CN114429024A - Simulation evaluation method for deep penetration segment value of steel pipeline in use - Google Patents

Simulation evaluation method for deep penetration segment value of steel pipeline in useDownload PDFInfo

- Publication number

- CN114429024A CN114429024ACN202011095001.0ACN202011095001ACN114429024ACN 114429024 ACN114429024 ACN 114429024ACN 202011095001 ACN202011095001 ACN 202011095001ACN 114429024 ACN114429024 ACN 114429024A

- Authority

- CN

- China

- Prior art keywords

- pipeline

- potential

- deep penetration

- data

- cathodic protection

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G06F30/20—Design optimisation, verification or simulation

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2111/00—Details relating to CAD techniques

- G06F2111/10—Numerical modelling

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F2113/00—Details relating to the application field

- G06F2113/14—Pipes

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Theoretical Computer Science (AREA)

- Computer Hardware Design (AREA)

- Evolutionary Computation (AREA)

- Geometry (AREA)

- General Engineering & Computer Science (AREA)

- General Physics & Mathematics (AREA)

- Testing Resistance To Weather, Investigating Materials By Mechanical Methods (AREA)

- Prevention Of Electric Corrosion (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种管道数值模拟评价方法,具体涉及一种在用钢质管道深穿段数值模拟评价方法。The invention relates to a pipeline numerical simulation evaluation method, in particular to a numerical simulation evaluation method of a deep penetration section of an in-use steel pipeline.

背景技术Background technique

国内外资料研究发现,对于定向钻穿越段管道防腐层的评价,人们已进行了一些探索。这些探索大致可总结为三种方法:电流电位法、通电电位切换法(通电电位法、极化偏移准则)和防腐层面电阻率法。Researches on domestic and foreign data have found that people have carried out some explorations on the evaluation of the anti-corrosion layer of the pipeline in the directional drilling crossing section. These explorations can be roughly summarized into three methods: current potential method, energized potential switching method (energized potential method, polarization shift criterion) and anti-corrosion layer resistivity method.

电位-电流馈电法:该方法计算结果受一些不确定因素的影响,需在管道未碰口时测试。对于已经碰口的在线管道,只能采用馈电法检测防腐层,估算电阻。只适用于水平定向钻穿越完成后尚未与其他管段连接的管道,不适用于在用钢质管道。通电电位偏移等方法受影响因素较多,结果偏差较大。R.A.Gummow提出的方法,数据获得困难,现场并不实用。Potential-current feeding method: The calculation result of this method is affected by some uncertain factors, and it needs to be tested when the pipeline does not touch. For on-line pipelines that have been touched, only the feeding method can be used to detect the anti-corrosion layer and estimate the resistance. It is only applicable to pipes that have not been connected to other pipe sections after the horizontal directional drilling is completed, not applicable to steel pipes in use. There are many factors affected by methods such as energization potential offset, and the deviation of the results is large. The method proposed by R.A.Gummow has difficulty in obtaining data and is not practical in the field.

黄雪松等人在《输气管道第三方破坏数值分析及安全评价方法》中通过经典赫兹接触理论,采用ANSYS有限元仿真软件,建立第三方挖掘机斗齿作用管道的数值模型,研究了不同斗齿冲击角度和冲击深度对管道的损伤程度。结果表明:随着挖掘机斗齿吃入深度增大,管道内外壁面的变形越大,卸载内压后管道凹坑变形更加明显。基于输气管道残余应力研究分析,本文考虑凹坑深度及应力综合评价,对破损管道进行了系统分析。结论以管道应变的百分之六为临界值,管道外表面凹坑深度的最大值为参考,给出破损管道更换的评价标准。最后,对某管段施工过程中挖掘机斗齿的影响进行了风险评价分析,为实际现场输气管道第三方破坏的风险防控预案提供科学依据。Huang Xuesong et al. established the numerical model of the third-party excavator bucket teeth acting on the pipeline through the classical Hertzian contact theory and the ANSYS finite element simulation software in "The Third Party Damage Numerical Analysis and Safety Evaluation Method of Gas Pipelines", and studied different bucket teeth. The degree of damage to the pipe caused by the tooth impact angle and impact depth. The results show that with the increase of the depth of the excavator bucket teeth, the deformation of the inner and outer walls of the pipeline is larger, and the deformation of the pipeline pit is more obvious after the internal pressure is unloaded. Based on the research and analysis of residual stress in gas pipelines, this paper takes into account the comprehensive evaluation of pit depth and stress, and conducts a systematic analysis of damaged pipelines. Conclusion Taking 6% of the pipeline strain as the critical value and the maximum value of the pit depth on the outer surface of the pipeline as the reference, the evaluation standard for the replacement of damaged pipelines is given. Finally, the risk assessment and analysis of the influence of the bucket teeth of the excavator during the construction of a pipeline section is carried out, which provides a scientific basis for the risk prevention and control plan of the third-party damage of the actual on-site gas pipeline.

中国专利申请CN111027240A公开了一种埋地管道安全评估方法及相关设备,在建立埋地管道的管-土三维非线性有限元模型之后,根据不同工况的管道应力影响参数和管道应力的对应关系建立训练集,其中,通过有限元数值模拟的方法得到对应不同工况的管道应力影响参数的管道应力,较理论计算的方式更精确、便捷;而由于神经网络具有强大的非线性处理能力,可以利用训练集进行神经网络训练以得到管道应力预测模型,在根据管道结构可靠度计算算法计算埋地管道的结构可靠度时,可以利用管道应力预测模型快速获取管道应力,在保证计算结果的准确度的前提下,减少管道应力所需的计算时间,提高了埋地管道的结构可靠度的计算效率,提高对埋地管道的安全运行管理及技术的水平。Chinese patent application CN111027240A discloses a buried pipeline safety assessment method and related equipment. After establishing a pipe-soil three-dimensional nonlinear finite element model of the buried pipeline, according to the corresponding relationship between the pipeline stress influencing parameters and the pipeline stress under different working conditions A training set is established, in which the pipeline stress corresponding to the pipeline stress influencing parameters of different working conditions is obtained by the method of finite element numerical simulation, which is more accurate and convenient than the theoretical calculation method. Use the training set to train the neural network to obtain the pipeline stress prediction model. When calculating the structural reliability of the buried pipeline according to the pipeline structure reliability calculation algorithm, the pipeline stress prediction model can be used to quickly obtain the pipeline stress, so as to ensure the accuracy of the calculation results. Under the premise of reducing the calculation time required for pipeline stress, the calculation efficiency of the structural reliability of the buried pipeline is improved, and the safety operation management and technical level of the buried pipeline are improved.

中国专利申请CN110020399A公开了一种管道内腐蚀评价位置的确定方法,属于管道腐蚀领域。所述方法包括:将目标管道划分成多个子管道;获取所述子管道的积水概率、腐蚀概率以及持液率;将所述积水概率与所述腐蚀概率相乘,获取所述子管道的腐蚀总概率;当所述子管道的腐蚀总概率大于第一预设值,且持液率大于第二预设值时,确定所述子管道为所述目标管道中需要进行内腐蚀评价的位置。该发明提供的方法同时考虑了积水概率、腐蚀概率以及持液率对管道内腐蚀的影响,能准确地确定该目标管道中需要进行内腐蚀评价的位置,可为管道整体内腐蚀评价提供可靠的判断依据。Chinese patent application CN110020399A discloses a method for determining the corrosion evaluation position in a pipeline, which belongs to the field of pipeline corrosion. The method includes: dividing the target pipeline into a plurality of sub-pipes; obtaining the water accumulation probability, corrosion probability and liquid holdup rate of the sub-pipeline; multiplying the water accumulation probability and the corrosion probability to obtain the sub-pipeline When the total corrosion probability of the sub-pipeline is greater than the first preset value and the liquid holdup is greater than the second preset value, it is determined that the sub-pipeline is the target pipeline that needs to be evaluated for internal corrosion Location. The method provided by the invention also considers the influence of water accumulation probability, corrosion probability and liquid holdup on the internal corrosion of the pipeline, can accurately determine the position in the target pipeline that needs to be evaluated for internal corrosion, and can provide reliable performance for the overall internal corrosion evaluation of the pipeline. basis of judgment.

中国专利申请CN106777760A公开了一种基于数值分析的金属管道杂散电流预测方法。目前,直接输电系统接地极会引起附近金属管道杂散电流而导致金属管道被电化学腐蚀。本发明先对目标金属管道与直流输电系统接地极情况进行简化处理;接着构建直流输电系统接地极导致的金属管道杂散电流的数学模型;然后基于数学模型,对金属管道及直流输电系统接地极的区域进行限制并确定相应的边界条件;构建目标金属管道的几何模型;最后利用所述的数学模型与几何模型,使用数值模拟软件进行模拟仿真,计算金属管道杂散电流的大小。该发明通过预估出直流输电系统接地极对附近金属管道的杂散电流大小,从而为金属管道的防腐蚀措施提供依据。Chinese patent application CN106777760A discloses a method for predicting stray current in metal pipelines based on numerical analysis. At present, the grounding electrode of the direct power transmission system will cause stray currents in the nearby metal pipelines and lead to electrochemical corrosion of the metal pipelines. The invention firstly simplifies the situation of the target metal pipeline and the grounding pole of the direct current transmission system; then builds a mathematical model of the stray current of the metal pipeline caused by the grounding pole of the direct current transmission system; then based on the mathematical model, the metal pipeline and the grounding pole of the direct current transmission system are Limit the area and determine the corresponding boundary conditions; build the geometric model of the target metal pipeline; finally, use the mathematical model and geometric model described above, and use numerical simulation software to simulate and calculate the magnitude of the stray current of the metal pipeline. The invention provides a basis for anti-corrosion measures for metal pipes by estimating the magnitude of the stray current of the grounding pole of the DC power transmission system to the nearby metal pipes.

目前,需要提供一种对管道深穿段防腐层评价更为准确、且易于操作的方法。At present, it is necessary to provide a more accurate and easy-to-operate method for evaluating the anti-corrosion layer of the deep penetration section of the pipeline.

发明内容SUMMARY OF THE INVENTION

为解决上述问题,本发明提供一种在用钢质管道深穿段数值模拟评价方法,本发明方法通过测量测量深穿段管道入土点、出土点保护电位及其他参数,推算深穿段管道阴极保护电流密度等相关参数,进而对深穿段管道防腐层完好情况进行评估,克服了管道深穿段防腐层状态难以检测的难题。In order to solve the above problems, the present invention provides a numerical simulation evaluation method for the deep penetration section of the steel pipeline in use. The method of the present invention calculates the cathode of the deep penetration section pipeline by measuring the earth entry point of the deep penetration section, the protection potential of the excavation point and other parameters. The protection current density and other related parameters are used to evaluate the integrity of the anti-corrosion layer of the pipeline in the deep penetration section, which overcomes the difficulty of detecting the state of the anti-corrosion layer in the deep penetration section of the pipeline.

为实现上述目的,本发明采用以下技术方案:To achieve the above object, the present invention adopts the following technical solutions:

本发明提供一种在用钢质管道深穿段数值模拟评价方法,其包括以下步骤:The invention provides a numerical simulation evaluation method for a deep penetration section of an in-use steel pipeline, which comprises the following steps:

模拟深穿管道防腐层受损情况,找出对应的入土点和出土点阴极保护电位及其他参数的变化规律和对应关系,建立数据分析模型;Simulate the damage of the anti-corrosion layer of the deep penetration pipeline, find out the variation law and corresponding relationship of the cathodic protection potential and other parameters at the corresponding entry point and excavation point, and establish a data analysis model;

对数据分析模型进行修正或改进;Make corrections or improvements to the data analysis model;

采集深穿段管道参数信息,将信息输入数据分析模型,模拟出电位和电流密度分布图;Collect the pipeline parameter information of the deep penetration section, input the information into the data analysis model, and simulate the potential and current density distribution map;

分析电位和电流密度分布图,得出深穿管道阴极保护检测结果。Analyze the potential and current density distribution diagrams, and obtain the detection results of cathodic protection of deep penetration pipelines.

优选地,采用边界元法建立杂散电流干扰和阴极保护数值、状态评估的数据分析模型。Preferably, the boundary element method is used to establish the data analysis model of stray current interference and cathodic protection numerical and state evaluation.

进一步优选地,建立数学分析模型如下:Further preferably, a mathematical analysis model is established as follows:

式中,电缆、阴极体和阳极体的电压降对模型的影响极小,可忽略不计,即:Δφa=0、Δφc=0、Δφcable1=0和Δφcable2=0,故模型简化为:In the formula, the influence of the voltage drop of the cable, the cathode body and the anode body on the model is very small and can be ignored, namely: Δφa = 0, Δφc = 0, Δφcable1 = 0 and Δφcable2 = 0, so the model is simplified as :

式中,V为计算求解的电解质区域;φ为求解区域内各处的电位;x、y、z为空间坐标;ΓA为围绕辅助阳极体的介质边界;φa/s为辅助阳极体周围的土壤电位;φa为辅助阳极体电位;Δφa/s为辅助阳极对电解质电位,即通常所说的辅助阳极极化电位;ja为辅助阳极表面极化电流密度;σ为电解质的电导率;ΓC为包围阴极体的电解质边界,φc为阴极体电位;Γ1为电解质绝缘边界。In the formula, V is the electrolyte area to be solved by calculation; φ is the potential of each place in the solution area; x, y, and z are the spatial coordinates; ΓA is the dielectric boundary around the auxiliary anode body; φa/s is the surrounding area of the auxiliary anode body φa is the body potential of the auxiliary anode; Δφa/s is the potential of the auxiliary anode to the electrolyte, commonly known as the auxiliary anode polarization potential; ja is the surface polarization current density of the auxiliary anode; σ is the conductance of the electrolyte ΓC is the electrolyte boundary surrounding the cathode body, φc is the cathode body potential; Γ1 is the electrolyte insulating boundary.

优选地,入土点和出土点阴极保护电位采集方法:将管道阴极保护智能测试桩安装在在管道穿越段入土点和出土点,定时将采集的电位数据通过网络远程发送数据至计算机数据库,实现阴极保护电位的自动采集、存档。Preferably, the method for collecting cathodic protection potential at the entry point and the excavation point: install the pipeline cathodic protection intelligent test pile at the entry point and the excavation point of the pipeline crossing section, and periodically send the collected potential data to the computer database through the network remotely, so as to realize the cathodic protection Automatic collection and archiving of protection potential.

优选地,对数据分析模型进行修正或改进的方法为:将数据模型应用到实际的管道上,采取开挖验证的方式采集管道入土点和出土点的实际电位及其他参数,对实验数据模块计算数据进行对比,对所建立的实验数据模型进行修正和改进;Preferably, the method of revising or improving the data analysis model is as follows: applying the data model to the actual pipeline, collecting the actual potential and other parameters of the pipeline entry point and excavation point by means of excavation verification, and calculating the experimental data module Comparing the data, correcting and improving the established experimental data model;

再选取其他深穿段进行开挖,采集所需数据,对修正后的数学模型进行校核,再次进行修正和改进,直到符合要求。Then select other deep penetration sections for excavation, collect the required data, check the corrected mathematical model, and make corrections and improvements again until the requirements are met.

进一步优选地,选取选取3-5段深穿管道开挖,采集管道数据、保护电位、通电电位、断电电位、土壤电阻率、保护电位分布、保护电流密度。Further preferably, 3-5 sections of deep-penetrating pipeline are selected for excavation, and pipeline data, protection potential, energization potential, power-off potential, soil resistivity, protection potential distribution, and protection current density are collected.

优选地,采集深穿段管道参数信息包括深穿段管道牺牲阳极埋深、管道直径、分布走向、土壤电阻率,出入土点的阴极保护电位、断电电位。Preferably, the parameter information collected in the deep penetration section of the pipeline includes the buried depth of the sacrificial anode of the deep penetration section, the diameter of the pipeline, the distribution trend, the soil resistivity, the cathodic protection potential of the entry and exit points, and the power failure potential.

优选地,将现场测量值与模型计算值绘制电位和电流密度分布图进行对比,根据偏离计算值正常范围的大小来判断深穿管道阴极保护效果。Preferably, the on-site measurement value is compared with the model calculated value to draw a potential and current density distribution map, and the cathodic protection effect of the deep penetration pipeline is judged according to the deviation from the normal range of the calculated value.

优选地,出入土点任一点电位大于-0.85V视为达不到管道保护要求,电流密度超过给定的范围,视为防腐层有破损点。Preferably, if the potential of any point at the entry and exit points is greater than -0.85V, it is considered that the pipeline protection requirements are not met, and if the current density exceeds the given range, it is considered that the anti-corrosion layer has a damaged point.

进一步优选地,采用1000Ω·cm对电导率进行归一化,并根据标准中的指标进行防腐层评价,电导率小于2μS/m2评价结论即为优秀。Further preferably, the electrical conductivity is normalized by 1000Ω·cm, and the anti-corrosion coating is evaluated according to the indexes in the standard. The evaluation conclusion of electrical conductivity less than 2 μS/m2 is excellent.

本发明还提供一种在用钢质管道深穿段评价系统,包括数据采集系统,数据处理系统和结果显示系统;数据采集系统用于采集深穿段管道牺牲阳极埋深、管道直径、分布走向、土壤电阻率,出入土点的阴极保护电位、断电电位;The invention also provides an evaluation system for the deep penetration section of the steel pipeline in use, which includes a data acquisition system, a data processing system and a result display system; the data acquisition system is used to collect the buried depth, pipe diameter and distribution trend of the sacrificial anode of the deep penetration pipe. , Soil resistivity, cathodic protection potential and power-off potential of entry and exit points;

数据处理系统包括以上所述评价方法中修正或改进后的数学模型。The data processing system includes the revised or improved mathematical model of the evaluation method described above.

与现有技术相比,本发明具有以下有益效果:Compared with the prior art, the present invention has the following beneficial effects:

本发明方法通过测量深穿段管道入土点、出土点保护电位及其他参数,推算深穿段管道阴极保护电流密度等相关参数,进而对深穿段管道防腐层完好情况进行评估的方法。本发明解决了管道深穿段防腐层状态无法检测的难题。The method of the invention calculates the relevant parameters such as the cathodic protection current density of the deep penetrating section pipeline by measuring the protection potential of the deep penetrating section pipeline, the protection potential of the excavation point and other parameters, and then evaluates the integrity of the anti-corrosion layer of the deep penetrating section pipeline. The invention solves the problem that the state of the anti-corrosion layer in the deep penetration section of the pipeline cannot be detected.

本发明方法可将管道阴极保护智能测试桩安装在管道穿越段入土点和出土点,定时将采集的电位数据通过网络远程发送数据至计算机数据库,实现阴极保护电位的自动采集、存档,通过计算机随时可以对管道穿越段防腐层进行评估或监视,无需到现场进行人工测量,降低了工作量。The method of the invention can install the pipeline cathodic protection intelligent test piles at the entry point and the excavation point of the pipeline crossing section, periodically send the collected potential data to the computer database through the network, and realize the automatic collection and archive of the cathodic protection potential. The anti-corrosion layer of the pipeline crossing section can be evaluated or monitored without manual measurement on site, which reduces the workload.

附图说明Description of drawings

构成本发明的一部分的说明书附图用来提供对本发明的进一步理解,本发明的示意性实施例及其说明用于解释本发明,并不构成对本发明的不当限定。The accompanying drawings forming a part of the present invention are used to provide further understanding of the present invention, and the exemplary embodiments of the present invention and their descriptions are used to explain the present invention, and do not constitute an improper limitation of the present invention.

图1为本发明一具体实施例所述在用钢质管道深穿段数值模拟评价方法中数值分析模型建立方法流程图;1 is a flowchart of a method for establishing a numerical analysis model in a numerical simulation evaluation method for a deep penetration section of a steel pipeline according to a specific embodiment of the present invention;

图2为本发明一具体实施例所述阴极边界条件反推算法的模拟过程示意图;2 is a schematic diagram of a simulation process of a cathode boundary condition inversion algorithm according to a specific embodiment of the present invention;

图3为本发明一具体实施例所述保护电位测量示意图;3 is a schematic diagram of the protection potential measurement according to a specific embodiment of the present invention;

图4为本发明一具体实施例所述所述长输管道电位衰减模型示意图;4 is a schematic diagram of the potential attenuation model of the long-distance pipeline according to a specific embodiment of the present invention;

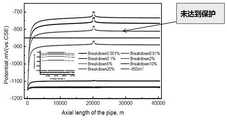

图5为本发明一具体实施例所述管道电位分布模拟结果图。FIG. 5 is a diagram showing the simulation result of the pipeline potential distribution according to a specific embodiment of the present invention.

具体实施方式Detailed ways

应该指出,以下详细说明都是示例性的,旨在对本发明提供进一步的说明。除非另有指明,本文使用的所有技术和科学术语具有与本发明所属技术领域的普通技术人员通常理解的相同含义。It should be noted that the following detailed description is exemplary and intended to provide further explanation of the invention. Unless otherwise defined, all technical and scientific terms used herein have the same meaning as commonly understood by one of ordinary skill in the art to which this invention belongs.

需要注意的是,这里所使用的术语仅是为了描述具体实施方式,而非意图限制根据本发明的示例性实施方式。如在这里所使用的,除非上下文另外明确指出,否则单数形式也意图包括复数形式,此外,还应当理解的是,当在本说明书中使用术语“包含”和/或“包括”时,其指明存在特征、步骤、操作和/或它们的组合。It should be noted that the terminology used herein is for the purpose of describing specific embodiments only, and is not intended to limit the exemplary embodiments according to the present invention. As used herein, unless the context clearly dictates otherwise, the singular is intended to include the plural as well, furthermore, it is to be understood that when the terms "comprising" and/or "including" are used in this specification, it indicates that There are features, steps, operations, and/or combinations thereof.

为了使得本领域技术人员能够更加清楚地了解本发明的技术方案,以下将结合具体的实施例详细说明本发明的技术方案。In order to enable those skilled in the art to understand the technical solutions of the present invention more clearly, the technical solutions of the present invention will be described in detail below with reference to specific embodiments.

实施例1Example 1

如图1所示,所述在用钢质管道深穿段数值模拟评价方法,包括以下步骤:As shown in Figure 1, the numerical simulation evaluation method of the deep penetration section of the steel pipeline in use includes the following steps:

模拟深穿管道防腐层受损情况,找出对应的入土点和出土点阴极保护电位及其他参数的变化规律和对应关系,建立数据分析模型;建立数学分析模型如下:Simulate the damage of the anti-corrosion layer of the deep penetration pipeline, find out the variation law and corresponding relationship of the cathodic protection potential and other parameters at the corresponding entry and exit points, and establish a data analysis model. The mathematical analysis model is established as follows:

式中,电缆、阴极体和阳极体的电压降对模型的影响极小,可忽略不计,即:Δφa=0、Δφc=0、Δφcable1=0和Δφcable2=0,故模型简化为:In the formula, the influence of the voltage drop of the cable, the cathode body and the anode body on the model is very small and can be ignored, namely: Δφa = 0, Δφc = 0, Δφcable1 = 0 and Δφcable2 = 0, so the model is simplified as :

式中,V为计算求解的电解质区域;φ为求解区域内各处的电位;x、y、z为空间坐标;ΓA为围绕辅助阳极体的介质边界;φa/s为辅助阳极体周围的土壤电位;φa为辅助阳极体电位;Δφa/s为辅助阳极对电解质电位,即通常所说的辅助阳极极化电位;ja为辅助阳极表面极化电流密度;σ为电解质的电导率;ΓC为包围阴极体的电解质边界,φc为阴极体电位;Γ1为电解质绝缘边界。In the formula, V is the electrolyte area to be solved by calculation; φ is the potential of each place in the solution area; x, y, and z are the spatial coordinates; ΓA is the dielectric boundary around the auxiliary anode body; φa/s is the surrounding area of the auxiliary anode body φa is the body potential of the auxiliary anode; Δφa/s is the potential of the auxiliary anode to the electrolyte, commonly known as the auxiliary anode polarization potential; ja is the surface polarization current density of the auxiliary anode; σ is the conductance of the electrolyte ΓC is the electrolyte boundary surrounding the cathode body, φc is the cathode body potential; Γ1 is the electrolyte insulating boundary.

选取3-5段深穿管道开挖,采集管道数据、保护电位、通(断)电电位、土壤电阻率、保护电位分布、保护电流密度等参数。Select 3-5 deep penetration pipeline excavation, collect pipeline data, protection potential, on (off) electric potential, soil resistivity, protection potential distribution, protection current density and other parameters.

将实际测量参数与数据分析模型计算结果比较,修正数据分析模型中的参数,对数据分析模型进行修正或改进;Compare the actual measurement parameters with the calculation results of the data analysis model, revise the parameters in the data analysis model, and revise or improve the data analysis model;

重复验证与修改数据分析模型,达到模拟准确率大于85%的要求。Repeatedly verify and modify the data analysis model to meet the requirement that the simulation accuracy rate is greater than 85%.

采集深穿段管道参数信息,将信息输入数据分析模型,模拟出电位和电流密度分布图;Collect the pipeline parameter information of the deep penetration section, input the information into the data analysis model, and simulate the potential and current density distribution map;

分析电位和电流密度分布图,得出深穿管道阴极保护检测结果。出入土点任一点电位大于-0.85V视为达不到管道保护要求,电流密度超过给定的范围,视为防腐层有破损点。Analyze the potential and current density distribution diagrams, and obtain the detection results of cathodic protection of deep penetration pipelines. If the potential of any point of the entry and exit points is greater than -0.85V, it is regarded as not meeting the requirements of pipeline protection, and the current density exceeds the given range, which is regarded as a damaged point of the anti-corrosion layer.

实施例2Example 2

所述在用钢质管道深穿段数值模拟评价方法,包括以下步骤:The numerical simulation evaluation method of the deep penetration section of the in-use steel pipeline includes the following steps:

模拟深穿管道防腐层受损情况,找出对应的入土点和出土点阴极保护电位及其他参数的变化规律和对应关系,建立数据分析模型;建立数学分析模型如下:Simulate the damage of the anti-corrosion layer of the deep penetration pipeline, find out the variation law and corresponding relationship of the cathodic protection potential and other parameters at the corresponding entry and exit points, and establish a data analysis model. The mathematical analysis model is established as follows:

式中,电缆、阴极体和阳极体的电压降对模型的影响极小,可忽略不计,即:Δφa=0、Δφc=0、Δφcable1=0和Δφcable2=0,故模型简化为:In the formula, the influence of the voltage drop of the cable, the cathode body and the anode body on the model is very small and can be ignored, namely: Δφa = 0, Δφc = 0, Δφcable1 = 0 and Δφcable2 = 0, so the model is simplified as :

式中,V为计算求解的电解质区域;φ为求解区域内各处的电位;x、y、z为空间坐标;ΓA为围绕辅助阳极体的介质边界;φa/s为辅助阳极体周围的土壤电位;φa为辅助阳极体电位;Δφa/s为辅助阳极对电解质电位,即通常所说的辅助阳极极化电位;ja为辅助阳极表面极化电流密度;σ为电解质的电导率;ΓC为包围阴极体的电解质边界,φc为阴极体电位;Γ1为电解质绝缘边界。In the formula, V is the electrolyte area to be solved by calculation; φ is the potential of each place in the solution area; x, y, and z are the spatial coordinates; ΓA is the dielectric boundary around the auxiliary anode body; φa/s is the surrounding area of the auxiliary anode body φa is the body potential of the auxiliary anode; Δφa/s is the potential of the auxiliary anode to the electrolyte, commonly known as the auxiliary anode polarization potential; ja is the surface polarization current density of the auxiliary anode; σ is the conductance of the electrolyte ΓC is the electrolyte boundary surrounding the cathode body, φc is the cathode body potential; Γ1 is the electrolyte insulating boundary.

阳极边界:通过电流测试桩、电压降/线电阻、电流环法及PCM电流衰减评估等方法测量得到流入穿越段的阴极保护电流。Anode boundary: The cathodic protection current flowing into the crossing section is obtained by measuring the current test pile, voltage drop/line resistance, current loop method and PCM current attenuation evaluation.

阴极边界:包含涂层和极化特性的综合影响,在定向钻情况下无法直接测量,由可直接测量参数进行反推阴极边界条件。Cathode boundary: It includes the combined effects of coating and polarization characteristics, which cannot be directly measured in the case of directional drilling. The cathode boundary conditions are inversely derived from directly measurable parameters.

阴极边界条件反推算法的模拟过程,如图2所示。The simulation process of the cathode boundary condition inversion algorithm is shown in Figure 2.

采用如图3所示保护电位测量装置进行深穿管道入土点、出土点保护电位的测量。The protection potential measurement device as shown in Figure 3 is used to measure the protection potential at the entry point and the excavation point of the deep penetration pipeline.

选取3-5段深穿管道开挖,采集管道数据、保护电位、通(断)电电位、土壤电阻率、保护电位分布、保护电流密度等参数。Select 3-5 deep penetration pipeline excavation, collect pipeline data, protection potential, on (off) electric potential, soil resistivity, protection potential distribution, protection current density and other parameters.

将实际测量参数与数据分析模型计算结果比较,修正数据分析模型中的参数,对数据分析模型进行修正或改进;Compare the actual measurement parameters with the calculation results of the data analysis model, revise the parameters in the data analysis model, and revise or improve the data analysis model;

重复验证与修改数据分析模型,达到模拟准确率大于85%的要求。Repeatedly verify and modify the data analysis model to meet the requirement that the simulation accuracy rate is greater than 85%.

采集深穿段管道参数信息,将信息输入数据分析模型,模拟出电位和电流密度分布图;Collect the pipeline parameter information of the deep penetration section, input the information into the data analysis model, and simulate the potential and current density distribution map;

分析电位和电流密度分布图,得出深穿管道阴极保护检测结果。Analyze the potential and current density distribution diagrams, and obtain the detection results of cathodic protection of deep penetration pipelines.

建立如图4所述长输管道电位衰减模型,利用所测量穿跨越出入土端的电位进行电位衰减计算。自穿跨越出入土端开始,将上下游连续体的管道沿轴向分成若干个管段,各管段在数目有限的结点处相互连接,组成一个代替连续体的管段集合体。The potential attenuation model of the long-distance pipeline as shown in Figure 4 is established, and the potential attenuation is calculated by using the measured potential across the entry and exit ends of the soil. Starting from crossing the entry and exit ends, the upstream and downstream continuum pipelines are divided into several pipe sections in the axial direction, and each pipe section is connected to each other at a limited number of nodes to form a pipe section aggregate instead of the continuum.

按照标准GBT 21246-2007《埋地钢质管道阴极保护参数测量方法》中进行外防腐层电阻率测量。各管段的纵向电阻首尾相接,并通过过渡电阻与大地相连。通断恒电位仪,于穿跨越入土端的电位差用U_1表示,出土端的电差位用U_2表示。当管道被分成n个管段时,R_(2i-1)表示第i管段的纵向电阻,R_2i表示第i管段的过渡电阻。According to the standard GBT 21246-2007 "Measurement Method of Cathodic Protection Parameters of Buried Steel Pipelines", the resistivity of the outer anti-corrosion layer was measured. The longitudinal resistances of each pipe section are connected end to end, and are connected to the ground through transition resistances. When the potentiostat is turned on and off, the potential difference across the submerged end is represented by U_1, and the potential difference at the unearthed end is represented by U_2. When the pipeline is divided into n segments, R_(2i-1) represents the longitudinal resistance of the i-th segment, and R_2i represents the transition resistance of the i-th segment.

设穿跨越长度为L;第i管段的外径为D_i,内径为d_i,长度为l_i,管材的电阻率为ρ_i,则该管段的线电阻为Let the spanning length be L; the outer diameter of the i-th pipe section is D_i, the inner diameter is d_i, the length is l_i, and the resistivity of the pipe is ρ_i, then the line resistance of this pipe section is

R_(2i-1)=4ρ_il_i/[π(D_i^2-d_i^2)]R_(2i-1)=4ρ_il_i/[π(D_i^2-d_i^2)]

解析法计算公式Analytical calculation formula

管道沿线外加电位E和电流I分布的计算通式为The general formula for calculating the distribution of applied potential E and current I along the pipeline is as follows

E=(Aeαx+Be-αx)R2iE=(Aeαx +Be-αx )R2i

式中:A,B—分别为由边界条件确定的常数;Where: A, B—respectively constants determined by boundary conditions;

rT—单位长度的管道电阻,Ω/m;rT —pipe resistance per unit length, Ω/m;

RT—单位长度管道的过渡电阻,Ω·m;RT —transition resistance per unit length of pipeline, Ω m;

通过现场测试,得到穿越段管线的电压降和管中电流衰减。其中,平均电压降:Through the field test, the voltage drop across the pipeline and the current attenuation in the pipeline are obtained. where the average voltage drop is:

假设穿越段有n个破损点,每个破损点的泄露电流为ΔI0,则有:Assuming that there are n damage points in the crossing section, and the leakage current of each damage point is ΔI0, there are:

n*ΔI0=ΔIn*ΔI0=ΔI

对于直径为D的单个破损点,电压降ΔV0:For a single damage point of diameter D, the voltage drop ΔV0:

推导得到:Derive:

进一步得到:Further get:

假设有n个缺陷,计算每个缺陷的电流、尺寸和电流密度,评价缺陷处的保护效果。n越大,电流密度越大,保护效果越好。n取1,即为最危险的情况。测试情况下针对防腐层电导率最大的穿越段,当电源输出为9.9V/1.4A时,流经电流为0.012A,不同缺陷数量下的电流密度和电位如下表1所示。Assuming that there are n defects, calculate the current, size and current density of each defect, and evaluate the protection effect at the defect. The larger the n, the larger the current density and the better the protection effect. n takes 1, which is the most dangerous situation. In the test case, for the pass-through section with the largest conductivity of the anti-corrosion layer, when the power output is 9.9V/1.4A, the passing current is 0.012A. The current density and potential under different number of defects are shown in Table 1 below.

表1Table 1

当且仅当只有一个缺陷时,保护电位不达标,为-0.85Vcse,其他情况下缺陷点电位较负,满足保护准则。If and only if there is only one defect, the protection potential is not up to the standard, which is -0.85Vcse. In other cases, the potential of the defect point is negative, which meets the protection criteria.

管道电位分布模拟结果如图5所示。The simulation results of the pipeline potential distribution are shown in Figure 5.

根据NACE TM0102-2002《Measurement of Protective Coating ElectricalConductance on Underground Pipelines》提供的方法进行防腐层面电阻率的计算。现场测试各处管段的管中电流,上下游电流相减得到流经管段泄露的电流,同时以上下游两端的平均电压降作为管段的电压降,即可得到这段管段的面电阻率/电导率。采用1000Ω·cm对电导率进行归一化,并根据标准中的指标进行防腐层评价,电导率小于2μS/m2评价结论即为优秀。According to the method provided by NACE TM0102-2002 "Measurement of Protective Coating Electrical Conductance on Underground Pipelines", the resistivity of the anti-corrosion layer is calculated. On-site test the current in the pipe of each pipe section, subtract the upstream and downstream currents to obtain the leakage current flowing through the pipe section, and at the same time take the average voltage drop at the upstream and downstream ends as the voltage drop of the pipe section, you can obtain the surface resistivity/conductivity of this section of the pipe section . The conductivity is normalized by 1000Ω·cm, and the anti-corrosion coating is evaluated according to the indicators in the standard. The evaluation conclusion that the conductivity is less than 2μS/m2 is excellent.

上述实施例为本发明较佳的实施方式,但本发明的实施方式并不受上述实施例的限制,其他的任何未背离本发明的精神实质与原理下所作的改变、修饰、替代、组合、简化,均应为等效的置换方式,都包含在本发明的保护范围之内。The above-mentioned embodiments are preferred embodiments of the present invention, but the embodiments of the present invention are not limited by the above-mentioned embodiments, and any other changes, modifications, substitutions, combinations, The simplification should be equivalent replacement manners, which are all included in the protection scope of the present invention.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011095001.0ACN114429024B (en) | 2020-10-14 | 2020-10-14 | Numerical simulation evaluation method for deep penetration section of steel pipeline in use |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011095001.0ACN114429024B (en) | 2020-10-14 | 2020-10-14 | Numerical simulation evaluation method for deep penetration section of steel pipeline in use |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114429024Atrue CN114429024A (en) | 2022-05-03 |

| CN114429024B CN114429024B (en) | 2025-05-20 |

Family

ID=81309042

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011095001.0AActiveCN114429024B (en) | 2020-10-14 | 2020-10-14 | Numerical simulation evaluation method for deep penetration section of steel pipeline in use |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114429024B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024222047A1 (en)* | 2023-04-24 | 2024-10-31 | 中国石油天然气股份有限公司 | Method and apparatus for determining effectiveness of cathodic protection in blind horizontal well |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20030189435A1 (en)* | 2002-04-04 | 2003-10-09 | Mark Yunovich | Automated cathodic protection monitor and control system |

| CN103279630A (en)* | 2013-06-19 | 2013-09-04 | 天津大学 | Keyhole dynamic forming numerical simulation method of laser deep melting point welding |

| CN104674228A (en)* | 2015-02-02 | 2015-06-03 | 深圳市燃气集团股份有限公司 | Detection method for cathode protection of directionally drilled and crossed pipeline |

| CN108507938A (en)* | 2018-07-03 | 2018-09-07 | 北京工业大学 | The lower buried metal pipeline anticorrosive coating peeling of DC stray current effect tests system |

| CN110008646A (en)* | 2019-05-06 | 2019-07-12 | 中国石油天然气集团公司 | A method of assessment tunnel interior conduit supporting steel structure connector cathodic protection effect |

| CN110210125A (en)* | 2019-05-31 | 2019-09-06 | 常州大学 | A kind of buried pipeline erosion resistant coating quality evaluating method based on cathodic protection data |

- 2020

- 2020-10-14CNCN202011095001.0Apatent/CN114429024B/enactiveActive

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20030189435A1 (en)* | 2002-04-04 | 2003-10-09 | Mark Yunovich | Automated cathodic protection monitor and control system |

| CN103279630A (en)* | 2013-06-19 | 2013-09-04 | 天津大学 | Keyhole dynamic forming numerical simulation method of laser deep melting point welding |

| CN104674228A (en)* | 2015-02-02 | 2015-06-03 | 深圳市燃气集团股份有限公司 | Detection method for cathode protection of directionally drilled and crossed pipeline |

| CN108507938A (en)* | 2018-07-03 | 2018-09-07 | 北京工业大学 | The lower buried metal pipeline anticorrosive coating peeling of DC stray current effect tests system |

| CN110008646A (en)* | 2019-05-06 | 2019-07-12 | 中国石油天然气集团公司 | A method of assessment tunnel interior conduit supporting steel structure connector cathodic protection effect |

| CN110210125A (en)* | 2019-05-31 | 2019-09-06 | 常州大学 | A kind of buried pipeline erosion resistant coating quality evaluating method based on cathodic protection data |

Non-Patent Citations (2)

| Title |

|---|

| BORTELS: "A user friendly simulation software for the cathodic protection of large networks of buried pipelines influenced by DC-traction stray currents", 《NACE CORROSION》, 31 December 2002 (2002-12-31), pages 1* |

| 葛艾天;李伟;杜艳霞;刘权;: "定向钻穿越管道防腐蚀层及阴极保护的评价方法", 腐蚀与防护, no. 05, 15 May 2017 (2017-05-15), pages 365 - 368* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2024222047A1 (en)* | 2023-04-24 | 2024-10-31 | 中国石油天然气股份有限公司 | Method and apparatus for determining effectiveness of cathodic protection in blind horizontal well |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114429024B (en) | 2025-05-20 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN106768736B (en) | A kind of subway tunnel monitoring of leakage and method for early warning | |

| CN113433057B (en) | Buried metal pipeline stray current corrosion rate prediction device and method | |

| CN106676541B (en) | A kind of metallic conduit stray current corrosion means of defence | |

| CN108827867B (en) | Method for extracting feature information of subway stray current corrosion based on data mining technology | |

| CN101493491B (en) | Comprehensive Diagnosis Method and Diagnosis System for Substation Ground Network Defects | |

| CN108680490B (en) | Device and method for detecting corrosion degree of reinforced concrete foundation steel bars of iron tower | |

| CN108844684A (en) | A method of monitoring diaphram wall seam crossing leakage scenarios | |

| CN109541317B (en) | Earth surface test method for resistance characteristics of coating defects of buried pipeline under stray current interference | |

| JP2007278843A (en) | Device and method for diagnosing corrosion in underground buried steel structure | |

| KR101207612B1 (en) | Testing cell for sensing of electric corrosion used galvanic sensor for sensingof electric corrosion of steel-concrete structure | |

| CN104897996A (en) | Transformer station grounding network corrosion diagnosis method based on magnetic field inverse problem solving | |

| CN105823932A (en) | Grounding resistance testing method for frozen earth and snow-covered environments | |

| CN114429024B (en) | Numerical simulation evaluation method for deep penetration section of steel pipeline in use | |

| CN111721830A (en) | Detecting, monitoring and early warning method of internal erosion of waterway regulation dam based on 3D tomography | |

| CN116926554A (en) | A fault diagnosis method and device for cathodic protection system of buried pipelines | |

| JP6871497B2 (en) | Electrical corrosion protection status grasping system and status grasping method | |

| Chen et al. | Study on the interference of the hvdc transmission grounding electrode to the pipeline cathodic protection system | |

| CN108663408A (en) | A kind of steel oil-gas pipeline Directional Drilling erosion resistant coating breakage rate determines method | |

| CN112632838A (en) | Dynamic evaluation and early warning method for cracking risk of dam crest of high core wall rock-fill dam | |

| CN106645301A (en) | Trenchless diagnosis method for corrosion degree of grounding electrode | |

| CN118064900A (en) | Method for calculating power-off potential based on power-on potential inversion | |

| Dzhala et al. | Information Technology of Surveys and Diagnostics of Underground Pipelines | |

| RU2626609C1 (en) | Method of estimating technical condition of insulating coating of underground pipeline | |

| CN115078888B (en) | High voltage DC interference test method, device and polarization characteristic test device | |

| CN204789418U (en) | Indoor multi -functional buried pipeline soil laboratory simulation platform |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |