CN114502084A - Compressible non-fibrous adjunct - Google Patents

Compressible non-fibrous adjunctDownload PDFInfo

- Publication number

- CN114502084A CN114502084ACN202080064833.8ACN202080064833ACN114502084ACN 114502084 ACN114502084 ACN 114502084ACN 202080064833 ACN202080064833 ACN 202080064833ACN 114502084 ACN114502084 ACN 114502084A

- Authority

- CN

- China

- Prior art keywords

- appendage

- tissue

- appendages

- cartridge

- cells

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Landscapes

- Surgical Instruments (AREA)

- Materials For Medical Uses (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese相关申请的交叉引用CROSS-REFERENCE TO RELATED APPLICATIONS

本申请要求于2019年9月16日提交的名称为“Bioabsorbable Resin forAdditive Manufacturing”的美国临时专利申请62/900,708、于2019年10月10日提交的名称为“Bioabsorbable Resin for Additive Manufacturing”的美国临时专利申请62/913,227和于2020年7月20日提交的名称为“Compressible3D Printed Scaffolds”的美国临时专利申请63/053,863的优先权,这些专利的公开内容全文以引用方式并入本文。This application claims U.S. Provisional Patent Application 62/900,708, filed September 16, 2019, entitled "Bioabsorbable Resin for Additive Manufacturing," and U.S. Provisional Patent Application 62/900,708, filed October 10, 2019, entitled "Bioabsorbable Resin for Additive Manufacturing." Priority to patent application 62/913,227 and US Provisional Patent Application 63/053,863, filed July 20, 2020, entitled "Compressible 3D Printed Scaffolds," the disclosures of which are incorporated herein by reference in their entirety.

技术领域technical field

提供了可压缩的非纤维附属物以及制造和使用该可压缩的非纤维附属物的方法。Compressible non-fibrous appendages and methods of making and using the compressible non-fibrous appendages are provided.

背景技术Background technique

外科缝合器用于外科手术中,以闭合在特定手术中所涉及的组织、血管、导管、分流管、或者其他物体或身体部分中的开口。这些开口可为天然存在的,诸如血管或类似于胃的内部器官中的通路,或者它们可为在外科手术期间由外科医生形成的,诸如通过穿刺组织或血管以形成旁路或吻合部或通过在缝合手术期间切割组织。Surgical staplers are used in surgical procedures to close openings in tissue, blood vessels, catheters, shunts, or other objects or body parts involved in a particular procedure. These openings may be naturally occurring, such as passages in blood vessels or internal organs like the stomach, or they may be created by the surgeon during surgical procedures, such as by puncturing tissue or blood vessels to create bypasses or anastomosis or through Tissue is cut during the suturing procedure.

一些外科缝合器需要外科医生为正被缝合的组织选择具有适当钉高度的适当钉。例如,外科医生可选择用于厚组织的长钉和用于薄组织的短钉。然而,在一些情况下,被缝合的组织不具有一致的厚度,因此钉不能在每个钉部位处实现期望的击发构型。因此,不能在所有缝合部位处或附近都形成期望的密封,从而允许血液、空气、胃肠液和其他流体通过未密封部位渗出。Some surgical staplers require the surgeon to select the appropriate staples with the appropriate staple height for the tissue being stapled. For example, a surgeon may choose long staples for thick tissue and short staples for thin tissue. However, in some cases, the tissue being stapled does not have a consistent thickness, so the staples cannot achieve the desired firing configuration at each staple site. As a result, the desired seal cannot be formed at or near all suture sites, allowing blood, air, gastrointestinal fluids, and other fluids to seep through the unsealed site.

另外,作为凹陷通道的钉与可结合类似于缝合的手术来植入的其他物体和材料一样,通常缺乏它们所植入的组织的一些特性。例如,钉以及其他物体和材料可缺乏它们所植入的组织的天然柔韧性,因此不能承受植入部位处的组织内压力不同。这会导致在缝合部位处或附近的不期望的组织撕裂,并因此导致渗漏。In addition, staples that are recessed channels, like other objects and materials that can be implanted in conjunction with suturing-like procedures, typically lack some of the properties of the tissue in which they are implanted. For example, staples and other objects and materials may lack the natural flexibility of the tissue in which they are implanted and therefore cannot withstand varying intra-tissue pressures at the implant site. This can lead to undesired tearing of tissue at or near the suture site, and thus to leakage.

因此,仍然需要用于解决外科缝合器的当前问题的改进的器械和方法。Accordingly, there remains a need for improved instruments and methods for addressing current problems with surgical staplers.

发明内容SUMMARY OF THE INVENTION

还提供了与外科缝合器一起使用的缝合组件。在一个示例性实施方案中,缝合组件包括具有设置在其中的多个钉的仓和非纤维附属物,该多个钉被构造成能够被部署到组织中,并且该非纤维附属物由至少一种熔融的可生物吸收聚合物形成,并且被构造成能够被可释放地保持在仓上,使得该附属物可通过仓中的该多个钉附接到组织,该附属物由多个重复互连的单元格形成,在该多个单元格之间形成有中空管状互连件,每个单元格具有限定内部体积的内表面,其中中空管状互连件允许单元格的内部体积流体连通,以促进附属物内加速的组织向内生长。Suture assemblies for use with surgical staplers are also provided. In an exemplary embodiment, a suturing assembly includes a cartridge having a plurality of staples disposed therein and a non-fibrous appendage configured to be deployable into tissue, and the non-fibrous appendage is comprised of at least one is formed of a molten bioabsorbable polymer and is configured to be releasably retained on the cartridge such that the appendage can be attached to tissue by the plurality of staples in the cartridge, the appendage being formed by a plurality of repeating interactions. Connected cells are formed with hollow tubular interconnects formed between the plurality of cells, each cell having an inner surface defining an interior volume, wherein the hollow tubular interconnects allow the interior volumes of the cells to be in fluid communication to Promotes accelerated tissue ingrowth within appendages.

在一些实施方案中,每个中空管状互连件可限定具有直径为100微米至3500微米的开口。In some embodiments, each hollow tubular interconnect can define an opening having a diameter of 100 microns to 3500 microns.

该多个重复单元格可具有多种构型。例如,在一些实施方案中,该多个重复单元格可包括三重周期性最小表面结构。在其他实施方案中,该多个重复单元格可包括Schwarz-P结构。在某些实施方案中,该多个重复单元格可包括调整的Schwarz-P结构。在其他实施方案中,在附属物处于组织部署状态时,中空互连件的至少一部分可至少部分地保持单元格的内部体积的至少一部分之间的流体连通,从而促进整个附属物中的细胞移动性。在某些实施方案中,每个单元格可具有0.1mm至0.3mm的壁厚。在其他实施方案中,每个单元格的表面与体积比可以是7至20。The plurality of repeating cells can have various configurations. For example, in some embodiments, the plurality of repeating cells can include a triple periodic minimal surface structure. In other embodiments, the plurality of repeating cells can comprise a Schwarz-P structure. In certain embodiments, the plurality of repeating cells can comprise an adjusted Schwarz-P structure. In other embodiments, at least a portion of the hollow interconnect can at least partially maintain fluid communication between at least a portion of the interior volume of the cells when the appendage is in a tissue-deployed state, thereby facilitating cell movement throughout the appendage sex. In certain embodiments, each cell may have a wall thickness of 0.1 mm to 0.3 mm. In other embodiments, the surface to volume ratio of each cell may be 7 to 20.

在一些实施方案中,该附属物在处于30kPa至90kPa范围内的施加应力下时可被构造成能够经历0.1至0.9范围内的应变。在某些实施方案中,该应变可处于0.1至0.7的范围内。In some embodiments, the appendage may be configured to experience a strain in the range of 0.1 to 0.9 when under an applied stress in the range of 30 kPa to 90 kPa. In certain embodiments, the strain may be in the range of 0.1 to 0.7.

在另一示例性实施方案中,缝合组件包括具有设置在其中的多个钉的仓和非纤维附属物,该多个钉被构造成能够被部署到组织中,并且该非纤维附属物由至少一种熔融的可生物吸收聚合物形成,并且被构造成能够被可释放地保持在仓上,使得该附属物可通过该仓中的该多个钉附接到组织,该附属物由互连的多个重复的中空单元格形成,使得在附属物单元格之间形成内腔,从而在附属物单元格之间产生通道,使得在所述附属物内存在通道的连续网络以允许一种或多种流体在附属物处于组织部署状态时进入和转移到整体该附属物。In another exemplary embodiment, a suturing assembly includes a cartridge having a plurality of staples disposed therein and a non-fibrous appendage, the plurality of staples being configured to be deployable into tissue, and the non-fibrous appendage consisting of at least A molten bioabsorbable polymer is formed and is configured to be releasably retained on a cartridge such that the appendages can be attached to tissue by the plurality of staples in the cartridge, the appendages being interconnected by Multiple repeating hollow cells are formed such that lumens are formed between the appendage cells, thereby creating channels between the appendage cells, such that a continuous network of channels exists within the appendages to allow for one or Various fluids enter and transfer to the entire appendage when the appendage is in a tissue-deployed state.

在一些实施方案中,每个内腔可具有100微米至3500微米的直径。In some embodiments, each lumen can have a diameter of 100 microns to 3500 microns.

该多个重复单元格可具有多种构型。例如,在一些实施方案中,该多个重复单元格可包括三重周期性最小表面结构。在其他实施方案中,该多个重复单元格可包括Schwarz-P结构。在某些实施方案中,每个单元格可具有0.1mm至0.3mm的壁厚。在其他实施方案中,每个单元格的表面与体积比可以是7至20。The plurality of repeating cells can have various configurations. For example, in some embodiments, the plurality of repeating cells can include a triple periodic minimal surface structure. In other embodiments, the plurality of repeating cells can comprise a Schwarz-P structure. In certain embodiments, each cell may have a wall thickness of 0.1 mm to 0.3 mm. In other embodiments, the surface to volume ratio of each cell may be 7 to 20.

在一些实施方案中,内腔的至少一部分可被构造成能够在附属物处于组织部署状态时至少部分地维持通道,从而促进整个附属物中的细胞移动性。In some embodiments, at least a portion of the lumen can be configured to at least partially maintain the channel when the appendage is in a tissue-deployed state, thereby promoting cell mobility throughout the appendage.

附图说明Description of drawings

通过以下结合附图所作的详细描述,将更充分地理解本发明,在附图中:The present invention will be more fully understood from the following detailed description in conjunction with the accompanying drawings, in which:

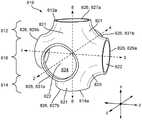

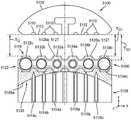

图1为常规外科缝合和切断器械的一个示例性实施方案的透视图;1 is a perspective view of an exemplary embodiment of a conventional surgical stapling and severing instrument;

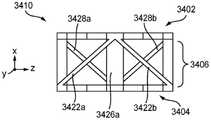

图2A为与图1的外科缝合和切断器械一起使用的钉仓的顶视图;2A is a top view of a staple cartridge for use with the surgical stapling and severing instrument of FIG. 1;

图2B为图2A的钉仓的侧视图;Figure 2B is a side view of the staple cartridge of Figure 2A;

图2C为图2A的钉仓的组织接触表面的一部分的透视图;Figure 2C is a perspective view of a portion of the tissue contacting surface of the staple cartridge of Figure 2A;

图3为可设置在图4的外科仓组件的钉仓内处于未击发(预部署)构型的钉的侧视图;3 is a side view of staples that may be disposed within the staple cartridge of the surgical cartridge assembly of FIG. 4 in an unfired (pre-deployed) configuration;

图4为图1的外科缝合和切断器械的刀和击发杆(“E形梁”)的透视图;Figure 4 is a perspective view of the knife and firing rod ("E-beam") of the surgical stapling and severing instrument of Figure 1;

图5为图1的外科缝合和切断器械的钉仓的楔形滑动件的透视图;5 is a perspective view of a wedge slide of the staple cartridge of the surgical stapling and severing instrument of FIG. 1;

图6A为具有附接到钉仓的顶表面或平台表面的可压缩非纤维附属物的外科仓组件的示例性实施方案的纵向剖面图;6A is a longitudinal cross-sectional view of an exemplary embodiment of a surgical cartridge assembly having compressible non-fibrous appendages attached to a top or platform surface of the staple cartridge;

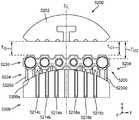

图6B为外科端部执行器的纵向剖面图,该外科端部执行器具有可枢转地联接到细长钉通道的砧座和图6A的设置在细长钉通道内并且联接到该细长钉通道的外科仓组件,该图示出了处于砧座与附属物之间没有任何组织的闭合位置的砧座;6B is a longitudinal cross-sectional view of a surgical end effector having an anvil pivotally coupled to an elongated staple channel and of FIG. 6A disposed within the elongated staple channel and coupled to the elongated staple channel. a surgical cartridge assembly for a staple channel, the figure showing the anvil in a closed position without any tissue between the anvil and the appendage;

图7为示出图6A至图6B的处于组织部署条件下的附属物的部分示意图;7 is a partial schematic diagram illustrating the appendage of FIGS. 6A-6B in a tissue-deployed condition;

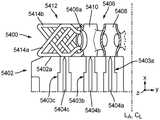

图8A为是可压缩非纤维附属物的另一示例性实施方案的透视图;8A is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage;

图8B为图8A的附属物的侧视图;Figure 8B is a side view of the appendage of Figure 8A;

图8C为图8A的附属物的顶视图;Figure 8C is a top view of the appendage of Figure 8A;

图8D为图8C的附属物在线8D-8D处截取的剖面图;8D is a cross-sectional view of the appendage of FIG. 8C taken at

图8E为图8C的附属物在线8E-8E处截取的剖面图;8E is a cross-sectional view of the appendage of FIG. 8C taken at

图8F为图8C的附属物的一部分在8F处截取的放大图;Figure 8F is an enlarged view of a portion of the appendage of Figure 8C taken at 8F;

图8G为示出图8A的处于组织部署状态的附属物的局部示意图;8G is a partial schematic diagram illustrating the appendage of FIG. 8A in a tissue-deployed state;

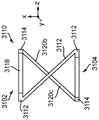

图9A为图8A的附属物的单个单元格的侧视图;Figure 9A is a side view of a single cell of the appendage of Figure 8A;

图9B为图9A的单个单元格的透视图;Figure 9B is a perspective view of the single cell of Figure 9A;

图10A为处于预压缩状态的示例性单元格的示意图;10A is a schematic diagram of an exemplary cell in a pre-compressed state;

图10B为图10A的处于第一压缩状态的单元格的示意图;FIG. 10B is a schematic diagram of the cell of FIG. 10A in a first compressed state;

图10C为图10A的处于第二压缩状态的单元格的示意图;FIG. 10C is a schematic diagram of the cell of FIG. 10A in a second compressed state;

图10D为图10A的处于致密状态的单元格的示意图;10D is a schematic diagram of the cell of FIG. 10A in a densified state;

图11为图10A至图10D的单元格的状态与所得可压缩非纤维附属物的应力-应变曲线之间的关系的示意图;11 is a schematic diagram of the relationship between the state of the cells of FIGS. 10A-10D and the stress-strain curves of the resulting compressible non-fibrous appendages;

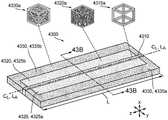

图12A为由调整的Schwarz-P结构的实施方案的重复单元格形成的可压缩非纤维附属物的示例性实施方案的顶视图;12A is a top view of an exemplary embodiment of a compressible non-fibrous appendage formed from repeating cells of an embodiment of the adjusted Schwarz-P structure;

图12B为由调整的Schwarz-P结构的另一实施方案的重复单元格形成的可压缩非纤维附属物的示例性实施方案的顶视图;12B is a top view of an exemplary embodiment of a compressible non-fibrous appendage formed from repeating cells of another embodiment of the tuned Schwarz-P structure;

图12C为由调整的Schwarz-P结构的另一实施方案的重复单元格形成的可压缩非纤维附属物的示例性实施方案的顶视图;Figure 12C is a top view of an exemplary embodiment of a compressible non-fibrous appendage formed from repeating cells of another embodiment of the tuned Schwarz-P structure;

图12D为由调整的Schwarz-P结构的另一实施方案的重复单元格形成的可压缩非纤维附属物的示例性实施方案的顶视图;12D is a top view of an exemplary embodiment of a compressible non-fibrous appendage formed from repeating cells of another embodiment of the tuned Schwarz-P structure;

图13A为单个单元格的另一示例性实施方案的透视图;13A is a perspective view of another exemplary embodiment of a single cell;

图13B为由图13A的重复单元格形成的可压缩非纤维附属物的示例性实施方案的俯视图;Figure 13B is a top view of an exemplary embodiment of a compressible non-fibrous appendage formed from the repeating cells of Figure 13A;

图14A为单个单元格的另一示例性实施方案的透视图;Figure 14A is a perspective view of another exemplary embodiment of a single cell;

图14B为由图14A的重复单元格形成的可压缩非纤维附属物的示例性实施方案的俯视图;Figure 14B is a top view of an exemplary embodiment of a compressible non-fibrous appendage formed from the repeating cells of Figure 14A;

图15A为单个单元格的另一示例性实施方案的透视图;Figure 15A is a perspective view of another exemplary embodiment of a single cell;

图15B为由图15A的重复单元格形成的可压缩非纤维附属物的示例性实施方案的俯视图;Figure 15B is a top view of an exemplary embodiment of a compressible non-fibrous appendage formed from the repeating cells of Figure 15A;

图16A为单个单元格的另一示例性实施方案的透视图;Figure 16A is a perspective view of another exemplary embodiment of a single cell;

图16B为由图16A的重复单元格形成的可压缩非纤维附属物的示例性实施方案的俯视图;Figure 16B is a top view of an exemplary embodiment of a compressible non-fibrous appendage formed from the repeating cells of Figure 16A;

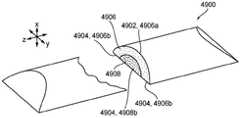

图17A为可压缩非纤维附属物的另一示例性实施方案的透视图;17A is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage;

图17B为图17A的附属物在线17B-17B处截取的剖面图;17B is a cross-sectional view of the appendage of FIG. 17A taken at

图17C为图17A的附属物在线17C-17C处截取的剖面图;17C is a cross-sectional view of the appendage of FIG. 17A taken at

图18为设置在钉仓上的可压缩非纤维附属物的另一示例性实施方案的透视图;18 is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage disposed on a staple cartridge;

图19A为具有通道附接件的可压缩非纤维附属物的另一示例性实施方案的透视图;19A is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage with channel attachments;

图19B为图19A的附属物在线19B-19B处截取的剖面图;Figure 19B is a cross-sectional view of the appendage of Figure 19A taken at

图20为具有通道附接件的可压缩非纤维附属物的另一示例性实施方案的局部透视图;20 is a partial perspective view of another exemplary embodiment of a compressible non-fibrous appendage with channel attachments;

图21为具有通道附接件的可压缩非纤维附属物的另一示例性实施方案的局部透视图;21 is a partial perspective view of another exemplary embodiment of a compressible non-fibrous appendage with channel attachments;

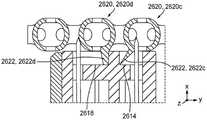

图22A为缝合组件的示例性实施方案的局部分解透视图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物,每个可压缩非纤维附属物具有对应的边缘附接特征部;22A is a partially exploded perspective view of an exemplary embodiment of a suturing assembly having compressible non-fibrous appendages releasably retained on a staple cartridge, each compressible non-fibrous appendage having a corresponding edge attachment feature;

图22B为缝合组件的一部分在线22B至22B处截取的放大剖面图,示出了在接合之前的两个边缘附接特征部;22B is an enlarged cross-sectional view of a portion of the suture assembly taken at

图22C为图22B的缝合组件的一部分的剖面图,示出了接合的两个边缘附接特征部;Figure 22C is a cross-sectional view of a portion of the suture assembly of Figure 22B showing two edge attachment features joined;

图23A为缝合组件的另一示例性实施方案的透视图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物,每个可压缩非纤维附属物具有对应的边缘附接特征部,该图示出了接合的边缘附接特征部;23A is a perspective view of another exemplary embodiment of a suturing assembly having compressible non-fibrous appendages releasably retained on a staple cartridge, each compressible non-fibrous appendage having a corresponding edge attachment a feature, the figure showing the engaged edge attachment feature;

图23B为图23B的缝合组件的一部分的放大图;Figure 23B is an enlarged view of a portion of the suturing assembly of Figure 23B;

图24为具有端部附接特征部的钉仓的另一示例性实施方案的透视图;24 is a perspective view of another exemplary embodiment of a staple cartridge having end attachment features;

图25为具有端部附接特征部的钉仓的另一示例性实施方案的透视图;25 is a perspective view of another exemplary embodiment of a staple cartridge having end attachment features;

图26A为具有钉仓和可压缩非纤维附属物的缝合组件的另一示例性实施方案的分解图,其中附接特征部可释放地保持在可压缩非纤维附属物上;26A is an exploded view of another exemplary embodiment of a suturing assembly having a staple cartridge and compressible non-fibrous appendages with attachment features releasably retained on the compressible non-fibrous appendages;

图26B为图26A的缝合组件在线26B-26B处截取的剖面图;26B is a cross-sectional view of the suture assembly of FIG. 26A taken at

图26C为图26A的缝合组件在线26C-26C处截取的剖面图;Figure 26C is a cross-sectional view of the suture assembly of Figure 26A taken at

图27为缝合组件的另一示例性实施方案的局部剖面图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物;27 is a partial cross-sectional view of another exemplary embodiment of a suturing assembly having compressible non-fibrous appendages releasably retained on a staple cartridge;

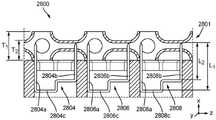

图28A为缝合组件的另一示例性实施方案的局部剖面图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物;28A is a partial cross-sectional view of another exemplary embodiment of a suturing assembly having compressible non-fibrous appendages releasably retained on a staple cartridge;

图28B为示出图28A的处于组织部署条件下的附属物的局部示意图;FIG. 28B is a partial schematic diagram illustrating the appendage of FIG. 28A in a tissue-deployed condition;

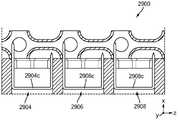

图29为缝合组件的另一示例性实施方案的局部剖面图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物;29 is a partial cross-sectional view of another exemplary embodiment of a suturing assembly having compressible non-fibrous appendages releasably retained on a staple cartridge;

图30A为可压缩非纤维附属物的另一示例性实施方案的透视图;30A is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage;

图30B为图30A的附属物的前平面图;Figure 30B is a front plan view of the appendage of Figure 30A;

图31A为可压缩非纤维附属物的一个实施方案的透视图;Figure 31A is a perspective view of one embodiment of a compressible non-fibrous appendage;

图31B为图31A的附属物的单个单元格的透视图;Figure 31B is a perspective view of a single cell of the appendage of Figure 31A;

图31C为图31B的单元格的侧视图;Figure 31C is a side view of the cell of Figure 31B;

图31D为图31B至图31C的单元格的替代侧视图;Figure 31D is an alternate side view of the cell of Figures 31B-31C;

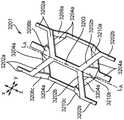

图32A为可压缩非纤维附属物的另一示例性实施方案的透视图;32A is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage;

图32B为图32A的附属物的单个单元格的透视图;Figure 32B is a perspective view of a single cell of the appendage of Figure 32A;

图32C为图32B的单元格的侧视图;Figure 32C is a side view of the cell of Figure 32B;

图32D为图32B至图32C的单元格沿着图32C的线32D-32D截取处的截面顶视图;Figure 32D is a cross-sectional top view of the cell of Figures 32B-32C taken along

图33A为可压缩非纤维附属物的另一示例性实施方案的透视图;33A is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage;

图33B为图33A的附属物的单个单元格的透视图;Figure 33B is a perspective view of a single cell of the appendage of Figure 33A;

图33C为图33B的单元格的侧视图;Figure 33C is a side view of the cell of Figure 33B;

图33D为图33B至图33C的单元格沿着图33C的线33D-33D截取处的截面顶视图;Figure 33D is a cross-sectional top view of the cell of Figures 33B-33C taken along

图33E为图33B至图33C的单元格的替代侧视图;Figure 33E is an alternate side view of the cell of Figures 33B-33C;

图34A为可压缩非纤维附属物的另一示例性实施方案的透视图;34A is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage;

图34B为图34A的附属物的单个单元格的透视图;Figure 34B is a perspective view of a single cell of the appendage of Figure 34A;

图34C为图34B的单元格的侧视图;Figure 34C is a side view of the cell of Figure 34B;

图34D为图34B至图34C的单元格的顶视图;Figure 34D is a top view of the cell of Figures 34B-34C;

图34E为图34B至图34C的单元格的替代侧视图;Figure 34E is an alternate side view of the cell of Figures 34B-34C;

图35为单元格的另一示例性实施方案的透视图;Figure 35 is a perspective view of another exemplary embodiment of a cell;

图36为单元格的另一示例性实施方案的透视图;Figure 36 is a perspective view of another exemplary embodiment of a cell;

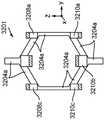

图37A为具有钉仓和可压缩非纤维附属物的缝合组件的另一示例性实施方案的局部分解透视图;37A is a partially exploded perspective view of another exemplary embodiment of a suturing assembly having a staple cartridge and compressible non-fibrous appendages;

图37B为图37A的缝合组件的一部分在线37B-37B处截取的剖面图;37B is a cross-sectional view of a portion of the suture assembly of FIG. 37A taken at

图38A为图37B的缝合组件的一部分的示意图,示出了设置到附属物上的组织;Fig. 38A is a schematic view of a portion of the suturing assembly of Fig. 37B showing tissue disposed on an appendage;

图38B为示出图37A的处于组织部署条件下的附属物的局部示意图;Fig. 38B is a partial schematic view showing the appendage of Fig. 37A in a tissue-deployed condition;

图39A为具有钉仓和附属物的缝合组件的示例性实施方案的分解图,其中仅示出了附属物的第二外层;39A is an exploded view of an exemplary embodiment of a suturing assembly with a staple cartridge and appendages, wherein only the second outer layer of the appendages is shown;

图39B为图39A的缝合组件的前视图;Figure 39B is a front view of the suturing assembly of Figure 39A;

图40为缝合组件的另一示例性实施方案的透视图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物;40 is a perspective view of another exemplary embodiment of a suturing assembly having compressible non-fibrous appendages releasably retained on a staple cartridge;

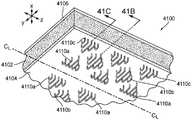

图41A为可压缩非纤维附属物的另一示例性实施方案的透视图;41A is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage;

