CN114547924A - Analysis method and system of transformer winding vibration voiceprint based on multi-physics coupling - Google Patents

Analysis method and system of transformer winding vibration voiceprint based on multi-physics couplingDownload PDFInfo

- Publication number

- CN114547924A CN114547924ACN202111341808.2ACN202111341808ACN114547924ACN 114547924 ACN114547924 ACN 114547924ACN 202111341808 ACN202111341808 ACN 202111341808ACN 114547924 ACN114547924 ACN 114547924A

- Authority

- CN

- China

- Prior art keywords

- transformer

- winding

- vibration

- transformer winding

- field

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G06F30/20—Design optimisation, verification or simulation

- G06F30/23—Design optimisation, verification or simulation using finite element methods [FEM] or finite difference methods [FDM]

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2119/00—Details relating to the type or aim of the analysis or the optimisation

- G06F2119/10—Noise analysis or noise optimisation

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Theoretical Computer Science (AREA)

- Computer Hardware Design (AREA)

- Evolutionary Computation (AREA)

- Geometry (AREA)

- General Engineering & Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Management, Administration, Business Operations System, And Electronic Commerce (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本申请涉及变压器绕组振动噪声技术领域,尤其涉及一种基于多物理场耦合的变压器绕组振动声纹分析方法及系统。The present application relates to the technical field of vibration and noise of transformer windings, and in particular, to a method and system for analyzing vibration and sound pattern of transformer windings based on multi-physical field coupling.

背景技术Background technique

作为电力系统的核心设备之一,电力变压器的安全性与可靠性对电网的可靠运行至关重要。据统计数据表明,变压器的机械故障主要由长期累积形成,包括变压器的主件和部分构件,其中由于绕组变形所引起的故障占绝大比例。As one of the core equipment of the power system, the safety and reliability of the power transformer are crucial to the reliable operation of the power grid. According to statistical data, the mechanical faults of transformers are mainly formed by long-term accumulation, including the main components and some components of the transformer, among which faults caused by winding deformation account for the vast majority.

长期以来,人们一直将变压器发出的声音视为噪声,但却忽略其内在价值,其运行声音包含着变压器运行状态信息。变压器的噪声主要是由铁芯磁致伸缩以及绕组受洛伦兹力振动产生。在变压器短路状态下,由于电压比较小,铁芯磁致伸缩的影响很小,所产生的声音与绕组振动产生的声音存在数量级上的差异,因此在这种运行状态下,只需要考虑变压器绕组振动所产生的声音。For a long time, people have regarded the sound emitted by the transformer as noise, but ignored its intrinsic value, and its operating sound contains the information of the operating state of the transformer. The noise of the transformer is mainly caused by the magnetostriction of the iron core and the vibration of the winding by the Lorentz force. In the short-circuit state of the transformer, due to the relatively small voltage, the influence of magnetostriction of the iron core is very small, and the sound produced is different from the sound produced by the winding vibration. Therefore, in this operating state, only the transformer winding needs to be considered. The sound produced by vibration.

目前国内外在变压器的声音信号的产生机理、降噪方法、声信号特征提取以及识别方法中已经取得了大量的成果,但在变压器正常及故障状态下的声音信号特性分析方面仍未有深入研究。这使得有效的特征量提取方法以及故障识别算法缺乏依据。At present, a lot of achievements have been made in the generation mechanism, noise reduction method, acoustic signal feature extraction and identification method of the sound signal of the transformer at home and abroad, but there is still no in-depth research on the analysis of the sound signal characteristics of the transformer under normal and fault conditions. . This makes the effective feature extraction methods and fault identification algorithms lack basis.

发明内容SUMMARY OF THE INVENTION

有鉴于此,本申请提供了一种基于多物理场耦合的变压器绕组振动声纹特性分析方法,包括如下步骤:In view of this, the present application provides a method for analyzing the vibration and voiceprint characteristics of transformer windings based on multi-physics field coupling, including the following steps:

步骤一:根据实际尺寸建立变压器几何模型,并对变压器几何模型进行网格划分;Step 1: Establish a geometric model of the transformer according to the actual size, and mesh the geometric model of the transformer;

步骤二:根据变压器实际运行情况,仿真变压器电磁场分布情况;Step 2: According to the actual operation of the transformer, simulate the distribution of the electromagnetic field of the transformer;

步骤三:根据变压器绕组中磁场与结构力场的耦合,仿真变压器绕组受力以及振动情况;Step 3: According to the coupling between the magnetic field and the structural force field in the transformer winding, simulate the stress and vibration of the transformer winding;

步骤四:根据变压器绕组结构力场与压力声场耦合,仿真变压器外围空间声场;Step 4: According to the coupling of the transformer winding structure force field and the pressure sound field, simulate the outer space sound field of the transformer;

步骤五:依据变压器绕组常见三种机械故障,仿真变压器绕组在故障状态下的声纹特性;Step 5: According to the three common mechanical faults of transformer windings, simulate the voiceprint characteristics of transformer windings under fault conditions;

步骤六:进行外围声场仿真结果分析以及实验验证分析。Step 6: Carry out the analysis of the simulation results of the peripheral sound field and the analysis of the experimental verification.

进一步地,所述步骤一包括:Further, the

根据实际参数对变压器进行几何建模,对绕组上下两端施加固定约束,模拟构件加紧作用,铁芯采用硅钢片叠压而成,绕组采用均匀多匝形式,并对变压器有限元模型进行有效的网格划分。The transformer is geometrically modeled according to the actual parameters, and fixed constraints are imposed on the upper and lower ends of the winding to simulate the tightening effect of the components. mesh division.

进一步地,所述步骤二中,Further, in the step 2,

变压器的磁场包括主磁场和漏磁场,漏磁场是变压器绕组振动的根源。The magnetic field of the transformer includes the main magnetic field and the leakage magnetic field. The leakage magnetic field is the source of the vibration of the transformer winding.

进一步地,变压器磁感应强度计算方法包括:Further, the method for calculating the magnetic induction intensity of the transformer includes:

当绕组之中流过电流时,由于交变漏磁场的存在,使得绕组上产生电磁力,假设稳态运行下流过绕组的电流I为:When a current flows through the winding, due to the existence of the alternating leakage magnetic field, an electromagnetic force is generated on the winding. Assuming that the current I flowing through the winding under steady-state operation is:

I=Imsin(ωt+φ0) (1)I=Im sin(ωt+φ0 ) (1)

其中Im为绕组电流幅值,ω为绕组中电流的角频率,φ0为绕组电流的初相位;Wherein Im is the amplitude of the winding current, ω is the angular frequency of the current in the winding, and φ0 is the initial phase of the winding current;

简化磁感应强度计算公式,在静态条件下,磁感应强度可表示为:Simplify the calculation formula of magnetic induction. Under static conditions, the magnetic induction can be expressed as:

其中为磁感应强度与电流之间的电动力系数。in is the electrodynamic coefficient between the magnetic induction and the current.

进一步地,所述步骤三包括:Further, the step 3 includes:

计算变压器绕组所受的电动力为:Calculate the electromotive force on the transformer winding as:

变压器绕组等效为多自由度线性弹簧质量系统,其固体力学微分方程可以表示为:The transformer winding is equivalent to a multi-degree-of-freedom linear spring-mass system, and its solid mechanics differential equation can be expressed as:

式中:M为模型质量矩阵;C为模型阻尼矩阵;K为模型弹性系数矩阵;z(t)、分别为绕组模型的形变位移、形变速度和形变加速度;F(t)为绕组所受的电动力大小;g为重力加速度。In the formula: M is the model mass matrix; C is the model damping matrix; K is the model elastic coefficient matrix; z(t), are the deformation displacement, deformation velocity and deformation acceleration of the winding model, respectively; F(t) is the magnitude of the electromotive force on the winding; g is the gravitational acceleration.

变压器绕组模型的振动形变位移计算如下:The vibration deformation displacement of the transformer winding model is calculated as follows:

将式(3)所推导出的电动力公式代入(4),可得:Substituting the electrodynamic formula derived from formula (3) into (4), we can get:

由式(5)可知,M、C、K皆为常数,其为二阶常系数微分方程,对于其齐次部分:It can be seen from equation (5) that M, C, and K are all constants, which are second-order constant coefficient differential equations. For its homogeneous part:

其通解可以表示为:Its general solution can be expressed as:

z=eαt(C1 cosβt+C2 sinβt) (7)z=eαt (C1 cosβt+C2 sinβt) (7)

式中:C1、C2为常数,其大小由初始条件确定;In the formula: C1 and C2 are constants whose magnitudes are determined by the initial conditions;

由式(5)可知,M、C、K、R、φ0等皆为常数,其为二阶常系数微分方程,求解方程可得:It can be seen from formula (5) that M, C, K, R, φ0 , etc. are all constants, which are second-order constant coefficient differential equations, which can be obtained by solving the equations:

其中:A、θ为常数且有初始条件决定;Among them: A and θ are constants and are determined by initial conditions;

所述步骤四中,声压的波动方程表示为In the step 4, the wave equation of sound pressure is expressed as

其中:in:

p(r,t)为声压,其为传播半径r和时间t的函数;c0为声速.p(r,t) is the sound pressure, which is a function of the propagation radius r and time t; c0 is the speed of sound.

进一步地,所述步骤四中,Further, in the step 4,

利用COMSOL中的声-结构边界模块,耦合固体力学与压力声学模块,在绕组表面与空气介质接触面向外辐射噪声,将固体力学仿真数据作为声场分析的基础,分别计算变压器前后以及左右两个面的辐射噪声。Using the Acoustic-Structural Boundary Module in COMSOL, coupled with the Solid Mechanics and Pressure Acoustics Modules, the noise is radiated from the surface of the winding surface in contact with the air medium, and the solid mechanics simulation data is used as the basis for the sound field analysis to calculate the front and rear and left and right surfaces of the transformer respectively radiated noise.

本发明还公开了一种基于前述方法的变压器绕组振动声纹特性分析系统,包括变压器建模模块、变压器电磁场分布仿真模块、变压器绕组受力及振动仿真模块、变压器外围空间声场仿真模块、变压器绕组声纹特性仿真模块;The invention also discloses a transformer winding vibration and voiceprint characteristic analysis system based on the foregoing method, including a transformer modeling module, a transformer electromagnetic field distribution simulation module, a transformer winding force and vibration simulation module, a transformer peripheral space sound field simulation module, and a transformer winding simulation module. Voiceprint feature simulation module;

所述变压器建模模块根据实际尺寸建立变压器几何模型,并对变压器几何模型进行网格划分;The transformer modeling module establishes a transformer geometric model according to the actual size, and performs grid division on the transformer geometric model;

所述变压器电磁场分布仿真模块根据变压器实际运行情况,仿真变压器电磁场分布;The transformer electromagnetic field distribution simulation module simulates the transformer electromagnetic field distribution according to the actual operation of the transformer;

所述变压器绕组受力及振动仿真模块根据变压器绕组中磁场与结构力场的耦合,仿真变压器绕组受力以及振动情况;The transformer winding stress and vibration simulation module simulates the transformer winding stress and vibration according to the coupling of the magnetic field and the structural force field in the transformer winding;

所述变压器外围空间声场仿真模块根据变压器绕组结构力场与压力声场耦合,仿真变压器外围空间声场;The transformer peripheral space sound field simulation module simulates the transformer peripheral space sound field according to the coupling of the transformer winding structure force field and the pressure sound field;

所述变压器绕组声纹特性仿真模块依据变压器绕组常见三种机械故障,仿真变压器绕组在故障状态下的声纹特性。The transformer winding voiceprint characteristic simulation module simulates the voiceprint characteristics of the transformer winding under fault conditions according to three common mechanical faults of the transformer winding.

进一步优选,Further preferably,

所述变压器绕组振动声纹特性分析系统还包括外围声场仿真结果分析以及实验验证分析模块,分析变压器外围声场状态,对于变压器噪声进行分析,对比仿真结果,验证模型有效性。The transformer winding vibration and voiceprint characteristic analysis system also includes a simulation result analysis of the peripheral sound field and an experimental verification analysis module, which analyzes the state of the peripheral sound field of the transformer, analyzes the noise of the transformer, compares the simulation results, and verifies the validity of the model.

本发明同时公开了一种计算机系统,包括处理器及存储介质;The invention also discloses a computer system, comprising a processor and a storage medium;

所述存储介质用于存储指令;the storage medium is used to store instructions;

所述处理器用于根据所述指令进行操作以执行根据基于多物理场耦合的变压器绕组振动声纹特性分析方法的步骤。The processor is configured to operate according to the instructions to perform steps according to the method for analyzing the vibration and voiceprint characteristics of transformer windings based on multiphysics coupling.

一种计算机可读存储介质,其上存储有计算机程序,该程序被处理器执行时实现基于多物理场耦合的变压器绕组振动声纹特性分析方法的步骤。A computer-readable storage medium on which a computer program is stored, when the program is executed by a processor, realizes the steps of a method for analyzing the vibration and voiceprint characteristics of transformer windings based on multi-physics field coupling.

本发明研究了三相油浸式变压器的振动噪声特性,对S13-M-200/10型号的油浸式变压器进行短路试验,并测量了表面的振动信号和噪声信号。根据真实的试验条件,建立基于有限元的变压器绕组振动噪声模型,并考虑变压器油对声学传播过程的影响。变压器的振动及声压仿真结果与实际测量结果误差很小,验证了计算模型及方法的有效性。在模型的基础上建立变压器机械故障的仿真模型,分析变压器绕组故障状态下的噪声特性,为变压器绕组故障诊断提供了依据。The invention studies the vibration and noise characteristics of the three-phase oil-immersed transformer, conducts a short-circuit test on the S13-M-200/10 model oil-immersed transformer, and measures the vibration signal and noise signal on the surface. According to the real test conditions, a finite element-based transformer winding vibration and noise model is established, and the influence of transformer oil on the acoustic propagation process is considered. The error between the simulation results of transformer vibration and sound pressure and the actual measurement results is very small, which verifies the validity of the calculation model and method. On the basis of the model, the simulation model of transformer mechanical fault is established, and the noise characteristics of transformer winding under fault state are analyzed, which provides a basis for transformer winding fault diagnosis.

附图说明Description of drawings

图1是本发明的方法流程图。Figure 1 is a flow chart of the method of the present invention.

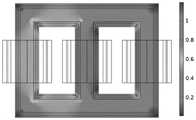

图2是变压器网格划分模型正视图。Figure 2 is a front view of the transformer meshing model.

图3是变压器网格划分模型俯视图。Figure 3 is a top view of the transformer meshing model.

图4是变压器外接仿真电路图图。Figure 4 is a schematic diagram of the external simulation circuit of the transformer.

图5是变压器绕组感应电流图。Figure 5 is a diagram of the transformer winding induced current.

图6是变压器绕组磁通密度模图。Fig. 6 is a transformer winding magnetic flux density model diagram.

图7是变压器铁芯磁通密度模图。Fig. 7 is a transformer core magnetic flux density model diagram.

图8是变压器绕组辐向受力图。Figure 8 is the radial force diagram of the transformer winding.

图9是高压绕组受力形变图。Figure 9 is a diagram of the stress and deformation of the high-voltage winding.

图10是低压绕组受力形变图。Figure 10 is a diagram of the stress and deformation of the low-voltage winding.

图11是变压器绕组轴向受力图。Figure 11 is the axial force diagram of the transformer winding.

图12是10kV变压器声信号测点图。Figure 12 is the measurement point diagram of the acoustic signal of the 10kV transformer.

图13是绕组松动故障模拟图。Figure 13 is a simulation diagram of a loose winding fault.

图14是绕组变形故障模拟图。Figure 14 is a simulation diagram of winding deformation failure.

图15是绕组绝缘脱落故障模拟图。Figure 15 is a simulation diagram of the fault of winding insulation shedding.

图16是变压器正面声场图。Fig. 16 is a sound field diagram of the front side of the transformer.

图17是变压器侧面声场图。Figure 17 is a side view of the sound field of the transformer.

图18是变压器正面实验图。Figure 18 is an experimental diagram of the front side of the transformer.

图19是变压器侧面实验图。Figure 19 is an experimental view of the side of the transformer.

具体实施方式Detailed ways

为使本发明实施例的目的、技术方案和优点更加清楚,下面将结合本发明实施例的附图,对本发明实施例的技术方案进行清楚、完整地描述。显然,所描述的实施例是本发明的一部分实施例,而不是全部的实施例。基于所描述的本发明的实施例,本领域普通技术人员所获得的所有其他实施例,都属于本发明保护的范围。In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions of the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings of the embodiments of the present invention. Obviously, the described embodiments are some, but not all, embodiments of the present invention. Based on the described embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art fall within the protection scope of the present invention.

如图1所示,本发明提供了一种基于多物理场耦合的变压器绕组振动声纹特性分析方法,包括如下步骤:As shown in FIG. 1 , the present invention provides a method for analyzing the vibration and voiceprint characteristics of transformer windings based on multi-physics field coupling, including the following steps:

步骤一:以S13-M-200/10型号的油浸式变压器仿真原型,建立变压器几何模型,并对变压器模型进行网格划分。Step 1: Use the S13-M-200/10 model oil-immersed transformer simulation prototype to establish the transformer geometric model and mesh the transformer model.

变压器结构复杂,由铁芯、绕组、油箱及其他辅助构件组成,本发明根据实际参数对变压器进行几何建模。本仿真主要构件包括铁芯、绕组、绝缘油、油箱壁、上夹件、下夹件、木制垫块、铁芯夹件和上顶板等构成。对绕组上下两端施加固定约束,模拟构件加紧作用,铁芯采用硅钢片叠压而成,绕组采用均匀多匝形式。The transformer has a complex structure and is composed of an iron core, a winding, an oil tank and other auxiliary components. The present invention performs geometric modeling of the transformer according to actual parameters. The main components of this simulation include iron core, winding, insulating oil, fuel tank wall, upper clamp, lower clamp, wooden spacer, iron core clamp and upper top plate. Fixed constraints are imposed on the upper and lower ends of the winding to simulate the tightening effect of the components.

对变压器有限元模型进行合理有效的网格划分,对于结构精细的部分,单元划分也更加精细,从而减少计算量,提高计算精度。The finite element model of the transformer is divided into reasonable and effective meshes, and for the fine-structured parts, the unit division is also more refined, thereby reducing the amount of calculation and improving the calculation accuracy.

图2示出了变压器网格划分模型正视图,图3示出了变压器网格划分模型俯视图。FIG. 2 shows a front view of the transformer meshing model, and FIG. 3 shows a top view of the transformer meshing model.

步骤二:根据变压器实际运行情况,仿真变压器绕组电磁场分布情况。Step 2: According to the actual operation of the transformer, simulate the distribution of the electromagnetic field of the transformer winding.

变压器的磁场主要包括主磁场和漏磁场,漏磁场是变压器绕组振动的根源。当绕组之中流过电流时,由于交变漏磁场的存在,使得绕组上产生电磁力。假设稳态运行下流过绕组的电流为:The magnetic field of the transformer mainly includes the main magnetic field and the leakage magnetic field. The leakage magnetic field is the source of the vibration of the transformer winding. When a current flows through the winding, due to the existence of the alternating leakage magnetic field, an electromagnetic force is generated on the winding. Assume that the current flowing through the winding in steady state operation is:

I=Im sin(ωt+φ0) (1)I=Im sin(ωt+φ0 ) (1)

其中Im为绕组电流幅值,ω为绕组中电流的角频率,φ0为绕组电流的初相位。Among them,Im is the amplitude of the winding current, ω is the angular frequency of the current in the winding, and φ0 is the initial phase of the winding current.

在漏磁通流经非铁磁材料时,主要经过主气隙、绕组、压紧结构或是油箱闭合,并且主要是轴向磁密分量。简化磁感应强度计算公式,在静态条件下,磁感应强度Bvt可表示为:When the leakage flux flows through the non-ferromagnetic material, it mainly passes through the main air gap, winding, compression structure or tank closure, and is mainly the axial magnetic density component. Simplifying the calculation formula of magnetic induction, under static conditions, the magnetic induction Bvt can be expressed as:

其中为磁感应强度与电流之间的电动力系数。in is the electrodynamic coefficient between the magnetic induction and the current.

变压器电路模型采用Dyn11接线方式,其高压侧电压源的电压为400V,频率为50Hz,且相位相差120°,外接仿真电路如图4所示,变压器绕组感应电流如图5所示,高压侧感应出的电流有效值为11.5A,低压侧感应出的电流有效值为288.7A,仿真结果与实际相符。The transformer circuit model adopts the Dyn11 wiring method. The voltage of the high-voltage side voltage source is 400V, the frequency is 50Hz, and the phase difference is 120°. The external simulation circuit is shown in Figure 4, and the transformer winding induced current is shown in Figure 5. The effective value of the output current is 11.5A, and the effective value of the current induced by the low-voltage side is 288.7A. The simulation results are consistent with the actual.

图6是变压器绕组磁通密度模图,图7是变压器铁芯磁通密度模图,如图6-7所示,漏磁通主要集中于高压绕组与低压绕组的气隙之中,最大值为0.0028T,变压器的主磁通主要集中铁芯之中,其最大值为1.16T,可知在激励电流的作用下,磁通密度较小,没有达到饱和磁通,且主磁通约占全部磁通的99%以上,漏磁通仅占全部磁通的1%以下,与实际情况相符。Figure 6 is a diagram of the magnetic flux density of the transformer winding, and Figure 7 is a diagram of the magnetic flux density of the transformer core. As shown in Figure 6-7, the leakage flux is mainly concentrated in the air gap between the high-voltage winding and the low-voltage winding, and the maximum value is It is 0.0028T, the main magnetic flux of the transformer is mainly concentrated in the iron core, and its maximum value is 1.16T. It can be seen that under the action of the excitation current, the magnetic flux density is small, does not reach the saturation magnetic flux, and the main magnetic flux accounts for about all More than 99% of the magnetic flux, the leakage flux only accounts for less than 1% of the total magnetic flux, which is consistent with the actual situation.

步骤三:根据变压器绕组中磁场与结构力场的耦合,仿真变压器绕组受力以及振动情况。Step 3: According to the coupling between the magnetic field and the structural force field in the transformer winding, simulate the stress and vibration of the transformer winding.

计算变压器绕组所受的电动力为:Calculate the electromotive force on the transformer winding as:

式中,指磁感应强度,R指线圈半径,I指稳态运行下流过绕组的电流,Im为绕组电流幅值,为磁感应强度与电流之间的电动力系数。In the formula, refers to the magnetic induction intensity, R refers to the coil radius, I refers to the current flowing through the winding under steady-state operation, Im refers to the winding current amplitude, is the electrodynamic coefficient between the magnetic induction and the current.

根据上式可知,绕组线圈的振动角频率为2ω,对于基波频率为50Hz的电网来说,100Hz是变压器绕组振动的主要频率。由于电网中存在其他谐波电流分量以及在变压器中非线性材料的作用下,变压器绕组振动信号中也存在着少量的其他频率的分量。According to the above formula, the vibration angular frequency of the winding coil is 2ω, and for a power grid with a fundamental frequency of 50Hz, 100Hz is the main frequency of the transformer winding vibration. Due to the presence of other harmonic current components in the power grid and the action of nonlinear materials in the transformer, there are also a small amount of other frequency components in the transformer winding vibration signal.

变压器绕组是一个典型的复杂的多自由度结构,可以等效为多自由度线性弹簧质量系统,其固体力学微分方程可以表示为:The transformer winding is a typical complex multi-degree-of-freedom structure, which can be equivalent to a multi-degree-of-freedom linear spring-mass system, and its solid mechanics differential equation can be expressed as:

式中:M为模型质量矩阵;C为模型阻尼矩阵;K为模型弹性系数矩阵;z(t)、分别为绕组模型的形变位移、形变速度和形变加速度;F(t)为绕组所受的电动力大小;g为重力加速度。In the formula: M is the model mass matrix; C is the model damping matrix; K is the model elastic coefficient matrix; z(t), are the deformation displacement, deformation velocity and deformation acceleration of the winding model, respectively; F(t) is the magnitude of the electromotive force on the winding; g is the gravitational acceleration.

将式(3)所推导出的电动力公式代入(4),可得:Substituting the electrodynamic formula derived from formula (3) into (4), we can get:

由式(5)可知,M、C、K皆为常数,其为二阶常系数微分方程,对于其齐次部分:It can be seen from equation (5) that M, C, and K are all constants, which are second-order constant coefficient differential equations. For its homogeneous part:

其通解可以表示为:Its general solution can be expressed as:

z=eαt(C1 cosβt+C2 sinβt) (7)z=eαt (C1 cosβt+C2 sinβt) (7)

式中:C1、C2为常数,其大小由初始条件确定;In the formula: C1 and C2 are constants whose magnitudes are determined by the initial conditions;

由式(5)可知,M、C、K、R、φ0等皆为常数,其为二阶常系数微分方程,求解方程可得:It can be seen from formula (5) that M, C, K, R, φ0 , etc. are all constants, which are second-order constant coefficient differential equations, which can be obtained by solving the equations:

其中:A、θ为常数且有初始条件决定;Among them: A and θ are constants and are determined by initial conditions;

由上式可知,绕组的振动位移大小取决于质量M、阻尼C、弹性系数K及绕组的几何结构,而对于确定的变压器,其质量以及阻尼式固定不变的,因此其振动位移大小主要取决于绕组的弹性系数及绕组的几何结构。It can be seen from the above formula that the vibration displacement of the winding depends on the mass M, the damping C, the elastic coefficient K and the geometric structure of the winding. For a certain transformer, its mass and damping type are fixed, so the vibration displacement is mainly determined by It depends on the elastic coefficient of the winding and the geometry of the winding.

变压器绕组在电磁力的作用下,受到辐向以及轴向两个方向的力。辐向力使得变压器绕组收到向内或者向外的牵引力作用,而轴向的作用力,则使得绕组受到向上或者向下的牵引力作用。Under the action of electromagnetic force, the transformer winding is subjected to radial and axial forces. The radial force causes the transformer winding to receive inward or outward traction, while the axial force causes the winding to receive upward or downward traction.

变压器绕组辐向受力如图8所示,B相和C相绕组延Y轴方向受力也相应较大,因此在沿Y轴方向上的形变程度也更为明显,而沿X轴方向上的受力相对较小。可知绕组所受的辐向力,在同一时刻的不同方向是不相同的,其大小由漏磁场的强度决定。如图9和10所示,高压绕组收到向外的牵引力,绕组对应有向外膨胀的趋势,而低压绕组受到向内的牵引力,绕组对应有向内收缩的趋势。并且越靠近绕组中心位置形变的程度越大。The radial force of the transformer winding is shown in Figure 8. The force of the B-phase and C-phase windings along the Y-axis is correspondingly larger, so the degree of deformation along the Y-axis is also more obvious. The force is relatively small. It can be known that the radial force on the winding is different in different directions at the same time, and its magnitude is determined by the strength of the leakage magnetic field. As shown in Figures 9 and 10, the high-voltage windings receive outward traction, and the windings tend to expand outward, while the low-voltage windings receive inward traction, and the windings tend to shrink inwards. And the closer to the center of the winding, the greater the degree of deformation.

如图11所示,B相和C相绕组上表面受到较大的向上的牵引力,而其他位置的轴向力相对来说较小,但是由于绕组上下表面施加了相对应的约束,因此没有发生大的形变,可知在生产以及使用过程中,对于绕组进行有效的固定,有助于防止绕组发生严重的形变。As shown in Figure 11, the upper surfaces of the B-phase and C-phase windings are subjected to a large upward traction force, while the axial force at other positions is relatively small, but due to the corresponding constraints imposed on the upper and lower surfaces of the windings, this does not occur. Large deformation, it can be seen that in the process of production and use, the effective fixing of the winding is helpful to prevent serious deformation of the winding.

步骤四:变压器绕组压力声学仿真建模:根据变压器绕组结构力场与压力声场耦合,仿真变压器外围空间声场。Step 4: Transformer winding pressure acoustic simulation modeling: According to the coupling between the transformer winding structure force field and the pressure sound field, simulate the outer space sound field of the transformer.

声波在介质中传播,但是在不同介质之中,声波的传播特性以及波的振动形式都是不同的,根据物理学三个基本定律:质量守恒定律、能量守恒定律和动量守恒定律,推导出流体之中的三个基本方程:连续性定律、状态方程和运动方程。根据声波振动的条件,并通过对三个方程的消元,可获得声压的波动方程:Sound waves propagate in media, but in different media, the propagation characteristics of sound waves and the vibration forms of waves are different. According to the three basic laws of physics: the law of conservation of mass, the law of conservation of energy and the law of conservation of momentum, the fluid is derived. The three fundamental equations are: the law of continuity, the equation of state, and the equation of motion. According to the conditions of sound wave vibration, and by eliminating the three equations, the wave equation of sound pressure can be obtained:

其中:p(r,t)为声压,其为传播半径r和时间t的函数;c0为声速。in: p(r,t) is the sound pressure, which is a function of the propagation radius r and time t; c0 is the speed of sound.

变压器绕组是变压器主要的振动源之一,其他辅助构件的振动噪声很小,本发明在研究绕组特性的仿真中忽略变压器其他辅助构件的振动噪声。利用COMSOL中的声-结构边界模块,耦合固体力学与压力声学模块,在绕组表面与空气介质接触面向外辐射噪声,将固体力学仿真数据作为声场分析的基础。分别计算变压器前后以及左右两个面的辐射噪声,将仿真测点布置离变压器30cm厘米处,高度为变压器油箱高度的一半。振动及声音信号仿真测点布置如图12所示。The transformer winding is one of the main vibration sources of the transformer, and the vibration noise of other auxiliary components is very small. The present invention ignores the vibration noise of other auxiliary components of the transformer in the simulation for studying the winding characteristics. Using the Acoustic-Structural Boundary Module in COMSOL, coupled with the Solid Mechanics and Pressure Acoustics Modules, the noise is radiated outward from the contact surface between the winding surface and the air medium, and the solid mechanics simulation data is used as the basis for the sound field analysis. Calculate the radiated noise on the front and back and on the left and right sides of the transformer respectively, and arrange the simulated measuring points at a distance of 30 cm from the transformer, and the height is half of the height of the transformer tank. The layout of vibration and sound signal simulation measurement points is shown in Figure 12.

步骤五:仿真变压器绕组三种机械故障,仿真变压器绕组在故障状态下的声纹特性。Step 5: Simulate three kinds of mechanical faults of the transformer winding, and simulate the voiceprint characteristics of the transformer winding in the fault state.

变压器绕组的松动程度即变压器绕组预紧力大小,与垫块及压紧结构件的材料特性相关。仿真几何模型在保证变压器绕组圈数不变的情况下,对变压器绕组松动、绕组变形及绕组绝缘脱落等故障进行模拟仿真。The looseness of the transformer winding is the magnitude of the transformer winding pre-tightening force, which is related to the material properties of the cushion block and the compression structure. The simulation geometry model simulates the transformer winding looseness, winding deformation and winding insulation shedding under the condition that the number of turns of the transformer winding remains unchanged.

垫块以及压紧结构件的材料非线性,导致其弹性模量随预紧力大小变化而变化,本发明通过改变变压器B相绕组弹性模量大小模拟B相绕组的松动故障,仿真模型如图13所示。The material of the cushion block and the compression structure is nonlinear, which causes its elastic modulus to change with the change of the pre-tightening force. The present invention simulates the loose fault of the B-phase winding by changing the elastic modulus of the B-phase winding of the transformer. The simulation model is shown in the figure. 13 shown.

变压器绕组的变形通常是由绕组轴向力产生,尤其是变压器绕组中流过短路电流或者发生励磁涌流时,此时绕组中流过的大电流对绕组损耗尤为严重。由上述仿真可知,变压器高压绕组受到向外的牵引力,使得绕组向外膨胀,而变压器低压绕组向内收缩,使得低压绕组向内扭曲变形。本发明通过将圆形绕组变成具有明显凸起的六边形圆柱体,来模拟变压器绕组变形,仿真模型如图14所示。The deformation of the transformer winding is usually caused by the axial force of the winding, especially when a short-circuit current or a magnetizing inrush current flows in the transformer winding. It can be seen from the above simulation that the high-voltage winding of the transformer is subjected to an outward traction force, which causes the winding to expand outward, while the low-voltage winding of the transformer contracts inward, causing the low-voltage winding to distort and deform inward. The present invention simulates the deformation of the transformer winding by changing the circular winding into a hexagonal cylinder with obvious protrusions, and the simulation model is shown in FIG. 14 .

变压器绕组绝缘脱落会对变压器安全稳定运行造成巨大影响,本发明通过改变变压器B相绕组的匝数来模拟变压器绕组绝缘脱落故障仿真模型如图15所示。The insulation shedding of the transformer winding will have a huge impact on the safe and stable operation of the transformer. The present invention simulates the transformer winding insulation shedding fault simulation model by changing the number of turns of the B-phase winding of the transformer, as shown in FIG. 15 .

步骤六:变压器外围声场仿真实验验证Step 6: Experimental verification of the sound field around the transformer

研究变压器周围的声场情况,本仿真简化为绕组的接触面在电磁场中运动而产生。To study the sound field around the transformer, this simulation is simplified as the contact surface of the winding moves in the electromagnetic field.

搭建实验室变压器数据测量平台,并分别对如调压器、采集仪等持续存在的噪声以及汽车声,脚步声等随机出现的噪声进行数据采集。完成对变压器短路运行情况下的数据采集,并采集不同位置的变压器噪声信号,变压器正面以及侧面的声场如图16-17所示,实验测点布置如18-19所示,分析变压器外围声场状态,对于变压器噪声进行分析,对比仿真结果,验证模型有效性。Build a laboratory transformer data measurement platform, and collect data on persistent noise such as voltage regulators and collectors, as well as random noises such as car sounds and footsteps. Complete the data collection under the short-circuit operation of the transformer, and collect the noise signals of the transformer at different positions. The sound field on the front and side of the transformer is shown in Figure 16-17, and the layout of the experimental measurement points is shown in Figure 18-19. Analyze the sound field status of the transformer periphery , analyze the transformer noise, compare the simulation results, and verify the validity of the model.

基于本发明的精神,本领域技术人员能够容易想到基于前述变压器绕组振动声纹特性分析方法可以得到一种计算机程序产品。计算机程序产品可以包括计算机可读存储介质,其上载有用于使处理器实现本公开的各个方面的计算机可读程序指令。即本申请还包括一种计算机系统,包括处理器及存储介质;Based on the spirit of the present invention, those skilled in the art can easily think that a computer program product can be obtained based on the aforementioned method for analyzing the vibration and voiceprint characteristics of transformer windings. The computer program product may include a computer-readable storage medium having computer-readable program instructions loaded thereon for causing a processor to implement various aspects of the present disclosure. That is, the present application also includes a computer system, including a processor and a storage medium;

所述存储介质用于存储指令;the storage medium is used to store instructions;

所述处理器用于根据所述指令进行操作以执行根据前述变压器绕组振动声纹特性分析方法的步骤。The processor is configured to operate according to the instructions to perform the steps according to the foregoing method for analyzing the vibration and voiceprint characteristics of transformer windings.

一种计算机可读存储介质,其上存储有计算机程序,该程序被处理器执行时实现前述变压器绕组振动声纹特性分析方法的步骤。A computer-readable storage medium on which a computer program is stored, and when the program is executed by a processor, implements the steps of the foregoing method for analyzing the vibration and voiceprint characteristics of transformer windings.

计算机可读存储介质可以是可以保持和存储由指令执行设备使用的指令的有形设备。计算机可读存储介质例如可以是――但不限于――电存储设备、磁存储设备、光存储设备、电磁存储设备、半导体存储设备或者上述的任意合适的组合。计算机可读存储介质的更具体的例子(非穷举的列表)包括:便携式计算机盘、硬盘、随机存取存储器(RAM)、只读存储器(ROM)、可擦式可编程只读存储器(EPROM或闪存)、静态随机存取存储器(SRAM)、便携式压缩盘只读存储器(CD-ROM)、数字多功能盘(DVD)、记忆棒、软盘、机械编码设备、例如其上存储有指令的打孔卡或凹槽内凸起结构、以及上述的任意合适的组合。这里所使用的计算机可读存储介质不被解释为瞬时信号本身,诸如无线电波或者其它自由传播的电磁波、通过波导或其它传输媒介传播的电磁波(例如,通过光纤电缆的光脉冲)、或者通过电线传输的电信号。A computer-readable storage medium may be a tangible device that can hold and store instructions for use by the instruction execution device. The computer-readable storage medium may be, for example, but not limited to, an electrical storage device, a magnetic storage device, an optical storage device, an electromagnetic storage device, a semiconductor storage device, or any suitable combination of the foregoing. More specific examples (non-exhaustive list) of computer readable storage media include: portable computer disks, hard disks, random access memory (RAM), read only memory (ROM), erasable programmable read only memory (EPROM) or flash memory), static random access memory (SRAM), portable compact disk read only memory (CD-ROM), digital versatile disk (DVD), memory sticks, floppy disks, mechanically encoded devices, such as printers with instructions stored thereon Hole cards or raised structures in grooves, and any suitable combination of the above. Computer-readable storage media, as used herein, are not to be interpreted as transient signals per se, such as radio waves or other freely propagating electromagnetic waves, electromagnetic waves propagating through waveguides or other transmission media (eg, light pulses through fiber optic cables), or through electrical wires transmitted electrical signals.

这里所描述的计算机可读程序指令可以从计算机可读存储介质下载到各个计算/处理设备,或者通过网络、例如因特网、局域网、广域网和/或无线网下载到外部计算机或外部存储设备。网络可以包括铜传输电缆、光纤传输、无线传输、路由器、防火墙、交换机、网关计算机和/或边缘服务器。每个计算/处理设备中的网络适配卡或者网络接口从网络接收计算机可读程序指令,并转发该计算机可读程序指令,以供存储在各个计算/处理设备中的计算机可读存储介质中。The computer readable program instructions described herein may be downloaded to various computing/processing devices from a computer readable storage medium, or to an external computer or external storage device over a network such as the Internet, a local area network, a wide area network, and/or a wireless network. The network may include copper transmission cables, fiber optic transmission, wireless transmission, routers, firewalls, switches, gateway computers, and/or edge servers. A network adapter card or network interface in each computing/processing device receives computer-readable program instructions from a network and forwards the computer-readable program instructions for storage in a computer-readable storage medium in each computing/processing device .

用于执行本公开操作的计算机程序指令可以是汇编指令、指令集架构(ISA)指令、机器指令、机器相关指令、微代码、固件指令、状态设置数据、或者以一种或多种编程语言的任意组合编写的源代码或目标代码,所述编程语言包括面向对象的编程语言—诸如Smalltalk、C++等,以及常规的过程式编程语言—诸如“C”语言或类似的编程语言。计算机可读程序指令可以完全地在用户计算机上执行、部分地在用户计算机上执行、作为一个独立的软件包执行、部分在用户计算机上部分在远程计算机上执行、或者完全在远程计算机或服务器上执行。在涉及远程计算机的情形中,远程计算机可以通过任意种类的网络—包括局域网(LAN)或广域网(WAN)—连接到用户计算机,或者,可以连接到外部计算机(例如利用因特网服务提供商来通过因特网连接)。在一些实施例中,通过利用计算机可读程序指令的状态信息来个性化定制电子电路,例如可编程逻辑电路、现场可编程门阵列(FPGA)或可编程逻辑阵列(PLA),该电子电路可以执行计算机可读程序指令,从而实现本公开的各个方面。以上实例仅用于说明本发明的设计思想和特点,其目的在于使本领域内的技术人员能够了解本发明的内容并据以实施,本发明的保护范围不限于上述实例,所以,凡依据本发明所揭示的原理、设计思路所作的等同变化或修饰,例如改变评价指标等,均在本发明的保护范围之内。Computer program instructions for carrying out operations of the present disclosure may be assembly instructions, instruction set architecture (ISA) instructions, machine instructions, machine-dependent instructions, microcode, firmware instructions, state setting data, or instructions in one or more programming languages. Source or object code, written in any combination, including object-oriented programming languages, such as Smalltalk, C++, etc., and conventional procedural programming languages, such as the "C" language or similar programming languages. The computer readable program instructions may execute entirely on the user's computer, partly on the user's computer, as a stand-alone software package, partly on the user's computer and partly on a remote computer, or entirely on the remote computer or server implement. In the case of a remote computer, the remote computer may be connected to the user's computer through any kind of network, including a local area network (LAN) or a wide area network (WAN), or may be connected to an external computer (eg, using an Internet service provider through the Internet connect). In some embodiments, custom electronic circuits, such as programmable logic circuits, field programmable gate arrays (FPGAs), or programmable logic arrays (PLAs), can be personalized by utilizing state information of computer readable program instructions. Computer readable program instructions are executed to implement various aspects of the present disclosure. The above examples are only used to illustrate the design ideas and characteristics of the present invention, and its purpose is to enable those skilled in the art to understand the content of the present invention and implement them accordingly. The protection scope of the present invention is not limited to the above examples. Equivalent changes or modifications made to the principles and design ideas disclosed in the invention, such as changing evaluation indicators, etc., all fall within the protection scope of the invention.

申请人结合说明书附图对本发明的实施例做了详细的说明与描述,但是本领域技术人员应该理解,以上实施例仅为本发明的优选实施方案,详尽的说明只是为了帮助读者更好地理解本发明精神,而并非对本发明保护范围的限制,相反,任何基于本发明的发明精神所作的任何改进或修饰都应当落在本发明的保护范围之内。The applicant has described and described the embodiments of the present invention in detail with reference to the accompanying drawings, but those skilled in the art should understand that the above embodiments are only preferred embodiments of the present invention, and the detailed description is only to help readers better understand The spirit of the present invention is not intended to limit the protection scope of the present invention. On the contrary, any improvement or modification made based on the spirit of the present invention should fall within the protection scope of the present invention.

Claims (12)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111341808.2ACN114547924A (en) | 2021-11-12 | 2021-11-12 | Analysis method and system of transformer winding vibration voiceprint based on multi-physics coupling |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111341808.2ACN114547924A (en) | 2021-11-12 | 2021-11-12 | Analysis method and system of transformer winding vibration voiceprint based on multi-physics coupling |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114547924Atrue CN114547924A (en) | 2022-05-27 |

Family

ID=81668833

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202111341808.2APendingCN114547924A (en) | 2021-11-12 | 2021-11-12 | Analysis method and system of transformer winding vibration voiceprint based on multi-physics coupling |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114547924A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115166393A (en)* | 2022-06-29 | 2022-10-11 | 国网河南省电力公司平顶山供电公司 | Intelligent diagnosis and state evaluation method for transformer |

| CN115358110A (en)* | 2022-07-25 | 2022-11-18 | 国网江苏省电力有限公司淮安供电分公司 | Transformer fault detection system based on acoustic sensor array |

| CN119180183A (en)* | 2024-11-22 | 2024-12-24 | 南方电网科学研究院有限责任公司 | Sound field determining method and device of magnetic control transformer, electronic equipment and storage medium |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20080300807A1 (en)* | 2004-03-23 | 2008-12-04 | The University Of British Columbia | Electric Winding Displacement Detection Method and Apparatus |

| CN111707897A (en)* | 2020-06-30 | 2020-09-25 | 国网黑龙江省电力有限公司大庆供电公司 | Transformer operating state analysis method based on wavelet energy spectrum characteristics of vibration signal |

- 2021

- 2021-11-12CNCN202111341808.2Apatent/CN114547924A/enactivePending

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20080300807A1 (en)* | 2004-03-23 | 2008-12-04 | The University Of British Columbia | Electric Winding Displacement Detection Method and Apparatus |

| CN111707897A (en)* | 2020-06-30 | 2020-09-25 | 国网黑龙江省电力有限公司大庆供电公司 | Transformer operating state analysis method based on wavelet energy spectrum characteristics of vibration signal |

Non-Patent Citations (4)

| Title |

|---|

| 刘石,杨毅,田丰,高庆水,张楚: "变压器绕组振动传递特性仿真研究", 西安交通大学学报, no. 06, 2 February 2018 (2018-02-02), pages 74 - 80* |

| 吴书煜等: "基于多物理场耦合的特高压并联电抗器振动噪声仿真分析与实验研究", 电力自动化设备, no. 03, 31 March 2020 (2020-03-31), pages 122 - 127* |

| 李辉等: "基于多物理场耦合方法的变压器绕组振动仿真与试验研究", 东北电力技术, no. 02, 20 February 2015 (2015-02-20), pages 6 - 9* |

| 赵莉华等: "基于振动信号分形维数的变压器松动诊断方法", 电测与仪表, no. 03, 10 February 2018 (2018-02-10), pages 7 - 12* |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115166393A (en)* | 2022-06-29 | 2022-10-11 | 国网河南省电力公司平顶山供电公司 | Intelligent diagnosis and state evaluation method for transformer |

| CN115358110A (en)* | 2022-07-25 | 2022-11-18 | 国网江苏省电力有限公司淮安供电分公司 | Transformer fault detection system based on acoustic sensor array |

| CN119180183A (en)* | 2024-11-22 | 2024-12-24 | 南方电网科学研究院有限责任公司 | Sound field determining method and device of magnetic control transformer, electronic equipment and storage medium |

| CN119180183B (en)* | 2024-11-22 | 2025-04-08 | 南方电网科学研究院有限责任公司 | Method, device, electronic device and storage medium for determining sound field of magnetically controlled transformer |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN114547924A (en) | Analysis method and system of transformer winding vibration voiceprint based on multi-physics coupling | |

| Jingzhu et al. | Electromagnetic vibration noise analysis of transformer windings and core | |

| Zhang et al. | A novel approach to investigate the core vibration in power transformers | |

| Rausch et al. | Combination of finite and boundary element methods in investigation and prediction of load-controlled noise of power transformers | |

| CN108920731B (en) | Method for calculating vibration acceleration of turn-to-turn short circuit of transformer winding | |

| JP2017106893A (en) | Diagnosis method and apparatus for transformer internal abnormality and deterioration | |

| CN105550435A (en) | Winding magnetic flux leakage and electrodynamic force calculation method based on transformer segmented model | |

| CN114580235A (en) | A Design Method for Vibration Scale Model of Converter Transformer | |

| CN111324944A (en) | A COMSOL-based Calculation Method of Iron Core Vibration Characteristics | |

| Zhang et al. | Comprehensive vibration generation model of transformer winding under load current | |

| Pan et al. | Winding vibration analysis of unbalanced transformer based on electromagnetic-mechanical coupling | |

| Zhang et al. | Investigation on the action of eddy current on tank vibration characteristics in dry-type transformer | |

| Wang | Transformer vibration and its application to condition monitoring | |

| Wu et al. | A review of the research progress of motor vibration and noise | |

| Li et al. | Modal analysis of the stator system of a permanent magnet synchronous motor with integer slot multi‐pole pair for electric vehicles | |

| Case | Numerical analysis of the vibration and acoustic characteristics of large power transformers | |

| Amini et al. | A multi-objective and multi level optimization of IPMSM case study dynamometer | |

| CN111597681B (en) | Three-phase group type transformer core vibration calculation method under direct-current magnetic biasing condition | |

| Zhou et al. | Electromagnetic anisotropic homogeneous model for eddy‐current field in single‐phase wound core | |

| CN114894415A (en) | Method for determining optimal measuring point of sensor based on vibration signal of surface of transformer box body | |

| He et al. | Design and analysis of a novel eddy current damper based on three-dimensional transient analysis | |

| Yang et al. | Simulation analysis and experiment validation of vibration and noise of oil-immersed transformer | |

| Ibrahim et al. | Effects of stator laminations on acoustic noise of electrical machines | |

| Haettel et al. | Prediction of transformer core noise | |

| CN120688275A (en) | A simulation analysis method and system for transformer vibration noise under DC bias |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |