CN114556898A - Vehicle-mounted multi-eye assembly, assembly method and vehicle - Google Patents

Vehicle-mounted multi-eye assembly, assembly method and vehicleDownload PDFInfo

- Publication number

- CN114556898A CN114556898ACN202080069097.5ACN202080069097ACN114556898ACN 114556898 ACN114556898 ACN 114556898ACN 202080069097 ACN202080069097 ACN 202080069097ACN 114556898 ACN114556898 ACN 114556898A

- Authority

- CN

- China

- Prior art keywords

- circuit board

- bracket

- lens

- vehicle

- image sensor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N23/00—Cameras or camera modules comprising electronic image sensors; Control thereof

- H04N23/45—Cameras or camera modules comprising electronic image sensors; Control thereof for generating image signals from two or more image sensors being of different type or operating in different modes, e.g. with a CMOS sensor for moving images in combination with a charge-coupled device [CCD] for still images

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60R—VEHICLES, VEHICLE FITTINGS, OR VEHICLE PARTS, NOT OTHERWISE PROVIDED FOR

- B60R11/00—Arrangements for holding or mounting articles, not otherwise provided for

- B60R11/04—Mounting of cameras operative during drive; Arrangement of controls thereof relative to the vehicle

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/02—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/02—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness

- G01B11/022—Measuring arrangements characterised by the use of optical techniques for measuring length, width or thickness by means of tv-camera scanning

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N13/00—Stereoscopic video systems; Multi-view video systems; Details thereof

- H04N13/20—Image signal generators

- H04N13/204—Image signal generators using stereoscopic image cameras

- H04N13/239—Image signal generators using stereoscopic image cameras using two 2D image sensors having a relative position equal to or related to the interocular distance

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N23/00—Cameras or camera modules comprising electronic image sensors; Control thereof

- H04N23/50—Constructional details

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N23/00—Cameras or camera modules comprising electronic image sensors; Control thereof

- H04N23/50—Constructional details

- H04N23/54—Mounting of pick-up tubes, electronic image sensors, deviation or focusing coils

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N23/00—Cameras or camera modules comprising electronic image sensors; Control thereof

- H04N23/50—Constructional details

- H04N23/55—Optical parts specially adapted for electronic image sensors; Mounting thereof

- H—ELECTRICITY

- H05—ELECTRIC TECHNIQUES NOT OTHERWISE PROVIDED FOR

- H05K—PRINTED CIRCUITS; CASINGS OR CONSTRUCTIONAL DETAILS OF ELECTRIC APPARATUS; MANUFACTURE OF ASSEMBLAGES OF ELECTRICAL COMPONENTS

- H05K7/00—Constructional details common to different types of electric apparatus

- H05K7/14—Mounting supporting structure in casing or on frame or rack

Landscapes

- Engineering & Computer Science (AREA)

- Multimedia (AREA)

- Signal Processing (AREA)

- Mechanical Engineering (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Human Computer Interaction (AREA)

- Studio Devices (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本申请涉及车载技术领域,特别涉及一种车载多目组件、组装方法和车辆。The present application relates to the field of vehicle technology, and in particular, to a vehicle-mounted multi-purpose assembly, an assembling method and a vehicle.

背景技术Background technique

在相关技术中,双目摄像头是将镜头、图像传感器封装到镜筒中以形成相机模组,再将相机模组安装到双目支架上,如此导致双目摄像头的结构复杂,从而容易导致两个相机模组的位置存在偏差,使得两个相机模组的测距精度下降。In the related art, the binocular camera is to encapsulate the lens and the image sensor into the lens barrel to form a camera module, and then install the camera module on the binocular bracket, which leads to the complex structure of the binocular camera, which easily leads to two There is a deviation in the position of the camera modules, which reduces the ranging accuracy of the two camera modules.

发明内容SUMMARY OF THE INVENTION

本申请提供了一种车载多目组件、组装方法和车辆。The present application provides an in-vehicle multi-purpose assembly, an assembly method and a vehicle.

本申请提供了一种车载多目组件,所述车载多目组件包括支架、第一电路板、第二电路板、第一镜头和第二镜头;所述第一电路板固定在所述支架上,所述第一电路板上设置有第一图像传感器;所述第二电路板固定在所述支架上,所述第二电路板上设置有第二图像传感器;所述第一镜头固定在所述支架上,所述第一镜头与所述第一图像传感器对准;所述第二镜头固定在所述支架上,所述第二镜头与所述第二图像传感器对准;其中,所述第一镜头、所述第一电路板、所述第一图像传感器能够形成第一拍摄组件,所述第二镜头、所述第二电路板、所述第二图像传感器能够形成第二拍摄组件,所述第一拍摄组件与所述第二拍摄组件具有重叠的第一观测范围,所述第一拍摄组件与所述第二拍摄组件用于测量所述第一观测范围内的场景对象与自身的距离。The application provides a vehicle-mounted multi-eye assembly, which includes a bracket, a first circuit board, a second circuit board, a first lens and a second lens; the first circuit board is fixed on the bracket , the first circuit board is provided with a first image sensor; the second circuit board is fixed on the bracket, the second circuit board is provided with a second image sensor; the first lens is fixed on the bracket On the bracket, the first lens is aligned with the first image sensor; the second lens is fixed on the bracket, and the second lens is aligned with the second image sensor; wherein the The first lens, the first circuit board, and the first image sensor can form a first photographing component, and the second lens, the second circuit board, and the second image sensor can form a second photographing component, The first photographing component and the second photographing component have an overlapping first observation range, and the first photographing component and the second photographing component are used to measure the distance between the scene object within the first observation range and itself. distance.

本申请还提供了一种组装方法,用于组装车载多目组件,所述车载多目组件包括支架、第一电路板、第二电路板、第一镜头和第二镜头,所述第一电路板上设置有第一图像传感器;所述第二电路板上设置有第二图像传感器;所述组装方法包括:将所述第一电路板固定在所述支架上;将所述第二电路板固定在所述支架上;将所述第一镜头固定在所述支架上,所述第一镜头与所述第一图像传感器对准;将所述第二镜头固定在所述支架上,所述第二镜头与所述第二图像传感器对准;其中,所述第一镜头、所述第一电路板、所述第一图像传感器能够形成第一拍摄组件,所述第二镜头、所述第二电路板、所述第二图像传感器能够形成第二拍摄组件,所述第一拍摄组件与所述第二拍摄组件具有重叠的第一观测范围,所述第一拍摄组件与所述第二拍摄组件用于测量所述第一观测范围内的场景对象与自身的距离。The present application also provides an assembly method for assembling a vehicle-mounted multi-eye assembly, the vehicle-mounted multi-eye assembly comprising a bracket, a first circuit board, a second circuit board, a first lens and a second lens, the first circuit a first image sensor is arranged on the board; a second image sensor is arranged on the second circuit board; the assembling method includes: fixing the first circuit board on the bracket; fixing the second circuit board fixed on the bracket; the first lens is fixed on the bracket, the first lens is aligned with the first image sensor; the second lens is fixed on the bracket, the The second lens is aligned with the second image sensor; wherein, the first lens, the first circuit board, and the first image sensor can form a first photographing component, and the second lens, the first The two circuit boards and the second image sensor can form a second photographing component, the first photographing component and the second photographing component have an overlapping first observation range, the first photographing component and the second photographing component The component is used to measure the distance between the scene object within the first observation range and itself.

本申请还提供了一种车辆,所述车辆包括车辆本体及上述的车载多目组件,所述车载多目组件安装在所述车辆本体上。The present application also provides a vehicle, which includes a vehicle body and the above-mentioned vehicle-mounted multi-eye assembly, where the vehicle-mounted multi-eye assembly is mounted on the vehicle body.

本申请的车载多目组件、组装方法和车辆中,第一电路板、第二电路板、第一镜头和第二镜头直接固定在支架上,从而使得车载多目组件的结构简单,第一图像传感器、第一镜头、第二图像传感器和第二镜头形成的双目摄像头的位置偏差较小,从而能够提高双目摄像头的测距精度。In the vehicle-mounted multi-eye assembly, assembling method and vehicle of the present application, the first circuit board, the second circuit board, the first lens and the second lens are directly fixed on the bracket, so that the structure of the vehicle-mounted multi-eye assembly is simple, and the first image The positional deviation of the binocular camera formed by the sensor, the first lens, the second image sensor and the second lens is small, so that the ranging accuracy of the binocular camera can be improved.

本申请的附加方面和优点将在下面的描述中部分给出,部分将从下面的描述中变得明显,或通过本申请的实践了解到。Additional aspects and advantages of the present application will be set forth, in part, from the following description, and in part will become apparent from the following description, or may be learned by practice of the present application.

附图说明Description of drawings

本申请的上述和/或附加的方面和优点从结合下面附图对实施方式的描述中将变得明显和容易理解,其中:The above and/or additional aspects and advantages of the present application will become apparent and readily understood from the following description of embodiments taken in conjunction with the accompanying drawings, wherein:

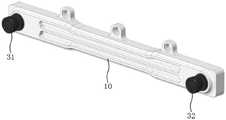

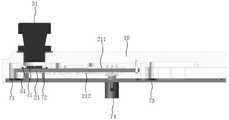

图1至图5是本申请某些实施方式的车载多目组件的结构示意图;1 to 5 are schematic structural diagrams of vehicle-mounted multi-purpose assemblies according to certain embodiments of the present application;

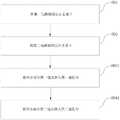

图6至图9是本申请某些实施方式的组装方法的流程图;6 to 9 are flowcharts of assembly methods of certain embodiments of the present application;

图10至图12是本申请某些实施方式的车载多目组件的结构示意图;10 to 12 are schematic structural diagrams of vehicle-mounted multi-purpose assemblies according to some embodiments of the present application;

图13是本申请某些实施方式的组装方法的流程图;Figure 13 is a flowchart of an assembly method of certain embodiments of the present application;

图14至图17是本申请某些实施方式的车载多目组件的结构示意图;14 to 17 are schematic structural diagrams of vehicle-mounted multi-purpose assemblies according to some embodiments of the present application;

图18是本申请某些实施方式的组装方法的流程图;Figure 18 is a flowchart of an assembly method of certain embodiments of the present application;

图19是本申请某些实施方式的车辆的示意图。19 is a schematic diagram of a vehicle of certain embodiments of the present application.

具体实施方式Detailed ways

下面详细描述本申请的实施方式,所述实施方式的示例在附图中示出,其中自始至终相同或类似的标号表示相同或类似的元件或具有相同或类似功能的元件。下面通过参考附图描述的实施方式是示例性的,仅用于解释本申请,而不能理解为对本申请的限制。Embodiments of the present application are described in detail below, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary, only used to explain the present application, and should not be construed as a limitation on the present application.

在本申请的描述中,需要理解的是,术语“中心”、“纵向”、“横向”、“长度”、“宽度”、“厚度”、“上”、“下”、“前”、“后”、“左”、“右”、“竖直”、“水平”、“顶”、“底”、“内”、“外”、“顺时针”、“逆时针”等指示的方位或位置关系为基于附图所示的方位或位置关系,仅是为了便于描述本申请和简化描述,而不是指示或暗示所指的装置或元件必须具有特定的方位、以特定的方位构造和操作,因此不能理解为对本申请的限制。此外,术语“第一”、“第二”仅用于描述目的,而不能理解为指示或暗示相对重要性或者隐含指明所指示的技术特征的数量。由此,限定有“第一”、“第二”的特征可以明示或者隐含地包括一个或者更多个所述特征。在本申请的描述中,“多个”的含义是两个或两个以上,除非另有明确具体的限定。In the description of this application, it should be understood that the terms "center", "longitudinal", "lateral", "length", "width", "thickness", "upper", "lower", "front", " rear, left, right, vertical, horizontal, top, bottom, inside, outside, clockwise, counterclockwise, etc., or The positional relationship is based on the orientation or positional relationship shown in the accompanying drawings, which is only for the convenience of describing the present application and simplifying the description, rather than indicating or implying that the referred device or element must have a specific orientation, be constructed and operated in a specific orientation, Therefore, it should not be construed as a limitation on this application. In addition, the terms "first" and "second" are only used for descriptive purposes, and should not be construed as indicating or implying relative importance or implying the number of indicated technical features. Thus, features defined as "first", "second" may expressly or implicitly include one or more of said features. In the description of the present application, "plurality" means two or more, unless otherwise expressly and specifically defined.

在本申请的描述中,需要说明的是,除非另有明确的规定和限定,术语“安装”、“相连”、“连接”应做广义理解,例如,可以是固定连接,也可以是可拆卸连接,或一体地连接。可以是机械连接,也可以是电连接。可以是直接相连,也可以通过中间媒介间接相连,可以是两个元件内部的连通或两个元件的相互作用关系。对于本领域的普通技术人员而言,可以根据具体情况理解上述术语在本申请中的具体含义。In the description of this application, it should be noted that, unless otherwise expressly specified and limited, the terms "installed", "connected" and "connected" should be understood in a broad sense, for example, it may be a fixed connection or a detachable connection connected, or integrally connected. It can be a mechanical connection or an electrical connection. It can be directly connected, or indirectly connected through an intermediate medium, and it can be the internal communication between two elements or the interaction relationship between the two elements. For those of ordinary skill in the art, the specific meanings of the above terms in this application can be understood according to specific situations.

下文的公开提供了许多不同的实施方式或例子用来实现本申请的不同结构。为了简化本申请的公开,下文中对特定例子的部件和设置进行描述。当然,它们仅仅为示例,并且目的不在于限制本申请。The following disclosure provides many different embodiments or examples for implementing different structures of the present application. To simplify the disclosure of the present application, the components and arrangements of specific examples are described below. Of course, they are only examples and are not intended to limit the application.

请参阅图1至图5,本申请提供了一种车载多目组件100,车载多目组件100包括支架10、第一电路板21、第二电路板22、第一镜头31和第二镜头32;第一电路板21固定在支架10上,第一电路板21上设置有第一图像传感器41;第二电路板22固定在支架10上,第二电路板22上设置有第二图像传感器42;第一镜头31固定在支架10上,第一镜头31与第一图像传感器41对准;第二镜头32固定在支架10上,第二镜头32与第二图像传感器42对准;其中,第一镜头31、第一电路板21、第一图像传感器41能够形成第一拍摄组件,第二镜头32、第二电路板22、第二图像传感器42能够形成第二拍摄组件,第一拍摄组件与第二拍摄组件具有重叠的第一观测范围,第一拍摄组件与第二拍摄组件用于测量第一观测范围内的场景对象与自身的距离。Referring to FIGS. 1 to 5 , the present application provides a vehicle-mounted

请参阅图6,本申请实施方式的组装方法,用于组装车载多目组件100,车载多目组件100包括支架10、第一电路板21、第二电路板22、第一镜头31和第二镜头32,第一电路板21上设置有第一图像传感器41;第二电路板22上设置有第二图像传感器42;组装方法包括:Please refer to FIG. 6 , the assembling method of the embodiment of the present application is used for assembling the vehicle-mounted

001,将第一电路板21固定在支架10上;001, fixing the

002,将第二电路板22固定在支架10上;002, fixing the

003,将第一镜头31固定在支架10上,第一镜头31与第一图像传感器41对准;003, the

004,将第二镜头32固定在支架10上,第二镜头32与第二图像传感器42对准;004, the

其中,第一镜头31、第一电路板21、第一图像传感器41能够形成第一拍摄组件,第二镜头32、第二电路板22、第二图像传感器42能够形成第二拍摄组件,第一拍摄组件与第二拍摄组件具有重叠的第一观测范围,第一拍摄组件与第二拍摄组件用于测量第一观测范围内的场景对象与自身的距离。Wherein, the

所述支架10整体呈矩形,支架10上侧边缘形成多个定位结构,支架10可以通过多个定位结构安装在其他位置,具体可以采用螺栓连接、铆接、胶粘等连接方式。The

第一电路板21和第二电路板22间隔一定距离固定在支架10上左右对称的位置,第一图像传感器41和第二图像传感器42分别设置在第一电路板21和第二电路板22上,第一镜头31和第二镜头32呈圆柱体状并分别与第一图像传感器41和第二图像传感器42对准,第一图像传感器41和第二图像传感器42可以接收第一镜头31和第二镜头32采集到的图像,并融合车速、IMU等信息配合第一电路板21和第二电路板22的运算功能实现基于双目视觉的感知方案。The

第一镜头31、第一电路板21、第一图像传感器41形成第一拍摄组件,第二镜头32、第二电路板22、第二图像传感器42形成第二拍摄组件,由于第一镜头31与第二镜头32朝向相同方向并间隔一定距离、镜头的视场角也相同,故第一镜头31和第二镜头32采集图像的范围会有部分重叠,称重叠部分为第一观测范围,第一拍摄组件与第二拍摄组件用于测量第一观测范围内的场景对象与自身的距离。The

在一种实施方式中,第一拍摄组件和第二拍摄组件可以采用短焦模组相机或长焦模组相机,第一拍摄组件与第二拍摄组件在支架10上的排列方式不固定。其中,第一拍摄组件与第二拍摄组件均采用短焦模组相机时,重叠的第一观测范围呈沿车辆1000宽度方向延伸的胖三角形状,以便能够获取近景视野及准确的近景距离。而第一拍摄组件与第二拍摄组件均采用长焦模组相机时,重叠的第二观测范围呈沿车辆1000长度方向延伸的细长三角形状,以便能够获取远景视野及准确的远景距离。In an embodiment, the first photographing assembly and the second photographing assembly may adopt a short-focus module camera or a long-focus module camera, and the arrangement of the first photographing assembly and the second photographing assembly on the

需要说明的是,第一拍摄组件和第二拍摄组件还可以是广角模组相机、近景模组相机、中景模组相机及远景模组相机的组合,即通过广角模组相机拍摄广角视频和图像,能够看到较大范围的景物,而通过近景模组相机侧重于拍摄车辆1000较近区域(如10米范围内)的图像和视频;中景模组相机相对于近景相机而言距离稍远,如与车辆1000的距离为10-50米之间的景物;而远景模组相机则会远些,如50米外。总体来说,本申请的第一拍摄组件和第二拍摄组件不仅仅限制于短焦模组相机和长焦模组相机的组合。It should be noted that the first shooting component and the second shooting component can also be a combination of a wide-angle module camera, a close-range module camera, a medium-view module camera, and a long-range module camera, that is, the wide-angle module camera is used to shoot wide-angle video and image, which can see a wide range of scenery, and the close-range module camera focuses on shooting images and videos of the

其中,第一拍摄组件与第二拍摄组件的数量不做限定,在测量观测范围内的场景对象与车辆1000的距离可以通过第一拍摄组件与第二拍摄组件重叠的区域进行计算,以提高测量的精度。The number of the first photographing component and the second photographing component is not limited, and the distance between the scene object and the

如此,第一电路板21、第二电路板22、第一镜头31和第二镜头32直接固定在支架10上,从而使得车载多目组件100的结构简单,第一图像传感器41、第一镜头31、第二图像传感器42和第二镜头32形成的双目摄像头的位置偏差较小,从而能够提高双目摄像头的测距精度。In this way, the

在本申请某些实施方式中,支架10上开设有第一安装部11和第二安装部12,第一安装部11用于安装第一电路板21,第二安装部12用于安装第二电路板22。In some embodiments of the present application, the

请参阅图1至图7,在本申请某些实施方式中,步骤001包括:Please refer to FIG. 1 to FIG. 7, in some embodiments of the present application,

0011,将第一电路板21安装到第一安装部11;0011, mount the

步骤002包括:Step 002 includes:

0021,将第二电路板22安装到第二安装部12。0021 , mount the

具体地,支架10上开设有第一安装部11和第二安装部12。Specifically, the

第一安装部11与第二安装部12分别位于支架10的左右两侧,第一安装部11与第二安装部12可以形成有螺纹孔,第一电路板21和第二电路板22可以采用螺栓连接安装到第一安装部11与第二安装部12。The first mounting

其中,第一安装部11设置有第一电路板21,第二安装部12设置有第二电路板22。The first mounting

第一安装部11和第二安装部12在支架10上对称设置,位于第一安装部11的第一电路板21和位于第二安装部12的第二电路板22在支架10上对称设置。The first mounting

在本申请某些实施方式中,第一安装部11开设有第一收容槽111,和/或第二安装部12开设有第二收容槽121,第一电路板21设置在第一收容槽111中,第二电路板22设置在第二收容槽121中。In some embodiments of the present application, the first mounting

请参阅图8,在本申请某些实施方式中,第一安装部11开设有第一收容槽111,和/或第二安装部12开设有第二收容槽121,步骤0011包括:Referring to FIG. 8 , in some embodiments of the present application, the first mounting

00111,将第一电路板21设置在第一收容槽111中;00111, set the

步骤0021包括:

00211,将第二电路板22设置在第二收容槽121中。00211, disposing the

第一收容槽111和第二收容槽121是开设在第一安装部11和第二安装部12上的两个凹槽,开设厚度与电路板的厚度匹配,并可以形成有卡扣、限位部等结构实现固定电路板的功能,第一电路板21和第二电路板22设置在第一收容槽111和第二收容槽121内。The first

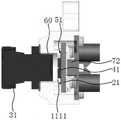

请参阅图1和图9,在本申请某些实施方式中,支架10上还开设有第一通孔131和第二通孔132,第一通孔131与第一收容槽111连通,第二通孔132与第二收容槽121连通,至少部分第一镜头31伸入第一通孔131中,至少部分第二镜头32伸入第二通孔132中。Referring to FIGS. 1 and 9 , in some embodiments of the present application, the

在本申请某些实施方式中,支架10上还开设有第一通孔131和第二通孔132,第一通孔131与第一收容槽111连通,第二通孔132与第二收容槽121连通,步骤003包括:In some embodiments of the present application, the

0031,将至少部分第一镜头31伸入第一通孔131中;0031, extending at least part of the

步骤004包括:Step 004 includes:

0041,将至少部分第二镜头32伸入第二通孔132中。0041 , extending at least part of the

第一通孔131开设在支架10上对准第一图像传感器41的位置,第一镜头31伸入第一通孔131对准第一图像传感器41。第一镜头31伸入第一通孔131中,第一镜头31与第一通孔131的连接处可以使用双组份胶水并采用AA制程工艺实现第一镜头31的固定。The first through

第二通孔132开设在支架10上对准第二图像传感器42的位置,第二镜头32伸入第二通孔132对准第二图像传感器42。第二镜头32伸入第二通孔132中,第二镜头32与第二通孔132的连接处可以使用双组份胶水并采用AA制程工艺实现第二镜头32的固定。The second through

如此,可以减少镜头安装的偏差,能提高车载多目结构的测量精确度。In this way, the deviation of the lens installation can be reduced, and the measurement accuracy of the vehicle-mounted multi-eye structure can be improved.

请参阅图10和图11,在本申请某些实施方式中,第一收容槽111内还包括环绕第一通孔131的第一突起1111,车载多目组件100还包括套设在第一突起1111上的第一密封件51,第一密封件51位于第一电路板21及支架10之间,第一密封件51环绕第一图像传感器41以密封第一图像传感器41;和/或第二收容槽121内还包括环绕第二通孔132的第二突起1211,车载多目组件100还包括套设在第二突起1211上的第二密封件52,第二密封件52位于第二电路板22及支架10之间,第二密封件52环绕第二图像传感器42以密封第二图像传感器42。Referring to FIGS. 10 and 11 , in some embodiments of the present application, the

在本申请某些实施方式中,第一收容槽111内还包括环绕第一通孔131的第一突起1111,车载多目组件100还包括套设在第一突起1111上的第一密封件51,第一密封件51位于第一电路板21及支架10之间;和/或第二收容槽121内还包括环绕第二通孔132的第二突起1211,车载多目组件100还包括套设在第二突起1211上的第二密封件52,第二密封件52位于第二电路板22及支架10之间,组装方法还包括:In some embodiments of the present application, the

005,将第一密封件51环绕第一图像传感器41;005, wrapping the first sealing

006,将第二密封件52环绕第二图像传感器42。006 , wrapping the second seal 52 around the second image sensor 42 .

第一突起1111将第一通孔131与第一电路板21间隔,间隔处容纳第一图像传感器41,第一突起1111可以支撑第一电路板21,也可以对第一镜头31在伸入第一通孔131的方向进行限位。The

第一密封件51呈环形,套设在第一突起1111上,环绕第一图像传感器41,紧贴第一突起1111和第一电路板21的缝隙处。The

第二突起1211将第二通孔132与第二电路板22间隔,间隔处容纳第二图像传感器42,第二突起1211可以支撑第二电路板22,也可以对第二镜头32在伸入第二通孔132的方向进行限位。The second protrusion 1211 separates the second through

第二密封件52呈环形,套设在第二突起1211上,环绕第二图像传感器42,紧贴第二突起1211和第二电路板22的缝隙处。The second sealing member 52 is annular, is sleeved on the second protrusion 1211 , surrounds the second image sensor 42 , and is close to the gap between the second protrusion 1211 and the

在本申请某些实施方式中,第一密封件51、第二密封件52包括密封圈。In some embodiments of the present application, the first sealing

第一密封件51和第二密封件52均呈环形,整体为O形的密封圈,密封圈可以采用橡胶、氟胶、硅胶O型圈或其他材质的密封部件。Both the first sealing

如此,密封圈可以对缝隙处进行填充和封闭,防止外界灰尘、水蒸气或能影响车载多目组件的物质进入,增强了车载多目设备的防护性能。In this way, the sealing ring can fill and seal the gap to prevent the entry of external dust, water vapor or substances that can affect the vehicle-mounted multi-purpose component, thereby enhancing the protection performance of the vehicle-mounted multi-purpose equipment.

在本申请某些实施方式中,支架10包括第一定位件14,第一电路板21和第二电路板22均包括第二定位件25,第一定位件14与第二定位件25对准安装以将第一电路板21及第二电路板22安装在支架10上。In some embodiments of the present application, the

在本申请某些实施方式中,支架10包括第一定位件14,第一电路板21和第二电路板22均包括第二定位件25,组装方法还包括:In some embodiments of the present application, the

007,将第一定位件14与第二定位件25对准安装。007, align and install the

第一电路板21及第二电路板22通过第一定位件14与第二定位件25配合安装在支架10上。The

例如,在一种实施方式中,支架10的第一定位件14可以是多个定位柱,电路板上的第二定位件25是多个定位孔,定位孔与定位柱位置一一对应,第一电路板21和第二电路板22通过定位孔插入到定位柱上固定电路板的位置,实现对准安装。For example, in one embodiment, the

在另一种实施方式中,支架10的第一定位件14可以是多个卡扣,电路板上的第二定位件25是多个卡槽,卡扣与卡槽位置一一对应,支架10的卡扣可以卡住电路板的卡槽,实现对准安装。In another embodiment, the

可以理解的是,第一定位件14与第二定位件25还可以采用花键连接、平键连接、圆柱销连接、铰制孔螺栓连接等其他多种结构,在此不做赘述。It can be understood that the

在本申请某些实施方式中,支架10包括用于安装第一电路板21的第一装配面151及用于安装第二电路板22的第二装配面152,第一装配面151与第二装配面152处于同一平面上。In some embodiments of the present application, the

请参阅图10,在本申请某些实施方式中,支架10包括用于安装第一电路板21的第一装配面151及用于安装第二电路板22的第二装配面152,组装方法还包括:Referring to FIG. 10 , in some embodiments of the present application, the

008,调整第一装配面151至与第二装配面152处于同一平面。008 , adjusting the

若第一装配面151与第二装配面152不处于同一平面可能导致图像处理受到影响,故应调整第一装配面151至与第二装配面152处于同一平面。If the first mounting

第一装配面151与第二装配面152处于同一平面时,第一电路板21、第一图像传感器41、第一镜头31与第二电路板22、第二图像传感器42、第二镜头32具有相同的图像采集参数(图像采集角度、采集范围等)。When the first mounting

在本申请某些实施方式中,支架10还包括用于安装第一镜头31的第一连接面161及用于安装第二镜头32的第二连接面162,第一连接面161与第一装配面151及第二装配面152平行,第二连接面162与第一装配面151及第二装配面152平行。In some embodiments of the present application, the

请参阅图3和图12,在本申请某些实施方式中,支架10还包括用于安装第一镜头31的第一连接面161及用于安装第二镜头32的第二连接面162,组装方法还包括:Referring to FIGS. 3 and 12 , in some embodiments of the present application, the

009,调整第一连接面161至与第一装配面151及第二装配面152平行;009, adjust the

010,调整第二连接面162至与第一装配面151及第二装配面152平行。010 , adjust the second connecting

第一连接面161与第一装配面151及第二装配面152平行,保证安装第一镜头31时镜头中轴与第一电路板21垂直。The first connecting

第二连接面162与第一装配面151及第二装配面152平行,保证安装第二镜头32时镜头中轴与第二电路板22垂直。The second connecting

在本申请某些实施方式中,车载多目组件100还包括连接件60,第一镜头31和第二镜头32均通过连接件60设置在支架10上。In some embodiments of the present application, the vehicle-mounted

在本申请某些实施方式中,车载多目组件100还包括连接件60,组装方法还包括:In some embodiments of the present application, the vehicle-mounted

011,将第一镜头31和第二镜头32通过连接件60设置在支架10上。011 , set the

连接件60呈柱形杯状,一侧容纳镜头,另一侧形成有开口伸入通孔中,对准图像传感器。The connecting

连接件60与通孔间可以采用螺纹连接、胶水填充等方式固定。The

在本申请某些实施方式中,支架10包括用于安装第一镜头31的第一连接面161及用于安装第二镜头32的第二连接面162,第一连接面161与第二连接面162处于同一平面上。In some embodiments of the present application, the

第一连接面161和第二连接面162处于同一平面,并均与第一装配面151及第二装配面152平行,保证了第一镜头31和第二镜头32的中轴平行。The first connecting

在本申请某些实施方式中,支架10包括用于安装第一镜头31的第一连接面161及用于安装第二镜头32的第二连接面162,第一连接面161的粗糙度和第二连接面162的粗糙度均大于预设粗糙度。In some embodiments of the present application, the

粗糙度是指加工表面具有的较小间距和微小峰谷的不平度。Roughness refers to the unevenness of small distances and small peaks and valleys that the machined surface has.

第一连接面161的粗糙度和第二连接面162的粗糙度均大于预设粗糙度,使得第一镜头31和第二镜头32安装在第一连接面161和第二连接面162时会存在很小的间隙,间隙可以用胶水填充。The roughness of the

如此,实行平面度管控(即调整连接面、装配面及表面粗糙度至规定范围)可以减小安装误差,提高设备安装稳定性和车载多目组件的测量性能。In this way, the implementation of flatness control (that is, adjusting the connection surface, assembly surface and surface roughness to the specified range) can reduce installation errors, improve equipment installation stability and the measurement performance of vehicle-mounted multi-purpose components.

在本申请某些实施方式中,车载多目组件100还包括后盖70,后盖70与支架10相连接。In some embodiments of the present application, the vehicle-mounted

在本申请某些实施方式中,车载多目组件100还包括后盖70,组装方法还包括:In some embodiments of the present application, the vehicle-mounted

012,将后盖70与支架10连接。012 , connect the back cover 70 to the

后盖70安装在支架10上与第一镜头31、第二镜头32相反的一侧,后盖70与支架10配合将第一电路板21、第二电路板22、第一传感器、第二传感器容置于后盖70与支架10间。The rear cover 70 is installed on the

在本申请某些实施方式中,支架10上设有第一定位部17,后盖70上设有第二定位部71,第一定位部17与第二定位部71配合安装以将后盖70安装在支架10上。In some embodiments of the present application, the

在本申请某些实施方式中,其特征在于,支架10上设有第一定位部17,后盖70上设有第二定位部71,组装方法还包括:In some embodiments of the present application, it is characterized in that the

013,将第一定位部17与第二定位部71配合安装。013, the

例如,在一种实施方式中,支架10的第一定位部17可以是多个螺孔,后盖70上的第二定位部71是多个定位孔,定位孔与螺孔位置一一对应,通过螺栓或螺钉将定位孔与螺孔固定,实现后盖70与支架10的配合安装。For example, in one embodiment, the

在另一种实施方式中,支架10的第一定位部17可以是多个卡扣,后盖70上的第二定位部71是多个卡槽,卡扣与卡槽位置一一对应,支架10的卡扣可以卡住后盖70的卡槽,实现对准安装。In another embodiment, the

可以理解的是,第一定位件14与第二定位件25还可以采用粘接、花键连接、平键连接、圆柱销连接等其他多种结构,在此不做赘述。It can be understood that the

在本申请某些实施方式中,后盖70包括导热部件72,导热部件72用于将第一拍摄组件、第二拍摄组件工作时产生的热量进行发散。In some embodiments of the present application, the back cover 70 includes a heat-conducting

在一种实施方式中,后盖70上的导热部件72可以采用导热凸台的结构,在后盖70内部(朝向电路板的一侧)延伸出两个或多个圆柱形的凸台,凸台与第一电路板21、第二电路板22紧贴,在电路板产生热量时将热量部分导出至后盖70进行散热。In one embodiment, the heat-conducting

在其他实施方式中,导热凸台也可以配合导热材料实现导热散热功能,例如在导热凸台与电路板间填充导热胶、导热凝脂等。In other embodiments, the thermally conductive boss can also cooperate with a thermally conductive material to achieve thermal conduction and heat dissipation, for example, a thermally conductive glue, thermally conductive grease, etc. are filled between the thermally conductive boss and the circuit board.

在本申请某些实施方式中,第一电路板21包括相背的第一安装面211和第一散热面212,第一图像传感器41设置在第一安装面211上,第一散热面212上与第一图像传感器41对应的位置形成有第一露铜区域213,后盖70安装在支架10上时,导热部件72与第一露铜区域213连接以将第一图像传感器41和/或第一电路板21的温度传导至外界;和/或第二电路板22包括相背的第二安装面221和第二散热面222,第二图像传感器42设置在第二安装面221上,第二散热面222上与第二图像传感器42对应的位置形成有第二露铜区域223,后盖70安装在支架10上时,导热部件72与第二露铜区域223连接以将第二图像传感器42和/或第二电路板22的温度传导至外界。In some embodiments of the present application, the

第一电路板21包括相背的第一安装面211和第一散热面212,其中第一安装面211为第一电路板21上朝向第一通孔131的一侧,第一散热面212为第一电路板21朝向后盖70的一侧,第一图像传感器41设置在第一安装面211上,第一散热面212上与第一图像传感器41对应的位置形成有第一露铜区域213,导热部件72可以对第一露铜区域213进行散热。The

第二电路板22包括相背的第二安装面221和第二散热面222,其中第二安装面221为第二电路板22上朝向第二通孔132的一侧,第二散热面222为第二电路板22朝向后盖70的一侧,第二图像传感器42设置在第二安装面221上,第二散热面222上与第二图像传感器42对应的位置形成有第二露铜区域223,导热部件72可以对第二露铜区域223进行散热。The

在本申请某些实施方式中,后盖70包括后盖本体73,导热部件72突出于后盖本体73;当后盖70安装于支架10时,第一电路板21、第二电路板22与后盖本体73间隔预设距离。In some embodiments of the present application, the back cover 70 includes a

在本申请某些实施方式中,后盖70包括后盖本体73,导热部件72突出于后盖本体73;组装方法还包括:In some embodiments of the present application, the back cover 70 includes a

014,将后盖70安装于支架10时,第一电路板21、第二电路板22与后盖本体73间隔预设距离。014 , when the rear cover 70 is installed on the

后盖70包括后盖本体73,导热部件72朝向支架10并突出于后盖本体73,支架10上可以形成有限位结构对导热部件72进行限位,防止后盖本体73直接接触电路板。The rear cover 70 includes a

第一电路板21、第二电路板22与后盖本体73间隔预设距离,导热部件72与第一电路板21、第二电路板22直接接触。The

如此,在电路板和后盖本体73间形成空隙,提高了内部散热能力。In this way, a gap is formed between the circuit board and the

在本申请某些实施方式中,导热部件72与后盖本体73一体成型;和/或,导热部件72与后盖本体73可拆卸连接。In some embodiments of the present application, the heat-conducting

若导热部件72与后盖本体73一体成型,后盖70应采用导热性能较好的材料,例如铜合金、硅铝合金等材料。If the heat-conducting

若导热部件72与后盖本体73可拆卸连接,导热部件72应采用导热性能较好的材料,后盖本体73则可以采用其他材质(但仍需保证足够的散热性能)。If the heat-conducting

在本申请某些实施方式中,后盖70设有输出接口74,输出接口74与拍摄组件电性连接。In some embodiments of the present application, the back cover 70 is provided with an

在本申请某些实施方式中,后盖70设有输出接口74,组装方法还包括:In some embodiments of the present application, the back cover 70 is provided with an

015,将输出接口74与拍摄组件电性连接。015. Electrically connect the

后盖70设有输出接口74,输出接口74与拍摄组件电性连接,输出接口74可以将拍摄组件采集处理后的数据传输到其他装置(例如中控显示屏)。The back cover 70 is provided with an

例如,在一种实施方式中,后盖70上可以设有接口安装槽,输出接口74嵌设在接口安装槽中,当然,输出接口74也可以通过注塑的形式与后盖70一体成型,本申请不加以限制。For example, in one embodiment, the rear cover 70 may be provided with an interface installation slot, and the

在本申请某些实施方式中,输出接口74的数量与拍摄组件的数量相匹配,使得每个拍摄组件与输出接口74对应连接。In some embodiments of the present application, the number of

在本申请某些实施方式中,输出接口74的数量与拍摄组件的数量相匹配,组装方法还包括:In some embodiments of the present application, the number of

016,将每个拍摄组件与输出接口74对应连接。016 , connect each photographing component to the

具体地,第一电路板21、第二电路板22上都形成有电路输出端,可以通过连接线将电路输出端与输出接口74连接。Specifically, circuit output terminals are formed on both the

输出接口74的数量与拍摄组件的数量相匹配,本申请实施方式中包括第一拍摄组件和第二拍摄组件,故对应的输出接口74的数量也为两个。The number of

在本申请某些实施方式中,车载多目组件100还包括:第三电路板、第四电路板、第三镜头和第四镜头。第三电路板固定在支架10上,第三电路板上设置有第三图像传感器;第四电路板固定在支架10上,第四电路板上设置有第四图像传感器;第三镜头固定在支架10上,第三镜头与第三图像传感器对准;第四镜头固定在支架10上,第四镜头与第四图像传感器对准;其中,第三镜头、第三电路板、第三图像传感器能够形成第三拍摄组件,第四镜头、第四电路板、第四图像传感器能够形成第四拍摄组件,第三拍摄组件与第四拍摄组件具有重叠的第二观测范围,第三拍摄组件与第四拍摄组件用于测量第二观测范围内的场景对象与自身的距离。In some embodiments of the present application, the vehicle-mounted

请参阅图13,在本申请某些实施方式中,车载多目组件100还包括第三电路板、第四电路板、第三镜头和第四镜头,第三电路板上设置有第三图像传感器;第四电路板上设置有第四图像传感器;组装方法还包括:Referring to FIG. 13 , in some embodiments of the present application, the vehicle-mounted

017,将第三电路板固定在支架10上;017, fixing the third circuit board on the

018,将第四电路板固定在支架10上;018, fixing the fourth circuit board on the

019,将第三镜头固定在支架10上,第三镜头与第三图像传感器对准;019, the third lens is fixed on the

020,将第四镜头固定在支架10上,第四镜头与第四图像传感器对准;020, fixing the fourth lens on the

其中,第三镜头、第三电路板、第三图像传感器能够形成第三拍摄组件,第四镜头、第四电路板、第四图像传感器能够形成第四拍摄组件,第三拍摄组件与第四拍摄组件具有重叠的第二观测范围,第三拍摄组件与第四拍摄组件用于测量第二观测范围内的场景对象与自身的距离。Wherein, the third lens, the third circuit board, and the third image sensor can form a third photographing component, the fourth lens, the fourth circuit board, and the fourth image sensor can form a fourth photographing component, and the third photographing component and the fourth photographing component The components have overlapping second observation ranges, and the third photographing component and the fourth photographing component are used to measure the distance between the scene object within the second observation range and itself.

在其他实施方式中,车载多目组件100也可以包括第一拍摄组件、第二拍摄组件、第三拍摄组件、第四拍摄组件共四个拍摄组件。In other embodiments, the vehicle-mounted

第三拍摄组件与第四拍摄组件具有重叠的第二观测范围,第三拍摄组件与第四拍摄组件用于测量第二观测范围内的场景对象与自身的距离。与第一拍摄组件和第二拍摄组件配合,四个拍摄组件同时工作即可实现同时测量第一观测范围和第二观测范围两个范围。The third photographing component and the fourth photographing component have an overlapping second observation range, and the third photographing component and the fourth photographing component are used to measure the distance between the scene object within the second observation range and itself. In cooperation with the first photographing component and the second photographing component, the four photographing components work at the same time to realize the simultaneous measurement of two ranges of the first observation range and the second observation range.

如此,采用四个拍摄组件观测范围更大,计算能力更强,可以更精确的测量对象与自身的距离。In this way, using four shooting components has a larger observation range and stronger computing power, and can measure the distance between the object and itself more accurately.

请参阅图14,在本申请某些实施方式中,支架10用于与遮光罩80直接地或间接地连接;其中,遮光罩80用于防止杂光进入拍摄组件内。Referring to FIG. 14 , in some embodiments of the present application, the

在本申请某些实施方式中,组装方法还包括:In certain embodiments of the present application, the assembling method further includes:

021,将支架10与遮光罩80直接地或间接地连接。021, connect the

请参阅图14和图15,遮光罩80是一个形成有容置腔的壳体,支架10可以直接安装在遮光罩80内,遮光罩80在对应支架10第一镜头31和第二镜头32处、输出接口74处形成有多个开口,使得遮光罩80不会遮挡第一镜头31和第二镜头32处、输出接口74。Please refer to FIG. 14 and FIG. 15 , the

具体地,遮光罩80的形状类似双铲子形状,外侧凸缘82为遮光罩80外侧的两个边缘,内侧凸缘81为遮光罩80内侧的两个边缘,遮光罩80内侧的两个边缘将遮光罩80形成一个三角状的避空位,该避空位的形状与第一表面与遮光罩80连接部分的形状相同,使得上端面能够与第一表面形成一个与前挡玻璃的表面曲率相同的贴合面,拍摄组件的镜头穿设在上端面与内表面之间的镜头孔中。Specifically, the shape of the

示例性的,遮光罩80包括第一遮光区和第二遮光区,第一遮光区对应第一安装部11设置,第二遮光区对应第二安装部12设置。Exemplarily, the light-shielding

在一个可选的实施方式中,第一遮光区的外沿与第二遮光区的外沿对称设置。In an optional implementation manner, the outer edge of the first light-shielding area and the outer edge of the second light-shielding area are symmetrically arranged.

请参阅图16和图17,在本申请某些实施方式中,遮光罩80的外侧具有外侧凸缘82,外侧凸缘82与遮光罩80的中轴线的角度是基于其中一个拍摄组件的最大视场角进行设定的。Referring to FIGS. 16 and 17 , in some embodiments of the present application, the outer side of the

在本申请某些实施方式中,遮光罩80的内侧具有内侧凸缘81,组装方法还包括:In some embodiments of the present application, the inner side of the

022,基于其中一个拍摄组件的最大视场角设定内侧凸缘81与遮光罩80的中轴线的角度。022 , set the angle between the

在本申请某些实施方式中,外侧凸缘82与遮光罩80的中轴线的角度是根据最外侧的拍摄组件的最大视场角设定的。In some embodiments of the present application, the angle between the

在本申请某些实施方式中,组装方法还包括:In certain embodiments of the present application, the assembling method further includes:

023,根据最外侧的拍摄组件的最大视场角设定外侧凸缘82与遮光罩80的中轴线的角度。023. Set the angle between the

在本申请某些实施方式中,遮光罩80的内侧具有内侧凸缘81,内侧凸缘81与遮光罩80的中轴线的角度是基于其中一个拍摄组件的最大视场角进行设定的。In some embodiments of the present application, the inner side of the

在本申请某些实施方式中,遮光罩80的内侧具有内侧凸缘81,组装方法还包括:In some embodiments of the present application, the inner side of the

024,基于其中一个拍摄组件的最大视场角设定内侧凸缘81与遮光罩80的中轴线的角度。024 , set the angle between the

在本申请某些实施方式中,内侧凸缘81与遮光罩80的中轴线的角度是根据最内侧的拍摄组件的最大视场角进行设定的。In some embodiments of the present application, the angle between the

在本申请某些实施方式中,组装方法还包括:In certain embodiments of the present application, the assembling method further includes:

025,根据最内侧的拍摄组件的最大视场角设定内侧凸缘81与遮光罩80的中轴线的角度。025. Set the angle between the

在本申请某些实施方式中,遮光罩80用于贴合在汽车的前挡玻璃上,遮光罩80的表面曲率和前挡玻璃的曲率相对应,使得部分或全部遮光罩80能够贴合在前挡玻璃上。In some embodiments of the present application, the

在本申请某些实施方式中,组装方法还包括:In certain embodiments of the present application, the assembling method further includes:

026,将遮光罩80贴合在汽车的前挡玻璃上。026, attach the

遮光罩80的表面曲率和前挡玻璃的曲率相对应,使得部分或全部遮光罩80能够贴合在前挡玻璃上,具体地,遮光罩80贴合在汽车的前挡风玻璃上、内后视镜的上方。The surface curvature of the

在本申请某些实施方式中,遮光罩80周侧的边缘上设置有翻边结构,用于与前挡玻璃粘接。In some embodiments of the present application, a flanging structure is provided on the peripheral edge of the

遮光罩80的表面曲率和前挡玻璃的曲率相对应,遮光罩80周侧的边缘上的翻边结构可以将部分的车载多目组件100贴合于车辆1000的前挡玻璃,使得多个拍摄组件沿车辆1000的宽度方向依次排列,保证了第一拍摄组件和第二拍摄组件能够可能多地穿过前挡玻璃后用于观测范围内的场景对象与车辆1000的距离。The surface curvature of the

例如,第一拍摄组件与第二拍摄组件穿过前挡玻璃后用于第一观测范围内的场景对象与车辆1000的距离;第三拍摄组件与第四拍摄组件穿过前挡玻璃后用于第二观测范围内的场景对象与车辆1000的距离。For example, after the first photographing component and the second photographing component pass through the windshield, they are used for the distance between the scene object in the first observation range and the

在本申请某些实施方式中,遮光罩80上设有消光结构,用于遮蔽杂光。In some embodiments of the present application, a light-extinguishing structure is provided on the

例如,消光结构可以采用消光绒布,消光绒布贴合在遮光罩80的内表面,或者消光结构也可以采用设置在遮光罩80表面上的消光纹,消光纹呈锯齿状。For example, the matting structure can use matting flannel, and the matting flannel is attached to the inner surface of the

在本申请某些实施方式中,支架10还用于与第三安装部相连接,第三安装部用于与外部装置相连接,以将支架10固定于外部装置。In some embodiments of the present application, the

请参阅图18,在本申请某些实施方式中,组装方法还包括:Referring to FIG. 18, in some embodiments of the present application, the assembling method further includes:

027,将支架10与第三安装部相连接;027, connect the

028,将第三安装部与外部装置相连接。028, connect the third installation part with the external device.

支架10与第三安装部相连接,第三安装部与外部装置相连接从而使得支架10固定在外部装置上。The

在本申请某些实施方式中,第三安装部用于安装遮光罩80。In some embodiments of the present application, the third mounting portion is used to mount the

在本申请某些实施方式中,组装方法还包括:In certain embodiments of the present application, the assembling method further includes:

029,将遮光罩80安装到第三安装部。029, mount the

在本申请某些实施方式中,遮光罩80设有第三定位部83,第三定位部83与第三安装部连接。In some embodiments of the present application, the

在本申请某些实施方式中,遮光罩80设有第三定位部83,组装方法还包括:In some embodiments of the present application, the

030,将第三定位部83与第三安装部连接。030, connect the

如此,通过连接第三定位部83和第三安装部可以将遮光罩80安装在支架10上。In this way, the

在本申请某些实施方式中,第三安装部为设置在支架10上的定位柱,第三定位部83为设置在遮光罩80的定位孔,定位孔安装在定位柱上。In some embodiments of the present application, the third mounting portion is a positioning post provided on the

在本申请某些实施方式中,第三安装部为设置在支架10上的定位柱,第三定位部83为设置在遮光罩80的定位孔,组装方法还包括:In some embodiments of the present application, the third mounting portion is a positioning post provided on the

031,将定位孔安装在定位柱上。031, install the positioning hole on the positioning column.

将定位孔安装在定位柱上即可实现第三定位部83与第三安装部的连接,从而使遮光罩80安装到支架10上。The connection between the

在本申请某些实施方式中,步骤003包括:In some embodiments of the present application,

0032,利用主动对位制程将第一镜头31固定在支架10上;0032, using the active alignment process to fix the

步骤004包括:Step 004 includes:

0042,利用主动对位制程将第二镜头32固定在支架10上。0042 , using an active alignment process to fix the

主动对位制程是一种确定零配件装配过程中相对位置的技术,在安装每一个组件/零件时,对转增在组装的半成品进行检测,并根据半成品的实际情况主动对准,然后将下一个组件/零件组装到位。The active alignment process is a technology to determine the relative position of the spare parts during the assembly process. When installing each component/part, the semi-finished products that are transferred during the assembly are inspected, and they are actively aligned according to the actual situation of the semi-finished products. A component/part is assembled in place.

具体地,在安装第一镜头31和第二镜头32时,通过主动对位制程,设备会对第一镜头31、第二镜头32、支架10进行主动对准然后进行安装。Specifically, when installing the

如此,应用主动对位制程可以有效的减少装配公差,有效的提升了安装精确度、产品一致性。In this way, the application of the active alignment process can effectively reduce assembly tolerances and effectively improve installation accuracy and product consistency.

请参阅图19,本申请实施方式的车辆1000包括车辆本体1001及车载多目组件100,车载多目组件100安装在车辆本体1001上。Referring to FIG. 19 , a

在本申请中,除非另有明确的规定和限定,第一特征在第二特征之“上”或之“下”可以包括第一和第二特征直接接触,也可以包括第一和第二特征不是直接接触而是通过它们之间的另外的特征接触。而且,第一特征在第二特征“之上”、“上方”和“上面”包括第一特征在第二特征正上方和斜上方,或仅仅表示第一特征水平高度高于第二特征。第一特征在第二特征“之下”、“下方”和“下面”包括第一特征在第二特征正下方和斜下方,或仅仅表示第一特征水平高度小于第二特征。In this application, unless otherwise expressly specified and defined, a first feature "on" or "under" a second feature may include direct contact between the first and second features, or may include the first and second features Not directly but through additional features between them. Also, the first feature being "above", "over" and "above" the second feature includes the first feature being directly above and obliquely above the second feature, or simply means that the first feature is level higher than the second feature. The first feature is "below", "below" and "below" the second feature includes the first feature being directly below and diagonally below the second feature, or simply means that the first feature has a lower level than the second feature.

本申请可以在不同例子中重复参考数字和/或参考字母,这种重复是为了简化和清楚的目的,其本身不指示所讨论各种实施方式和/或设置之间的关系。此外,本申请提供了的各种特定的工艺和材料的例子,但是本领域普通技术人员可以意识到其他工艺的应用和/或其他材料的使用。The application may repeat reference numerals and/or reference letters in different instances for the purpose of simplicity and clarity and not in itself indicative of the relationship between the various embodiments and/or arrangements discussed. In addition, this application provides examples of various specific processes and materials, but one of ordinary skill in the art will recognize the application of other processes and/or the use of other materials.

在本说明书的描述中,参考术语“一个实施方式”、“一些实施方式”、“示意性实施方式”、“示例”、“具体示例”、或“一些示例”等的描述意指结合实施方式或示例描述的具体特征、结构、材料或者特点包含于本申请的至少一个实施方式或示例中。在本说明书中,对上述术语的示意性表述不一定指的是相同的实施方式或示例。而且,描述的具体特征、结构、材料或者特点可以在任何的一个或多个实施方式或示例中以合适的方式结合。In the description of this specification, reference to the terms "one embodiment," "some embodiments," "exemplary embodiment," "example," "specific example," or "some examples", etc., is meant to incorporate the embodiments A particular feature, structure, material, or characteristic described or exemplified is included in at least one embodiment or example of the present application. In this specification, schematic representations of the above terms do not necessarily refer to the same embodiment or example. Furthermore, the particular features, structures, materials or characteristics described may be combined in any suitable manner in any one or more embodiments or examples.

尽管已经示出和描述了本申请的实施方式,本领域的普通技术人员可以理解:在不脱离本申请的原理和宗旨的情况下可以对这些实施方式进行多种变化、修改、替换和变型,本申请的范围由权利要求及其等同物限定。Although the embodiments of the present application have been shown and described, those of ordinary skill in the art will appreciate that various changes, modifications, substitutions and alterations can be made to these embodiments without departing from the principles and spirit of the present application, The scope of the application is defined by the claims and their equivalents.

Claims (68)

Translated fromChineseApplications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| PCT/CN2020/128108WO2022099505A1 (en) | 2020-11-11 | 2020-11-11 | Vehicle-mounted multi-view assembly, assembling method, and vehicle |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114556898Atrue CN114556898A (en) | 2022-05-27 |

| CN114556898B CN114556898B (en) | 2025-06-10 |

Family

ID=81601849

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202080069097.5AActiveCN114556898B (en) | 2020-11-11 | 2020-11-11 | Vehicle-mounted multi-objective component, assembly method and vehicle |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN114556898B (en) |

| WO (1) | WO2022099505A1 (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118338107A (en)* | 2024-04-15 | 2024-07-12 | 深圳森云智能科技有限公司 | Electronic camera with heating module and assembling method thereof |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN119026326B (en)* | 2024-07-29 | 2025-05-30 | 广州优创电子有限公司 | Method and system for enhancing bonding force of active alignment process surface of camera |

Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN205075748U (en)* | 2015-02-04 | 2016-03-09 | Lg电子株式会社 | Stereoscopic shooting device |

| US20160142596A1 (en)* | 2014-10-06 | 2016-05-19 | Roberto DePaschoal | Vision systems using multiple cameras |

| CN105691299A (en)* | 2014-12-10 | 2016-06-22 | Lg电子株式会社 | Vehicle driving assistance apparatus and vehicle |

| CN106828341A (en)* | 2017-01-25 | 2017-06-13 | 驭势(上海)汽车科技有限公司 | A kind of vehicle-mounted camera |

| CN109196557A (en)* | 2016-06-08 | 2019-01-11 | 索尼公司 | Image processing apparatus, image processing method and vehicle |

| CN208782984U (en)* | 2018-02-02 | 2019-04-23 | 北京中科慧眼科技有限公司 | A kind of more mesh cameras of modularization |

| US20190152392A1 (en)* | 2014-10-06 | 2019-05-23 | CoPilot Vision Systems | Vehicle mounted collision avoidance systems and related methods |

| CN209517303U (en)* | 2019-02-28 | 2019-10-18 | 深圳市大疆创新科技有限公司 | A kind of optical sensor, moveable platform |

| CN111225831A (en)* | 2019-03-29 | 2020-06-02 | 深圳市大疆创新科技有限公司 | Sensor support applied to vehicle, sensor module and vehicle |

| CN211184040U (en)* | 2019-07-26 | 2020-08-04 | 北京中科慧眼科技有限公司 | Vehicle, camera module and shell assembly thereof |

| CN211531170U (en)* | 2020-03-25 | 2020-09-18 | 南昌欧菲光电技术有限公司 | Lens assembly, camera module and electronic equipment |

Family Cites Families (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP4031104B2 (en)* | 1998-02-20 | 2008-01-09 | 富士重工業株式会社 | Stereo camera |

| US7967745B2 (en)* | 2006-09-28 | 2011-06-28 | Given Imaging, Ltd. | In vivo imaging device and method of manufacture thereof |

| CN106647112A (en)* | 2015-10-28 | 2017-05-10 | 南昌欧菲光电技术有限公司 | Dual camera module and camera device with same |

| CN206569009U (en)* | 2017-01-25 | 2017-10-20 | 驭势(上海)汽车科技有限公司 | A kind of vehicle-mounted camera |

| CN210807350U (en)* | 2019-11-27 | 2020-06-19 | Oppo广东移动通信有限公司 | Mobile terminal |

- 2020

- 2020-11-11WOPCT/CN2020/128108patent/WO2022099505A1/ennot_activeCeased

- 2020-11-11CNCN202080069097.5Apatent/CN114556898B/enactiveActive

Patent Citations (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20160142596A1 (en)* | 2014-10-06 | 2016-05-19 | Roberto DePaschoal | Vision systems using multiple cameras |

| US20190152392A1 (en)* | 2014-10-06 | 2019-05-23 | CoPilot Vision Systems | Vehicle mounted collision avoidance systems and related methods |

| CN105691299A (en)* | 2014-12-10 | 2016-06-22 | Lg电子株式会社 | Vehicle driving assistance apparatus and vehicle |

| CN205075748U (en)* | 2015-02-04 | 2016-03-09 | Lg电子株式会社 | Stereoscopic shooting device |

| CN109196557A (en)* | 2016-06-08 | 2019-01-11 | 索尼公司 | Image processing apparatus, image processing method and vehicle |

| CN106828341A (en)* | 2017-01-25 | 2017-06-13 | 驭势(上海)汽车科技有限公司 | A kind of vehicle-mounted camera |

| CN208782984U (en)* | 2018-02-02 | 2019-04-23 | 北京中科慧眼科技有限公司 | A kind of more mesh cameras of modularization |

| CN209517303U (en)* | 2019-02-28 | 2019-10-18 | 深圳市大疆创新科技有限公司 | A kind of optical sensor, moveable platform |

| CN111225831A (en)* | 2019-03-29 | 2020-06-02 | 深圳市大疆创新科技有限公司 | Sensor support applied to vehicle, sensor module and vehicle |

| CN211184040U (en)* | 2019-07-26 | 2020-08-04 | 北京中科慧眼科技有限公司 | Vehicle, camera module and shell assembly thereof |

| CN211531170U (en)* | 2020-03-25 | 2020-09-18 | 南昌欧菲光电技术有限公司 | Lens assembly, camera module and electronic equipment |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118338107A (en)* | 2024-04-15 | 2024-07-12 | 深圳森云智能科技有限公司 | Electronic camera with heating module and assembling method thereof |

| CN118338107B (en)* | 2024-04-15 | 2024-11-19 | 深圳森云智能科技有限公司 | Electronic camera with heating module and assembling method thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2022099505A1 (en) | 2022-05-19 |

| CN114556898B (en) | 2025-06-10 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US10766431B2 (en) | Imaging apparatus and vehicle | |

| CN108780267B (en) | Vehicle image processing device | |

| KR101724300B1 (en) | Stereo camera | |

| CN104106004B (en) | Module arrangement for a camera system, retaining spring device and corresponding camera system | |

| US8970700B2 (en) | Imaging apparatus | |

| EP3054666A1 (en) | Triple camera | |

| CN104717410A (en) | Camera with heating element | |

| JP2022189609A (en) | Imaging device and method for assembling imaging device | |

| JP2017118445A (en) | On-vehicle camera | |

| JP7541844B2 (en) | Imaging device and vehicle | |

| CN114556898A (en) | Vehicle-mounted multi-eye assembly, assembly method and vehicle | |

| CN101848326B (en) | Imaging apparatus | |

| WO2022052057A1 (en) | Vehicle-mounted multi-view structure and vehicle | |

| JP2014011565A (en) | Camera module | |

| CN113170035B (en) | Camera module and movable platform | |

| WO2021149404A1 (en) | Imaging device | |

| CN104065856A (en) | stereo camera unit | |

| WO2019119365A1 (en) | Camera, photographing device and unmanned aerial vehicle | |

| KR102344461B1 (en) | Camera module | |

| JP2021069006A (en) | Imaging apparatus, detection method, and mobile unit | |

| CN217216725U (en) | Camera device and processing system of images in vehicle cabin | |

| EP3796085B1 (en) | Camera device | |

| JP2022067299A (en) | Imaging apparatus | |

| CN211209788U (en) | Functional assembly, cloud platform equipment and moving platform | |

| CN216599766U (en) | Camera module |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| TA01 | Transfer of patent application right | Effective date of registration:20240515 Address after:Building 3, Xunmei Science and Technology Plaza, No. 8 Keyuan Road, Science and Technology Park Community, Yuehai Street, Nanshan District, Shenzhen City, Guangdong Province, 518057, 1634 Applicant after:Shenzhen Zhuoyu Technology Co.,Ltd. Country or region after:China Address before:518057 Shenzhen Nanshan District, Shenzhen, Guangdong Province, 6/F, Shenzhen Industry, Education and Research Building, Hong Kong University of Science and Technology, No. 9 Yuexingdao District, Nanshan District, Shenzhen City, Guangdong Province Applicant before:SZ DJI TECHNOLOGY Co.,Ltd. Country or region before:China | |

| TA01 | Transfer of patent application right | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |