CN114441250A - A semen sample preparation device - Google Patents

A semen sample preparation deviceDownload PDFInfo

- Publication number

- CN114441250A CN114441250ACN202011195611.8ACN202011195611ACN114441250ACN 114441250 ACN114441250 ACN 114441250ACN 202011195611 ACN202011195611 ACN 202011195611ACN 114441250 ACN114441250 ACN 114441250A

- Authority

- CN

- China

- Prior art keywords

- sample

- conveying

- semen

- slide

- processed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 210000000582semenAnatomy0.000titleclaimsabstractdescription147

- 238000002360preparation methodMethods0.000titleclaimsdescription46

- 230000007246mechanismEffects0.000claimsabstractdescription377

- 239000011521glassSubstances0.000claimsabstractdescription120

- 238000012546transferMethods0.000claimsabstractdescription96

- 230000033001locomotionEffects0.000claimsabstractdescription50

- 230000007723transport mechanismEffects0.000claimsabstractdescription21

- 238000005070samplingMethods0.000claimsdescription80

- 238000007605air dryingMethods0.000claimsdescription56

- 238000004519manufacturing processMethods0.000claimsdescription51

- 238000011068loading methodMethods0.000claimsdescription40

- 238000006243chemical reactionMethods0.000claimsdescription37

- 238000007639printingMethods0.000claimsdescription37

- 230000032258transportEffects0.000claimsdescription35

- 238000010186stainingMethods0.000claimsdescription33

- 238000009792diffusion processMethods0.000claimsdescription31

- 239000003153chemical reaction reagentSubstances0.000claimsdescription20

- 238000004043dyeingMethods0.000claimsdescription17

- 238000002347injectionMethods0.000claimsdescription8

- 239000007924injectionSubstances0.000claimsdescription8

- 238000002156mixingMethods0.000claimsdescription8

- 238000002791soakingMethods0.000claimsdescription7

- 238000010438heat treatmentMethods0.000claimsdescription5

- 238000005057refrigerationMethods0.000claimsdescription5

- 239000000203mixtureSubstances0.000claimsdescription4

- 239000011248coating agentSubstances0.000claims1

- 238000000576coating methodMethods0.000claims1

- 230000009471actionEffects0.000abstractdescription17

- 230000002349favourable effectEffects0.000abstractdescription2

- 238000003860storageMethods0.000description16

- 238000004140cleaningMethods0.000description15

- 210000000078clawAnatomy0.000description14

- 230000006870functionEffects0.000description14

- 230000000875corresponding effectEffects0.000description13

- 238000001514detection methodMethods0.000description13

- 238000010586diagramMethods0.000description12

- 238000009826distributionMethods0.000description11

- 238000013467fragmentationMethods0.000description11

- 238000006062fragmentation reactionMethods0.000description11

- 230000035899viabilityEffects0.000description10

- 238000000034methodMethods0.000description8

- 239000000975dyeSubstances0.000description7

- 238000010923batch productionMethods0.000description6

- 239000000499gelSubstances0.000description6

- 230000008569processEffects0.000description5

- 230000019100sperm motilityEffects0.000description5

- 230000005484gravityEffects0.000description4

- 230000001276controlling effectEffects0.000description3

- 239000003085diluting agentSubstances0.000description3

- 230000002093peripheral effectEffects0.000description3

- 206010047700VomitingDiseases0.000description2

- 238000011534incubationMethods0.000description2

- 238000003825pressingMethods0.000description2

- 230000008093supporting effectEffects0.000description2

- 230000004083survival effectEffects0.000description2

- 238000012360testing methodMethods0.000description2

- 230000009286beneficial effectEffects0.000description1

- 230000008859changeEffects0.000description1

- 230000015271coagulationEffects0.000description1

- 238000005345coagulationMethods0.000description1

- 238000012790confirmationMethods0.000description1

- 238000012864cross contaminationMethods0.000description1

- 238000003745diagnosisMethods0.000description1

- 238000007865dilutingMethods0.000description1

- 201000010099diseaseDiseases0.000description1

- 208000037265diseases, disorders, signs and symptomsDiseases0.000description1

- 230000000694effectsEffects0.000description1

- 230000035558fertilityEffects0.000description1

- 239000012634fragmentSubstances0.000description1

- 238000005470impregnationMethods0.000description1

- 238000011031large-scale manufacturing processMethods0.000description1

- 238000007648laser printingMethods0.000description1

- 239000007788liquidSubstances0.000description1

- 239000000463materialSubstances0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 230000000877morphologic effectEffects0.000description1

- 230000000704physical effectEffects0.000description1

- 238000004321preservationMethods0.000description1

- 238000011002quantificationMethods0.000description1

- 238000011160researchMethods0.000description1

- 239000000243solutionSubstances0.000description1

- 239000005315stained glassSubstances0.000description1

- 238000007447staining methodMethods0.000description1

- 239000012128staining reagentSubstances0.000description1

- 238000006467substitution reactionMethods0.000description1

- 230000007306turnoverEffects0.000description1

- 238000005406washingMethods0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N1/00—Sampling; Preparing specimens for investigation

- G01N1/28—Preparing specimens for investigation including physical details of (bio-)chemical methods covered elsewhere, e.g. G01N33/50, C12Q

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N1/00—Sampling; Preparing specimens for investigation

- G01N1/28—Preparing specimens for investigation including physical details of (bio-)chemical methods covered elsewhere, e.g. G01N33/50, C12Q

- G01N1/2813—Producing thin layers of samples on a substrate, e.g. smearing, spinning-on

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N1/00—Sampling; Preparing specimens for investigation

- G01N1/28—Preparing specimens for investigation including physical details of (bio-)chemical methods covered elsewhere, e.g. G01N33/50, C12Q

- G01N1/30—Staining; Impregnating ; Fixation; Dehydration; Multistep processes for preparing samples of tissue, cell or nucleic acid material and the like for analysis

- G01N1/31—Apparatus therefor

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N1/00—Sampling; Preparing specimens for investigation

- G01N1/28—Preparing specimens for investigation including physical details of (bio-)chemical methods covered elsewhere, e.g. G01N33/50, C12Q

- G01N1/42—Low-temperature sample treatment, e.g. cryofixation

Landscapes

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Physics & Mathematics (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Biomedical Technology (AREA)

- Molecular Biology (AREA)

- Engineering & Computer Science (AREA)

- Sampling And Sample Adjustment (AREA)

- Investigating Or Analysing Biological Materials (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及医疗检测技术领域,具体涉及一种精液样本制片装置。The invention relates to the technical field of medical detection, in particular to a semen sample preparation device.

背景技术Background technique

精子质量分析是评估男性生育能力的重要手段,也是男科疾病诊断以及疗效观察的实验依据,因此,精子质量分析对于科研和临床具有非常重要的指导意义。精子质量分析一般包括精子理学性质、精子活力、精子存活率、精子形态学、精子DNA碎片化程度等检测分析项目;其中,在进行精子存活率、精子形态学、精子DNA碎片化程度等检测分析项目的过程中,需要对精液样本进行制片与染色,以便更好地观察与分析。Sperm quality analysis is an important means of evaluating male fertility, and it is also the experimental basis for the diagnosis of andrological diseases and the observation of curative effects. Therefore, sperm quality analysis has very important guiding significance for scientific research and clinical practice. Sperm quality analysis generally includes sperm physical properties, sperm motility, sperm viability, sperm morphology, sperm DNA fragmentation and other testing and analysis items; among them, sperm survival rate, sperm morphology, sperm DNA fragmentation and other testing and analysis During the project, semen samples need to be prepared and stained for better observation and analysis.

目前,针对精液样本的制片、染色大多是采用手工操作,不但费时费力、效率低,而且无法做到标准量化,无法满足大批量制片的需求。At present, the production and dyeing of semen samples are mostly manual operations, which are not only time-consuming, labor-intensive, and inefficient, but also unable to achieve standard quantification and cannot meet the needs of large-scale production.

发明内容SUMMARY OF THE INVENTION

本发明主要解决的问题是提供一种精液样本制片装置,以实现精液样本的自动化制片。The main problem to be solved by the present invention is to provide a semen sample production device, so as to realize the automatic production of semen samples.

一种实施例中提供了一种精液样本制片装置,包括:In one embodiment, a semen sample preparation device is provided, comprising:

转运机构,所述转运机构可控地进行运动,沿所述转运机构的运动轨迹定义有加样位和制片位,所述转运机构用于转移运输载玻片;a transfer mechanism, the transfer mechanism can move in a controllable manner, a sample loading position and a filming position are defined along the movement track of the transfer mechanism, and the transfer mechanism is used for transferring and transporting the slides;

加样机构,所述加样机构可控地运动至加样位,用于在所述转运机构将载玻片转移至加样位时,向所述载玻片添加待处理样本,所述待处理样本为精液样本或由精液样本和反应试剂混合而成;以及a sample adding mechanism, the sample adding mechanism can be controllably moved to the sample adding position, and is used for adding a sample to be processed to the slide glass when the transfer mechanism transfers the slide glass to the sample adding position, and the to-be-processed sample is added to the slide glass. The processed sample is a semen sample or a mixture of a semen sample and a reaction reagent; and

制片机构,所述制片机构位于制片位,用于在所述转运机构将载玻片转移至制片位时,对所述载玻片上的待处理样本进行制片,以制成成片样本。The film-making mechanism, the film-making mechanism is located at the film-making position, and is used for filming the samples to be processed on the glass slide when the transfer mechanism transfers the slide glass to the film-making position, so as to make a finished product. slice samples.

一个实施例中,所述转运机构包括输送机构和转移机构,所述制片机构包括涂片机构和翻转机构,所述制片位包括涂片位、翻转位、浸染位和风干位;In one embodiment, the transfer mechanism includes a conveying mechanism and a transfer mechanism, the film-making mechanism includes a smear mechanism and a turning mechanism, and the film-making position includes a smear position, a turning position, a dyeing position and an air-drying position;

所述输送机构可控地进行运动,所述加样位、涂片位和翻转位沿输送机构的运动轨迹依次分布,所述输送机构用于承载和输送载玻片;The conveying mechanism moves in a controllable manner, and the sample adding position, the smearing position and the inversion position are sequentially distributed along the movement track of the conveying mechanism, and the conveying mechanism is used for carrying and conveying the slides;

所述涂片机构位于涂片位,用于在所述输送机构将载玻片输送至涂片位时,对所述载玻片上的待处理样本进行涂片;The smearing mechanism is located at the smearing position, and is used to smear the samples to be processed on the glass slide when the conveying mechanism transports the glass slide to the smearing position;

所述翻转机构位于翻转位,用于在所述输送机构将载玻片输送至翻转位时,将所述载玻片翻转至预设角度;The inversion mechanism is located at the inversion position, and is used for inverting the glass slide to a preset angle when the conveying mechanism transports the glass slide to the inversion position;

所述转移机构可控地运动至翻转位,所述翻转位、浸染位和风干位沿转移机构的运动轨迹依次分布,所述浸染位用于放置盛装有染色试剂的染色容器,所述转移机构用于将载玻片从翻转位转移至染色容器内进行染色,以及用于将所述载玻片从染色容器内转移至风干位进行风干,以制成成片样本;其中,所述待处理样本为精液样本。The transfer mechanism is controllably moved to the flip position, the flip position, the soaking position and the air-drying position are sequentially distributed along the movement track of the transfer mechanism, and the soaking position is used to place the dyeing container containing the dyeing reagent, and the transfer mechanism It is used for transferring the slide glass from the inversion position to the staining container for staining, and for transferring the slide glass from the staining container to the air-drying position for air-drying, so as to make a piece of sample; wherein, the to-be-treated The sample is a semen sample.

一个实施例中,所述转运机构包括输送机构,所述制片机构包括涂片机构,所述制片位包括涂片位和风干位;In one embodiment, the transfer mechanism includes a conveying mechanism, the film-making mechanism includes a smear mechanism, and the film-making position includes a smear position and an air-drying position;

所述输送机构可控地进行运动,所述加样位、涂片位和风干位沿输送机构的运动轨迹依次分布,所述输送机构用于承载和输送载玻片;The conveying mechanism moves in a controllable manner, and the sample adding position, the smearing position and the air-drying position are sequentially distributed along the movement track of the conveying mechanism, and the conveying mechanism is used for carrying and conveying the slides;

所述涂片机构位于涂片位,用于在所述输送机构将载玻片输送至涂片位时,对所述载玻片上的待处理样本进行涂片;The smearing mechanism is located at the smearing position, and is used to smear the samples to be processed on the glass slide when the conveying mechanism transports the glass slide to the smearing position;

其中,所述待处理样本由精液样本和反应试剂混合而成,所述输送机构将载玻片输送至风干位时,在完成对所述载玻片上的待处理样本的风干后,制成成片样本。Wherein, the sample to be processed is formed by mixing a semen sample and a reaction reagent, and when the transport mechanism transports the glass slide to the air-drying position, after the sample to be processed on the glass slide is air-dried, it is made into a slice samples.

一个实施例中,所述转运机构包括输送机构和转移机构,所述制片机构包括扩散机构和冷藏机构,所述制片位包括扩散位、冷藏位、浸染位和风干位;In one embodiment, the transfer mechanism includes a conveying mechanism and a transfer mechanism, the tableting mechanism includes a diffusion mechanism and a refrigerating mechanism, and the tableting position includes a diffusion position, a refrigerated position, a dyeing position and an air-drying position;

所述输送机构可控地进行运动,所述加样位、扩散位和冷藏位沿输送机构的运动轨迹依次分布,所述输送机构用于承载和输送载玻片;The conveying mechanism moves in a controllable manner, and the sample adding position, the diffusion position and the refrigerating position are sequentially distributed along the movement track of the conveying mechanism, and the conveying mechanism is used for carrying and conveying the slides;

所述扩散机构位于扩散位,用于在所述输送机构将载玻片输送至扩散位时,向所述载玻片添加扩散工具,以使所述待处理样本扩散在载玻片上;The diffusing mechanism is located at the diffusing position, and is used for adding a diffusing tool to the glass slide when the conveying mechanism transports the glass slide to the diffusing position, so as to spread the sample to be processed on the slide glass;

所述冷藏机构位于冷藏位,用于在所述输送机构将载玻片输送至冷藏位时,对所述载玻片冷藏保存,以使所述扩散工具脱离载玻片;The refrigerating mechanism is located at the refrigerating position, and is used for refrigerating and storing the glass slide when the conveying mechanism transports the glass slide to the refrigerating position, so that the diffusion tool is separated from the glass slide;

所述转移机构可控地运动至冷藏位,所述冷藏位、浸染位和风干位沿转移机构的运动轨迹依次分布,所述浸染位用于放置盛装有染色试剂的染色容器,所述转移机构用于将所述载玻片从冷藏位转移至染色容器内进行染色,以及用于将所述载玻片从染色容器内转移至风干位进行风干,以制成成片样本;The transfer mechanism can be controllably moved to the refrigerating position, and the refrigerating position, the dyeing position and the air-drying position are sequentially distributed along the movement trajectory of the transfer mechanism. for transferring the glass slide from the refrigerated position to the staining container for staining, and for transferring the glass slide from the staining container to the air-drying position for air-drying, so as to make a piece of sample;

其中,所述待处理样本由精液样本和反应试剂混合而成。Wherein, the sample to be processed is formed by mixing a semen sample and a reaction reagent.

一个实施例中,所述加样机构包括:In one embodiment, the sample adding mechanism includes:

采样管路,用于采集待处理样本;Sampling pipeline, used to collect samples to be processed;

采样驱动件,所述采样驱动件与采样管路连接,用于驱动所述采样管路采集待处理样本;a sampling driver, which is connected to the sampling pipeline and used to drive the sampling pipeline to collect samples to be processed;

采样行走驱动件,所述采样管路安装在采样行走驱动件上,所述采样行走驱动件用于带动采样管路运动;以及a sampling traveling driver, the sampling pipeline is mounted on the sampling traveling driver, and the sampling traveling driver is used to drive the sampling pipeline to move; and

粘度检测器,所述粘度检测器安装在采样管路上,用于检测所述待处理样本的粘度。A viscosity detector, which is installed on the sampling pipeline and used to detect the viscosity of the sample to be processed.

一个实施例中,还包括上片机构,所述转运机构的运动轨迹还定义有上片位,所述上片位、加样位和制片位沿所述转运机构的运动轨迹依次分布,所述上片机构用于从上片位向转运机构添加载玻片。In one embodiment, it also includes a film loading mechanism, and the motion track of the transfer mechanism is also defined with a film loading position, and the film loading position, the sample adding position and the film production position are sequentially distributed along the motion track of the transfer mechanism, so The loading mechanism described above is used to add slides from the loading position to the transport mechanism.

