CN114698466A - Car is picked to mangosteen - Google Patents

Car is picked to mangosteenDownload PDFInfo

- Publication number

- CN114698466A CN114698466ACN202210511291.5ACN202210511291ACN114698466ACN 114698466 ACN114698466 ACN 114698466ACN 202210511291 ACN202210511291 ACN 202210511291ACN 114698466 ACN114698466 ACN 114698466A

- Authority

- CN

- China

- Prior art keywords

- picking

- han guo

- luo han

- fixed

- driven

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 240000006053Garcinia mangostanaSpecies0.000titledescription2

- 235000017048Garcinia mangostanaNutrition0.000titledescription2

- 238000001514detection methodMethods0.000claimsabstractdescription23

- 241001409321Siraitia grosvenoriiSpecies0.000claimsabstractdescription22

- 238000012545processingMethods0.000claimsdescription30

- 230000005540biological transmissionEffects0.000claimsdescription20

- 230000001360synchronised effectEffects0.000claimsdescription9

- 230000003044adaptive effectEffects0.000claimsdescription4

- 210000000078clawAnatomy0.000claimsdescription4

- 238000007599dischargingMethods0.000claimsdescription3

- 238000007689inspectionMethods0.000claimsdescription3

- 235000011171Thladiantha grosvenoriiNutrition0.000abstract6

- 241000345998Calamus mananSpecies0.000description5

- 235000012950rattan caneNutrition0.000description5

- 238000010586diagramMethods0.000description4

- 238000000034methodMethods0.000description3

- 230000000007visual effectEffects0.000description2

- 238000004458analytical methodMethods0.000description1

- 230000009286beneficial effectEffects0.000description1

- 238000010191image analysisMethods0.000description1

- 230000004048modificationEffects0.000description1

- 238000012986modificationMethods0.000description1

- 238000012805post-processingMethods0.000description1

- 238000011179visual inspectionMethods0.000description1

Images

Classifications

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01D—HARVESTING; MOWING

- A01D46/00—Picking of fruits, vegetables, hops, or the like; Devices for shaking trees or shrubs

- A01D46/24—Devices for picking apples or like fruit

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01D—HARVESTING; MOWING

- A01D46/00—Picking of fruits, vegetables, hops, or the like; Devices for shaking trees or shrubs

- A01D46/22—Baskets or bags attachable to the picker

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Environmental Sciences (AREA)

- Warehouses Or Storage Devices (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及罗汉果采摘技术领域,具体涉及一种罗汉果采摘车。The invention relates to the technical field of Luo Han Guo picking, in particular to a Luo Han Guo picking vehicle.

背景技术Background technique

在对罗汉果进行采摘时,现有的采摘车往往利用切割刀来切割藤杆从而达到采摘的目的,但是如此切割后,罗汉果依旧会保留部分藤杆,后期才处理时还需清理藤杆,并且在采摘时无法预先对罗汉果进行初步分类,导致后期处理工作量大。When picking Luo Han Guo, the existing picking vehicles often use cutting knives to cut the rattan rods to achieve the purpose of picking, but after such cutting, the monk fruit will still retain some rattan rods, and the rattan rods need to be cleaned in the later processing, and It is impossible to preliminarily classify Luo Han Guo during picking, resulting in a large workload of post-processing.

因此,有必要提供一种罗汉果采摘车以解决上述问题。Therefore, it is necessary to provide a Luo Han Guo picking vehicle to solve the above problems.

发明内容SUMMARY OF THE INVENTION

为实现上述目的,本发明提供如下技术方案:一种罗汉果采摘车,包括:To achieve the above object, the present invention provides the following technical solutions: a Luo Han Guo picking vehicle, comprising:

车体,其上设置有第一仓体和第二仓体;a car body, on which a first warehouse body and a second warehouse body are arranged;

高度调节柱,其竖向固定于所述车体上,且具有一高度调节端;a height adjustment column, which is vertically fixed on the vehicle body and has a height adjustment end;

水平驱动机构,其水平固定于高度调节端,且具有一水平调节端;a horizontal drive mechanism, which is horizontally fixed on the height adjustment end and has a horizontal adjustment end;

处理仓,其固定于所述水平驱动机构的水平调节端,且处理仓中设置有采摘组件和检测组件,其中,所述采摘组件对罗汉果进行采摘后由检测组件进行外观检测;以及a processing bin, which is fixed on the horizontal adjustment end of the horizontal drive mechanism, and is provided with a picking component and a detection component, wherein, after the picking component picks the monk fruit, the detection component performs appearance detection; and

第一管体,其用于接收合格罗汉果,并送至第一仓体中;所述第一管体的一侧连通有第二管体,用于接收非合格罗汉果,并送至第二仓体中。The first pipe body is used for receiving qualified monk fruit and sent to the first warehouse body; one side of the first pipe body is communicated with a second pipe body for receiving unqualified monk fruit and sent to the second warehouse in the body.

进一步,作为优选,所述检测组件包括:Further, preferably, the detection component includes:

对称转动设置于处理仓中的传动齿轮;Symmetrically rotate the transmission gear arranged in the processing bin;

传动连接于两个传动齿轮之间的传动链;以及a drive chain drivingly connected between the two drive gears; and

阵列固定于所述传动链上的限位座;an array of limit seats fixed on the transmission chain;

其中,所述限位座上设置有收料机构,用于接收来自于采摘组件的罗汉果;Wherein, the limit seat is provided with a receiving mechanism for receiving the Luo Han Guo from the picking assembly;

还包括位于处理仓顶部的视觉传感器。Also includes a vision sensor on top of the processing bin.

进一步,作为优选,其中一个传动齿轮上同轴固定有从动同步轮,所述从动同步轮采用同步带与主动同步轮传动相连,所述主动同步轮设置于采摘组件中驱动电机的输出端,且所述驱动电机驱动采摘组件进行一次采摘时,能够带动从动同步轮进行转动,且使得收料机构行走一个步距,该步距满足下一收料机构能够移动至采摘组件的出料端。Further, preferably, a driven synchronizing wheel is coaxially fixed on one of the transmission gears, the driven synchronizing wheel is connected to the driving synchronizing wheel by a synchronous belt, and the driving synchronizing wheel is arranged at the output end of the driving motor in the picking assembly. , and when the driving motor drives the picking assembly for one picking, it can drive the driven synchronizing wheel to rotate, and make the receiving mechanism walk a step distance, which is sufficient for the next receiving mechanism to move to the discharging of the picking assembly. end.

进一步,作为优选,所述收料机构包括收料框,所述收料框的底部固定有随动齿轮,所述随动齿轮能够绕其中心竖轴线转动设置于所述限位座上;Further, preferably, the receiving mechanism includes a receiving frame, and a follower gear is fixed on the bottom of the receiving frame, and the follower gear can rotate around its central vertical axis and is arranged on the limit seat;

所述处理仓中还固定有位于传动链上方的齿条,所述齿条能够与随动齿轮相啮合。A rack located above the transmission chain is also fixed in the processing bin, and the rack can be engaged with the driven gear.

进一步,作为优选,所述处理仓中还固定有沿限位座移动轨迹分布的支撑轨道,所述支撑轨道与所述限位座滑动相连。Further, preferably, a support rail distributed along the movement track of the limit seat is also fixed in the processing bin, and the support track is slidably connected to the limit seat.

进一步,作为优选,所述采摘组件包括:Further, preferably, the picking assembly includes:

导料槽,其固定于所述处理仓的顶部;a feeding chute, which is fixed on the top of the processing bin;

安装座,其嵌入至所述导料槽的底部;a mounting seat, which is embedded into the bottom of the material guide groove;

基座,其转动设置于所述安装座上,且所述基座上对称滑动设置有滑座,且所述滑座由双头伸缩杆所驱动;以及a base, which is rotatably arranged on the mounting seat, and a sliding seat is symmetrically slidable on the base, and the sliding seat is driven by a double-ended telescopic rod; and

采摘臂,其固定于所述滑座上;且所述采摘臂上铰接有弧形自适应爪。The picking arm is fixed on the sliding seat; and the picking arm is hinged with an arc-shaped adaptive claw.

进一步,作为优选,所述基座采用轴体转动设置于所述安装座上,轴体一端穿出安装座且连接有从动齿轮,所述从动齿轮与主动齿轮相啮合,所述主动齿轮同轴固定于贯穿轴上,所述贯穿轴贯穿转动设置于传动仓中,且由驱动电机所驱动。Further, preferably, the base is rotatably arranged on the mounting seat by a shaft body, one end of the shaft body penetrates the mounting seat and is connected with a driven gear, the driven gear is meshed with the driving gear, and the driving gear The through shaft is coaxially fixed on the through shaft, and the through shaft is arranged in the transmission chamber through rotation and driven by the drive motor.

进一步,作为优选,所述贯穿轴远离主动齿轮的一端同轴固定有主动锥齿轮,所述主动锥齿轮与从动锥齿轮相啮合,所述从动锥齿轮上同轴固定有主动同步轮。Further, preferably, a driving bevel gear is coaxially fixed at one end of the through shaft away from the driving gear, the driving bevel gear is meshed with the driven bevel gear, and a driving synchronizing wheel is coaxially fixed on the driven bevel gear.

进一步,作为优选,所述伸缩杆上采用多个弹簧连接有底板,所述底板为弧形结构。Further, preferably, the telescopic rod is connected with a bottom plate by a plurality of springs, and the bottom plate is an arc structure.

进一步,作为优选,所述第一管体的一端竖向连通于所述处理仓的底部,所述第二管体水平连通于所述第一管体的一侧,所述第一管体的另一侧还设置有导料杆,所述导料杆能够伸缩,且伸长时能够为罗汉果提供导向,使其在导料杆的导向下进入至第二管体中。Further, preferably, one end of the first pipe body is vertically connected to the bottom of the processing bin, the second pipe body is horizontally connected to one side of the first pipe body, and the first pipe body is The other side is also provided with a material guide rod, the material guide rod can be extended and retracted, and can provide guidance for Luo Han Guo when extended, so that it can enter the second pipe body under the guidance of the material guide rod.

与现有技术相比,本发明提供了一种罗汉果采摘车,具有以下有益效果:Compared with the prior art, the present invention provides a Luo Han Guo picking vehicle, which has the following beneficial effects:

本发明实施例中,在处理仓中设置有采摘组件和检测组件,因此,在对罗汉果进行采摘时,可以利用检测组件对其外观进行初步检测,从而实现初步分拣,便于对于罗汉果进行分类存储;In the embodiment of the present invention, a picking component and a detection component are arranged in the processing bin. Therefore, when picking Luo Han Guo, the detection component can be used to perform preliminary inspection on its appearance, thereby realizing preliminary sorting and facilitating classification and storage of Luo Han Guo. ;

并且,驱动电机驱动采摘组件进行一次采摘时,能够带动从动同步轮进行转动,且使得收料机构行走一个步距,该步距满足下一收料机构能够移动至采摘组件的出料端,从而将采摘动作和送料检测动作进行同步,保证采摘和送料检测的统一性,使得各个罗汉果均能够被依次送料检测,Moreover, when the driving motor drives the picking assembly for one picking, it can drive the driven synchronizing wheel to rotate, and make the receiving mechanism walk a step distance, which is sufficient for the next receiving mechanism to move to the discharging end of the picking assembly. In this way, the picking action and the feeding detection action are synchronized to ensure the unity of the picking and feeding detection, so that each Luo Han Guo can be fed and detected in sequence.

另外,当收料机构进行移动时,随动齿轮能够与齿条相啮合,从而使得在收料机构进行移动时,收料框能够在齿条的作用下进行转动,从而使得视觉传感器能够拍摄罗汉果的多个角度的图片并上传至处理器进行图片分析。In addition, when the receiving mechanism moves, the follower gear can mesh with the rack, so that when the receiving mechanism moves, the receiving frame can rotate under the action of the rack, so that the visual sensor can take pictures of Luo Han Guo The images from multiple angles are uploaded to the processor for image analysis.

附图说明Description of drawings

图1为一种罗汉果采摘车的整体结构示意图;Fig. 1 is the overall structure schematic diagram of a kind of Luo Han Guo picking vehicle;

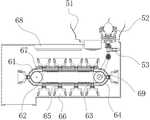

图2为一种罗汉果采摘车中视检测组件的结构示意图;2 is a schematic structural diagram of a mid-view detection assembly in a Luo Han Guo picking vehicle;

图3为一种罗汉果采摘车中采摘组件的结构示意图;3 is a schematic structural diagram of a picking assembly in a Luo Han Guo picking vehicle;

图4为一种罗汉果采摘车中采摘组件的立体结构示意图;Fig. 4 is a three-dimensional schematic diagram of a picking assembly in a Luo Han Guo picking vehicle;

图中:1、车体;2、高度调节柱;3、水平驱动机构;4、处理仓;5、采摘组件;6、检测组件;7、第一管体;8、第二管体;9、导料杆;10、第一仓体;11、第二仓体;51、导料槽;52、采摘臂;53、驱动电机;54、自适应爪;55、伸缩杆;56、滑座;57、基座;58、底板;59、传动仓;510、贯穿轴;511、从动锥齿轮;512、安装座;513、从动齿轮;61、传动齿轮;62、传动链;63、限位座;64、支撑轨道;65、随动齿轮;66、收料框;67、齿条;68、视觉传感器;69、从动同步轮。In the figure: 1. Vehicle body; 2. Height adjustment column; 3. Horizontal drive mechanism; 4. Processing bin; 5. Picking assembly; 6. Detection assembly; 7. First tube body; 8. Second tube body; 9 , material guide rod; 10, first warehouse body; 11, second warehouse body; 51, material guide groove; 52, picking arm; 53, drive motor; 54, adaptive claw; 55, telescopic rod; 56, sliding seat ;57, base; 58, bottom plate; 59, transmission bin; 510, through shaft; 511, driven bevel gear; 512, mounting seat; 513, driven gear; 61, transmission gear; 62, transmission chain; 63, Limit seat; 64, support track; 65, driven gear; 66, receiving frame; 67, rack; 68, vision sensor; 69, driven synchronous wheel.

具体实施方式Detailed ways

请参阅图1~4,本发明提供了一种罗汉果采摘车,包括:Please refer to Figures 1 to 4, the present invention provides a Luo Han Guo picking vehicle, including:

车体1,其上设置有第一仓体10和第二仓体11;Vehicle body 1, on which a

高度调节柱2,其竖向固定于所述车体1上,且具有一高度调节端;a

水平驱动机构3,其水平固定于高度调节端,且具有一水平调节端;a

处理仓4,其固定于所述水平驱动机构3的水平调节端,且处理仓4中设置有采摘组件5和检测组件6,其中,所述采摘组件5对罗汉果进行采摘后由检测组件6进行外观检测;以及The

第一管体7,其用于接收合格罗汉果,并送至第一仓体10中;所述第一管体7的一侧连通有第二管体8,用于接收非合格罗汉果,并送至第二仓体11中。The

其中,高度调节柱2和水平驱动机构3可以采用同样的结构;Wherein, the

在一可选的实施例中,高度调节柱2和水平驱动机构3可以是气缸,利用气缸能够进行伸缩调节,并且该调节能够为处理仓4的移动提供一定的缓冲;In an optional embodiment, the

在一可选的实施例中,高度调节柱2和水平驱动机构3可以是丝杠螺母副结构,其可以精确的提供伸缩驱动,保证了处理仓4移动的精确性。In an optional embodiment, the

在一可选的实施例中,高度调节柱2和水平驱动机构3可以是液压缸,其可提供较大的液压力,保证处理仓4移动的稳定性与高效性;In an optional embodiment, the

另外,本实施例中,在处理仓4中设置有采摘组件5和检测组件6,因此,在对罗汉果进行采摘时,可以利用检测组件6对其外观进行初步检测,从而实现初步分拣,便于对于罗汉果进行分类存储。In addition, in this embodiment, the

本实施例中,如图2,所述检测组件6包括:In this embodiment, as shown in FIG. 2 , the

对称转动设置于处理仓4中的传动齿轮61;Symmetrically rotate the

传动连接于两个传动齿轮61之间的传动链62;以及

阵列固定于所述传动链62上的限位座63;the

其中,所述限位座63上设置有收料机构,用于接收来自于采摘组件5的罗汉果;Wherein, the

还包括位于处理仓4顶部的视觉传感器68。A

另外,其中一个传动齿轮61上同轴固定有从动同步轮69,所述从动同步轮69采用同步带与主动同步轮传动相连,所述主动同步轮设置于采摘组件5中驱动电机53的输出端,且所述驱动电机53驱动采摘组件5进行一次采摘时,能够带动从动同步轮69进行转动,且使得收料机构行走一个步距,该步距满足下一收料机构能够移动至采摘组件5的出料端。In addition, a driven

也就是说,本实施例中,可以将采摘动作和送料检测动作进行同步,保证采摘和送料检测的统一性,使得各个罗汉果均能够被依次送料检测。That is to say, in this embodiment, the picking action and the feeding detection action can be synchronized to ensure the unity of picking and feeding detection, so that each Luo Han Guo can be fed and detected in sequence.

作为较佳的实施例,所述收料机构包括收料框66,所述收料框66的底部固定有随动齿轮65,所述随动齿轮65能够绕其中心竖轴线转动设置于所述限位座63上;As a preferred embodiment, the receiving mechanism includes a receiving

所述处理仓4中还固定有位于传动链62上方的齿条67,所述齿条67能够与随动齿轮65相啮合。A

也就是说,当收料机构进行移动时,随动齿轮能够与齿条相啮合,从而使得在收料机构进行移动时,收料框能够在齿条的作用下进行转动,从而使得视觉传感器能够拍摄罗汉果的多个角度的图片并上传至处理器进行图片分析。That is to say, when the receiving mechanism moves, the follower gear can mesh with the rack, so that when the receiving mechanism moves, the receiving frame can rotate under the action of the rack, so that the visual sensor can Take pictures of Luo Han Guo from multiple angles and upload them to the processor for picture analysis.

作为较佳的实施例,所述处理仓4中还固定有沿限位座63移动轨迹分布的支撑轨道64,所述支撑轨道64与所述限位座63滑动相连。As a preferred embodiment, a

本实施例中,如图3和4,所述采摘组件5包括:In this embodiment, as shown in Figures 3 and 4, the picking assembly 5 includes:

导料槽51,其固定于所述处理仓4的顶部;A

安装座512,其嵌入至所述导料槽51的底部;a mounting

基座57,其转动设置于所述安装座512上,且所述基座57上对称滑动设置有滑座56,且所述滑座56由双头伸缩杆55所驱动;以及a

采摘臂52,其固定于所述滑座56上;且所述采摘臂52上铰接有弧形自适应爪54。The picking

另外,所述基座57采用轴体转动设置于所述安装座512上,轴体一端穿出安装座512且连接有从动齿轮513,所述从动齿轮513与主动齿轮相啮合,所述主动齿轮同轴固定于贯穿轴510上,所述贯穿轴510贯穿转动设置于传动仓59中,且由驱动电机53所驱动。In addition, the

另外,所述贯穿轴510远离主动齿轮的一端同轴固定有主动锥齿轮,所述主动锥齿轮与从动锥齿轮相啮合,所述从动锥齿轮上同轴固定有主动同步轮。In addition, a driving bevel gear is coaxially fixed at one end of the through

作为较佳的实施例,所述伸缩杆55上采用多个弹簧连接有底板58,所述底板58为弧形结构。As a preferred embodiment, the

在利用所述采摘臂进行采摘时,所述驱动电机53驱动所述基座57进行转动从而将罗汉果脱离藤杆,其中,在转动过程中,采摘臂相互远离,使得罗汉果接触束缚并甩出,另外需注意的是,收料框的收料空间较大,且大于导料槽中的排料口,例如,每次在采摘罗汉果时,驱动电机可驱动基座转动4周,其中,在第3.5周时,下一收料框的左侧位于排料口的左侧,此时采摘臂相互远离,使得罗汉果接触束缚并甩出,再转动0.5周时,该收料框刚好位于排料口的正下方,从而保证罗汉果被收集。When the picking arms are used for picking, the driving

本实施例中,所述第一管体7的一端竖向连通于所述处理仓4的底部,所述第二管体8水平连通于所述第一管体7的一侧,所述第一管体7的另一侧还设置有导料杆9,所述导料杆9能够伸缩,且伸长时能够为罗汉果提供导向,使其在导料杆的导向下进入至第二管体8中。In this embodiment, one end of the

在具体实施时,在对罗汉果进行采摘时,驱动电机53驱动所述基座57进行转动从而将罗汉果脱离藤杆,其中,在转动过程中,采摘臂相互远离,使得罗汉果接触束缚并甩出,罗汉果进入至收料框中,并能够随着收料框进行移动和转动,从而利用检测组件6对其外观进行初步检测,从而实现初步分拣,便于对于罗汉果进行分类存储。In the specific implementation, when picking the monk fruit, the

以上所述的,仅为本发明较佳的具体实施方式,但本发明的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本发明揭露的技术范围内,根据本发明的技术方案及其发明构思加以等同替换或改变,都应涵盖在本发明的保护范围之内。The above are only preferred specific embodiments of the present invention, but the protection scope of the present invention is not limited thereto. The equivalent replacement or modification of the solution and its inventive concept shall be included within the protection scope of the present invention.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210511291.5ACN114698466B (en) | 2022-05-11 | 2022-05-11 | Car is picked to mangosteen |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210511291.5ACN114698466B (en) | 2022-05-11 | 2022-05-11 | Car is picked to mangosteen |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114698466Atrue CN114698466A (en) | 2022-07-05 |

| CN114698466B CN114698466B (en) | 2023-04-18 |

Family

ID=82176524

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210511291.5AActiveCN114698466B (en) | 2022-05-11 | 2022-05-11 | Car is picked to mangosteen |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114698466B (en) |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2036909A1 (en)* | 1990-04-18 | 1993-06-01 | Ind Albajar S A | Artificial vision system for the robotic collection of fruits |

| CN108464114A (en)* | 2018-04-03 | 2018-08-31 | 仲恺农业工程学院 | All-in-one is picked and collects to high-order fruit |

| CN108839045A (en)* | 2018-07-22 | 2018-11-20 | 丁宏遂 | A kind of scrap car recycle bin mechanical clamp |

| CN109618670A (en)* | 2019-03-01 | 2019-04-16 | 南通理工学院 | Intelligent fruit and vegetable picking and sorting robot |

| CN110352703A (en)* | 2019-08-15 | 2019-10-22 | 成秀东 | A kind of Intelligentized mechanical harvesting apparatus |

| WO2020051620A1 (en)* | 2018-05-16 | 2020-03-19 | Universal Field Robotics Pty Ltd | Automated vehicle |

| CN210995299U (en)* | 2019-11-20 | 2020-07-14 | 新疆大学 | Flower and leaf separating device of hop cleaning and sorting machine |

| CN111656960A (en)* | 2020-07-20 | 2020-09-15 | 湖南翰坤实业有限公司 | Picking mechanical arm and intelligent fruit picking machine |

| CN112740912A (en)* | 2021-02-01 | 2021-05-04 | 桂林航天工业学院 | Adjustable type momordica grosvenori is planted with picking frame |

| CN113661828A (en)* | 2021-08-26 | 2021-11-19 | 中以集知(广州)科技有限公司 | Classifiable watermelon harvesting and transporting machine based on machine vision |

| CN215122223U (en)* | 2021-07-13 | 2021-12-14 | 西北农林科技大学 | Rotary separating type kiwi fruit picking end effector |

- 2022

- 2022-05-11CNCN202210511291.5Apatent/CN114698466B/enactiveActive

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| ES2036909A1 (en)* | 1990-04-18 | 1993-06-01 | Ind Albajar S A | Artificial vision system for the robotic collection of fruits |

| CN108464114A (en)* | 2018-04-03 | 2018-08-31 | 仲恺农业工程学院 | All-in-one is picked and collects to high-order fruit |

| WO2020051620A1 (en)* | 2018-05-16 | 2020-03-19 | Universal Field Robotics Pty Ltd | Automated vehicle |

| CN108839045A (en)* | 2018-07-22 | 2018-11-20 | 丁宏遂 | A kind of scrap car recycle bin mechanical clamp |

| CN109618670A (en)* | 2019-03-01 | 2019-04-16 | 南通理工学院 | Intelligent fruit and vegetable picking and sorting robot |

| CN110352703A (en)* | 2019-08-15 | 2019-10-22 | 成秀东 | A kind of Intelligentized mechanical harvesting apparatus |

| CN210995299U (en)* | 2019-11-20 | 2020-07-14 | 新疆大学 | Flower and leaf separating device of hop cleaning and sorting machine |

| CN111656960A (en)* | 2020-07-20 | 2020-09-15 | 湖南翰坤实业有限公司 | Picking mechanical arm and intelligent fruit picking machine |

| CN112740912A (en)* | 2021-02-01 | 2021-05-04 | 桂林航天工业学院 | Adjustable type momordica grosvenori is planted with picking frame |

| CN215122223U (en)* | 2021-07-13 | 2021-12-14 | 西北农林科技大学 | Rotary separating type kiwi fruit picking end effector |

| CN113661828A (en)* | 2021-08-26 | 2021-11-19 | 中以集知(广州)科技有限公司 | Classifiable watermelon harvesting and transporting machine based on machine vision |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114698466B (en) | 2023-04-18 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN216728316U (en) | Intelligent sorting device | |

| CN207210457U (en) | A kind of leather detection cuts sorting integration apparatus | |

| CN107600598B (en) | Automatic bag and automatic loading device of opening of immunochromatography reagent card aluminium foil bag | |

| CN114698466A (en) | Car is picked to mangosteen | |

| CN206702408U (en) | A kind of ultrasonic aluminum wire press welder | |

| CN221148537U (en) | Multifunctional intelligent machine vision detection device | |

| CN115673410B (en) | Automatic processing device for battery accessories | |

| CN109499923B (en) | A device for selecting high-quality battery plates | |

| CN117665017A (en) | Food foreign matter detection device with three light source x-ray functions | |

| CN113663389B (en) | Water making device for improving quality of domestic drinking water and preparation method thereof | |

| CN117000619A (en) | Capacitance detection machine convenient to quick screening | |

| CN213133967U (en) | Grain sampling screening running gear | |

| CN115649577A (en) | A detect and receive material system for silver contact | |

| CN213875435U (en) | EL infrared tester | |

| CN110238041B (en) | Two-stage classification device for traditional Chinese medicine particles | |

| CN208249161U (en) | A kind of capacitor charging equipment feeding mechanism | |

| CN114113134A (en) | Offline appearance detection platform | |

| CN209049764U (en) | Automatic rejecting machine for defective electronic cigarettes | |

| CN210928644U (en) | Tomato picking robot | |

| CN207510870U (en) | A kind of immunochromatography reagent card aluminium foil bag automatic bag-opening and automatic loading device | |

| CN208370297U (en) | Prepositioning vibration falling layered picking machine | |

| CN208082864U (en) | A kind of blueberry storting apparatus | |

| CN207292571U (en) | One kind dress rest device | |

| CN221329907U (en) | Fly maggot breeding device | |

| CN111960090A (en) | A multifunctional reclaiming device for jewelry weighing |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| EE01 | Entry into force of recordation of patent licensing contract | ||

| EE01 | Entry into force of recordation of patent licensing contract | Application publication date:20220705 Assignee:GUANGXI AGLYCONE PLANT PRODUCTS Co.,Ltd. Assignor:GUILIN University OF AEROSPACE TECHNOLOGY Contract record no.:X2023980043449 Denomination of invention:A kind of Siraitia grosvenorii picking car Granted publication date:20230418 License type:Common License Record date:20231013 | |

| EE01 | Entry into force of recordation of patent licensing contract | ||

| EE01 | Entry into force of recordation of patent licensing contract | Application publication date:20220705 Assignee:Guilin Yicheng Intelligent Equipment Co.,Ltd. Assignor:GUILIN University OF AEROSPACE TECHNOLOGY Contract record no.:X2024980017014 Denomination of invention:A kind of Siraitia grosvenorii picking car Granted publication date:20230418 License type:Common License Record date:20240930 | |

| EE01 | Entry into force of recordation of patent licensing contract | ||

| EE01 | Entry into force of recordation of patent licensing contract | Application publication date:20220705 Assignee:Guangxi Junling Technology Development Co.,Ltd. Assignor:GUILIN University OF AEROSPACE TECHNOLOGY Contract record no.:X2024980024801 Denomination of invention:A kind of Siraitia grosvenorii picking car Granted publication date:20230418 License type:Common License Record date:20241121 |