图41B为图41A的在线41B-41B处截取并且可释放地保持在钉仓上的附属物的一部分的剖面图;41B is a cross-sectional view of a portion of the appendage of FIG. 41A taken at

图41C为图41A的在线41C-41C处截取并且可释放地保持在钉仓上的附属物的一部分的剖面图;41C is a cross-sectional view of a portion of the appendage of FIG. 41A taken at

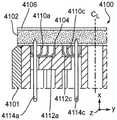

图42A为可压缩非纤维附属物的另一示例性实施方案的透视图;42A is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage;

图42B为示出图42A的处于组织部署条件下的附属物的局部示意图;FIG. 42B is a partial schematic diagram illustrating the appendage of FIG. 42A in a tissue-deployed condition;

图43A为可压缩非纤维附属物的另一示例性实施方案的透视图;43A is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage;

图43B为图43A的附属物在线43B-43B处截取的剖面图;Figure 43B is a cross-sectional view of the appendage of Figure 43A taken at

图44A为可压缩非纤维附属物的另一示例性实施方案的剖面图,仅示出了附属物的一部分被可释放地保持在钉仓上;44A is a cross-sectional view of another exemplary embodiment of a compressible non-fibrous appendage showing only a portion of the appendage being releasably retained on the staple cartridge;

图44B为示出被夹持在砧座与图44A的附属物的一部分之间的组织的局部示意图,其中钉从钉仓部分地部署通过附属物;44B is a partial schematic view showing tissue clamped between the anvil and a portion of the appendage of FIG. 44A with staples partially deployed from the staple cartridge through the appendage;

图44C为示出图44A的处于组织部署条件下的附属物的局部示意图;Figure 44C is a partial schematic diagram showing the appendage of Figure 44A in a tissue deployment condition;

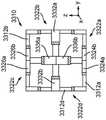

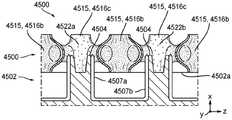

图45A为缝合组件的另一示例性实施方案的局部分解透视图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物;45A is a partially exploded perspective view of another exemplary embodiment of a suturing assembly having compressible non-fibrous appendages releasably retained on a staple cartridge;

图45B为图45A的缝合组件的一部分的俯视图;Figure 45B is a top view of a portion of the suture assembly of Figure 45A;

图45C为图45B的缝合组件在线45C-45C处截取的剖面图;Figure 45C is a cross-sectional view of the suture assembly of Figure 45B taken at

图46A为具有可释放地保持在钉仓上的可压缩非纤维附属物的缝合组件的一部分的另一示例性实施方案的透视图;46A is a perspective view of another exemplary embodiment of a portion of a suture assembly having compressible non-fibrous appendages releasably retained on a staple cartridge;

图46B为图46A的缝合组件的一部分的俯视图;Figure 46B is a top view of a portion of the suturing assembly of Figure 46A;

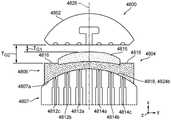

图47A为具有砧座和缝合组件的外科端部执行器的示例性实施方案的剖面前视图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物,该图示出了处于砧座与缝合组件之间没有组织定位的闭合位置的外科端部执行器;47A is a cross-sectional front view of an exemplary embodiment of a surgical end effector having an anvil and a stapling assembly with compressible non-fibrous appendages releasably retained on a staple cartridge, showing a surgical end effector in a closed position with no tissue positioning between the anvil and the stapling assembly;

图47B为图47A的外科端部执行器的剖面前视图,示出了夹持在砧座与缝合组件之间并且缝合到可压缩非纤维附属物之间的组织;47B is a cutaway front view of the surgical end effector of FIG. 47A showing tissue clamped between the anvil and the stapling assembly and stapled between the compressible non-fibrous appendages;

图47C为图47A的仅缝合组件的剖面前视图;Figure 47C is a cross-sectional front view of the suture-only assembly of Figure 47A;

图48A为具有砧座和缝合组件的外科端部执行器的另一示例性实施方案的横截面前视图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物,该图示出了处于砧座与缝合组件之间没有组织定位的闭合位置的外科端部执行器;Figure 48A is a cross-sectional front view of another exemplary embodiment of a surgical end effector having an anvil and a stapling assembly with compressible non-fibrous appendages releasably retained on a staple cartridge, the figure showing the surgical end effector in a closed position with no tissue positioning between the anvil and the stapling assembly;

图48B为图48A的外科端部执行器的横截面前视图,示出了夹持在砧座与缝合组件之间并且缝合到可压缩非纤维附属物之间的组织;Figure 48B is a cross-sectional front view of the surgical end effector of Figure 48A, showing tissue clamped between the anvil and the stapling assembly and stapled between the compressible non-fibrous appendages;

图48C为图48A的仅缝合组件的剖面前视图;Figure 48C is a cross-sectional front view of the suture-only assembly of Figure 48A;

图49为可压缩非纤维附属物的另一示例性实施方案的透视图;Figure 49 is a perspective view of another exemplary embodiment of a compressible non-fibrous appendage;

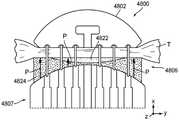

图50A为具有砧座和缝合组件的外科端部执行器的示例性实施方案的侧视图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物,该图示出了处于砧座与缝合组件之间没有组织定位的闭合位置的外科端部执行器;50A is a side view of an exemplary embodiment of a surgical end effector having an anvil and a stapling assembly with compressible non-fibrous appendages releasably retained on a staple cartridge, shown in a surgical end effector in a closed position without tissue positioning between the anvil and the stapling assembly;

图50B为图50A的外科端部执行器的侧视图,示出了夹持在砧座与缝合组件之间的组织;Figure 50B is a side view of the surgical end effector of Figure 50A showing tissue clamped between the anvil and the stapling assembly;

图50C为图50A的仅缝合组件的侧视图;Figure 50C is a side view of the suture only assembly of Figure 50A;

图51A为具有砧座和缝合组件的外科端部执行器的另一示例性实施方案的横截面前视图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物,该图示出了处于砧座与缝合组件之间没有组织定位的闭合位置的外科端部执行器;51A is a cross-sectional front view of another exemplary embodiment of a surgical end effector having an anvil and a stapling assembly having compressible non-fibrous appendages releasably retained on a staple cartridge, the figure showing the surgical end effector in a closed position with no tissue positioning between the anvil and the stapling assembly;

图51B为图51A的仅可压缩非纤维附属物的剖面前视图;Figure 51B is a cross-sectional front view of the compressible only non-fibrous appendage of Figure 51A;

图52A为具有砧座和缝合组件的外科端部执行器的另一示例性实施方案的横截面前视图,该缝合组件具有可释放地保持在钉仓上的可压缩非纤维附属物,该图示出了处于砧座与缝合组件之间没有组织定位的闭合位置的外科端部执行器;Figure 52A is a cross-sectional front view of another exemplary embodiment of a surgical end effector having an anvil and a stapling assembly with compressible non-fibrous appendages releasably retained on a staple cartridge, the figure showing the surgical end effector in a closed position with no tissue positioning between the anvil and the stapling assembly;

图52B为图52A的仅缝合组件的一部分的剖面前视放大图;Figure 52B is an enlarged cross-sectional front view of only a portion of the suture assembly of Figure 52A;

图53为可释放地保持在钉仓上的可压缩非纤维附属物的另一示例性实施方案的一部分的剖面图;53 is a cross-sectional view of a portion of another exemplary embodiment of a compressible non-fibrous appendage releasably retained on a staple cartridge;

图54为可释放地保持在钉仓上的可压缩非纤维附属物的另一示例性实施方案的一部分的剖面图,仅示出了来自钉仓的三个钉排的三个钉;54 is a cross-sectional view of a portion of another exemplary embodiment of a compressible non-fibrous appendage releasably retained on a staple cartridge, showing only three staples from three staple rows of the staple cartridge;

图55为图54的附属物在三个钉中的每一个钉处的应力-应变曲线的示意图;Fig. 55 is a schematic diagram of the stress-strain curve of the appendage of Fig. 54 at each of the three pegs;

图56为示出示例9和示例10的示例性可压缩非纤维附属物(附属物1)的应力-应变曲线的图;56 is a graph showing stress-strain curves for an exemplary compressible non-fibrous appendage (Appendix 1 ) of Examples 9 and 10;

图57为示出示例9和示例10的示例性可压缩非纤维附属物(附属物2-5)的应力-应变曲线的图;并且57 is a graph showing stress-strain curves for exemplary compressible non-fibrous appendages (Appendages 2-5) of Examples 9 and 10; and

图58为示出示例11的可压缩非纤维附属物的六个示例性实施方案的应力-应变曲线的图。58 is a graph showing stress-strain curves for six exemplary embodiments of the compressible non-fibrous appendage of Example 11. FIG.

具体实施方式Detailed ways

现在将描述某些示例性实施方案,以得到对本文所公开的附属物、系统和方法的结构、功能、制造和使用的原理的全面理解。这些实施方案的一个或多个示例在附图中示出。本领域的技术人员将会理解,在本文中具体描述的和在附图中示出的附属物、系统和方法是非限制性的示例性实施方案,并且本发明的范围仅由权利要求书限定。结合一个示例性实施方案示出或描述的特征部可与其它实施方案的特征部进行组合。此类修改和变型旨在包括在本发明的范围之内。Certain exemplary embodiments will now be described in order to gain a thorough understanding of the principles of structure, function, manufacture, and use of the appendages, systems and methods disclosed herein. One or more examples of these embodiments are illustrated in the accompanying drawings. Those skilled in the art will understand that the appendices, systems and methods specifically described herein and illustrated in the accompanying drawings are non-limiting exemplary embodiments and that the scope of the present invention is limited only by the claims. Features shown or described in connection with one exemplary embodiment may be combined with features of other embodiments. Such modifications and variations are intended to be included within the scope of the present invention.

提供了外科缝合组件及其制造和使用该外科缝合组件的方法。通常,外科缝合组件可包括钉仓,该钉仓具有设置在其中的钉和被构造成能够被可释放地保持在该钉仓上的可压缩的可生物吸收的非纤维附属物。在一些实施方案中,非纤维附属物可由包括至少一种熔融可生物吸收聚合物的基质形成,并且因此该非纤维附属物可以是三维打印的。在其他实施方案中,非纤维附属物可通过任何合适的非增材制造工艺(诸如,如本领域的技术人员所理解的注塑、发泡和成型工艺)部分或完全地形成。如本文所讨论的,多种附属物可被构造成能够补偿组织特性的变化(诸如组织厚度的变化),以及/或者当将该附属物缝合到组织上时促进组织向内生长。例如,附属物可被构造成能够使得该附属物在处于约30kPa至90kPa范围内的施加应力下时经历约0.1(10%变形)至0.9(变形90%)范围内的应变。也就是说,当本文所述的附属物处于介于(和/或包括)约30kPa至90kPa之间的应力下时,例如,当该附属物处于组织部署状态时,该附属物可被构造成能够发生从约10%至90%的变形。Surgical stapling assemblies and methods of making and using the same are provided. Generally, a surgical stapling assembly may include a staple cartridge having staples disposed therein and compressible bioabsorbable non-fibrous appendages configured to be releasably retained on the staple cartridge. In some embodiments, the non-fibrous appendages can be formed from a matrix comprising at least one fused bioabsorbable polymer, and thus the non-fibrous appendages can be three-dimensionally printed. In other embodiments, the non-fibrous appendages may be partially or fully formed by any suitable non-additive manufacturing process, such as injection molding, foaming, and molding processes as understood by those skilled in the art. As discussed herein, various appendages can be configured to compensate for changes in tissue properties, such as changes in tissue thickness, and/or to promote tissue ingrowth when the appendage is sutured to tissue. For example, the appendage may be configured such that the appendage experiences a strain in the range of about 0.1 (10% deformation) to 0.9 (90% deformation) when under an applied stress in the range of about 30 kPa to 90 kPa. That is, when the appendages described herein are under stress between (and/or including) about 30 kPa to 90 kPa, for example, when the appendage is in a tissue deployed state, the appendage can be configured to Deformation from about 10% to 90% can occur.

示例性缝合组件可包括各种特征部以促进外科钉的施用,如本文所述和附图中所示。然而,本领域技术人员将会知道,缝合组件可以仅仅包括这些特征部中的一些和/或其可以包括本领域已知的多个其它特征部。本文所述的缝合组件仅仅旨在表示某些示例性实施方案。此外,虽然附属物结合外科钉仓组件进行描述,但是附属物可结合不是基于钉仓的钉再装载器或任何类型的外科器械使用。Exemplary stapling assemblies may include various features to facilitate application of surgical staples, as described herein and shown in the accompanying drawings. However, those skilled in the art will appreciate that the suture assembly may include only some of these features and/or it may include various other features known in the art. The suture assemblies described herein are intended to represent only certain exemplary embodiments. Additionally, although the appendage is described in conjunction with a surgical staple cartridge assembly, the appendage may be used in conjunction with a staple reloader or any type of surgical instrument that is not based on a staple cartridge.

图1示出了适于与可植入附属物一起使用的示例性外科缝合和切断装置100。所例示的外科缝合和切断装置100包括钉施用组件106或端部执行器,该钉施用组件或端部执行器具有可枢转地联接到细长钉通道104的砧座102。因此,钉施用组件106可在打开位置(如图1所示)与闭合位置之间运动,其中砧座102邻近细长钉通道104而定位以接合其间的组织。钉施用组件106可在其近侧端部处附接到形成工具部分110的细长轴108。当钉施用组件106闭合或至少基本上闭合时(例如,砧座102从图1中的打开位置朝向细长钉通道运动),工具部分110可呈现足够小的适于将钉施用组件106插入通过套管针的横截面。虽然装置100被构造成能够缝合和切断组织,但是本文也考虑了被构造成能够缝合但不切断组织的外科装置。Figure 1 shows an exemplary surgical stapling and severing

在各种情况下,钉施用组件106可由连接到细长轴108的柄部112操纵。柄部112可包括:用户控件诸如旋钮114,该旋钮使细长轴108和钉施用组件106围绕细长轴108的纵向轴线旋转;以及闭合触发器116,该闭合触发器可相对于手枪式握持部118枢转以闭合钉施用组件106。例如,当闭合触发器116被夹紧时,闭合释放按钮120可向外存在于柄部112上,使得闭合释放按钮120可被压下以松开闭合触发器116并打开钉施用组件106。In various cases,

可相对于闭合触发器116枢转的击发触发器122可使钉施用组件106同时切断和缝合被夹紧在其中的组织。在各种情况下,可使用击发触发器122来采用多个击发行程以减少每行程需要由外科医生的手施加的力的量。在某些实施方案中,柄部112可包括一个或多个可旋转指示器轮,诸如可指示击发进程的可旋转指示器轮124。如果需要,手动击发释放杠杆126可允许击发系统在完全击发行进完成之前回缩,并且此外,在击发系统卡住和/或失效的情况下,击发释放杠杆126可允许外科医生或其他临床医生使击发系统回缩。The firing

关于外科缝合和切断装置100和适于与本公开一起使用的其他外科缝合和切断装置的附加细节例如在美国专利号9,332,984和美国专利公布号2009/0090763中有所描述,这些专利的公开内容全文以引用方式并入本文。另外,外科缝合和切断装置不需要包括柄部,而是可具有被构造成能够联接到外科机器人的外壳,例如,如美国专利申请号2019/0059889中所述的,该专利申请的公开内容全文以引用方式并入本文。Additional details regarding surgical stapling and severing

如图1进一步所示,钉仓200可与器械100一起使用。在使用中,钉仓200被放置在细长钉通道104内并且联接到该细长钉通道。虽然钉仓200可具有各种构型,但在该例示的实施方案中,图2A至图2B中更详细地示出的钉仓200具有近侧端部202a和远侧端部202b,其中纵向轴线(LC)在其间延伸。因此,当钉仓200插入到细长钉通道104(图1)时,纵向轴线(LC)与细长轴108的纵向轴线(LS)对准。另外,钉仓200包括纵向狭槽210,该纵向狭槽由两个相对的壁210a、210b限定并且被构造成能够接纳击发组件的击发构件的至少一部分,如图4中的击发组件400,如下文进一步讨论的。如图所示,纵向狭槽202从钉仓200的近侧端部202a朝向远侧端部202b延伸。本文还考虑在其他实施方案中,可省略纵向狭槽202。As further shown in FIG. 1 ,

所例示的钉仓200包括限定在其中的钉腔212、214,其中每个钉腔212、214被构造成能够可移除地容纳钉(未示出)的至少一部分。钉腔的数量、形状和位置可变化并且可至少取决于可拆卸地设置在其中的钉的尺寸和形状。在该例示的实施方案中,以两组三个纵向排布置钉腔,其中第一组钉腔212被定位在纵向狭槽210的第一侧上,并且第二组钉腔214被定位在纵向狭槽210的第二侧上。在纵向狭槽210的每一侧上,并且因此对于每组排,第一纵向排的钉腔212a、214a沿着纵向狭槽210延伸,第二排钉腔212b、214b沿着第一排钉腔212a、214b延伸,并且第三排钉腔212c、214c沿着第二排钉腔延伸212b、214b延伸。对于每组排,第一排钉腔212a、214b,第二排钉腔212b、214b和第三排钉腔214c、214c与彼此和纵向狭槽210平行。另外,如图所示,对于每组排,第二排钉腔212b、214b相对于第一排钉腔212a、212c和第三排钉腔214a、214c交错。在其他实施方案中,每个组中的钉腔排212、214不与彼此和/或纵向狭槽210平行。The illustrated

可释放地存储在钉腔212、214中的钉可具有各种构型。可以可释放地存储在钉腔212、214中的每一者中的示例性钉300以其未击发(预部署、未成形)构型示出在图3中。所例示的钉300包括冠部(基底)302和从冠部302的每个端部延伸的两个腿304。在此实施方案中,冠部302在线性方向上延伸,并且钉腿304具有相同的未成形高度,而在其他实施方案中,该冠部可以是台阶式冠部,如类似于图28A中的冠部2804c、2806c、2808c,并且/或者钉腿可具有不同的未形成高度(参见图29)。另外,在钉300被部署之前,钉冠部302可由定位在钉仓200内的钉驱动器支撑,并且同时,钉腿304可至少部分地容纳在钉腔212、214内。另外,当钉300处于其未击发位置时,钉腿304可延伸超过钉仓200的顶表面,如顶表面206。在某些情况下,如图3中所示,钉腿304的末端306可以是尖锐而锋利的,该末端可切入和穿透组织。The staples releasably stored in the

在使用中,钉300可从未击发位置变形到击发位置,使得钉腿304运动通过钉腔212、214,穿透定位在砧座102与钉仓200之间的组织,并且接触砧座102。在钉腿304抵靠砧座102变形时,每个钉300的腿304可将组织的一部分捕获在每个钉300内,并且将压缩力施加到该组织。另外,每个钉300的腿304可朝向钉300的冠部302向下变形,以形成其中可捕获组织的钉截留区域。在各种情况下,钉截留区域可被限定在已变形的腿的内表面与钉的冠部的内表面之间。例如,钉截留区域的尺寸可取决于若干因素,诸如腿的长度、腿的直径、冠部的宽度和/或腿变形的程度。In use, the

在一些实施方案中,设置在钉仓200内的所有钉可具有相同的未击发(预部署、未成形)构型。在其他实施方案中,钉可包括至少两组钉,每组钉具有相对于彼此的不同的未击发(预部署、未成形)构型,例如,相对于彼此在高度和/或形状上变化等。例如,钉仓200可包括具有第一高度的设置在第一排钉腔212a、214a内的第一组钉,具有第二高度的设置在第二排钉腔212b、214b内的第二组钉,和具有第三高度的设置在第三排钉腔212c、214c内的第三组钉。在一些实施方案中,第一高度、第二高度和第三高度可不同,其中该第三高度大于该第一高度和该第二高度。在其他实施方案中,第一高度和第二高度相同,但第三高度不同于且大于该第一高度和该第二高度。本领域的技术人员将理解,本文考虑了钉的其他组合。In some embodiments, all of the staples disposed within

另外,钉可包括一个或多个外部涂层,例如,硬脂酸钠润滑剂和/或抗微生物剂。抗微生物剂可作为其自身的涂层或结合到另一涂层(诸如润滑剂)中而施加到钉。合适的抗微生物剂的非限制性示例包括5-氯-2-(2,4-二氯苯氧基)苯酚、氯己定、银制剂(例如,纳米晶银)、月桂酸精氨酸乙酯(LAE)、奥替尼啶、聚六亚甲基双胍(PHMB)、牛磺罗定、乳酸、柠檬酸、乙酸及其盐。Additionally, the staples may include one or more outer coatings, eg, sodium stearate lubricants and/or antimicrobials. The antimicrobial agent may be applied to the nail as a coating on its own or incorporated into another coating such as a lubricant. Non-limiting examples of suitable antimicrobial agents include 5-chloro-2-(2,4-dichlorophenoxy)phenol, chlorhexidine, silver formulations (eg, nanocrystalline silver), arginine laurate ester (LAE), octenidine, polyhexamethylene biguanide (PHMB), taurolidine, lactic acid, citric acid, acetic acid and salts thereof.

重新参考图2A至图2B,钉仓200从顶表面或平台表面206延伸到底表面208,其中该顶表面206被构造为面向组织的表面,并且该底表面208被构造为面向通道的表面。因此,当钉仓200被插入到细长钉通道104中时,如图1所示,顶表面206面向砧座102,并且底表面208(被遮挡)面向细长钉通道104。Referring back to FIGS. 2A-2B,

在一些实施方案中,顶表面206可包括限定在其中的表面特征部。例如,表面特征部可以是限定在顶表面206内的凹陷通道。如图2C中更详细地示出的,第一凹陷通道216围绕每个第一钉腔212a、214a。每个第一凹陷通道216由基本上三角形的壁216a限定,该壁具有向近侧指向的顶点、向远侧指向的顶点和横向向外指向的顶点。另外,每个第一凹陷通道216包括第一底板206a,该第一底板在距顶表面206的第一高度处。第二凹陷通道218围绕每个第二钉腔212b、214b。每个第二凹陷通道218由基本上菱形的壁218a限定,该壁包括向近侧指向的顶点、向远侧指向的顶点、横向向内指向的顶点和相对于纵向轴线横向向外指向的顶点。另外,每个第二凹陷通道218包括第二底板206b,该第二底板在距顶表面206的第二高度处。第三凹陷通道220围绕每个第三钉腔212c、214c。每个第三凹陷通道220由基本上三角形的壁220a限定,该壁包括向近侧指向的顶点、向远侧指向的顶点,以及相对于纵向轴线横向向内指向的顶点。另外,每个第三凹陷通道220包括第三底板206c,该第三底板在距顶表面206的第三高度处。在一些实施方案中,第一凹陷通道216的第一高度、第二凹陷通道218的第二高度和第三凹陷通道220的第三高度可具有相同的高度。在其他情况下,第一高度、第二高度和/或第三高度可不同。关于表面特征部和其他示例性表面特征部的附加细节可在美国专利号2016/0106427中找到,其全文以引用方式并入本文。另外,如下文将更详细地讨论,这些凹陷通道216、218、220可用于与附属物相互作用,如图26A至图26C中的附属物2600,该附属物可在钉部署之前可释放地保持在仓的顶表面。In some embodiments, the

参考图4和图5,击发组件诸如击发组件400可与外科缝合和切断装置(如图1中的装置100)一起使用。击发组件400可被构造成能够推进具有楔形件502的楔形滑动件500,该楔形件被构造成能够将钉从钉仓200部署到被捕获在砧座(如图1中的砧座102)与钉仓(如图1中的钉仓200)之间的组织中。此外,击发组件400的远侧部分处的E形梁402可从钉仓击发钉。在击发期间,E形梁402还可使砧座朝向钉仓枢转,并且因此将钉施用组件从打开位置运动到闭合位置。所例示的E形梁402包括一对顶销404、一对可跟随楔形滑动件500的一部分504的中间销406以及底销或底脚408。E形梁402还可包括锋利的切割刃410,该切割刃被构造成能够在击发组件400朝远侧推进时切断所捕获的组织,并且因此朝向钉仓的远侧端部。此外,托住切割刃410的每个竖直端部的一体成形的朝近侧突出的顶部导向件412和中间导向件414可进一步限定组织集结区域416,从而有助于在切断组织前将组织引导至锋利的切割刃410。中间导向件414还可用于通过邻接楔形滑动件500的阶梯式中央构件506来接合并击发钉仓内的钉,该楔形滑动件通过钉施用组件106影响钉形成。Referring to Figures 4 and 5, a firing assembly such as firing

在使用中,通过按压图1中的闭合触发器以推进图4中的E形梁402,图1中的砧座102可运动到闭合位置中。砧座可将组织抵靠如2A至图2C中的钉仓200的至少顶表面206而定位。一旦砧座已被适当地定位,图3中的设置在钉仓内的钉300就可被部署。In use, the

为了从钉仓部署钉,如上所讨论的,图5中的滑动件500可从近侧端部朝向仓体的远侧端部运动,并且因此朝向钉仓的远侧端部运动。当图4中的击发组件400被推进时,滑动件可在钉腔212、214内向上接触和提升钉仓内的钉驱动器。在至少一个示例中,滑动件和钉驱动器可各自包括一个或多个斜坡或倾斜表面,该一个或多个斜坡或倾斜表面可协作以使钉驱动器从其未击发位置向上运动。当钉驱动器在它们相应的钉腔内被向上提升时,钉被向上推进,使得钉从它们的钉腔中出现并穿透到组织中。在各种情况下,作为击发序列的一部分,滑动件可同时使若干钉向上运动。To deploy staples from a staple cartridge, as discussed above, the

如上所述,缝合装置可与可压缩附属物组合使用。本领域技术人员将会理解,虽然下面示出并描述了附属物,但是这里公开的附属物可以与其它外科器械一起使用,并且不需要如所述的那样联接到钉仓。此外,本领域技术人员还将理解,钉仓不需要是可替换的。As mentioned above, the suturing device can be used in combination with a compressible appendage. Those skilled in the art will appreciate that although the appendages are shown and described below, the appendages disclosed herein may be used with other surgical instruments and need not be coupled to a staple cartridge as described. Furthermore, those skilled in the art will also understand that the staple cartridge need not be replaceable.

如上所讨论的,对于一些外科缝合器,外科医生通常需要为待缝合的组织选择具有适当钉高度的适当钉。例如,外科医生将利用用于厚组织的长钉和用于薄组织的短钉。然而,在一些情况下,被缝合的组织不具有一致的厚度,并且因此对于被缝合的组织的每个部分(例如,厚的和薄的组织部分),钉不能实现期望的击发构型。当使用具有相同或基本上较大高度的钉时,特别是当钉部位在钉部位处和/或沿着钉线暴露于组织内压力时,组织不一致的厚度还可导致钉部位处的不期望的组织的渗漏和/或撕裂。As discussed above, with some surgical staplers, the surgeon generally needs to select the appropriate staples with the appropriate staple height for the tissue to be stapled. For example, a surgeon will utilize long staples for thick tissue and short staples for thin tissue. However, in some cases, the tissue being stapled does not have a consistent thickness, and thus for each portion of the tissue being stapled (eg, thick and thin tissue portions), the staples cannot achieve the desired firing configuration. When using staples of the same or substantially greater height, particularly when the staple site is exposed to intra-tissue pressure at the staple site and/or along the staple line, the non-uniform thickness of the tissue can also lead to undesirable effects at the staple site leakage and/or tearing of the tissue.

因此,提供了非纤维附属物的各种实施方案,该附属物可被构造成能够补偿被捕获在击发(部署)钉内的组织的厚度变化,以避免在外科手术期间缝合组织时需要考虑钉高度。也就是说,本文所述的附属物可允许具有相同或类似高度的一组钉用于缝合具有变化的厚度的组织(例如,从薄到厚的组织),同时还与附属物组合,在击发的钉内和钉之间提供足够的组织压缩。因此,本文所述的附属物可保持对缝合到该附属物的薄或厚组织的适当压缩,从而最大程度地减小缝合部位处的组织的渗漏和/或撕裂。Accordingly, various embodiments of non-fibrous appendages are provided that can be configured to compensate for variations in the thickness of tissue captured within the fired (deployed) staples to avoid the need to consider staples when stapling tissue during surgery high. That is, the appendages described herein may allow a set of staples of the same or similar height to be used to suture tissue with varying thicknesses (eg, from thin to thick tissue), while also being combined with the appendages during firing Provides adequate tissue compression within and between the staples. Thus, the appendages described herein can maintain proper compression of thin or thick tissue sutured to the appendage, thereby minimizing leakage and/or tearing of tissue at the suture site.

另选地或除此之外,非纤维附属物可被构造成能够促进组织向内生长。在各种情况下,希望促进组织在植入式附属物中的向内生长以促进被处理组织(例如,缝合组织和/或切入组织)的愈合并且/或者加速患者的恢复。更具体地,组织在植入式附属物中的向内生长可降低外科部位处的炎症的发生率、范围和/或持续时间。组织在植入式附属物中和/或周围的向内生长可控制例如外科部位处的感染的扩散。血管尤其是白血细胞例如在植入式附属物中和/或周围的向内生长可抵抗植入式附属物及相邻组织中和/或周围的感染。组织向内生长还可促进异物(例如,植入式附属物和钉)被患者身体的接受,并且可降低患者身体拒绝异物的可能性。异物的拒绝可导致外科部位处的感染和/或炎症。Alternatively or additionally, the non-fibrous appendages can be configured to promote tissue ingrowth. In various instances, it is desirable to promote tissue ingrowth within the implantable appendage to promote healing of the treated tissue (eg, sutured and/or incised tissue) and/or to accelerate patient recovery. More specifically, tissue ingrowth within the implanted appendage can reduce the incidence, extent, and/or duration of inflammation at the surgical site. Tissue ingrowth in and/or around the implanted appendage can control the spread of infection, eg, at the surgical site. Ingrowth of blood vessels, especially white blood cells, for example, in and/or around the implanted appendage may counteract infection in and/or around the implanted appendage and adjacent tissue. Tissue ingrowth may also facilitate the acceptance of foreign bodies (eg, implantable appendages and staples) by the patient's body and may reduce the likelihood that the patient's body will reject the foreign body. Rejection of the foreign body can lead to infection and/or inflammation at the surgical site.

与常规附属物(例如,非三维打印的附属物,诸如泡沫附属物和织造/非织造非纤维附属物)不同,这些非纤维附属物是三维(3D)打印的并且因此可形成有一致的和可再现的微结构(单元)。也就是说,与其他制造方法不同,3D打印显著地改善了对微结构特征(诸如元件的放置和连接)的控制。因此,与常规附属物相比,本发明的附属物的微结构和伴随特性两者的可变性都降低。例如,本发明的附属物可被结构化为使得它们以基本上均匀的方式压缩预先确定的量。对微结构的精细控制还可允许定制附属物的孔隙度以增强组织向内生长。本发明的非纤维附属物也可适于与多种钉和组织类型一起使用。Unlike conventional appendages (eg, non-3D printed appendages such as foam appendages and woven/non-woven non-fibrous appendages), these non-fibrous appendages are three-dimensional (3D) printed and thus can be formed with consistent and Reproducible microstructures (units). That said, unlike other fabrication methods, 3D printing significantly improves control over microstructural features such as placement and connection of components. Thus, the variability in both the microstructure and accompanying properties of the appendages of the present invention is reduced compared to conventional appendages. For example, the appendages of the present invention may be structured such that they compress a predetermined amount in a substantially uniform manner. Fine control over the microstructure may also allow tailoring of the porosity of the appendages to enhance tissue ingrowth. The non-fibrous appendages of the present invention may also be suitable for use with a variety of staples and tissue types.

一般来讲,本文提供的附属物被设计并定位在钉仓(如钉仓200)的顶部。当钉从仓击发(部署)时,钉穿透附属物并进入组织。当钉的腿抵靠与钉仓相对地定位的砧座变形时,变形的腿捕获每个钉内的附属物的一部分和组织的一部分。也就是说,当钉被击发到组织中时,附属物的至少一部分变得定位在组织和击发的钉之间。虽然本文所述的附属物可被构造成能够附接到钉仓上,但本文还设想,该附属物可被构造成能够与其他器械部件诸如外科缝合器的砧座配合。本领域的普通技术人员将会理解,本文提供的附属物可与可替换仓或不基于仓的钉再装载器一起使用。Generally, the appendages provided herein are designed and positioned on top of a staple cartridge (eg, staple cartridge 200). When the staples are fired (deployed) from the cartridge, the staples penetrate the appendages and enter the tissue. When the legs of the staples are deformed against an anvil positioned opposite the staple cartridge, the deformed legs capture a portion of the appendages and a portion of the tissue within each staple. That is, when the staples are fired into tissue, at least a portion of the appendages become positioned between the tissue and the fired staples. While the appendages described herein can be configured to be attached to a staple cartridge, it is also contemplated herein that the appendages can be configured to mate with other instrument components, such as an anvil of a surgical stapler. One of ordinary skill in the art will understand that the accessories provided herein can be used with either a replaceable cartridge or a non-cartridge based staple reloader.

缝合组织的方法method of suturing tissue

图6A至图6B示出了缝合组件600的示例性实施方案,该缝合组件包括钉仓602和附属物604。为简单起见,附属物604通常在图6A至图6B中示出,并且下文更详细地描述附属物的各种结构构型。除了下文详细描述的差异之外,钉仓602可类似于钉仓200(图1至图3),因此本文未详细描述共同特征。如图所示,附属物604抵靠钉仓602定位。虽然在图6中被部分地遮挡,但是钉仓602包括可类似于图3中的钉300的钉606,该钉被构造成能够被部署到组织中。钉606可具有任何合适的未成形(预部署)高度。例如,钉606可具有介于约2mm至4.8mm之间的未成形高度。在部署之前,该钉的冠部可由钉驱动器(未示出)支撑。FIGS. 6A-6B illustrate an exemplary embodiment of a

在例示的实施方案中,附属物604可与钉仓602的顶表面或平台表面608的至少一部分配合。在一些实施方案中,钉仓602的顶表面608可包括一个或多个表面特征部,立体,如图2A和图2C所示的凹陷通道216、218、220。该一个或多个表面特征部可被构造成能够接合附属物604,以避免附属物604相对于钉仓602的不期望运动并且/或者防止附属物604从钉仓602的过早释放。示例性表面特征部描述于美国专利公布号2016/0106427,该专利公布全文以引用方式并入本文。In the illustrated embodiment, the

图6B示出了被放置在与图1中的外科端部执行器106类似的外科端部执行器601的细长钉通道610内并且联接到该细长钉通道的缝合组件600。砧座612枢转地联接到细长钉通道610,并且因此相对于细长钉通道610(并且因此相对于钉仓602)在打开位置与闭合位置之间运动。砧座612示出为处于图6B中的闭合位置,并且示出了在钉仓602与砧座612之间产生组织间隙TG。更具体地,组织间隙TG由砧座612的组织-压缩表面612a(例如,砧座中的钉成形凹坑之间的组织接合表面)与附属物604的组织接触表面604a之间的距离限定。在该例示的实施方案中,砧座612的组织-压缩表面612a和附属物604的组织接触表面604a均为平面的或基本上平面的(例如,在制造公差内是平面的)。因此,当砧座612处于闭合位置时,如图6B所示,当没有组织放置在其中时,组织间隙TG通常是均匀的(例如,在制造公差内标称相同)。换句话说,组织间隙TG跨端部执行器601(例如,在y方向上)通常是恒定的(例如,在制造公差内是恒定的)。在其他实施方案中,砧座的组织-压缩表面可包括阶梯式表面,该阶梯式表面在相邻纵向部分之间具有纵向台阶,并且因此产生阶梯式轮廓(例如,在y方向上)。在此类实施方案中,组织间隙TG可发生变化。FIG. 6B shows stapling

附属物604可压缩以允许附属物压缩到的高度不同,从而补偿被捕获在部署的钉内的组织厚度不同。附属物604具有未压缩(未变形)或预部署高度,并且被构造成能够变形到多个压缩(变形)或部署高度中的一个高度。例如,附属物604可具有大于设置在钉仓602内的钉606的击发高度(例如,图7中的击发钉606a的高度(H))的未压缩高度。也就是说,附属物604可具有未变形状态,其中附属物604的最大高度大于击发钉(例如,处于成型构型的钉)的最大高度。在一个实施方案中,附属物604的未压缩高度可比钉606的击发高度高约10%、高约20%、高约30%、高约40%、高约50%、高约60%、高约70%、高约80%、高约90%或高约100%。在某些实施方案中,例如,附属物604的未压缩高度可比钉606的击发高度高超过100%。The

在使用中,一旦手术缝合和切断装置(如图1中的装置100)被引导到外科部位,组织被定位在砧座612与缝合组件600之间,使得砧座612邻近组织的第一侧而定位,并且缝合组件600邻近组织的第二侧而定位(例如,组织可抵靠附属物604的组织接触表面604a而定位)。一旦组织被定位在砧座612与缝合组件600之间,外科缝合器就可被致动,例如如上所讨论的,从而将组织夹持在砧座612与缝合组件600之间(例如,在砧座612的组织-压缩表面612a与附属物604的组织接触表面604a之间),并且将钉从仓部署通过附属物并进入组织以将该附属物缝合并附接到组织。In use, once a surgical stapling and severing device (such as

如图7中所示,当钉606被击发时,组织(T)和附属物604的一部分被击发(成形)的钉606a捕获。如上所讨论的,击发钉606a各自在其中限定截留区域,用于容纳捕获的附属物604和组织(T)。由击发钉606a限定的截留区域至少部分地受到击发钉606a的高度(H)的限制。例如,击发钉606a的高度可以是约0.160英寸或更小。在一些实施方案中,击发钉606a的高度可以是约0.130英寸或更小。在一个实施方案中,击发钉606a的高度可以是约0.020英寸至0.130英寸。在另一实施方案中,击发钉606a的高度可以是约0.060英寸至0.160英寸。As shown in Figure 7, when the

如上所述,附属物604可被压缩在多个击发的钉内,而不管被捕获在钉内的组织的厚度在每个击发的钉内是相同的还是不同的。在至少一个示例性实施方案中,钉线或钉排内的钉可变形,使得击发高度为例如约2.75mm,其中组织(T)和附属物604可在该高度内被压缩。在某些情况下,组织(T)可具有约1.0mm的压缩高度,并且附属物604可具有约1.75mm的压缩高度。在某些情况下,组织(T)可具有约1.50mm的压缩高度,并且附属物604可具有约1.25mm的压缩高度。在某些情况下,组织(T)可具有约1.75mm的压缩高度,并且附属物604可具有约1.00mm的压缩高度。在某些情况下,组织(T)可具有约2.00mm的压缩高度,并且附属物604可具有约0.75mm的压缩高度。在某些情况下,组织(T)可具有约2.25mm的压缩高度,并且附属物604可具有约0.50mm的压缩高度。因此,捕获的组织(T)和附属物604的压缩高度之和可等于或至少基本上等于击发钉606a的高度(H)。As described above, the

另外,大多数结构通常以其中材料的应变(变形)随着施加在材料上的应力增加而增加的方式表现。然而,对于外科缝合,期望附属物的应变在相对窄的应力范围内增加,并且因此如下文更详细地讨论的,本文所述的附属物可以这样的方式结构化,使得它们可以表现出平坦或中度倾斜的“应力平台”。通常,应力平台是在多孔材料的应力-应变曲线中在压缩时的方案,该方案对应于通过弹性屈曲的渐进的单元塌缩,并且取决于制造材料的固体的性质。也就是说,当给定结构在压缩下变形时,应变可增加,而不会显著增加应力,并且因此导致应力平台,从而有利地延迟结构的致密化(例如,固体高度)。因此,本文所述的附属物可被设计成在整个应力范围内在延长的时间段内经历压缩,该应力通常在附属物处于组织部署状态时施加到该附属物(例如,当附属物缝合到组织体内时)。In addition, most structures generally behave in a manner in which the strain (deformation) of the material increases as the stress applied to the material increases. However, for surgical suturing, it is desirable that the strain of the appendages increase within a relatively narrow range of stress, and thus, as discussed in more detail below, the appendages described herein can be structured in such a way that they can appear flat or Moderately sloped "stress plateau". In general, a stress plateau is the regime in compression in the stress-strain curve of a porous material, which corresponds to progressive cell collapse by elastic buckling, and depends on the properties of the solid from which the material is fabricated. That is, when a given structure is deformed under compression, the strain can increase without a significant increase in stress, and thus result in a stress plateau, advantageously delaying densification (eg, solid height) of the structure. Accordingly, the appendages described herein can be designed to undergo compression for extended periods of time across the range of stresses typically applied to the appendage when the appendage is in a tissue deployed state (eg, when the appendage is sutured to tissue). in the body).

因此,可设计附属物的结构,使得当附属物和组织被捕获在击发钉内时,该附属物在处于30kPa至90kPa范围内的施加应力下时可经历0.1至0.9范围内的应变。当附属物处于组织部署状态时,所施加的应力是缝合组织抵靠附属物施加的应力。本领域的技术人员将理解,组织所施加的应力取决于各种缝合条件(例如,组织厚度、成型的钉高度、组织内压力)。例如,高血压通常被认为是210mmHg,并且因此期望本发明的附属物在预先确定的时间段内承受等于或大于210mmHg的施加应力而不达到致密化。在其他实施方案中,该应变可处于约0.1至0.8、约0.1至0.7、约0.1至0.6、约0.2至0.8、约0.2至0.7、约0.3至0.7、约0.3至0.8、约0.3至0.9、约0.4至0.9、约0.4至0.8、约0.4至0.7、约0.5至0.8,或约0.5至0.9的范围内。因此,本文所述的附属物可被构造成能够变形,并且因此在预先确定量的施加应力下不会达到其固体高度。Accordingly, the appendage can be structured such that when the appendage and tissue are captured within the firing pin, the appendage can experience a strain in the range of 0.1 to 0.9 when under an applied stress in the range of 30 kPa to 90 kPa. When the appendage is in the tissue-deployed state, the applied stress is the stress applied by the sutured tissue against the appendage. Those skilled in the art will understand that the stress exerted by the tissue depends on various suturing conditions (eg, tissue thickness, shaped staple height, intra-tissue pressure). For example, hypertension is generally considered to be 210 mmHg, and it is therefore desirable for the appendages of the present invention to withstand an applied stress equal to or greater than 210 mmHg for a predetermined period of time without achieving densification. In other embodiments, the strain may be about 0.1 to 0.8, about 0.1 to 0.7, about 0.1 to 0.6, about 0.2 to 0.8, about 0.2 to 0.7, about 0.3 to 0.7, about 0.3 to 0.8, about 0.3 to 0.9, In the range of about 0.4 to 0.9, about 0.4 to 0.8, about 0.4 to 0.7, about 0.5 to 0.8, or about 0.5 to 0.9. Accordingly, the appendages described herein can be configured to deform and thus not reach their solid height under a predetermined amount of applied stress.

为了设计被构造成能够在所施加的约30kPa至90kPa范围内的应力下时经历约0.1至0.9的范围内的应变的附属物,可使用胡克定律(F=kD)的原理。例如,已知将施加到组织部署附属物的力(应力),可设计附属物以具有预先确定的刚度(k)。刚度可通过调谐附属物的几何形状(例如,单元格的形状、壁厚、高度和/或互连性,例如,单元格之间的角度和空间和/或单元格的撑条的直径和/或单元格的撑条的互联性,例如,撑条之间的角度和空间)来设置。另外,可将附属物设计成对于最小组织厚度(例如,1mm)具有最大压缩位移量,并且因此位移D的长度可以是最小组织厚度(例如,1mm)加上当在给定最大钉高度(例如,2.75mm)下缝合到组织上时附属物的厚度的组合。举例来说,在一个实施方案中,附属物可被结构化为具有大于2.75mm的最大成型缝合高度的高度,并且当被缝合到具有1mm最小厚度的组织上时,可以被压缩到1.75mm的高度。因此,该附属物可以在可压缩性上变化,以保持位移D的恒定长度,使得捕获的组织和附属物的刚度(k)和总厚度(D)可向捕获的组织施加3gf/mm2的应力。应当指出的是,本领域的技术人员将理解,可修改前述公式以考虑温度的变化,例如,当植入后将附属物从室温带到体温时。另外,前面对胡克定律的讨论表示一种近似。因此,本领域的技术人员将理解,大变形力学(也称为有限弹性)原理可用于通过使用为感兴趣的材料定制的本构方程来更准确地预测应力与应变之间的关系。To design appendages that are configured to experience strains in the range of about 0.1 to 0.9 when under applied stresses in the range of about 30 kPa to 90 kPa, the principles of Hooke's law (F=kD) can be used. For example, knowing the force (stress) that will be applied to the tissue to deploy the appendage, the appendage can be designed to have a predetermined stiffness (k). Stiffness can be achieved by tuning the geometry of the appendages (e.g., cell shape, wall thickness, height, and/or interconnectivity, e.g., angles and spaces between cells and/or diameters and/or diameters of cell struts). or the interconnectivity of the struts of the cell, for example, the angle and space between the struts). Additionally, the appendage can be designed to have a maximum amount of compressive displacement for a minimum tissue thickness (eg, 1 mm), and thus the length of displacement D can be the minimum tissue thickness (eg, 1 mm) plus when at a given maximum staple height (eg, 2.75mm) the combination of thicknesses of the appendages when sutured to tissue. For example, in one embodiment, the appendage can be structured to have a height greater than a maximum shaped suture height of 2.75mm, and can be compressed to a height of 1.75mm when sutured to tissue having a minimum thickness of 1mm high. Thus, the appendage can be varied in compressibility to maintain a constant length of displacement D such that the stiffness (k) and overall thickness (D) of the captured tissue and appendage can apply3 gf/mm to the captured tissue stress. It should be noted that those skilled in the art will understand that the foregoing formula may be modified to account for changes in temperature, eg, when the appendage is brought from room temperature to body temperature after implantation. Additionally, the preceding discussion of Hooke's law represents an approximation. Thus, those skilled in the art will understand that the principles of large deformation mechanics (also known as finite elasticity) can be used to more accurately predict the relationship between stress and strain by using constitutive equations tailored for the material of interest.

因此,可通过至少单元格的结构构型和它们之间的互连性来控制附属物的可压缩性轮廓。因此,可定制单元格的结构构型以实现具有用于缝合组织的期望机械特性的附属物。由于存在有限范围的组织内压力、组织厚度和成型钉高度,因此可确定附属物的适当几何结构,并且因此确定单元格,该几何结构可有效地允许附属物在施加期望量的应力的同时以基本上恒定的速率经受期望量的应变。换句话说,单元格的结构构型可被设计成产生附属物,该附属物可在一定范围的缝合条件下对缝合组织施加基本上连续的期望应力(例如,至少3gf/mm2)达持续给定量的时间。也就是说,如下文更详细地描述的,本发明的附属物由可压缩材料形成,并且被几何构造成当被缝合到组织上时,允许附属物在预先确定的平面内压缩到不同的高度。此外,当附属物暴露于组织内压力的波动时,由附属物进行的这种变化的响应也可以允许附属物保持其对组织施加连续的期望应力,其中该组织内压力的波动可以在附属物被缝合到组织时发生(例如,血压的峰值)。Thus, the compressibility profile of the appendages can be controlled by at least the structural configuration of the cells and the interconnectivity between them. Thus, the structural configuration of the cells can be tailored to achieve appendages with desired mechanical properties for suturing tissue. Since there is a limited range of intra-tissue pressures, tissue thicknesses, and shaped nail heights, an appropriate geometry of the appendage, and thus a cell, can be determined that effectively allows the appendage to be A substantially constant rate is subjected to the desired amount of strain. In other words, the structural configuration of the cells can be designed to create appendages that can apply a substantially continuous desired stress (eg, at least 3 gf/mm2 ) to the sutured tissue for a sustained period of time under a range of suture conditions a given amount of time. That is, as described in more detail below, the appendages of the present invention are formed from compressible materials and are geometrically configured to allow the appendages to compress to different heights within a predetermined plane when sutured to tissue . In addition, this varied response by the appendage may also allow the appendage to maintain its continuous desired stress on the tissue when exposed to fluctuations in intra-tissue pressure that may be attributable to the appendage. Occurs when sutured to tissue (eg, spikes in blood pressure).

附属物appendage

该附属物可具有多种构型。该附属物通常包括组织接触表面和仓接触表面,其中细长主体(例如,内部结构)定位在其间。在某些实施方案中,组织接触表面和/或仓接触表面可具有与细长主体不同的结构,从而形成组织接触层和仓接触层。如下文更详细地所述,附属物可具有基于撑条的构型、基于非撑条的构型或其组合。The appendage can have a variety of configurations. The appendage typically includes a tissue-contacting surface and a cartridge-contacting surface with an elongated body (eg, an internal structure) positioned therebetween. In certain embodiments, the tissue-contacting surface and/or the cartridge-contacting surface may have a different structure than the elongated body, thereby forming a tissue-contacting layer and a cartridge-contacting layer. As described in more detail below, the appendages may have a strut-based configuration, a non-strut-based configuration, or a combination thereof.

另外,每个示例性附属物以部分形式(例如,不是全长的)示出,因此本领域的技术人员将会理解,附属物的长度(即沿其纵向轴线(LA))可更长,如在每个实施方案中所识别的。该长度可基于钉仓或砧座的长度变化。宽度也可根据需要变化。另外,每个示例性附属物被构造成能够定位在仓或砧座表面,使得每个附属物的纵向轴线L与仓或砧座的纵向轴线(LA)对准并沿该纵向轴线延伸。这些附属物被结构化为当暴露于压缩力(例如,应力或负载)时压缩。Additionally, each exemplary appendage is shown in partial form (eg, not full length), so those skilled in the art will appreciate that the appendage may be longer in length (ie, along its longitudinal axis (LA) ) , as identified in each embodiment. The length may vary based on the length of the staple cartridge or anvil. The width can also be varied as required. Additionally, each exemplary appendage is configured to be positioned on the cartridge or anvil surface such that the longitudinal axis L of each appendage is aligned with and extends along the longitudinal axis (LA ) of the cartridge or anvil. These appendages are structured to compress when exposed to a compressive force (eg, stress or load).

本文所述的附属物可具有各种平均长度、宽度和厚度。例如,在一些实施方案中,附属物可具有处于约20mm至100mm或约40mm至100mm的范围内的平均长度。在其他实施方案中,附属物可具有处于约5mm至10mm的范围内的平均宽度。在又一实施方案中,附属物可具有处于约1mm至6mm、约1mm至8mm、约2mm至6mm,或约2mm至8mm的范围内的平均厚度。在一个实施方案中,示例性附属物可具有处于约20mm至100mm的范围内的平均长度,处于5mm至10mm的范围内的平均厚度以及处于约1mm至8mm的范围内的平均厚度。The appendages described herein can have various average lengths, widths and thicknesses. For example, in some embodiments, the appendages may have an average length in the range of about 20 mm to 100 mm or about 40 mm to 100 mm. In other embodiments, the appendages may have an average width in the range of about 5 mm to 10 mm. In yet another embodiment, the appendages may have an average thickness in the range of about 1 mm to 6 mm, about 1 mm to 8 mm, about 2 mm to 6 mm, or about 2 mm to 8 mm. In one embodiment, exemplary appendages may have an average length in the range of about 20 mm to 100 mm, an average thickness in the range of 5 mm to 10 mm, and an average thickness in the range of about 1 mm to 8 mm.

细长主体可以由各自由互连单元格形成的一个或多个格栅结构形成。虽然单元格可以具有各种构型,但在一些实施方案中,单元格可以是基于无撑条的单元格,而在其他实施方案中,单元格可以是基于撑条的单元格。撑条可以是完全或基本上由固体材料形成的非中空杆或棒。在某些实施方案中,一个或多个格栅结构可由互连的重复单元格形成。另外,在某些实施方案中,细长主体可包括至少一个基于无撑条的单元格形成的格栅结构和由基于撑条的单元格形成的至少一个格栅结构(参见图54)。The elongated body may be formed of one or more lattice structures each formed of interconnected cells. While the cells can have various configurations, in some embodiments, the cells can be non-strut-based cells, while in other embodiments, the cells can be strut-based cells. The struts may be non-hollow rods or rods formed entirely or substantially of solid material. In certain embodiments, one or more lattice structures may be formed from interconnected repeating cells. Additionally, in certain embodiments, the elongated body can include at least one grid structure formed from unstrut-based cells and at least one grid structure formed from strut-based cells (see Figure 54).

每个格栅结构从第一表面(例如,顶表面)延伸到第二表面(例如,底表面)。根据附属物的总体结构构型,至少一个格栅结构的第一表面的至少一部分可用作附属物的组织接触表面,并且至少一个格栅结构的第二表面的至少一部分可用作附属物的仓接触表面。本领域的技术人员将理解,每个格栅结构可具有附加的组织接触表面(例如,相对于顶表面的一个或多个横侧表面)。Each grid structure extends from a first surface (eg, top surface) to a second surface (eg, bottom surface). Depending on the overall structural configuration of the appendage, at least a portion of the first surface of the at least one lattice structure may serve as the tissue-contacting surface of the appendage, and at least a portion of the second surface of the at least one lattice structure may serve as the appendage's tissue-contacting surface. silo contact surface. Those skilled in the art will appreciate that each grid structure may have additional tissue-contacting surfaces (eg, one or more lateral surfaces relative to the top surface).

在某些实施方案中,附属物可包括组织接触层,该组织接触层设置在内部结构的至少一个格栅结构的第一表面的至少一部分上。组织接触层具有在第一表面(例如,顶表面)与第二表面(例如,底表面)之间延伸的厚度。因此,单独或与至少一个格栅结构的第一表面的至少一部分组合的组织接触层的第一表面可用作所得附属物的组织接触表面。该组织接触层可具有多种构型。例如,在一些实施方案中,组织接触层呈由互连的重复格形成的格栅结构的形式,该重复格可与细长主体的格栅结构不同,而在其他实施方案中,组织接触层呈膜的形式。In certain embodiments, the appendage can include a tissue-contacting layer disposed on at least a portion of the first surface of the at least one grid structure of the inner structure. The tissue-contacting layer has a thickness extending between a first surface (eg, top surface) and a second surface (eg, bottom surface). Thus, the first surface of the tissue-contacting layer, alone or in combination with at least a portion of the first surface of the at least one grid structure, may serve as the tissue-contacting surface of the resulting appendage. The tissue-contacting layer can have a variety of configurations. For example, in some embodiments, the tissue-contacting layer is in the form of a lattice structure formed of interconnected repeating cells, which may be different from the lattice structure of the elongated body, while in other embodiments, the tissue-contacting layer is in the form of a membrane.

另选地或除此之外,附属物可包括仓接触层,该仓接触层设置在至少一个格栅结构的第二表面的至少一部分上。仓接触层可具有从第一表面(例如,顶表面)延伸到第二表面(例如,底表面)的厚度。因此,单独或与至少一个格栅结构的第二表面的至少一部分组合的仓接触层的第二表面可以用作所得附属物的仓接触表面。该仓接触层可具有多种构型。例如,在一些实施方案中,仓接触层呈由互连的重复格形成的格栅结构的形式,该重复格可与细长主体的格栅结构不同,而在其他实施方案中,仓接触层呈膜的形式。在一些实施方案中,膜可以是压敏粘合剂,而在其他实施方案中,膜可包括延伸的一个或多个附接特征部。Alternatively or additionally, the appendage may comprise a bin contact layer disposed on at least a portion of the second surface of the at least one grid structure. The bin contact layer may have a thickness extending from a first surface (eg, top surface) to a second surface (eg, bottom surface). Thus, the second surface of the bin contact layer, alone or in combination with at least a portion of the second surface of the at least one grid structure, may serve as the bin contact surface of the resulting appendage. The bin contact layer can have a variety of configurations. For example, in some embodiments, the bin contact layer is in the form of a grid structure formed of interconnected repeating cells, which may be different from the grid structure of the elongated body, while in other embodiments, the bin contact layer in the form of a membrane. In some embodiments, the film can be a pressure sensitive adhesive, while in other embodiments, the film can include one or more attachment features that extend.

基于非撑条的附属物non-strut based appendages

如上所述,附属物可包括由基于无撑条的单元格(例如,重复的基于无撑条的单元格)形成的格栅结构。换句话说,与通过锐角或尖角的存在来表征的基于撑条的单元格相比,基于无撑条的单元格可通过弯曲表面来表征。例如,单元格可基于三重周期性最小表面(TPMS)。TPMS是在三维中自身重复的最小表面。如本说明书中所使用的术语“最小表面”是指如数学中已知的最小表面。因此,在一些实施方案中,单元格可以是Schwarz结构(例如,Schwarz-P、Schwarz Diamond)、调整的Schwarz结构、螺旋(例如,Schoen Gyroid)结构、余弦结构和焦炭罐结构。As described above, the appendages may include grid structures formed from unstretched cells (eg, repeating unstretched based cells). In other words, strut-free based cells can be characterized by curved surfaces compared to strut-based cells characterized by the presence of acute or sharp corners. For example, cells may be based on triple periodic minimal surfaces (TPMS). A TPMS is the smallest surface that repeats itself in three dimensions. The term "minimum surface" as used in this specification refers to the smallest surface as known in mathematics. Thus, in some embodiments, cells may be Schwarz structures (eg, Schwarz-P, Schwarz Diamond), tuned Schwarz structures, helical (eg, Schoen Gyroid) structures, cosine structures, and coke pot structures.

如下文更详细地讨论的,基于无撑条的单元格可具有各种结构构型(例如,高度、宽度、壁厚、形状)。在一些实施方案中,附属物的基于撑条的单元格可以是大致均匀的(例如,在制造公差内标称相同),而在其他实施方案中,附属物的基于无撑条的单元格的至少一部分可相对于基于撑条的单元格的其余部分在形状和/或尺寸上发生变化。As discussed in more detail below, strut-based cells can have various structural configurations (eg, height, width, wall thickness, shape). In some embodiments, the strut-based cells of the appendages may be substantially uniform (eg, nominally identical within manufacturing tolerances), while in other embodiments, the strut-based cells of the appendages may be substantially uniform. At least a portion may vary in shape and/or size relative to the remainder of the strut-based cell.

例如,在一些实施方案中,基于无撑条的单元格中的每个单元格可具有约0.05mm至0.6mm的壁厚。在某些实施方案中,壁厚可以是约0.1mm至0.3mm。在一个实施方案中,壁厚可以是约0.2mm。在某些实施方案中,附属物的所有基于无撑条的单元格的壁厚可以是大致均匀的(例如,在制造公差内标称相同)。在其他实施方案中,例如,在附属物由两组或更多组单元格形成的情况下,每组单元格可以具有不同的壁厚。例如,在一个实施方案中,附属物可包括各自具有第一壁厚的第一重复单元格,各自具有大于该第一壁厚的第二壁厚的第二重复单元格,以及各自具有大于该第二壁厚的第三壁厚的第三重复单元格。另选地或除此之外,第一重复单元格可具有第一高度(例如,最大高度)、大于该第一高度的第二高度(例如,最大高度),以及大于该第二高度的第三高度(例如,最大高度)。For example, in some embodiments, each of the strut-based cells may have a wall thickness of about 0.05 mm to 0.6 mm. In certain embodiments, the wall thickness may be about 0.1 mm to 0.3 mm. In one embodiment, the wall thickness may be about 0.2 mm. In certain embodiments, the wall thickness of all strut-free-based cells of the appendage may be substantially uniform (eg, nominally the same within manufacturing tolerances). In other embodiments, for example, where the appendage is formed from two or more groups of cells, each group of cells may have different wall thicknesses. For example, in one embodiment, the appendages can include first repeating cells each having a first wall thickness, second repeating cells each having a second wall thickness greater than the first wall thickness, and each having a second wall thickness greater than the first wall thickness The third repeating cell of the third wall thickness of the second wall thickness. Alternatively or additionally, the first repeating cell may have a first height (eg, a maximum height), a second height (eg, a maximum height) greater than the first height, and a second height greater than the second height Three heights (eg, maximum height).

在一些实施方案中,每个单元格的表面与体积比可以是约5至30。在某些实施方案中,每个单元格的表面与体积比可以是约7到20。In some embodiments, the surface to volume ratio of each cell can be about 5 to 30. In certain embodiments, the surface to volume ratio of each cell can be about 7 to 20.

Schwarz-P结构Schwarz-P structure

图8A至图8F是附属物800的示例性实施方案,该附属物具有组织接触表面802和仓接触表面804。附属物800包括互连的重复无撑条单元格810,其中的一个单元格在图9A至图9B中更详细地示出。虽然附属物800被示出为具有各自具有20个重复单元格810的四个纵向排(L1、L2、L3、L4),本领域的技术人员将理解,附属物的单元格的排数和数量可至少取决于附属物将被施加到其上的钉仓和/或砧座的尺寸和形状,并且因此附属物不限于图中所示的纵向排和单元格的数量。另外,虽然仅示出了一种类型的重复的无撑条单元格,但是在其他实施方案中,附属物可由第一重复的无撑条单元格和不同于该第一重复的无撑条单元格的第二重复的无撑条单元格的组合形成等。FIGS. 8A-8F are exemplary embodiments of an

鉴于附属物800由具有基本相同的结构构型(例如,在制造公差内标称相同)的重复单元格810形成,以下讨论关于一个重复单元格810。如图9A至图9B所示,重复单元格810具有顶部部分812、底部部分814和在其间延伸的中间部分816。Given that

在该例示的实施方案中,重复单元格810被构造为Schwarz-P结构,并且因此,单元格810的表面轮廓由最小表面限定。也就是说,单元格810的外部表面820和内部表面822各自由最小表面限定。因此,在该例示的实施方案中,外部表面820和内部表面822通常是凹形的,从而形成单元格810的弓形侧面821。另外,内部表面822限定单元格810的内部体积824。因此,单元格810可以被表征为是空心的。Schwarz-P最小表面可功能性地表示为:cos(x)+cos(y)+cos(z)=0。In the illustrated embodiment, the repeating

单元格810还包括连接接口826,该连接接口可用于将单元格810互连到其他单元格810,从而形成图8A至图8E中所示的附属物800。在该例示的实施方案中,单元格包括六个连接接口826,该六个连接接口形成单元格810的六个最外侧表面,例如,顶部和底部最外侧表面827a、827b、左和右最外侧表面829a、829b以及前和后最外侧表面831a、831b。顶部和底部最外侧表面827a、827b相对于彼此是大致平面的(例如,在制造公差内是平面的)并且在x方向上偏移,左右最外侧表面829a、829b相对于彼此是大致平面的(例如,在制造公差内是平面的)并且在y方向上偏移,并且前后最外侧表面831a、831b相对于彼此是大致平面的(例如,在制造公差内是平面的)并且在z方向上偏移。因此,单元格810的总外表面包括平面表面(例如,最外侧表面827a、827b、829a、829b、831a、831b)和非平面表面(例如,在连接接口826之间延伸的外部表面820)。另外,由于附属物800仅由重复单元格810形成,因此包括最顶部外表面812a的顶部部分812形成附属物800的组织接触表面802,并且单元格的底部部分814的最底部外表面814a(例如,在x方向上)形成附属物800的仓接触表面804。因此,组织接触表面802由平面表面和非平面表面形成。

另外,基于重复单元格810的总体几何形状和它们彼此对应的连接接口826处的相互连接,所得附属物800的总外表面由被非平面表面分开的大致平面的(例如,制造公差内是平面的)表面形成。如图所示,附属物800的顶部和底部最外侧表面850a、850b距在YZ平面内延伸的平分线最远,附属物800的左和右最外侧表面852a、852b距在XZ平面内延伸的平分线最远,并且附属物的前和后最外侧表面854a、854b距在XY平面内延伸的平分线最远。另外,如图所示,顶部和底部最外侧表面850a、850b相对于彼此是大致平面的(例如,在制造公差内是平面的)并且在x方向上偏移,左右最外侧表面852a、852b相对于彼此是大致平面的(例如,在制造公差内是平面的)并且在y方向上偏移,并且前后最外侧表面854a、854b相对于彼此是大致平面的(例如,在制造公差内是平面的)并且在z方向上偏移。因此,这些最外侧表面850a、850b、852a、852b、854a、854b形成附属物800的外表面的平面段。可以理解的是,在这些最外侧表面850a、850b、852a、852b、854a、854b之间延伸的附属物800的部分由相邻单元格810的外部表面820限定,从而形成附属物800的外表面的非平面表面。Additionally, based on the overall geometry of the repeating

如进一步所示,六个连接接口826限定与单元格810的内部体积824流体连通的相应圆形开口。因此,单元格810在所有六个笛卡尔侧面(在图9B中表示为箭头1、2、3、4、5、6)中具有开口。这些开口可提供多种功能,例如:促进与相邻单元的连接;产生开口,该开口可允许当附属物缝合到组织时立即组织生长;允许排出在所得附属物的生产中使用的制造材料,例如在3D制造过程期间使用的材料;允许体液易于转移整个附属物;有助于附属物的机械特性,例如,产生阻断附属物的致密化的压缩轮廓的机械特性;和/或最小化完全压缩的附属物的固体高度。As further shown, the six

此外,当单元格810在对应的连接接口(例如,至少两个连接接口)处彼此互连时,在其间形成中空管状互连件828(例如,内腔),如图8D至图8E所示,该互连件允许互连单元格810的内部体积824彼此流体连通。因此,通道或路径的连续网络存在于附属物内。因此,当附属物800被缝合到组织(T)并且处于组织部署状态时,如图8G所示,一种或多种流体(包括进入附属物800中的细胞),例如通过至少一个单元格810的顶部部分812的连接接口826a的开口,因此可在组织部署状态中通过互连单元格迁移通过附属物800,如图8G所示,并且因此可最终加速附属物800内的组织向内生长。也就是说,虽然附属物800处于组织部署状态,但是中空管状互连件828的至少一部分可至少部分地维持单元格810的至少一部分或通过所有内部体积之间的流体连通,并且从而鼓励在整个附属物800中的细胞移动性。Furthermore, when the

虽然中空管状互连件828限定了可具有各种尺寸(例如,直径)的开口,但是在一些实施方案中,该开口的直径可以是约100微米至3500微米。例如,开口的直径可以是约100微米至2500微米或约500微米至2500微米。在某些实施方案中,开口的直径可以是约945微米至1385微米。在一个实施方案中,开口的直径可大于2000微米。在某些实施方案中,所有开口的直径基本上相同(例如,在制造公差内标称相同)。如本文所用,开口的“直径”是开口的任何一对顶点之间的最大距离。While the hollow

由于重复单元格810在对应的连接接口826处彼此互连,因此附属物800呈具有预定的压缩区域830和预定的非压缩区域840的格栅结构的形式,如图8C中更清楚地示出的。虽然预定的压缩区域830和预定的非压缩区域840可具有各种构型,但在该例示的实施方案中,预定的压缩区域830由单元格810限定,并且预定的非压缩区域840呈限定在单元格810之间的空隙845的形式。在该实施方案中,每个空隙845形成在四个相邻的互连单元格810之间。例如,如图8F所示,在四个相邻单元格810a、810b、810c、810d之间限定空隙845a。因此,相邻单元格之间存在的空间限定预定的非压缩区域。换句话说,附属物的非压缩区域840不由单元格的内部体积限定。Since the repeating

如下文更详细地所述,重复单元格的结构构型可允许单元格在施加的应力下在一段时间内沿其高度H(参见图9A)在不同位置连续地变形或屈曲(例如,直到单元格的内部表面的相对侧彼此接触)。因此,在此类时间期间,单元格在施加的应力(例如,30kPa至90kPa)下时可以恒定或基本上恒定的速率变形或屈曲。换句话说,在某些实施方案中,当附属物在施加的应力下时,重复单元格的结构可导致应力平台,例如,如图11中示意性地示出的。As described in more detail below, repeating the structural configuration of a cell may allow the cell to continuously deform or buckling at different locations along its height H (see FIG. 9A ) under an applied stress over a period of time (eg, until the cell Opposite sides of the interior surfaces of the cells are in contact with each other). Thus, during such times, the cells can deform or buckle at a constant or substantially constant rate when under an applied stress (eg, 30 kPa to 90 kPa). In other words, in certain embodiments, when the appendage is under applied stress, the structure of the repeating cell can result in a stress plateau, eg, as schematically shown in FIG. 11 .

图10A至图10D示意性地示出了一个重复单元格(例如,图8A至图9B中的单元格810)在一定范围的施加的应力下时的压缩行为。具体地,在图10A中以预压缩(未变形)状态示出重复单元格1010;在图10B中以第一压缩状态示出该重复单元格,其中单元格1010的顶部部分1012和底部部分1014中的每一者开始朝向单元格1010的中间部分1016压缩,使得中间部分1016开始偏转;在图10C中以第二压缩状态示出该重复单元格,其中中间部分1016继续向外偏转;并且在图10D中以致密状态示出该重复单元格,其中中间部分1016的内部表面1018的相对侧1018a、1018b彼此接触,使得单元格810达到其固体高度。Figures 10A-10D schematically illustrate the compressive behavior of a repeating cell (eg,

在图11中示意性地示出了重复单元格1010的未变形状态U(图10A)、压缩状态C1、C2(图10B至图10C)和致密状态D(图10D)与所得附属物的应力-应变曲线之间的关系。The undeformed state U ( FIG. 10A ), compressed states C1 , C2 ( FIGS. 10B-10C ) and dense state D ( FIG. 10D ) of the repeating

附属物的应力-应变响应以由杨氏模量表征的弹性变形(弯曲)开始,例如,随着重复单元从其未压缩状态朝向其第一压缩状态开始变形。这种弹性变形继续直到达到屈服应力。一旦达到屈服应力,就可以发生应力平台,该应力平台对应于通过弹性屈曲的渐进单元格塌缩,例如,随着重复单元格继续通过其第一压缩状态和第二压缩状态变形。本领域的技术人员将理解,应力平台至少取决于制造单元格的材料的性质。应力平台继续直到致密化发生,这表示单元格在整个附属物中塌缩,例如,随着重复单元格达到其致密状态,并且因此,该附属物已达到其固体高度。The stress-strain response of the appendage begins with elastic deformation (bending) characterized by Young's modulus, eg, as the repeating unit begins to deform from its uncompressed state toward its first compressed state. This elastic deformation continues until the yield stress is reached. Once the yield stress is reached, a stress plateau can occur that corresponds to progressive cell collapse through elastic buckling, eg, as the repeating cell continues to deform through its first and second compression states. Those skilled in the art will understand that the stress plateau depends at least on the properties of the material from which the cell is fabricated. The stress plateau continues until densification occurs, which means that the cell collapses throughout the appendage, eg, as the repeating cell reaches its dense state, and thus, the appendage has reached its solid height.

本领域的技术人员将理解,附属物的应力-应变曲线取决于各种因素,例如未压缩高度、组成成分(包括材料特性)和/或结构构型。举例来说,下表1示出了示例性附属物的应力-应变响应,仅在未压缩高度(UH)上有所不同,并且该附属物在30kPa的施加应力下被压缩到具有1.75mm的第一压缩高度(CH1),在90kPa的施加应力下被压缩到具有0.75mm的第二压缩高度(CH2),并且90kPa的施加应力下被压缩到具有0.45mm的第三压缩高度(CH3)。Those skilled in the art will understand that the stress-strain curve of an appendage depends on various factors, such as uncompressed height, composition (including material properties), and/or structural configuration. As an example, Table 1 below shows the stress-strain response of an exemplary appendage that differs only in uncompressed height (UH), and the appendage was compressed to have a 1.75mm under an applied stress of 30kPa A first compressed height (CH1), compressed to a second compressed height (CH2) of 0.75 mm under an applied stress of 90 kPa, and a third compressed height (CH3) of 0.45 mm under an applied stress of 90 kPa.

表1:用于各种附属物高度的应力-应变关系Table 1: Stress-strain relationships for various appendage heights

在另一实施方案中,基于重复的无撑条单元格可以是调整的Schwarz-P结构。例如,Schwarz-P结构可在一个或多个方向上拉伸以形成经拉伸的Schwarz-P结构,例如,如图12A所示。另选地或除此之外,在某些实施方案中,可以使Schwarz-P结构的壁厚变薄。例如,如图12B所示,Schwarz-P结构被拉伸并变薄。在又一实施方案中,如图12C所示,Schwarz-P结构可被裁剪,例如,其中Schwarz-P结构的顶部部分HT(参见图9A)和/或底部部分HB(参见图9A)的高度被减小。另选地或除了前述示例性调整之外,可通过Schwarz-P结构的壁添加附加的开口,例如,如图12D所示,这可以帮助使所得附属物致密化。In another embodiment, the repeat-based unstretched cells can be adjusted Schwarz-P structures. For example, Schwarz-P structures can be stretched in one or more directions to form stretched Schwarz-P structures, eg, as shown in Figure 12A. Alternatively or in addition, in certain embodiments, the wall thickness of the Schwarz-P structure can be thinned. For example, as shown in Figure 12B, the Schwarz-P structure is stretched and thinned. In yet another embodiment, as shown in Figure 12C, the Schwarz-P structure may be tailored, eg, wherein the top portionHT (see Figure 9A) and/or the bottom portionHB (see Figure 9A) of the Schwarz-P structure height is reduced. Alternatively or in addition to the foregoing exemplary adjustments, additional openings can be added through the walls of the Schwarz-P structure, eg, as shown in Figure 12D, which can help densify the resulting appendages.

基于重复的无撑条单元格可采用其他TPMS结构的形式。例如,如图13A中所示,基于无撑条的单元格1300可由具有金刚石最小面积的片状金刚石结构形成,该金刚石最小面积具有Schwarz D表面格栅结构。这种特定的最小表面被称为“金刚石”,因为其具有两个相互交织的全等迷宫,其中每个迷宫具有金刚石键结构的管状形式的形状。Schwarz D可被功能性地表达为:Repeat-based unstretched cells can take the form of other TPMS structures. For example, as shown in FIG. 13A, a strut-free based

sin(x)sin(y)sin(z)+sin(x)cos(y)cos(z)+cos(x)sin(y)cos(z)+cos(x)cos(y)sin(z)=0。sin(x)sin(y)sin(z)+sin(x)cos(y)cos(z)+cos(x)sin(y)cos(z)+cos(x)cos(y)sin(z )=0.

图13B中示出了由重复单元格1300和因此片状金刚石结构形成的示例性附属物1310。

在另一实施方案中,如图14A所示,基于无撑条的单元格1400可以是螺旋结构。螺旋最小表面可被功能性地表达为:In another embodiment, as shown in Figure 14A, strut-free based

sin(x)cos(y)+sin(y)cos(z)+sin(z)cos(x)=0。sin(x)cos(y)+sin(y)cos(z)+sin(z)cos(x)=0.

图14B中示出了由重复单元格1500和因此螺旋结构形成的示例性附属物1410。在其他实施方案中,基于无撑条的单元格可呈余弦结构1500(图15A)的形式或呈焦炭罐结构1600(图16A)的形式,这两种形式中的每一者由弯曲的最小表面限定。图15B和图16B示出了由相应重复单元格1500(余弦结构)、1600(焦炭罐结构)形成的示例性附属物1510、1610。

边缘条件edge condition

在一些实施方案中,某些基于无撑条的单元格当互连以形成附属物时可形成用于组织缝合的不期望的边缘条件。例如,当组织在使用期间滑动跨过附属物时,边缘条件可以使得附属物的至少一部分过早地从钉仓中脱离的方式与组织相互作用。这些边缘条件可以是几何形状的结果(例如,具有大致平面(例如,制造公差内是平面的)和非平面外表面)和构成附属物的基于无撑条的单元格的互连性。因此,为了改进这些边缘条件,并且因此抑制附属物的过早脱离,可将具有不同几何形状的外层放置在附属物的一个或多个组织接触表面的顶部。In some embodiments, certain strut-based cells, when interconnected to form appendages, can create undesired edge conditions for tissue suturing. For example, the edge condition may interact with the tissue in such a way that at least a portion of the appendage is prematurely dislodged from the staple cartridge when the tissue slides across the appendage during use. These edge conditions may be the result of geometry (eg, having substantially planar (eg, planar within manufacturing tolerances) and non-planar outer surfaces) and interconnectivity of the strut-based cells that make up the appendages. Therefore, to improve these edge conditions, and thus inhibit premature detachment of the appendage, outer layers with different geometries may be placed on top of one or more tissue contacting surfaces of the appendage.

重新参考图9A至图9B,如上所述,Schwarz-P结构810具有形成在单元格810的连接接口826之间延伸的弓形侧面821的非平面外部表面。因此,当Schwarz-P结构810互连以形成附属物诸如图8A至图8F中的附属物800时,组织接触表面可形成具有平面和非平面表面,如图8A至图8B中的组织接触表面802。这是至少每个单元格810的顶部部分812的结构构型(例如,暴露的最顶部外表面827a和顶部部分812的弓形侧面821)以及它们之间的间隔开关系的结果。因此,附属物的边缘条件可通过施加具有大致平面(例如,在制造公差内平面)的几何形状的外层来最小化,该几何形状定位在附属物的至少一个另外的组织接触表面上,如图8A至图8F中的附属物800的组织接触表面802。因此,这可在放置缝合装置期间降低附属物上的组织负载(施加的应力)。另外,这可简化附属物与仓之间的附接要求。Referring back to FIGS. 9A-9B , as described above, the Schwarz-

虽然外层可具有各种构型,但在一些实施方案中,外层可由撑条的一个或多个平面阵列(图17A至图17C)形成,而在其他实施方案中,该外层可呈膜的形式(图18)。While the outer layer may have various configurations, in some embodiments the outer layer may be formed from one or more planar arrays of struts (FIGS. 17A-17C), while in other embodiments the outer layer may be in the form of membranes (Figure 18).

图17A至图17C示出了具有由互连重复的单元格1704和至少一个平面阵列1706、1708形成的第一格栅结构1702的示例性附属物1700。每个单元格1704类似于图9A至图9B中的单元格810,并且因此本文未详细描述公共特征。在该例示的实施方案中,存在两个平面阵列1706、1708,其中第一平面阵列1706(例如,在YZ平面中)延伸跨过第一格栅结构1702的顶部面向组织的表面1712,并且第二平面阵列1706(例如,在XZ平面中)延伸跨过第一格栅结构1702的至少一个侧面面向组织的表面1714。在其他实施方案中,可省略第一平面阵列1706或第二平面阵列1708。在另外的实施方案中,附属物1700可包括附加的平面阵列。FIGS. 17A-17C illustrate an

虽然平面阵列1706、1708可具有各种构型,但在该例示的实施方案中,第一平面阵列1706和第二平面阵列1708各自包括平行于附属物1700的纵向轴线(LA)并沿着该纵向轴线延伸的纵向撑条1716。虽然未示出,但也能设想可将附加的撑条添加到第一平面阵列1706和第二平面阵列1708。例如,在一个实施方案中,第一平面阵列1706和/或第二平面阵列1708可包括相对于纵向轴线以一角度延伸并且与第一纵向撑条和/或第二纵向撑条相交(例如,由此产生重复的X图案)的交叉撑条。While the

在使用中,当附属物1700被可释放地保持在仓上,诸如图1至图2C中的仓200时,附属物1700与设置在仓内的钉排重叠。因此,第一平面阵列1706可添加到附属物1700的最终固体高度,并且因此加速其致密化。然而,为了最小化第一平面阵列1706对致密化的影响,第一平面阵列1706可以其不与钉排重叠的方式来设计。例如,如图17A至图17C所示,第一平面阵列1706被分成四个间隔开的部分1706a、1706b、1706c、1706d,使得三个间隙1718、1720、1722在其间形成并沿着附属物1700的纵向轴线(LA)。如图17C所示,这三个间隙1718、1720、1722可与仓(未示出)的三个钉排1724、1726、1728重合,并且因此第一平面阵列1706将不会被捕获,或在部署期间由钉最小化。In use, when the