一个实施例中,还包括打印机构,所述转运机构的运动轨迹上还定义有打印位,所述上片位、打印位、加样位和制片位沿所述转运机构的运动轨迹依次分布,所述打印机构位于打印位,用于在所述转运机构将载玻片转移至打印位时,将制片信息打印至所述载玻片上。In one embodiment, a printing mechanism is also included, and a printing position is also defined on the motion track of the transfer mechanism, and the upper film position, the printing position, the sample adding position and the filming position are sequentially distributed along the motion track of the transfer mechanism. , the printing mechanism is located at the printing position, and is used for printing the production information on the glass slide when the transfer mechanism transfers the slide glass to the printing position.

一个实施例中,还包括进样机构,所述进样机构包括进样输送件和温育件,沿所述加样机构的运动轨迹定义有进样位;In one embodiment, a sample feeding mechanism is further included, the sample feeding mechanism includes a sample feeding conveying member and an incubating member, and a sample feeding position is defined along the movement trajectory of the sample feeding mechanism;

所述进样输送件用于承载和输送盛装有精液样本的样本容器,以供所述加样机构从位于进样位的样本容器内采集精液样本;The sample feeding and conveying member is used to carry and transport the sample container containing the semen sample, so that the sample adding mechanism can collect the semen sample from the sample container located at the sample feeding position;

所述温育件安装在进样输送件上,用于加热所述样本容器,以使所述样本容器内的精液样本的温度保持在预设范围内。The incubator is installed on the sample feeding and conveying member, and is used for heating the sample container, so as to keep the temperature of the semen sample in the sample container within a preset range.

一个实施例中,还包括扫描机构,沿所述进样输送件的输送方向定义有扫描位,所述扫描机构位于扫描位,用于在所述进样输送件将样本容器输送至扫描位时,对所述样本容器进行信息扫描,以获取所述样本容器内的精液样本的信息。In one embodiment, a scanning mechanism is further included, a scanning position is defined along the conveying direction of the sample feeding and conveying member, the scanning mechanism is located at the scanning position, and is used when the sample feeding and conveying member transports the sample container to the scanning position , performing information scanning on the sample container to obtain the information of the semen sample in the sample container.

一个实施例中,还包括反应机构,用于盛放精液样本和反应试剂,所述加样机构的运动轨迹定义有采样位,所述采样位和加样位沿所述加样机构的运动轨迹依次分布;In one embodiment, a reaction mechanism is further included for containing semen samples and reaction reagents, the motion trajectory of the sample adding mechanism defines a sampling position, and the sampling position and the sample adding position are along the motion trajectory of the sample adding mechanism. distributed in sequence;

所述反应机构位于采样位,以使得所述加样机构从反应机构内采集待处理样本,并将所述待处理样本添加至载玻片;其中,所述待处理样本由精液样本和反应试剂混合而成。The reaction mechanism is located at the sampling position, so that the sample adding mechanism collects the sample to be processed from the reaction mechanism, and adds the sample to be processed to the slide; wherein the sample to be processed consists of a semen sample and a reaction reagent mixed.

依据上述实施例的精液样本制片装置,包括加样机构、制片机构和用于转移运输载玻片的转运机构;其中,沿转运机构的运动轨迹定义有加样位和制片位,加样机构可控地运动至加样位以向载玻片上添加待处理样本,制片机构则位于制片位,以对载玻片上的待处理样本进行制片,从而制成成片样本。通过各机构之间的配合,可连续自动地完成样本采集、加样和制片动作,实现针对精液样本的自动化、批量化制片,有利于提高制片效率和保证成片样本的质量,并且解决了手工制片所产生的系列问题。The semen sample preparation device according to the above-mentioned embodiment comprises a sample adding mechanism, a preparation mechanism and a transfer mechanism for transferring and transporting the slides; wherein, a sample adding position and a production position are defined along the motion track of the transfer mechanism, and the adding The sample mechanism is controllably moved to the sample adding position to add the sample to be processed on the glass slide, and the preparation mechanism is located at the preparation position to slice the to-be-processed sample on the glass slide, thereby making the sample into a slice. Through the cooperation between various institutions, sample collection, sample addition and production can be continuously and automatically completed, and automatic and batch production of semen samples can be realized, which is conducive to improving production efficiency and ensuring the quality of finished samples. Solved the series of problems caused by manual production.

附图说明Description of drawings

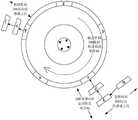

图1为第一种实施例中精液样本制片装置的功能位分布示意图(一);Fig. 1 is the functional position distribution schematic diagram (1) of the semen sample preparation device in the first embodiment;

图2为第一种实施例中精液样本制片装置的功能位分布示意图(二);Fig. 2 is the functional position distribution schematic diagram (two) of the semen sample preparation device in the first embodiment;

图3为第二种实施例中精液样本制片装置的功能位分布示意图(一);Fig. 3 is the functional position distribution schematic diagram (1) of the semen sample preparation device in the second embodiment;

图4为第二种实施例中精液样本制片装置的功能位分布示意图(二);Fig. 4 is the functional position distribution schematic diagram (two) of the semen sample preparation device in the second embodiment;

图5为第三种实施例中精液样本制片装置的功能位分布示意图(一);Fig. 5 is the functional position distribution schematic diagram (1) of the semen sample preparation device in the third embodiment;

图6为第三种实施例中精液样本制片装置的功能位分布示意图(二);Fig. 6 is the functional position distribution schematic diagram (two) of the semen sample preparation device in the third embodiment;

图7为第四种实施例中精液样本制片装置的功能位分布示意图(一);Fig. 7 is the functional position distribution schematic diagram (1) of the semen sample preparation device in the fourth embodiment;

图8为第四种实施例中精液样本制片装置的功能位分布示意图(二);Fig. 8 is the functional position distribution schematic diagram (2) of the semen sample preparation device in the fourth embodiment;

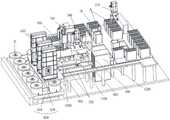

图9为一种实施例中的精液样本制片装置的各机构结构布局参考示意图;Fig. 9 is a schematic diagram of the structure layout reference of each mechanism of the semen sample preparation device in an embodiment;

图10为9中进样机构的结构参考示意图;Fig. 10 is the structural reference schematic diagram of the sampling mechanism in 9;

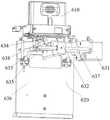

图11为图9中上片机构的结构参考示意图;Fig. 11 is the structural reference schematic diagram of the loading mechanism in Fig. 9;

图12为第五种实施例中精子形态分析仪的系统功能原理参考示意图;FIG. 12 is a schematic diagram illustrating the system function principle of the sperm morphology analyzer in the fifth embodiment;

图中:In the picture:

a、加样位;b、涂片位;c、翻转位;d、采样位;e、浸染位;f、风干位;g、上片位;h、打印位;k、进样位;m、扫描位;n、扩散位;p、冷藏位;a, sample loading position; b, smear position; c, flip position; d, sampling position; e, dip-dye position; f, air-drying position; g, upper film position; h, printing position; k, injection position; m , scanning position; n, diffusion position; p, cold storage position;

A、染色容器;B、清洗容器;D、样本容器;A, staining container; B, cleaning container; D, sample container;

100、加样机构;110、采样驱动件;120、粘度检测器;130、采样针;100. Sampling mechanism; 110. Sampling driver; 120. Viscosity detector; 130. Sampling needle;

200、输送机构;210、第一输送单元;220、第二输送单元;230、第三输送单元;200, conveying mechanism; 210, first conveying unit; 220, second conveying unit; 230, third conveying unit;

300、转移机构;310、抓取功能件;400、涂片机构;500、翻转机构;300, transfer mechanism; 310, grab functional parts; 400, smear mechanism; 500, turn over mechanism;

600、上片机构;610、储片仓;620、上片驱动件;621、丝杆电机;622、定位座;623、拨爪;624、上止位销;625、下止位销;626、上片支架;627、限位导向轨;628、转轴;600, film loading mechanism; 610, film storage bin; 620, film loading drive; 621, screw motor; 622, positioning seat; 623, claw; 624, upper stop pin; 625, lower stop pin; 626 , Loading bracket; 627, Limiting guide rail; 628, Rotating shaft;

700、打印机构;800、进样机构;810、进样输送件;820、温育件;900、扫描机构;1000、反应机构;1100、扩散机构;1200、冷藏机构;1300、阅片装置。700, printing mechanism; 800, sample feeding mechanism; 810, sample feeding and conveying member; 820, incubation member; 900, scanning mechanism; 1000, reaction mechanism; 1100, diffusion mechanism; 1200, refrigeration mechanism; 1300, film reading device.

具体实施方式Detailed ways

下面通过具体实施方式结合附图对本发明作进一步详细说明。其中不同实施方式中类似元件采用了相关联的类似的元件标号。在以下的实施方式中,很多细节描述是为了使得本申请能被更好的理解。然而,本领域技术人员可以毫不费力的认识到,其中部分特征在不同情况下是可以省略的,或者可以由其他元件、材料、方法所替代。在某些情况下,本申请相关的一些操作并没有在说明书中显示或者描述,这是为了避免本申请的核心部分被过多的描述所淹没,而对于本领域技术人员而言,详细描述这些相关操作并不是必要的,他们根据说明书中的描述以及本领域的一般技术知识即可完整了解相关操作。The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings. Wherein similar elements in different embodiments have used associated similar element numbers. In the following embodiments, many details are described so that the present application can be better understood. However, those skilled in the art will readily recognize that some of the features may be omitted under different circumstances, or may be replaced by other elements, materials, and methods. In some cases, some operations related to the present application are not shown or described in the specification, in order to avoid the core part of the present application from being overwhelmed by excessive description, and for those skilled in the art, these are described in detail. The relevant operations are not necessary, and they can fully understand the relevant operations according to the descriptions in the specification and general technical knowledge in the field.

另外,说明书中所描述的特点、操作或者特征可以以任意适当的方式结合形成各种实施方式。同时,方法描述中的各步骤或者动作也可以按照本领域技术人员所能显而易见的方式进行顺序调换或调整。因此,说明书和附图中的各种顺序只是为了清楚描述某一个实施例,并不意味着是必须的顺序,除非另有说明其中某个顺序是必须遵循的。Additionally, the features, acts, or characteristics described in the specification may be combined in any suitable manner to form various embodiments. At the same time, the steps or actions in the method description can also be exchanged or adjusted in order in a manner obvious to those skilled in the art. Therefore, the various sequences in the specification and drawings are only for the purpose of clearly describing a certain embodiment and are not meant to be a necessary order unless otherwise stated, a certain order must be followed.

本文中为部件所编序号本身,例如“第一”、“第二”等,仅用于区分所描述的对象,不具有任何顺序或技术含义。而本申请所说“连接”、“联接”,如无特别说明,均包括直接和间接连接(联接)。The serial numbers themselves, such as "first", "second", etc., for the components herein are only used to distinguish the described objects, and do not have any order or technical meaning. The "connection" and "connection" mentioned in this application, unless otherwise specified, include both direct and indirect connections (connections).

本申请提供的精液样本制片装置,主要用于精液样本进行制片染色,以为后续的诸如精子存活率、精子形态学、精子DNA碎片化程度等检测分析项目提供可供使用的成片样本,其设置有转运机构、加样机构和制片机构;其中:转运机构可控地进行运动,并且沿转运机构的运动轨迹定义有多个功能位,该多个功能位包括加样位和制片位,以用于将载玻片输送至加样位和制片位;加样机构可控地运动至加样位,用于在载玻片被输送至加样位时,向载玻片上添加待处理样本;制片机构则位于制片位,用于在载玻片被输送至制片位时,对载玻片上的待处理样本进行制片,以制成可满足检测分析需求的成片样本;以此,通过各机构之间的配合,可连续自动地完成样本采集、加样和制片动作,实现针对精液样本的自动化、批量化制片,有利于提高制片效率和保证成片样本的质量,并且解决了手工制片所产生的系列问题。The semen sample preparation device provided in this application is mainly used for the preparation and staining of semen samples, so as to provide ready-to-use sliced samples for subsequent detection and analysis items such as sperm viability, sperm morphology, and sperm DNA fragmentation. It is provided with a transfer mechanism, a sample adding mechanism and a production mechanism; wherein: the transfer mechanism can move in a controllable manner, and a plurality of functional positions are defined along the movement track of the transfer mechanism, and the plurality of functional positions include a sample adding position and a production position. position for transporting the slides to the sample loading position and the preparation position; the sample loading mechanism is controllably moved to the sample loading position for adding to the slides when the slides are transported to the loading position The sample to be processed; the production mechanism is located at the production position, which is used to produce the sample to be processed on the slide when the slide is transported to the production position, so as to make a finished film that can meet the needs of detection and analysis. In this way, through the cooperation between various institutions, the sample collection, sample addition and production can be continuously and automatically completed, and the automatic and batch production of semen samples can be realized, which is beneficial to improve the production efficiency and ensure the production of films. The quality of the samples, and solve the series of problems caused by manual production.

本申请的精液样本制片装置可针对精液样本检测分析项目,适应性或有针对性地完成相应制片动作,如:仅针对精子存活率、精子形态学、精子DNA碎片化程度等检测分析项目中的其中一个项目,具备制作相应的成片样本的单一功能,形成专用制片装置;也可针对精子存活率、精子形态学、精子DNA碎片化程度等检测分析项目中的其中两个项目或者全部项目,具备制作相应成片样本的多种功能,形成多功能制片装置。The semen sample production device of the present application can adaptively or targetedly complete corresponding production actions for semen sample detection and analysis items, such as: only for detection and analysis items such as sperm survival rate, sperm morphology, and sperm DNA fragmentation degree One of the items has the single function of producing corresponding pieces of samples, forming a special production device; it can also detect and analyze two of the items such as sperm viability, sperm morphology, and sperm DNA fragmentation. All items have various functions for making corresponding finished samples, forming a multi-functional filming device.

实施例一Example 1

请参阅图1、图2、图9、图10和图11以及结合图12,本实施例提供一种精液样本制片装置,主要用于针对精子形态学检测分析项目进行自动化、批量化制片,包括加样机构100、由输送机构200和转移机构300组成或配合形成的转运机构、由涂片机构400和翻转机构500组成或配合形成的制片机构以及用于控制加样机构100、输送机构200、转移机构300、涂片机构400和翻转机构500执行各自功能动作的控制系统。其中:Please refer to Fig. 1, Fig. 2, Fig. 9, Fig. 10 and Fig. 11 and in conjunction with Fig. 12, this embodiment provides a semen sample preparation device, which is mainly used for automatic and batch preparation for sperm morphology detection and analysis items , including the

输送机构200主要用于承载和输送载玻片,输送机构200可控地进行运动,沿其运动轨迹定义有多个功能位,该多个功能位包括加样位a以及由涂片位b和翻转位c所组成的制片位,加样位a、涂片位b和翻转位c沿输送机构200的运动轨迹依次分布;基于输送机构200的结构构造以及动作远离选择的不同,各功能位在输送机构200上的分布形式亦有所不同,如:请参阅图2,输送机构200采用现有的转盘式输送机构或转环式输送机构时,输送机构200则可控地绕其轴心进行旋转,此时,加样位a、涂片位b和翻转位c则沿输送机构200的圆周方向依次分布。请参阅图1,输送机构200采用现有的直线式输送机构时,输送机构200可沿其输送方向进行移动,此时,加样位a、涂片位b和翻转位c则沿输送机构的输送方向依次分布。以此,利用输送机构200通过将载玻片亦或者添加了待处理样本的载玻片依次输送至不同功能位,以在相应功能位完成相应动作。The conveying

涂片机构400主要用于对载玻片上的待处理样本进行涂片处理,以使待处理样本被均匀地涂抹在载玻片上;涂片机构400设置于涂片位b,在输送机构200将添加了待处理样本的载玻片输送至涂片位b时,涂片机构400执行自动涂片操作;具体的,在输送机构200采用转盘式输送机构或者转环式输送机构时,可将涂片机构400布置于输送机构200的周侧或架设于输送机构200的表面侧;在输送机构200采用直线式输送机构时,则涂片机构400可布置于输送机构200的边侧或架设于输送机构200的表面侧;通过以预定角度反复推拉涂片片材,使其能够将待处理样本均匀地涂抹在载玻片上。The

翻转机构500主要用于将载玻片翻转至预设角度,以便转移机构300能够以诸如抓取等方式将载玻片从输送机构200上转移而出;翻转机构500设置于翻转位c,在输送机构200将经过涂片处理的载玻片输送至翻转位c时,翻转机构500执行载玻片翻转操作;翻转机构500与输送机构200之间的布局可参考涂片机构400与输送机构200之间的布局进行设置;具体的,利用翻转机构500将载玻片的一端或一侧逐步顶起,使载玻片的一端或一侧逐渐分离输送机构200的表面,从而将载玻片翻转至预设角度,而后转移机构300通过抓取载玻片的一端或一侧,即可进行后续的转移动作。The flipping

请参阅图10,加样机构100主要包括采样行走驱动件、采样驱动件110、粘度检测器120以及主要由采样管和采样针130连接而成的采样管路等;采样驱动件120通过采样管连接采样针130,以驱动采样针130采集精液样本,并通过反复吸吐精液样本将其混匀,以最终形成待处理样本。采样管路安装在采样行走驱动件上,采样行走驱动件能够带动采样管路进行运动,在采样管路的运动轨迹上则定义有采样位d,采样位d和加样位a沿采样管路的运动轨迹依次分布,从而利用采样驱动件带动采样针130可在采样位d与加样位a之间进行移动,以完成采样和加样功能。粘度检测器120安装在采样管路上,用于检测待处理样本的粘度,如粘度检测器采用压力传感器时,可安装在采样针130或采样管远离采样驱动件110的一端,通过检测采样管路的内部压力变化,来判断待处理样本的粘度。该实施例中,采样行走驱动件可根据实际情况采用诸如机械手、龙门桁架等现有装置,以使加样机构100具备至少在一个方向或一个维度上运动的特点,如同时具备沿X轴方向、Y轴方向和Z轴方向同时进行运动的特点。Please refer to FIG. 10 , the

转移机构300主要用于将载玻片从输送机构200上转移至其他功能位,以在相应功能位处完成对载玻片上的待处理样本的染色、风干等处理;转移机构300包括抓取功能件310(如电爪、机械手等等)和转移行走驱动件,抓取功能件310安装在转移行走驱动件,转移行走驱动件能够带动抓取功能件310进行运动,在抓取功能件310的运动轨迹上则定义有由浸染位e和风干位f组成的制片位,翻转位c、浸染位e和风干位f沿抓取功能件310的运动轨迹依次分布,从而利用转移行走驱动件带动抓取功能件310在翻转位c、浸染位e和风干位f之间进行移动,以完成载玻片转移至相关功能位的动作;其中,在浸染位e放置盛装有染色试剂的染色容器A和盛装有清洗液的清洗容器B,针对精子形态学检测分析项目,可预先在染色容器A注入适用于巴氏染色法、邵氏染色法(即:shorr染色法)或迪夫快速染色法(即:Diff-Quick染色法)的染色试剂,或者在抓取功能件310的运动轨迹上设置多个浸染位e,以放置清洗容器B或多个盛装有不同染色试剂的染色容器A,使得转移机构300在将载玻片从翻转位c转移至染色容器A内进行染色处理,并在完成染色处理后,再将载玻片转移至清洗容器B内,以清洗载玻片上残留的染色试剂;而后再将载玻片转移至风干位f进行风干处理,从而最终制成成片样本。该实施例中,可在风干位f处设置可承载载玻片的诸如置物台等配套装置,以为经过染色处理的载玻片提供放置空间;同时,载玻片在被转移机构300转移至风干位f后,可采用自然风干的方式对其进行风干处理,也可通过在风干位f布置诸如风扇等排风系统对载玻片上的待处理样本进行强制风干处理。一个实施例中,转移行走驱动件可参考采样行走驱动件进行结构选择设置。在另一个实施例中,转移机构300也可由多个抓取功能件310和对应的多个转移行走驱动件组成,尤其是翻转位c、浸染位e和风干位f布置于不同方位,或者浸染位e所在的区域空间较大,需要转移机构300具备多维度或多方向运动功能的情况下。The

同时,需要指出的是,加样位a、涂片位b和翻转位c沿输送机构的输送方向依次分布,翻转位c、浸染位e和风干位f沿抓取动能件310的运动轨迹依次分布中,所述及的“依次分布”可以是结构布局意义或者物理构造上的顺序排布,又可以是动作时序意义或者控制时序意义上的顺序排布。At the same time, it should be pointed out that the sample adding position a, the smear position b and the flip position c are sequentially distributed along the conveying direction of the conveying mechanism, and the flip position c, the impregnation position e and the air-drying position f are sequentially distributed along the movement trajectory of the grabbing

基于此,利用加样机构100、输送机构200和转移机构300等功能机构的可行走或可运动的特点,通过对各个功能位的布局及分配,将加样机构100、输送机构200、转移机构300、涂片机构400和翻转机构500等进行衔接配合,可连续自动地完成样本采集、加样和制片动作,实现针对精液样本的自动化、批量化制片作业,有利于提高制片效率和保证成片样本的质量,并且解决了手工制片所产生的诸如制片效率低、劳动强度大、成片质量无法标准量化等系列问题。Based on this, using the walkable or movable characteristics of functional mechanisms such as the

一个实施例中,请参阅请参阅图1、图2、图9和图11,精液样本制片装置还包括上片机构600,在输送机构200的运动轨迹定义有上片位g,上片位g、加样位a、涂片位b和翻转位c沿输送机构200的运动轨迹依次分布,上片机构600固定对准或可移动对准上片位g,主要用于从上片位g向输送机构200添加载玻片,以使整个制片装置具备自动添加载玻片的功能,通过最大限度地减少人工操作步骤,为提高制片效率和自动化程度创造有利条件,上片机构600包括储片仓610和上片驱动件620;其中,储片仓610根据输送机构200的结构构造和动作远离可选择地布置于输送机构200的周侧或边侧,主要用于存放容纳未使用的载玻片。上片驱动件620主要由丝杆电机621、定位座622、拨爪623、上止位销624、下止位销625、上片支架626和限位导向轨627组成;其中:In one embodiment, please refer to FIG. 1 , FIG. 2 , FIG. 9 and FIG. 11 , the semen sample production device further includes a

储片仓610安装在上片支架626上,储片仓610的底部设置有出片通道,丝杆电机621的本体安装在上片支架626上,限位导向轨627沿第二方向安装在上片支架626上并位于储片仓610的底端侧,定位座622螺纹连接丝杆电机621的动力轴,并且同时与限位导向轨627滑动连接,拨爪623通过转轴628可转动地设置在定位座622上,并且拨爪623的重心位于拨爪623的下端,上止位销624安装在定位座622上并位于拨爪623出片方向的上端侧,下止位销625安装在定位座622上并位于拨爪623与出片方向相反方向的下端侧。在初始状态下,拨爪623在重力的作用下绕转轴628旋转,并在接触到下止位销625后停止,此时拨爪623的顶端会经由出片通道伸入储片仓610内,从而与载玻片远离上片位g的一侧相抵;当丝杆电机621驱动定位座622朝上片位g所在侧进行移动时,即可使拨爪623同步带动载玻片进行移动,从而最终将载玻片从储片仓610内推出并在上片位g进入输送机构200;当丝杆电机621驱动定位座622复位时,由于储片仓610内载玻片的抵压作用会使得拨爪623绕转轴623转动,从而使得拨爪623的顶端从储片仓610内移出,进而与上止位销624相抵,直至回退至原始位置,在拨爪623脱离载玻片的抵压后,会再次在重力作用下旋转,使其顶端经由出片进入储片仓610内,以与下一个载玻片远离上片位g的一侧相抵;如此往复循环,即可持续不断地向输送机构200添加载玻片。The

一个实施例中,沿输送机构200的运动轨迹可定义两个上片位g,并且配置两个上片机构600,使两个上片机构600互为备用,相较于配置一个上片机构600,可有效避免因上片机构600发生故障、缺片、补充载玻片等而需要对装置进行停机处理的问题,为提高装置运行的效率创造条件。In one embodiment, two loading positions g can be defined along the movement track of the conveying

一个实施例中,请参阅图1、图2和图9,精液样本制片装置还包括打印机构700,在输送机构200的运动轨迹上还定义有打印位h;其中,上片位g、打印位h、加样位a、涂片位b和翻转位c可沿输送机构200的运动轨迹依次分布,上片位g、加样位a、涂片位b、翻转位c和打印位h也可沿输送机构200的运动轨迹依次分布;打印机构700布置于打印位h,以在输送机构200将载玻片从上片位g输送至打印位h时,通过固定对准载玻片或可移动对准载玻片将制片信息(如该载玻片后续所承载的样本适用于何种检测分析项目、该样本的属性信息等等)打印至载玻片上,不但便于后期对样本进行检测分析,如进行精子形态学分析等,也可为控制系统控制相关功能机构的进行配套动作提供数据或信号支持。该实施例中,打印机构700可采用现有的玻片打印装置,如激光打印装置等等,在此不作赘述。In one embodiment, please refer to FIG. 1 , FIG. 2 and FIG. 9 , the semen sample production device further includes a

一个实施例中,请参阅图1、图2和图9,精液样本制片装置还包括用于提供精液样本以供加样机构100进行采样的进样机构800,进样机构800包括进样输送件810和温育件820;其中:In one embodiment, please refer to FIG. 1 , FIG. 2 and FIG. 9 , the semen sample preparation device further includes a

沿加样机构100的运动轨迹还定义有进样位k,进样位k可等同于采样位d(即:在该实施例中,可理解为两个功能位是同一个位置),进样输送件810主要用于承载和输送盛装有精液样本的样本容器D,以使样本容器D在经过并停留在进样位k时,加样机构100能够从样本容器D内吸取或采集精液样本。该实施例中,进样输送件810可采用沿某一方向往复运动的直线式输送装置(如皮带输送装置),也可采用能够绕某一轴心进行顺时针和/或逆时针转动的循环式输送装置,主要是能够使样本容器D能够经过并停留在进样位k。温育件820则设置在进样输送件810上,用于加热样本容器D,从而使样本容器D内的精液样本的温度能够保持在预设范围内(37℃左右),进而便于精液样本能够从凝固状态转变为液化状态,促使待测精液样本尽快液化。该实施例中,温育件820为加热膜,加热膜贴设于进样输送件810靠近样本容器D的一侧。A sampling position k is also defined along the motion trajectory of the

一个实施例中,请参阅图1、图2和图9,精液样本制片装置还包括用于对样本容器D进行信息扫描以获取样本容器D内的精液样本的属性信息的扫描机构900,沿进样输送件810的输送方向定义有扫描位m,扫描机构900设置于扫描位m;由于每个样本容器D内所盛装的精液样本均具有各自属性(如属于不同的人员等等),因此通常会在样本容器D上设置相应的信息标签(如二维码、条形码等等),此时,当进样输送件810将样本容器D输送(或同时停留)至扫描位m,扫描机构900可移动对准或固定对准样本容器D,从而即可执行信息扫描,以确认并记录精液样本的信息;如此,不但能够自动实现对精液样本的信息记录和确认,而且还可以通过控制系统将前述实施例中的打印机构700与扫描机构900进行关联控制,使得载玻片与精液样本的一一对应。该实施例中,扫描机构900可采用现有技术中的信息扫描枪、摄像头等等装置。In one embodiment, please refer to FIG. 1 , FIG. 2 and FIG. 9 , the semen sample preparation device further includes a

另外,为避免样本与样本之间、样本与试剂之间发生交叉污染,还可同时配置可对加样机构100(尤其是采样针130和采样管)进行内外壁清洗的清洗机构,或者在加样机构100的运动轨迹上设置清洗位,在清洗位布置盛装有清洗液的相关容器,以便加样机构100在采集精液样本、相关试剂前,首先进行清洗作业;清洗机构或清洗位的具体结构或布局可依据实际情况进行选择设置,在此不作赘述。同时,精液样本制片装置在运行时,可在控制系统的控制下进行,该控制系统可以为精液样本制片装置本身的控制系统,也可为可用于控制精液样本制片装置的控制系统,其则可根据实际情况采用计算机、单片机、PLC控制器等等现有功能器件,亦或者现有的分布式或集中式控制系统,利用控制系统来完成对精液样本制片装置中的各个功能机构进行协调管理和控制,包括但不限于对各个机构的启停控制、信号的接收与反馈等等,并且控制系统具有间接控制或直接控制各功能机构执行相应操作动作的功能,该功能可基于植入控制系统内的软件算法、系统功能架构或者两者的结合来实现。In addition, in order to avoid cross-contamination between samples and between samples and reagents, a cleaning mechanism that can clean the inner and outer walls of the sample adding mechanism 100 (especially the

以针对一个精液样本进行精子形态学制片过程为例,精液样本制片装置可参考如下流程执行作业任务,具体为:Taking the sperm morphology production process for a semen sample as an example, the semen sample production device can refer to the following process to perform the task, specifically:

步骤11,在将样本容器D放入进样输送件810上后,即可通过温育件820对样本容器D内精液样本进行加热,在进样输送件810将依次样本容器D输送至扫描位m时,扫描机构900对精液样本进行依次扫描,以确认记录精液样本,与此同时,开始记录精液样本被加热的时间(即:液化时间),在精液样本的液化时间达到预设时间后(如可将液化时间划分为诸如5min、20min等若干个时间段),加样机构100从位于进样位k(即:采样位d)的样本容器D中采集精液样本,而后执行步骤12。Step 11, after the sample container D is placed on the sample feeding and conveying

步骤12,利用粘度检测器120检测采集的精液样本是否完全液化,若是,则执行步骤13;若否,则将精液样本返送至样本容器D内并执行步骤11,或者将该精液样本转移至某一盛装有稀释液的容器内(当然,可将该容器布置于加样机构100的移动轨迹上),进行稀释,直至精液样本完全液化。Step 12, use the

步骤13,加样机构100运动至加样位a处,将精液样本添加至载玻片上,执行步骤15。Step 13 , the

步骤14,在执行步骤11或步骤12的同时,上片机构600将载玻片从上片位g添加至输送机构200上,在输送机构200将载玻片输送至打印位h时,打印机构700执行信息打印动作,而后输送机构200再将载玻片输送至加样位a。Step 14, while performing step 11 or step 12, the

步骤15,输送机构200将载玻片输送至涂片位b,涂片机构400执行涂片动作,而后执行步骤16。Step 15 , the

步骤16,输送机构200将载玻片输送至翻转位c,翻转机构500将载玻片翻转至预设角度,转移机构300从翻转位c抓取载玻片,而后执行步骤17。Step 16 , the

步骤17,转移机构300将载玻片依次转移至位于浸染位e的染色容器A和清洗容器B内,从而完成对精液样本的染色处理,而后执行步骤18。In step 17, the

步骤18,转移机构300将载玻片转移至风干位f,以在风干位f完成精液样本的自然风干或强制风干,从而即可制成成片样本。In step 18, the

实施例二Embodiment 2

请参阅图3、图4、图9、图10和图11以及结合图12,本实施例提供一种精液样本制片装置,其与实施例一的差别在于:转运机构包括输送机构200,但省略转移机构300;制片机构包括涂片机构400,但省略翻转机构500;相应地,沿输送机构200的运动轨迹定义有加样位a、涂片位b和风干位g,从而使得精液样本制片装置主要用于针对精子活率检测分析项目进行自动化、批量化制片。Please refer to FIGS. 3 , 4 , 9 , 10 and 11 and in conjunction with FIG. 12 , this embodiment provides a semen sample preparation device, which is different from the first embodiment in that the transport mechanism includes a

该实施例中,加样机构100从采样位d采集由精液样本和活率染色剂混匀而成的待处理样本,并将待处理样本添加至位于加样位a的载玻片上,而后输送机构200将该载玻片输送至涂片位b,涂片机构400对载玻片上的待处理样本进行涂片处理,最后输送机构200再将载玻片输送至风干位g处进行自然风干或强制风干,以最终制成成片样本。In this embodiment, the

一个实施例中,请参阅图3、图4和图9,精液样本制片装置还包括反应机构1000,主要用于盛放精液样本和如活率染色剂等反应试剂,反应机构1000设置于采样位d(需要注意的是,在实施例一中的进样位k同时存在的情况下,两者属于不同的功能位);以便加样机构100通过分别采集精液样本和反应试剂后,将两者添加至反应机构1000内进行混合,并基于加样机构100的结构及功能构造,通过反复吸吐精液样本和活率染色剂的混合物,将两者进行充分混匀,从而形成待处理样本,而后再将待处理样本添加至位于加样位a的载玻片上。该实施例中,反应机构1000可主要由一反应容器组成,以为精液样本和反应试剂提供可盛放的空间。In one embodiment, please refer to FIG. 3 , FIG. 4 and FIG. 9 , the semen sample preparation device further includes a

以针对一个精液样本进行精子活率制片过程为例,精液样本制片装置可参考如下流程执行作业任务,具体为:Taking the production process of sperm motility rate for a semen sample as an example, the semen sample production device can refer to the following process to perform tasks, specifically:

步骤21,在将样本容器D放入进样输送件810上后,即可通过温育件820对样本容器D内精液样本进行加热,在进样输送件810将依次样本容器D输送至扫描位m时,扫描机构900对精液样本进行依次扫描,以确认记录精液样本,与此同时,开始记录精液样本被加热的时间(即:液化时间),在精液样本的液化时间达到预设时间后(如可将液化时间划分为诸如5min、20min等若干个时间段),加样机构100从位于进样位k(即:采样位d)的样本容器D中采集精液样本,而后执行步骤22。Step 21, after the sample container D is placed on the sample feeding and conveying

步骤22,利用粘度检测器120检测采集的精液样本是否完全液化,若是,则执行步骤23;若否,则将精液样本返送至样本容器D内并执行步骤21,或者将该精液样本转移至反应机构1000内,通过向反应机构1000内添加稀释液,对样本进行稀释,并直至精液样本完全液化。Step 22, use the

步骤23,加样机构100运动至采样位d将精液样本添加至反应机构1000内,而后再采集活率染色剂并将活率染色剂添加至反应容器1000,使精液样本和活率染色剂混匀,最后执行步骤25。Step 23, the

步骤24,在执行步骤21、步骤22或步骤23的同时,上片机构600将载玻片从上片位g添加至输送机构200上,在输送机构200将载玻片输送至打印位h时,打印机构700执行信息打印动作,而后输送机构200再将载玻片输送至加样位a。Step 24, while performing step 21, step 22 or step 23, the

步骤25,加样机构100运动至加样位a并将待处理样本添加至载玻片上,执行步骤26。Step 25 , the

步骤26,输送机构200将载玻片输送至涂片位b,涂片机构400执行涂片动作,而后执行步骤27。Step 26 , the

步骤27,输送机构200将载玻片输送至风干位f,以在风干位f完成精液样本的自然风干或强制风干,从而即可制成成片样本。In step 27, the conveying

实施例三Embodiment 3

请参阅图5、图6、图9、图10和图11以及结合图12,本实施例提供一种精液样本制片装置,其与实施例一的差别在于,制片机构包括扩散机构1100和冷藏机构1200,省略涂片机构400和翻转机构500;相应地,沿输送机构200的运动轨迹定义有依次分布的加样位a、扩散位n和冷藏位p,从而使得精液样本制片装置主要用于针对精子DNA碎片化程度检测分析项目进行自动化、批量化制片。Please refer to FIGS. 5 , 6 , 9 , 10 and 11 and in conjunction with FIG. 12 , this embodiment provides a semen sample preparation device, which differs from the first embodiment in that the preparation mechanism includes a

该实施例中,加样机构100从采样位d采集由精液样本和易融凝胶混匀而成的待处理样本,并将待处理样本添加至位于加样位a的载玻片上。扩散机构1100则设置于扩散位n,主要用于在输送机构200将载玻片从加样位a输送至扩散位n,向载玻片上添加扩散工具(如片材式扩散工具),以使扩散工具能够叠置在载玻片上,从依靠扩散工具的重力或者虹吸原理使载玻片上的待处理样本均匀地扩散在载玻片上。冷藏机构1200则设置于冷藏位p,主要用于对载玻片与扩散工具的叠置结构体进行冷藏保存(如在2-8℃的条件下,冷藏20-25min等),从而使扩散工具能够脱离载玻片,进而使得转移机构300能够抓取载玻片,并将载玻片依次转移至位于浸染位e的染色容器A和清洗容器B内进行DNA碎片染色和清洗,最后再将载玻片转移至风干位g处进行自然风干或强制风干,以最终制成成片样本。In this embodiment, the

该实施例中,扩散机构1100可采用现有技术中能够以层叠方式向载玻片添加扩散工具的相关装置,如利用吸盘装置吸取扩散工具,并最终将扩散工具叠置在载玻片上。In this embodiment, the

一个实施例中,请参阅图5、图6和图9,精液样本制片装置还包括反应机构1000,主要用于盛放精液样本和如易融凝胶等反应试剂,反应机构1000设置于采样位d(需要注意的是,在实施例一中的进样位k同时存在的情况下,两者属于不同的功能位);以便加样机构100通过分别采集精液样本和反应试剂后,将两者添加至反应机构1000内进行混合,并基于加样机构100的结构及功能构造,通过反复吸吐精液样本和易融凝胶的混合物,将两者进行充分混匀,从而形成待处理样本,而后再将待处理样本添加至位于加样位a的载玻片上。该实施例中,反应机构1000可主要由一反应容器组成,以为精液样本和反应试剂提供可盛放的空间。In one embodiment, please refer to FIG. 5 , FIG. 6 and FIG. 9 , the semen sample preparation device further includes a

以针对一个精液样本进行精子DNA碎片化程度制片过程为例,精液样本制片装置可参考如下流程执行作业任务,具体为:Taking the production process of sperm DNA fragmentation degree for a semen sample as an example, the semen sample production device can refer to the following process to perform tasks, specifically:

步骤31,在将样本容器D放入进样输送件810上后,即可通过温育件820对样本容器D内精液样本进行加热,在进样输送件810将依次样本容器D输送至扫描位m时,扫描机构900对精液样本进行依次扫描,以确认记录精液样本,与此同时,开始记录精液样本被加热的时间(即:液化时间),在精液样本的液化时间达到预设时间后(如可将液化时间划分为诸如5min、20min等若干个时间段),加样机构100从位于进样位k(即:采样位d)的样本容器D中采集精液样本,而后执行步骤32。Step 31, after the sample container D is placed on the sample feeding and conveying

步骤32,利用粘度检测器120检测采集的精液样本是否完全液化,若是,则执行步骤33;若否,则将精液样本返送至样本容器D内并执行步骤31,或者将该精液样本转移至反应机构1000内,通过向反应机构1000内添加稀释液,对样本进行稀释,并直至精液样本完全液化。Step 32, use the

步骤33,加样机构100运动至采样位d将精液样本添加至反应机构1000内,而后再采集易融凝胶并将易融凝胶添加至反应容器1000,使精液样本和易融凝胶混匀,最后执行步骤35。Step 33, the

步骤34,在执行步骤31、步骤32或步骤33的同时,上片机构600将载玻片从上片位g添加至输送机构200上,在输送机构200将载玻片输送至打印位h时,打印机构700执行信息打印动作,而后输送机构200再将载玻片输送至加样位a。Step 34, while performing step 31, step 32 or step 33, the

步骤35,输送机构200将载玻片输送至扩散位n,扩散机构1100执行添加扩散工具动作,而后执行步骤36。Step 35 , the

步骤36,输送机构200将载玻片连同扩散工具输送至冷藏位p,由冷藏机构1200对两者进行冷藏保存处理,待冷藏保存完毕后,以人工操作或者配置相应的结构使扩散工具脱离载玻片,转移机构300从冷藏位p抓取载玻片,而后执行步骤37。In step 36, the

步骤37,转移机构300将载玻片依次转移至位于浸染位e的染色容器A和清洗容器B内,从而完成对精液样本的染色处理,而后执行步骤38。Step 37 , the

步骤18,转移机构300将载玻片转移至风干位f,以在风干位f完成精液样本的自然风干或强制风干,从而即可制成成片样本。In step 18, the

实施例四Embodiment 4

请参阅图7、图8、图9、图10和图11以及结合图12,本实施例提供一种精液样本制片装置,其与实施例一、实施例二和实施三的差别在于,转运机构同时包括输送机构200和转移机构300,制片机构同时包括涂片机构400、翻转机构500、扩散机构1100和冷藏机构1200;相应地,沿输送机构200的运动轨迹同时定义有加样位a、涂片位b、翻转位c、扩散位n和冷藏位p,而风干位f则同时位于转移机构300和输送机构200的运动轨迹上,从而使得精液样本制片装置具备针对精子活率、精子形态学、精子DNA碎片化程度等多个检测分析项目进行自动化、批量化制片的功能,在具体制片作业过程中,根据制片的需求,可由控制系统来协调管理相关功能机构。Please refer to FIGS. 7 , 8 , 9 , 10 and 11 and in conjunction with FIG. 12 , this embodiment provides a semen sample preparation device, which differs from Embodiment 1, Embodiment 2 and Embodiment 3 in that the transportation The mechanism also includes a conveying

该实施例中,请参阅图7和图10,输送机构200可由多个直线式输送单元(如皮带传送装置)组成,如包括沿某一方向进行并排放置的第一输送单元210、第二输送单元220和第三输送单元230;在第一输送单元210的输送方向上依次定义上片位g、打印位h、加样位a、涂片位b和风干位g,以适应精子活率制片的需求;在第二输送单元220的输送方向上则依次定义上片位g、打印位h、加样位a、涂片位b和翻转位c,以适应精子形态学制片的需求;在第三输送单元230的输送方向上则依次定义上片位g、打印位h、加样位a、扩散位n和冷藏位p,以适应精子DNA碎片化制片的需求。In this embodiment, please refer to FIG. 7 and FIG. 10 , the conveying

在一个实施例中,请参阅图8,输送机构200也可采用转盘式或转环式输送机构,将各个功能机构依序布置于输送机构200的周侧,如将上片位g、打印位h、加样位a、涂片位b、翻转位c、扩散位n、冷藏位p和风干位g沿圆周方向依次定义在输送机构200的旋转轨迹上;通过控制系统依据制片模式对输送机构200的正反转旋转时序进行控制(如在进行精子DNA碎片化制片时,可控制输送机构200将承载的载玻片直接从加样位a转动至扩散n,从而跃过涂片位b和翻转位c),将载玻片输送至相应功能位,再由与功能位相对应的功能机构来执行相应动作。In one embodiment, please refer to FIG. 8 , the conveying

实施例五Embodiment 5

请参阅图1至图12,本实施例提供一种精子形态分析仪,主要包括阅片装置1300和前述任一实施例的精液样本制片装置;其中,阅片装置1300用于对精液样本制片装置制成的成片样本进行影像扫描分析,以获取成片样本上的精液样本的活率信息、形态学信息和DNA碎片化程度信息中的一种信息;精液样本制片装置与阅片装置之间可通过诸如输送机构200或者转运机构300进行衔接,以在制成成片样本后,直接将成片样本输送至阅片装置1300上,从而形成集自动采样、自动加样、自动制片、自动阅片等功能于一体的多功能精子形态分析仪,为快速且批量化地进行精子检测分析创造了条件。需要指出的是:图12中的箭头连接线仅代表各功能机构之间所存在的对位关系或者配合关系,并不指代各功能机构之间的控制关系、动作时序关系等。Referring to FIGS. 1 to 12 , this embodiment provides a sperm morphology analyzer, which mainly includes a

以上应用了具体个例对本发明进行阐述,只是用于帮助理解本发明,并不用以限制本发明。对于本发明所属技术领域的技术人员,依据本发明的思想,还可以做出若干简单推演、变形或替换。The above specific examples are used to illustrate the present invention, which are only used to help understand the present invention, and are not intended to limit the present invention. For those skilled in the art to which the present invention pertains, according to the idea of the present invention, several simple deductions, modifications or substitutions can also be made.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011195611.8ACN114441250A (en) | 2020-10-30 | 2020-10-30 | A semen sample preparation device |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011195611.8ACN114441250A (en) | 2020-10-30 | 2020-10-30 | A semen sample preparation device |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114441250Atrue CN114441250A (en) | 2022-05-06 |

Family

ID=81356837

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011195611.8APendingCN114441250A (en) | 2020-10-30 | 2020-10-30 | A semen sample preparation device |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114441250A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116106094A (en)* | 2022-12-16 | 2023-05-12 | 深圳市瑞图生物技术有限公司 | Pushing device and pushing dyeing machine |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101610846A (en)* | 2006-12-19 | 2009-12-23 | 因弗因斯医药瑞士股份有限公司 | equipment |

| CN108717111A (en)* | 2018-04-24 | 2018-10-30 | 金华市人民医院 | Full-automatic sperm detection device and method |

| CN110894464A (en)* | 2019-12-21 | 2020-03-20 | 南京中医药大学 | A sperm motility detection device |

| CN111238909A (en)* | 2020-02-28 | 2020-06-05 | 桂林优利特医疗电子有限公司 | Full-automatic push piece dyeing machine capable of continuously feeding samples and used for preparing blood smears |

| CN111337321A (en)* | 2014-04-28 | 2020-06-26 | 深圳迈瑞生物医疗电子股份有限公司 | Smear preparation device and smear preparation method |

| CN211668916U (en)* | 2020-03-13 | 2020-10-13 | 新乡医学院第三附属医院 | Procreation medical science branch of academic or vocational study is with stirring mixing device |

| CN213456339U (en)* | 2020-10-30 | 2021-06-15 | 深圳市瑞图生物技术有限公司 | Sperm sample film-making device |

- 2020

- 2020-10-30CNCN202011195611.8Apatent/CN114441250A/enactivePending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101610846A (en)* | 2006-12-19 | 2009-12-23 | 因弗因斯医药瑞士股份有限公司 | equipment |

| CN111337321A (en)* | 2014-04-28 | 2020-06-26 | 深圳迈瑞生物医疗电子股份有限公司 | Smear preparation device and smear preparation method |

| CN108717111A (en)* | 2018-04-24 | 2018-10-30 | 金华市人民医院 | Full-automatic sperm detection device and method |

| CN110894464A (en)* | 2019-12-21 | 2020-03-20 | 南京中医药大学 | A sperm motility detection device |

| CN111238909A (en)* | 2020-02-28 | 2020-06-05 | 桂林优利特医疗电子有限公司 | Full-automatic push piece dyeing machine capable of continuously feeding samples and used for preparing blood smears |

| CN211668916U (en)* | 2020-03-13 | 2020-10-13 | 新乡医学院第三附属医院 | Procreation medical science branch of academic or vocational study is with stirring mixing device |

| CN213456339U (en)* | 2020-10-30 | 2021-06-15 | 深圳市瑞图生物技术有限公司 | Sperm sample film-making device |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116106094A (en)* | 2022-12-16 | 2023-05-12 | 深圳市瑞图生物技术有限公司 | Pushing device and pushing dyeing machine |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US12399194B2 (en) | Automated method and system for obtaining and preparing microorganism sample for both identification and antibiotic susceptibility tests | |

| JP6457125B2 (en) | Biological sample processing device | |

| CN108802413B (en) | External quantitative detecting instrument | |

| CN109073664B (en) | Automatic diagnostic analyzer and method of operation thereof | |

| JP3931150B2 (en) | Automatic analyzer | |

| WO2018049926A1 (en) | Automatic liquid handling system | |

| WO2022143456A1 (en) | Nucleic acid extraction and fluorescent pcr detection system | |

| JP7289288B2 (en) | Fluid transport system | |

| CN114324948A (en) | Advance appearance subassembly and gynaecology's secretion detection device | |

| EP3714035A1 (en) | Fermentation automation workcell | |

| CN112776478A (en) | Automatic production line for clinical laboratory sample tube inspection | |

| CN110699253A (en) | Gene detection system and gene detection method | |

| JP2014122892A5 (en) | ||

| CN213456339U (en) | Sperm sample film-making device | |

| CN114441250A (en) | A semen sample preparation device | |

| CN107782885A (en) | A kind of high throughput screening system based on Single Mechanical hand | |

| WO2024250533A1 (en) | Sample processing system | |

| CN110275037A (en) | An unmanned production line and method for making cytological pathological test samples | |

| CN117169537B (en) | Sample distribution device and sample analysis system | |

| CN114324942A (en) | Sample conveying device and gynecological secretion detection device | |

| CN117946849A (en) | Biological fermentation liquid automatic detection system, method and related products | |

| CN117110635A (en) | Sample pretreatment system | |

| CN110093250A (en) | Full-automatic mycoplasma culture sample adding detector and culture sample adding detection method thereof | |

| CN114907964A (en) | Sampling system and sampling method | |

| CN114985028A (en) | A single-channel multi-reagent sucking and mixing device and its use method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |