CN114527172A - Method for evaluating stability of battery positive electrode material - Google Patents

Method for evaluating stability of battery positive electrode materialDownload PDFInfo

- Publication number

- CN114527172A CN114527172ACN202210155965.2ACN202210155965ACN114527172ACN 114527172 ACN114527172 ACN 114527172ACN 202210155965 ACN202210155965 ACN 202210155965ACN 114527172 ACN114527172 ACN 114527172A

- Authority

- CN

- China

- Prior art keywords

- positive electrode

- battery

- electrode material

- stability

- positive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 239000007774positive electrode materialSubstances0.000titleclaimsabstractdescription66

- 238000000034methodMethods0.000titleclaimsabstractdescription34

- 230000008859changeEffects0.000claimsabstractdescription31

- 238000011156evaluationMethods0.000claimsabstractdescription27

- 238000012360testing methodMethods0.000claimsabstractdescription25

- 239000010406cathode materialSubstances0.000claimsabstractdescription24

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000claimsdescription18

- 229910052744lithiumInorganic materials0.000claimsdescription16

- WHXSMMKQMYFTQS-UHFFFAOYSA-NLithiumChemical compound[Li]WHXSMMKQMYFTQS-UHFFFAOYSA-N0.000claimsdescription13

- 239000011888foilSubstances0.000claimsdescription7

- 238000013461designMethods0.000claimsdescription6

- GELKBWJHTRAYNV-UHFFFAOYSA-Klithium iron phosphateChemical compound[Li+].[Fe+2].[O-]P([O-])([O-])=OGELKBWJHTRAYNV-UHFFFAOYSA-K0.000claimsdescription4

- 238000010277constant-current chargingMethods0.000claimsdescription3

- 239000000463materialSubstances0.000abstractdescription39

- 230000001568sexual effectEffects0.000abstract1

- 239000011267electrode slurrySubstances0.000description10

- 229910001416lithium ionInorganic materials0.000description10

- 238000002360preparation methodMethods0.000description10

- HBBGRARXTFLTSG-UHFFFAOYSA-NLithium ionChemical compound[Li+]HBBGRARXTFLTSG-UHFFFAOYSA-N0.000description9

- HFCVPDYCRZVZDF-UHFFFAOYSA-N[Li+].[Co+2].[Ni+2].[O-][Mn]([O-])(=O)=OChemical compound[Li+].[Co+2].[Ni+2].[O-][Mn]([O-])(=O)=OHFCVPDYCRZVZDF-UHFFFAOYSA-N0.000description8

- 239000011230binding agentSubstances0.000description8

- 239000006258conductive agentSubstances0.000description8

- 239000002904solventSubstances0.000description8

- SECXISVLQFMRJM-UHFFFAOYSA-NN-MethylpyrrolidoneChemical compoundCN1CCCC1=OSECXISVLQFMRJM-UHFFFAOYSA-N0.000description7

- 239000003792electrolyteSubstances0.000description7

- 239000000203mixtureSubstances0.000description7

- 230000008569processEffects0.000description7

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical compound[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000description6

- 238000000576coating methodMethods0.000description6

- 230000000052comparative effectEffects0.000description6

- 230000001351cycling effectEffects0.000description5

- 230000014759maintenance of locationEffects0.000description5

- -1nickel-aluminum-cobaltChemical compound0.000description5

- KMTRUDSVKNLOMY-UHFFFAOYSA-NEthylene carbonateChemical groupO=C1OCCO1KMTRUDSVKNLOMY-UHFFFAOYSA-N0.000description4

- 239000002033PVDF binderSubstances0.000description4

- 239000006230acetylene blackSubstances0.000description4

- 239000011248coating agentSubstances0.000description4

- 238000010586diagramMethods0.000description4

- 239000007773negative electrode materialSubstances0.000description4

- 229920002981polyvinylidene fluoridePolymers0.000description4

- 239000007787solidSubstances0.000description4

- 239000002562thickening agentSubstances0.000description4

- 239000000654additiveSubstances0.000description3

- 230000000996additive effectEffects0.000description3

- 229910052782aluminiumInorganic materials0.000description3

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000description3

- 238000007600chargingMethods0.000description3

- 239000011889copper foilSubstances0.000description3

- 125000004122cyclic groupChemical group0.000description3

- IEJIGPNLZYLLBP-UHFFFAOYSA-Ndimethyl carbonateChemical compoundCOC(=O)OCIEJIGPNLZYLLBP-UHFFFAOYSA-N0.000description3

- 238000007599dischargingMethods0.000description3

- 238000001035dryingMethods0.000description3

- JBTWLSYIZRCDFO-UHFFFAOYSA-Nethyl methyl carbonateChemical compoundCCOC(=O)OCJBTWLSYIZRCDFO-UHFFFAOYSA-N0.000description3

- 229910003002lithium saltInorganic materials0.000description3

- 159000000002lithium saltsChemical class0.000description3

- 238000004519manufacturing processMethods0.000description3

- 238000003825pressingMethods0.000description3

- 229920003048styrene butadiene rubberPolymers0.000description3

- BQCIDUSAKPWEOX-UHFFFAOYSA-N1,1-DifluoroetheneChemical compoundFC(F)=CBQCIDUSAKPWEOX-UHFFFAOYSA-N0.000description2

- VAYTZRYEBVHVLE-UHFFFAOYSA-N1,3-dioxol-2-oneChemical compoundO=C1OC=CO1VAYTZRYEBVHVLE-UHFFFAOYSA-N0.000description2

- 238000004458analytical methodMethods0.000description2

- 239000003153chemical reaction reagentSubstances0.000description2

- 238000010280constant potential chargingMethods0.000description2

- VEWLDLAARDMXSB-UHFFFAOYSA-Nethenyl sulfate;hydronChemical compoundOS(=O)(=O)OC=CVEWLDLAARDMXSB-UHFFFAOYSA-N0.000description2

- 239000010439graphiteSubstances0.000description2

- 229910002804graphiteInorganic materials0.000description2

- 230000002427irreversible effectEffects0.000description2

- IGILRSKEFZLPKG-UHFFFAOYSA-Mlithium;difluorophosphinateChemical compound[Li+].[O-]P(F)(F)=OIGILRSKEFZLPKG-UHFFFAOYSA-M0.000description2

- 238000010998test methodMethods0.000description2

- 230000007704transitionEffects0.000description2

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description2

- 229920002134Carboxymethyl cellulosePolymers0.000description1

- DGAQECJNVWCQMB-PUAWFVPOSA-MIlexoside XXIXChemical compoundC[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+]DGAQECJNVWCQMB-PUAWFVPOSA-M0.000description1

- QTHKJEYUQSLYTH-UHFFFAOYSA-N[Co]=O.[Ni].[Li]Chemical compound[Co]=O.[Ni].[Li]QTHKJEYUQSLYTH-UHFFFAOYSA-N0.000description1

- LTHNASGMNUUKRZ-UHFFFAOYSA-N[Mg].[Mn].[Ni]Chemical compound[Mg].[Mn].[Ni]LTHNASGMNUUKRZ-UHFFFAOYSA-N0.000description1

- KFDQGLPGKXUTMZ-UHFFFAOYSA-N[Mn].[Co].[Ni]Chemical compound[Mn].[Co].[Ni]KFDQGLPGKXUTMZ-UHFFFAOYSA-N0.000description1

- DPXJVFZANSGRMM-UHFFFAOYSA-Nacetic acid;2,3,4,5,6-pentahydroxyhexanal;sodiumChemical compound[Na].CC(O)=O.OCC(O)C(O)C(O)C(O)C=ODPXJVFZANSGRMM-UHFFFAOYSA-N0.000description1

- 239000003513alkaliSubstances0.000description1

- 238000004364calculation methodMethods0.000description1

- 239000001768carboxy methyl celluloseSubstances0.000description1

- 235000010948carboxy methyl celluloseNutrition0.000description1

- 239000002131composite materialSubstances0.000description1

- 238000007796conventional methodMethods0.000description1

- 239000013078crystalSubstances0.000description1

- 238000005520cutting processMethods0.000description1

- 230000007547defectEffects0.000description1

- ZFTFAPZRGNKQPU-UHFFFAOYSA-Ndicarbonic acidChemical compoundOC(=O)OC(O)=OZFTFAPZRGNKQPU-UHFFFAOYSA-N0.000description1

- 238000009826distributionMethods0.000description1

- 229910021385hard carbonInorganic materials0.000description1

- 229920003063hydroxymethyl cellulosePolymers0.000description1

- 229940031574hydroxymethyl celluloseDrugs0.000description1

- BDKWOJYFHXPPPT-UHFFFAOYSA-Nlithium dioxido(dioxo)manganese nickel(2+)Chemical compound[Mn](=O)(=O)([O-])[O-].[Ni+2].[Li+]BDKWOJYFHXPPPT-UHFFFAOYSA-N0.000description1

- 229910001496lithium tetrafluoroborateInorganic materials0.000description1

- DVATZODUVBMYHN-UHFFFAOYSA-Klithium;iron(2+);manganese(2+);phosphateChemical compound[Li+].[Mn+2].[Fe+2].[O-]P([O-])([O-])=ODVATZODUVBMYHN-UHFFFAOYSA-K0.000description1

- VGYDTVNNDKLMHX-UHFFFAOYSA-Nlithium;manganese;nickel;oxocobaltChemical compound[Li].[Mn].[Ni].[Co]=OVGYDTVNNDKLMHX-UHFFFAOYSA-N0.000description1

- 230000007774longtermEffects0.000description1

- ZAUUZASCMSWKGX-UHFFFAOYSA-Nmanganese nickelChemical compound[Mn].[Ni]ZAUUZASCMSWKGX-UHFFFAOYSA-N0.000description1

- 229910052751metalInorganic materials0.000description1

- 239000002184metalSubstances0.000description1

- 150000004702methyl estersChemical class0.000description1

- 239000004005microsphereSubstances0.000description1

- 239000012046mixed solventSubstances0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 239000003960organic solventSubstances0.000description1

- 239000011164primary particleSubstances0.000description1

- RUOJZAUFBMNUDX-UHFFFAOYSA-Npropylene carbonateChemical compoundCC1COC(=O)O1RUOJZAUFBMNUDX-UHFFFAOYSA-N0.000description1

- 229910052708sodiumInorganic materials0.000description1

- 239000011734sodiumSubstances0.000description1

- 235000019812sodium carboxymethyl celluloseNutrition0.000description1

- 229920001027sodium carboxymethylcellulosePolymers0.000description1

- 229910021384soft carbonInorganic materials0.000description1

- 238000010561standard procedureMethods0.000description1

- 230000007847structural defectEffects0.000description1

- 238000001291vacuum dryingMethods0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N27/00—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means

- G01N27/26—Investigating or analysing materials by the use of electric, electrochemical, or magnetic means by investigating electrochemical variables; by using electrolysis or electrophoresis

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/052—Li-accumulators

- H01M10/0525—Rocking-chair batteries, i.e. batteries with lithium insertion or intercalation in both electrodes; Lithium-ion batteries

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/13—Electrodes for accumulators with non-aqueous electrolyte, e.g. for lithium-accumulators; Processes of manufacture thereof

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M2004/026—Electrodes composed of, or comprising, active material characterised by the polarity

- H01M2004/028—Positive electrodes

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- Engineering & Computer Science (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Analytical Chemistry (AREA)

- Physics & Mathematics (AREA)

- Molecular Biology (AREA)

- Manufacturing & Machinery (AREA)

- Battery Electrode And Active Subsutance (AREA)

- Secondary Cells (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于电池材料性能测试技术领域,具体涉及一种电池正极材料稳定性的评估方法。The invention belongs to the technical field of battery material performance testing, and in particular relates to a method for evaluating the stability of a positive electrode material of a battery.

背景技术Background technique

锂离子电池因具有较高的能量密度和较长的循环寿命,被大量应用于手机、平板电脑以及动力设备。锂离子电池的循环性能是其使用寿命及保值能力的关键。而正极材料性能是影响锂离子电池循环稳定性的关键所在,如正极材料的晶体结构、掺杂包覆、结构缺陷,以及材料制备过程中的残碱、材料的晶粒分布和一次粒径等都会直接影响正极材料的性能。但是,目前各公司提供的正极材料良莠不齐,就需要预先筛选出性能可靠的正极材料。Lithium-ion batteries are widely used in mobile phones, tablet computers and power equipment due to their high energy density and long cycle life. The cycle performance of lithium-ion batteries is the key to their service life and ability to preserve value. The performance of the cathode material is the key to affecting the cycle stability of lithium-ion batteries, such as the crystal structure, doping coating, structural defects of the cathode material, residual alkali in the material preparation process, grain distribution and primary particle size of the material, etc. will directly affect the performance of the cathode material. However, at present, the cathode materials provided by various companies are of different quality, so it is necessary to screen out the cathode materials with reliable performance in advance.

现有技术中电池材料性能的评估方法主要有:一是,基于材料或极片层级,探讨材料某些或某种特性,缺乏对电池整体性能的评估,评估全面性及准确性较低;二是,基于电池进行较长的循环,对比多款材料循环过程中的容量衰减,该方法虽比较综合,评估准确性较高,但长期循环耗时较大,评估速度较慢,对资源耗费较高。例如,目前评测三元正极材料需要循环大于1000次,约4个月。然而,在锂离子电池高速更新迭代的背景下,对正极材料性能进行快速的评价意味着产品能否抢占市场先机。因此,开发可靠而迅速的正极材料评估方法至关重要。例如,现有技术中还存在一种dQ/dV的测试方法,但是该方法需依靠超高精度库伦仪(UHPC)进行测试,尽管可将循环次数减少至200次以内,但循环所使用的倍率较小,实际耗时也相对较长,并且该设备价格昂贵,不具有普及性。The evaluation methods of battery material performance in the prior art mainly include: first, based on the material or pole piece level, some or certain characteristics of the material are discussed, lack of evaluation of the overall performance of the battery, and the evaluation comprehensiveness and accuracy are low; second Yes, based on a long cycle of the battery, comparing the capacity decay of various materials during the cycle, this method is relatively comprehensive and has high evaluation accuracy, but the long-term cycle time is long, the evaluation speed is slow, and the resource consumption is relatively high. high. For example, the current evaluation of ternary cathode materials requires more than 1000 cycles, about 4 months. However, in the context of high-speed update and iteration of lithium-ion batteries, rapid evaluation of the performance of cathode materials means whether the product can seize the market opportunity. Therefore, it is crucial to develop reliable and rapid evaluation methods for cathode materials. For example, there is also a dQ/dV test method in the prior art, but this method needs to rely on ultra-high-precision coulomb (UHPC) for testing. Although the number of cycles can be reduced to less than 200 times, the rate of Smaller, the actual time-consuming is relatively long, and the device is expensive and not universal.

有鉴于此,亟待开发一种可在短期循环内,基于电池层级,不需要昂贵的仪器设备对电池正极材料在循环中的稳定性进行评估的方法。In view of this, it is urgent to develop a method that can evaluate the stability of battery cathode materials in short-term cycles, based on the battery level, and does not require expensive equipment.

发明内容SUMMARY OF THE INVENTION

因此,本发明要解决的技术问题在于克服现有技术中的正极材料的测试方法测试时间较长、需要依赖昂贵的仪器设备等缺陷,从而提供一种电池正极材料稳定性的评估方法。Therefore, the technical problem to be solved by the present invention is to overcome the defects of the testing method of the positive electrode material in the prior art, such as long testing time and need to rely on expensive equipment, so as to provide a method for evaluating the stability of the positive electrode material of a battery.

本发明的测试原理为:理想情况下,在电池中,充电过程中在正极脱出的锂离子,应在放电过程中全部回嵌入正极。由于正极材料的不可逆相变及各向异性的体积膨胀导致正极材料活性位点减少,导致嵌入负极的Li离子在放电过程中无法回嵌正极,表现为正极电位的改变。The testing principle of the present invention is as follows: ideally, in the battery, the lithium ions released from the positive electrode during the charging process should all be inserted back into the positive electrode during the discharging process. Due to the irreversible phase transition and anisotropic volume expansion of the positive electrode material, the active sites of the positive electrode material are reduced, so that the Li ions embedded in the negative electrode cannot be inserted back into the positive electrode during the discharge process, which is manifested as a change in the positive electrode potential.

本发明就是利用正极电位随循环过程改变的这一现象,通过三电极电池,监测循环过程中正极对参比电极的电位(下文简称:正参电位)变化。一般,结构稳定、循环性能良好的正极材料在循环过程中,正参电位的波动性较小;结构稳定性差、循环性能较差的正极材料在循环过程中由于结构坍塌或不可逆相变较多,导致正参电位变化较大。从而,通过对比相同循环次数下正参电位的变化率,可确定正极材料在循环过程中的稳定性,优选的,通过对比相同循环次数下100%SoC(电池的荷电状态)满充电池状态下正参电位的变化率,这是因为,满充时,正极电位高,存在一个极大值,容易确定和准确对比。The present invention utilizes the phenomenon that the potential of the positive electrode changes with the cycle process, and monitors the change of the potential of the positive electrode to the reference electrode (hereinafter referred to as positive reference potential) during the cycle process through a three-electrode battery. Generally, cathode materials with stable structure and good cycle performance have less fluctuation of positive potential during cycling; cathode materials with poor structural stability and poor cycle performance have more structural collapses or irreversible phase transitions during cycling. This results in a large change in the positive potential. Therefore, by comparing the rate of change of the positive parameter potential under the same number of cycles, the stability of the cathode material during the cycle can be determined, preferably, by comparing the state of 100% SoC (state of charge of the battery) fully charged battery under the same number of cycles The change rate of the lower positive parameter potential is because, when fully charged, the positive electrode potential is high and there is a maximum value, which is easy to determine and accurately compare.

为此,本发明提供如下技术方案:For this reason, the present invention provides the following technical solutions:

本发明提供一种电池正极材料稳定性的评估方法,包括以下步骤:The present invention provides a method for evaluating the stability of a positive electrode material of a battery, comprising the following steps:

S1,将待测正极材料制备成三电极电池;S1, preparing the positive electrode material to be tested into a three-electrode battery;

具体地,三电极电池的制备方法为领域内的标准方法,可参照专利CN107293778A、CN108987836A、CN108630980A、CN203562453U。典型非限定性的,所述三电极电池的制作是将铜丝置于电池的正极和负极间,并用隔膜隔开,将铜丝引出电池,作为一极,然后对正极/铜丝电极对进行恒流充电(铜丝做为负极,电流0.1mA或其他),至电压为0V停止(例如:0.1mA充电2h)。然后对负极/铜丝电极对进行恒流充电(铜丝做为负极,电流0.1mA或其他),至电压为0V停止(例如:0.1mA充电2h),获得三电极电池;上述铜丝还可以是多孔锂箔、锂带等锂金属电极(应用锂金属参比电极时不需要对参比电极充电,制作完成后即为三电极电池)。Specifically, the preparation method of the three-electrode battery is a standard method in the field, and can refer to patents CN107293778A, CN108987836A, CN108630980A, CN203562453U. Typical and non-limiting, the three-electrode battery is made by placing a copper wire between the positive electrode and the negative electrode of the battery, separated by a separator, and pulling the copper wire out of the battery to serve as one pole, and then performing a test on the positive electrode/copper wire electrode pair. Constant current charging (copper wire as negative electrode, current 0.1mA or other), stop when the voltage is 0V (for example: 0.1mA charging for 2h). Then charge the negative electrode/copper wire electrode pair with constant current (copper wire is used as negative electrode, current 0.1mA or other), and stop when the voltage is 0V (for example: 0.1mA charge for 2h) to obtain a three-electrode battery; the above copper wire can also be It is a lithium metal electrode such as porous lithium foil and lithium strip (the reference electrode does not need to be charged when using a lithium metal reference electrode, and it is a three-electrode battery after the production is completed).

S2,按照三电极电池设计要求及评估要求设置循环参数,对三电极电池进行循环,监测正参电位;S2, set the cycle parameters according to the design requirements and evaluation requirements of the three-electrode battery, cycle the three-electrode battery, and monitor the positive parameter potential;

具体地,循环参数设置是根据所评测材料及电池设计需求(满足快充或者长寿命等)确定的,实验目标不同,参数不同,本领域技术人员可以随待评测电池的使用目的决定。Specifically, the cycle parameter settings are determined according to the material to be evaluated and the battery design requirements (meeting fast charging or long life, etc.). The experimental objectives and parameters are different, and those skilled in the art can decide according to the use purpose of the battery to be evaluated.

S3,以正参电位为纵坐标,循环次数为横坐标进行作图,对比相同循环次数时待测正极材料的正参电位相比于初始状态的变化率,确定正极材料的循环稳定性。S3, take the positive potential as the ordinate and the number of cycles as the abscissa to draw a graph, and compare the rate of change of the positive potential of the positive electrode material to be tested compared to the initial state at the same number of cycles to determine the cycle stability of the positive electrode material.

具体地,初始正参电位是V0,循环到某圈后正参电位是Vx,变化率(正参电位变化率)=(Vx-V0)/V0。Specifically, the initial positive potential is V0 , the positive potential is Vx after a certain cycle, and the rate of change (change rate of positive potential)=(Vx -V0 )/V0 .

可选的,步骤S2中的循环参数包括:测试温度,循环电压,循环倍率,循环圈数。Optionally, the cycle parameters in step S2 include: test temperature, cycle voltage, cycle magnification, and cycle number.

可选的,所述测试可以为恒温测试也可以为变温测试,测试温度介于-20℃至60℃之间。可选的,所述测试温度为30℃至55℃,优选的,测试温度在45℃为宜。Optionally, the test can be a constant temperature test or a variable temperature test, and the test temperature is between -20°C and 60°C. Optionally, the test temperature is 30°C to 55°C, preferably, the test temperature is 45°C.

可选的,所述循环电压为放电截止电压~充电截止电压V;例如磷酸铁锂电池循环电压是2.5-3.65V;NCM电池的循环电压是2.8-4.35V。Optionally, the cycle voltage is the discharge cut-off voltage to the charge cut-off voltage V; for example, the cycle voltage of a lithium iron phosphate battery is 2.5-3.65V; the cycle voltage of an NCM battery is 2.8-4.35V.

可选的,所述循环圈数≤500;可选的,循环圈数为100-350圈。Optionally, the number of cyclic turns is less than or equal to 500; optionally, the number of cyclic turns is 100-350 turns.

可选的,步骤S1中,三电极电池的参比电极为本领域的常规残币电极,典型非限定性的,所述残币电极可以是铜丝,进行镀锂,还可以是直接植入的多孔锂箔、锂带等锂金属电极。Optionally, in step S1, the reference electrode of the three-electrode battery is a conventional residual coin electrode in the field. Typically and non-limitingly, the residual coin electrode can be copper wire, which is plated with lithium, or can be directly implanted. Porous lithium foil, lithium ribbon and other lithium metal electrodes.

可选的,所述正极材料为二元正极材料,三元正极材料或磷酸铁锂正极材料。其中,所述二元正极材料为镍锰基材料中的至少一种;所述三元正极材料为镍钴锰基、镍铝钴基、镍镁锰基中的至少一种。Optionally, the positive electrode material is a binary positive electrode material, a ternary positive electrode material or a lithium iron phosphate positive electrode material. Wherein, the binary positive electrode material is at least one of nickel-manganese-based materials; the ternary positive electrode material is at least one of nickel-cobalt-manganese-based, nickel-aluminum-cobalt-based, and nickel-magnesium-manganese-based.

对于具体三电极电池的制备方法为本领域的常规方法,典型非限定性的,可参照可参照专利CN107293778A、CN108987836A、CN108630980A、CN203562453U,只要保证待测正极材料所制备出的三电极电池除正极材料本身不同外,其他参数均相同即可(包括但不限于:匀浆、涂布、电解液、隔膜、负极等)。The preparation method of the specific three-electrode battery is a conventional method in the field, which is typical and non-limiting, and can refer to patents CN107293778A, CN108987836A, CN108630980A, CN203562453U, as long as it is ensured that the three-electrode battery prepared from the positive electrode material to be tested is in addition to the positive electrode material. Except for the difference in itself, other parameters can be the same (including but not limited to: homogenate, coating, electrolyte, separator, negative electrode, etc.).

典型非限定性的,所述三电极电池的正极包括集流体和涂覆在集流体上的正极活性材料,所述正极活性材料选自磷酸铁锂、磷酸锰铁锂、镍锰酸锂材料、镍酸锂材料、钴酸锂材料、镍钴酸锂材料、镍锰钴酸锂材料中的至少一种。涂覆的工艺可以采用现有的涂布和冷压工艺。具体地,将正极活性物质、导电剂、粘结剂按照常规比例混合均匀并加入到溶剂中,制成正极浆料;将正极浆料均匀涂布在正极集流体铝箔上,烘干后冷压,再进行模切、分条,制成正极片。其中该正极浆料的固含量可以为70-75%,导电剂可以为常规导电剂,例如乙炔黑,粘结剂可以为常规粘结剂,例如丁苯橡胶或偏氟乙烯PVDF,溶剂可采用常规有机溶剂,例如N-甲基吡咯烷酮NMP。Typical and non-limiting, the positive electrode of the three-electrode battery includes a current collector and a positive electrode active material coated on the current collector, and the positive electrode active material is selected from lithium iron phosphate, lithium manganese iron phosphate, lithium nickel manganate material, At least one of lithium nickelate materials, lithium cobaltate materials, lithium nickel cobalt oxide materials, and lithium nickel manganese cobalt oxide materials. The coating process can adopt the existing coating and cold pressing process. Specifically, the positive electrode active material, the conductive agent, and the binder are uniformly mixed according to the conventional ratio and added to the solvent to prepare the positive electrode slurry; the positive electrode slurry is uniformly coated on the positive electrode current collector aluminum foil, and then cold-pressed after drying. , and then die-cut and slit to make a positive electrode sheet. The solid content of the positive electrode slurry can be 70-75%, the conductive agent can be a conventional conductive agent, such as acetylene black, the binder can be a conventional binder, such as styrene-butadiene rubber or vinylidene fluoride PVDF, and the solvent can be Conventional organic solvents such as N-methylpyrrolidone NMP.

所述三电极电池的负极包括集流体和涂覆在集流体上的负极活性材料,所述负极活性材料选自石墨、硬碳、软碳、中间相碳微球中的至少一种。涂覆的工艺可以采用现有的涂布和冷压工艺。具体地,将负极活性物质、导电剂、增稠剂、粘结剂按照常规比例混合,加入溶剂水中混合均匀并制成负极浆料;将负极浆料均匀涂布在负极集流体铜箔上,烘干后进行冷压,制成负极片。其中该负极浆料的固含量可以为50-55%,导电剂可以为常规导电剂,例如乙炔黑,粘结剂可以为常规粘结剂,例如丁苯橡胶或者偏氟乙烯PVDF,增稠剂可采用常规增稠剂,例如羟甲基纤维素钠。The negative electrode of the three-electrode battery includes a current collector and a negative electrode active material coated on the current collector, and the negative electrode active material is selected from at least one of graphite, hard carbon, soft carbon, and mesocarbon microspheres. The coating process can adopt the existing coating and cold pressing process. Specifically, the negative electrode active material, the conductive agent, the thickener and the binder are mixed according to the conventional ratio, added into the solvent water and mixed evenly to make the negative electrode slurry; the negative electrode slurry is uniformly coated on the negative electrode current collector copper foil, After drying, cold pressing is carried out to make a negative electrode sheet. The solid content of the negative electrode slurry can be 50-55%, the conductive agent can be a conventional conductive agent, such as acetylene black, the binder can be a conventional binder, such as styrene-butadiene rubber or vinylidene fluoride PVDF, thickener Conventional thickeners such as sodium carboxymethylcellulose can be employed.

所述三电极电池的参比电极包括铜丝镀锂、多孔锂箔、锂带等任何形式金属锂电极。The reference electrode of the three-electrode battery includes any form of metal lithium electrode such as copper wire plated with lithium, porous lithium foil, and lithium ribbon.

本发明的电解液可采用常规市售的锂离子电解液,也可采用现有常规材料自制,例如可采用包括溶剂、锂盐和添加剂的电解液,所述溶剂选自碳酸乙烯酯、碳酸二甲酯和碳酸甲乙酯中的至少一种。所述锂盐选自六氟磷酸锂和/或四氟硼酸锂;所述添加剂选自碳酸亚乙烯酯、碳酸丙烯酯、硫酸乙烯酯和二氟磷酸锂中的至少一种。锂盐的摩尔浓度为0.8-1.2mol/L,可采用体积比为1:1:1-1:2:2的碳酸乙烯酯(EC)、碳酸二甲酯(DEC)、碳酸甲乙酯(EMC)的混合液为溶剂。添加剂的体积百分数可以为0.5-5%。本发明的可采用现有的传统隔膜,例如PE隔膜、PP隔膜、PP/PE复合薄膜,或者其他市售隔膜。The electrolyte of the present invention can be conventional commercially available lithium ion electrolyte, or can be made from existing conventional materials, for example, an electrolyte comprising a solvent, a lithium salt and an additive can be used, and the solvent is selected from ethylene carbonate, dicarbonate At least one of methyl ester and methyl ethyl carbonate. The lithium salt is selected from lithium hexafluorophosphate and/or lithium tetrafluoroborate; the additive is selected from at least one of vinylene carbonate, propylene carbonate, vinyl sulfate and lithium difluorophosphate. The molar concentration of lithium salt is 0.8-1.2mol/L, and ethylene carbonate (EC), dimethyl carbonate (DEC), ethyl methyl carbonate ( EMC) mixture is a solvent. The volume percent of the additive can be 0.5-5%. The present invention can use existing traditional separators, such as PE separators, PP separators, PP/PE composite films, or other commercially available separators.

可选的,所述步骤S3中,正参电位相比于初始状态的变化率在某需求温度下进行循环,相同循环次数时100%SoC对应的正参电位变化率越小,代表正极材料稳定性好。Optionally, in the step S3, the rate of change of the positive reference potential compared to the initial state is cycled at a certain required temperature, and the smaller the rate of change of the positive reference potential corresponding to 100% SoC at the same number of cycles, the less stable the positive electrode material is. good sex.

优选的,循环温度设置在30℃~55℃(45℃为宜),循环次数在100~500圈(350圈内为宜)。Preferably, the cycle temperature is set at 30°C to 55°C (45°C is suitable), and the number of cycles is 100 to 500 cycles (350 cycles are preferred).

本发明技术方案,具有如下优点:The technical scheme of the present invention has the following advantages:

本发明提供的电池正极材料稳定性的评估方法,包括以下步骤:S1,将待测正极材料制备成三电极电池;S2,按照三电极电池设计要求及评估要求设置循环参数,对三电极电池进行循环,监测正参电位;S3,以正参电位为纵坐标,循环次数为横坐标进行作图,对比待测正极材料的正参电位相比于初始状态的变化率,确定正极材料的循环稳定性。本发明具备对正极材料快速性评估和综合性评估的特点,区别于现有的仅基于材料层级的单一评估,或基于电池层级的综合性长循环评估。相较于材料层级评估,本发明兼具综合性考虑的同时,还具有较高的评估准确性;相较于电池层级的评估,本方法在兼顾对材料的综合性评估前提下,在无需借助价格昂贵的仪器设备的前提下,可在较短时间内准确地评估出多款正极材料的循环性能的差异。这是因为,电池容量的衰减受到正极、负极、电解液等多重因素影响,在较小的循环次数下,容量的衰减不一定是正极材料导致的,这会导致在较短的循环次数内,容量保持率处于波动状态,无法区分多种正极材料的循环性能的差异。但正参电位是直接检测正极材料的性能变化,正极细微的电压变化都会被正参电位所捕获,随着循环过程中正极结构变化的累积,正参电位不断增大,能够较容易地区分多种正极材料的循环性能的差异。The method for evaluating the stability of the positive electrode material of a battery provided by the present invention includes the following steps: S1, preparing the positive electrode material to be tested into a three-electrode battery; S2, setting cycle parameters according to the design requirements and evaluation requirements of the three-electrode battery, and performing a test on the three-electrode battery. Cycle, monitor the positive potential; S3, take the positive potential as the ordinate and the number of cycles as the abscissa to draw a graph, compare the rate of change of the positive potential of the positive electrode material to be tested compared to the initial state, and determine the cycle stability of the positive electrode material sex. The present invention has the characteristics of rapid evaluation and comprehensive evaluation of the positive electrode material, which is different from the existing single evaluation based only on the material level or the comprehensive long-cycle evaluation based on the battery level. Compared with material-level evaluation, the present invention not only has comprehensive consideration, but also has higher evaluation accuracy; On the premise of expensive equipment, the difference in cycle performance of various cathode materials can be accurately evaluated in a relatively short period of time. This is because the attenuation of battery capacity is affected by multiple factors such as positive electrode, negative electrode, electrolyte, etc. At a small number of cycles, the attenuation of capacity is not necessarily caused by the positive electrode material, which will lead to a short cycle number. The capacity retention rate is in a state of fluctuation, and the difference in cycle performance of various cathode materials cannot be distinguished. However, the positive potential is to directly detect the performance change of the positive electrode material, and the slight voltage change of the positive electrode will be captured by the positive potential. Differences in the cycling performance of different cathode materials.

本发明提供的电池正极材料稳定性的评估方法,通过对测试温度的进一步限定,可以加速正极材料的衰退速率,但不影响电池其他材料和性能的变化,因此可大幅缩短循环周期,在相同的循环周期下能更明显地表现出多款正极材料正参电位的差异。The method for evaluating the stability of the positive electrode material of the battery provided by the present invention can accelerate the decay rate of the positive electrode material by further limiting the test temperature, but does not affect the changes of other materials and properties of the battery, so the cycle period can be greatly shortened. The difference in positive potential of various cathode materials can be more clearly displayed under the cycle period.

附图说明Description of drawings

为了更清楚地说明本发明具体实施方式或现有技术中的技术方案,下面将对具体实施方式或现有技术描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图是本发明的一些实施方式,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to illustrate the specific embodiments of the present invention or the technical solutions in the prior art more clearly, the following briefly introduces the accompanying drawings that need to be used in the description of the specific embodiments or the prior art. Obviously, the accompanying drawings in the following description The drawings are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained based on these drawings without creative efforts.

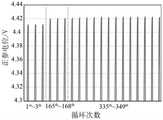

图1是本发明实施例1中正极材料镍钴锰酸锂(型号:NCM613,命名材料1)的正参电位变化图;Fig. 1 is the positive potential change diagram of positive electrode material nickel-cobalt manganate lithium (model: NCM613, named material 1) in Example 1 of the present invention;

图2是本发明实施例1中正极材料镍钴锰酸锂(型号:NCM613,命名材料2)的正参电位变化图;Fig. 2 is the positive parameter potential change diagram of positive electrode material nickel-cobalt-manganate lithium (model: NCM613, named material 2) in Example 1 of the present invention;

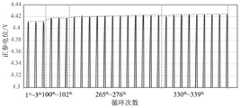

图3是本发明实施例2中正极材料镍钴锰酸锂(型号:NCM613,命名材料1)的正参电位变化图;Fig. 3 is the positive potential change diagram of the positive electrode material nickel cobalt manganate lithium (model: NCM613, named material 1) in Example 2 of the present invention;

图4是本发明实施例2中正极材料镍钴锰酸锂(型号:NCM613,命名材料2)的正参电位变化图;Fig. 4 is the positive potential change diagram of positive electrode material nickel cobalt manganate lithium (model: NCM613, named material 2) in Example 2 of the present invention;

图5是本发明对比例中正极材料镍钴锰酸锂(型号:NCM613,命名材料2)的常规循环容量保持率曲线(25℃)。FIG. 5 is a conventional cycle capacity retention rate curve (25° C.) of the positive electrode material lithium nickel cobalt manganate (model: NCM613, named material 2) in the comparative example of the present invention.

具体实施方式Detailed ways

提供下述实施例是为了更好地进一步理解本发明,并不局限于所述最佳实施方式,不对本发明的内容和保护范围构成限制,任何人在本发明的启示下或是将本发明与其他现有技术的特征进行组合而得出的任何与本发明相同或相近似的产品,均落在本发明的保护范围之内。The following examples are provided for a better understanding of the present invention, and are not limited to the best embodiments, and do not limit the content and protection scope of the present invention. Any product identical or similar to the present invention obtained by combining with the features of other prior art shall fall within the protection scope of the present invention.

实施例中未注明具体实验步骤或条件者,按照本领域内的文献所描述的常规实验步骤的操作或条件即可进行。所用试剂或仪器未注明生产厂商者,均为可以通过市购获得的常规试剂产品。If the specific experimental steps or conditions are not indicated in the examples, it can be carried out according to the operations or conditions of the conventional experimental steps described in the literature in this field. The reagents or instruments used without the manufacturer's indication are all conventional reagent products that can be obtained from the market.

本发明实施例中的三电极电池均采用如下方法制备:三电极电池的制备包括:The three-electrode batteries in the embodiments of the present invention are prepared by the following methods: the preparation of the three-electrode batteries includes:

(1)正极片的制备:分别取正极材料、导电剂乙炔黑、粘结剂聚偏氟乙烯PVDF按照质量比96:2:2混合均匀,得到混合物,加入溶剂N-甲基-2-吡咯烷酮(NMP)中,制得正极浆料(固含量为70%),将正极浆料按照19mg/cm2的面密度均匀涂布在正极集流体铝箔上,铝箔的厚度为12μm,在100℃下烘干后冷压,再进行模切、分条,制成锂离子电池正极片。(1) Preparation of positive electrode sheet: respectively take the positive electrode material, the conductive agent acetylene black, and the binder polyvinylidene fluoride PVDF and mix them uniformly according to the mass ratio of 96:2:2 to obtain a mixture, add the solvent N-methyl-2-pyrrolidone (NMP), the positive electrode slurry (solid content of 70%) was prepared, and the positive electrode slurry was uniformly coated on the positive electrode current collector aluminum foil according to the areal density of 19 mg/cm2 , the thickness of the aluminum foil was 12 μm, at 100 ° C After drying, it is cold-pressed, and then die-cutting and slitting to make a positive electrode sheet for lithium ion batteries.

(2)负极片的制备:取负极活性物质石墨、导电剂乙炔黑、增稠剂羟甲基纤维素钠(CMC)、粘结剂丁苯橡胶(SBR)按质量比95:1.5:1.5:2混合,得到混合物,将混合物加入溶剂水中混合均匀并制成负极浆料(固含量为50%);将负极浆料按照11mg/cm2的面密度均匀涂布在负极集流体铜箔上,铜箔的厚度6μm,在90℃下烘干后进行冷压,制成待制作锂离子电池负极片。(2) Preparation of negative electrode sheet: take the negative electrode active material graphite, conductive agent acetylene black, thickener sodium hydroxymethyl cellulose (CMC), and binder styrene-butadiene rubber (SBR) in a mass ratio of 95:1.5:1.5: 2 Mix to obtain a mixture, add the mixture into solvent water and mix evenly and make a negative electrode slurry (solid content of 50%); evenly coat the negative electrode slurry on the negative electrode current collector copper foil according to the areal density of 11 mg/cm2 , The thickness of the copper foil is 6 μm, which is dried at 90° C. and then cold-pressed to prepare the negative electrode sheet of the lithium ion battery to be produced.

(3)参比电极片的制备:将0.2微米的铜丝置于正极和负极间,并用隔膜隔开,将铜丝引出电池,作为一极,然后对正极/铜丝电极对进行恒流充电至电压为0V停止(0.1mA充电2h)。然后对负极/铜丝电极对进行恒流充电,至电压为0V停止(0.1mA充电2h),获得三电极电池。(3) Preparation of reference electrode sheet: place a 0.2-micron copper wire between the positive electrode and the negative electrode, and separate them with a separator. The copper wire is drawn out of the battery as one pole, and then the positive/copper wire electrode pair is charged with constant current. Stop when the voltage is 0V (0.1mA charge for 2h). Then, the negative electrode/copper wire electrode pair was charged with constant current until the voltage reached 0V and stopped (charged at 0.1 mA for 2 hours) to obtain a three-electrode battery.

(4)电解液的制备:将六氟磷酸锂溶解于体积比为5:3:2的碳酸乙烯酯、碳酸二甲酯和碳酸甲乙酯的混合溶剂中,得到浓度为1.15mol/L的六氟磷酸锂溶液,加入碳酸亚乙烯酯1vt%,二氟磷酸锂0.5vt%,硫酸乙烯酯DTD 0.5vt%,得到锂离子电池电极液。(4) preparation of electrolyte: dissolving lithium hexafluorophosphate in a mixed solvent of ethylene carbonate, dimethyl carbonate and ethyl methyl carbonate with a volume ratio of 5:3:2, obtaining a lithium hexafluorophosphate solution with a concentration of 1.15mol/L, 1 vt% of vinylene carbonate, 0.5vt% of lithium difluorophosphate and 0.5vt% of vinyl sulfate DTD were added to obtain an electrode solution for lithium ion batteries.

(5)将正极片、PE隔膜(购自恩捷公司,型号:SV12)、负极片按照层叠的方式组装得到电池极组,真空干燥箱中干燥,注入电解液,封口,即得电池(型号33220102,厚度为33mm,宽度为220mm,高度为102mm,标称电压为3.72V)。(5) Assemble the positive electrode sheet, the PE separator (purchased from Enjie, model: SV12) and the negative electrode sheet in a stacked manner to obtain a battery electrode group, dry in a vacuum drying box, inject electrolyte, and seal to obtain a battery (model 33220102, thickness is 33mm, width is 220mm, height is 102mm, nominal voltage is 3.72V).

本发明对比例中的电池的制备方法参照上述三电极电池的制备方法,区别在于不包括参比电极。The preparation method of the battery in the comparative example of the present invention refers to the preparation method of the above-mentioned three-electrode battery, except that the reference electrode is not included.

实施例1Example 1

本实施例提供一种电池正极材料稳定性的评估方法,包括以下步骤:This embodiment provides a method for evaluating the stability of a positive electrode material for a battery, comprising the following steps:

步骤一:准备待评估的两款正极材料,材料均属于镍钴锰酸锂,型号均为NCM613,来自不同厂家,保证除待评估正极材料不同外,其他制作技术参数及用料参数均相同,按照上述方法制备三电极电池;Step 1: Prepare two positive electrode materials to be evaluated, both of which are nickel cobalt lithium manganate and NCM613 models, from different manufacturers. It is guaranteed that except for the different positive electrode materials to be evaluated, other production technical parameters and material parameters are the same. Prepare a three-electrode battery according to the above method;

步骤二:按照电池设计参数及评测要求,选择合适的温度T,将电池置于目标温度环境,在合适的电压循环区间内,通过合适的倍率对电池进行n次循环,记录正极对参比电极电位变化;在本实施例中,温度为45℃,循环电压区间为2.8V~4.35V,采用恒流恒压(4.35)充电/恒流放电,倍率为1C/1C,循环次数为350。Step 2: According to the battery design parameters and evaluation requirements, select the appropriate temperature T, place the battery in the target temperature environment, and perform n cycles of the battery at an appropriate rate within the appropriate voltage cycle range, and record the positive electrode versus the reference electrode. Potential change; in this embodiment, the temperature is 45°C, the cycle voltage range is 2.8V to 4.35V, constant current and constant voltage (4.35) charge/constant current discharge is used, the rate is 1C/1C, and the number of cycles is 350.

步骤三:将正参电位对循环次数作图,以100%SoC时的正参电位为分析对象,对比目标待测正极材料所制备电池的正参电位变化率(相较于初始状态),确定材料的循环稳定性。Step 3: Plot the positive potential against the number of cycles, take the positive potential at 100% SoC as the analysis object, and compare the positive potential change rate (compared to the initial state) of the battery prepared with the target cathode material to be tested. Determine Cycling stability of the material.

正参电位变化率的计算方法为:c=(Vx-V0)/V0,其中c为正参电位变化率,Vx为循环x圈后的正参电位(100%SoC),V0为初始正参电位(100%SoC)。The calculation method of the rate of change of positive potential is: c=(Vx -V0 )/V0 , where c is the rate of change of positive potential, Vx is the positive potential after x cycles (100%SoC), V0 is the initial positive potential (100% SoC).

将两款正极材料制作的三电极电池在45℃下循环350圈后,性能较差的材料1(图1)正参变化率为0.502%,性能较好的材料2(图2)正参变化率为0.235%。After the three-electrode battery made of the two cathode materials was cycled for 350 cycles at 45°C, the positive parameter change rate of material 1 (Fig. 1) with poor performance was 0.502%, and the positive parameter change rate of material 2 (Fig. 2) with better performance The rate is 0.235%.

实施例2Example 2

本实施例提供一种电池正极材料稳定性的评估方法,包括以下步骤:This embodiment provides a method for evaluating the stability of a positive electrode material for a battery, comprising the following steps:

步骤一:准备待评估的两款正极材料,材料均属于镍钴锰酸锂,型号均为NCM613,来自不同厂家(同实施例1),保证除待评估正极材料不同外,其他制作技术参数及用料参数均相同,按照上述方法制备三电极电池;Step 1: Prepare two positive electrode materials to be evaluated, both of which are nickel cobalt lithium manganate, and the model is NCM613, from different manufacturers (same as Example 1). It is guaranteed that apart from the different positive electrode materials to be evaluated, other production technical parameters and The material parameters are the same, and the three-electrode battery is prepared according to the above method;

步骤二:按照电池设计参数及评测要求,选择合适的温度T,将电池置于目标温度环境,在合适的电压循环区间内,通过合适的倍率对电池进行n次循环,记录正极对参比电极电位变化;在本实施例中,温度为-15℃,循环电压区间为2.8V~4.35V,采用恒流恒压充电/恒流放电,倍率为1C/1C,循环次数为350。Step 2: According to the battery design parameters and evaluation requirements, select the appropriate temperature T, place the battery in the target temperature environment, and perform n cycles of the battery at an appropriate rate within the appropriate voltage cycle range, and record the positive electrode versus the reference electrode. Potential change; in this embodiment, the temperature is -15°C, the cycle voltage range is 2.8V to 4.35V, constant current and constant voltage charging/constant current discharging is used, the rate is 1C/1C, and the number of cycles is 350.

步骤三:将正参电位对循环次数作图,以100%SoC是正参电位为分析对象,对比目标待测正极材料所制备电池的正参电位变化率(相较于初始状态),确定材料的循环稳定性。Step 3: Plot the positive potential against the number of cycles, take 100% SoC as the positive potential as the analysis object, compare the positive potential change rate (compared to the initial state) of the battery prepared with the target cathode material to be tested, and determine the material's Cyclic stability.

将两款正极材料制作的三电极电池在-15℃下循环约350圈后,性能较差的材料1(图3)正参变化率为0.04%,性能较好的材料2(图4)正参变化率为0.02%。After cycling the three-electrode battery made of the two cathode materials at -15°C for about 350 cycles, the material 1 with poor performance (Fig. 3) has a positive parameter change rate of 0.04%, and the material 2 with better performance (Fig. The parameter change rate was 0.02%.

对比例1Comparative Example 1

本对比例提供一种电池正极材料稳定性的评估方法,包括以下步骤:This comparative example provides a method for evaluating the stability of battery cathode materials, including the following steps:

准备待评估的两款正极材料,材料均属于镍钴锰酸锂,型号均为NCM613,来自不同厂家(同实施例1),将材料1和材料2制备好的电池在25℃下进行恒流恒压充电/恒流放电,倍率为1C/1C,容量保持率见图5,从图中可以看出,在循环1500次后,通过线性预测材料1循环稳定性要优于材料2。但实际循环至约2600次后,材料1的循环稳定性的劣势才显现出来,当材料1衰减到容量保持率为80%时,材料2的容量保持率仍有86%。Two positive electrode materials to be evaluated, both of which are nickel-cobalt lithium manganate, and the models are NCM613, from different manufacturers (same as Example 1). Constant voltage charging/constant current discharging, the rate is 1C/1C, and the capacity retention rate is shown in Figure 5. It can be seen from the figure that after 1500 cycles, the cycle stability of material 1 is better than that of material 2 by linear prediction. However, the disadvantage of the cycle stability of material 1 appeared only after the actual cycle to about 2600 times. When the material 1 decayed to the capacity retention rate of 80%, the capacity retention rate of material 2 was still 86%.

从上述测试结果可知,本发明实施例提供的测试方法相比于对比例,在循环350圈时即可测试出不同正极材料的优劣,测试结果与对比例循环2600圈的结果一致,证明测试结果的准确性。通过本发明实施例之间的数据对比可知,在优选的测试温度下,可以加速正极材料的衰退速率,因此可大幅缩短循环周期,在相同的循环周期下能更明显地表现出多款正极材料正参电位的差异。It can be seen from the above test results that, compared with the comparative example, the test method provided in the embodiment of the present invention can test the pros and cons of different positive electrode materials in 350 cycles, and the test results are consistent with the results of the comparative example in 2600 cycles, which proves the test accuracy of results. From the data comparison between the examples of the present invention, it can be seen that at the preferred test temperature, the decay rate of the positive electrode material can be accelerated, so the cycle period can be greatly shortened, and a variety of positive electrode materials can be more clearly displayed under the same cycle period. difference in positive potential.

显然,上述实施例仅仅是为清楚地说明所作的举例,而并非对实施方式的限定。对于所属领域的普通技术人员来说,在上述说明的基础上还可以做出其它不同形式的变化或变动。这里无需也无法对所有的实施方式予以穷举。而由此所引申出的显而易见的变化或变动仍处于本发明创造的保护范围之中。Obviously, the above-mentioned embodiments are only examples for clear description, and are not intended to limit the implementation manner. For those of ordinary skill in the art, changes or modifications in other different forms can also be made on the basis of the above description. There is no need and cannot be exhaustive of all implementations here. However, the obvious changes or changes derived from this are still within the protection scope of the present invention.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210155965.2ACN114527172B (en) | 2022-02-21 | 2022-02-21 | Evaluation method for stability of battery anode material |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210155965.2ACN114527172B (en) | 2022-02-21 | 2022-02-21 | Evaluation method for stability of battery anode material |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114527172Atrue CN114527172A (en) | 2022-05-24 |

| CN114527172B CN114527172B (en) | 2024-05-03 |

Family

ID=81624295

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210155965.2AActiveCN114527172B (en) | 2022-02-21 | 2022-02-21 | Evaluation method for stability of battery anode material |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114527172B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN119643648A (en)* | 2025-02-19 | 2025-03-18 | 四川富临新能源科技有限公司 | Evaluation method for cycling stability of lithium iron phosphate anode material |

Citations (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003157910A (en)* | 2001-11-26 | 2003-05-30 | Shin Kobe Electric Mach Co Ltd | Lead storage battery negative electrode plate deterioration determination method |

| US20090104510A1 (en)* | 2007-09-14 | 2009-04-23 | A123 Systems, Inc. | Lithium rechargeable cell with reference electrode for state of health monitoring |

| US20130009604A1 (en)* | 2011-07-06 | 2013-01-10 | Apple Inc. | Using reference electrodes to manage batteries for portable electronic devices |

| DE102013215316A1 (en)* | 2013-08-05 | 2015-02-05 | Robert Bosch Gmbh | Method for detecting the state of an energy storage |

| CN107026282A (en)* | 2017-06-02 | 2017-08-08 | 中天储能科技有限公司 | A kind of lithium ion battery three-electrode system and its method of testing |

| CN107768708A (en)* | 2017-08-28 | 2018-03-06 | 天津力神电池股份有限公司 | The fast appraisement method of lithium battery graphite cathode material cycle performance |

| JP2018101582A (en)* | 2016-12-21 | 2018-06-28 | 住友金属鉱山株式会社 | Method of evaluating capacity of positive electrode material for nonaqueous electrolyte secondary battery |

| JP6490882B1 (en)* | 2018-04-17 | 2019-03-27 | 三菱電機株式会社 | Storage battery diagnosis device, storage battery diagnosis method, and storage battery control system |

| WO2019058666A1 (en)* | 2017-09-22 | 2019-03-28 | 積水化学工業株式会社 | Secondary battery deterioration detection system |

| CN109613443A (en)* | 2018-12-20 | 2019-04-12 | 天津市捷威动力工业有限公司 | A kind of evaluation method of health state of lithium ion battery |

| CN110045293A (en)* | 2019-03-15 | 2019-07-23 | 天津力神电池股份有限公司 | A kind of method of nondestructive analysis cell active materials material failure |

| CN110988086A (en)* | 2019-10-11 | 2020-04-10 | 天津力神电池股份有限公司 | Method for detecting structural stability of electrode material in battery circulation process |

| CN111208160A (en)* | 2020-02-20 | 2020-05-29 | 东莞维科电池有限公司 | Method for evaluating cycle performance of ternary material |

| EP3678255A1 (en)* | 2019-01-02 | 2020-07-08 | Commissariat à l'énergie atomique et aux énergies alternatives | Method for calibrating a family of lithium-ion battery elements, charging method, associated computer program product and charging device |

| CN112526357A (en)* | 2020-11-25 | 2021-03-19 | 上海空间电源研究所 | Lithium ion battery power matching performance evaluation method |

| CN112703125A (en)* | 2020-08-10 | 2021-04-23 | 华为技术有限公司 | Lithium analysis detection method and device for lithium battery |

| CN113013395A (en)* | 2021-03-26 | 2021-06-22 | 蜂巢能源科技有限公司 | Positive electrode material and preparation method and application thereof |

| CN113533988A (en)* | 2021-06-04 | 2021-10-22 | 上海空间电源研究所 | Long-term circulation capacity attenuation analysis method for lithium ion battery |

| CN113711407A (en)* | 2020-01-02 | 2021-11-26 | 株式会社Lg新能源 | Electrode assembly for evaluating electrode performance and electrode performance evaluation method |

- 2022

- 2022-02-21CNCN202210155965.2Apatent/CN114527172B/enactiveActive

Patent Citations (19)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JP2003157910A (en)* | 2001-11-26 | 2003-05-30 | Shin Kobe Electric Mach Co Ltd | Lead storage battery negative electrode plate deterioration determination method |

| US20090104510A1 (en)* | 2007-09-14 | 2009-04-23 | A123 Systems, Inc. | Lithium rechargeable cell with reference electrode for state of health monitoring |

| US20130009604A1 (en)* | 2011-07-06 | 2013-01-10 | Apple Inc. | Using reference electrodes to manage batteries for portable electronic devices |

| DE102013215316A1 (en)* | 2013-08-05 | 2015-02-05 | Robert Bosch Gmbh | Method for detecting the state of an energy storage |

| JP2018101582A (en)* | 2016-12-21 | 2018-06-28 | 住友金属鉱山株式会社 | Method of evaluating capacity of positive electrode material for nonaqueous electrolyte secondary battery |

| CN107026282A (en)* | 2017-06-02 | 2017-08-08 | 中天储能科技有限公司 | A kind of lithium ion battery three-electrode system and its method of testing |

| CN107768708A (en)* | 2017-08-28 | 2018-03-06 | 天津力神电池股份有限公司 | The fast appraisement method of lithium battery graphite cathode material cycle performance |

| WO2019058666A1 (en)* | 2017-09-22 | 2019-03-28 | 積水化学工業株式会社 | Secondary battery deterioration detection system |

| JP6490882B1 (en)* | 2018-04-17 | 2019-03-27 | 三菱電機株式会社 | Storage battery diagnosis device, storage battery diagnosis method, and storage battery control system |

| CN109613443A (en)* | 2018-12-20 | 2019-04-12 | 天津市捷威动力工业有限公司 | A kind of evaluation method of health state of lithium ion battery |

| EP3678255A1 (en)* | 2019-01-02 | 2020-07-08 | Commissariat à l'énergie atomique et aux énergies alternatives | Method for calibrating a family of lithium-ion battery elements, charging method, associated computer program product and charging device |

| CN110045293A (en)* | 2019-03-15 | 2019-07-23 | 天津力神电池股份有限公司 | A kind of method of nondestructive analysis cell active materials material failure |

| CN110988086A (en)* | 2019-10-11 | 2020-04-10 | 天津力神电池股份有限公司 | Method for detecting structural stability of electrode material in battery circulation process |

| CN113711407A (en)* | 2020-01-02 | 2021-11-26 | 株式会社Lg新能源 | Electrode assembly for evaluating electrode performance and electrode performance evaluation method |

| CN111208160A (en)* | 2020-02-20 | 2020-05-29 | 东莞维科电池有限公司 | Method for evaluating cycle performance of ternary material |

| CN112703125A (en)* | 2020-08-10 | 2021-04-23 | 华为技术有限公司 | Lithium analysis detection method and device for lithium battery |

| CN112526357A (en)* | 2020-11-25 | 2021-03-19 | 上海空间电源研究所 | Lithium ion battery power matching performance evaluation method |

| CN113013395A (en)* | 2021-03-26 | 2021-06-22 | 蜂巢能源科技有限公司 | Positive electrode material and preparation method and application thereof |

| CN113533988A (en)* | 2021-06-04 | 2021-10-22 | 上海空间电源研究所 | Long-term circulation capacity attenuation analysis method for lithium ion battery |

Non-Patent Citations (2)

| Title |

|---|

| 余仲宝, 万新华, 王静, 刘庆国: "MCMB/LiCoO_2电池的循环稳定性", 电池, no. 01, 25 February 2005 (2005-02-25), pages 52 - 54* |

| 汪惟源;朱寰;高正平;李琥;李冰洁;: "储能锂离子电池高温循环衰减机制分析", 电源技术, no. 07, 20 July 2020 (2020-07-20), pages 22 - 25* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN119643648A (en)* | 2025-02-19 | 2025-03-18 | 四川富临新能源科技有限公司 | Evaluation method for cycling stability of lithium iron phosphate anode material |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114527172B (en) | 2024-05-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN110208716B (en) | Battery and method for testing residual active lithium capacity in negative pole piece after battery discharge | |

| AU2015100980A4 (en) | A new lithium pre-insertion method for lithium ion capacitors | |

| US20180366720A1 (en) | Positive active material and lithium-ion secondary battery | |

| CN112993379A (en) | High-energy-density quick-charging polymer lithium ion battery and preparation method thereof | |

| CN107681214B (en) | Lithium ion cell lithium supplementing method | |

| US20250023191A1 (en) | Separator, electrochemical device containing same, and electronic device | |

| CN116111041B (en) | Positive electrode plate, secondary battery and electronic device | |

| CN106684320B (en) | A kind of positive pole piece, its preparation method and secondary battery | |

| CN110739484A (en) | wide-temperature-resistant lithium battery and manufacturing method thereof | |

| US20220328832A1 (en) | Electrochemical device and electronic device | |

| CN116759646A (en) | Secondary battery and electricity utilization device | |

| CN112687956A (en) | Non-aqueous electrolyte of lithium battery and lithium ion battery based on same | |

| CN112952200A (en) | Method for manufacturing lithium ion battery | |

| WO2024244066A1 (en) | Negative pressure formation method for lithium manganese iron phosphate battery and battery applying method | |

| CN115275105B (en) | Silicon-based negative electrode plate, secondary battery and power utilization device | |

| CN102956932A (en) | Lithium ion secondary battery core aging method | |

| CN114527172B (en) | Evaluation method for stability of battery anode material | |

| CN107247239A (en) | The determination method of high-temperature lithium ion battery ageing time | |

| CN102520363A (en) | Low-temperature performance evaluation method of lithium ion battery | |

| CN108110254B (en) | Application of Iron Phosphate and Iron Phosphate Composites as Negative Electrodes in Lithium Ion Batteries | |

| CN114300818A (en) | Liquid injection synthesis process of lithium ion battery and lithium ion battery | |

| WO2017214852A1 (en) | Battery charging method and device and battery system | |

| CN118645707A (en) | Secondary batteries and electronic devices | |

| CN115632106B (en) | Composite negative plate and secondary battery | |

| CN114459963B (en) | An evaluation method for lithium ion diffusion ability in cathode materials |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |