CN114755887A - Dual-response photoresist composition and application thereof - Google Patents

Dual-response photoresist composition and application thereofDownload PDFInfo

- Publication number

- CN114755887A CN114755887ACN202210268813.3ACN202210268813ACN114755887ACN 114755887 ACN114755887 ACN 114755887ACN 202210268813 ACN202210268813 ACN 202210268813ACN 114755887 ACN114755887 ACN 114755887A

- Authority

- CN

- China

- Prior art keywords

- photoresist composition

- polymer

- femtosecond laser

- photoinitiator

- response

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 229920002120photoresistant polymerPolymers0.000titleclaimsabstractdescription62

- 239000000203mixtureSubstances0.000titleclaimsabstractdescription54

- 230000004044responseEffects0.000titleclaimsabstractdescription40

- 230000009977dual effectEffects0.000titleclaimsabstractdescription23

- 239000000178monomerSubstances0.000claimsabstractdescription28

- 229920000642polymerPolymers0.000claimsabstractdescription27

- 239000011521glassSubstances0.000claimsdescription42

- 125000000217alkyl groupChemical group0.000claimsdescription10

- NIXOWILDQLNWCW-UHFFFAOYSA-MAcrylateChemical compound[O-]C(=O)C=CNIXOWILDQLNWCW-UHFFFAOYSA-M0.000claimsdescription8

- XMLYCEVDHLAQEL-UHFFFAOYSA-N2-hydroxy-2-methyl-1-phenylpropan-1-oneChemical compoundCC(C)(O)C(=O)C1=CC=CC=C1XMLYCEVDHLAQEL-UHFFFAOYSA-N0.000claimsdescription6

- 238000003756stirringMethods0.000claimsdescription6

- UFHFLCQGNIYNRP-UHFFFAOYSA-NHydrogenChemical compound[H][H]UFHFLCQGNIYNRP-UHFFFAOYSA-N0.000claimsdescription4

- 229910052739hydrogenInorganic materials0.000claimsdescription4

- 239000001257hydrogenSubstances0.000claimsdescription4

- 238000002360preparation methodMethods0.000claimsdescription4

- 239000000758substrateSubstances0.000claimsdescription4

- 2390000129561-hydroxycyclohexylphenyl-ketoneSubstances0.000claimsdescription2

- GJKGAPPUXSSCFI-UHFFFAOYSA-N2-Hydroxy-4'-(2-hydroxyethoxy)-2-methylpropiophenoneChemical compoundCC(C)(O)C(=O)C1=CC=C(OCCO)C=C1GJKGAPPUXSSCFI-UHFFFAOYSA-N0.000claimsdescription2

- XUIMIQQOPSSXEZ-UHFFFAOYSA-NSiliconChemical compound[Si]XUIMIQQOPSSXEZ-UHFFFAOYSA-N0.000claimsdescription2

- WURBFLDFSFBTLW-UHFFFAOYSA-NbenzilChemical compoundC=1C=CC=CC=1C(=O)C(=O)C1=CC=CC=C1WURBFLDFSFBTLW-UHFFFAOYSA-N0.000claimsdescription2

- MQDJYUACMFCOFT-UHFFFAOYSA-Nbis[2-(1-hydroxycyclohexyl)phenyl]methanoneChemical compoundC=1C=CC=C(C(=O)C=2C(=CC=CC=2)C2(O)CCCCC2)C=1C1(O)CCCCC1MQDJYUACMFCOFT-UHFFFAOYSA-N0.000claimsdescription2

- 125000003178carboxy groupChemical group[H]OC(*)=O0.000claimsdescription2

- VFHVQBAGLAREND-UHFFFAOYSA-Ndiphenylphosphoryl-(2,4,6-trimethylphenyl)methanoneChemical compoundCC1=CC(C)=CC(C)=C1C(=O)P(=O)(C=1C=CC=CC=1)C1=CC=CC=C1VFHVQBAGLAREND-UHFFFAOYSA-N0.000claimsdescription2

- 229910052736halogenInorganic materials0.000claimsdescription2

- 150000002367halogensChemical group0.000claimsdescription2

- 125000002887hydroxy groupChemical group[H]O*0.000claimsdescription2

- 125000002496methyl groupChemical group[H]C([H])([H])*0.000claimsdescription2

- 238000002156mixingMethods0.000claimsdescription2

- 125000002924primary amino groupChemical group[H]N([H])*0.000claimsdescription2

- 239000010453quartzSubstances0.000claimsdescription2

- 239000011347resinSubstances0.000claimsdescription2

- 229920005989resinPolymers0.000claimsdescription2

- 229910052594sapphireInorganic materials0.000claimsdescription2

- 239000010980sapphireSubstances0.000claimsdescription2

- 229910052710siliconInorganic materials0.000claimsdescription2

- 239000010703siliconSubstances0.000claimsdescription2

- VYPSYNLAJGMNEJ-UHFFFAOYSA-Nsilicon dioxideInorganic materialsO=[Si]=OVYPSYNLAJGMNEJ-UHFFFAOYSA-N0.000claimsdescription2

- 230000001678irradiating effectEffects0.000claims1

- 239000000463materialSubstances0.000abstractdescription7

- 239000000126substanceSubstances0.000abstractdescription6

- 238000000034methodMethods0.000abstractdescription5

- 239000002994raw materialSubstances0.000abstractdescription5

- 230000008569processEffects0.000abstractdescription4

- 230000000638stimulationEffects0.000abstractdescription3

- 238000006116polymerization reactionMethods0.000abstractdescription2

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000description20

- YXFVVABEGXRONW-UHFFFAOYSA-NTolueneChemical compoundCC1=CC=CC=C1YXFVVABEGXRONW-UHFFFAOYSA-N0.000description12

- 238000004132cross linkingMethods0.000description12

- 239000000243solutionSubstances0.000description11

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterChemical compoundOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description11

- 239000006059cover glassSubstances0.000description8

- 239000008367deionised waterSubstances0.000description8

- 229910021641deionized waterInorganic materials0.000description8

- 238000004506ultrasonic cleaningMethods0.000description8

- 239000002520smart materialSubstances0.000description7

- HEMHJVSKTPXQMS-UHFFFAOYSA-MSodium hydroxideChemical compound[OH-].[Na+]HEMHJVSKTPXQMS-UHFFFAOYSA-M0.000description6

- 230000004043responsivenessEffects0.000description6

- JKNCOURZONDCGV-UHFFFAOYSA-N2-(dimethylamino)ethyl 2-methylprop-2-enoateChemical compoundCN(C)CCOC(=O)C(C)=CJKNCOURZONDCGV-UHFFFAOYSA-N0.000description4

- YFPJFKYCVYXDJK-UHFFFAOYSA-NDiphenylphosphine oxideChemical compoundC=1C=CC=CC=1[P+](=O)C1=CC=CC=C1YFPJFKYCVYXDJK-UHFFFAOYSA-N0.000description4

- 239000002202Polyethylene glycolSubstances0.000description4

- HVVWZTWDBSEWIH-UHFFFAOYSA-N[2-(hydroxymethyl)-3-prop-2-enoyloxy-2-(prop-2-enoyloxymethyl)propyl] prop-2-enoateChemical compoundC=CC(=O)OCC(CO)(COC(=O)C=C)COC(=O)C=CHVVWZTWDBSEWIH-UHFFFAOYSA-N0.000description4

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000description4

- 229910052782aluminiumInorganic materials0.000description4

- 239000007864aqueous solutionSubstances0.000description4

- 239000003599detergentSubstances0.000description4

- 125000004386diacrylate groupChemical group0.000description4

- 230000008020evaporationEffects0.000description4

- 238000001704evaporationMethods0.000description4

- 239000011888foilSubstances0.000description4

- 239000000017hydrogelSubstances0.000description4

- 229920001223polyethylene glycolPolymers0.000description4

- -1trimethylbenzoylChemical group0.000description4

- 238000010521absorption reactionMethods0.000description3

- 239000002253acidSubstances0.000description3

- 230000009471actionEffects0.000description3

- 238000005516engineering processMethods0.000description3

- ZWEHNKRNPOVVGH-UHFFFAOYSA-N2-ButanoneChemical compoundCCC(C)=OZWEHNKRNPOVVGH-UHFFFAOYSA-N0.000description2

- VEXZGXHMUGYJMC-UHFFFAOYSA-NHydrochloric acidChemical compoundClVEXZGXHMUGYJMC-UHFFFAOYSA-N0.000description2

- 239000012670alkaline solutionSubstances0.000description2

- 238000005452bendingMethods0.000description2

- 238000004519manufacturing processMethods0.000description2

- 230000003287optical effectEffects0.000description2

- 238000002791soakingMethods0.000description2

- WGAMPSFECQDLRN-UHFFFAOYSA-N2,2-diethoxyhexanalChemical compoundCCCCC(OCC)(OCC)C=OWGAMPSFECQDLRN-UHFFFAOYSA-N0.000description1

- 206010034972Photosensitivity reactionDiseases0.000description1

- 230000003044adaptive effectEffects0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000008859changeEffects0.000description1

- 230000007423decreaseEffects0.000description1

- 230000007547defectEffects0.000description1

- 238000010586diagramMethods0.000description1

- 230000007613environmental effectEffects0.000description1

- 239000007789gasSubstances0.000description1

- 239000000499gelSubstances0.000description1

- 239000007769metal materialSubstances0.000description1

- 230000036211photosensitivityEffects0.000description1

- 239000002265redox agentSubstances0.000description1

- 230000035440response to pHEffects0.000description1

- 230000006903response to temperatureEffects0.000description1

- 230000008961swellingEffects0.000description1

- 125000001302tertiary amino groupChemical group0.000description1

Images

Classifications

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G03F7/027—Non-macromolecular photopolymerisable compounds having carbon-to-carbon double bonds, e.g. ethylenic compounds

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/004—Photosensitive materials

- G—PHYSICS

- G03—PHOTOGRAPHY; CINEMATOGRAPHY; ANALOGOUS TECHNIQUES USING WAVES OTHER THAN OPTICAL WAVES; ELECTROGRAPHY; HOLOGRAPHY

- G03F—PHOTOMECHANICAL PRODUCTION OF TEXTURED OR PATTERNED SURFACES, e.g. FOR PRINTING, FOR PROCESSING OF SEMICONDUCTOR DEVICES; MATERIALS THEREFOR; ORIGINALS THEREFOR; APPARATUS SPECIALLY ADAPTED THEREFOR

- G03F7/00—Photomechanical, e.g. photolithographic, production of textured or patterned surfaces, e.g. printing surfaces; Materials therefor, e.g. comprising photoresists; Apparatus specially adapted therefor

- G03F7/20—Exposure; Apparatus therefor

- G03F7/2051—Exposure without an original mask, e.g. using a programmed deflection of a point source, by scanning, by drawing with a light beam, using an addressed light or corpuscular source

- G03F7/2053—Exposure without an original mask, e.g. using a programmed deflection of a point source, by scanning, by drawing with a light beam, using an addressed light or corpuscular source using a laser

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Spectroscopy & Molecular Physics (AREA)

- Optics & Photonics (AREA)

- Polymerisation Methods In General (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及光刻胶及激光直写技术领域。更具体地,涉及一种双重响应的光刻胶组合物及其应用。The invention relates to the technical field of photoresist and laser direct writing. More specifically, it relates to a dual-responsive photoresist composition and applications thereof.

背景技术Background technique

飞秒激光加工技术是实现微结构制备的重要手段。该技术利用飞秒激光作为光源对光刻胶进行光照,使得光照射处的光刻胶同时吸收两个及两个以上的光子发生聚合反应。因此,飞秒激光直写技术具有高精度、无掩模、突破光学衍射极限、可加工三维微结构的能力。目前广泛用于制备微纳机器人,微流体结构和光学结构等。光刻胶是一种对飞秒激光具有双光子吸收的材料体系,但现阶段使用的传统商用光刻胶以及无机非金属材料所得到的微结构在加工完成后无法灵活改变自身结构,无刺激响应或可控自适应变形能力。CN113835296A公开了一种飞秒激光直写光刻胶组合物,涉及一种丙烯酸酯类单体、光引发剂和聚合物组合形式,通过特定结构的单体和聚合物,所述光刻胶组合物具有双色光敏性,不仅提高了飞秒激光直写精度,同时降低了飞秒激光直写阈值、增强了机械强度,但文中并未涉及有关于刺激响应的技术概念。Femtosecond laser processing technology is an important means to realize the preparation of microstructures. The technology utilizes a femtosecond laser as a light source to illuminate the photoresist, so that the photoresist where the light is irradiated simultaneously absorbs two or more photons to cause a polymerization reaction. Therefore, femtosecond laser direct writing technology has the capability of high precision, no mask, breaking the optical diffraction limit, and processing three-dimensional microstructures. At present, it is widely used in the preparation of micro-nano robots, microfluidic structures and optical structures. Photoresist is a material system that has two-photon absorption for femtosecond lasers, but the microstructures obtained from traditional commercial photoresists and inorganic non-metallic materials cannot be flexibly changed after processing without stimulation. Responsive or controllable adaptive deformation capabilities. CN113835296A discloses a femtosecond laser direct writing photoresist composition, which relates to a combination of acrylate monomer, photoinitiator and polymer. The object has two-color photosensitivity, which not only improves the accuracy of femtosecond laser direct writing, but also reduces the threshold of femtosecond laser direct writing and enhances the mechanical strength, but the technical concept of stimulus response is not involved in this paper.

