CN114516482A - Application of heat-sensitive spiral spring in flexible filling container - Google Patents

Application of heat-sensitive spiral spring in flexible filling containerDownload PDFInfo

- Publication number

- CN114516482A CN114516482ACN202111619387.5ACN202111619387ACN114516482ACN 114516482 ACN114516482 ACN 114516482ACN 202111619387 ACN202111619387 ACN 202111619387ACN 114516482 ACN114516482 ACN 114516482A

- Authority

- CN

- China

- Prior art keywords

- spring

- flexible

- memory alloy

- filled container

- heat sensitive

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D33/00—Details of, or accessories for, sacks or bags

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21F—WORKING OR PROCESSING OF METAL WIRE

- B21F3/00—Coiling wire into particular forms

- B21F3/02—Coiling wire into particular forms helically

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21F—WORKING OR PROCESSING OF METAL WIRE

- B21F35/00—Making springs from wire

- B—PERFORMING OPERATIONS; TRANSPORTING

- B21—MECHANICAL METAL-WORKING WITHOUT ESSENTIALLY REMOVING MATERIAL; PUNCHING METAL

- B21F—WORKING OR PROCESSING OF METAL WIRE

- B21F35/00—Making springs from wire

- B21F35/006—Double twist coil springs

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Cookers (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及螺旋弹簧领域,具体涉及一种热敏螺旋弹簧在柔性填充容器中的应用。The invention relates to the field of coil springs, in particular to the application of a heat-sensitive coil spring in a flexible filling container.

背景技术Background technique

根据统计,家庭中最大的两类安全隐患:(1)家中绳索,容易导致儿童缠绕窒息和绊倒摔伤等危险。(2)炉具等加热烧伤和烫伤:儿童皮肤比成人更薄,一杯热咖啡5秒钟可导致儿童重度烫伤,多数时候刚停止加热的锅具、炉具和电水壶等在70-90℃,儿童误触极易导致烫伤。According to statistics, the two biggest safety hazards in the family are: (1) The ropes at home can easily lead to dangers such as entanglement and suffocation of children, tripping and falling. (2) Heating burns and scalds such as stoves: Children's skin is thinner than that of adults. A cup of hot coffee for 5 seconds can cause severe burns in children. Most of the time, pots, stoves and electric kettles that have just stopped heating are at 70-90 ℃ , children's accidental touch can easily lead to burns.

如果有一系列方便的给低幼儿童设计的安全防护用具,不仅能够提高家中儿童的安全性,也能让家长安心放手让孩子们动手做家务,锻炼自理能力。目前并没有这类简单、便宜的自动化的儿童家庭生活安全防护用具。If there is a series of convenient safety equipment designed for young children, it can not only improve the safety of children at home, but also allow parents to let their children do housework and exercise self-care ability. At present, there is no such simple and cheap automatic safety protection device for children's family life.

形状记忆合金制造的卫星天线是一种利用形状记忆合金(SMA)加热升温后能完全消除其在较低的温度下发生的变形,恢复其变形前原始形状的特点实现小体积收纳和大面积展开的设计——即拥有"记忆"效应特点的金属材料工程应用,如图1。The satellite antenna made of shape memory alloy is a kind of satellite antenna made of shape memory alloy (SMA), which can completely eliminate its deformation at lower temperature after heating up, and restore its original shape before deformation to realize small volume storage and large area expansion. The design of the metal material engineering application with the characteristics of "memory" effect, as shown in Figure 1.

SMA在牙齿正畸器、各类腔内支架和手术缝合线也有很广泛使用。另外,形状记忆合金材料在控制浴室水管的水温、启动消防报警装置和暖气的阀门内有了应用。在我们的生活中主要用作结构材料,还没有用于各种安全防护用具的自动弹出驱动元件的公开资料。SMAs are also widely used in orthodontic appliances, various endoluminal stents and surgical sutures. In addition, shape memory alloy materials have applications in valves that control water temperature in bathroom plumbing, activate fire alarms and heating. It is mainly used as a structural material in our life, and there is no public information on automatic pop-up drive elements for various safety protection appliances.

发明内容SUMMARY OF THE INVENTION

本发明的目的就是为了克服上述现有技术存在的缺陷而提供一种可实现自动伸展导致体积膨胀,无需电路驱动,且结构简单、反应敏捷、价格低廉、通用性好的热敏螺旋弹簧在柔性填充容器中的应用。The purpose of the present invention is to provide a thermal coil spring with simple structure, quick response, low price and good versatility in order to overcome the above-mentioned defects of the prior art and provide a thermal coil spring that can realize automatic expansion and lead to volume expansion without circuit driving. Application in filling container.

本发明的目的可以通过以下技术方案来实现:The object of the present invention can be realized through the following technical solutions:

本发明就家庭中收纳袋绳索和炉灶给低幼儿童带来的安全风险问题,设计并制作一类可以实现室温下随意折叠收纳,使用时候加热迅速自动撑开,填充容器体积的封口开关。The invention designs and manufactures a type of sealing switch that can be freely folded and stored at room temperature, and automatically opened when heated to fill the volume of the container.

根据形状记忆合金可恢复变形大、输出力大的重复伸缩特点,本发明提出采用形状记忆合金(SMA)丝线制造不同形态弹簧的设想,希望结合弹簧的能量储存和记忆合金丝的形变可逆重复输出力的特性,做出简单、经济和智能的驱动弹簧元件。这种驱动弹簧可放入大口径收纳袋、球体玩具和防热等安全用具等容器的内胆中,实现室温下随意折叠收纳,使用时候短时受热自动伸长,形成大体积填充支撑各种容器的目的。这个SMA驱动弹簧可以解决了大体积容器占用空间大、携带不方便的问题,而且不需要电池电能、反应敏捷、结构简单且价格低廉、通用性好。According to the repeated expansion and contraction characteristics of shape memory alloys with large recoverable deformation and large output force, the present invention proposes the idea of using shape memory alloy (SMA) wires to manufacture springs of different shapes, hoping to combine the energy storage of springs and the reversible and repeated output of memory alloy wires force characteristics to make simple, economical and intelligent actuating spring elements. This driving spring can be put into the inner tank of containers such as large-diameter storage bags, spherical toys, and heat-proof appliances, etc., and can be freely folded and stored at room temperature. the purpose of the container. This SMA driving spring can solve the problems of large volume container occupying a large space and being inconvenient to carry, and it does not require battery power, has agile response, simple structure, low price and good versatility.

一种热敏螺旋弹簧在柔性填充容器中的应用,该弹簧用作柔性填充容器的自支撑驱动开关。An application of a thermally sensitive coil spring in a flexible filling container, the spring being used as a self-supporting drive switch for the flexible filling container.

进一步地,该弹簧的结构为单螺旋、双螺旋或三螺旋。Further, the structure of the spring is a single helix, a double helix or a triple helix.

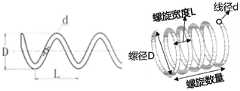

发明人了解到,自然界中很多植物和动物都有弹簧的螺旋结构和形态,比如电鳗、蛇类的身体骨骼就是弹簧结构,给这类软体动物提供足够的体积缩小能力,以躲避天敌。蛛丝的内部结构也是三种不同螺旋形态构成,提供很大的弹力和收缩力,电影里面蜘蛛侠的蛛丝同样具有科学原理。基因DNA也是著名的双螺旋结构,双螺旋提供了极大的结构稳定性和互补性,并且局部DNA还可以形成三螺旋甚至四螺旋的形式。双螺旋的主链有二条,它们似“麻花状”绕一共同轴心以右手方向盘旋,提供超大变形,如图2。因此本发明中选择模仿DNA结构,制作单螺旋、双螺旋和三螺旋的弹簧。本发明中螺旋弹簧的结构、宽度、直径和数量四个参数设计如图3-4所示。The inventors have learned that many plants and animals in nature have the spiral structure and shape of springs. For example, the body bones of electric eels and snakes are spring structures, which provide such mollusks with sufficient volume reduction ability to avoid natural enemies. The internal structure of the spider silk is also composed of three different spiral shapes, which provide great elasticity and contraction force. The spider silk of Spider-Man in the movie also has scientific principles. Gene DNA is also famous for its double helix structure, which provides great structural stability and complementarity, and local DNA can also form triple or even quadruple helices. There are two main chains of the double helix, which are like "twisted" around a common axis and rotate with the right hand, providing super deformation, as shown in Figure 2. Therefore, in the present invention, a single-helix, double-helix and triple-helix springs are selected to imitate the structure of DNA. The four parameter designs of the structure, width, diameter and quantity of the coil spring in the present invention are shown in Figures 3-4.

进一步地,该弹簧的材质为形状记忆合金。Further, the material of the spring is shape memory alloy.

进一步地,该弹簧的材质为镍-钛记忆合金。Further, the material of the spring is nickel-titanium memory alloy.

进一步地,所述弹簧的螺径D为1-4cm,螺距L为1-7cm。Further, the screw diameter D of the spring is 1-4 cm, and the screw pitch L is 1-7 cm.

进一步地,所述弹簧的螺径D为1-2cm,螺距L为1.8-2.2cm。Further, the thread diameter D of the spring is 1-2 cm, and the thread pitch L is 1.8-2.2 cm.

进一步地,所述弹簧的螺旋数量为4-36组。Further, the number of coils of the spring is 4-36 groups.

进一步地,所述弹簧的螺旋数量为4-8组。Further, the number of coils of the spring is 4-8 groups.

进一步地,该应用的具体方法为:Further, the specific method of this application is:

将弹簧煅烧后,使其形状固定至收缩态,然后冷却至室温;After the spring is calcined, its shape is fixed to the contracted state and then cooled to room temperature;

将弹簧连接到柔性填充容器上,再将弹簧加热后,弹簧伸展,将柔性填充容器撑开。柔性填充容器包括收纳袋、厨房透明防护罩内胆或玩偶。The spring is attached to the flexible filling container, and after the spring is heated, the spring expands and the flexible filling container is stretched. Flexible filling containers include storage bags, kitchen clear hood liners or dolls.

进一步地,所述煅烧的温度为350-450℃,时间为10-20min;所述加热的温度为60-70℃。Further, the calcination temperature is 350-450°C, and the time is 10-20min; the heating temperature is 60-70°C.

与现有技术相比,本发明针对家庭中收纳袋绳索和炉灶给低幼儿童带来的安全风险问题,设计并制作一类可以实现室温下随意折叠收纳,使用时候加热迅速自动撑开,填充容器体积的封口开关。利用形状记忆合金SMA可恢复变形大、输出力大的重复伸缩特点,提出仿照DNA双螺旋结构,采用镍-钛形状记忆合金丝线绕制“智能弹簧”的设想,结合弹簧的能量储存特点和记忆合金的形变可逆重复输出力的特性,做出简单和自动伸展的弹簧驱动元件作为封口开关。Compared with the prior art, the present invention aims at the safety risk problem brought by the storage bag rope and the stove in the family to the young children, and designs and manufactures a type that can be freely folded and stored at room temperature. Seal switch for container volume. Using the shape memory alloy SMA to restore the repeated expansion and contraction characteristics of large deformation and large output force, the idea of imitating the DNA double helix structure and using nickel-titanium shape memory alloy wire to wind the "smart spring" is proposed. The alloy's deformable, reversible, repetitive output force characteristics make for a simple and self-extending spring-driven element that acts as a seal switch.

附图说明Description of drawings

图1为形状记忆合金变形恢复原理图;Figure 1 is a schematic diagram of shape memory alloy deformation recovery;

图2为DNA弹性杆模型的超大变形;Figure 2 shows the super deformation of the DNA elastic rod model;

图3为本发明螺旋几何尺寸设计示意图;Fig. 3 is a schematic diagram of spiral geometry design of the present invention;

图4为本发明三种螺旋的形状结构设计示意图;4 is a schematic diagram of the shape structure design of three kinds of spirals of the present invention;

图5为本发明镍-钛记忆合金金属丝室温中尺寸设计、绕制和测试过程图;5 is a process diagram of size design, winding and testing of the nickel-titanium memory alloy wire of the present invention at room temperature;

图6为本发明用于研究的弹簧样品照片;Figure 6 is a photo of the spring sample used for research in the present invention;

图7为本发明中不同长度的SMA弹簧受热后自动伸长的响应速度对比实验;Fig. 7 is the response speed comparison experiment of automatic elongation after SMA springs of different lengths are heated in the present invention;

图8为本发明中弹簧加热伸展的过程形态对比;Fig. 8 is the process morphological comparison of spring heating and stretching in the present invention;

图9为本发明中弹簧受热后膨胀的驱动力演示实验;Fig. 9 is the driving force demonstration experiment that the spring expands after being heated in the present invention;

图10为填充实施例2中优化尺寸的弹簧原件后收纳袋电吹风加热后膨胀演示图;FIG. 10 is a demonstration diagram of the expansion of the storage bag after being heated by the hair dryer after filling the spring element of the optimized size in Example 2;

图11为用SMA弹簧作为温度感应的自动膨胀和支撑的生活物品。Figure 11 is a living article using SMA springs as temperature-sensing self-expanding and support.

具体实施方式Detailed ways

下面结合附图和具体实施例对本发明进行详细说明。本实施例在以本发明技术方案为前提下进行实施,给出了详细的实施方式和具体的操作过程,但本发明的保护范围不限于下述的实施例。The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention, and provides a detailed implementation manner and a specific operation process, but the protection scope of the present invention is not limited to the following embodiments.

本发明采用镍-钛记忆合金丝线,直径为1.0mm,输出力大约800MPa,预形变约4-5%,必要时还要使用金属剪刀钳,游标卡尺、电子计时器、直径为1-4cm的陶瓷管模具,加热台,加热炉,烧杯,自来水,电吹风,若干家用布料、无纺布、海绵块和透明耐热塑料布。The present invention adopts nickel-titanium memory alloy wire, the diameter is 1.0mm, the output force is about 800MPa, the pre-deformation is about 4-5%, and if necessary, metal scissors, vernier calipers, electronic timers, ceramics with a diameter of 1-4cm are used. Tube moulds, heating tables, heating furnaces, beakers, tap water, hair dryers, some household fabrics, non-woven fabrics, sponge blocks and transparent heat-resistant plastic sheets.

螺旋弹簧的制备具体参数如下表1中。使用镍-钛记忆合金丝线在直径为1-4cm的不同陶瓷管是缠扰形成弹簧,如图5所示。然后使用400℃加热炉热固定形状15分钟,取出冷却到室温。然后将用电吹风和热水加热弹簧样品至60-70℃,观测记录伸展时间和弹出力。最后将优选出弹力大、变形速度最快的弹簧样品装入家用布料、无纺布、海绵块和透明耐热塑料布做成大袋子和防护罩容器,观测这些容器的受热后体积变化时间和体积增加量。The specific parameters for the preparation of the coil spring are listed in Table 1 below. Different ceramic tubes with diameters of 1-4 cm were entangled to form springs using nickel-titanium memory alloy wires, as shown in Figure 5. Then, the shape was heat-fixed using a 400°C heating furnace for 15 minutes, taken out and cooled to room temperature. The spring sample was then heated to 60-70°C with a hair dryer and hot water, and the extension time and ejection force were observed and recorded. Finally, the spring samples with the best elasticity and the fastest deformation speed were put into household fabrics, non-woven fabrics, sponge blocks and transparent heat-resistant plastic cloths to make large bags and protective cover containers, and the volume change time and volume of these containers after being heated were observed. volume increase.

图6给出了不同螺旋直径、螺旋宽度、螺旋长度和螺旋结构的测试样品照片。由于受弹簧制备工具的精度限制,样品制备的尺寸精度有0.05-0.10cm的偏差。Figure 6 presents photographs of test samples for different helix diameters, helix widths, helix lengths and helix structures. Due to the limitation of the precision of the spring preparation tool, the dimensional accuracy of the sample preparation has a deviation of 0.05-0.10cm.

表1螺旋制备的具体参数和性能测试方案Table 1 Specific parameters and performance test scheme of spiral preparation

实施例1Example 1

本实施例中,弹簧为单螺旋结构,具体参数如表2所示In this embodiment, the spring is a single helix structure, and the specific parameters are shown in Table 2

表2单螺旋结构的性能测试数据Table 2 Performance test data of single helical structure

数据结果表明:最快速伸展的单螺旋弹簧样品几何尺寸为宽度2cm,直径2cm,含有4组螺旋,它的伸长开始时间为5秒,完全伸长时间为29秒,见图7。并且所有研究的单螺旋弹簧样品均可以实现20次以上的缠绕-伸长测试。The data results show that the geometric size of the fastest extending single-coil spring sample is 2 cm in width and 2 cm in diameter, and contains 4 sets of spirals. And all the single-coil spring samples studied can achieve more than 20 winding-elongation tests.

实施例2Example 2

本实施例中,弹簧为双螺旋结构,具体参数如表3所示In this embodiment, the spring is a double helix structure, and the specific parameters are shown in Table 3

表3双螺旋结构的性能测试数据Table 3 Performance test data of double helix structure

双螺旋弹簧样品的数据表明:最快速伸展的弹簧样品几何尺寸为宽度2cm,直径2cm,含有4组螺旋,它的伸长开始时间为9-11秒,完全伸长时间为35-61秒。并且所有研究的双螺旋弹簧样品均可以实现20次以上的缠绕-伸长测试,见图8。图8(a-b)双螺旋弹簧经历多次重复缠绕-加热伸长20个循环前后的形貌,(c)三种螺旋结构弹簧加热伸展的过程形态对比。The data for the double-coil spring samples showed that the fastest expanding spring samples had geometric dimensions of 2 cm in width and 2 cm in diameter, contained 4 sets of spirals, and had an elongation onset time of 9-11 seconds and a full elongation time of 35-61 seconds. And all the double-coil spring samples studied can achieve more than 20 winding-elongation tests, see Figure 8. Figure 8(a-b) The morphologies of the double helical springs before and after repeated winding-heating and stretching for 20 cycles, (c) the comparison of the morphologies of the three types of helical springs during heating and stretching.

实施例3Example 3

本实施例中,弹簧为三螺旋结构,具体参数如表4所示In this embodiment, the spring is a triple helix structure, and the specific parameters are shown in Table 4

表4三螺旋结构的性能测试数据Table 4 Performance test data of triple helix structure

三螺旋弹簧样品的数据表明:最快速伸展的弹簧样品几何尺寸同样为宽度2cm,直径2cm,含有4组螺旋,它的伸长开始时间为19~20秒,加热10分钟后所有受测试样品也无法实现完全伸长。因此就没有继续测试三螺旋弹簧样品的缠绕-伸长性能。测试中发现三螺旋弹簧无法完全伸展的原因是,三根螺旋结构伸长速度不一致,导致螺旋结构发生大角度转动、穿插和二次缠绕,见图8(c),因而形成了伸长的相互阻碍。The data of the three-coil spring samples show that the geometric dimensions of the fastest expanding spring samples are also 2 cm in width and 2 cm in diameter, and contain 4 sets of spirals. Its elongation start time is 19 to 20 seconds. Full elongation cannot be achieved. Therefore, the winding-elongation properties of the triple helical spring samples were not further tested. In the test, it was found that the reason why the three-coil spring could not be fully stretched was that the elongation speed of the three helical structures was inconsistent, which led to the large-angle rotation, interpenetration and secondary winding of the helical structure, as shown in Figure 8(c), thus forming mutual obstacles to elongation. .

针对单螺旋弹簧、双螺旋弹簧和螺旋弹簧样品的推力大小进行加热测试数据表明,见图9,三螺旋弹簧的推力最大,双螺旋次之,单螺旋推力最弱。The heating test data for the thrust of the single-coil spring, double-coil spring and coil spring samples show that, as shown in Figure 9, the thrust of the triple-coil spring is the largest, followed by the double-coil spring, and the single-coil thrust is the weakest.

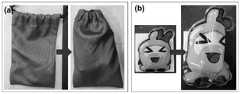

以上的弹簧样品的实验观测和分析发现:弹簧的螺旋形态和螺旋宽度是影响伸展和弹力的最重要因素,宽度2cm,直径2cm,含有4组螺旋结构的双螺旋弹簧具有伸长最快速和完全伸长时间最短的特点,并且也能提供较大的推力。在收纳袋中和橡胶玩偶中分别装入将5根和3根这种双螺旋弹簧,电吹风加热中收纳袋和玩偶迅速膨胀和撑开,如图10。但是玩偶的体积增加更多,这是由于香蕉玩偶的材料更容易伸展。这个实验证明了在家用电吹风和热水等热源,即>60℃的短时间加热后,形状记忆合金制作的单螺旋和双螺旋结构弹簧可以提供反复瞬时膨胀撑开的功能。The experimental observation and analysis of the above spring samples found that the helical shape and helical width of the spring are the most important factors affecting the stretching and elastic force. The double helical spring with a width of 2 cm and a diameter of 2 cm has 4 groups of helical structures with the fastest and complete elongation. It has the characteristics of the shortest extension time and can also provide a large thrust. Put 5 and 3 double-coil springs into the storage bag and the rubber doll, respectively, and the storage bag and the doll expand and stretch quickly during the heating of the hair dryer, as shown in Figure 10. But the bulk of the doll increases more, due to the fact that the banana doll's material stretches more easily. This experiment proves that the single-helix and double-helix structure springs made of shape memory alloys can provide the function of repeated instantaneous expansion and opening after heating sources such as household hair dryers and hot water, that is, >60 °C for a short time.

依据目标容器的容积、质量和使用温度热源选择把双螺旋结构弹簧数量,封入其内胆,如图11展示的三个家庭中可能应用的产品案例。图11(a)中的收纳袋口封入SMA双螺旋弹簧,取代绳子打结封口的设计,儿童可以手持电吹风加热弹簧位置即可打开收纳袋。图11(b)为厨房透明防护罩内胆中放置SMA双螺旋弹簧做支撑框架,可放置在停止加热的灶台上端、有蒸汽冒出的锅灶上方,当热源温度高于60℃,内胆中的弹簧的长度迅速伸长为丝线,膨胀填充或者形成支撑骨架,便于低龄儿童快速知道不能触碰高温部位。如果需要再次收纳,可放到冷水中,它会立即恢复原状。也可以将弹簧装入孩子喜欢的玩偶内部,图11(c),充当温度报警器,当某处温度过高时报警娃娃快速膨胀,直观、快速地提醒父母和孩子。According to the volume, quality and use temperature of the target container, the number of double-helix structure springs is selected and sealed into its inner tank, as shown in Figure 11. The product cases that may be used in three families are shown. In Figure 11(a), the opening of the storage bag is sealed with SMA double coil springs. Instead of the rope knotted and sealed design, children can open the storage bag by holding a hair dryer to heat the spring position. Figure 11(b) shows the SMA double helical spring placed in the inner tank of the transparent protective cover of the kitchen as a supporting frame, which can be placed on the upper end of the stove that stops heating and above the stove with steam coming out. When the temperature of the heat source is higher than 60 ℃, the inner The length of the spring in the bladder is quickly elongated into silk threads, which expand to fill or form a support frame, so that young children can quickly know that they cannot touch high-temperature parts. If you need to store it again, you can put it in cold water and it will return to its original shape immediately. The spring can also be installed inside the child's favorite doll, as shown in Figure 11(c), to act as a temperature alarm. When the temperature somewhere is too high, the alarm doll expands rapidly, which intuitively and quickly reminds parents and children.

以上所述,仅是本发明的较佳实施例而已,并非是对本发明作其它形式的限制,任何熟悉本专业的技术人员可能利用上述揭示的技术内容加以变更或改型为等同变化的等效实施例。但是凡是未脱离本发明技术方案内容,依据本发明的技术实质对以上实施例所作的任何简单修改、等同变化与改型,仍属于本发明技术方案的保护范围。The above are only preferred embodiments of the present invention, and are not intended to limit the present invention in other forms. Any person skilled in the art may use the technical content disclosed above to make changes or modifications to equivalent changes. Example. However, any simple modifications, equivalent changes and modifications made to the above embodiments according to the technical essence of the present invention without departing from the content of the technical solutions of the present invention still belong to the protection scope of the technical solutions of the present invention.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111619387.5ACN114516482A (en) | 2021-12-27 | 2021-12-27 | Application of heat-sensitive spiral spring in flexible filling container |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111619387.5ACN114516482A (en) | 2021-12-27 | 2021-12-27 | Application of heat-sensitive spiral spring in flexible filling container |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114516482Atrue CN114516482A (en) | 2022-05-20 |

Family

ID=81596947

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202111619387.5APendingCN114516482A (en) | 2021-12-27 | 2021-12-27 | Application of heat-sensitive spiral spring in flexible filling container |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114516482A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116212682A (en)* | 2022-12-28 | 2023-06-06 | 内蒙古农业大学 | A single-screw continuous mixing device for high-viscosity materials and its design method |

Citations (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4211208A (en)* | 1976-12-24 | 1980-07-08 | Deutsche Forschungs- Und Versuchsanstalt Fur Luft- Und Raumfahrt E.V. | Container for a heat storage medium |

| US4546659A (en)* | 1983-04-08 | 1985-10-15 | Her Majesty The Queen In Right Of Canada, As Represented By The Minister Of National Defence | Atmospheric air sample collection device |

| JPH0777484A (en)* | 1993-09-08 | 1995-03-20 | Japan Marine Sci & Technol Center | Automatic water dispenser |

| CN2252781Y (en)* | 1995-08-12 | 1997-04-23 | 夏毅 | Extensible vessel with spring support |

| US6022144A (en)* | 1997-06-30 | 2000-02-08 | Arthur D. Little Enterprises, Inc. | Closure system for pliable container and method and apparatus for producing same |

| US20010037627A1 (en)* | 1997-06-30 | 2001-11-08 | Arthur D. Little Enterprises, Inc. | Closure system for a pliable container |

| CN2511267Y (en)* | 2001-09-20 | 2002-09-18 | 白昌平 | Hot packer |

| US20070073251A1 (en)* | 2003-10-17 | 2007-03-29 | Xing Zhou | Easily retrieved biological specimen pouch |

| US20070277425A1 (en)* | 2006-05-12 | 2007-12-06 | Beck Michael K | Snake trap with extensible structure |

| CN101362339A (en)* | 2008-09-28 | 2009-02-11 | 哈尔滨工业大学 | Extending/folding arms actuated by shape memory alloy springs |

| CN101861253A (en)* | 2007-09-18 | 2010-10-13 | 通用汽车环球科技运作公司 | Active material activated cover |

| US20110197687A1 (en)* | 2010-02-16 | 2011-08-18 | Nextteq, Llc | Device for Fluid Sampling |

| CN102883960A (en)* | 2010-02-16 | 2013-01-16 | 耐斯特科技有限公司 | Containers for fluids with composite agile walls |

| CN105584341A (en)* | 2014-08-19 | 2016-05-18 | 陈时军 | Vehicle shield and vehicle |

| EP3248902A1 (en)* | 2016-05-25 | 2017-11-29 | Erik Krompský | Container with flexible pressure element |

| CN109932805A (en)* | 2019-03-04 | 2019-06-25 | 杭州电子科技大学 | An adaptive support method for large aperture mirrors |

| US20210123654A1 (en)* | 2018-06-23 | 2021-04-29 | Elizabeth Dahnken | Ice Sleeve, Method of Manufacturing, Method of Filling, Kit |

| CN112773583A (en)* | 2017-08-11 | 2021-05-11 | 万能医药公司 | Opening support |

| CN113460480A (en)* | 2021-07-09 | 2021-10-01 | 淮北德昇科技有限公司 | Self-adjusting and temperature-adaptive chemical product packaging bag |

| CN214870565U (en)* | 2020-12-28 | 2021-11-26 | 上海交通大学 | Flexible arm structure based on memory alloy |

- 2021

- 2021-12-27CNCN202111619387.5Apatent/CN114516482A/enactivePending

Patent Citations (20)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4211208A (en)* | 1976-12-24 | 1980-07-08 | Deutsche Forschungs- Und Versuchsanstalt Fur Luft- Und Raumfahrt E.V. | Container for a heat storage medium |

| US4546659A (en)* | 1983-04-08 | 1985-10-15 | Her Majesty The Queen In Right Of Canada, As Represented By The Minister Of National Defence | Atmospheric air sample collection device |

| JPH0777484A (en)* | 1993-09-08 | 1995-03-20 | Japan Marine Sci & Technol Center | Automatic water dispenser |

| CN2252781Y (en)* | 1995-08-12 | 1997-04-23 | 夏毅 | Extensible vessel with spring support |

| US6022144A (en)* | 1997-06-30 | 2000-02-08 | Arthur D. Little Enterprises, Inc. | Closure system for pliable container and method and apparatus for producing same |

| US20010037627A1 (en)* | 1997-06-30 | 2001-11-08 | Arthur D. Little Enterprises, Inc. | Closure system for a pliable container |

| CN2511267Y (en)* | 2001-09-20 | 2002-09-18 | 白昌平 | Hot packer |

| US20070073251A1 (en)* | 2003-10-17 | 2007-03-29 | Xing Zhou | Easily retrieved biological specimen pouch |

| US20070277425A1 (en)* | 2006-05-12 | 2007-12-06 | Beck Michael K | Snake trap with extensible structure |

| CN101861253A (en)* | 2007-09-18 | 2010-10-13 | 通用汽车环球科技运作公司 | Active material activated cover |

| CN101362339A (en)* | 2008-09-28 | 2009-02-11 | 哈尔滨工业大学 | Extending/folding arms actuated by shape memory alloy springs |

| US20110197687A1 (en)* | 2010-02-16 | 2011-08-18 | Nextteq, Llc | Device for Fluid Sampling |

| CN102883960A (en)* | 2010-02-16 | 2013-01-16 | 耐斯特科技有限公司 | Containers for fluids with composite agile walls |

| CN105584341A (en)* | 2014-08-19 | 2016-05-18 | 陈时军 | Vehicle shield and vehicle |

| EP3248902A1 (en)* | 2016-05-25 | 2017-11-29 | Erik Krompský | Container with flexible pressure element |

| CN112773583A (en)* | 2017-08-11 | 2021-05-11 | 万能医药公司 | Opening support |

| US20210123654A1 (en)* | 2018-06-23 | 2021-04-29 | Elizabeth Dahnken | Ice Sleeve, Method of Manufacturing, Method of Filling, Kit |

| CN109932805A (en)* | 2019-03-04 | 2019-06-25 | 杭州电子科技大学 | An adaptive support method for large aperture mirrors |

| CN214870565U (en)* | 2020-12-28 | 2021-11-26 | 上海交通大学 | Flexible arm structure based on memory alloy |

| CN113460480A (en)* | 2021-07-09 | 2021-10-01 | 淮北德昇科技有限公司 | Self-adjusting and temperature-adaptive chemical product packaging bag |

Non-Patent Citations (4)

| Title |

|---|

| 孙晋良著: "《纤维新材料》", 31 August 2007, 上海:上海大学出版社, pages: 439 - 441* |

| 曾光廷: "《现代新型材料》", 30 April 2006, 北京:中国轻工业出版社, pages: 46 - 48* |

| 杨杰,吴月华著: "《形状记忆合金及其应用》", 31 May 1993, 合肥:中国科学技术大学出版社, pages: 208 - 212* |

| 苑伟政,乔大勇,虞益挺著: "《微机电系统 第2版》", 30 June 2021, 西安:西北工业大学出版社, pages: 36 - 39* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116212682A (en)* | 2022-12-28 | 2023-06-06 | 内蒙古农业大学 | A single-screw continuous mixing device for high-viscosity materials and its design method |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP2011505987A5 (en) | ||

| CN114516482A (en) | Application of heat-sensitive spiral spring in flexible filling container | |

| CN2904980Y (en) | A left atrial appendage occluder | |

| CN204394034U (en) | A kind of container that can be out of shape with warming | |

| US2501193A (en) | Combined warmer and sterilizer for bottles and the like | |

| Takaoka et al. | Applications and development of shape-memory and superelastic alloys in Japan | |

| CN105555504A (en) | Packaging material and methods of making and using same | |

| KR100834554B1 (en) | Bidirectional shape memory device and its manufacturing method and thermal insulation product using the same | |

| CN109916213A (en) | A kind of solid-liquid phase change accumulation of heat heating bag | |

| US3519793A (en) | Hair curler | |

| JP2005512656A5 (en) | ||

| CN104257452B (en) | A kind of hot water bag | |

| CN109044046A (en) | An anti-scald cup and its working method | |

| CN206125893U (en) | Hot circulation heating device of instant food | |

| CN209074053U (en) | An anti-scald cup | |

| CN108720596A (en) | A kind of energy automatic takeup constant temperature kettle | |

| CN209644667U (en) | A kind of multi-purpose heating kettle that can be stretched | |

| CN202740201U (en) | Novel electric thermal bag | |

| CN2152518Y (en) | A recyclable heat pack | |

| CN208405406U (en) | A kind of feeding-bottle suction tube ball with anti-scald flow-limiting valve | |

| CN2822458Y (en) | Constant temp milk heater | |

| CN207640163U (en) | An automatic power-off split type heating appliance | |

| CN219721555U (en) | Infusion heater | |

| Jordan | What Smart Metal | |

| CN206295205U (en) | Tubulose intelligence tea bag |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20220520 | |

| RJ01 | Rejection of invention patent application after publication |