CN114436708A - A kind of NaHS coated slow-release agent, preparation method and application - Google Patents

A kind of NaHS coated slow-release agent, preparation method and applicationDownload PDFInfo

- Publication number

- CN114436708A CN114436708ACN202210153286.1ACN202210153286ACN114436708ACN 114436708 ACN114436708 ACN 114436708ACN 202210153286 ACN202210153286 ACN 202210153286ACN 114436708 ACN114436708 ACN 114436708A

- Authority

- CN

- China

- Prior art keywords

- nahs

- release

- parts

- coated

- water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- HYHCSLBZRBJJCH-UHFFFAOYSA-Msodium hydrosulfideChemical compound[Na+].[SH-]HYHCSLBZRBJJCH-UHFFFAOYSA-M0.000titleclaimsabstractdescription83

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription12

- 239000003795chemical substances by applicationSubstances0.000claimsabstractdescription36

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription31

- 229920002261Corn starchPolymers0.000claimsabstractdescription20

- 239000008120corn starchSubstances0.000claimsabstractdescription20

- 238000000034methodMethods0.000claimsabstractdescription17

- 239000002245particleSubstances0.000claimsabstractdescription15

- 201000010099diseaseDiseases0.000claimsabstractdescription9

- 208000037265diseases, disorders, signs and symptomsDiseases0.000claimsabstractdescription9

- 239000011230binding agentSubstances0.000claimsabstractdescription6

- 238000013268sustained releaseMethods0.000claimsdescription25

- 239000012730sustained-release formSubstances0.000claimsdescription25

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000claimsdescription22

- PPBRXRYQALVLMV-UHFFFAOYSA-NStyreneChemical compoundC=CC1=CC=CC=C1PPBRXRYQALVLMV-UHFFFAOYSA-N0.000claimsdescription18

- WERYXYBDKMZEQL-UHFFFAOYSA-Nbutane-1,4-diolChemical compoundOCCCCOWERYXYBDKMZEQL-UHFFFAOYSA-N0.000claimsdescription18

- 238000003756stirringMethods0.000claimsdescription11

- 239000000203mixtureSubstances0.000claimsdescription10

- DBCAQXHNJOFNGC-UHFFFAOYSA-N4-bromo-1,1,1-trifluorobutaneChemical compoundFC(F)(F)CCCBrDBCAQXHNJOFNGC-UHFFFAOYSA-N0.000claimsdescription9

- DBMJMQXJHONAFJ-UHFFFAOYSA-MSodium laurylsulphateChemical compound[Na+].CCCCCCCCCCCCOS([O-])(=O)=ODBMJMQXJHONAFJ-UHFFFAOYSA-M0.000claimsdescription9

- WHMDKBIGKVEYHS-IYEMJOQQSA-LZinc gluconateChemical compound[Zn+2].OC[C@@H](O)[C@@H](O)[C@H](O)[C@@H](O)C([O-])=O.OC[C@@H](O)[C@@H](O)[C@H](O)[C@@H](O)C([O-])=OWHMDKBIGKVEYHS-IYEMJOQQSA-L0.000claimsdescription9

- STVZJERGLQHEKB-UHFFFAOYSA-Nethylene glycol dimethacrylateSubstancesCC(=C)C(=O)OCCOC(=O)C(C)=CSTVZJERGLQHEKB-UHFFFAOYSA-N0.000claimsdescription9

- 239000000843powderSubstances0.000claimsdescription9

- 229940111630tea tree oilDrugs0.000claimsdescription9

- 239000010677tea tree oilSubstances0.000claimsdescription9

- 229960000306zinc gluconateDrugs0.000claimsdescription9

- 235000011478zinc gluconateNutrition0.000claimsdescription9

- 239000011670zinc gluconateSubstances0.000claimsdescription9

- 238000009472formulationMethods0.000claimsdescription7

- 238000005096rolling processMethods0.000claimsdescription7

- 238000002156mixingMethods0.000claimsdescription4

- 239000000839emulsionSubstances0.000claimsdescription3

- 238000004519manufacturing processMethods0.000claimsdescription3

- 239000000126substanceSubstances0.000claimsdescription3

- 230000001580bacterial effectEffects0.000claimsdescription2

- 238000006116polymerization reactionMethods0.000claimsdescription2

- IPCXNCATNBAPKW-UHFFFAOYSA-Nzinc;hydrateChemical compoundO.[Zn]IPCXNCATNBAPKW-UHFFFAOYSA-N0.000claimsdescription2

- 238000007865dilutingMethods0.000claims2

- 229940083575sodium dodecyl sulfateDrugs0.000claims2

- 241000233647Phytophthora nicotianae var. parasiticaSpecies0.000claims1

- 239000000853adhesiveSubstances0.000claims1

- 230000001070adhesive effectEffects0.000claims1

- 239000013556antirust agentSubstances0.000claims1

- 238000001035dryingMethods0.000claims1

- 229960004756ethanolDrugs0.000claims1

- 230000000694effectsEffects0.000abstractdescription19

- 239000008187granular materialSubstances0.000abstractdescription10

- 239000002689soilSubstances0.000abstractdescription8

- 235000015097nutrientsNutrition0.000abstractdescription7

- 239000000463materialSubstances0.000abstractdescription5

- 244000061176Nicotiana tabacumSpecies0.000abstractdescription3

- 235000002637Nicotiana tabacumNutrition0.000abstractdescription3

- 239000011248coating agentSubstances0.000abstractdescription3

- 238000000576coating methodMethods0.000abstractdescription3

- 238000009776industrial productionMethods0.000abstractdescription2

- DGAQECJNVWCQMB-PUAWFVPOSA-MIlexoside XXIXChemical compoundC[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+]DGAQECJNVWCQMB-PUAWFVPOSA-M0.000abstract1

- 229910052708sodiumInorganic materials0.000abstract1

- 239000011734sodiumSubstances0.000abstract1

- 238000004090dissolutionMethods0.000description17

- 230000001186cumulative effectEffects0.000description15

- 229940099112cornstarchDrugs0.000description13

- RWSOTUBLDIXVET-UHFFFAOYSA-NDihydrogen sulfideChemical compoundSRWSOTUBLDIXVET-UHFFFAOYSA-N0.000description12

- 241000196324EmbryophytaSpecies0.000description12

- 229910000037hydrogen sulfideInorganic materials0.000description12

- 239000003337fertilizerSubstances0.000description10

- MWUXSHHQAYIFBG-UHFFFAOYSA-NNitric oxideChemical compoundO=[N]MWUXSHHQAYIFBG-UHFFFAOYSA-N0.000description6

- 238000009825accumulationMethods0.000description6

- 235000019333sodium laurylsulphateNutrition0.000description6

- 239000007789gasSubstances0.000description5

- 230000011664signalingEffects0.000description5

- 238000012360testing methodMethods0.000description5

- 241001465754MetazoaSpecies0.000description3

- 238000012271agricultural productionMethods0.000description3

- 230000009418agronomic effectEffects0.000description3

- 239000011162core materialSubstances0.000description3

- 238000002474experimental methodMethods0.000description3

- 230000012010growthEffects0.000description3

- 230000008569processEffects0.000description3

- 230000001737promoting effectEffects0.000description3

- 230000035882stressEffects0.000description3

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical compound[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000description2

- 108010064851Plant ProteinsProteins0.000description2

- QAOWNCQODCNURD-UHFFFAOYSA-LSulfateChemical compound[O-]S([O-])(=O)=OQAOWNCQODCNURD-UHFFFAOYSA-L0.000description2

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000description2

- 230000008033biological extinctionEffects0.000description2

- 238000013270controlled releaseMethods0.000description2

- 238000011161developmentMethods0.000description2

- 230000018109developmental processEffects0.000description2

- 230000006806disease preventionEffects0.000description2

- 238000011156evaluationMethods0.000description2

- 230000004345fruit ripeningEffects0.000description2

- 230000014634leaf senescenceEffects0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 229910052760oxygenInorganic materials0.000description2

- 239000001301oxygenSubstances0.000description2

- 230000029553photosynthesisEffects0.000description2

- 238000010672photosynthesisMethods0.000description2

- 235000021118plant-derived proteinNutrition0.000description2

- 230000001105regulatory effectEffects0.000description2

- 230000014793stomatal movementEffects0.000description2

- RBTBFTRPCNLSDE-UHFFFAOYSA-N3,7-bis(dimethylamino)phenothiazin-5-iumChemical compoundC1=CC(N(C)C)=CC2=[S+]C3=CC(N(C)C)=CC=C3N=C21RBTBFTRPCNLSDE-UHFFFAOYSA-N0.000description1

- 241000186361Actinobacteria <class>Species0.000description1

- 241000228245Aspergillus nigerSpecies0.000description1

- 241000894006BacteriaSpecies0.000description1

- 241001678559COVID-19 virusSpecies0.000description1

- 241000222122Candida albicansSpecies0.000description1

- 241000233866FungiSpecies0.000description1

- 206010061218InflammationDiseases0.000description1

- -1NaHS compoundChemical class0.000description1

- 241000228143PenicilliumSpecies0.000description1

- 241000192142ProteobacteriaSpecies0.000description1

- 241000589771Ralstonia solanacearumSpecies0.000description1

- 240000005384Rhizopus oryzaeSpecies0.000description1

- 235000013752Rhizopus oryzaeNutrition0.000description1

- 240000004808Saccharomyces cerevisiaeSpecies0.000description1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-NSilicium dioxideChemical compoundO=[Si]=OVYPSYNLAJGMNEJ-UHFFFAOYSA-N0.000description1

- XUIMIQQOPSSXEZ-UHFFFAOYSA-NSiliconChemical compound[Si]XUIMIQQOPSSXEZ-UHFFFAOYSA-N0.000description1

- NINIDFKCEFEMDL-UHFFFAOYSA-NSulfurChemical compound[S]NINIDFKCEFEMDL-UHFFFAOYSA-N0.000description1

- 230000036579abiotic stressEffects0.000description1

- 239000002671adjuvantSubstances0.000description1

- 230000032683agingEffects0.000description1

- 230000033228biological regulationEffects0.000description1

- 230000004790biotic stressEffects0.000description1

- 210000004204blood vesselAnatomy0.000description1

- 229940095731candida albicansDrugs0.000description1

- 239000006229carbon blackSubstances0.000description1

- 229910002091carbon monoxideInorganic materials0.000description1

- 230000015556catabolic processEffects0.000description1

- 210000004027cellAnatomy0.000description1

- 230000001413cellular effectEffects0.000description1

- 239000003153chemical reaction reagentSubstances0.000description1

- 235000019506cigarNutrition0.000description1

- 238000010835comparative analysisMethods0.000description1

- 238000001816coolingMethods0.000description1

- 230000006378damageEffects0.000description1

- 239000003405delayed action preparationSubstances0.000description1

- 238000010586diagramMethods0.000description1

- 210000002249digestive systemAnatomy0.000description1

- 238000011978dissolution methodMethods0.000description1

- 239000003814drugSubstances0.000description1

- 230000002526effect on cardiovascular systemEffects0.000description1

- 230000007613environmental effectEffects0.000description1

- 235000019441ethanolNutrition0.000description1

- 230000003203everyday effectEffects0.000description1

- 235000013312flourNutrition0.000description1

- 238000010438heat treatmentMethods0.000description1

- 229910001385heavy metalInorganic materials0.000description1

- 230000003832immune regulationEffects0.000description1

- 230000004054inflammatory processEffects0.000description1

- 230000002401inhibitory effectEffects0.000description1

- 230000007246mechanismEffects0.000description1

- 230000004060metabolic processEffects0.000description1

- 229960000907methylthioninium chlorideDrugs0.000description1

- 230000000813microbial effectEffects0.000description1

- 210000005036nerveAnatomy0.000description1

- 210000000653nervous systemAnatomy0.000description1

- 230000005305organ developmentEffects0.000description1

- 230000004792oxidative damageEffects0.000description1

- 244000052769pathogenSpecies0.000description1

- 239000008188pelletSubstances0.000description1

- 230000001766physiological effectEffects0.000description1

- 230000035790physiological processes and functionsEffects0.000description1

- 231100000572poisoningToxicity0.000description1

- 230000000607poisoning effectEffects0.000description1

- 230000008092positive effectEffects0.000description1

- 230000035755proliferationEffects0.000description1

- 230000007363regulatory processEffects0.000description1

- 238000011160researchMethods0.000description1

- 230000029058respiratory gaseous exchangeEffects0.000description1

- 230000004044responseEffects0.000description1

- 230000021749root developmentEffects0.000description1

- 230000007226seed germinationEffects0.000description1

- 230000007727signaling mechanismEffects0.000description1

- 239000011863silicon-based powderSubstances0.000description1

- 210000002460smooth muscleAnatomy0.000description1

- 210000000329smooth muscle myocyteAnatomy0.000description1

- 241000894007speciesSpecies0.000description1

- 229910052717sulfurInorganic materials0.000description1

- 239000011593sulfurSubstances0.000description1

- 239000013076target substanceSubstances0.000description1

- 239000002341toxic gasSubstances0.000description1

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C05—FERTILISERS; MANUFACTURE THEREOF

- C05G—MIXTURES OF FERTILISERS COVERED INDIVIDUALLY BY DIFFERENT SUBCLASSES OF CLASS C05; MIXTURES OF ONE OR MORE FERTILISERS WITH MATERIALS NOT HAVING A SPECIFIC FERTILISING ACTIVITY, e.g. PESTICIDES, SOIL-CONDITIONERS, WETTING AGENTS; FERTILISERS CHARACTERISED BY THEIR FORM

- C05G3/00—Mixtures of one or more fertilisers with additives not having a specially fertilising activity

- C05G3/40—Mixtures of one or more fertilisers with additives not having a specially fertilising activity for affecting fertiliser dosage or release rate; for affecting solubility

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N25/00—Biocides, pest repellants or attractants, or plant growth regulators, characterised by their forms, or by their non-active ingredients or by their methods of application, e.g. seed treatment or sequential application; Substances for reducing the noxious effect of the active ingredients to organisms other than pests

- A01N25/26—Biocides, pest repellants or attractants, or plant growth regulators, characterised by their forms, or by their non-active ingredients or by their methods of application, e.g. seed treatment or sequential application; Substances for reducing the noxious effect of the active ingredients to organisms other than pests in coated particulate form

- A—HUMAN NECESSITIES

- A01—AGRICULTURE; FORESTRY; ANIMAL HUSBANDRY; HUNTING; TRAPPING; FISHING

- A01N—PRESERVATION OF BODIES OF HUMANS OR ANIMALS OR PLANTS OR PARTS THEREOF; BIOCIDES, e.g. AS DISINFECTANTS, AS PESTICIDES OR AS HERBICIDES; PEST REPELLANTS OR ATTRACTANTS; PLANT GROWTH REGULATORS

- A01N59/00—Biocides, pest repellants or attractants, or plant growth regulators containing elements or inorganic compounds

- A01N59/02—Sulfur; Selenium; Tellurium; Compounds thereof

- C—CHEMISTRY; METALLURGY

- C05—FERTILISERS; MANUFACTURE THEREOF

- C05G—MIXTURES OF FERTILISERS COVERED INDIVIDUALLY BY DIFFERENT SUBCLASSES OF CLASS C05; MIXTURES OF ONE OR MORE FERTILISERS WITH MATERIALS NOT HAVING A SPECIFIC FERTILISING ACTIVITY, e.g. PESTICIDES, SOIL-CONDITIONERS, WETTING AGENTS; FERTILISERS CHARACTERISED BY THEIR FORM

- C05G3/00—Mixtures of one or more fertilisers with additives not having a specially fertilising activity

- C05G3/60—Biocides or preservatives, e.g. disinfectants, pesticides or herbicides; Pest repellants or attractants

- C—CHEMISTRY; METALLURGY

- C05—FERTILISERS; MANUFACTURE THEREOF

- C05G—MIXTURES OF FERTILISERS COVERED INDIVIDUALLY BY DIFFERENT SUBCLASSES OF CLASS C05; MIXTURES OF ONE OR MORE FERTILISERS WITH MATERIALS NOT HAVING A SPECIFIC FERTILISING ACTIVITY, e.g. PESTICIDES, SOIL-CONDITIONERS, WETTING AGENTS; FERTILISERS CHARACTERISED BY THEIR FORM

- C05G5/00—Fertilisers characterised by their form

- C05G5/10—Solid or semi-solid fertilisers, e.g. powders

- C05G5/12—Granules or flakes

- C—CHEMISTRY; METALLURGY

- C05—FERTILISERS; MANUFACTURE THEREOF

- C05G—MIXTURES OF FERTILISERS COVERED INDIVIDUALLY BY DIFFERENT SUBCLASSES OF CLASS C05; MIXTURES OF ONE OR MORE FERTILISERS WITH MATERIALS NOT HAVING A SPECIFIC FERTILISING ACTIVITY, e.g. PESTICIDES, SOIL-CONDITIONERS, WETTING AGENTS; FERTILISERS CHARACTERISED BY THEIR FORM

- C05G5/00—Fertilisers characterised by their form

- C05G5/30—Layered or coated, e.g. dust-preventing coatings

Landscapes

- Life Sciences & Earth Sciences (AREA)

- Pest Control & Pesticides (AREA)

- Chemical & Material Sciences (AREA)

- Organic Chemistry (AREA)

- General Health & Medical Sciences (AREA)

- Plant Pathology (AREA)

- Health & Medical Sciences (AREA)

- Dentistry (AREA)

- Engineering & Computer Science (AREA)

- Wood Science & Technology (AREA)

- Zoology (AREA)

- Environmental Sciences (AREA)

- Agronomy & Crop Science (AREA)

- Inorganic Chemistry (AREA)

- Toxicology (AREA)

- Agricultural Chemicals And Associated Chemicals (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于烟草病害防治技术领域,尤其涉及一种NaHS包膜缓释剂、制备方法及应用。The invention belongs to the technical field of tobacco disease prevention and control, in particular to a NaHS coated slow-release agent, a preparation method and an application.

背景技术Background technique

H2S被诱导为第三个最新的信号分子(Goodwin等人1989年;Wang R.等人2002年;Virender等人2018年),经过全面研究(Aroca等人2020年),其不仅应用于皮肤病(Coavoy-Sánchez等人2020年)、细胞行为(Wang Y等人2020年)、血管(Cirino等人2017年)、神经(Paul等人2018年),和消化系统(Wallace et al.2017),也用于农业(Corpas FJ et al.2020),甚至用于对抗新冠病毒-19(Yang et al.2020;Citi et al.2020)。H2S has been induced as the third most recent signaling molecule (Goodwin et al. 1989; Wang R. et al. 2002; Virender et al. 2018), which has been extensively studied (Aroca et al. 2020) for applications not only in Dermatology (Coavoy-Sánchez et al. 2020), cell behavior (Wang Y et al. 2020), blood vessels (Cirino et al. 2017), nerves (Paul et al. 2018), and digestive system (Wallace et al. 2017 ), also in agriculture (Corpas FJ et al. 2020), and even against SARS-CoV-2 (Yang et al. 2020; Citi et al. 2020).

植物领域的大量研究表明,H2S直接或间接参与广泛的生理过程,包括种子萌发、根系器官发生、光合作用、气孔运动、果实成熟以及叶片、叶片和果实的衰老等。H2S还被证明参与了对有害生物和非生物环境条件的反应机制。研究表明,H2S和一氧化氮(NO)的功能之间存在显著相关性,一氧化氮是另一种简单的分子,其代谢似乎相互调节(Francisco J等人,2020年)。Numerous studies in the field of plants have shown that H2 S is directly or indirectly involved in a wide range of physiological processes, including seed germination, root organogenesis, photosynthesis, stomatal movement, fruit ripening, and leaf, leaf and fruit senescence.H2S has also been shown to be involved in response mechanisms to harmful biotic and abiotic environmental conditions. Studies have shown a significant correlation between the functions of H2S and nitricoxide (NO), another simple molecule whose metabolism appears to regulate each other (Francisco J et al., 2020).

最早的气体信号分子NO和CO已被证明在动物和植物中起着重要作用,而H2S作为一种新的气体信号分子,也被证明与前两种气体信号分子相似,并参与动物的多种生理调节过程(Yang G et al.2008;Wang et al.2012)。在以前的研究中,硫化氢被认为是地球上许多物种灭绝的根本原因。当氧气含量降至极低水平时,硫细菌使用溶解在水中的硫酸盐代替氧气呼吸,随后产生的H2S导致动植物灭绝(Wang et al.2012)。直到有毒气体H2S作为一种神经活性物质被发现,它才逐渐在生物学和医学中得到广泛研究(Abe等人,1996)。H2S在调节心脑血管平滑肌、传递神经系统信号、抑制平滑肌细胞增殖等方面发挥作用,减轻炎症反应,参与免疫调节(Paul BD et al.2014;Ferlito et al.2014;M et al.2014;Yanget al.2008)。研究发现植物中的H2S参与生长发育过程中的许多重要生理活动,如促进光合作用速率,调节气孔运动和植物根系发育(Zhang等人2011;Dooley等人2013)。当植物受到各种生物和非生物胁迫时,H2S有助于提高植物抗性,减轻各种胁迫对植物造成的损害(Lin等人2012;Sun等人2013)。The earliest gas-signaling molecules, NO and CO, have been shown to play important roles in animals and plants, while H2S, as a new gas- signaling molecule, has also been shown to be similar to the first two gas-signaling molecules and involved in animal Various physiological regulatory processes (Yang G et al. 2008; Wang et al. 2012). In previous studies, hydrogen sulfide was thought to be the root cause of the extinction of many species on Earth. When oxygen levels drop to extremely low levels, sulfur bacteria usesulfate dissolved in water instead of oxygen for respiration, and the subsequent production of H2S leads to the extinction of plants and animals (Wang et al. 2012). It was not until the discovery of the toxic gas H2S as aneuroactive substance that it gradually became widely studied in biology and medicine (Abe et al., 1996). H2 S plays a role in regulating cardiovascular and cerebrovascular smooth muscle, transmitting nervous system signals, inhibiting the proliferation of smooth muscle cells, reducing inflammation, and participating in immune regulation (Paul BD et al. 2014; Ferlito et al. 2014; M et al. 2014 ; Yang et al. 2008). Studies have found thatH2S in plants is involved in many important physiological activities during growth and development, such as promoting photosynthesis rate, regulating stomatal movement and plant root development (Zhang et al. 2011; Dooley et al. 2013). When plants are subjected to various biotic and abiotic stresses, H2 S helps to improve plant resistance and reduce damage to plants caused by various stresses (Lin et al. 2012; Sun et al. 2013).

研究表明,硫化氢也会影响微生物的多样性(细菌等人2019)。放线菌、真菌、一些植物土壤中的变形菌会处理硫酸盐离子并将其转化为植物蛋白质,而植物蛋白质的分解会导致H2S的释放。硫化氢作为第三个气体信号分子,在植物信号机制中也很活跃,能够通过改善细胞氧化损伤来保护植物免受各种胁迫,包括重金属、干旱和盐分诱导的胁迫。H2S还可以减少各种病原体的生长,包括白色念珠菌、黑曲霉、米根霉和意大利青霉。这表明H2S可能对青枯菌有效。Studies have shown that hydrogen sulfide also affects microbial diversity (Bacteria et al. 2019). Actinomycetes, fungi, and some proteobacteria in plant soils processsulfate ions and convert them into plant proteins, and the breakdown of plant proteins results in the release of H2S. Hydrogen sulfide, as a third gas signaling molecule, is also active in plant signaling mechanisms and can protect plants from various stresses, including heavy metals, drought, and salinity-induced stresses, by ameliorating cellular oxidative damage. H2S also reduces the growth of various pathogens, including Candida albicans, Aspergillus niger, Rhizopus oryzae, and Penicilliumitaliensis . This suggests that H2 S may be effective against R. solanacearum.

虽然NaHS具有抗病,促生等作用,但是NaHS化学性质很活跃,遇水后迅速转换成H2S气体,在大田实验中研究发现NaHS释放H2S的速率过快,导致H2S时效过短,需要不断补施;而且会导致田间气味过大,严重可致人中毒;另外大田中直接施用NaHS,会导致土壤黑化,且田间促生效果不显著(表一)。因此,严重制约了NaHS在农业生产中的大量应用与推广。Although NaHS has anti-disease and growth-promoting effects, NaHS is very active chemically, and it is rapidly converted into H2 S gas when it encounters water. In field experiments, it was found that the rate of NaHS releasing H2 S was too fast, resulting in the aging of H2 S. If it is too short, it needs to be supplemented continuously; and it will lead to excessive odor in the field, which can seriously cause human poisoning; in addition, the direct application of NaHS in the field will lead to soil blackening, and the effect of promoting growth in the field is not significant (Table 1). Therefore, the extensive application and popularization of NaHS in agricultural production is seriously restricted.

表1.施用NaHS复合剂后六周龄烟株的农艺性状Table 1. Agronomic traits of six-week-old tobacco plants after NaHS compound application

缓释剂具有前期溶出量少,中期溶出稳定,后期溶出效长的特性,在农业生产中应用非常广泛,因此,研发NaHS缓释剂是推进NaHS产业化应用的关键。缓释剂以靶标物质为核心材料,辅助其他材料,将核心材料与外界水分分离,从而达到保护核心材料进而实现缓释效果的目的。但是,由于NaHS非常活跃,很难找到合适的辅助剂。这是限制NaHS在农业生产中大量应用与推广的第二个关键因素。Sustained-release agent has the characteristics of less dissolution in the early stage, stable dissolution in the middle stage, and long dissolution effect in the later stage. It is widely used in agricultural production. Therefore, the development of NaHS sustained-release agent is the key to promoting the industrial application of NaHS. The slow-release agent takes the target substance as the core material, assists other materials, and separates the core material from the external moisture, so as to achieve the purpose of protecting the core material and achieving the slow-release effect. However, since NaHS is very active, it is difficult to find suitable adjuvants. This is the second key factor limiting the large-scale application and promotion of NaHS in agricultural production.

发明内容SUMMARY OF THE INVENTION

针对现有技术存在的问题,本发明提供了一种NaHS包膜缓释剂、制备方法及应用,目的在于解决现有技术中的一部分问题或至少缓解现有技术中的一部分问题。Aiming at the problems existing in the prior art, the present invention provides a NaHS coated slow-release agent, a preparation method and an application, aiming at solving some problems in the prior art or at least alleviating some problems in the prior art.

本发明是这样实现的,一种NaHS包膜缓释剂,包括:NaHS粉末、玉米淀粉和粘结剂。The present invention is realized in this way, a NaHS coated slow-release agent comprises: NaHS powder, corn starch and a binder.

进一步地,所述粘结剂包括:1,4-丁二醇、苯乙烯、乙二醇二甲基丙烯酸酯、乙醇、十二烷基硫酸钠、茶树油、葡萄糖酸锌,水。Further, the binder includes: 1,4-butanediol, styrene, ethylene glycol dimethacrylate, ethanol, sodium lauryl sulfate, tea tree oil, zinc gluconate, and water.

进一步地,各物质用量的重量份分别为:NaHS粉末、玉米淀粉、1,4-丁二醇1-3份、苯乙烯8-12份、乙二醇二甲基丙烯酸酯1-3份、乙醇5-8份、十二烷基硫酸钠2-4份、茶树油10-12份、葡萄糖酸锌15-20份,适量的水。本发明还提供了一种NaHS包膜缓释剂的制备方法,包括以下步骤:Further, the parts by weight of each material consumption are respectively: NaHS powder, corn starch, 1-3 parts of 1,4-butanediol, 8-12 parts of styrene, 1-3 parts of ethylene glycol dimethacrylate, 5-8 parts of ethanol, 2-4 parts of sodium lauryl sulfate, 10-12 parts of tea tree oil, 15-20 parts of zinc gluconate, appropriate amount of water. The present invention also provides a preparation method of NaHS coated slow-release agent, comprising the following steps:

(1)将NaHS粉末快速滚动得到NaHS颗粒;接着迅速加入玉米淀粉,持续滚动,直至玉米淀粉完全包裹NaHS颗粒;(1) the NaHS powder is rapidly rolled to obtain NaHS granules; then the cornstarch is rapidly added, and the rolling is continued until the cornstarch completely wraps the NaHS granules;

(2)将乙醇用水稀释,然后依次加入苯乙烯和乙二醇二甲基丙烯酸酯,迅速搅拌进行聚合;(2) ethanol is diluted with water, then styrene and ethylene glycol dimethacrylate are added successively, and rapid stirring is carried out to polymerize;

(3)在容器中混合十二烷基硫酸钠、茶树油和葡萄糖酸锌,兑入水,持续搅拌直至成乳剂;(3) mix sodium lauryl sulfate, tea tree oil and zinc gluconate in a container, add water, continue stirring until emulsion;

(4)混合步骤(2)和(3)所得产物,同时加入1,4-丁二醇,搅拌均匀;(4) mixing the products obtained in steps (2) and (3), adding 1,4-butanediol simultaneously, and stirring uniformly;

(5)将步骤(1)所得产物在圆盘快速滚动,边滚动边加入步骤(4)所得产物及玉米淀粉,直至颗粒表面被完全包裹;(5) the product obtained in step (1) is rapidly rolled on the disc, and the product obtained in step (4) and cornstarch are added while rolling, until the particle surface is completely wrapped;

(6)烘干即可。(6) It can be dried.

进一步地,步骤(1)中NaHS颗粒的粒径为4-5mm。Further, the particle size of the NaHS particles in step (1) is 4-5 mm.

进一步地,步骤(2)中将乙醇用8倍的水稀释;搅拌时间为20分钟。Further, in step (2), the ethanol is diluted with 8 times of water; the stirring time is 20 minutes.

进一步地,步骤(3)中兑入3倍其总重量份的水。Further, in step (3), add 3 times its total weight of water.

本发明还提供了NaHS包膜缓释剂在防治大田病害中的应用。The invention also provides the application of the NaHS coated slow-release agent in preventing and treating field diseases.

进一步地,所述病害包括青枯病和/或黑胫病。Further, the diseases include bacterial wilt and/or blackleg.

综上所述,本发明的优点及积极效果为:To sum up, the advantages and positive effects of the present invention are:

本申请发明人经过大量探索,最终发现NaHS与玉米淀粉能够稳定共存。因此,选择将玉米淀粉作为包膜基料,结合粘结剂,制备NaHS包膜缓释颗粒。所制备的NaHS包膜缓释颗粒初期养分释放率≤15%,符合GB/T 23348-2009中缓释肥料的规定。本发明中还检测了所制备的NaHS包膜缓释颗粒在不同含水量的土壤、不同温度以及不同pH条件下H2S累积释放量,以及对大田病害防治的功效。实验结果证明,本申请制备的NaHS包膜缓释颗粒具有较好的缓释效果,且大田应用效果较佳,同时制备工艺简单,易于工业化生产。After extensive exploration, the inventors of the present application finally found that NaHS and corn starch can coexist stably. Therefore, corn starch was selected as the coating base material, combined with a binder, to prepare NaHS coated sustained-release granules. The initial nutrient release rate of the prepared NaHS-coated slow-release granules is less than or equal to 15%, which conforms to the regulations of slow-release fertilizers in GB/T 23348-2009. In the present invention, the H2 S cumulative release amount of the prepared NaHS-coated slow-release granules under different water content soils, different temperatures and different pH conditions, and the efficacy of field disease prevention and control are also tested. The experimental results show that the NaHS coated sustained-release granules prepared in the present application have good sustained-release effect, and the effect of field application is better, and the preparation process is simple and easy for industrial production.

附图说明Description of drawings

图1是NaHS包膜缓释剂的制备流程示意图;Fig. 1 is the preparation flow schematic diagram of NaHS coated slow-release agent;

图2是NaHS包膜缓释剂粒径的选择;Fig. 2 is the selection of particle size of NaHS coated slow-release agent;

图3是NaHS及NaHS包膜缓释剂8天内在水溶试验中H2S累积释放曲线;Fig. 3 is the H2 S cumulative release curve of NaHS and NaHS-coated sustained-release preparations in the water-soluble test within 8 days;

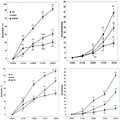

图4是NaHS包膜缓释剂30天内在水溶试验中H2S累积释放曲线;Fig. 4 is the cumulative release curve of H2 S in the water-soluble test of NaHS-coated sustained-release agent within 30 days;

图5是土壤含水量对NaHS包膜缓释剂中H2S累积量的影响;Figure 5 is the effect of soil water content on the accumulation of H2 S in the NaHS-coated slow-release agent;

图6是温度对NaHS包膜缓释剂中H2S累积量的影响;Fig. 6 is the influence of temperature on the accumulation amount of H2 S in the NaHS-coated slow-release agent;

图7是PH对NaHS包膜缓释剂中H2S累积量的影响;Fig. 7 is the influence of pH on H2 S accumulation in NaHS coated sustained-release agent;

图8是病害防治效果。Figure 8 is the disease control effect.

具体实施方式Detailed ways

为了使本发明的目的、技术方案及优点更加清楚明白,以下结合实施例,对本发明进行进一步详细说明,各实施例及试验例中所用的设备和试剂如无特殊说明,均可从商业途径得到。此处所描述的具体实施例仅用以解释本发明,并不用于限定本发明。In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with the examples. The equipment and reagents used in each embodiment and test example can be obtained from commercial channels unless otherwise specified. . The specific embodiments described herein are only used to explain the present invention, and are not intended to limit the present invention.

根据本申请包含的信息,对于本领域技术人员来说可以轻而易举地对本发明的精确描述进行各种改变,而不会偏离所附权利要求的精神和范围。应该理解,本发明的范围不局限于所限定的过程、性质或组分,因为这些实施方案以及其他的描述仅仅是为了示意性说明本发明的特定方面。实际上,本领域或相关领域的技术人员明显能够对本发明实施方式作出的各种改变都涵盖在所附权利要求的范围内。From the information contained in this application, various changes to the precise description of the present invention can be readily made by those skilled in the art without departing from the spirit and scope of the appended claims. It is to be understood that the scope of the invention is not limited to the processes, properties or components defined, as these embodiments and other descriptions are intended to be illustrative only of particular aspects of the invention. Indeed, various modifications of the embodiments of the invention that are obvious to those skilled in the art or related fields are intended to be within the scope of the appended claims.

为了更好地理解本发明而不是限制本发明的范围,在本申请中所用的表示用量、百分比的所有数字、以及其他数值,在所有情况下都应理解为以词语“大约”所修饰。因此,除非特别说明,否则在说明书和所附权利要求书中所列出的数字参数都是近似值,其可能会根据试图获得的理想性质的不同而加以改变。各个数字参数至少应被看作是根据所报告的有效数字和通过常规的四舍五入方法而获得的。本发明中,“约”指给定值或范围的10%以内,优选为5%以内。For a better understanding of the invention and not to limit the scope of the invention, all numbers expressing amounts, percentages, and other numerical values used in this application should in all cases be understood as modified by the word "about". Accordingly, unless expressly stated otherwise, the numerical parameters set forth in the specification and attached claims are approximations that may vary depending upon the desired properties sought to be obtained. At a minimum, each numerical parameter shall be deemed to have been obtained from the reported significant digits and by conventional rounding methods. In the present invention, "about" means within 10% of a given value or range, preferably within 5%.

本发明下述各实施例中未特别限定温度时,则均为常温条件。常温是指四季中自然室温条件,不进行额外的冷却或加热处理,一般常温控制在10~30℃,最好是15~25℃。In the following embodiments of the present invention, when the temperature is not particularly limited, the conditions are all at room temperature. Normal temperature refers to the natural room temperature in the four seasons without additional cooling or heating treatment. Generally, the normal temperature is controlled at 10-30°C, preferably 15-25°C.

本发明披露了一种NaHS包膜缓释剂、制备方法及应用。下面将结合本发明实施例,对本发明的技术方案进行清楚、完整地描述。The invention discloses a NaHS coated slow-release agent, a preparation method and an application. The technical solutions of the present invention will be clearly and completely described below with reference to the embodiments of the present invention.

实施例Example

1、NaHS包膜缓释剂的制备1. Preparation of NaHS coated sustained-release agent

本申请发明人在研究中发现NaHS与面粉、硅粉、酵母粉、白炭黑、活性炭等常规肥料配方物均无法混合施用,因为混合后会快速释放出大量的H2S。经过大量探索,发现NaHS与玉米淀粉能够稳定共存。The inventors of the present application found in their research that NaHS and conventional fertilizer formulations such as flour, silicon powder, yeast powder, white carbon black, and activated carbon cannot be mixed and applied, because a large amount of H2 S will be released quickly after mixing. After a lot of exploration, it was found that NaHS and corn starch can coexist stably.

因此,实验确定包膜基料为玉米淀粉;粘结剂为:1,4-丁二醇1-3份、苯乙烯8-12份、乙二醇二甲基丙烯酸酯1-3份、乙醇5-8份、十二烷基硫酸钠2-4份、茶树油10-12份、葡萄糖酸锌15-20份。NaHS包膜缓释剂粒径为7.5mm(图2,粒径由左至右、由上至下依次为:>10.0mm、7.5mm、5.0mm、<3.0mm)。Therefore, the experiment determines that the coating base material is corn starch; the binder is: 1-3 parts of 1,4-butanediol, 8-12 parts of styrene, 1-3 parts of ethylene glycol dimethacrylate, ethanol 5-8 parts, 2-4 parts of sodium lauryl sulfate, 10-12 parts of tea tree oil, 15-20 parts of zinc gluconate. The particle size of the NaHS coated sustained-release agent is 7.5mm (Fig. 2, the particle size is from left to right, top to bottom: >10.0mm, 7.5mm, 5.0mm, <3.0mm).

制备流程如图1所示,具体包括:The preparation process is shown in Figure 1, which specifically includes:

(1)将NaHS粉末倒入圆盘快速滚动得到粒径为4-5mm的颗粒;接着迅速加入玉米淀粉,圆盘持续滚动,直至玉米淀粉完全包裹NaHS圆粒。(1) Pour the NaHS powder into the disc and roll quickly to obtain particles with a particle size of 4-5mm; then quickly add cornstarch, and continue to roll the disc until the cornstarch completely wraps the NaHS pellets.

(2)将乙醇用8倍的水稀释,然后依次加入苯乙烯和乙二醇二甲基丙烯酸酯,迅速搅拌20分钟进行聚合。(2) Dilute ethanol with 8 times of water, then add styrene and ethylene glycol dimethacrylate in sequence, and rapidly stir for 20 minutes to carry out polymerization.

(3)在容器中,混合十二烷基硫酸钠、茶树油和葡萄糖酸锌,兑入3倍其总重量份的水,持续搅拌直至成乳剂。(3) In a container, mix sodium lauryl sulfate, tea tree oil and zinc gluconate, add 3 times its total weight of water, and continue stirring until it becomes an emulsion.

(4)混合步骤(2)和(3)所得产物,同时加入1,4-丁二醇,搅拌均匀,约50分钟。(4) Mix the products obtained in steps (2) and (3), add 1,4-butanediol at the same time, and stir evenly for about 50 minutes.

(5)将步骤(1)所得产物在圆盘快速滚动,边滚动边加入步骤(4)所得产物及玉米淀粉,直至颗粒表面被完全包裹。(5) The product obtained in step (1) is rapidly rolled on a disc, and the product obtained in step (4) and corn starch are added while rolling until the particle surface is completely wrapped.

(6)放入90℃烘箱烘干即可。(6) Put it in a 90°C oven to dry.

即制备一粒NaHS包膜缓释颗粒的过程中约需要NaHS粉末1mg,玉米淀粉3-5mg、1,4-丁二醇1ml、苯乙烯8ml、乙二醇二甲基丙烯酸酯2ml、乙醇8ml、十二烷基硫酸钠4mg、茶树油12ml、葡萄糖酸锌20mg。That is, in the process of preparing one NaHS coated slow-release granule, about 1 mg of NaHS powder, 3-5 mg of corn starch, 1 ml of 1,4-butanediol, 8 ml of styrene, 2 ml of ethylene glycol dimethacrylate, and 8 ml of ethanol are required. , Sodium Lauryl Sulfate 4mg, Tea Tree Oil 12ml, Zinc Gluconate 20mg.

2、NaHS包膜缓释剂的测评(水溶性)2. Evaluation of NaHS coated sustained-release agent (water-soluble)

对于缓释肥料的评判标准,欧洲标准委员会做了以下描述即温度在25℃时:1.在24h内,有效养分在肥料中的释放率≤15%:2.在28天内,释放率≤75%:3.在一定时间内,释放率≥75%。通常肥料在水中的溶出率可以用来评价肥料的缓释效果,目前7d静置水溶出率法是经常使用的经典方法,这一方法人为干扰因素少,系统稳定,可做函数描述。7d静置水溶出率法在许多国家得到了发展和应用。该法是在250mL水中放入50g肥料样品(温度为25℃左右,肥水比为1:5),7d内,养分释放速率通过每天测定养分浓度来确定。For the evaluation criteria of slow-release fertilizers, the European Standards Committee has made the following descriptions, that is, when the temperature is 25 °C: 1. Within 24 hours, the release rate of effective nutrients in fertilizers is ≤ 15%: 2. Within 28 days, the release rate is ≤ 75 %: 3. In a certain period of time, the release rate is ≥ 75%. Usually, the dissolution rate of fertilizers in water can be used to evaluate the slow-release effect of fertilizers. At present, the 7-day standing water dissolution rate method is a classic method that is often used. This method has few human interference factors and the system is stable, and can be described as a function. The 7d standing water dissolution method has been developed and applied in many countries. The method is to put 50g of fertilizer samples in 250mL of water (the temperature is about 25°C, and the fertilizer-water ratio is 1:5), and within 7 days, the nutrient release rate is determined by measuring the nutrient concentration every day.

参照我国2007年颁布的《缓控释肥料》化工行业标准中关于缓控释肥料的要求,将NaHS及NaHS包膜缓释剂静置密闭于水中,于8天内不同时段测定H2S累计释放量,H2S累计释放量采用亚甲基蓝法。结果如图3,仅4天NaHS在水溶试验中H2S累积释放量已达最大释放量。NaHS包膜缓释剂的累积溶出率曲线则比较平缓,溶出速率基本恒定,缓释效果较好。Referring to the requirements for slow and controlled release fertilizers in the chemical industry standard of "Slow and Controlled Release Fertilizers" promulgated in China in 2007, NaHS and NaHS coated slow release agents were placed in water and sealed in water, and the cumulative release of H2 S was measured at different time periods within 8 days. The methylene blue method was used for the cumulative release of H2 S. The results are shown in Figure 3. The cumulative release amount of H2 S in the water-soluble test of NaHS has reached the maximum release amount in only 4 days. The cumulative dissolution rate curve of NaHS-coated sustained-release agent is relatively flat, the dissolution rate is basically constant, and the sustained-release effect is better.

图4是NaHS包膜缓释剂30天内在水溶试验中H2S累积释放曲线。由图4可知,NaHS包膜缓释剂的初期养分释放率分别为11.53%,均符合GB/T 23348-2009中缓释肥料的初期养分释放率≤15%的规定。NaHS包膜缓释剂的累积溶出率曲线比较平缓,接近直线,溶出速率基本恒定,缓释效果较好。NaHS包膜缓释剂的H2S累积溶出率与溶出时间的线性关系良好,由线性方程预测得出:在水中溶出率法中H2S累积溶出80%分别需要116d。具有缓释的效果。FIG. 4 is the cumulative release curve of H2 S in the water solubility test of NaHS coated sustained-release agent within 30 days. It can be seen from Figure 4 that the initial nutrient release rates of NaHS-coated slow-release agents are 11.53%, respectively, which are in line with the initial nutrient release rate of slow-release fertilizers in GB/T 23348-2009 ≤ 15%. The cumulative dissolution rate curve of NaHS-coated sustained-release agent is relatively flat, close to a straight line, the dissolution rate is basically constant, and the sustained-release effect is better. The linear relationship between the H2 S cumulative dissolution rate and the dissolution time of the NaHS-coated sustained-release agent is good. The linear equation predicts that it takes 116 days for the H2 S cumulative dissolution rate to be 80% in the water dissolution rate method. Has a slow release effect.

预测方法如下:The prediction method is as follows:

根据线性方程,以NaHS在水溶实验中H2S最大累计释放量作为y值,计算x值。即NaHS包膜缓释剂在水中溶出率法中H2S累积溶出最大值需要的天数。According to the linear equation, the maximum cumulative release of H2 S of NaHS in the water-solubility experiment was taken as the y value, and the x value was calculated. That is, the number of days required for the maximum cumulative dissolution of H2 S in the dissolution rate method of NaHS coated sustained-release agent in water.

3、不同土壤环境下NaHS包膜缓释剂H2S累积溶出量3. Cumulative dissolution of H2 S from NaHS-coated slow-release agent in different soil environments

测定了在不同土壤环境下,NaHS包膜缓释剂H2S累积溶出量,方法同上。结果如图5-7所示。The cumulative dissolution amount of H2 S from the NaHS-coated slow-release agent was determined in different soil environments, and the method was the same as above. The result is shown in Figure 5-7.

其中,图5是土壤含水量对NaHS包膜缓释剂中H2S累积量的影响。图6是温度对NaHS包膜缓释剂中H2S累积量的影响。图7是PH对NaHS包膜缓释剂中H2S累积量的影响。Among them, Figure 5 shows the effect of soil water content on the accumulation of H2 S in the NaHS-coated slow-release agent. Figure 6 is the effect of temperature on the accumulation of H2 S in the NaHS-coated sustained-release agent. Figure 7 is the effect of pH on the accumulation of H2 S in the NaHS-coated sustained-release formulation.

大田应用病害防治效果比较分析如图8所示,其中清水:(CK);缓冲液(NaHS);缓释剂(NaHSK)。The comparative analysis of field application disease control effect is shown in Figure 8, in which clear water: (CK); buffer (NaHS); sustained release agent (NaHSK).

农艺经济性状如下表所示。Agronomic and economic traits are shown in the table below.

由上表可知:大田施用NaHS包膜缓释剂后,显著提高雪茄烟的农艺性状及经济指标。It can be seen from the above table that after applying NaHS coated slow-release agent in the field, the agronomic properties and economic indicators of cigars are significantly improved.

以上所述仅为本发明的较佳实施例而已,并不用以限制本发明,凡在本发明的精神和原则之内所作的任何修改、等同替换和改进等,均应包含在本发明的保护范围之内。The above descriptions are only preferred embodiments of the present invention and are not intended to limit the present invention. Any modifications, equivalent replacements and improvements made within the spirit and principles of the present invention shall be included in the protection of the present invention. within the range.

Claims (9)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210153286.1ACN114436708A (en) | 2022-02-18 | 2022-02-18 | A kind of NaHS coated slow-release agent, preparation method and application |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210153286.1ACN114436708A (en) | 2022-02-18 | 2022-02-18 | A kind of NaHS coated slow-release agent, preparation method and application |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114436708Atrue CN114436708A (en) | 2022-05-06 |

Family

ID=81373941

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210153286.1APendingCN114436708A (en) | 2022-02-18 | 2022-02-18 | A kind of NaHS coated slow-release agent, preparation method and application |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114436708A (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101973808A (en)* | 2010-09-28 | 2011-02-16 | 湖北富邦化工科技有限公司 | Starch coating material and application thereof in coated sustained/controlled release fertilizers |

| CN102167647A (en)* | 2011-05-09 | 2011-08-31 | 湖北富邦科技股份有限公司 | Degradable composite coating material and preparation method and application thereof in controlled release fertilizer |

| CN104194012A (en)* | 2014-08-27 | 2014-12-10 | 黑龙江省科学院高技术研究院 | Preparation method of biodegradable coating material |

| CN104860753A (en)* | 2015-05-05 | 2015-08-26 | 马鞍山科邦生态肥有限公司 | Membrane-coated microbial slow-release fertilizer and production method thereof |

| CN104973929A (en)* | 2015-05-05 | 2015-10-14 | 马鞍山科邦生态肥有限公司 | Biomass charcoal-enveloped controlled-release fertilizer and preparation method thereof |

| CN112262855A (en)* | 2020-10-28 | 2021-01-26 | 湖北省烟草科学研究院 | A method for preventing and controlling tobacco bacterial wilt and application of NaHS in controlling tobacco bacterial wilt |

- 2022

- 2022-02-18CNCN202210153286.1Apatent/CN114436708A/enactivePending

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101973808A (en)* | 2010-09-28 | 2011-02-16 | 湖北富邦化工科技有限公司 | Starch coating material and application thereof in coated sustained/controlled release fertilizers |

| CN102167647A (en)* | 2011-05-09 | 2011-08-31 | 湖北富邦科技股份有限公司 | Degradable composite coating material and preparation method and application thereof in controlled release fertilizer |

| CN104194012A (en)* | 2014-08-27 | 2014-12-10 | 黑龙江省科学院高技术研究院 | Preparation method of biodegradable coating material |

| CN104860753A (en)* | 2015-05-05 | 2015-08-26 | 马鞍山科邦生态肥有限公司 | Membrane-coated microbial slow-release fertilizer and production method thereof |

| CN104973929A (en)* | 2015-05-05 | 2015-10-14 | 马鞍山科邦生态肥有限公司 | Biomass charcoal-enveloped controlled-release fertilizer and preparation method thereof |

| CN112262855A (en)* | 2020-10-28 | 2021-01-26 | 湖北省烟草科学研究院 | A method for preventing and controlling tobacco bacterial wilt and application of NaHS in controlling tobacco bacterial wilt |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Zia et al. | Effect of water management and silicon on germination, growth, phosphorus and arsenic uptake in rice | |

| CN105961104B (en) | A kind of implantation methods, the plantation fertilizer of SOD contents paddy rice high | |

| Han et al. | Nitrogen release dynamics and transformation of slow release fertiliser products and their effects on tea yield and quality | |

| Nagdalian et al. | Effect of selenium nanoparticles on biological and morphofunctional parameters of barley seeds (Hordéum vulgáre L.) | |

| Banakar et al. | Red-seaweed biostimulants differentially alleviate the impact of fungicidal stress in rice (Oryza sativa L.) | |

| Alharbi et al. | Zinc oxide nanoparticles and PGPR strengthen salinity tolerance and productivity of wheat irrigated with saline water in sodic-saline soil | |

| CN102976803A (en) | Additive for accelerating crop straws to efficiently maturate and application thereof | |

| Kokila et al. | Elevated CO2 along with inoculation of cyanobacterial biofilm or its partners differentially modulates C–N metabolism and quality of tomato beneficially | |

| CN102503712A (en) | Microbial organic fertilizer and application thereof | |

| CN119330786A (en) | A microbial agent for preventing and treating angelica root knot nematode disease and its application | |

| Shi et al. | Nitrogen fertilizer reduction based on bioorganic fertilizer improves the yield and quality of fresh leaves of alpine tea in summer | |

| CN114436708A (en) | A kind of NaHS coated slow-release agent, preparation method and application | |

| Kashif et al. | Improving seed germination and green pod yield in okra (Hibiscus esculentus l.) using calcium carbide—A new source of ethylene | |

| Segatto et al. | Pretreatment of maize seeds with different magnesium nanoparticles improves the germinating performance and storability | |

| Wang et al. | The effects of Piriformospora indica on the growth of cuttings from three species of woody ornamental plants | |

| CN114847297B (en) | A kind of pesticide composition for preventing and treating rice diseases | |

| Rath et al. | Effect of application of ammonium thiosulphate on production and emission of methane in a tropical rice soil | |

| Akçay et al. | Synergistic effects of salicylic acid and magnesium oxide nanoparticles on cold stress and miRNA expression in alfalfa (Medicago sativa L.) genotypes | |

| Kong et al. | Insights into tomato growth stimulation and induced resistance against Fusarium oxysporum f. sp. lycopersici by magnetite nanoparticles | |

| Prabha et al. | Carboxymethylcellulose stabilized ZnO nanoparticles: an efficient nano-nutrient for the growth and development of Trigonella foenum-graecum (fenugreek) seeds | |

| CN116535265A (en) | Humate-containing nutrient for promoting plant growth, its preparation method and application | |

| CN117337833A (en) | Application of 2-amino-3-methylhexanoic acid as phytotoxicity relieving agent | |

| CN117426190A (en) | Fertilizing method for reducing incidence rate of cloud tobacco 87 bacterial wilt | |

| CN104396962A (en) | Pesticide composition | |

| CN110950705B (en) | Composite wood vinegar not prone to oxidative discoloration and preparation method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20220506 | |

| RJ01 | Rejection of invention patent application after publication |