CN114444313B - Biological tissue recognition system - Google Patents

Biological tissue recognition systemDownload PDFInfo

- Publication number

- CN114444313B CN114444313BCN202210110212.XACN202210110212ACN114444313BCN 114444313 BCN114444313 BCN 114444313BCN 202210110212 ACN202210110212 ACN 202210110212ACN 114444313 BCN114444313 BCN 114444313B

- Authority

- CN

- China

- Prior art keywords

- cutting

- surgical

- surgical instrument

- biological tissue

- linear

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G06F30/20—Design optimisation, verification or simulation

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/32—Surgical cutting instruments

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B90/00—Instruments, implements or accessories specially adapted for surgery or diagnosis and not covered by any of the groups A61B1/00 - A61B50/00, e.g. for luxation treatment or for protecting wound edges

- A61B90/06—Measuring instruments not otherwise provided for

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B17/00—Surgical instruments, devices or methods

- A61B17/32—Surgical cutting instruments

- A61B2017/320052—Guides for cutting instruments

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61B—DIAGNOSIS; SURGERY; IDENTIFICATION

- A61B90/00—Instruments, implements or accessories specially adapted for surgery or diagnosis and not covered by any of the groups A61B1/00 - A61B50/00, e.g. for luxation treatment or for protecting wound edges

- A61B90/06—Measuring instruments not otherwise provided for

- A61B2090/064—Measuring instruments not otherwise provided for for measuring force, pressure or mechanical tension

- A61B2090/065—Measuring instruments not otherwise provided for for measuring force, pressure or mechanical tension for measuring contact or contact pressure

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2111/00—Details relating to CAD techniques

- G06F2111/10—Numerical modelling

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2119/00—Details relating to the type or aim of the analysis or the optimisation

- G06F2119/14—Force analysis or force optimisation, e.g. static or dynamic forces

Landscapes

- Health & Medical Sciences (AREA)

- Engineering & Computer Science (AREA)

- Surgery (AREA)

- Life Sciences & Earth Sciences (AREA)

- Molecular Biology (AREA)

- Public Health (AREA)

- Theoretical Computer Science (AREA)

- Biomedical Technology (AREA)

- Heart & Thoracic Surgery (AREA)

- Medical Informatics (AREA)

- Nuclear Medicine, Radiotherapy & Molecular Imaging (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Physics & Mathematics (AREA)

- Veterinary Medicine (AREA)

- Pathology (AREA)

- Computer Hardware Design (AREA)

- Evolutionary Computation (AREA)

- Geometry (AREA)

- General Engineering & Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Oral & Maxillofacial Surgery (AREA)

- Surgical Instruments (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及医疗器械技术领域,特别涉及一种生物组织识别系统。The invention relates to the technical field of medical devices, in particular to a biological tissue identification system.

背景技术Background technique

外科手术过程中,特别是骨科微创手术环境中,与手术工具接触的组织识别是医生判断手术操作安全性的关键。大部分情况下,是医生凭借经验判断,或采用器械与组织的接触力来判断组织材料。由于接触力与材料的属性没有显著的对应关系,因此判断正确率存在不足。也有部分现有技术是基于切割过程中的切割力和切割声音等物理特征,推断人体组织。然而,由于切割过程复杂,包括利用切割手术器械将组织从人体上剪切下来的切削运动和驱动切割手术器械进入人体的进给运动。进给运动是机器人/医生根据临床需求提供,切削运动是临床动力设备提供。动力设备不同,进给速度不同,对切割力的影响各不一样。同时,人体的个性化差异,人体组织的材料属性也有很大区别。因此,现有的人体组织识别技术还无法满足临床需求。During surgical operations, especially in orthopedic minimally invasive surgical environments, tissue identification in contact with surgical tools is the key for doctors to judge the safety of surgical operations. In most cases, doctors rely on empirical judgment, or use the contact force between the instrument and the tissue to judge the tissue material. Since there is no significant correspondence between the contact force and the properties of the material, the correct rate of judgment is insufficient. There are also some existing technologies that infer human tissue based on physical characteristics such as cutting force and cutting sound during the cutting process. However, because the cutting process is complicated, it includes a cutting motion of cutting tissue from the human body by using the cutting surgical instrument and a feeding motion of driving the cutting surgical instrument into the human body. The feeding movement is provided by the robot/doctor according to clinical needs, and the cutting movement is provided by clinical power equipment. The power equipment is different, the feed speed is different, and the influence on the cutting force is different. At the same time, the individual differences of the human body and the material properties of human tissue are also very different. Therefore, the existing human tissue recognition technology cannot meet the clinical needs.

发明内容Contents of the invention

鉴于现有技术中的上述缺陷或不足,本发明提供了一种生物组织识别系统,通过建立切削效率和被切割材料属性之间的关系,建立不同组织材料的属性数据库,从而实现组织材料的精准识别,为提高机器人的手术状态识别率和自主操作能力提供支持。In view of the above-mentioned defects or deficiencies in the prior art, the present invention provides a biological tissue identification system, which establishes the attribute database of different tissue materials by establishing the relationship between the cutting efficiency and the properties of the material to be cut, so as to realize the accurate identification of tissue materials. Recognition, providing support for improving the robot's surgical status recognition rate and autonomous operation capabilities.

本发明提供了一种生物组织识别系统,包括:The invention provides a biological tissue recognition system, comprising:

外科切割手术器械、手术器械驱动系统、压力传感器、直线进给单元、直线驱动装置和控制装置;Surgical cutting surgical instruments, surgical instrument drive systems, pressure sensors, linear feed units, linear drive devices and control devices;

外科切割手术器械、手术器械驱动系统和压力传感器安装在直线进给单元上;直线进给单元在直线驱动装置的驱动下,带动外科切割手术器械、手术器械驱动系统和压力传感器做直线运动;The surgical cutting surgical instrument, the surgical instrument drive system and the pressure sensor are installed on the linear feed unit; driven by the linear drive device, the linear feed unit drives the surgical cutting surgical instrument, the surgical instrument drive system and the pressure sensor to perform linear motion;

力传感器用于检测外科切割手术器械的受力;The force sensor is used to detect the force of the surgical cutting instrument;

控制装置用于对受力进行分析,并对手术器械驱动系统和直线驱动装置进行控制。The control unit is used to analyze the force and to control the drive system of the surgical instrument and the linear drive.

更进一步的,该控制装置被配置为:Furthermore, the control device is configured to:

将已知剪切应力的材料作为切割对象,用固定的进给速度驱动外科切割手术器械切割该已知剪切应力的材料,以获取系统的切割效率;Use a material with known shear stress as the cutting object, and use a fixed feed rate Drive the surgical cutting surgical instrument to cut the material with known shear stress to obtain the cutting efficiency of the system ;

用标定切割效率后的生物组织识别系统以标定时的进给速度切割待识别的生物组织,以获取该生物组织的剪切应力;calibrated cutting efficiency The post-biological tissue identification system is calibrated at the feed rate Cut the biological tissue to be identified to obtain the shear stress of the biological tissue ;

通过获取的剪切应力识别该生物组织类型。The shear stress obtained by Identify the type of biological tissue.

进一步的,上述生物组织识别系统的具体识别方法,包括:Further, the specific identification method of the above-mentioned biological tissue identification system includes:

将已知剪切应力的材料作为切割对象,用固定的进给速度驱动外科切割手术系统切割该已知剪切应力的材料,以获取该外科切割手术系统的切割效率;Use a material with known shear stress as the cutting object, and use a fixed feed rate Drive the surgical cutting operation system to cut the material with known shear stress to obtain the cutting efficiency of the surgical cutting operation system ;

用标定切割效率后的外科切割手术系统以标定时的进给速度切割待识别的生物组织,以获取该生物组织的剪切应力;calibrated cutting efficiency The post-surgical cutting operation system is at the calibrated feed rate Cut the biological tissue to be identified to obtain the shear stress of the biological tissue ;

通过获取的剪切应力识别该生物组织类型。The shear stress obtained by Identify the type of biological tissue.

更进一步的,根据以下数学模型计算剪切应力:Furthermore, the shear stress is calculated according to the following mathematical model :

其中,是与外科切割手术器械的刀刃构型和刀具材料相关的参数,为进给速度,为切割效率。in, is a parameter related to the blade configuration and blade material of surgical cutting instruments, is the feed rate, for cutting efficiency.

更进一步的,剪切应力的数学模型的获取步骤为:Furthermore, the shear stress The steps to obtain the mathematical model of are:

建立外科切割手术器械的主切削刃的轴向作用力的数学模型;Axial force to establish the main cutting edge of a surgical cutting surgical instrument mathematical model;

建立外科切割手术器械的横刃的轴向作用力的数学模型;Axial forces to establish the chisel edge of a surgical cutting instrument mathematical model;

建立外科切割手术器械的横刃压进点轴向作用力的数学模型;Establishing the Axial Force of the Chisel Blade Pressing Point of Surgical Cutting Instruments mathematical model;

根据主切削刃的轴向作用力的数学模型、横刃的轴向作用力的数学模型和横刃压进点轴向作用力的数学模型,获得切割运动的总进给力的数学模型;According to the axial force of the main cutting edge The mathematical model of the chisel edge axial force The mathematical model and the axial force of the chisel edge indentation point The mathematical model of the total feed force of the cutting motion is obtained mathematical model;

根据切割运动的总进给力、切割运动的切削力、进给速度和切削速度,计算切割运动的切割效率的数学模型;Total feed force according to cutting motion , cutting force of cutting motion ,Feed rate and cutting speed , to calculate the cutting efficiency of the cutting motion mathematical model;

根据切割效率、与外科切割手术系统的刀刃构型和刀具材料相关的参数和进给速度,获取生物组织的剪切应力的数学模型。According to cutting efficiency , parameters related to the blade configuration and blade material of the surgical cutting system and feed rate , to obtain the shear stress of biological tissue mathematical model.

更进一步的,外科切割手术器械的主切削刃的轴向作用力的数学模型为:Furthermore, the axial force of the main cutting edge of the surgical cutting instrument The mathematical model of is:

其中,是剪切面分布的剪切应力,为切削厚度,为切屑与刀面的摩擦角,为前倾角,为刃倾角,为主剪切面角度,为中间参数。in, is the shear stress distributed on the shear plane, is the cutting thickness, is the friction angle between chips and cutter face, is the forward inclination angle, is the blade inclination angle, is the principal shear plane angle, as an intermediate parameter.

更进一步的,外科切割手术器械的横刃的轴向作用力的数学模型为:Furthermore, the axial force of the chisel edge of the surgical cutting instrument The mathematical model of is:

其中,是剪切面分布的剪切应力,为切削厚度,为主剪切面角度,为切屑与刀面的摩擦角,为前倾角,为切削厚度,为中间参数。in, is the shear stress distributed on the shear plane, is the cutting thickness, is the principal shear plane angle, is the friction angle between chips and cutter face, is the forward inclination angle, is the cutting thickness, as an intermediate parameter.

更进一步的,外科切割手术器械的横刃压进点轴向作用力的数学模型为:Furthermore, the axial force of the chisel blade pressing point of the surgical cutting instrument The mathematical model of is:

其中,是滑移线的解,是剪切面分布的剪切应力,是楔体夹角,为压进区半径,为横刃斜角,横刃的静态后角,为切削厚度,为进给速度,为中间参数。in, is the solution of the slip line, is the shear stress distributed on the shear plane, is the wedge angle, is the radius of the indentation zone, is the chisel bevel angle, Static relief angle of the chisel edge, is the cutting thickness, is the feed rate, as an intermediate parameter.

更进一步的,切割运动的总进给力数学模型为:。Furthermore, the total feed force of the cutting motion The mathematical model is:.

更进一步的,切割运动的切割效率的数学模型为:Furthermore, the cutting efficiency of the cutting motion The mathematical model of is:

其中,为切割运动的总进给力,为切割运动的切削力,为进给速度,为切削速度,为与外科切割手术器械的刀刃构型和刀具材料相关的参数。in, is the total feed force of the cutting motion, is the cutting force of the cutting motion, is the feed rate, is the cutting speed, is a parameter related to the blade configuration and blade material of surgical cutting instruments.

本发明提供的一种生物组织识别系统,可以在手术过程中,准确的识别与手术器械接触的人体材料,从而为机器人进入临床辅助医生自主完成椎板减压手术提供依据。The biological tissue identification system provided by the present invention can accurately identify human body materials in contact with surgical instruments during the operation, thereby providing a basis for the robot to enter the clinic to assist doctors to independently complete laminar decompression operations.

附图说明Description of drawings

通过阅读参照以下附图所作的对非限制性实施例所作的详细描述,本申请的其它特征、目的和优点将会变得更明显:Other characteristics, objects and advantages of the present application will become more apparent by reading the detailed description of non-limiting embodiments made with reference to the following drawings:

图1是一个实施例提供的生物组织识别系统的硬件示意图;Fig. 1 is a hardware schematic diagram of a biological tissue recognition system provided by an embodiment;

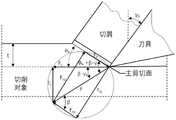

图2是一个实施例提供的平面剪切模型示意图;Fig. 2 is a schematic diagram of a plane shear model provided by an embodiment;

图3是一个实施例提供的平面剪切模型的切削受力示意图;Fig. 3 is a schematic diagram of cutting force of a plane shear model provided by an embodiment;

图4是一个实施例提供的平面剪切模型的切屑受力示意图;Fig. 4 is a schematic diagram of chip stress of a plane shear model provided by an embodiment;

图5是一个实施例提供的手术器械的切削刃示意图;Fig. 5 is a schematic diagram of a cutting edge of a surgical instrument provided by an embodiment;

图6是一个实施例提供的手术器械的横刃压进区示意图;Fig. 6 is a schematic diagram of the chisel edge press-in area of the surgical instrument provided by one embodiment;

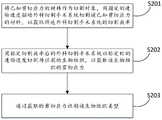

图7是另一个实施例提供的生物组织识别方法的逻辑流程图;Fig. 7 is a logic flowchart of a biological tissue identification method provided by another embodiment;

图8是另一个实施例提供的生物组织识别系统的逻辑结构图。Fig. 8 is a logical structure diagram of a biological tissue identification system provided by another embodiment.

具体实施方式detailed description

为使本发明实施例的目的、技术方案和优点更加清楚,下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整的描述,显然,所描述的实施例是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。In order to make the purpose, technical solutions and advantages of the embodiments of the present invention clearer, the technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the drawings in the embodiments of the present invention. Obviously, the described embodiments It is a part of embodiments of the present invention, but not all embodiments. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

在本发明实施例中使用的术语是仅仅出于描述特定实施例的目的,而非旨在限制本发明。在本发明实施例和所附权利要求书中所使用的单数形式的“一种”“所述”和“该”也旨在包括多数形式,除非上下文清楚地表示其他含义。Terms used in the embodiments of the present invention are only for the purpose of describing specific embodiments, and are not intended to limit the present invention. As used in the embodiments of the present invention and the appended claims, the singular forms "a", "said" and "the" are also intended to include plural forms unless the context clearly indicates otherwise.

应当理解,尽管在本发明实施例中可能采用术语第一、第二、第三等来描述获取模块,但这些获取模块不应限于这些术语。这些术语仅用来将获取模块彼此区分开。It should be understood that although terms such as first, second, and third may be used to describe the acquisition modules in the embodiments of the present invention, these acquisition modules should not be limited to these terms. These terms are only used to distinguish acquisition modules from one another.

取决于语境,如在此所使用的词语“如果”可以被解释成为“在……时”或“当……时”或“响应于确定”或“响应于检测”。类似地,取决于语境,短语“如果确定”或“如果检测(陈述的条件或事件)”可以被解释成为“当确定时”或“响应于确定”或“当检测(陈述的条件或事件)时”或“响应于检测(陈述的条件或事件)”。Depending on the context, the word "if" as used herein may be interpreted as "at" or "when" or "in response to determining" or "in response to detecting". Similarly, depending on the context, the phrases "if determined" or "if detected (the stated condition or event)" could be interpreted as "when determined" or "in response to the determination" or "when detected (the stated condition or event) )" or "in response to detection of (stated condition or event)".

需要注意的是,本发明实施例所描述的“上”“下”“左”“右”等方位词是以附图所示的角度来进行描述的,不应理解为对本发明实施例的限定。此外在上下文中,还需要理解的是,当提到一个元件被形成在另一个元件“上”或“下”时,其不仅能够直接形成在另一个元件“上”或者“下”,也可以通过中间元件间接形成在另一元件“上”或者“下”。It should be noted that the orientation words such as "up", "down", "left" and "right" described in the embodiments of the present invention are described from the angles shown in the drawings, and should not be construed as limiting the embodiments of the present invention . Also in this context, it also needs to be understood that when it is mentioned that an element is formed "on" or "under" another element, it can not only be directly formed "on" or "under" another element, but also can be formed "on" or "under" another element. Formed "on" or "under" another element indirectly through intervening elements.

现有技术在外科椎板切除操作中存在神经/脊髓易受损伤和手术机器人自主操作能力不足等难题。外科切削手术,特别是椎板切除手术的环境复杂且封闭,手术信息量少,医生不知道神经所在具体位置,容易导致切割刀具伤害到神经。现有脊柱机器人实现了精准位置跟踪,但无法识别手术中椎体和脊髓/神经的形状/相对位置变化,无法完成椎板切除,机器人功能还停留在定位操作。也有现有技术试图利用手术中的切割力和声音等物理特征,识别手术状态,判断手术器械与神经的相对位置关系,从而实现椎板的精准切除,但由于人体的个性化差异,这些物理特征存在很大的不确定性,因此这些利用手术机器人的椎板切除技术还停留在实验室阶段。In the prior art, there are problems such as nerve/spinal cord susceptibility to injury and insufficient autonomous operation ability of surgical robots during surgical laminectomy. Surgical cutting operations, especially laminectomy, are performed in a complex and closed environment, with little surgical information, and doctors do not know the exact location of the nerves, which may easily cause the cutting tools to injure the nerves. Existing spine robots have achieved precise position tracking, but they cannot recognize the shape/relative position changes of the vertebral body and spinal cord/nerves during the operation, and cannot complete laminectomy, and the robot's function is still limited to positioning operations. There are also existing technologies that attempt to use physical characteristics such as cutting force and sound during surgery to identify the state of the operation and judge the relative positional relationship between surgical instruments and nerves, thereby achieving precise laminectomy. However, due to individual differences in the human body, these physical characteristics cannot There is a lot of uncertainty, so these laminectomy techniques using surgical robots are still in the laboratory stage.

实际上,椎板切除的关键就是识别手术器械接触的人体组织,切割椎板同时不伤害神经。由于切割过程复杂,包括利用切割手术器械将组织从人体上剪切下来的切削运动和驱动切割手术器械进入人体的进给运动。进给运动是机器人/医生根据临床需求提供,切削运动是临床动力设备提供。动力设备不同,进给速度不同,对切割力的影响各不一样。同时,人体的个性化差异,人体组织的材料属性也有很大区别。因此,现有的人体组织识别方法还无法满足临床需求。In fact, the key to laminectomy is to identify the body tissue that the surgical instrument touches, and cut the lamina without damaging the nerves. Due to the complexity of the cutting process, it includes the cutting motion of cutting the tissue from the human body with the cutting surgical instrument and the feeding motion of driving the cutting surgical instrument into the human body. The feeding movement is provided by the robot/doctor according to clinical needs, and the cutting movement is provided by clinical power equipment. The power equipment is different, the feed speed is different, and the influence on the cutting force is different. At the same time, the individual differences of the human body and the material properties of human tissue are also very different. Therefore, existing human tissue recognition methods cannot meet clinical needs.

本申请提供了一种生物组织识别系统,其利用切割理论建立切削效率(切割进给力/进给速度)和被切割材料属性之间的关系,实现材料的精准识别,为提高机器人的手术状态识别率和自主操作能力提供方法和设备支持。This application provides a biological tissue identification system, which uses cutting theory to establish the relationship between cutting efficiency (cutting feed force/feed speed) and the properties of the material to be cut, to achieve accurate identification of materials, in order to improve the surgical state identification of robots Provide method and equipment support for efficiency and autonomous operation capabilities.

参见图1,生物组织识别系统100,包括:外科切割手术器械101、手术器械驱动系统102、压力传感器103、直线进给单元104、直线驱动装置105和控制装置106。本实施例的生物组织系统100可以是一种外科切割手术装置,也可以是单纯的用于识别材料性质的装置。Referring to FIG. 1 , a biological tissue identification system 100 includes: a

其中,该外科切割手术器械101、手术器械驱动系统102和压力传感器103安装在所述直线进给单元104上;直线进给单元104在直线驱动装置的驱动下,带动外科切割手术器械101、手术器械驱动系统102和压力传感器103做直线运动;压力传感器103用于检测外科切割手术系统100的受力状况;控制装置106用于对受力状态进行分析,并对手术器械驱动系统和直线驱动装置进行控制。具体的,控制装置106对压力传感器103检测到的压力数据进行分析以获取手术对象的组织类型,并根据压力数据获取外科切割手术器械101是否穿透手术对象的生物组织,若穿透该生物组织,控制装置106控制手术器械驱动系统102和直线驱动装置105停止工作。Wherein, the surgical cutting

进一步的,外科切割手术器械101可以是旋转切割手术器械,也可以是超声振动切割刀具,本申请并不做具体类型的限定。本实施例以旋转切割手术器械为例进行说明。Further, the surgical cutting

进一步的,手术器械驱动系统102可以是各种类型的旋转电机,用于带动旋转切割手术器械转动以完成对人体组织的切削。Further, the surgical

进一步的,压力传感器103可为单个或多个传感器配合采集,其在系统开始工作时即一直运行,将采集全过程中的受力信息供系统判断使用。通常的,传感器信息采集到电脑软件端(未显示在图上),由软件实时分析当前的受力信息,当压力传感器出现穿透特征时,软件将判定切割完毕,控制外科切割手术器械101、直线进给单元104和直线驱动装置105停止运行。通过压力传感器103采集的受力信息、系统已知的切削效率和刀具类型参数值,控制装置106可以准确的判断和识别出切削组织的种类,具体判断方法参见方法实施例。Further, the

具体的,该系统100为单自由度系统,在测试或工作状态下,由直线驱动装置105,如直线单元电机,带动直线进给单元104实现安装于该直线进给单元104上的一个或多个压力传感器103及外科切割手术器械101的直线运动。在AI识别学习训练过程中,首先打开外科切割手术器械101,固定好不同的组织材料,控制装置106控制直线进给单元104进行直线运动,并对上述过程中采集到的压力传感器数据进行归类,提取出材料的特征参数,如每种组织材料对应的力学特征值,并存储于系统存储器中。在手术过程中或测定过程中,控制装置106通过获取手术中的切削压力数据即可准确判定人体组织的类别。Specifically, the system 100 is a single-degree-of-freedom system. In a test or working state, a

进一步的,上述控制装置106可以是用于生物组织识别系统100的嵌入式系统,如单片机、PLC、FPGA、CPLD或DSP,还可以是上位机系统,如PC机或服务器。Further, the above-mentioned control device 106 may be an embedded system used in the biological tissue identification system 100, such as a single-chip microcomputer, PLC, FPGA, CPLD or DSP, or an upper computer system such as a PC or a server.

本申请的另一实施例,还提供了一种基于外科手术切削效率的生物组织识别方法,该方法可以被产品实施例中的生物组织识别系统100执行。Another embodiment of the present application also provides a biological tissue identification method based on surgical cutting efficiency, which can be executed by the biological tissue identification system 100 in the product embodiment.

本实施例的组织识别主要是识别外科手术工具正在切割的组织材料种类,如皮质骨、松质骨、软组织、空切。在骨科手术中,外层一般为皮质骨,中间松质骨,内层又为皮质骨,类似三明治结构,通过识别组织,手术机器人可判断是否继续进行切割,例如已经切割到内层皮质骨,并识别出空切,说明已经切穿整个三明治结构,需要立刻停止切割,以保证安全。The tissue identification in this embodiment is mainly to identify the type of tissue material being cut by the surgical tool, such as cortical bone, cancellous bone, soft tissue, and air section. In orthopedic surgery, the outer layer is generally cortical bone, the middle cancellous bone, and the inner layer is cortical bone, similar to a sandwich structure. By identifying the tissue, the surgical robot can determine whether to continue cutting, for example, the inner cortical bone has been cut, And identify the empty cut, indicating that the entire sandwich structure has been cut, and the cutting needs to be stopped immediately to ensure safety.

为了实现本发明的生物组织识别方法,需要建立基于切割效率的人体组织识别模型,过程如下:In order to realize the biological tissue recognition method of the present invention, it is necessary to establish a human tissue recognition model based on cutting efficiency, and the process is as follows:

一、进行手术切割过程和切削运动的分析:1. Analysis of surgical cutting process and cutting movement:

具体的,手术切削过程十分复杂,基于本发明提出的平行面剪切模型,可以很好的描述切削过程中主剪切区的主要滑移剪切过程。Specifically, the surgical cutting process is very complicated. Based on the parallel plane shearing model proposed by the present invention, the main slip shearing process in the main shearing area during the cutting process can be well described.

参见图2,主剪切面 A-B 平行于始剪切线 C-D 和终剪切线 E-F,并且平分剪切区,V是切割运动的切削速度,VC是切屑的速度,是主剪切面的角度。See Figure 2, the main shear plane AB is parallel to the initial shear line CD and the final shear line EF, and bisects the shear area,V is the cutting speed of the cutting motion,VC is the speed of the chips, is the angle of the principal shear plane.

参见图3所示的平面剪切模型的受力分析和图4所示的切屑受力分析。在稳态切割下,切割力可以根据切削运动方向分解成平行切削速度的切削力和垂直切削速度的进给力,也可以分为沿主剪切面的剪切力和垂直于主剪切面的法向力的合力。图4中的为切割力的平衡力,两个力大小相等,方向相反。为切割力在垂直于切削方向上的分力,为切割力在轴向(即切削流动方向)上的分力。Refer to the force analysis of the plane shear model shown in Figure 3 and the chip force analysis shown in Figure 4. Under steady state cutting, the cutting force Cutting force that can be decomposed into parallel cutting speeds according to the direction of cutting motion and vertical cutting speed feed force , which can also be divided into the shear force along the principal shear plane and the normal force perpendicular to the principal shear plane the resultant force. in Figure 4 for the cutting force Two forces are equal in magnitude and opposite in direction. for the cutting force The force component perpendicular to the cutting direction, for the cutting force The component force in the axial direction (that is, the cutting flow direction).

外科手术中,外科器械切割生物组织的运动,可以分为工具剥离组织的切削运动,和刀具进入组织的刀具进给运动。以骨科常见的旋转切割器械为例,刀具的旋转运动让刀具的切削刃剥离组织构成了切割过程的切削运动,工具的进给运动让工具的切削刃进入组织构成了切割过程的进给运动,两个力的合理构成了切割运动的切割力。外科器械的切削运动一般由器械驱动系统提供,进给运动一般由医生根据手术状态实时调节和控制。切削运动与进给运动在切割过程中相互作用和影响,共同完成组织切割剥离任务。In surgery, the movement of surgical instruments to cut biological tissue can be divided into the cutting movement of the tool to peel off the tissue, and the knife feeding movement of the knife entering the tissue. Taking the common rotary cutting instrument in orthopedics as an example, the rotary motion of the tool makes the cutting edge of the tool peel off the tissue to constitute the cutting motion of the cutting process, and the feeding motion of the tool allows the cutting edge of the tool to enter the tissue to constitute the feeding motion of the cutting process. The rationality of the two forces constitutes the cutting force of the cutting movement. The cutting motion of surgical instruments is generally provided by the instrument drive system, and the feed motion is generally adjusted and controlled by the doctor in real time according to the operation status. The cutting motion and the feeding motion interact and influence during the cutting process, and jointly complete the tissue cutting and stripping task.

二、建立切削力的模型:2. Establish the cutting force model:

参见图5,在切割过程中,切割手术器械的主切削刃、横刃和横刃压进区等三个部分参与切削,且对切削运动的作用各有不同,需要分别建立三个部分的切削力模型。See Figure 5. During the cutting process, three parts, including the main cutting edge, the chisel edge, and the chisel edge press-in area, participate in the cutting, and have different effects on the cutting movement. It is necessary to establish the three parts of the cutting force model.

1、建立主切削刃的轴向作用力模型:1. Establish the axial force of the main cutting edge Model:

假设主剪切平面内的剪切应力是均匀的,剪切力与剪切应力成正比例,则主剪切面的剪切力为:Assuming that the shear stress in the principal shear plane is uniform, and the shear force is proportional to the shear stress, the shear force of the principal shear plane is:

其中,为主剪切面的剪切力,是剪切面的大小,是剪切面分布的剪切应力。in, The shear force on the principal shear plane, is the size of the shear plane, is the shear stress distributed on the shear plane.

其中 t为切削厚度,b为主切削刃宽度,为剪切材料的剪切面上分布的剪切应力,为刃倾角,为主剪切面角度。Where t is the cutting thickness, b is the main cutting edge width, is the shear stress distributed on the shear plane of the shear material, is the blade inclination angle, The main shear plane angle.

根据平行面剪切区模型可知:According to the shear region model of parallel planes, it can be known that:

其中,垂直切削速度的进给力,为前倾角,为切屑与刀面的摩擦角,和两个接触的材料摩擦属性相关。为剪切材料的剪切面上分布的剪切应力。不同的组织材料,其剪切应力不同。Among them, the feed force of the vertical cutting speed , is the forward inclination angle, is the friction angle between the chip and the cutter face, which is related to the friction properties of the two materials in contact. is the shear stress distributed on the shear plane of the shear material. different tissue materials, the The shear stress is different.

令:make:

则有:Then there are:

其中,为用于后续计算的中间参量。in, is an intermediate parameter for subsequent calculations.

2、建立第二切削刃的轴向作用力模型:2. Establish the axial force of the second cutting edge Model:

横刃上微分单元dl的轴向力可以描述为:The axial force of the differential unit dl on the chisel edge can be described as:

横刃的总的轴向力为:The total axial force of the chisel edge is:

则有:Then there are:

3、建立横刃压进区轴向作用力模型:3. Establish the axial force in the pressing area of the chisel edge Model:

参见图6,横刃压进区半径的计算公式为:Referring to Figure 6, the formula for calculating the radius of the chisel edge press-in zone is:

其中,是进给速度,数值为2倍的厚度t,是横刃的静态后角,大小等于楔体夹角。in, is the feed rate, the value is twice the thickness t, is the static relief angle of the chisel edge, which is equal to the wedge angle .

其中,是滑移线的解,钻尖半锋角,ψ为横刃斜角。in, is the solution of the slip line, Drill point half-edge angle, ψ is chisel edge bevel angle.

楔入的总载荷为:The total load on the wedge is:

其中,为用于后续计算的中间参量。in, is an intermediate parameter for subsequent calculations.

4、建立切割运动的总进给力模型:4. Establish the total feed force of the cutting motion Model:

则有:Then there are:

其中:是与器械的切削刃的形状相关的参数,在切割过程中的不变量。是人体组织的剪切应力,与组织的属性相关,也是判别人体组织的关键参数。是切削刃的进给速度,也是切削刃切割的深度。in: is a parameter related to the shape of the cutting edge of the instrument, which is invariant during the cutting process. It is the shear stress of human tissue, which is related to the properties of tissue and is also a key parameter for judging human tissue. is the feed rate of the cutting edge and also the depth of cut by the cutting edge.

5、建立切割运动的切削效率和组织材料属性的关系模型:5. Establish the relationship model between the cutting efficiency of the cutting motion and the properties of the tissue material:

切割运动可以解耦为切削运动和进给运动,切削运动由手术器械及其动力系统实现。在稳定切削条件下,切削运动的效率(最大切削力和切削速度的乘积)表征了手术器械及其动力系统的性能。The cutting motion can be decoupled into cutting motion and feeding motion, and the cutting motion is realized by the surgical instrument and its power system. Under stable cutting conditions, the efficiency of the cutting motion (the product of maximum cutting force and cutting speed) characterizes the performance of the surgical instrument and its power system.

根据平行剪切区模型可知,存在以下关系:According to the parallel shear zone model, the following relationship exists:

切割运动的切削力和切割运动进给力关系为:cutting force and cutting motion feed force The relationship is:

例如,在麻花钻构型下,进给速度f是切割厚度t的2倍:For example, in the twist drill configuration, the feed rate f is twice the cutting thickness t:

切削速度V和进给速度存在以下关系:Cutting speed V and feed rate The following relationship exists:

因此,切割效率可以描述为:Therefore, the cutting efficiency Can be described as:

令:make:

是与手术器械的刀刃构型和刀具材料相关参数。是人体组织的剪切应力,与组织的属性相关,也是判别人体组织的关键参数。 It is a parameter related to the blade configuration and material of the surgical instrument. It is the shear stress of human tissue, which is related to the properties of tissue and is also a key parameter for judging human tissue.

根据以上各个参数之间的关系模型可知,当切削工具构型和切削效率一定的时候,切割材料的属性与切削效率和进给速度相关。According to the relationship model between the above parameters, it can be known that when the cutting tool configuration and cutting efficiency Certainly, the properties of cutting material are related to cutting efficiency and feed rate.

参见图7,根据上述关系模型可以得到以下的生物组织识别方法:Referring to Fig. 7, the following biological tissue identification method can be obtained according to the above relational model:

步骤S201,将已知剪切应力的材料作为切割对象,用固定的进给速度驱动外科切割手术系统切割该已知剪切应力的材料,以获取所述外科切割手术系统的切割效率。Step S201, take the material with known shear stress as the cutting object, and use a fixed feed rate Drive the surgical cutting operation system to cut the material with known shear stress, so as to obtain the cutting efficiency of the surgical cutting operation system .

步骤S202,用标定切割效率后的外科切割手术系统以标定时的进给速度切割待识别的生物组织,以获取该生物组织的剪切应力;Step S202, use the calibration cutting efficiency The post-surgical cutting operation system is at the calibrated feed rate Cut the biological tissue to be identified to obtain the shear stress of the biological tissue ;

步骤S203,通过获取的剪切应力识别该生物组织类型。Step S203, by obtaining the shear stress Identify the type of biological tissue.

在具体实施过程中,可以预先针对多种不同的人体组织材料进行切割测定,获取针对不同人体组织的剪切应力,并建立人体组织和剪切应力之间的对应关系,并将对应关系存储在手术系统的计算机中,正式测试或正式手术时,手术系统通过检测手术对象的剪切应力即可准确获得该手术对象的组织类型。In the specific implementation process, cutting measurements can be performed on a variety of different human tissue materials in advance to obtain the shear stress for different human tissues , and builds up human tissue and shear stress The corresponding relationship between them is stored in the computer of the surgical system. During formal testing or formal surgery, the surgical system can accurately obtain the tissue type of the surgical object by detecting the shear stress of the surgical object.

进一步的,为了使识别结果更为快速、准确,可以结合人工神经网络或其它AI算法对识别过程进行训练,本实施例不再赘述。Further, in order to make the recognition result faster and more accurate, the recognition process may be trained in combination with artificial neural network or other AI algorithms, which will not be described in detail in this embodiment.

参见图8,本发明的另一实施例,还提供了一种生物组织识别装置300,包括切割效率获取模块301,剪切应用获取模块302,组织类型识别模块303。该生物组织识别装置300可以是用于实现上述实施例中的生物组织识别方法的软件虚拟功能模块,也可以是硬件装置。具体的:Referring to FIG. 8 , another embodiment of the present invention also provides a biological

切割效率获取模块301,被配置为将已知剪切应力的材料作为切割对象,用固定的进给速度驱动外科切割手术系统切割该已知剪切应力的材料,以获取所述外科切割手术系统的切割效率。The cutting

剪切应用获取模块302,被配置为用标定切割效率后的外科切割手术系统以标定时的进给速度切割待识别的生物组织,以获取该生物组织的剪切应力。The cutting

组织类型识别模块303,被配置为通过获取的剪切应力识别该生物组织类型。The tissue

需要说明的是,本实施例提供的生物组织识别装置300是上述生物组织识别方法的软件虚拟功能模块,其对应的可用于执行各方法实施例的技术方案,其实现原理和技术效果与方法类似,此处不再赘述。It should be noted that the biological

以上描述仅为本发明的较佳实施例。本领域技术人员应当理解,本发明中所涉及的公开范围,并不限于上述技术特征的特定组合而成的技术方案,同时也应涵盖在不脱离上述公开构思的情况下,由上述技术特征或其等同特征进行任意组合而形成的其它技术方案。例如上述特征与本发明中公开的(但不限于)具有类似功能的技术特征进行互相替换而形成的技术方案。The above descriptions are only preferred embodiments of the present invention. Those skilled in the art should understand that the scope of the disclosure involved in the present invention is not limited to the technical solution formed by the specific combination of the above technical features, but also covers the technical solutions formed by the above technical features or Other technical solutions formed by any combination of equivalent features. For example, a technical solution formed by replacing the above-mentioned features with technical features with similar functions disclosed in the present invention (but not limited to).

Claims (1)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210110212.XACN114444313B (en) | 2022-01-29 | 2022-01-29 | Biological tissue recognition system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210110212.XACN114444313B (en) | 2022-01-29 | 2022-01-29 | Biological tissue recognition system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114444313A CN114444313A (en) | 2022-05-06 |

| CN114444313Btrue CN114444313B (en) | 2022-12-06 |

Family

ID=81371513

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210110212.XAActiveCN114444313B (en) | 2022-01-29 | 2022-01-29 | Biological tissue recognition system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114444313B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114903566B (en)* | 2022-05-10 | 2025-03-14 | 北京水木天蓬医疗设备有限公司 | Ultrasonic bone knife position determination method and system |

| CN115349919B (en)* | 2022-07-14 | 2024-07-19 | 深圳普汇医疗科技有限公司 | Ultrasonic knife cutting tissue recognition system and method based on neural network |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101534728A (en)* | 2006-09-29 | 2009-09-16 | 伊西康内外科公司 | Surgical cutting and stapling device with closure apparatus for limiting maximum tissue compression force |

| CN101879080A (en)* | 2009-03-27 | 2010-11-10 | 德普伊米特克公司 | Method and apparatus for preparing and implanting tissue scaffolds |

| CN105963018A (en)* | 2016-04-27 | 2016-09-28 | 何滨 | Intelligent spinal anesthesia puncture robot system |

| CN106725711A (en)* | 2016-12-13 | 2017-05-31 | 中国科学院深圳先进技术研究院 | Sclerotin grinding machine people, vertebral plate grinding surgery operation robot control system and method |

| CN107348981A (en)* | 2011-10-26 | 2017-11-17 | 直观外科手术操作公司 | The surgical operating instrument of scalpel blade with entirety |

| CN107530077A (en)* | 2015-03-06 | 2018-01-02 | 伊西康有限责任公司 | For the adaptive tissue compression technology for the closure speed for adjusting Various Tissues type |

| CN111281479A (en)* | 2020-04-04 | 2020-06-16 | 华中科技大学 | Self-sensing ultrasonic osteotome system with high safety |

| CN114469270A (en)* | 2022-04-19 | 2022-05-13 | 厚凯(北京)医疗科技有限公司 | Control method of ultrasonic surgical instrument, surgical device and readable storage medium |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9060770B2 (en)* | 2003-05-20 | 2015-06-23 | Ethicon Endo-Surgery, Inc. | Robotically-driven surgical instrument with E-beam driver |

| US8579176B2 (en)* | 2005-07-26 | 2013-11-12 | Ethicon Endo-Surgery, Inc. | Surgical stapling and cutting device and method for using the device |

| US8560047B2 (en)* | 2006-06-16 | 2013-10-15 | Board Of Regents Of The University Of Nebraska | Method and apparatus for computer aided surgery |

| US10136869B2 (en)* | 2016-03-25 | 2018-11-27 | Perkinelmer Health Sciences, Inc. | Systems and methods for characterizing a central axis of a bone from a 3D anatomical image |

| US10709511B2 (en)* | 2016-08-16 | 2020-07-14 | Ethicon Llc | Control of jaw or clamp arm closure in concert with advancement of device |

| CN107981917B (en)* | 2017-12-18 | 2024-06-14 | 高峰 | Tubular cutter for minimally invasive human vein graft acquisition |

| CN109009434A (en)* | 2018-08-15 | 2018-12-18 | 苏州大学张家港工业技术研究院 | Abdominal minimally invasive Robot Virtual operation method |

| CN113848085B (en)* | 2021-08-12 | 2024-05-31 | 澎立检测技术(上海)有限公司 | Pathological hard tissue slicing system |

- 2022

- 2022-01-29CNCN202210110212.XApatent/CN114444313B/enactiveActive

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101534728A (en)* | 2006-09-29 | 2009-09-16 | 伊西康内外科公司 | Surgical cutting and stapling device with closure apparatus for limiting maximum tissue compression force |

| CN101879080A (en)* | 2009-03-27 | 2010-11-10 | 德普伊米特克公司 | Method and apparatus for preparing and implanting tissue scaffolds |

| CN107348981A (en)* | 2011-10-26 | 2017-11-17 | 直观外科手术操作公司 | The surgical operating instrument of scalpel blade with entirety |

| CN107530077A (en)* | 2015-03-06 | 2018-01-02 | 伊西康有限责任公司 | For the adaptive tissue compression technology for the closure speed for adjusting Various Tissues type |

| CN105963018A (en)* | 2016-04-27 | 2016-09-28 | 何滨 | Intelligent spinal anesthesia puncture robot system |

| CN106725711A (en)* | 2016-12-13 | 2017-05-31 | 中国科学院深圳先进技术研究院 | Sclerotin grinding machine people, vertebral plate grinding surgery operation robot control system and method |

| CN111281479A (en)* | 2020-04-04 | 2020-06-16 | 华中科技大学 | Self-sensing ultrasonic osteotome system with high safety |

| CN114469270A (en)* | 2022-04-19 | 2022-05-13 | 厚凯(北京)医疗科技有限公司 | Control method of ultrasonic surgical instrument, surgical device and readable storage medium |

Non-Patent Citations (2)

| Title |

|---|

| Cutting Depth Monitoring Based on Milling Force for Robot-Assisted Laminectomy;Zhongliang Jiang等;《 IEEE Transactions on Automation Science and Engineering》;20190626;全文* |

| 基于真实切割的虚拟手术中力觉模型建模方法研究;臧爱云等;《中国体视学与图像分析》;20040630(第02期);第114-119页* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114444313A (en) | 2022-05-06 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN114444313B (en) | Biological tissue recognition system | |

| US20180242985A1 (en) | Surgical tool monitoring system and methods of use | |

| US10342622B2 (en) | System and method for estimating the spatial position of a tool within an object | |

| CN108227634B (en) | Machine learning apparatus, CNC apparatus, and machine learning method | |

| Brett et al. | Automatic surgical tools for penetrating flexible tissues | |

| WO2017206920A1 (en) | Drilling control apparatus and drilling control method | |

| Torun et al. | A new breakthrough detection method for bone drilling in robotic orthopedic surgery with closed-loop control approach | |

| EP3672501A1 (en) | Sensing of surgical instrument placement relative to anatomic structures | |

| US20220218421A1 (en) | Safety mechanism for robotic bone cutting | |

| Li et al. | Tactile perception for surgical status recognition in robot-assisted laminectomy | |

| CN104287836B (en) | Surgical robot semi-rigid intelligent instrument arm capable of achieving drilling and grinding state monitoring | |

| MX2014003504A (en) | Dynamic orthoscopic sensing. | |

| KR20170121113A (en) | Electrically controllable rotating and pressuring apparatus and method for controlling same | |

| CN119205612A (en) | A tongue image feature extraction method | |

| Ying et al. | Autonomous penetration perception for bone cutting during laminectomy | |

| Osa et al. | Autonomous penetration detection for bone cutting tool using demonstration-based learning | |

| US10258252B1 (en) | Wound measurement and tracking system and method | |

| CN116585007B (en) | Safety control method, system and equipment for lamina cutting based on multi-mode information fusion | |

| Shen et al. | Automatic identification of otologic drilling faults: a preliminary report | |

| Li et al. | State sensing of spinal surgical robot based on fusion of sound and force signals | |

| Sai et al. | Diabetes mellitus (DM) detection using SVM algorithm and adaptive neuro fuzzy inference system (ANFIS) for accuracy, specificity, and sensitivity improvement | |

| Gil et al. | Inferring material properties in robotic bone drilling processes | |

| US20240087715A1 (en) | Surgical instrument operation monitoring using artificial intelligence | |

| Wang et al. | Bone cutting status detection based on vibration sensor array | |

| CN114310488B (en) | Method for generating cutter fracture detection model, detection method, equipment and medium |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right | Effective date of registration:20231107 Address after:100081 No. 8 Xueyuan Road, Haidian District, Beijing Patentee after:PEKING UNIVERSITY THIRD Hospital Patentee after:Beijing Zhuzheng robot Co.,Ltd. Address before:100163 room 703, building A8, Zhongke e-commerce Valley, Jichang Road, Daxing District, Beijing Patentee before:Li Weishi |