CN114477383A - A low-voltage direct current U-shaped tubular protein flocculator - Google Patents

A low-voltage direct current U-shaped tubular protein flocculatorDownload PDFInfo

- Publication number

- CN114477383A CN114477383ACN202210161640.5ACN202210161640ACN114477383ACN 114477383 ACN114477383 ACN 114477383ACN 202210161640 ACN202210161640 ACN 202210161640ACN 114477383 ACN114477383 ACN 114477383A

- Authority

- CN

- China

- Prior art keywords

- electrode

- flocculator

- container

- valve

- protein

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/46—Treatment of water, waste water, or sewage by electrochemical methods

- C02F1/461—Treatment of water, waste water, or sewage by electrochemical methods by electrolysis

- C02F1/463—Treatment of water, waste water, or sewage by electrochemical methods by electrolysis by electrocoagulation

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2201/00—Apparatus for treatment of water, waste water or sewage

- C02F2201/46—Apparatus for electrochemical processes

- C02F2201/461—Electrolysis apparatus

- C02F2201/46105—Details relating to the electrolytic devices

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2201/00—Apparatus for treatment of water, waste water or sewage

- C02F2201/46—Apparatus for electrochemical processes

- C02F2201/461—Electrolysis apparatus

- C02F2201/46105—Details relating to the electrolytic devices

- C02F2201/4616—Power supply

- C02F2201/4617—DC only

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F2301/00—General aspects of water treatment

- C02F2301/08—Multistage treatments, e.g. repetition of the same process step under different conditions

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Hydrology & Water Resources (AREA)

- Engineering & Computer Science (AREA)

- Environmental & Geological Engineering (AREA)

- Water Supply & Treatment (AREA)

- Organic Chemistry (AREA)

- Water Treatment By Electricity Or Magnetism (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及絮凝及污水处理设备技术领域,具体涉及一种低压直流电U型管蛋白絮凝器。The invention relates to the technical field of flocculation and sewage treatment equipment, in particular to a low-voltage direct current U-shaped tubular protein flocculator.

背景技术Background technique

絮凝是指使水或液体中悬浮微粒集聚变大,或形成絮团,从而加快粒子的聚沉,达到固一液分离的目的,这一现象或操作称作絮凝。目前市场上的絮凝装备普遍使用交流电,能耗高、价格比较贵,且使用时不能有效的对水体中的絮状物进行清除,而且传统的絮凝反应器在除絮凝质量较低。Flocculation refers to the aggregation of suspended particles in water or liquid, or the formation of flocs, thereby accelerating the coagulation of particles and achieving the purpose of solid-liquid separation. This phenomenon or operation is called flocculation. At present, the flocculation equipment on the market generally uses alternating current, which has high energy consumption and high price, and cannot effectively remove flocs in the water body during use, and the traditional flocculation reactor has low flocculation quality.

发明内容SUMMARY OF THE INVENTION

本发明的目的就是为了克服上述现有技术存在的不足而设计制造,以解决现有的技术缺陷和不能达到的技术要求。为此本发明提供了一款低成本、易推广的低压直流电生物质污染物U型管絮凝器,解决了传统的电絮凝反应器使用不便及成本高等问题。The purpose of the present invention is to design and manufacture to overcome the above-mentioned deficiencies of the prior art, so as to solve the existing technical defects and unattainable technical requirements. Therefore, the present invention provides a low-cost and easy-to-promote low-voltage direct current U-tube flocculator for biomass pollutants, which solves the problems of inconvenience and high cost of traditional electric flocculation reactors.

为实现上述目的,本发明提供如下技术方案:To achieve the above object, the present invention provides the following technical solutions:

一种低压直流电U型管蛋白絮凝器,包括多个连接的U型管絮凝单元,A low-voltage direct current U-shaped tube protein flocculator, comprising a plurality of connected U-shaped tube flocculation units,

所述的U型管絮凝单元包括:The U-shaped tube flocculation unit includes:

两个容器,所述的两个容器的底部通过U型管连接;Two containers, the bottoms of the two containers are connected by a U-shaped pipe;

各自分别设置在所述两个容器中的电极阴极和电极阳极,即在一个容器中设置电极阴极,在另一个容器中设置电极阳极;The electrode cathodes and the electrode anodes are respectively arranged in the two containers, that is, the electrode cathodes are arranged in one container, and the electrode anodes are arranged in the other container;

与所述电极阴极和电极阳极连接的直流电源;a DC power supply connected to the electrode cathode and the electrode anode;

设置在所述电极阴极所在容器顶部的氢气收集装置;a hydrogen collecting device arranged on the top of the container where the electrode cathode is located;

设置在所述电极阳极所在容器上的第一阀门;a first valve arranged on the container where the electrode anode is located;

设置在所述电极阴极所在容器上的第二阀门。A second valve provided on the container where the electrode cathode is located.

本发明中,通电一定时间后打开第二阀门,再打开第一阀门,最后打开底部橡胶盖得到浓缩后的蛋白,从而对蛋白达到浓缩,对水体的净化作用。U型管絮凝单元可以串联,对水中蛋白絮凝浓缩,依次对水体的净化。In the present invention, the second valve is turned on after a certain period of time, then the first valve is opened, and finally the bottom rubber cover is opened to obtain the concentrated protein, so as to achieve the concentration of the protein and the purification of the water body. The U-tube flocculation unit can be connected in series to flocculate and concentrate the protein in the water, and purify the water in turn.

优选的,所述的容器为圆筒型,材质为聚苯乙烯、聚氯乙烯、聚乙烯、聚甲基丙烯酸甲酯、聚碳酸酯中的一种。圆筒型容器的直径与其高度之比在1:2~1:5,壁厚在0.2~2cm。Preferably, the container is cylindrical, and the material is one of polystyrene, polyvinyl chloride, polyethylene, polymethyl methacrylate, and polycarbonate. The ratio of the diameter of the cylindrical container to its height is 1:2-1:5, and the wall thickness is 0.2-2cm.

两个容器的底部设置有橡胶盖,两个容器的底部通过U型管连接到橡胶盖上。The bottoms of the two containers are provided with rubber caps, and the bottoms of the two containers are connected to the rubber caps through U-shaped pipes.

优选的,所述的电极阴极为石墨。Preferably, the electrode cathode is graphite.

优选的,所述的电极阳极为铝片、铜铝合金片、铂片和钛片中的一种,片的厚度为1~6mm,长和宽的比例5:1~10:1。Preferably, the electrode anode is one of aluminum sheet, copper-aluminum alloy sheet, platinum sheet and titanium sheet, the thickness of the sheet is 1-6 mm, and the ratio of length to width is 5:1-10:1.

优选的,所述的电极阴极和电极阳极(即两片电极)之间的距离为容器宽度的3/5~3/4,每片电极离仪器内壁的距离相同。Preferably, the distance between the electrode cathode and the electrode anode (ie, two electrodes) is 3/5 to 3/4 of the width of the container, and the distance between each electrode and the inner wall of the instrument is the same.

优选的,所述的直流电源的电压范围是在5~40V可调,电流在0.1~3A可调。Preferably, the voltage range of the DC power supply is adjustable at 5-40V, and the current is adjustable at 0.1-3A.

阴极处有氢气收集管道,可外连收集气瓶,氢气收集管道和收集气瓶形成氢气收集装置。There is a hydrogen collection pipe at the cathode, which can be connected with a collection gas cylinder, and the hydrogen collection pipe and the collection gas cylinder form a hydrogen collection device.

优选的,所述的第一阀门位于所在容器距离底部距离1/4处。Preferably, the first valve is located at 1/4 of the distance from the bottom of the container where it is located.

优选的,所述的第二阀门位于所在容器距离底部距离1/3处。Preferably, the second valve is located at 1/3 of the distance from the bottom of the container where it is located.

所述的U型管絮凝单元为多个,最优选为两个,所述的U型管絮凝单元的第一阀门与下一个U型管絮凝单元的电极阴极所在容器的顶部连接。There are multiple U-shaped tube flocculation units, most preferably two, and the first valve of the U-shaped tube flocculation unit is connected to the top of the container where the electrode cathode of the next U-shaped tube flocculation unit is located.

与现有技术相比,本发明的有益效果如下:Compared with the prior art, the beneficial effects of the present invention are as follows:

本发明所述的低压直流电U型管蛋白絮凝器搭建简单方便,可根据工艺需要灵活设计,成本低,能耗低,能够长久使用,易于推广使用。The low-voltage direct current U-shaped tubular protein flocculator of the present invention is simple and convenient to build, can be flexibly designed according to process requirements, has low cost, low energy consumption, can be used for a long time, and is easy to popularize and use.

附图说明Description of drawings

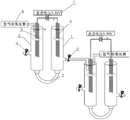

图1为本发明低压直流电U型管蛋白絮凝器的结构示意图。FIG. 1 is a schematic structural diagram of a low-voltage direct current U-shaped tubulin flocculator according to the present invention.

具体实施方式Detailed ways

下面结合具体实施例对本发明的技术方案作进一步详细的描述。本领域技术人员应理解,下面的实施例仅用于本说明,并不用于限制本发明的范围。The technical solutions of the present invention will be described in further detail below with reference to specific embodiments. It should be understood by those skilled in the art that the following examples are only used for the description and are not used to limit the scope of the present invention.

下述实施例中所采用的蛋白为丝胶蛋白(分子量8000)、丝胶蛋白(分子量3000)、牛血清蛋白(分子量50000),蛋白浓度配置为12g/L,电极之间距离为40cm,U型管絮凝器的直径为50cm,U型管絮凝器整体高度为200cm,电极位置在靠近U型管絮凝器中间位置。具体装置图如图1所示。一种低压直流电U型管蛋白絮凝器,包括两个连接的U型管絮凝单元,每个U型管絮凝单元包括:两个容器(容器5和容器1),两个容器的底部设置有橡胶盖,通过U型管3连接;设置在容器5中的电极阴极8;设置在容器1中的电极阳极9;与电极阴极8和电极阳极9连接的直流电源7;设置在电极阴极9所在容器5顶部的氢气收集装置;设置在电极阳极9所在容器1上的第一阀门2;设置在电极阴极8所在容器1上的第二阀门4。第一阀门2位于容器1距离底部距离1/4处。第二阀门4位于所在容器5距离底部距离1/3处。The proteins used in the following examples are sericin (molecular weight 8000), sericin (molecular weight 3000), and bovine serum albumin (molecular weight 50000). The diameter of the type tube flocculator is 50cm, the overall height of the U type tube flocculator is 200cm, and the electrode position is close to the middle position of the U type tube flocculator. The specific device diagram is shown in Figure 1. A low-voltage direct current U-shaped tube protein flocculator, comprising two connected U-shaped tube flocculation units, each U-shaped tube flocculation unit including: two containers (

实施例1Example 1

在室温25℃条件下取U型管絮凝器容量4/5的分子量为8000的丝胶粉水溶液于U型管絮凝器中,阳极材料为铂电极,电极表面积为100mm×20mm,阴极为石墨电极,电极表面积为100mm×20mm。接通低压直流电源,通电30分钟后将最上层液体通过阀门1排出,然后将剩余上层混合液通过阀门2排至2号U型管絮凝器中,最后将1号处理池剩余的混合物通过底部排出。蒸发溶液,获得粉末,计算固含量为56.7%,蛋白一次絮凝回收率为49.3%。Under the condition of room temperature and 25 ℃, take the sericin powder aqueous solution with a molecular weight of 8000, which is 4/5 of the capacity of the U-tube flocculator, and put it in the U-tube flocculator. The anode material is a platinum electrode, the electrode surface area is 100mm×20mm, and the cathode is a graphite electrode. , the electrode surface area is 100mm × 20mm. Turn on the low-voltage DC power supply, and after 30 minutes of power-on, discharge the top layer liquid through valve 1, then discharge the remaining upper layer mixed liquid through valve 2 to the No. 2 U-tube flocculator, and finally pass the remaining mixture in the No. 1 treatment tank through the bottom. discharge. The solution was evaporated to obtain a powder with a calculated solid content of 56.7% and a protein flocculation recovery rate of 49.3%.

实施例2Example 2

室温25℃条件下取U型管絮凝器容量4/5的分子量为8000的丝胶粉水溶液于U型管絮凝器中,阳极材料为铜铝合金电极,电极表面积为100mm×20mm,阴极为石墨电极,电极表面积为100mm×20mm。接通低压直流电源,通电40分钟后将最上层液体通过阀门1排出,然后将剩余上层混合液通过阀门2排至2号U型管絮凝器中,最后将1号处理池剩余的混合物通过底部排出。蒸发溶液,获得粉末,计算固含量为68.5%,蛋白一次絮凝回收率为57.3%。Under the condition of room temperature and 25 ℃, take the sericin powder aqueous solution with a molecular weight of 8000, which is 4/5 of the capacity of the U-tube flocculator, and put it in the U-tube flocculator. The anode material is copper-aluminum alloy electrode, the electrode surface area is 100mm×20mm, and the cathode is graphite. Electrode, the electrode surface area is 100mm × 20mm. Turn on the low-voltage DC power supply, and after 40 minutes of power-on, discharge the top layer liquid through valve 1, then discharge the remaining upper layer mixed liquid through valve 2 to the No. 2 U-tube flocculator, and finally pass the remaining mixture in the No. 1 treatment tank through the bottom. discharge. The solution was evaporated to obtain a powder, the calculated solid content was 68.5%, and the protein flocculation recovery rate was 57.3%.

实施例3Example 3

室温25℃条件下取U型管絮凝器容量4/5的分子量为8000的丝胶粉水溶液于U型管絮凝器中,阳极材料为铝电极,电极表面积为100mm×20mm,阴极为石墨电极,电极表面积为100mm×20mm。接通低压直流电源,通电50分钟后将最上层液体通过阀门1排出,然后将剩余上层混合液通过阀门2排至2号U型管絮凝器中,最后将1号处理池剩余的混合物通过底部排出。蒸发溶液,获得粉末,计算固含量为68.5%,蛋白一次絮凝回收率为51.2%。Under the condition of room temperature and 25℃, take the sericin powder aqueous solution with a molecular weight of 8000, which is 4/5 of the capacity of the U-tube flocculator, and put it in the U-tube flocculator. The anode material is an aluminum electrode, the electrode surface area is 100mm×20mm, and the cathode is a graphite electrode. The electrode surface area was 100 mm x 20 mm. Turn on the low-voltage DC power supply, and after 50 minutes of power-on, discharge the top layer liquid through valve 1, then discharge the remaining upper layer mixed liquid through valve 2 to the No. 2 U-tube flocculator, and finally pass the remaining mixture in the No. 1 treatment tank through the bottom. discharge. The solution was evaporated to obtain a powder with a calculated solid content of 68.5% and a protein flocculation recovery rate of 51.2%.

实施例4Example 4

室温25℃条件下取U型管絮凝器容量4/5的分子量为8000的丝胶粉水溶液于U型管絮凝器中,阳极材料为铂电极,电极表面积为100mm×20mm,阴极为石墨电极,电极表面积为100mm×20mm。接通低压直流电源,通电60分钟后将最上层液体通过阀门1排出,然后将剩余上层混合液通过阀门2排至2号U型管絮凝器中,最后将1号处理池剩余的混合物通过底部排出。蒸发溶液,获得粉末,计算固含量为79.6%,蛋白一次絮凝回收率为64.3%。Under the condition of room temperature and 25℃, take the sericin powder aqueous solution with a molecular weight of 8000, which is 4/5 of the capacity of the U-tube flocculator, and put it in the U-tube flocculator. The anode material is a platinum electrode, the electrode surface area is 100mm × 20mm, and the cathode is a graphite electrode. The electrode surface area was 100 mm x 20 mm. Turn on the low-voltage DC power supply, and after 60 minutes of power-on, discharge the top layer liquid through valve 1, then discharge the remaining upper layer mixed liquid through valve 2 to the No. 2 U-tube flocculator, and finally pass the remaining mixture in the No. 1 treatment tank through the bottom. discharge. The solution was evaporated to obtain a powder with a calculated solid content of 79.6% and a protein flocculation recovery rate of 64.3%.

实施例5Example 5

室温25℃条件下取U型管絮凝器容量4/5的分子量为8000的丝胶粉水溶液于U型管絮凝器中,阳极材料为铂电极,电极表面积为100mm×20mm,阴极为石墨电极,电极表面积为100mm×20mm。接通低压直流电源,通电70分钟后将最上层液体通过阀门1排出,然后将剩余上层混合液通过阀门2排至2号U型管絮凝器中,最后将1号处理池剩余的混合物通过底部排出。蒸发溶液,获得粉末,计算固含量为83.9%,蛋白一次絮凝回收率为54.8%。Under the condition of room temperature and 25℃, take the sericin powder aqueous solution with a molecular weight of 8000, which is 4/5 of the capacity of the U-tube flocculator, and put it in the U-tube flocculator. The anode material is a platinum electrode, the electrode surface area is 100mm × 20mm, and the cathode is a graphite electrode. The electrode surface area was 100 mm x 20 mm. Turn on the low-voltage DC power supply, and after 70 minutes of power-on, discharge the top layer liquid through valve 1, then discharge the remaining upper layer mixed liquid through valve 2 to the No. 2 U-tube flocculator, and finally pass the remaining mixture in the No. 1 treatment tank through the bottom. discharge. The solution was evaporated to obtain a powder with a calculated solid content of 83.9% and a protein flocculation recovery rate of 54.8%.

实施例6Example 6

室温25℃条件下取U型管絮凝器容量4/5的分子量为8000的丝胶粉水溶液于U型管絮凝器中,阳极材料为铂电极,电极表面积为100mm×20mm,阴极为石墨电极,电极表面积为100mm×20mm。接通低压直流电源,通电80分钟后将最上层液体通过阀门1排出,然后将剩余上层混合液通过阀门2排至2号U型管絮凝器中,最后将1号处理池剩余的混合物通过底部排出。蒸发溶液,获得粉末,计算固含量为84.1%,蛋白一次絮凝回收率为57.2%。Under the condition of room temperature and 25℃, take the sericin powder aqueous solution with a molecular weight of 8000, which is 4/5 of the capacity of the U-tube flocculator, and put it in the U-tube flocculator. The anode material is a platinum electrode, the electrode surface area is 100mm × 20mm, and the cathode is a graphite electrode. The electrode surface area was 100 mm x 20 mm. Turn on the low-voltage DC power supply, and after 80 minutes of power-on, discharge the top layer liquid through valve 1, then discharge the remaining upper layer mixed liquid through valve 2 to the No. 2 U-tube flocculator, and finally pass the remaining mixture in the No. 1 treatment tank through the bottom. discharge. The solution was evaporated to obtain a powder with a calculated solid content of 84.1% and a protein flocculation recovery rate of 57.2%.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210161640.5ACN114477383A (en) | 2022-02-22 | 2022-02-22 | A low-voltage direct current U-shaped tubular protein flocculator |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210161640.5ACN114477383A (en) | 2022-02-22 | 2022-02-22 | A low-voltage direct current U-shaped tubular protein flocculator |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114477383Atrue CN114477383A (en) | 2022-05-13 |

Family

ID=81482233

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210161640.5APendingCN114477383A (en) | 2022-02-22 | 2022-02-22 | A low-voltage direct current U-shaped tubular protein flocculator |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114477383A (en) |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4219417A (en)* | 1976-12-21 | 1980-08-26 | Dravo Corporation | Wastewater flotation utilizing streaming potential adjustment |

| US4271028A (en)* | 1976-07-02 | 1981-06-02 | Ciba-Geigy Corporation | Process for purifying effluents containing proteins |

| US20110266203A1 (en)* | 2010-04-01 | 2011-11-03 | Sean Frisky | Method and apparatus for electrocoagulation |

| CN106186516A (en)* | 2014-10-24 | 2016-12-07 | 吴昊 | A kind of Waste Water Treatment |

| CN211004910U (en)* | 2019-09-11 | 2020-07-14 | 佛山市叶绿体环保科技有限公司 | Electric flocculation precipitation device for sewage treatment |

| CN112520913A (en)* | 2020-11-09 | 2021-03-19 | 产学研(广州)环境服务有限公司 | Pretreatment process for treating refractory organic wastewater by electric flocculation |

| CN214551390U (en)* | 2021-01-22 | 2021-11-02 | 山东普尼奥水处理有限公司 | Precipitation device is used in production of high-efficient phosphorus removal agent |

- 2022

- 2022-02-22CNCN202210161640.5Apatent/CN114477383A/enactivePending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4271028A (en)* | 1976-07-02 | 1981-06-02 | Ciba-Geigy Corporation | Process for purifying effluents containing proteins |

| US4219417A (en)* | 1976-12-21 | 1980-08-26 | Dravo Corporation | Wastewater flotation utilizing streaming potential adjustment |

| US20110266203A1 (en)* | 2010-04-01 | 2011-11-03 | Sean Frisky | Method and apparatus for electrocoagulation |

| CN106186516A (en)* | 2014-10-24 | 2016-12-07 | 吴昊 | A kind of Waste Water Treatment |

| CN211004910U (en)* | 2019-09-11 | 2020-07-14 | 佛山市叶绿体环保科技有限公司 | Electric flocculation precipitation device for sewage treatment |

| CN112520913A (en)* | 2020-11-09 | 2021-03-19 | 产学研(广州)环境服务有限公司 | Pretreatment process for treating refractory organic wastewater by electric flocculation |

| CN214551390U (en)* | 2021-01-22 | 2021-11-02 | 山东普尼奥水处理有限公司 | Precipitation device is used in production of high-efficient phosphorus removal agent |

Non-Patent Citations (1)

| Title |

|---|

| 王仲旭等: "污水治理技术与运行管理", 中国环境科学出版社* |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN101958424B (en) | Sleeve-type non-membrane microbial electrolytic cell for hydrogen production | |

| CN103936106B (en) | Electrochemical synchronous nitrogen and phosphorus removal apparatus and municipal sewage treatment method | |

| CN112939155B (en) | Method for degrading medical wastewater by using active carbon fiber electrode capacitance to activate persulfate | |

| CN114956264B (en) | Method for separating bromine in liquid by using electrochemistry | |

| CN101942675A (en) | A kind of electrolytic reduction reclaims the method for Sn2+ in waste water | |

| CN110559841A (en) | Electrochemistry improved biological filter tower purification device and application thereof | |

| CN114477383A (en) | A low-voltage direct current U-shaped tubular protein flocculator | |

| CN114394665B (en) | Electric flocculation reinforced self-air-floatation anaerobic bioreactor | |

| CN2076099U (en) | Sewage treatment apparatus by electrochemical method | |

| CN115676978A (en) | An electrochemical reaction device and method for simultaneously recovering nitrogen and phosphorus in sewage | |

| CN219217665U (en) | A low-voltage direct current protein flocculator | |

| CN204607785U (en) | Novel energy-conserving effluent treatment plant | |

| CN201415954Y (en) | Vertical flow electric floating solid-liquid separation reactor | |

| CN110642340A (en) | Circulating flow type electric-assisted ozone water treatment equipment and method for treating water by using same | |

| CN112939158B (en) | Flow electrode capacitance deionization and amplification device based on front current collector | |

| CN108298682A (en) | A new type of anaerobic membrane electrobiological treatment process for low-strength organic wastewater | |

| CN205590808U (en) | Whirl electrolytic device | |

| CN201141042Y (en) | An electrochemical reactor for reducing and regenerating lead with lead-containing paste slime cathode | |

| CN102010034B (en) | Preparation device of ferron used for water treatment and application method thereof | |

| CN213121716U (en) | Experimental device for electrophoretic separation protein | |

| CN108793399A (en) | External immersion electro-catalysis anaerobic membrane biological reaction device | |

| WO2021233300A1 (en) | Apparatus and method for preparing high-purity iron using consumable anode electrolytic deposition | |

| CN108217984A (en) | Three-diemsnional electrode coupling microorganism electrolysis cell processing ammonia nitrogen waste water recycling ammonia device | |

| CN108640441A (en) | A kind of new and effective buried sewage treatment equipment | |

| CN108623059A (en) | A kind of method and device for freezing Precipitating pressure reverse osmosis removal water pollutant |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20220513 |