目前在本领域出现一类刺激响应材料,也称为智能材料,可以接收外部环境的刺激信号,会根据特定的触发因素(例如热、光、电场和磁场、pH、氧化还原剂、气体等)使自身分子结构或状态发生改变,从而影响其物理或化学性质,进而体现出相应的功能。这些刺激响应材料通常被认为是智能的,因为它们能够感知周围环境并产生人为可控的响应。刺激响应材料已被用于传感器、致动器、可穿戴设备和生物医学设备等领域。人们越来越关注智能材料及其广泛应用的同时,开始将智能材料与微结构相结合,以充分利用其材料特性。然而,制备这种可刺激响应的微结构具有制造时间长、成本高、和有限的可用材料等问题,可刺激响应的微结构制造仍然具有挑战性。At present, a class of stimuli-responsive materials, also known as smart materials, has emerged in the field, which can receive stimulus signals from the external environment and respond to specific triggering factors (such as heat, light, electric and magnetic fields, pH, redox agents, gases, etc.) Change its own molecular structure or state, thereby affecting its physical or chemical properties, and then reflecting the corresponding function. These stimuli-responsive materials are generally considered intelligent because of their ability to sense their surroundings and generate human-controllable responses. Stimuli-responsive materials have been used in fields such as sensors, actuators, wearables, and biomedical devices. While people are paying more and more attention to smart materials and their wide range of applications, they have begun to combine smart materials with microstructures to fully utilize their material properties. However, the fabrication of such stimuli-responsive microstructures is still challenging due to the long fabrication time, high cost, and limited available materials.

因此,需要开发一种具备多重刺激响应特性的光刻胶组合物,从而实现多重响应微结构的制备。Therefore, it is necessary to develop a photoresist composition with multiple stimuli-responsive properties, so as to realize the preparation of multiple-responsive microstructures.

发明内容SUMMARY OF THE INVENTION

基于以上缺陷,本发明的第一个目的在于提供一种双重响应的光刻胶组合物。该光刻胶组合物中的功能单体和聚合物在光引发剂作用下被飞秒激光引发聚合,功能单体结合到聚合物链中,从而实现对pH和温度的双重刺激的智能响应,同时具有较低的飞秒激光直写阈值,飞秒激光直写速度快。Based on the above defects, the first object of the present invention is to provide a dual-response photoresist composition. The functional monomers and polymers in the photoresist composition are polymerized by a femtosecond laser under the action of a photoinitiator, and the functional monomers are incorporated into the polymer chains, thereby realizing an intelligent response to the dual stimulation of pH and temperature, At the same time, it has a low femtosecond laser direct writing threshold, and the femtosecond laser direct writing speed is fast.

本发明的第二个目的在于提供一种利用如上光刻胶组合物在制备双重响应的微结构方面的应用。本发明制备的光刻胶组合物可以在飞秒激光照射区域内快速成型,获得高分辨率的复杂三维微结构;得到的微结构无需添加额外物质,便可以实现稳定、可重复的温度响应与pH响应行为。The second object of the present invention is to provide an application of the above photoresist composition in preparing dual-responsive microstructures. The photoresist composition prepared by the invention can be rapidly formed in the femtosecond laser irradiation area to obtain a complex three-dimensional microstructure with high resolution; the obtained microstructure can achieve stable and repeatable temperature response and temperature response without adding additional substances. pH-responsive behavior.

为达到上述第一个目的,本发明采用下述技术方案:For reaching above-mentioned first purpose, the present invention adopts following technical scheme:

本发明公开一种双重响应的光刻胶组合物,包含功能单体、光引发剂和聚合物;The invention discloses a dual-response photoresist composition, comprising functional monomers, photoinitiators and polymers;

所述功能单体包含具有如下结构式Ⅰ的丙烯酸酯类单体和结构式Ⅱ的丙烯酸酯类单体;The functional monomer comprises an acrylate-based monomer having the following structural formula I and an acrylate-based monomer of the structural formula II;

其中,m1表示1-50的整数,R1、R2各自对立地表示为C1-C5的直链或支链烷基;Wherein, m1 represents an integer of 1-50, and R1 and R2 are each oppositely represented as a C1-C5 straight-chain or branched-chain alkyl group;

X-(Y)m2 Ⅱ;X-(Y)m2 II;

其中,X表示C1-C50的直链或支链烷基,m2表示1-20的整数;Wherein, X represents a straight-chain or branched alkyl group of C1-C50, and m2 represents an integer of 1-20;

Y表示-OOC-CR3=CH2;R3表示甲基或氢;Y represents -OOC-CR3 =CH2 ; R3 represents methyl or hydrogen;

所述聚合物为具有如下结构式Ⅲ的聚合物:The polymer is a polymer having the following structural formula III:

在本发明的技术方案中,功能单体包含结构式Ⅰ和结构式Ⅱ两种丙烯酸酯类单体,结构式Ⅰ的丙烯酸酯类单体,与结构式Ⅱ单体复配使用在光引发剂和飞秒激光的作用下聚合到聚合物链上,形成的微结构具有对pH和温度的双重响应特性,在不同的pH和温度下微结构可以根据环境变化发生形变,实现稳定、可重复的温度响应与pH响应行为,并且该光刻胶组合物多为烯烃类物质,原料易得、容易合成,简化了智能材料的获取流程,同时具有较低的飞秒激光直写阈值,飞秒激光直写速度快,有望广泛应用于智能材料领域。In the technical solution of the present invention, the functional monomer includes two acrylate monomers of structural formula I and structural formula II, and the acrylate monomer of structural formula I is compounded with the monomer of structural formula II for use in photoinitiators and femtosecond lasers. It is polymerized to the polymer chain under the action of the action of the microstructure, and the formed microstructure has the dual response characteristics of pH and temperature. At different pH and temperature, the microstructure can be deformed according to the environmental changes, achieving stable and repeatable temperature response and pH. Response behavior, and the photoresist composition is mostly olefinic substances, the raw materials are easily available and easy to synthesize, which simplifies the acquisition process of smart materials, and has a low femtosecond laser direct writing threshold and fast femtosecond laser direct writing. , which is expected to be widely used in the field of smart materials.

具体地说,结构式Ⅰ为一类叔胺基丙烯酸酯类单体,由于该类单体的存在能够对pH和温度进行响应,经发明人发现将其结合到特定结构的聚合物链上能产生一定刺激响应的行为,但加工难度大、稳定性差、成型性低,为了改善上述问题,引入另外一种结构式Ⅱ丙烯酸酯类单体,在本发明的技术方案中主要起交联的作用以提高光刻胶的稳定性和成型性。Specifically, structural formula I is a kind of tertiary amino acrylate monomers, because the existence of this kind of monomers can respond to pH and temperature, the inventors found that it can be combined with polymer chains of specific structures to produce The behavior of certain stimulus response, but the processing difficulty, poor stability, low formability, in order to improve the above problems, the introduction of another structural formula II acrylate monomer, in the technical scheme of the present invention mainly plays the role of crosslinking to improve the Photoresist stability and formability.

进一步,所述聚合物的平均分子量为200-20000;优选地,所述聚合物的平均分子量为500-5000;更优选地,所述聚合物的平均分子量为700-3000。Further, the average molecular weight of the polymer is 200-20000; preferably, the average molecular weight of the polymer is 500-5000; more preferably, the average molecular weight of the polymer is 700-3000.

进一步,结构式Ⅰ中的m1表示1-20的整数;优选地,m1表示1-10的整数。Further, m1 in structural formula I represents an integer of 1-20; preferably, m1 represents an integer of 1-10.

进一步,结构式Ⅰ中的R1表示C1-C3的直链或支链烷基;R2表示C1-C2的直链或支链烷基。Further, R1 in the structural formula I represents a C1-C3 straight-chain or branched-chain alkyl group; R2 represents a C1-C2 straight-chain or branched-chain alkyl group.

进一步,结构式Ⅱ中的X表示C1-C30的直链或支链烷基;优选地,结构式Ⅱ中的X的氢选择性被羟基、卤素、羧基或氨基部分取代。Further, X in structural formula II represents a C1-C30 straight-chain or branched alkyl group; preferably, the hydrogen of X in structural formula II is selectively substituted with a hydroxyl, halogen, carboxyl or amino moiety.

进一步,m2表示1-10的整数;优选地,m2表示3-6的整数。Further, m2 represents an integer of 1-10; preferably, m2 represents an integer of 3-6.

进一步,所述结构式Ⅰ具有如下Ⅰ-1~Ⅰ-3任一所示的结构:Further, the structural formula I has the structure shown in any of the following I-1 to I-3:

进一步,所述光引发剂选自双光子吸收的光引发剂;优选地,所述光引发剂包括但不限于二苯基乙二酮、2,2-二乙氧基-1-苯己酮、2-羟基-2-甲基-1-苯基-1-丙酮、1-羟基环己基苯基甲酮、2-羟基-4-(2-羟乙氧基)-2-甲基苯丙酮、2-苄基-2-二甲基氨基-1-(4-吗啉苯基)丁酮、2,4,6-三甲基苯甲酰基-二苯基氧化膦中的一种或多种。Further, the photoinitiator is selected from two-photon absorption photoinitiators; preferably, the photoinitiator includes, but is not limited to, diphenylethanedione, 2,2-diethoxy-1-hexanone , 2-hydroxy-2-methyl-1-phenyl-1-propanone, 1-hydroxycyclohexyl phenyl ketone, 2-hydroxy-4-(2-hydroxyethoxy)-2-methylpropiophenone , one or more of 2-benzyl-2-dimethylamino-1-(4-morpholinophenyl)butanone, 2,4,6-trimethylbenzoyl-diphenylphosphine oxide kind.

进一步,按重量份数计,所述光刻胶组合物包含5-95份功能单体,5-80份聚合物以及0.01-20份光引发剂。Further, in parts by weight, the photoresist composition comprises 5-95 parts of functional monomer, 5-80 parts of polymer and 0.01-20 parts of photoinitiator.

进一步,按重量份数计,所述光刻胶组合物包含10-50份功能单体,10-60份聚合物以及0.01-10份光引发剂。Further, in parts by weight, the photoresist composition comprises 10-50 parts of functional monomer, 10-60 parts of polymer and 0.01-10 parts of photoinitiator.

为了达到上述第二个目的,本发明采用下述技术方案:In order to achieve the above-mentioned second purpose, the present invention adopts the following technical scheme:

本发明公开一种利用如上光刻胶组合物在制备双重响应的微结构方面的应用,制备微结构的具体步骤为:The invention discloses an application of the above photoresist composition in preparing a dual-response microstructure. The specific steps for preparing the microstructure are as follows:

(1)在黄光暗室内将功能单体、光引发剂和聚合物按比例混合于棕色玻璃容器中,搅拌后得光刻胶组合物;(1) mixing functional monomer, photoinitiator and polymer in a brown glass container in proportion in a yellow light-dark room, and stirring to obtain a photoresist composition;

(2)取光刻胶组合物滴加在衬底上,使用飞秒激光对光刻胶组合物进行照射;(2) get the photoresist composition and drip it on the substrate, and use the femtosecond laser to irradiate the photoresist composition;

(3)将照射后的光刻胶组合物在显影液中进行显影,得到双重响应的微结构。(3) developing the irradiated photoresist composition in a developer to obtain a dual-responsive microstructure.

所述微结构可以通过飞秒激光加工系统对其进行模型设计,并生成坐标作为飞秒激光加工路径,在实际制备过程中,可根据应用需要得到多种形状的三维微结构,例如微形方台结构、微臂结构等。The microstructure can be modeled by a femtosecond laser processing system, and the coordinates can be generated as the femtosecond laser processing path. table structure, micro-arm structure, etc.

进一步,所述衬底包括但不限于玻璃片、硅片、柔性树脂薄膜、石英片、蓝宝石或导电玻璃ITO。Further, the substrate includes but is not limited to glass sheet, silicon wafer, flexible resin film, quartz sheet, sapphire or conductive glass ITO.

进一步,所述飞秒激光的波长为200-1100nm;飞秒激光功率范围为5-40mW;扫描速度范围为5-100μm/s。Further, the wavelength of the femtosecond laser is 200-1100 nm; the power range of the femtosecond laser is 5-40 mW; and the scanning speed range is 5-100 μm/s.

本发明的有益效果如下:The beneficial effects of the present invention are as follows:

(1)本发明提供的光刻胶组合物具有较低的双光子加工阈值,可以实现较快的速度加工。(1) The photoresist composition provided by the present invention has a lower two-photon processing threshold, and can achieve faster speed processing.

(2)本发明提供的光刻胶组合物具有双重响应特性,加工得到的微结构可以实现稳定、可重复的温度响应与pH响应行为。(2) The photoresist composition provided by the present invention has dual response characteristics, and the microstructure obtained by processing can realize stable and repeatable temperature response and pH response behavior.

(3)本发明提供的光刻胶组合物多为烯烃类物质,原料易得、容易合成,简化了智能材料的获取流程。(3) Most of the photoresist compositions provided by the present invention are olefinic substances, and the raw materials are readily available and easy to synthesize, which simplifies the acquisition process of smart materials.

因此本发明提供的光刻胶组合物通过特定结构的功能单体和聚合物,不仅实现了微结构的双重响应特性,同时简化了智能材料的获取流程,降低了双光子加工阈值,提高了加工效率。Therefore, the photoresist composition provided by the present invention not only realizes the dual response characteristics of the microstructure through functional monomers and polymers with specific structures, but also simplifies the acquisition process of smart materials, reduces the two-photon processing threshold, and improves processing. efficiency.

附图说明Description of drawings

下面结合附图对本发明的具体实施方式作进一步详细的说明。The specific embodiments of the present invention will be described in further detail below with reference to the accompanying drawings.

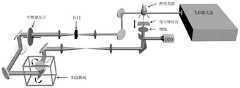

图1示出飞秒激光加工系统示意图。Figure 1 shows a schematic diagram of a femtosecond laser processing system.

图2示出实施例1所述光刻胶组合物加工的双重响应的微形方台结构对不同pH的响应。FIG. 2 shows the response of the dual-response micro-square mesa structures processed by the photoresist composition described in Example 1 to different pH.

图3示出实施例2所述光刻胶组合物加工的双重响应的微形方台结构对不同温度的响应。3 shows the response to different temperatures of a dual-response micro-square mesa structure processed by the photoresist composition described in Example 2. FIG.

图4示出实施例3所述光刻胶组合物加工的双重响应的微臂结构对不同pH的响应。FIG. 4 shows the response of the dual-response micro-arm structure processed by the photoresist composition described in Example 3 to different pH.

图5示出实施例4所述光刻胶组合物加工的双重响应的微臂结构对不同温度的响应。FIG. 5 shows the response of the dual-response micro-arm structure processed by the photoresist composition described in Example 4 to different temperatures.

具体实施方式Detailed ways

为了更清楚地说明本发明,下面结合优选实施例和附图对本发明做进一步的说明。附图中相似的部件以相同的附图标记进行表示。本领域技术人员应当理解,下面所具体描述的内容是说明性的而非限制性的,不应以此限制本发明的保护范围。In order to illustrate the present invention more clearly, the present invention will be further described below with reference to the preferred embodiments and accompanying drawings. Similar parts in the figures are denoted by the same reference numerals. Those skilled in the art should understand that the content specifically described below is illustrative rather than restrictive, and should not limit the protection scope of the present invention.

本申请如无特殊说明,使用的原料均为市售产品,其制备的光刻胶组合物和微结构的刺激响应行为与原料来源无关。Unless otherwise specified in this application, the raw materials used are all commercially available products, and the stimuli-response behavior of the photoresist compositions and microstructures prepared therefrom has nothing to do with the source of the raw materials.

实施例1Example 1

a)首先准备干净的5mL带盖玻璃瓶,依次加入0.53g聚乙二醇二丙烯酸酯,0.15g甲基丙烯酸二甲氨基乙酯,0.01g 2,4,6(三甲基苯甲酰基)二苯基氧化膦,0.01g 2-羟基-2-甲基-1-苯基-1-丙酮和0.3g季戊四醇三丙烯酸酯。然后加入1个干净磁子,用铝箔将玻璃瓶包裹,标记后置于磁力搅拌器上避光搅拌4小时至澄清透明,得光刻胶组合物,备用。a) First prepare a clean 5mL glass bottle with a lid, add 0.53g polyethylene glycol diacrylate, 0.15g dimethylaminoethyl methacrylate, 0.01g 2,4,6 (trimethylbenzoyl) in turn Diphenylphosphine oxide, 0.01 g of 2-hydroxy-2-methyl-1-phenyl-1-propanone and 0.3 g of pentaerythritol triacrylate. Then add a clean magnet, wrap the glass bottle with aluminum foil, mark and place it on a magnetic stirrer to avoid light and stir for 4 hours until it is clear and transparent to obtain a photoresist composition for use.

b)准备厚度为0.15mm的长方形玻璃盖玻片,将玻璃盖玻片放在含有洗涤剂的去离子水中进行30分钟的超声清洗,随后用去离子水重复超声清洗6次,然后在烘箱中干燥。将干燥的玻璃盖玻片在5wt%KH-570/甲苯溶液中浸泡2小时,然后用无水乙醇快速清洗玻璃盖玻片并干燥。b) Prepare rectangular glass coverslips with a thickness of 0.15 mm, place the glass coverslips in deionized water containing detergent for 30 minutes ultrasonic cleaning, then repeat ultrasonic cleaning with deionized water 6 times, and then place them in an oven dry. The dried glass coverslips were soaked in 5wt% KH-570/toluene solution for 2 hours, then the glass coverslips were quickly washed with absolute ethanol and dried.

c)本发明所使用的飞秒激光加工系统如附图1所示。飞秒激光波长为780nm,所使用物镜放大倍数为60倍,数值孔径1.42。将配置好的光刻胶组合物滴在清洗好的玻璃盖玻片上,然后将玻璃盖玻片放置于飞秒激光加工系统的压电移动台上。使用飞秒激光功率为30mW,扫描速度为40μm/s,制备出设计的方台结构。激光移动路径由连续坐标组成,由电脑软件对设计的加工模型进行缩放并生成坐标作为飞秒激光加工路径。c) The femtosecond laser processing system used in the present invention is shown in FIG. 1 . The wavelength of the femtosecond laser is 780 nm, the magnification of the objective lens used is 60 times, and the numerical aperture is 1.42. The prepared photoresist composition was dropped on the cleaned glass cover glass, and then the glass cover glass was placed on the piezoelectric moving stage of the femtosecond laser processing system. The designed square mesa structure was fabricated using a femtosecond laser power of 30 mW and a scanning speed of 40 μm/s. The laser moving path consists of continuous coordinates, and the computer software scales the designed processing model and generates the coordinates as the femtosecond laser processing path.

d)加工完成后将玻璃盖玻片从压电移动台上移开,用乙醇去除未反应的光刻胶。在乙醇自然蒸发后可以得到所设计的具有双重响应特性的微结构,所述微结构为直径8μm圆柱结构支撑的悬空方台结构,其中方台结构的边长为28μm。d) After processing, remove the glass coverslip from the piezoelectric moving stage and remove the unreacted photoresist with ethanol. After the natural evaporation of ethanol, the designed microstructure with dual response characteristics can be obtained. The microstructure is a suspended square mesa structure supported by a cylindrical structure with a diameter of 8 μm, wherein the side length of the square mesa structure is 28 μm.

e)然后将加工完成后的边长为28μm的方形微结构置于稀盐酸与氢氧化钠配制pH值为1及13的溶液中,观察微结构的pH响应特性,所得结果见图2。由图2中发现,在未加入酸液中时,微结构的长度为28μm,浸泡在pH=1的酸溶液后,微结构发生膨胀,长度增加到33μm,当从pH=1的酸溶液转入到pH=13的碱溶液时,微结构又出现尺寸缩小的情况,长度降为29μm,充分展示其pH响应性。e) The processed square microstructures with a side length of 28 μm were then placed in solutions with pH 1 and 13 prepared by dilute hydrochloric acid and sodium hydroxide, and the pH response characteristics of the microstructures were observed. The results obtained are shown in Figure 2. It can be found from Figure 2 that the length of the microstructure is 28 μm when no acid solution is added. After soaking in the acid solution of pH=1, the microstructure expands and the length increases to 33 μm. When entering into the alkaline solution of pH=13, the size of the microstructure was reduced again, and the length was reduced to 29 μm, which fully demonstrated its pH responsiveness.

实施例2Example 2

a)首先准备干净的5mL带盖玻璃瓶,依次加入0.53g聚乙二醇二丙烯酸酯,0.15g甲基丙烯酸二甲氨基乙酯,0.01g 2,4,6(三甲基苯甲酰基)二苯基氧化膦,0.01g 2-羟基-2-甲基-1-苯基-1-丙酮和0.3g季戊四醇三丙烯酸酯。然后加入1个干净磁子,用铝箔将玻璃瓶包裹,标记后置于磁力搅拌器上避光搅拌4小时至澄清透明,得光刻胶组合物,备用。a) First prepare a clean 5mL glass bottle with a lid, add 0.53g polyethylene glycol diacrylate, 0.15g dimethylaminoethyl methacrylate, 0.01g 2,4,6 (trimethylbenzoyl) in turn Diphenylphosphine oxide, 0.01 g of 2-hydroxy-2-methyl-1-phenyl-1-propanone and 0.3 g of pentaerythritol triacrylate. Then add a clean magnet, wrap the glass bottle with aluminum foil, mark and place it on a magnetic stirrer to avoid light and stir for 4 hours until it is clear and transparent to obtain a photoresist composition for use.

b)准备厚度为0.15mm的长方形玻璃盖玻片,将玻璃盖玻片放在含有洗涤剂的去离子水中进行30分钟的超声清洗,随后用去离子水重复超声清洗6次,然后在烘箱中干燥。将干燥的玻璃盖玻片在5wt%KH-570/甲苯溶液中浸泡2小时,然后用无水乙醇快速清洗玻璃盖玻片并干燥。b) Prepare rectangular glass coverslips with a thickness of 0.15 mm, place the glass coverslips in deionized water containing detergent for 30 minutes ultrasonic cleaning, then repeat ultrasonic cleaning with deionized water 6 times, and then place them in an oven dry. The dried glass coverslips were soaked in 5wt% KH-570/toluene solution for 2 hours, then the glass coverslips were quickly washed with absolute ethanol and dried.

c)本发明所使用的飞秒激光加工系统如附图1所示。飞秒激光波长为780nm,所使用物镜放大倍数为60倍,数值孔径1.42。将配置好的光刻胶组合物滴在清洗好的玻璃盖玻片上,然后将玻璃盖玻片放置于飞秒激光加工系统的压电移动台上。使用飞秒激光功率为40mW,扫描速度为40μm/s,制备出设计的方台结构。激光移动路径由连续坐标组成,由电脑软件对设计的加工模型进行缩放并生成坐标作为飞秒激光加工路径。c) The femtosecond laser processing system used in the present invention is shown in FIG. 1 . The wavelength of the femtosecond laser is 780 nm, the magnification of the objective lens used is 60 times, and the numerical aperture is 1.42. The prepared photoresist composition was dropped on the cleaned glass cover glass, and then the glass cover glass was placed on the piezoelectric moving stage of the femtosecond laser processing system. Using a femtosecond laser power of 40 mW and a scanning speed of 40 μm/s, the designed square mesa structure was fabricated. The laser moving path consists of continuous coordinates, and the computer software scales the designed processing model and generates the coordinates as the femtosecond laser processing path.

d)加工完成后将玻璃盖玻片从压电移动台上移开,用乙醇去除未反应的光刻胶。在乙醇自然蒸发后可以得到所设计的具有双重响应特性的微结构,如图3所示,是由直径8μm圆柱结构支撑的悬空方台结构,其中方台结构的边长为32μm。d) After processing, remove the glass coverslip from the piezoelectric moving stage and remove the unreacted photoresist with ethanol. After the natural evaporation of ethanol, the designed microstructure with dual response characteristics can be obtained. As shown in Figure 3, it is a suspended square mesa structure supported by a cylindrical structure with a diameter of 8 μm, where the side length of the square mesa structure is 32 μm.

e)将加工完成后的边长为32μm的方形微结构置于水溶液中,水溶液先缓慢升温再缓慢降温,观察微结构对温度的响应特性,所得结果见图3。随着温度的升高至80℃,微结构出现缩小的情况,长度降为29μm,但当温度下降恢复到初始温度时,微结构也恢复到原有尺寸,充分展示其温度响应性。e) Place the processed square microstructure with a side length of 32 μm in an aqueous solution. The aqueous solution is slowly heated up and then cooled down slowly to observe the response characteristics of the microstructure to temperature. The results are shown in Figure 3. As the temperature rises to 80 °C, the microstructure shrinks, and the length decreases to 29 μm, but when the temperature drops back to the initial temperature, the microstructure also returns to its original size, fully demonstrating its temperature responsiveness.

实施例3Example 3

a)首先准备干净的5mL带盖玻璃瓶,依次加入0.53g聚乙二醇二丙烯酸酯,0.15g甲基丙烯酸二甲氨基乙酯,0.01g 2,4,6(三甲基苯甲酰基)二苯基氧化膦,0.01g 2-羟基-2-甲基-1-苯基-1-丙酮和0.3g季戊四醇三丙烯酸酯。然后加入1个干净磁子,用铝箔将玻璃瓶包裹,标记后置于磁力搅拌器上避光搅拌4小时至澄清透明,得光刻胶组合物,备用。a) First prepare a clean 5mL glass bottle with a lid, add 0.53g polyethylene glycol diacrylate, 0.15g dimethylaminoethyl methacrylate, 0.01g 2,4,6 (trimethylbenzoyl) in turn Diphenylphosphine oxide, 0.01 g of 2-hydroxy-2-methyl-1-phenyl-1-propanone and 0.3 g of pentaerythritol triacrylate. Then add a clean magnet, wrap the glass bottle with aluminum foil, mark and place it on a magnetic stirrer to avoid light and stir for 4 hours until it is clear and transparent to obtain a photoresist composition for use.

b)准备厚度为0.15mm的长方形玻璃盖玻片,将玻璃盖玻片放在含有洗涤剂的去离子水中进行30分钟的超声清洗,随后用去离子水重复超声清洗6次,然后在烘箱中干燥。将干燥的玻璃盖玻片在5wt%KH-570/甲苯溶液中浸泡2小时,然后用无水乙醇快速清洗玻璃盖玻片并干燥。b) Prepare rectangular glass coverslips with a thickness of 0.15 mm, place the glass coverslips in deionized water containing detergent for 30 minutes ultrasonic cleaning, then repeat ultrasonic cleaning with deionized water 6 times, and then place them in an oven dry. The dried glass coverslips were soaked in 5wt% KH-570/toluene solution for 2 hours, then the glass coverslips were quickly washed with absolute ethanol and dried.

c)本发明所使用的飞秒激光加工系统如附图1所示。飞秒激光波长为780nm,所使用物镜放大倍数为60倍,数值孔径1.42。将配置好的光刻胶组合物滴在清洗好的玻璃盖玻片上,然后将玻璃盖玻片放置于飞秒激光加工系统的压电移动台上。飞秒激光功率范围为30mW,扫描速度为40μm/s。激光移动路径由连续坐标组成,通过调节连续坐标的疏密程度,制备具有不对称交联密度的微臂结构。c) The femtosecond laser processing system used in the present invention is shown in FIG. 1 . The wavelength of the femtosecond laser is 780 nm, the magnification of the objective lens used is 60 times, and the numerical aperture is 1.42. The prepared photoresist composition was dropped on the cleaned glass cover glass, and then the glass cover glass was placed on the piezoelectric moving stage of the femtosecond laser processing system. The femtosecond laser power range is 30 mW and the scanning speed is 40 μm/s. The laser moving path is composed of continuous coordinates. By adjusting the density of the continuous coordinates, the micro-arm structure with asymmetric crosslink density is prepared.

d)加工完成后将玻璃盖玻片从压电移动台上移开,用乙醇去除未反应的光刻胶。在乙醇自然蒸发后可以得到所设计的具有双重响应特性的微结构,如图4所示,为具有不对称交联密度的微臂结构,这种微臂结构依靠交联密度带来的响应性的不同,通过弯曲角度表现出对pH的响应。d) After processing, remove the glass coverslip from the piezoelectric moving stage and remove the unreacted photoresist with ethanol. After the natural evaporation of ethanol, the designed microstructure with dual response characteristics can be obtained. As shown in Figure 4, it is a micro-arm structure with asymmetric cross-linking density. This micro-arm structure depends on the responsiveness brought by the cross-linking density. showed a response to pH through the bending angle.

e)然后将加工完成后的微臂结构置于稀盐酸与氢氧化钠配制pH值为1及13的溶液中,观察微臂结构的pH响应特性,所得结果见图4。由图4中发现,浸泡在pH=1的酸溶液后,低交联侧水凝胶吸水溶胀率大于高交联侧,微臂结构向右侧弯曲;当从pH=1的酸溶液转入到pH=13的碱溶液时,低交联侧水凝胶失水收缩率大于高交联侧,微臂结构向左侧弯曲。展示出明显的pH响应性。e) The processed micro-arm structure is then placed in a solution with a pH of 1 and 13 prepared by dilute hydrochloric acid and sodium hydroxide, and the pH response characteristics of the micro-arm structure are observed. The results obtained are shown in Figure 4. It can be found from Figure 4 that after soaking in the acid solution of pH=1, the water absorption and swelling rate of the hydrogel on the low-crosslinking side is greater than that on the high-crosslinking side, and the micro-arm structure bends to the right; When reaching the alkaline solution of pH=13, the hydrogel shrinkage rate of the hydrogel on the low cross-linking side is greater than that on the high cross-linking side, and the micro-arm structure bends to the left. Demonstrated pronounced pH responsiveness.

实施例4Example 4

a)首先准备干净的5mL带盖玻璃瓶,依次加入0.53g聚乙二醇二丙烯酸酯,0.15g甲基丙烯酸二甲氨基乙酯,0.01g 2,4,6(三甲基苯甲酰基)二苯基氧化膦,0.01g 2-羟基-2-甲基-1-苯基-1-丙酮和0.3g季戊四醇三丙烯酸酯。然后加入1个干净磁子,用铝箔将玻璃瓶包裹,标记后置于磁力搅拌器上避光搅拌4小时至澄清透明,得光刻胶组合物,备用。a) First prepare a clean 5mL glass bottle with a lid, add 0.53g polyethylene glycol diacrylate, 0.15g dimethylaminoethyl methacrylate, 0.01g 2,4,6 (trimethylbenzoyl) in turn Diphenylphosphine oxide, 0.01 g of 2-hydroxy-2-methyl-1-phenyl-1-propanone and 0.3 g of pentaerythritol triacrylate. Then add a clean magnet, wrap the glass bottle with aluminum foil, mark and place it on a magnetic stirrer to avoid light and stir for 4 hours until it is clear and transparent to obtain a photoresist composition for use.

b)准备厚度为0.15mm的长方形玻璃盖玻片,将玻璃盖玻片放在含有洗涤剂的去离子水中进行30分钟的超声清洗,随后用去离子水重复超声清洗6次,然后在烘箱中干燥。将干燥的玻璃盖玻片在5wt%KH-570/甲苯溶液中浸泡2小时,然后用无水乙醇快速清洗玻璃盖玻片并干燥。b) Prepare rectangular glass coverslips with a thickness of 0.15 mm, place the glass coverslips in deionized water containing detergent for 30 minutes ultrasonic cleaning, then repeat ultrasonic cleaning with deionized water 6 times, and then place them in an oven dry. The dried glass coverslips were soaked in 5wt% KH-570/toluene solution for 2 hours, then the glass coverslips were quickly washed with absolute ethanol and dried.

c)本发明所使用的飞秒激光加工系统如附图1所示。飞秒激光波长为780nm,所使用物镜放大倍数为60倍,数值孔径1.42。将配置好的光刻胶组合物滴在清洗好的玻璃盖玻片上,然后将玻璃盖玻片放置于飞秒激光加工系统的压电移动台上。飞秒激光功率范围为30mW,扫描速度为40μm/s。激光移动路径由连续坐标组成,通过调节连续坐标的疏密程度,制备具有不对称交联密度的微臂结构。c) The femtosecond laser processing system used in the present invention is shown in FIG. 1 . The wavelength of the femtosecond laser is 780 nm, the magnification of the objective lens used is 60 times, and the numerical aperture is 1.42. The prepared photoresist composition was dropped on the cleaned glass cover glass, and then the glass cover glass was placed on the piezoelectric moving stage of the femtosecond laser processing system. The femtosecond laser power range is 30 mW and the scanning speed is 40 μm/s. The laser moving path is composed of continuous coordinates. By adjusting the density of the continuous coordinates, the micro-arm structure with asymmetric crosslink density is prepared.

d)加工完成后将玻璃盖玻片从压电移动台上移开,用乙醇去除未反应的光刻胶。在乙醇自然蒸发后可以得到所设计的具有双重响应特性的微结构,如图5所示,为具有不对称交联密度的微臂结构,这种微臂结构依靠交联密度带来的响应性的不同,通过弯曲角度表现出对于温度的响应。d) After processing, remove the glass coverslip from the piezoelectric moving stage and remove the unreacted photoresist with ethanol. After the natural evaporation of ethanol, the designed microstructure with dual response characteristics can be obtained, as shown in Figure 5, it is a microarm structure with asymmetric crosslinking density, which depends on the responsiveness brought by the crosslinking density. , the response to temperature is shown by the bending angle.

e)将加工完成后的微臂结构置于水溶液中,水溶液先缓慢升温再缓慢降温,观察微结构对温度的响应特性,所得结果见图5。随着温度的升高至80℃,低交联侧水凝胶失水收缩率大于高交联侧,微臂结构向左侧弯曲;但当温度下降恢复到初始温度时,低交联侧水凝胶吸水溶胀率大于高交联侧,微臂结构向右侧弯曲。充分展示其温度响应性。e) The micro-arm structure after processing is placed in an aqueous solution, the aqueous solution is slowly heated up and then cooled down slowly, and the response characteristics of the microstructure to temperature are observed, and the obtained results are shown in Figure 5. As the temperature increased to 80 °C, the water loss shrinkage rate of the hydrogel on the low-crosslinking side was greater than that on the high-crosslinking side, and the micro-arm structure was bent to the left; but when the temperature dropped back to the initial temperature, the water on the low-crosslinking side was The water-swelling rate of the gel is larger than that of the high cross-linked side, and the micro-arm structure is bent to the right. Fully demonstrate its temperature responsiveness.

本发明制备的光刻胶组合物可以在飞秒激光照射区域内快速成型,获得高分辨率的复杂三维微结构;得到的微结构无需添加额外物质,可以实现稳定、可重复的温度响应与pH响应行为。The photoresist composition prepared by the invention can be rapidly formed in the femtosecond laser irradiation area to obtain a complex three-dimensional microstructure with high resolution; the obtained microstructure does not need to add additional substances, and can achieve stable and repeatable temperature response and pH Responsive behavior.

显然,本发明的上述实施例仅仅是为清楚地说明本发明所作的举例,而并非是对本发明的实施方式的限定,对于所属领域的普通技术人员来说,在上述说明的基础上还可以做出其它不同形式的变化或变动,这里无法对所有的实施方式予以穷举,凡是属于本发明的技术方案所引伸出的显而易见的变化或变动仍处于本发明的保护范围之列。Obviously, the above-mentioned embodiments of the present invention are only examples for clearly illustrating the present invention, and are not intended to limit the embodiments of the present invention. Changes or changes in other different forms cannot be exhausted here, and all obvious changes or changes derived from the technical solutions of the present invention are still within the protection scope of the present invention.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210268813.3ACN114755887A (en) | 2022-03-18 | 2022-03-18 | Dual-response photoresist composition and application thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210268813.3ACN114755887A (en) | 2022-03-18 | 2022-03-18 | Dual-response photoresist composition and application thereof |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114755887Atrue CN114755887A (en) | 2022-07-15 |

Family

ID=82327705

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210268813.3APendingCN114755887A (en) | 2022-03-18 | 2022-03-18 | Dual-response photoresist composition and application thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114755887A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115236936A (en)* | 2022-09-22 | 2022-10-25 | 之江实验室 | Femtosecond laser cured and crosslinked polyamic acid photoresist and preparation method, use method and application thereof |

| CN117464164A (en)* | 2023-11-02 | 2024-01-30 | 合肥工业大学 | Laser processing of chirality-switchable microstructures and chirality switching methods |

| CN119407824A (en)* | 2024-12-16 | 2025-02-11 | 北京理工大学 | A pH-responsive micro end effector and a method for manufacturing the same |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20040007051A1 (en)* | 2002-03-20 | 2004-01-15 | Purdue Research Foundation | Microscale sensor element and related device and method of manufacture |

| CN105418838A (en)* | 2014-11-07 | 2016-03-23 | 湖南工业大学 | Preparation method for multi-stimulative responsive and ultrafast responsive gel with soft-hard transition |

| CN106842817A (en)* | 2017-02-15 | 2017-06-13 | 上海集成电路研发中心有限公司 | A kind of photoetching compositions and preparation method thereof |

| CN109467648A (en)* | 2018-06-03 | 2019-03-15 | 北方民族大学 | A kind of preparation method and application of triple stimulus-responsive polyserine hydrogel |

| CN111983892A (en)* | 2020-09-02 | 2020-11-24 | 之江实验室 | A kind of light-induced anti-oxidative polymerization inhibition femtosecond laser photoresist and preparation method |

- 2022

- 2022-03-18CNCN202210268813.3Apatent/CN114755887A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20040007051A1 (en)* | 2002-03-20 | 2004-01-15 | Purdue Research Foundation | Microscale sensor element and related device and method of manufacture |

| CN105418838A (en)* | 2014-11-07 | 2016-03-23 | 湖南工业大学 | Preparation method for multi-stimulative responsive and ultrafast responsive gel with soft-hard transition |

| CN106842817A (en)* | 2017-02-15 | 2017-06-13 | 上海集成电路研发中心有限公司 | A kind of photoetching compositions and preparation method thereof |

| CN109467648A (en)* | 2018-06-03 | 2019-03-15 | 北方民族大学 | A kind of preparation method and application of triple stimulus-responsive polyserine hydrogel |

| CN111983892A (en)* | 2020-09-02 | 2020-11-24 | 之江实验室 | A kind of light-induced anti-oxidative polymerization inhibition femtosecond laser photoresist and preparation method |

Non-Patent Citations (1)

| Title |

|---|

| YAN LIU ET AL: "Facile access to poly(DMAEMA-co-AA) hydrogels via infrared laser-ignited frontal polymerization and their polymerization in the horizontal direction", THE ROYAL SOCIETY OF CHEMISTRY, no. 5, 31 December 2015 (2015-12-31), pages 30514 - 30521* |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115236936A (en)* | 2022-09-22 | 2022-10-25 | 之江实验室 | Femtosecond laser cured and crosslinked polyamic acid photoresist and preparation method, use method and application thereof |

| CN115236936B (en)* | 2022-09-22 | 2022-12-06 | 之江实验室 | Femtosecond laser cured and crosslinked polyamic acid photoresist and preparation method, use method and application thereof |

| CN117464164A (en)* | 2023-11-02 | 2024-01-30 | 合肥工业大学 | Laser processing of chirality-switchable microstructures and chirality switching methods |

| CN119407824A (en)* | 2024-12-16 | 2025-02-11 | 北京理工大学 | A pH-responsive micro end effector and a method for manufacturing the same |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN114755887A (en) | Dual-response photoresist composition and application thereof | |

| TWI506373B (en) | Photosensitive resin composition and display unit | |

| Luo et al. | Photomechanical polymer hydrogels based on molecular photoswitches | |

| Jayaramudu et al. | Poly (acrylic acid)-Poly (vinyl alcohol) hydrogels for reconfigurable lens actuators | |

| TWI474118B (en) | Photo-sensitive polysiloxane composition and protecting film and element containing said protecting film | |

| CN104428713A (en) | Photosensitive resin composition, conductive wire protection film, and touch panel member | |

| CN105190440B (en) | Photosensitive resin composition, optical spacer, protective film for color filter, protective film or insulating film for touch panel | |

| JPH0751061B2 (en) | Manufacturing method of cell array control tool | |

| KR101890633B1 (en) | Resin composition, method for producing cured product, method for producing resin pattern, cured product and optical member | |

| JP4200145B2 (en) | Polymer of alkyl cyclic olefin having secondary hydroxyl group and acrylic compound and chemically amplified resist composition containing the same | |

| CN116719207A (en) | Preparation of laser direct-writing photoresist containing heteropoly acid with adjustable refractive index and patterning method based on photoresist | |

| WO2015076309A1 (en) | Curable composition, cured product, camera module and method for manufacturing imaging device | |

| KR102174272B1 (en) | Polyfunctional (meth)acrylic acid ester copolymer, and curable resin composition and cured product thereof | |

| Du et al. | The synthesis of poly (vinyl cinnamates) with light-induced shape fixity properties | |

| Cezan et al. | Fast Photoactuation Driven by Supramolecular Polymers Integrated into Covalent Networks | |

| WO2008144822A1 (en) | Holographic recording medium | |

| JP2015152726A (en) | Photosensitive resin composition | |

| JP5571968B2 (en) | Curable composition and cured product thereof | |

| JP2019136894A (en) | Gel material for 3d printers, method for manufacturing structure and 3d printer | |

| Chen et al. | Photopolymerized 3D Printing Materials for Optical Elements | |

| CN117126436A (en) | Stretchable color-changing liquid crystal polymer optical driver and preparation method and application thereof | |

| CN117304394A (en) | Polymer for photoresist top layer coating, preparation method and application | |

| CN114326295B (en) | A femtosecond laser direct writing method of zinc oxide micro-nano pattern | |

| JPWO2018116501A1 (en) | Weatherability improver, resin composition for metal nanowire layer coating, and metal nanowire-containing laminate | |

| TWI534539B (en) | Negative type photosensitive resin composition |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |