CN114486913A - Method for detecting geometric characteristics of edge of steel coil - Google Patents

Method for detecting geometric characteristics of edge of steel coilDownload PDFInfo

- Publication number

- CN114486913A CN114486913ACN202210065525.8ACN202210065525ACN114486913ACN 114486913 ACN114486913 ACN 114486913ACN 202210065525 ACN202210065525 ACN 202210065525ACN 114486913 ACN114486913 ACN 114486913A

- Authority

- CN

- China

- Prior art keywords

- edge

- steel coil

- data

- coil

- defect

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 229910000831SteelInorganic materials0.000titleclaimsabstractdescription73

- 239000010959steelSubstances0.000titleclaimsabstractdescription73

- 238000000034methodMethods0.000titleclaimsdescription29

- 230000007547defectEffects0.000claimsabstractdescription65

- 238000001514detection methodMethods0.000claimsabstractdescription34

- 238000012545processingMethods0.000claimsabstractdescription21

- 230000005540biological transmissionEffects0.000claimsabstractdescription13

- 238000004519manufacturing processMethods0.000claimsdescription9

- 238000006073displacement reactionMethods0.000claimsdescription6

- 238000004458analytical methodMethods0.000claimsdescription5

- 238000009434installationMethods0.000claimsdescription4

- 230000003993interactionEffects0.000claimsdescription4

- 238000003672processing methodMethods0.000claimsdescription4

- 230000006698inductionEffects0.000claimsdescription3

- 238000005336crackingMethods0.000claimsdescription2

- 238000011179visual inspectionMethods0.000claims1

- 238000007689inspectionMethods0.000abstractdescription14

- 238000007405data analysisMethods0.000abstractdescription2

- 238000010586diagramMethods0.000description5

- 239000011324beadSubstances0.000description4

- 238000005097cold rollingMethods0.000description4

- 230000032258transportEffects0.000description4

- 230000009286beneficial effectEffects0.000description2

- 238000005516engineering processMethods0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 238000012800visualizationMethods0.000description2

- 238000004891communicationMethods0.000description1

- 230000007812deficiencyEffects0.000description1

- 238000009776industrial productionMethods0.000description1

- 238000006467substitution reactionMethods0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/84—Systems specially adapted for particular applications

- G01N21/88—Investigating the presence of flaws or contamination

- G01N21/8851—Scan or image signal processing specially adapted therefor, e.g. for scan signal adjustment, for detecting different kinds of defects, for compensating for structures, markings, edges

- G—PHYSICS

- G01—MEASURING; TESTING

- G01B—MEASURING LENGTH, THICKNESS OR SIMILAR LINEAR DIMENSIONS; MEASURING ANGLES; MEASURING AREAS; MEASURING IRREGULARITIES OF SURFACES OR CONTOURS

- G01B11/00—Measuring arrangements characterised by the use of optical techniques

- G01B11/24—Measuring arrangements characterised by the use of optical techniques for measuring contours or curvatures

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/84—Systems specially adapted for particular applications

- G01N21/88—Investigating the presence of flaws or contamination

- G01N21/8851—Scan or image signal processing specially adapted therefor, e.g. for scan signal adjustment, for detecting different kinds of defects, for compensating for structures, markings, edges

- G01N2021/8887—Scan or image signal processing specially adapted therefor, e.g. for scan signal adjustment, for detecting different kinds of defects, for compensating for structures, markings, edges based on image processing techniques

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Chemical & Material Sciences (AREA)

- Signal Processing (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- Computer Vision & Pattern Recognition (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Investigating Or Analyzing Materials By The Use Of Magnetic Means (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及钢卷检测技术领域,具体为一种钢卷边部几何特征的检测方法。The invention relates to the technical field of steel coil detection, in particular to a detection method for geometric features of a steel coil edge.

背景技术Background technique

智慧制造是当前工业生产追求的目标,通过智慧制造技术可以实现提高产品的品质,减轻工人的劳动强度。对于热轧钢卷,其端部存在塔形、溢出边、边裂、边损等类型的缺陷,这些缺陷对后续的冷轧工序的连续性存在重要的影响。为此一般的冷轧厂在钢卷的入口测,通常需要对每个上冷轧线的钢卷进行端部的检查,判断钢卷能否进入冷轧生产线进行生产。由于需要对每个钢卷进行检查,所检测的钢卷有时还存在高温,因此对钢卷端部缺陷进行检查是一项繁重的工作,迫切需要采用先进的视觉系统来实现自动检查。Smart manufacturing is the goal pursued by current industrial production. Through smart manufacturing technology, the quality of products can be improved and the labor intensity of workers can be reduced. For hot-rolled steel coils, there are defects such as tower shape, overflow edge, edge crack, edge loss, etc. For this reason, in general cold rolling mills, at the entrance of the steel coil, it is usually necessary to inspect the end of each steel coil on the cold rolling line to determine whether the steel coil can enter the cold rolling production line for production. Because each coil needs to be inspected, and the inspected coils sometimes have high temperatures, the inspection of coil end defects is a heavy task, and advanced vision systems are urgently needed to realize automatic inspection.

为实现钢卷端部的自动检查,现有的方法是采用多个相机对钢卷的端部进行拍照,将所得到的照片进行图像的拼接,从而得到钢卷端部的图像,对该图像进行分析可以的端部缺陷信息。由于采用面群相机所拍摄到的图像存在精度低的问题,用这种低精度的图像进行分析所得到的几何特征信息的进度也低,无法满足生产的实际需求。In order to realize the automatic inspection of the end of the steel coil, the existing method is to use multiple cameras to take pictures of the end of the steel coil, and splicing the obtained photos to obtain an image of the end of the steel coil. End defect information that can be analyzed. Due to the low precision of the images captured by the area group camera, the progress of the geometric feature information obtained by analyzing the low-precision images is also low, which cannot meet the actual needs of production.

为此开发一种能快捷得到钢卷端部几何特征的检查方法,再从所得到的几何特征中提取端部缺陷的信息,对于提高钢卷端部缺陷的设备具有重要的现实意义。Therefore, it is of great practical significance to develop an inspection method that can quickly obtain the geometric features of the coil ends, and then extract the information of the end defects from the obtained geometric features.

发明内容SUMMARY OF THE INVENTION

(一)解决的技术问题(1) Technical problems solved

针对现有技术的不足,本发明提供了一种钢卷边部几何特征的检测方法,解决了上述背景技术中所存在的问题。In view of the deficiencies of the prior art, the present invention provides a method for detecting the geometrical features of a steel bead, which solves the problems existing in the above-mentioned background technology.

(二)技术方案(2) Technical solutions

为实现上述目的,本发明提供如下技术方案:一种钢卷边部几何特征的检测方法,包括检测系统,所述检测系统包括几何特征采集系统、数据处理单元、数据传输单元和缺陷报警单元,所述几何特征采集系统包括两台高精度线扫描相机和两台6轴机械臂,两台高精度线扫描相机分别安装在两台6轴机械臂上,6轴机械臂安装在机组入口侧的卷钢鞍座之间,所述数据处理单元主要作用是对相机采集到的数据进行分析,判断钢卷边部是否存在塔形、溢出边、边裂、边损等缺陷,所述数据传输单元的主要作用是确保几何特征采集系统与数据处理单元之间的数据高速传输,所述缺陷报警单元在接收到相应的缺陷信息后,通过设置在操作室的音响向操作人员发出警报,并在旁边设置人机交互界面中显示当前边裂缺陷的二维图像,能让操作人员更直观的看到带钢端部的缺陷形貌信息,通知操作人员及时进行处理;In order to achieve the above purpose, the present invention provides the following technical solutions: a method for detecting geometrical features of a steel bead, including a detection system, the detection system includes a geometrical feature acquisition system, a data processing unit, a data transmission unit and a defect alarm unit, The geometric feature acquisition system includes two high-precision line scan cameras and two 6-axis robotic arms. The two high-precision line scan cameras are respectively installed on the two 6-axis robotic arms, and the 6-axis robotic arms are installed on the inlet side of the unit. Between the coiled steel saddles, the main function of the data processing unit is to analyze the data collected by the camera to determine whether there are defects such as tower shape, overflow edge, edge crack, edge loss, etc. The main function is to ensure high-speed data transmission between the geometric feature acquisition system and the data processing unit. After the defect alarm unit receives the corresponding defect information, it will send an alarm to the operator through the sound set in the operating room, and beside it. Setting the two-dimensional image of the current edge crack defect in the human-computer interaction interface allows the operator to see the defect morphology information at the end of the strip more intuitively, and inform the operator to deal with it in time;

所述方法的具体步骤为:The specific steps of the method are:

S1、无人小车将钢卷运送至检测位置,在此过程通过安装位置感应传感器检测钢卷鞍座是否有钢卷;S1. The unmanned trolley transports the steel coil to the detection position. During this process, the installation position induction sensor detects whether there is a steel coil in the saddle of the steel coil;

S2、中空系统接收无人小车暂停指令后,控制机器人6轴法兰携标签识别相机识别钢卷卷号,同时根据钢卷标号请求生产线控制系统传输钢卷信息;S2. After the hollow system receives the unmanned trolley pause instruction, it controls the 6-axis flange of the robot to carry a label identification camera to identify the coil number, and at the same time requests the production line control system to transmit the coil information according to the coil label;

S3、机械手携带工业相机对钢卷端面组合拍照,并发送图片至服务端进行处理和识别,提取端面边裂和边损等缺陷,同时识别出内圈奪头情况,并在上位工控机提供可视化检验结构指示;S3. The manipulator carries an industrial camera to take pictures of the steel coil end face combination, and sends the pictures to the server for processing and identification, extracting defects such as end face edge cracks and edge damage, and at the same time, identifying the situation of the inner ring winning, and providing visualization on the upper industrial computer. Inspection structure instructions;

S4、机器人通过快换装置换装超高精度位移传感器和激光定距传感器,检测钢卷内外径,同时可识别钢卷溢出边、塔形、扁卷、松卷和整体塌卷缺陷;S4. The robot is equipped with ultra-high-precision displacement sensors and laser fixed-distance sensors through the quick-change device to detect the inner and outer diameters of the steel coil, and at the same time, it can identify the overflow edge, tower shape, flat coil, loose coil and overall collapse of the coil defect;

S5、机器人携带二维位移传感器对边损和边裂区域进行重点扫描,识别出边损和边裂的深度参数;S5. The robot carries a two-dimensional displacement sensor to focus on scanning the edge damage and edge crack areas, and identifies the depth parameters of edge damage and edge cracks;

S6、前述检测结果在上位机画面上指示后,有操作工判定是否进行钢卷回退或者通过,机器人恢复原始位置并解锁无人小车进行运送钢卷至后续工位。S6. After the aforementioned detection result is indicated on the upper computer screen, an operator determines whether to roll back or pass the steel coil, and the robot restores the original position and unlocks the unmanned trolley to transport the steel coil to the subsequent station.

优选的,所述几何特征采集系统中选用的线扫描相机的分辨率不低于0.1mm,并且在非工作状态下,6轴机械臂收缩至地面。Preferably, the resolution of the line scan camera selected in the geometric feature acquisition system is not less than 0.1 mm, and in a non-working state, the 6-axis robotic arm is retracted to the ground.

优选的,所述数据处理单元判断钢卷边部是否存在塔形、溢出边、边裂、边损等缺陷采用的处理方法为:Preferably, the processing method adopted by the data processing unit for judging whether there are defects such as tower shape, overflow edge, edge crack, edge loss, etc. in the steel curling part is:

(1)对单条线扫描相机所得到的轮廓数据取出两边的无效数据,得到钢卷端部的轮廓数据,根据该有效数据进行缺陷分析;(1) Take out the invalid data on both sides of the contour data obtained by a single line scanning camera, obtain the contour data of the coil end, and perform defect analysis according to the valid data;

(2)对于塔形缺陷是指在端部存在与常规高度之间的高度差,将所测得的最高高度与常规区域所得的高度相减即可得到塔形的数据;(2) For the tower-shaped defect, it refers to the height difference between the end and the conventional height, and the tower-shaped data can be obtained by subtracting the highest measured height from the height obtained in the conventional area;

(3)对于溢出边缺陷是指在端部的内圈区域存在钢卷溢出的现象,根据钢卷内圈区域所检测到的高度值与常规区域所得的高度相减即可得到溢出边的数据;(3) For the overflow edge defect, it refers to the phenomenon that the coil overflows in the inner ring area of the end. The data of the overflow edge can be obtained by subtracting the height value detected in the inner ring area of the steel coil and the height obtained in the conventional area. ;

(4)边裂和边损缺陷的判断是根据所检测到的线扫描数据,如检测到的线扫描数据上存在某段区域远低于常规区域的值,即可判断为存在边裂和边损缺陷,缺陷的长度根据则根据所产生的轮廓数量进行判断。(4) The judgment of edge cracks and edge damage defects is based on the detected line scan data. If there is a certain area on the detected line scan data that is much lower than the value of the conventional area, it can be judged that there are edge cracks and edges. If the defect is damaged, the length of the defect is judged according to the number of contours produced.

优选的,所述数据传输单元将两台线扫描相机采集到的高度数据成组发送给数据处理单元,每组包含的线扫描轮廓条数在500-2000条之间。Preferably, the data transmission unit sends the height data collected by the two line scan cameras to the data processing unit in groups, and each group contains between 500 and 2000 line scan contours.

优选的,所述步骤S2中,标签识别相机可以识别包括一维标签、二维标签和数字标号在内的钢卷卷号。Preferably, in the step S2, the label identification camera can identify the coil number including the one-dimensional label, the two-dimensional label and the digital label.

优选的,所述步骤S2中传输的钢卷信息包括卷号、内外径、卷宽等钢卷属性信息。Preferably, the steel coil information transmitted in the step S2 includes steel coil attribute information such as coil number, inner and outer diameter, and coil width.

(三)有益效果(3) Beneficial effects

本发明提供了一种钢卷边部几何特征的检测方法,具备以下有益效果:The invention provides a method for detecting the geometrical features of a steel bead, which has the following beneficial effects:

以本发明公开的检测方法形成的检查装置,可实现对钢卷端部几何特征的自动检测,根据所检测到的几何数据分析可检查钢卷端部的塔形、溢出边、边裂、边损等缺陷的种类和大小,检测精度可达到0.5mm。同时可检测到钢卷的卷径尺寸,检测的精度可达到1.0mm。The inspection device formed by the detection method disclosed in the present invention can realize the automatic detection of the geometric features of the ends of the steel coils, and can inspect the tower shape, overflow edges, edge cracks and edges of the steel coil ends according to the analysis of the detected geometric data. The type and size of defects such as damage, the detection accuracy can reach 0.5mm. At the same time, the coil diameter size of the steel coil can be detected, and the detection accuracy can reach 1.0mm.

附图说明Description of drawings

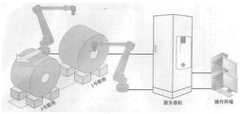

图1为本发明中检测系统的工作原理示意图;Fig. 1 is the working principle schematic diagram of detection system in the present invention;

图2为本发明中检测系统的结构示意图;Fig. 2 is the structural representation of detection system in the present invention;

图3为本发明检测单条轮廓的原始数据示意图;3 is a schematic diagram of the original data of the present invention to detect a single contour;

图4为本发明中边裂缺陷的检测结果示意图;4 is a schematic diagram of the detection results of edge crack defects in the present invention;

图5为本命中SCAL机组现场安装位置示意图;Figure 5 is a schematic diagram of the site installation location of the SCAL unit;

图6为本发明中机械臂地柜布局示意图。FIG. 6 is a schematic diagram of the layout of the robot arm base cabinet in the present invention.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

如图1所示,本发明提供一种技术方案:一种钢卷边部几何特征的检测方法,包括检测系统,所述检测系统包括几何特征采集系统、数据处理单元、数据传输单元和缺陷报警单元,所述几何特征采集系统包括两台高精度线扫描相机和两台6轴机械臂,线扫描相机的分辨率不低于0.1mm,两台高精度线扫描相机分别安装在两台6轴机械臂上,6轴机械臂安装在机组入口侧的卷钢鞍座之间,如图2所示,在非工作状态下,6轴机械臂收缩至地面,所述数据处理单元主要作用是对相机采集到的数据进行分析,判断钢卷边部是否存在塔形、溢出边、边裂、边损等缺陷,具体采用的处理方法为:As shown in FIG. 1 , the present invention provides a technical solution: a method for detecting geometrical features of a steel bead, including a detection system, the detection system includes a geometrical feature acquisition system, a data processing unit, a data transmission unit and a defect alarm unit, the geometric feature acquisition system includes two high-precision line scan cameras and two 6-axis robotic arms, the resolution of the line scan cameras is not less than 0.1mm, and the two high-precision line scan cameras are respectively installed on the two 6-axis On the manipulator, the 6-axis manipulator is installed between the coiled steel saddles on the inlet side of the unit. As shown in Figure 2, in the non-working state, the 6-axis manipulator is retracted to the ground. The main function of the data processing unit is to The data collected by the camera is analyzed to determine whether there are defects such as tower shape, overflow edge, edge crack, edge damage, etc. in the edge of the steel coil. The specific processing methods are as follows:

(1)对单条线扫描相机所得到的轮廓数据取出两边的无效数据,得到钢卷端部的轮廓数据,根据该有效数据进行缺陷分析,如图3所示;(1) Take out the invalid data on both sides of the contour data obtained by a single line scanning camera, obtain the contour data of the coil end, and perform defect analysis according to the valid data, as shown in Figure 3;

(2)对于塔形缺陷是指在端部存在与常规高度之间的高度差,将所测得的最高高度与常规区域所得的高度相减即可得到塔形的数据;(2) For the tower-shaped defect, it refers to the height difference between the end and the conventional height, and the tower-shaped data can be obtained by subtracting the highest measured height from the height obtained in the conventional area;

(3)对于溢出边缺陷是指在端部的内圈区域存在钢卷溢出的现象,根据钢卷内圈区域所检测到的高度值与常规区域所得的高度相减即可得到溢出边的数据;(3) For the overflow edge defect, it refers to the phenomenon that the coil overflows in the inner ring area of the end. The data of the overflow edge can be obtained by subtracting the height value detected in the inner ring area of the steel coil and the height obtained in the conventional area. ;

(4)边裂和边损缺陷的判断是根据所检测到的线扫描数据,如检测到的线扫描数据上存在某段区域远低于常规区域的值,即可判断为存在边裂和边损缺陷,如图4所示,缺陷的长度根据则根据所产生的轮廓数量进行判断。所述数据传输单元的主要作用是确保几何特征采集系统与数据处理单元之间的数据高速传输,将两台线扫描相机采集到的高度数据成组发送给数据处理单元,每组包含的线扫描轮廓条数在500-2000条之间,所述缺陷报警单元在接收到相应的缺陷信息后,通过设置在操作室的音响向操作人员发出警报,并在旁边设置人机交互界面中显示当前边裂缺陷的二维图像,能让操作人员更直观的看到带钢端部的缺陷形貌信息,通知操作人员及时进行处理;(4) The judgment of edge cracks and edge damage defects is based on the detected line scan data. If there is a certain area on the detected line scan data that is much lower than the value of the conventional area, it can be judged that there are edge cracks and edges. Damage defects, as shown in Figure 4, the length of the defect is judged according to the number of contours produced. The main function of the data transmission unit is to ensure high-speed data transmission between the geometric feature acquisition system and the data processing unit, and to send the height data collected by the two line scan cameras to the data processing unit in groups. The number of contour lines is between 500 and 2000. After receiving the corresponding defect information, the defect alarm unit sends an alarm to the operator through the sound set in the operating room, and displays the current edge in the human-computer interaction interface set next to it. The two-dimensional image of the crack defect allows the operator to see the defect morphology information at the end of the strip more intuitively, and inform the operator to deal with it in time;

所述方法的具体步骤为:The specific steps of the method are:

S1、无人小车将钢卷运送至检测位置,在此过程通过安装位置感应传感器检测钢卷鞍座是否有钢卷;S1. The unmanned trolley transports the steel coil to the detection position. During this process, the installation position induction sensor detects whether there is a steel coil in the saddle of the steel coil;

S2、中空系统接收无人小车暂停指令后,控制机器人6轴法兰携标签识别相机识别包括一维标签、二维标签和数字标号在内的钢卷卷号,同时根据钢卷标号请求生产线控制系统传输包括卷号、内外径、卷宽等钢卷属性信息;S2. After the hollow system receives the unmanned trolley pause command, it controls the robot's 6-axis flange-carrying label recognition camera to identify the coil number including one-dimensional labels, two-dimensional labels and digital labels, and at the same time requests the production line control according to the steel coil labels. The system transmits coil attribute information including coil number, inner and outer diameter, and coil width;

S3、机械手携带工业相机对钢卷端面组合拍照,并发送图片至服务端进行处理和识别,提取端面边裂和边损等缺陷,同时识别出内圈奪头情况,并在上位工控机提供可视化检验结构指示;S3. The manipulator carries an industrial camera to take pictures of the steel coil end face combination, and sends the pictures to the server for processing and identification, extracting defects such as end face edge cracks and edge damage, and at the same time, identifying the situation of the inner ring winning, and providing visualization on the upper industrial computer. Inspection structure instructions;

S4、机器人通过快换装置换装超高精度位移传感器和激光定距传感器,检测钢卷内外径,同时可识别钢卷溢出边、塔形、扁卷、松卷和整体塌卷缺陷;S4. The robot is equipped with ultra-high-precision displacement sensors and laser fixed-distance sensors through the quick-change device to detect the inner and outer diameters of the steel coil, and at the same time, it can identify the overflow edge, tower shape, flat coil, loose coil and overall collapse of the coil defect;

S5、机器人携带二维位移传感器对边损和边裂区域进行重点扫描,识别出边损和边裂的深度参数;S5. The robot carries a two-dimensional displacement sensor to focus on scanning the edge damage and edge crack areas, and identifies the depth parameters of edge damage and edge cracks;

S6、前述检测结果在上位机画面上指示后,有操作工判定是否进行钢卷回退或者通过,机器人恢复原始位置并解锁无人小车进行运送钢卷至后续工位。S6. After the aforementioned detection result is indicated on the upper computer screen, an operator determines whether to roll back or pass the steel coil, and the robot restores the original position and unlocks the unmanned trolley to transport the steel coil to the subsequent station.

实施例Example

某冷轧厂的SACL机组入口测钢卷端部的检查由人工完成,为提高机组的智慧制造水平,减轻操作人员的劳动负荷,提高检查精度,在此区域增设钢卷端部自动检测系统。The inspection of the coil ends at the entrance of the SACL unit of a cold rolling mill is done manually. In order to improve the intelligent manufacturing level of the unit, reduce the labor load of operators, and improve the inspection accuracy, an automatic coil end inspection system is added in this area.

(1)检测系统包含二台高精度线扫描相机和二台6轴机械臂,6轴机械臂安装在机组入口测的1#和2#卷鞍座之间,分别检查钢卷二端部的缺陷,如图5所示。检测系统线扫描相机的高度检测精度为2μm,水平方向的检测精度为25μm,机械臂地轨布置如图6所示。(1) The detection system includes two high-precision line scan cameras and two 6-axis robotic arms. The 6-axis robotic arm is installed between the 1# and 2# coil saddles measured at the entrance of the unit, and checks the two ends of the steel coil respectively. defects, as shown in Figure 5. The height detection accuracy of the line scan camera of the detection system is 2 μm, and the detection accuracy in the horizontal direction is 25 μm. The ground rail layout of the manipulator is shown in Figure 6.

(2)检测机械臂上安装有位置传感器,利用该传感器可控制线扫描相机于钢卷端部之间的距离。(2) A position sensor is installed on the detection robot arm, and the distance between the line scan camera and the end of the steel coil can be controlled by this sensor.

(3)检查系统受机组控制,当检查系统接到机组发出的检查信号后,机械臂将线扫描相机移到指定位置,机械臂上的传感器检查到相机到达指定位置后,相机开始扫面带感端部。(3) The inspection system is controlled by the crew. When the inspection system receives the inspection signal from the crew, the robotic arm moves the line scan camera to the designated position. After the sensor on the robotic arm detects that the camera has reached the designated position, the camera starts to scan the face belt. sense end.

(4)相机检测到的数据采用通讯的方式输送到数据处理单元,数据处理单元通过对检测数据的分析,判断钢卷边部是否存在塔形、溢出边、边裂、边损等缺陷。所采用的处理方法为:(4) The data detected by the camera is sent to the data processing unit by means of communication, and the data processing unit analyzes the detected data to determine whether there are defects such as tower shape, overflow edge, edge crack, edge damage, etc. The processing method used is:

①、对单条线扫描相机所得到的轮廓数据去除二边的无效数据,得到钢卷端部的轮廓数据,根据该有效数据进行缺陷分析。①. Remove the invalid data on both sides from the contour data obtained by a single line scanning camera, obtain the contour data of the coil end, and perform defect analysis according to the valid data.

②、对于塔形缺陷是指在端部存在于常规高度之间的高度差,将所测得的最高高度与常规区域所得的高度相减即可得到塔形的数据。②. For the tower-shaped defect, it refers to the height difference between the conventional heights at the end, and the tower-shaped data can be obtained by subtracting the highest measured height from the height obtained in the conventional area.

③、对于溢出边缺陷是指在端部的内圈区域存在钢卷溢出的现象,根据钢卷内圈区域所检测到的高度值与常规区域所得的高度相减即可得到溢出边的数据。③ For the overflow edge defect, it refers to the phenomenon that the coil overflows in the inner ring area of the end. The data of the overflow edge can be obtained by subtracting the height value detected in the inner ring area of the steel coil and the height obtained in the conventional area.

④、边裂和边损缺陷的判断是根据所检测到的线扫描数据,如检测到的线扫描数据上存在某段(带钢的厚度)区域远低于常规区域的值,即可判断为存在边裂和边损缺陷。缺陷的长度根据则根据所产生的轮廓数量进行判断。④. The judgment of edge cracking and edge damage defects is based on the detected line scan data. If there is a certain section (strip thickness) area on the detected line scan data, the value is much lower than that of the conventional area, which can be judged as There are edge cracks and edge damage defects. The length of the defect is judged according to the number of contours produced.

(5)数据传输单元的功能是确保数据采集系统与数据处理系统之间的数据高速传输,将两台激光相机采集到的高度数据成组发送给数据分析系统,每组包含的线扫描轮廓条数在1000条。(5) The function of the data transmission unit is to ensure high-speed data transmission between the data acquisition system and the data processing system, and to send the height data collected by the two laser cameras to the data analysis system in groups. Count in 1000.

(6)缺陷报警系统在接收到相应的缺陷信息后通过设置在操作室的音响向操作人员发出警报,并在旁边设置人机交互界面中显示当前边裂缺陷的二维图像,能让操作人员更直观得看到带钢端部的缺陷形貌信息,通知操作人员及时进行处理。(6) After receiving the corresponding defect information, the defect alarm system will send an alarm to the operator through the sound set in the operating room, and set up a human-computer interaction interface next to it to display the two-dimensional image of the current edge crack defect, which allows the operator to It is more intuitive to see the defect morphology information at the end of the strip, and notify the operator to deal with it in time.

需要说明的是,在本文中,诸如第一和第二等之类的关系术语仅仅用来将一个实体或者操作与另一个实体或操作区分开来,而不一定要求或者暗示这些实体或操作之间存在任何这种实际的关系或者顺序。而且,术语“包括”、“包含”或者其任何其他变体意在涵盖非排他性的包含,从而使得包括一系列要素的过程、方法、物品或者设备不仅包括那些要素,而且还包括没有明确列出的其他要素,或者是还包括为这种过程、方法、物品或者设备所固有的要素。It should be noted that, in this document, relational terms such as first and second are only used to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply any relationship between these entities or operations. any such actual relationship or sequence exists. Moreover, the terms "comprising", "comprising" or any other variation thereof are intended to encompass a non-exclusive inclusion such that a process, method, article or device that includes a list of elements includes not only those elements, but also includes not explicitly listed or other elements inherent to such a process, method, article or apparatus.

尽管已经示出和描述了本发明的实施例,对于本领域的普通技术人员而言,可以理解在不脱离本发明的原理和精神的情况下可以对这些实施例进行多种变化、修改、替换和变型,本发明的范围由所附权利要求及其等同物限定。Although embodiments of the present invention have been shown and described, it will be understood by those skilled in the art that various changes, modifications, and substitutions can be made in these embodiments without departing from the principle and spirit of the invention and modifications, the scope of the present invention is defined by the appended claims and their equivalents.

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210065525.8ACN114486913A (en) | 2022-01-20 | 2022-01-20 | Method for detecting geometric characteristics of edge of steel coil |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210065525.8ACN114486913A (en) | 2022-01-20 | 2022-01-20 | Method for detecting geometric characteristics of edge of steel coil |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114486913Atrue CN114486913A (en) | 2022-05-13 |

Family

ID=81471919

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210065525.8APendingCN114486913A (en) | 2022-01-20 | 2022-01-20 | Method for detecting geometric characteristics of edge of steel coil |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114486913A (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115541601A (en)* | 2022-11-30 | 2022-12-30 | 江苏永钢集团有限公司 | Steel low-power digital detection method based on machine vision |

| CN118533096A (en)* | 2024-06-13 | 2024-08-23 | 特变电工京津冀智能科技有限公司 | Transformer coil appearance check out test set |

| WO2025045589A1 (en)* | 2023-08-29 | 2025-03-06 | Hitachi Energy Ltd | Inspection of steel element |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103207185A (en)* | 2012-01-11 | 2013-07-17 | 宝山钢铁股份有限公司 | Steel coil end portion quality detection system and method thereof |

| JP2014069216A (en)* | 2012-09-28 | 2014-04-21 | Jfe Steel Corp | Method and apparatus for detecting edge defect of steel belt coil |

| CN104084426A (en)* | 2014-07-02 | 2014-10-08 | 济钢集团有限公司 | Cold rolled product plate type control system based on hot rolling process control |

| CN110017784A (en)* | 2018-01-09 | 2019-07-16 | 宝山钢铁股份有限公司 | A kind of online quality inspection device of curling steel roll end and method |

| CN110245663A (en)* | 2019-06-26 | 2019-09-17 | 上海电器科学研究所(集团)有限公司 | One kind knowing method for distinguishing for coil of strip information |

| CN112432592A (en)* | 2019-08-26 | 2021-03-02 | 宝山钢铁股份有限公司 | Horizontal steel coil shape quality detection device and detection method thereof |

| CN113269759A (en)* | 2021-05-28 | 2021-08-17 | 中冶赛迪重庆信息技术有限公司 | Steel coil information detection method, system, medium and terminal based on image recognition |

| CN113465511A (en)* | 2021-06-19 | 2021-10-01 | 精锐视觉智能科技(上海)有限公司 | Online measurement and omnibearing end surface defect online detection method for steel coil size |

| CN113844743A (en)* | 2020-06-28 | 2021-12-28 | 上海梅山钢铁股份有限公司 | Robot automatic tape searching and labeling control method |

- 2022

- 2022-01-20CNCN202210065525.8Apatent/CN114486913A/enactivePending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103207185A (en)* | 2012-01-11 | 2013-07-17 | 宝山钢铁股份有限公司 | Steel coil end portion quality detection system and method thereof |

| JP2014069216A (en)* | 2012-09-28 | 2014-04-21 | Jfe Steel Corp | Method and apparatus for detecting edge defect of steel belt coil |

| CN104084426A (en)* | 2014-07-02 | 2014-10-08 | 济钢集团有限公司 | Cold rolled product plate type control system based on hot rolling process control |

| CN110017784A (en)* | 2018-01-09 | 2019-07-16 | 宝山钢铁股份有限公司 | A kind of online quality inspection device of curling steel roll end and method |

| CN110245663A (en)* | 2019-06-26 | 2019-09-17 | 上海电器科学研究所(集团)有限公司 | One kind knowing method for distinguishing for coil of strip information |

| CN112432592A (en)* | 2019-08-26 | 2021-03-02 | 宝山钢铁股份有限公司 | Horizontal steel coil shape quality detection device and detection method thereof |

| CN113844743A (en)* | 2020-06-28 | 2021-12-28 | 上海梅山钢铁股份有限公司 | Robot automatic tape searching and labeling control method |

| CN113269759A (en)* | 2021-05-28 | 2021-08-17 | 中冶赛迪重庆信息技术有限公司 | Steel coil information detection method, system, medium and terminal based on image recognition |

| CN113465511A (en)* | 2021-06-19 | 2021-10-01 | 精锐视觉智能科技(上海)有限公司 | Online measurement and omnibearing end surface defect online detection method for steel coil size |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115541601A (en)* | 2022-11-30 | 2022-12-30 | 江苏永钢集团有限公司 | Steel low-power digital detection method based on machine vision |

| WO2025045589A1 (en)* | 2023-08-29 | 2025-03-06 | Hitachi Energy Ltd | Inspection of steel element |

| CN118533096A (en)* | 2024-06-13 | 2024-08-23 | 特变电工京津冀智能科技有限公司 | Transformer coil appearance check out test set |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN114486913A (en) | Method for detecting geometric characteristics of edge of steel coil | |

| CN104608799B (en) | Based on information fusion technology Railway wheelset tread damage on-line checking and recognition methodss | |

| CN110057198B (en) | Method and device for detecting working state of trolley wheel of sintering machine | |

| CN107525813A (en) | Steel plate defect on-line intelligence vision detection system | |

| CN108458668A (en) | Slab edge and Head and Tail Shape automatic checkout system based on binocular vision and method | |

| CN110044183B (en) | Fang detection automatic feeding method based on machine vision | |

| JP5974787B2 (en) | Edge defect detection method and edge defect detection apparatus for steel strip coil | |

| KR101622444B1 (en) | Shape inspection apparatus and method of bar steel | |

| CN102628812A (en) | System and method for automatically judging subvolume surface quality grade | |

| CN107803606A (en) | A kind of detection method for quality of welding line and device based on overall process mark | |

| CN106355590B (en) | Mold residue visual detection method and device based on image difference making | |

| CN110632110A (en) | Visual identification device and method for surface defects of steel sample by X-ray fluorescence spectrometer | |

| CN113532328B (en) | Real-time surface profile measuring system and method for medium plate straightening process | |

| CN114406014B (en) | Online detection system and method for edge crack defects of strip steel | |

| TW201217080A (en) | capable of detecting steel billet defect in real time and displaying detection results in order to determine the process stability and the features of steel grades | |

| CN112365538B (en) | Efficient target detection method of automatic reeling system | |

| CN113701652A (en) | Intelligent high-precision detection and defect diagnosis system for inner diameter of steel coil | |

| CN114565672A (en) | Section bar end position detection method for stretching and straightening of section bar based on depth camera | |

| JP2007187497A (en) | Method and apparatus for detecting inner diameter crush of rolled coil | |

| CN210533305U (en) | Ceramic tile roughness check out test set | |

| CN118329898A (en) | Visual-based forge piece surface defect detection system and detection method thereof | |

| CN112710238A (en) | Continuous casting billet length photographing and sizing device and method | |

| JP3155681B2 (en) | Coil winding shape measuring method, its measuring device, and coil winding shape monitoring device | |

| CN102519983B (en) | Method for detecting pressing mark of photovoltaic aluminum section on line | |

| CN202928965U (en) | Detection device for surface defects of billet |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20220513 | |

| RJ01 | Rejection of invention patent application after publication |