;1 is a well pattern layout diagram of an underground in-situ pyrolysis mining process of a huge thick coal seam provided by an embodiment of the present invention;

图2为煤层排水及生产示意图;Figure 2 is a schematic diagram of coal seam drainage and production;

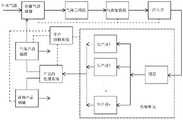

图3为煤地下原位开采流程图。Figure 3 is a flow chart of underground coal mining in situ.

附图标记说明:1、煤热解开采区域;2、生产井;3、注入井;4、排水井;5、地表;6、地层;7、煤层;8、热解气、煤焦油;9、煤层水。Description of reference numerals: 1. Coal pyrolysis mining area; 2. Production well; 3. Injection well; 4. Drainage well; 5. Surface; 6. Formation; 7. Coal seam; 8. Pyrolysis gas, coal tar; 9 , coal seam water.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

实施例1,一种巨厚煤层的地下原位热解开采工艺,包括以下具体步骤:

步骤一:对目标采煤区进行地质评估。通过评估来确定该区块煤层是否适合采用地下原位热解工艺进行开采,一般情况下,该工艺优先应用于单层厚度超过20米的厚煤层,要求煤层有完整致密的顶底板隔层,与水系没有直接沟通,一般要求与水系的距离大于50米,保证在煤层热解时水系的水不会有明显的侵入,同时通过勘探准确了解煤层的倾角、走向及断层情况,并对煤层进行渗透率、煤层气等项目测试并对煤样进行理化分析,如果评估该区块适合热解法开发,则进入下一步骤。Step 1: Carry out a geological assessment of the target coal mining area. Whether the coal seam in this block is suitable for mining by the underground in-situ pyrolysis process is determined through evaluation. Generally, this process is preferentially applied to the thick coal seam with a single layer thickness of more than 20 meters. There is no direct communication with the water system. Generally, the distance from the water system is required to be greater than 50 meters, so as to ensure that the water of the water system will not intrude significantly during the coal seam pyrolysis. Items such as permeability and coalbed methane are tested and the coal samples are subjected to physical and chemical analysis. If it is assessed that the block is suitable for pyrolysis development, proceed to the next step.

步骤二:热解单元建设。煤层的热解开采是通过在煤层部署热载体注入井及煤气、煤焦油生产井,由热载体将煤层发生低温热解需要的热量带入,煤层发生热解反应,形成低温热解煤气以及煤焦油并以气态方式由生产井产出来实现的,井网可以以反五点法部署,如图1所示,注入井及生产井均以垂直或接近垂直的角度穿过煤层,当其中一口井作为注入井时,其周围与其相邻的井则作为生产井,这一组井即构成了一个热解单元,相邻两个热解单元共有相邻井,通过多个热解单元的有序启动、运行来实现区块的热解开采,注入井与生产井的井距一般不超过一百米,主要由煤层厚度及煤层渗透率来确定,煤层较厚或煤层渗透率较低采用小的井距,反之则采用较大井距,为了保证热解产率及煤层利用率,在生产过程中注入井与生产井的角色可以互换,根据煤层地质情况,井网方案也可以是四点法或反七点法、反九点法等方案,只要井网的设置能够有利热解的均匀、可控进行即可,布井工程设计时,井型可以设计为定向井或直井,注入井及生产井生产套管均采用耐温耐蚀钢材,并设置热膨胀补偿短节,完井后,即进入下一步骤。Step 2: Pyrolysis unit construction. The pyrolysis mining of coal seam is to deploy heat carrier injection wells and gas and coal tar production wells in the coal seam. The tar is produced by the production well in a gaseous state, and the well pattern can be deployed in the reverse five-point method. As shown in Figure 1, both the injection well and the production well pass through the coal seam at a vertical or near-vertical angle. When one of the wells When used as injection wells, the surrounding wells are used as production wells. This group of wells constitutes a pyrolysis unit. Two adjacent pyrolysis units share adjacent wells. Start and run to realize the pyrolysis mining of the block. The distance between the injection well and the production well is generally not more than 100 meters, which is mainly determined by the thickness of the coal seam and the permeability of the coal seam. Well spacing, otherwise, use larger well spacing. In order to ensure the pyrolysis yield and coal seam utilization rate, the roles of injection wells and production wells can be interchanged in the production process. According to the geological conditions of the coal seam, the well pattern scheme can also be a four-point method. Or reverse seven-point method, reverse nine-point method and other schemes, as long as the well pattern can be set to facilitate the uniform and controllable pyrolysis. The production casing of the production well is made of temperature-resistant and corrosion-resistant steel, and a thermal expansion compensation sub is set. After the well is completed, the next step is entered.

步骤三:煤层水的排采。煤层中都含有多少不等的水分,特别是巨厚煤层,一般都为低变质煤,含水量较大,为了有效地实施煤层热解,必须在热解前将其中的游离水分排出,采取整体排水的工作流程,即区块内所有的井组在完井后都开始排水作业,排水采用目前油田机械式采油所使用设备来进行,在排水过程中,如果煤层含有煤层气,则同时对煤层气开采回收,在区块排水过程中,较高部位煤层的水分下降较快,当井内水位低于煤层底部时,则认为这口井的排水工作结束,其它产水的井则继续排水,当大部分井的排水工作结束时,在区块煤层构造较低部位适当保留一些井继续充当排水井的角色,保证区块生产井内水面始终低于煤层底部,完成排水要求的井组则进入热解作业环节,如果煤层比较致密,则首先需要对煤层进行压裂改造,保证井组内各口井之间的联通要求,然后进行排水作业,排出压裂液及煤层自由水,当煤层排水工作完成后,即进入下步煤层热解作业环节,如图2所示。Step 3: Drainage of coal seam water. Coal seams contain varying amounts of water, especially thick coal seams, which are generally low-metamorphic coals with large water content. The work flow of drainage, that is, all the well groups in the block start drainage after completion, and the drainage is carried out by the equipment used in the current oilfield mechanical oil recovery. During the drainage process, if the coal seam contains coalbed methane, the During the drainage process of the block, the moisture of the coal seam in the higher part drops rapidly. When the water level in the well is lower than the bottom of the coal seam, the drainage work of this well is considered to be over, and other wells producing water continue to drain. When the drainage work of most of the wells is completed, some wells are properly reserved in the lower part of the coal seam structure in the block to continue to act as drainage wells to ensure that the water surface of the production wells in the block is always lower than the bottom of the coal seam, and the well group that has completed the drainage requirements will enter the pyrolysis process. In the operation process, if the coal seam is relatively tight, fracturing of the coal seam should be carried out first to ensure the connection requirements between the wells in the well group, and then the drainage operation will be carried out to discharge the fracturing fluid and the free water of the coal seam. When the coal seam drainage work is completed After that, enter the next step of coal seam pyrolysis operation, as shown in Figure 2.

步骤四:煤层热解。首先给拆除排水设备的各个井组安装热解配套设施,包括用于热载体注入及热解气态产品产出的隔热管的下入安装,井底测温仪及专用井口的安装,地面热载体加热器、热载体加压泵及产出品处理系统的安装调试,以及相关管网、储罐及配套设施的建设,当热解单元启动热解流程时,经过加压的热载体气体经过地面加热器的加热后由注入井注入煤层,为保证加热强度,也可以在注入井井筒内设置加热器作为主加热器或辅助加热器,要求热载体在注入井井底温度不低于600℃,热载体气体可以是天然气、二氧化碳、氮气等,或是它们的混合体,也可以是区块内生产出的煤层热解气,可根据煤层厚度及煤层渗透率来确定热载体气体注入量,煤层较厚及煤层渗透率较高时采用较高的注入速率,反之采用较低的注入速率,注入速率随着热解过程的进行在不断调整,开始的时候较小一些,随着热解通道的逐步形成以及热解面的不断扩大而逐渐加大,其后当热解产品产率下降时,注入速率下调,直到热解完成,一般情况下,热解过程中热载体注入量按每米煤层厚度每小时50~150立方米(标准状态下)来调整,当热载体气体由注入井注入时,生产井井口阀门处于关闭状态,随着热载体气体的持续注入,注入井井口压力不断上升,同时生产井井口压力也会上升,但各个生产井井口压力上升的幅度不一定相同,当注入井井口压力上升到地层压力的百分之七十左右时,将生产井中压力上升较少的井的阀门依次打开开始生产,随着生产的进行,这些井的产量逐步增加,井口压力也逐步上升,同时要检测产出井产品的井口温度,通过对井口生产压力、产量及温度的监控来动态调整生产井井口阀门开启量,来达到各口井比较平衡的生产参数,最终实现煤层较高的热解率及利用率,当煤层参数相异性较大时,会发生煤层热解反应不均衡的情况,这时需要调整区域内生产井与注入井的搭配关系及相关生产参数,当区块内注入气体的量与产出气体的量基本相同且组分一致时,这个区块的煤的热解开采即告结束,巨厚煤层的地下原位热解开采流程如图3所示。Step 4: Coal seam pyrolysis. First of all, install pyrolysis supporting facilities for each well group where the drainage equipment is removed, including the installation of thermal insulation pipes for heat carrier injection and pyrolysis gaseous product production, installation of bottom-hole thermometers and special wellheads, and installation of surface heat Installation and commissioning of carrier heaters, heat carrier pressurization pumps and output processing systems, as well as construction of related pipeline networks, storage tanks and supporting facilities. When the pyrolysis unit starts the pyrolysis process, the pressurized heat carrier gas passes through the ground After the heater is heated, it is injected into the coal seam by the injection well. In order to ensure the heating intensity, a heater can also be set in the wellbore of the injection well as the main heater or auxiliary heater. The heat carrier gas can be natural gas, carbon dioxide, nitrogen, etc., or their mixtures, or the coal seam pyrolysis gas produced in the block. The heat carrier gas injection amount can be determined according to the thickness of the coal seam and the permeability of the coal seam. When the coal seam is thicker and the permeability is higher, a higher injection rate is used. Otherwise, a lower injection rate is used. The injection rate is constantly adjusted with the progress of the pyrolysis process. Gradually formed and the pyrolysis surface continued to expand and gradually increased. Then, when the yield of pyrolysis products decreased, the injection rate was reduced until the pyrolysis was completed. In general, the amount of heat carrier injected during the pyrolysis process was per meter of coal seam. The thickness is adjusted by 50-150 cubic meters per hour (under standard conditions). When the heat carrier gas is injected from the injection well, the wellhead valve of the production well is closed. At the same time, the wellhead pressure of the production well will also rise, but the magnitude of the rise of the wellhead pressure of each production well is not necessarily the same. When the wellhead pressure of the injection well rises to about 70% of the formation pressure, the pressure of the wellhead in the production well will rise less. The valves are opened in turn to start production. With the progress of production, the production of these wells gradually increases, and the wellhead pressure also gradually increases. At the same time, the wellhead temperature of the production well products should be detected, and the wellhead production pressure, production and temperature should be monitored. Dynamic adjustment The opening amount of the valve at the wellhead of the production well can achieve the relatively balanced production parameters of each well, and finally achieve a higher pyrolysis rate and utilization rate of the coal seam. When the coal seam parameters are very different, the unbalanced coal seam pyrolysis reaction occurs , at this time, it is necessary to adjust the collocation relationship between production wells and injection wells in the area and related production parameters. When the amount of injected gas in the block is basically the same as the amount of produced gas and the composition is consistent, the pyrolysis of coal in this block will The mining is over, and the underground in-situ pyrolysis mining process of the huge thick coal seam is shown in Figure 3.

本申请提出采用地下煤层热解开采,首先是具有安全、环保的特点,所有操作及控制工作在地面完成,由于煤层热解后原煤以半焦的形式存在于原位,不会产生地表的塌陷问题,不会出现水系的大规模污染及煤层自燃现象,也不会出现煤在开采及储运过程当中的氧化及碳氧化物气体的排放,且变固体矿的开采为气态矿开采,产出品煤气及煤焦油具有更高的综合产品价值,其次,用热解法开采厚煤层,无需保留煤柱及隔墙等工艺需求,同时也不存在剥采不完全、遗煤弃煤等问题,所以动用率比较高,同时,由于热解法开采巨厚煤层,热解单元建设简单,所需设施及装备简单,生产规模调整灵活方便,再加上产出品价值大,所以可期获得较好收益,还有一个明显的优势,就是采用热解法开采过的厚煤层,提升了采用井工方法开采的价值,这是因为不仅这些煤层在进一步采用井工方法开采时已没有自燃的风险,减少了工艺复杂性及成本,而且产出品为半焦,其热值得到提升,应用价值提高,总体提升项目的赢利水平。This application proposes to use underground coal seam pyrolysis mining. First of all, it has the characteristics of safety and environmental protection. All operations and control work are completed on the ground. Since the raw coal exists in the form of semi-coke after the coal seam pyrolysis, there will be no surface subsidence. The problem is that there will be no large-scale pollution of water systems and spontaneous combustion of coal seams, nor will there be oxidation and carbon oxide gas emissions during coal mining, storage and transportation, and the mining of solid ore will be gaseous ore mining. Coal gas and coal tar have higher comprehensive product value. Secondly, the use of pyrolysis to mine thick coal seams does not require process requirements such as retaining coal pillars and partition walls. At the same time, there are no problems such as incomplete stripping and coal abandonment. The utilization rate is relatively high. At the same time, due to the pyrolysis method for mining huge coal seams, the pyrolysis unit is simple to construct, the required facilities and equipment are simple, the production scale adjustment is flexible and convenient, and the value of the output products is large, so it can be expected to obtain better returns. , there is also an obvious advantage, that is, the thick coal seams mined by the pyrolysis method increase the value of mining by the well method, because not only these coal seams have no risk of spontaneous combustion when they are further mined by the well method, reducing the risk of spontaneous combustion. The process complexity and cost are reduced, and the output product is semi-coke, its calorific value is improved, the application value is improved, and the overall profitability of the project is improved.

显然,本领域的技术人员可以对本发明进行各种改动和变型而不脱离本发明的精神和范围。这样,倘若本发明的这些修改和变型属于本发明权利要求及其等同技术的范围之内,则本发明也意图包含这些改动和变型在内。It will be apparent to those skilled in the art that various modifications and variations can be made in the present invention without departing from the spirit and scope of the invention. Thus, provided that these modifications and variations of the present invention fall within the scope of the claims of the present invention and their equivalents, the present invention is also intended to include these modifications and variations.

Claims (10)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210500511.4ACN114810028A (en) | 2022-05-09 | 2022-05-09 | A kind of underground in-situ pyrolysis mining technology of huge thick coal seam |

| AU2022203377AAU2022203377A1 (en) | 2022-05-09 | 2022-05-18 | An underground in-situ pyrolysis mining technology for ultra-thick coal seams |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210500511.4ACN114810028A (en) | 2022-05-09 | 2022-05-09 | A kind of underground in-situ pyrolysis mining technology of huge thick coal seam |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114810028Atrue CN114810028A (en) | 2022-07-29 |

Family

ID=82513455

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210500511.4APendingCN114810028A (en) | 2022-05-09 | 2022-05-09 | A kind of underground in-situ pyrolysis mining technology of huge thick coal seam |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN114810028A (en) |

| AU (1) | AU2022203377A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116044356A (en)* | 2023-01-18 | 2023-05-02 | 西安科技大学 | A combined mining method of coalbed methane and coal in-situ pyrolysis |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20150247385A1 (en)* | 2012-09-21 | 2015-09-03 | ENN Coal Gasification Mining Co., Ltd. | Method for joint-mining of coalbed gas and coal |

| CN110541695A (en)* | 2019-09-05 | 2019-12-06 | 西安科技大学 | A high-efficiency oil extraction method for in-situ pyrolysis of oil-rich coal with superheated steam |

| CN111963137A (en)* | 2019-05-20 | 2020-11-20 | 中国石油天然气股份有限公司 | Underground gasification method for huge thick coal seam |

| CN112412430A (en)* | 2020-09-18 | 2021-02-26 | 西安交通大学 | System and method for underground in-situ pyrolysis of coal |

| CN112727405A (en)* | 2021-01-20 | 2021-04-30 | 王柱军 | Mining method for improving coal bed permeability of coal bed gas development well |

| CN112761613A (en)* | 2021-01-20 | 2021-05-07 | 王柱军 | Deep coal in-situ pyrolysis mining and utilizing process |

| CN114000860A (en)* | 2021-10-26 | 2022-02-01 | 王柱军 | A coal formation well group electric heating pyrolysis mining technology |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4444258A (en)* | 1981-11-10 | 1984-04-24 | Nicholas Kalmar | In situ recovery of oil from oil shale |

| AU2002360301B2 (en)* | 2001-10-24 | 2007-11-29 | Shell Internationale Research Maatschappij B.V. | In situ thermal processing and upgrading of produced hydrocarbons |

| CN101558216B (en)* | 2006-10-13 | 2013-08-07 | 埃克森美孚上游研究公司 | Enhanced shale oil production by in situ heating using hydraulically fractured producing wells |

| AU2012332851B2 (en)* | 2011-11-04 | 2016-07-21 | Exxonmobil Upstream Research Company | Multiple electrical connections to optimize heating for in situ pyrolysis |

| US9291043B1 (en)* | 2012-05-15 | 2016-03-22 | Joseph A. Affholter | In situ retorting of hydrocarbons and a selected metal |

- 2022

- 2022-05-09CNCN202210500511.4Apatent/CN114810028A/enactivePending

- 2022-05-18AUAU2022203377Apatent/AU2022203377A1/ennot_activeAbandoned

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20150247385A1 (en)* | 2012-09-21 | 2015-09-03 | ENN Coal Gasification Mining Co., Ltd. | Method for joint-mining of coalbed gas and coal |

| CN111963137A (en)* | 2019-05-20 | 2020-11-20 | 中国石油天然气股份有限公司 | Underground gasification method for huge thick coal seam |

| CN110541695A (en)* | 2019-09-05 | 2019-12-06 | 西安科技大学 | A high-efficiency oil extraction method for in-situ pyrolysis of oil-rich coal with superheated steam |

| CN112412430A (en)* | 2020-09-18 | 2021-02-26 | 西安交通大学 | System and method for underground in-situ pyrolysis of coal |

| CN112727405A (en)* | 2021-01-20 | 2021-04-30 | 王柱军 | Mining method for improving coal bed permeability of coal bed gas development well |

| CN112761613A (en)* | 2021-01-20 | 2021-05-07 | 王柱军 | Deep coal in-situ pyrolysis mining and utilizing process |

| CN114000860A (en)* | 2021-10-26 | 2022-02-01 | 王柱军 | A coal formation well group electric heating pyrolysis mining technology |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116044356A (en)* | 2023-01-18 | 2023-05-02 | 西安科技大学 | A combined mining method of coalbed methane and coal in-situ pyrolysis |

Also Published As

| Publication number | Publication date |

|---|---|

| AU2022203377A1 (en) | 2023-11-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108868706B (en) | A method of directional drilling supercritical carbon dioxide fracturing replacement to recover natural gas hydrate | |

| CN108487888B (en) | Auxiliary heating device and method for improving oil gas recovery ratio of oil shale in-situ exploitation | |

| CN103670338A (en) | Method for extracting coalbed methane and coal together | |

| CN106884638A (en) | A kind of In Situ Heating method of coal bed gas heating exploitation | |

| CN107387052A (en) | A kind of oil shale in-situ recovery method | |

| Hallam et al. | Thermal recovery of bitumen at Wolf Lake | |

| CN106437823B (en) | Method for eliminating outburst and standard exceeding of coal mine gas explosion | |

| WO2024103622A1 (en) | Coal-measure gas development method based on horizontal-well methane in-situ combustion explosion fracturing | |

| CN112065343B (en) | Shale oil development injection and production system and method | |

| CN113266314A (en) | Coal bed gas mine | |

| CN103161434A (en) | Mining method for low permeability reservoir of shale gas and the like | |

| Bi et al. | Geological characteristics and co-exploration and co-production methods of Upper Permian Longtan coal measure gas in Yangmeishu Syncline, Western Guizhou Province, China | |

| CN107939370A (en) | A kind of strip-type underground coal gasification system and production method | |

| CN113756857B (en) | Fire prevention and extraction method for high-efficiency ground extraction of coalbed methane in multi-layer old goaf area | |

| CN115163019B (en) | A high-temperature steam fracturing in-situ pyrolysis oil-rich coal separate mining system and method | |

| US20250290398A1 (en) | In-situ large-area drilling and furnace construction method for coal gasification and co-mining of kerosene and/or coalbed methane | |

| CN108952719A (en) | Coal seam gasification second mining loses the method for coal under the conditions of a kind of longwall top coal caving | |

| CN111734358A (en) | A comprehensive mining method of combustible ice in permafrost area | |

| CN112031723A (en) | Method for developing shale oil by electrically heating auxiliary hydrocracking kerogen | |

| CN114810028A (en) | A kind of underground in-situ pyrolysis mining technology of huge thick coal seam | |

| CN112727405A (en) | Mining method for improving coal bed permeability of coal bed gas development well | |

| CN113803048A (en) | Coal in-situ separation mining method based on pyrolysis | |

| US20130061592A1 (en) | Process for Maximization and Optimization of Coal Energy | |

| CN117489319B (en) | A method for thermal insulation of coal seams during in-situ coal gasification | |

| CN115306367B (en) | Underground in-situ conversion and economical evaluation method for oil-rich coal |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20220729 |