CN114418504A - Planning method and system for warehouse logistics scheme - Google Patents

Planning method and system for warehouse logistics schemeDownload PDFInfo

- Publication number

- CN114418504A CN114418504ACN202210086766.0ACN202210086766ACN114418504ACN 114418504 ACN114418504 ACN 114418504ACN 202210086766 ACN202210086766 ACN 202210086766ACN 114418504 ACN114418504 ACN 114418504A

- Authority

- CN

- China

- Prior art keywords

- logistics

- simulation

- warehouse

- planned

- planning

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/08—Logistics, e.g. warehousing, loading or distribution; Inventory or stock management

- G06Q10/087—Inventory or stock management, e.g. order filling, procurement or balancing against orders

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F30/00—Computer-aided design [CAD]

- G06F30/20—Design optimisation, verification or simulation

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/06—Resources, workflows, human or project management; Enterprise or organisation planning; Enterprise or organisation modelling

- G06Q10/063—Operations research, analysis or management

- G06Q10/0631—Resource planning, allocation, distributing or scheduling for enterprises or organisations

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/08—Logistics, e.g. warehousing, loading or distribution; Inventory or stock management

- G06Q10/083—Shipping

Landscapes

- Business, Economics & Management (AREA)

- Engineering & Computer Science (AREA)

- Economics (AREA)

- Human Resources & Organizations (AREA)

- Theoretical Computer Science (AREA)

- Physics & Mathematics (AREA)

- Strategic Management (AREA)

- Entrepreneurship & Innovation (AREA)

- General Physics & Mathematics (AREA)

- General Business, Economics & Management (AREA)

- Tourism & Hospitality (AREA)

- Quality & Reliability (AREA)

- Operations Research (AREA)

- Marketing (AREA)

- Development Economics (AREA)

- Finance (AREA)

- Accounting & Taxation (AREA)

- Educational Administration (AREA)

- Game Theory and Decision Science (AREA)

- Computer Hardware Design (AREA)

- Evolutionary Computation (AREA)

- Geometry (AREA)

- General Engineering & Computer Science (AREA)

- Management, Administration, Business Operations System, And Electronic Commerce (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及计算机技术领域,特别涉及一种仓储物流方案的规划方法及系统。The invention relates to the field of computer technology, in particular to a planning method and system for a warehouse logistics scheme.

背景技术Background technique

数字孪生应用是在虚拟空间中完成映射,反映相对应的实体装置的全生命周期过程的应用技术。当前的数字孪生应用主要在两个技术领域进行仿真,一个是三维呈现技术领域,另一个是调试技术领域。基于这两个技术领域,涌现出大量的专利文献。例如,可以在对数字工厂进行建模时采用数字孪生应用,或者在网络通信领域进行建模时采用数字通信应用等等。The digital twin application is an application technology that completes the mapping in the virtual space and reflects the whole life cycle process of the corresponding physical device. The current digital twin applications are mainly simulated in two technical fields, one is the field of 3D rendering technology, and the other is the field of debugging technology. Based on these two technical fields, a large number of patent documents have emerged. For example, digital twin applications can be used when modeling a digital factory, or digital communication applications when modeling network communications, and so on.

但是,目前数字孪生应用的主要功能还在于实体系统本身的仿真,没有涉及到与已有实体系统之间的通信交互,比如并未涉及与在智能化仓储技术领域中的物流仓库管理系统(WMS,Warehouse Management System)之间的通信交互。更进一步地,也未涉及与实体系统进行交互后,基于获得的交互信息进行后续的执行仿真过程。这样,导致了数字孪生应用的仿真功能受限,无法应用到智能化仓储技术领域中。However, the main function of the current digital twin application is the simulation of the entity system itself, and it does not involve the communication and interaction with the existing entity system, such as the logistics warehouse management system (WMS) in the field of intelligent warehousing technology. , Warehouse Management System) communication interaction. Furthermore, it does not involve a subsequent execution simulation process based on the obtained interaction information after interacting with the entity system. In this way, the simulation function of digital twin applications is limited and cannot be applied to the field of intelligent warehousing technology.

发明内容SUMMARY OF THE INVENTION

有鉴于此,本发明实施例提供一种仓储物流方案的规划方法,该方法能够实现基于与WMS之间的通信交互,对仓储物流方案进行规划。In view of this, the embodiment of the present invention provides a method for planning a warehousing logistics scheme, which can realize the planning of a warehousing logistics scheme based on the communication interaction with the WMS.

本发明实施例还提供一种仓储物流方案的规划系统,该系统能够实现基于与WMS之间的通信交互,对仓储物流方案进行规划。The embodiment of the present invention also provides a planning system for a warehousing and logistics scheme, which can realize the planning of a warehousing and logistics scheme based on the communication interaction with the WMS.

本发明实施例是这样实现的:The embodiments of the present invention are implemented as follows:

一种仓储物流方案的规划方法,所述方法包括:A planning method for a warehousing logistics scheme, the method comprising:

提供一实施规划的仓储物流方案的仿真模型系统,所述仿真模型系统接收仓储管理系统系统的物流任务信息,根据所述物流任务信息仿真运行规划的仓储物流方案,得到仿真输出结果;Provide a simulation model system for implementing the planned warehouse logistics scheme, the simulation model system receives the logistics task information of the warehouse management system, and simulates the operation of the planned warehouse logistics scheme according to the logistics task information, and obtains a simulation output result;

提供一实现规划的仓储物流方案涉及的终端装置,以使所述终端装置根据接收的所述仓储管理系统的物流任务信息,按照所述规划的仓储物流方案执行,得到实际执行输出结果;Provide a terminal device involved in realizing the planned warehousing and logistics scheme, so that the terminal device executes the planned warehousing and logistics scheme according to the received logistics task information of the warehouse management system, and obtains an actual execution output result;

根据所述仿真输出结果与所述实际执行输出结果,进行拟真度验证,得到拟真度验证结果;Perform fidelity verification according to the simulation output result and the actual execution output result, and obtain a fidelity verification result;

根据所述拟真度验证结果对所述规划的仓储物流方案修正,迭代上述过程,直到得到的所述拟真度验证结果达到设定的拟真度阈值为止。The planned warehousing logistics scheme is revised according to the fidelity verification result, and the above process is iterated until the obtained fidelity verification result reaches the set fidelity threshold.

可选的,所述规划的仓储物流方案包括:仓库中实体设备的布局规划、物流轨迹规划、物流工作流程规划及涉及系统参数的规划。Optionally, the planned warehouse logistics scheme includes: layout planning of physical equipment in the warehouse, logistics trajectory planning, logistics workflow planning, and planning involving system parameters.

可选的,所述规划的仓储物流方案为针对拣选物品业务规划的仓储物流方案时,Optionally, when the planned warehousing and logistics solution is a warehousing and logistics solution planned for the item-picking business,

所述仿真物流工作规划包括拣选物品任务流程、物品满箱换箱流程和物品满箱投线流程中的一种或多种组合;The simulated logistics work plan includes one or more combinations of a task process for picking items, a process for changing a case with a full case, and a line-throwing process for a full case;

所述仿真涉及的规划系统参数包括:拣选物品任务的作业时间、完成拣选物品任务的拣选人员的行进速度相关信息和拣选物品任务的作业切换时间,其中,所述完成拣选物品任务的拣选人员的行进速度相关信息包括完成拣选物品任务的拣选人员的行进的最大速度、加速度和减速度中的一种或多种组合。The planning system parameters involved in the simulation include: the operation time of the picking task, the travel speed-related information of the picking personnel who complete the picking task, and the operation switching time of the picking task, wherein the The travel speed-related information includes one or more combinations of the maximum travel speed, acceleration, and deceleration of the picker who completes the task of picking the item.

可选的,所述实施规划的仓储物流方案的仿真模型系统包括:Optionally, the simulation model system for implementing the planned warehousing logistics solution includes:

仿真仓库中实体设备的规划布局、仿真物流规划轨迹、仿真物流工作规划流程及仿真涉及的规划系统参数。Simulate the planning layout of physical equipment in the warehouse, simulate the logistics planning trajectory, simulate the logistics work planning process and the planning system parameters involved in the simulation.

可选的,所述规划的仓储物流方案为针对拣选物品业务规划的仓储物流方案时,Optionally, when the planned warehousing and logistics solution is a warehousing and logistics solution planned for the item-picking business,

所述仿真输出结果包括:仿真仓库中拣选物品的首次作业位置信息、仿真物流轨迹、仿真拣选人员发生变动时再次分配拣选物品的作业位置信息、和仿真拣选物品的作业效率值中的一种或多种组合。The simulation output results include: one or more of the first operation position information of the picked items in the simulated warehouse, the simulated logistics trajectory, the operation position information of the simulated picker's redistribution of the picked items when the simulated picker changes, and the operation efficiency value of the simulated picked items. Various combinations.

可选的,所述规划的仓储物流方案为针对拣选物品业务规划的仓储物流方案时,Optionally, when the planned warehousing and logistics solution is a warehousing and logistics solution planned for the item-picking business,

所述以使终端装置根据接收所述仓储管理系统的物流任务信息,按照所述规划的仓储物流方案执行,得到执行输出结果包括:Said to make the terminal device execute according to the planned warehouse logistics plan according to the logistics task information received from the warehouse management system, and obtain the execution output result including:

真实仓库中拣选物品的首次作业位置信息、真实物流轨迹、真实拣选人员发生变动时再次分配拣选物品的作业位置信息、和真实拣选物品的作业效率值中的一种或多种组合。One or more combinations of the first operation position information of the picked items in the real warehouse, the real logistics trajectory, the operation position information of the real picking personnel to redistribute the picked items when there is a change, and the operation efficiency value of the real picked items.

可选的,所述规划的仓储物流方案为针对拣选物品业务规划的仓储物流方案时,Optionally, when the planned warehousing and logistics solution is a warehousing and logistics solution planned for the item-picking business,

所述进行拟真度验证得到拟真度验证结果包括:The fidelity verification results obtained by performing the fidelity verification include:

将仿真仓库中拣选物品的首次作业位置信息与真实仓库中拣选物品的首次作业位置信息进行比较,得到两者之间的拟真度;Compare the first operation position information of the picked items in the simulated warehouse with the first operation position information of the picked items in the real warehouse to obtain the fidelity between the two;

将仿真物流轨迹与真实物流轨迹进行比较,得到两者之间的拟真度;Compare the simulated logistics trajectory with the real logistics trajectory to obtain the fidelity between the two;

将仿真拣选人员发生变动时再次分配拣选物品的作业位置信息与真实拣选人员发生变动时再次分拣物品的作业位置信息进行比较,得到两者之间的拟真度;Comparing the operation position information of re-assignment of picking items when the simulated picking personnel changes with the operation position information of re-sorting items when the real picking personnel changes, and obtaining the fidelity between the two;

将仿真拣选物品的作业效率值与真实拣选物品的作业效率值进行比较,得到两者之间的拟真度。The operation efficiency value of the simulated picking item is compared with the operation efficiency value of the real picking item, and the fidelity between the two is obtained.

一种仓储物流方案的规划系统,所述系统包括:设置单元、信息交互单元、仿真单元、结果输出单元及修正单元,其中,A planning system for a warehousing logistics scheme, the system includes: a setting unit, an information interaction unit, a simulation unit, a result output unit and a correction unit, wherein,

所述设置单元,用于提供实施规划的仓储物流方案的仿真模型系统;提供实现规划的仓储物流方案的终端设备,以使所述终端设备根据接收仓储管理系统的物流任务信息,按照所述规划的仓储物流方案执行,得到实际执行输出结果;The setting unit is used to provide a simulation model system for implementing the planned warehousing and logistics scheme; and to provide terminal equipment for implementing the planned warehousing and logistics scheme, so that the terminal equipment can follow the planning according to the logistics task information received from the warehouse management system. Execute the warehousing and logistics plan according to the actual implementation, and get the actual execution output result;

所述信息交互单元,用于接收所述仓储管理系统的物流任务信息及接收所述终端设备的实际执行输出结果;The information exchange unit is used for receiving the logistics task information of the warehouse management system and receiving the actual execution output result of the terminal device;

所述仿真单元,用于基于所述仿真模型系统根据所述物流任务信息仿真运行所述规划的仓储物流方案,得到仿真输出结果;The simulation unit is configured to simulate and run the planned warehouse logistics scheme according to the logistics task information based on the simulation model system, and obtain a simulation output result;

所述结果输出单元,用于根据所述仿真输出结果与所述实际执行输出结果,进行拟真度验证得到拟真度验证结果;the result output unit, configured to perform fidelity verification according to the simulation output result and the actual execution output result to obtain a fidelity verification result;

所述修正单元,用于根据所述拟真度验证结果对规划的仓储物流方案修正,基于修正的仓储物流方案,采用上述过程迭代执行,直到得到的拟真度验证结果达到所设定的拟真度阈值为止。The correction unit is used to correct the planned warehousing and logistics scheme according to the fidelity verification result, and based on the revised warehousing and logistics scheme, the above process is iteratively executed until the obtained fidelity verification result reaches the set simulation result. trueness threshold.

一种仓储物流方案的规划的装置,包括:A planning device for warehousing logistics scheme, comprising:

存储器;以及耦接至所述存储器的处理器,所述处理器被配置为基于存储在所述存储器中的指令,执行上述任一所述的仓储物流方案的规划方法。a memory; and a processor coupled to the memory, the processor configured to execute any one of the above-described planning methods for a warehouse logistics scheme based on instructions stored in the memory.

一种计算机可读存储介质,其特征在于,其上存储有计算机程序,该程序被处理器执行时实现上述任一所述的仓储物流方案的规划方法。A computer-readable storage medium, characterized in that a computer program is stored thereon, and when the program is executed by a processor, any one of the above-mentioned planning methods for warehousing and logistics solutions is implemented.

如上所见,本发明实施例提供实施规划的仓储物流方案的仿真模型系统,该仿真模型系统接收WMS的物流任务信息后,根据该物流任务信息仿真运行该规划的仓储物流方案,得到仿真输出结果;还提供实现规划的仓储物流方案涉及的诸如个人数字助理终端(PDA,Personal Digital Assistant)等的终端装置,以使该终端装置根据接收的该WMS的物流任务信息,按照该规划的仓储物流方案执行,得到实际执行输出结果;根据该仿真输出结果与该实际执行输出结果,进行拟真度验证得到拟真度验证结果;根据该拟真度验证结果对规划的仓储物流方案进行修正后,迭代上述过程,直到得到的拟真度验证结果达到所设定的拟真度阈值为止。这样,本发明实施例实现了基于与WMS之间的通信交互,对仓储物流方案进行规划。As can be seen above, the embodiment of the present invention provides a simulation model system for implementing a planned warehousing and logistics scheme. After receiving the logistics task information of the WMS, the simulation model system simulates and runs the planned warehousing and logistics scheme according to the logistics task information, and obtains a simulation output result. ; Also provide a terminal device such as a personal digital assistant terminal (PDA, Personal Digital Assistant) involved in realizing the planned warehousing and logistics solution, so that the terminal device can follow the planned warehousing and logistics solution according to the received logistics task information of the WMS. Execute to obtain the actual execution output result; according to the simulation output result and the actual execution output result, carry out the fidelity verification to obtain the fidelity verification result; after modifying the planned warehousing and logistics scheme according to the fidelity verification result, iterate The above process is performed until the obtained fidelity verification result reaches the set fidelity threshold. In this way, the embodiment of the present invention realizes the planning of the warehousing logistics scheme based on the communication interaction with the WMS.

附图说明Description of drawings

图1为本发明实施例提供的一种仓储物流方案的规划方法流程图;FIG. 1 is a flowchart of a planning method for a warehousing logistics scheme provided by an embodiment of the present invention;

图2为本发明实施例提供的仓储物流方案的规划方法执行过程框架图;2 is a framework diagram of an execution process of a planning method for a warehousing logistics solution provided by an embodiment of the present invention;

图3为本发明实施例提供的实施规划的仓储物流方案的仿真相关数据的输出流程图;Fig. 3 is the output flow chart of the simulation-related data of the implementation-planned warehousing logistics scheme provided by the embodiment of the present invention;

图4为本发明实施例提供的实施规划的仓储物流方案的仿真相关数据的输入流程图;Fig. 4 is the input flow chart of the simulation-related data of the implementation-planned warehousing logistics scheme provided by the embodiment of the present invention;

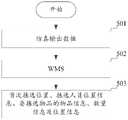

图5为本发明实施例提供的规划的仓储物流方案的WMS输出物流相关数据的方法流程图;5 is a flowchart of a method for outputting logistics-related data from the WMS of the planned warehousing logistics solution provided by an embodiment of the present invention;

图6为本发明实施例提供的规划的仓储物流方案的WMS输入物流相关数据的方法流程图;6 is a flowchart of a method for inputting logistics-related data in a WMS of a planned warehousing logistics solution provided by an embodiment of the present invention;

图7为本发明实施例提供的实施规划的拣选物品的物流方案的方法流程图;7 is a flowchart of a method for implementing a planned logistics solution for picking items provided by an embodiment of the present invention;

图8为本方实施例提供的实施规划的拣选业务的物流方案的仿真输出结果示意图;8 is a schematic diagram of a simulation output result of a logistics solution for implementing a planned picking business provided by an embodiment of the present invention;

图9为本发明实施例提供的仿真模型系统中的仿真涉及的规划系统参数的设置界面示意图;9 is a schematic diagram of a setting interface of planning system parameters involved in simulation in a simulation model system provided by an embodiment of the present invention;

图10为本发明实施例提供的一种仓储物流方案的规划系统结构示意图;FIG. 10 is a schematic structural diagram of a planning system of a warehousing and logistics solution provided by an embodiment of the present invention;

图11为本发明实施例提供的实现仓储物流方案规划的终端设备或服务器的计算机系统的结构示意图。FIG. 11 is a schematic structural diagram of a computer system of a terminal device or server for implementing warehousing and logistics solution planning according to an embodiment of the present invention.

具体实施方式Detailed ways

下面将结合本申请实施例中的附图,对本申请实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅是本申请一部分实施例,而不是全部的实施例。基于本申请中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本申请保护的范围。The technical solutions in the embodiments of the present application will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present application. Obviously, the described embodiments are only a part of the embodiments of the present application, but not all of the embodiments. Based on the embodiments in the present application, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present application.

本发明的说明书和权利要求书及上述附图中的术语“第一”、“第二”、“第三”、“第四”等(如果存在)是用于区别类似的对象,而不必用于描述特定的顺序或先后次序。应该理解这样使用的数据在适当情况下可以互换,以便这里描述的本发明的实施例例如能够以除了在这里图示或描述的那些以外的顺序实施。此外,术语“包括”和“具有”以及他们的任何变形,意图在于覆盖不排他的包含。例如,包含了一系列步骤或单元的过程、方法、系统、产品或设备不必限于清楚地列出的那些步骤或单元,而是可包括没有清楚地列出的或对于这些过程、方法、产品或设备固有的其他步骤或单元。The terms "first", "second", "third", "fourth", etc. (if present) in the description and claims of the present invention and the above-mentioned drawings are used to distinguish similar objects and are not necessarily used to describe a specific order or sequence. It is to be understood that the data so used are interchangeable under appropriate circumstances such that the embodiments of the invention described herein can, for example, be practiced in sequences other than those illustrated or described herein. Furthermore, the terms "comprising" and "having", and any variations thereof, are intended to cover non-exclusive inclusion. For example, a process, method, system, product or device comprising a series of steps or units is not necessarily limited to those steps or units expressly listed, but may include steps or units not expressly listed or for such process, method, product or Other steps or units inherent to the device.

下面以具体实施例对本发明的技术方案进行详细说明。下面几个具体实施例可以相互结合,对于相同或相似的概念或过程可能在某些实施例不再赘述。The technical solutions of the present invention will be described in detail below with specific embodiments. The following specific embodiments may be combined with each other, and the same or similar concepts or processes may not be repeated in some embodiments.

从背景技术可以看出,虽然数字孪生应用可以对诸如具有三维呈现功能或调试功能的实体系统进行仿真,但是这些方案都是对实体系统本身的仿真,而无法与已有实体系统之间进行通信交互,进一步也无法基于通信交互的信息进行后续的执行仿真过程。It can be seen from the background technology that although digital twin applications can simulate physical systems with three-dimensional rendering functions or debugging functions, these solutions are all simulations of the physical systems themselves, and cannot communicate with existing physical systems. interaction, and further, the subsequent execution simulation process cannot be performed based on the information of the communication interaction.

本发明实施例为了解决上述问题,本发明实施例提供实施规划的仓储物流方案的仿真模型系统,该仿真模型系统接收的该WMS的物流任务信息后,根据该物流任务信息仿真运行该规划的仓储物流方案,得到仿真输出结果;还提供实现规划的仓储物流方案涉及的诸如PDA等的终端装置,以使该终端装置根据接收WMS的物流任务信息,按照该规划的仓储物流方案执行,得到实际执行输出结果;根据该仿真输出结果与该实际执行输出结果,进行拟真度验证得到拟真度验证结果;根据该拟真度验证结果对规划的仓储物流方案进行修正后,迭代上述过程,直到得到的拟真度验证结果达到所设定的拟真度阈值为止。In order to solve the above problem, the embodiment of the present invention provides a simulation model system for implementing a planned warehouse logistics scheme. After receiving the logistics task information of the WMS, the simulation model system simulates and runs the planned warehouse according to the logistics task information. Logistics scheme, obtain the simulation output results; also provide terminal devices such as PDAs involved in realizing the planned warehousing logistics scheme, so that the terminal device can execute according to the planned warehousing logistics scheme according to the logistics task information received from the WMS, and get the actual implementation output results; according to the simulation output results and the actual execution output results, carry out fidelity verification to obtain the fidelity verification results; after modifying the planned warehousing and logistics scheme according to the fidelity verification results, iterate the above process until obtaining The fidelity verification result reaches the set fidelity threshold.

这样,本发明实施例通过数字孪生应用与WMS之间的通信交互,扩展了数字孪生应用的仿真功能,将数字孪生应用适用于对仓储物流的管理技术领域,具体实现了基于与WMS之间的通信交互信息,对仓储物流方案进行规划的方案。In this way, the embodiment of the present invention expands the simulation function of the digital twin application through the communication interaction between the digital twin application and the WMS, and applies the digital twin application to the technical field of management of warehousing and logistics. Communicate and exchange information and plan warehousing and logistics solutions.

图1为本发明实施例提供的一种仓储物流方案的规划方法流程图,其具体步骤包括:1 is a flowchart of a planning method for a warehousing and logistics solution provided by an embodiment of the present invention, and its specific steps include:

步骤101、提供一实施规划的仓储物流方案的仿真模型系统,该仿真模型系统接收WMS的物流任务信息,根据该物流任务信息仿真运行该规划的仓储物流方案,得到仿真输出结果;Step 101, providing a simulation model system for implementing the planned warehousing and logistics scheme, the simulation model system receiving the logistics task information of the WMS, and simulating and running the planned warehousing and logistics scheme according to the logistics task information, and obtaining a simulation output result;

步骤102、提供一实现该规划的仓储物流方案的终端设备,以使该终端设备根据接收的该WMS的物流任务信息,按照该规划的仓储物流方案执行,得到实际执行输出结果;Step 102: Provide a terminal device that implements the planned warehousing and logistics solution, so that the terminal device executes the planned warehousing and logistics solution according to the received logistics task information of the WMS, and obtains an actual execution output result;

步骤103、根据该仿真输出结果与该实际执行输出结果,进行拟真度验证得到拟真度验证结果;Step 103: According to the simulation output result and the actual execution output result, perform fidelity verification to obtain a fidelity verification result;

步骤104、根据该拟真度验证结果对规划的仓储物流方案修正,迭代步骤101~步骤103的过程,直到得到的该拟真度验证结果达到所设定的拟真度阈值为止。

可以看出,上述方法适用于仓储物流方案的规划阶段,在规划阶段中,频繁对规划的仓储物流方案进行修正,并对修正的仓储物流方案进行仿真验证,直到满足预设目标为止。后续再基于最终规划得到的仓储物流方案进行仓库中的终端装置的构建及工作流程的创建,完成仓储物流。这样,极大地提高规划效率及降低规划成本,为得到满足规划条件的仓储物流方案提供了快捷且科学的方法。It can be seen that the above method is suitable for the planning stage of the warehousing and logistics scheme. In the planning stage, the planned warehousing and logistics scheme is frequently revised, and the revised warehousing and logistics scheme is simulated and verified until the preset target is met. Subsequently, based on the warehousing logistics scheme obtained in the final planning, the terminal devices in the warehouse are constructed and the workflow is created to complete the warehousing logistics. In this way, the planning efficiency is greatly improved and the planning cost is reduced, and a fast and scientific method is provided for obtaining a warehousing and logistics solution that meets the planning conditions.

在该方法中,该规划的仓储物流方案为:针对拣选物品业务规划的仓储物流方案。In this method, the planned warehousing logistics scheme is: a warehousing logistics scheme planned for the business of picking items.

在该方法中,该规划的仓储物流方案包括:仓库中实体设备的布局规划、物流轨迹规划、物流工作流程规划及涉及系统参数的规划。在这里,是对仓储物料方案所涉及的实体设备布局、工作流程及实现系统的各个方案的整体规划。In the method, the planned warehouse logistics scheme includes: layout planning of physical equipment in the warehouse, logistics trajectory planning, logistics workflow planning, and planning involving system parameters. Here, it is the overall planning of the physical equipment layout, workflow and implementation of the various schemes of the system involved in the storage material scheme.

在该方法中,该实施规划的仓储物流方案的仿真模型系统包括:In the method, the simulation model system for implementing the planned warehouse logistics scheme includes:

仿真仓库中实体设备的规划布局、仿真物流规划轨迹、仿真物流工作规划流程及仿真涉及的规划系统参数。Simulate the planning layout of physical equipment in the warehouse, simulate the logistics planning trajectory, simulate the logistics work planning process and the planning system parameters involved in the simulation.

其中,该仿真物流工作规划包括拣选物品任务流程、物品满箱换箱流程和物品满箱投线流程中的一种或多种组合。更进一步地,该仿真物流工作规划还包括其他实施规划的仓储物流方案的规划等等。Wherein, the simulated logistics work plan includes one or more combinations of a task process for picking items, a process for changing a case with a full case, and a line-throwing process for a full case. Furthermore, the simulated logistics work plan also includes the planning of other warehousing logistics schemes that implement the planning and so on.

其中,该仿真涉及的规划系统参数包括:拣选物品任务的作业时间、完成拣选物品任务的拣选人员的行进速度相关信息和拣选物品任务的作业切换时间。具体地,完成拣选物品任务的拣选人员的行进速度相关信息包括了完成拣选物品任务的拣选人员的行进的最大速度、加速度和减速度中的一种或多种组合。Among them, the planning system parameters involved in the simulation include: the operation time of the picking task, the information related to the traveling speed of the picking personnel who complete the picking task, and the operation switching time of the picking task. Specifically, the travel speed-related information of the picker who completes the task of picking an item includes one or more combinations of the maximum speed, acceleration, and deceleration of the picker who completes the task of picking an item.

在该方法中,该仿真输出结果包括:仿真仓库中拣选物品的首次作业位置信息、仿真物流轨迹、仿真拣选人员发生变动时再次分配拣选物品的作业位置信息、以及仿真拣选物品的作业效率值中的一种或多种组合。In the method, the simulation output results include: the first operation position information of the picked items in the simulated warehouse, the simulated logistics trajectory, the operation position information of the simulated picking items reassigned when the picking personnel change, and the operation efficiency value of the simulated picking items. one or more combinations.

在该方法中,以使终端设备根据接收WMS的物流任务信息,按照该规划的仓储物流方案执行,得到执行输出结果包括:真实仓库中拣选物品的首次作业位置信息、真实物流轨迹、真实拣选人员发生变动时再次分配拣选物品的作业位置信息、和真实拣选物品的作业效率值中的一种或多种组合。In this method, the terminal equipment executes according to the planned warehousing logistics scheme according to the logistics task information received from the WMS, and the obtained execution output results include: the first operation position information of the picked items in the real warehouse, the real logistics track, and the real picking personnel. When a change occurs, one or more combinations of the operation position information of the picked item and the work efficiency value of the actual picked item are reassigned.

在该方法中,该进行拟真度验证得到拟真度验证结果包括:In this method, the fidelity verification results obtained by performing fidelity verification include:

将仿真仓库中拣选物品的首次作业位置信息与真实仓库中拣选物品的首次作业位置信息进行比较,得到两者之间的拟真度;Compare the first operation position information of the picked items in the simulated warehouse with the first operation position information of the picked items in the real warehouse to obtain the fidelity between the two;

将仿真物流轨迹与真实物流轨迹进行比较,得到两者之间的拟真度;Compare the simulated logistics trajectory with the real logistics trajectory to obtain the fidelity between the two;

将仿真拣选人员发生变动时再次分配拣选物品的作业位置信息与真实拣选人员发生变动时再次分拣物品的作业位置信息进行比较,得到两者之间的拟真度;Comparing the operation position information of re-assignment of picking items when the simulated picking personnel changes with the operation position information of re-sorting items when the real picking personnel changes, and obtaining the fidelity between the two;

将仿真拣选物品的作业效率值与真实拣选物品的作业效率值进行比较,得到两者之间的拟真度。The operation efficiency value of the simulated picking item is compared with the operation efficiency value of the real picking item, and the fidelity between the two is obtained.

在这里,最终得到的拟真度验证结果包括了:仿真物流轨迹与真实物流轨迹之间比较后的拟真度、仿真拣选人员发生变动时再次分配拣选物品的作业位置信息与真实拣选人员发生变动时再次分拣物品的作业位置信息之间比较后的拟真度、和仿真拣选物品的作业效率值与真实拣选物品的作业效率值之间比较后的拟真度。Here, the final fidelity verification results include: the fidelity after the comparison between the simulated logistics trajectory and the real logistics trajectory, the operation position information of the redistribution of the picking items when the simulated picking personnel changes, and the changes of the real picking personnel. The fidelity after the comparison between the operation position information of the re-sorted items, and the fidelity after the comparison between the operation efficiency value of the simulated picked item and the actual picked item.

以下以该规划的仓储物流方案为针对拣选物品业务规划的仓储物流方案,终端设备为PDA为例,对本发明实施例进行详细说明。The embodiment of the present invention will be described in detail below by taking the planned warehousing and logistics solution as a warehousing and logistics solution planned for a business of picking items, and the terminal device being a PDA as an example.

图2为本发明实施例提供的仓储物流方案的规划方法执行过程框架图,整个执行过程包括:2 is a framework diagram of an execution process of a planning method for a warehousing logistics solution provided by an embodiment of the present invention, and the entire execution process includes:

步骤201、提供实施规划的仓储物流方案的仿真模型系统,该仿真模型系统包括了仿真仓库中实体设备的规划布局、仿真物流规划轨迹、仿真物流工作规划流程及仿真涉及的规划系统参数。

步骤202、在订单池中预存多个物品订单及在仓库存储系统中存储有仓库中的物品相关信息,订单池将物品订单及仓库存储系统将物品相关信息提供给WMS。Step 202: Pre-store multiple item orders in the order pool and store the item-related information in the warehouse in the warehouse storage system. The order pool provides the item order and the item-related information from the warehouse storage system to the WMS.

步骤203、WMS根据接收到的物品订单及物品相关信息,以及接收的仿真输出结果,生成物流任务信息。Step 203: The WMS generates logistics task information according to the received item order and item-related information, as well as the received simulation output result.

在本步骤中,WMS预热,将订单池中的物品订单及仓储存储系统中的仓储信息导入,开发数据接口,进行通信交互。In this step, the WMS is preheated, the item orders in the order pool and the storage information in the storage storage system are imported, the data interface is developed, and the communication interaction is carried out.

步骤204、WMS将物流任务信息发送给仿真模型系统及实现规划的仓储物流方案涉及的PDA,由PDA根据接收WMS的物流任务信息,按照规划的仓储物流方案执行,得到实际执行输出结果,提供给仿真模型系统。

步骤205、仿真模型系统接收WMS的物流任务信息,根据所述物流任务信息仿真运行规划的仓储物流方案,得到仿真输出结果输出;仿真模型系统根据得到的仿真输出结果与得到的实际执行输出结果,进行拟真度验证得到拟真度验证结果输出后,执行步骤206及步骤207。Step 205: The simulation model system receives the logistics task information of the WMS, simulates the planned warehousing logistics scheme according to the logistics task information, and obtains a simulation output result output; the simulation model system obtains the simulation output result and the obtained actual execution output result, After the fidelity verification is performed and the fidelity verification result is output,

步骤206、将拟真度验证结果进行报告。

步骤207、将仿真模型系统的仿真输出结果,提供给WMS。Step 207: Provide the simulation output result of the simulation model system to the WMS.

在上述方法中,规划的仓储物流方案中包括了物流工作流程,物流工作流程包括拣选物品下架任务流程、满箱换箱流程和满箱投线流程中的一种或多种组合。在这里,当物流工作流程包括了拣选物品下架任务流程、满箱换箱流程和满箱投线流程时,其具体为:当提供仿真模型系统之后,在对该仿真模型系统初始化时,仿真拣选人员主动触发调取WMS的物流任务信息,仿真获取第一次拣货物品任务的目的地货位,进行拣货操作,拣货完成后再次触发调取WMS的物流任务信息,进行获取下一次拣货物品任务的目的地货位,进行拣货操作,完成后判断拣货物品是否满箱,若满箱则触发调取WMS的物流任务信息,进行满箱操作,否则,继续执行触发调取WMS的物流任务信息,进行下一次拣货物品任务。按照上述过程仿真拣货物品任务,得出仿真输出结果。In the above method, the planned warehousing logistics scheme includes a logistics workflow, and the logistics workflow includes one or more combinations of the task process of picking items off the shelf, the process of changing a box with a full case, and a line-throwing process with a full case. Here, when the logistics workflow includes the task process of picking items off the shelf, the process of changing boxes with full boxes, and the process of placing full boxes on the line, it is specifically: after the simulation model system is provided, when the simulation model system is initialized, the simulation The picker actively triggers and retrieves the logistics task information of the WMS, simulates the acquisition of the destination location of the first picking task, and performs the picking operation. After the picking is completed, the logistics task information of the WMS is triggered again to obtain the next time. The destination location of the picking item task, and the picking operation is performed. After completion, it is judged whether the picking item is full. If the case is full, the logistics task information of the WMS is triggered to retrieve the full case operation. Otherwise, the trigger retrieval is continued. The logistics task information of WMS, and carry out the next picking task. The picking task is simulated according to the above process, and the simulation output results are obtained.

图3为本发明实施例提供的实施规划的仓储物流方案的仿真相关数据的输出流程图,其具体步骤包括:Fig. 3 is the output flow chart of the simulation-related data of the implementation-planned warehousing logistics scheme provided by the embodiment of the present invention, and its specific steps include:

步骤301、实施规划的仓储物流方案的仿真模型系统接收到WMS的物流任务信息;

步骤302、该仿真模型系统进行规划的仓储物流方案的仿真;

步骤303、该仿真模型输出得到的仿真输出结果,包括了仓储三要素信息,即当前拣选人员信息、当前拣选物品容器号信息及当前拣选人员位置信息。

图4为本发明实施例提供的实施规划的仓储物流方案的仿真相关数据的输入流程图,其具体步骤包括:Fig. 4 is the input flow chart of the simulation-related data of the implementation-planned warehousing logistics scheme provided by the embodiment of the present invention, and its specific steps include:

步骤401、实施规划的仓储物流方案的仿真模型系统接收到WMS的物流任务信息,包括了仓库中的首次拣选位置、拣选人员位置信息、要拣选物品的物品信息、数量信息及位置信息;Step 401: The simulation model system implementing the planned warehousing logistics scheme receives the logistics task information of the WMS, including the first picking position in the warehouse, the position information of the picking personnel, the item information of the item to be picked, the quantity information and the position information;

在这里,上述物流任务信息是静态输入参数,静态输入参数包括了仓库中的储位分区、货架参数、拣选物品的位置坐标及物品满箱投线坐标等;而在仿真模型系统中包括了动态输入参数,这些动态输入参数包括:拣选人员数量、拣选人员行走速度、拣选物品时间、投线时间及首次拣选绑定容器号时间等;Here, the above-mentioned logistics task information is a static input parameter, and the static input parameter includes the storage space partition in the warehouse, the shelf parameters, the position coordinates of the picked items, and the line coordinates of the full box of the items. In the simulation model system, the dynamic input parameters are included. Input parameters, these dynamic input parameters include: the number of picking personnel, the walking speed of the picking personnel, the time of picking items, the time of casting the line, and the time of first picking the bound container number, etc.;

步骤402、该仿真模型系统进行规划的仓储物流方案的仿真;

步骤403、该仿真模型输出得到的仿真输出结果。

图5为本发明实施例提供的规划的仓储物流方案的WMS输出物流相关数据的方法流程图,其具体步骤包括:5 is a flowchart of a method for outputting logistics-related data from a WMS of a planned warehousing logistics solution provided by an embodiment of the present invention, and the specific steps include:

步骤501、WMS接收到实施规划的仓储物流方案的仿真模型系统输出的仿真输出结果;

步骤502、WMS根据该仿真输出结果、物品订单及物品相关信息,生成物流任务信息;

步骤503、WMS将所生成的物流任务信息输出给该仿真模型系统,包括了首次拣货位置、每个拣货员下一拣货位置信息、拣货物品信息及数量信息。

图6为本发明实施例提供的规划的仓储物流方案的WMS输入物流相关数据的方法流程图,其具体步骤包括:6 is a flowchart of a method for inputting logistics-related data in a WMS of a planned warehousing logistics solution provided by an embodiment of the present invention, and the specific steps include:

步骤601、WMS接收到物品订单及拣选物品相关信息,包括历史物品订单数据、物品储位信息、拣货员相关信息、仓储位置的格口阈值和当前可用的仓储位置的格口数量等等;

本步骤作为示例,物品订单及拣选物品信息包括以下的一种或多种组合:订单量、拣选物品的任务量、货架的属性信息、满包投线的位置、数量以及投线时间;具体的拣选物品的任务量包括每小时下发到仓库的任务量、任务平均的完成时间及任务等待阈值时间;货架的属性信息包括货架层数以及各个货架层层高、列数以及列宽、以及货架数量,与之对应的拣选物品时间。As an example in this step, the item order and picking item information include one or more combinations of the following: order quantity, task quantity for picking items, attribute information of the shelf, position and quantity of the full package delivery line, and line delivery time; specific The task volume of picking items includes the number of tasks sent to the warehouse per hour, the average completion time of the tasks and the task waiting threshold time; the attribute information of the shelves includes the number of shelf layers and the height of each shelf layer, the number of columns and column width, and the shelf. Quantity, corresponding to the time of picking the item.

步骤602、WMS根据仿真输出结果、物品订单及物品相关信息,生成物流相关数据;

步骤603、WMS输出物流任务信息。

图7为本发明实施例提供的实施规划的拣选物品的物流方案的方法流程图,其具体步骤包括:7 is a flowchart of a method for implementing a planned logistics solution for picking items provided by an embodiment of the present invention, and the specific steps include:

步骤701、确定规划的拣选物品的物流方案;Step 701: Determine the planned logistics scheme for picking items;

步骤702、根据该拣选物品的物流方案,建立仿真模型系统;

步骤703、利用所述的仿真模型系统实施该拣选物品的物流方案,得到仿真输出结果;

步骤704、判断所述仿真输出结果是否与实施该拣选物品的物流方案得到的实际执行输出结果是否一致,或者相比较的拟真度是否大于所设置的拟真度阈值,如果否,执行步骤705;如果是,执行步骤706;Step 704: Determine whether the simulation output result is consistent with the actual execution output result obtained by implementing the logistics plan for the picked item, or whether the compared fidelity is greater than the set fidelity threshold, if not, go to step 705 ; if yes, execute

步骤705、在所述仿真输出结果与实际执行输出结果之间的拟真度较大时,根据所述仿真输出结果,修改该拣选业务的物流方案,并基于修改的该拣选业务的流程方案,重新建立仿真模型系统,返回步骤703继续执行,直到相比较的拟真度小于等于拟真度阈值为止;Step 705: When the degree of fidelity between the simulation output result and the actual execution output result is relatively large, according to the simulation output result, modify the logistics plan of the picking business, and based on the modified process plan of the picking business, Re-establish the simulation model system, and return to step 703 to continue executing until the compared fidelity is less than or equal to the fidelity threshold;

步骤706、将得到的拣选业务的物流方案作为最终的拣选业务的物流方案。Step 706: Use the obtained logistics scheme of the picking business as the final logistics scheme of the picking business.

在上述过程的步骤701中,规划的仓储物流方案中包括了物流工作流程,工作物流流程包括拣选物品下架任务流程、满箱换箱流程和满箱投线流程。具体地说,当提供仿真模型系统之后,在对所述仿真模型系统初始化时,仿真拣选人员主动触发调取WMS的物流任务信息,仿真获取第一次拣货物品任务的目的地货位,进行拣货操作,拣货完成后再次触发调取WMS的物流任务信息,进行获取下一次拣货物品任务的目的地货位,进行拣货操作,完成后判断拣货物品是否满箱,若满箱则触发调取WMS的物流任务信息,进行满箱操作,否则,继续执行触发调取WMS的物流任务信息,进行下一次拣货物品任务。按照上述过程仿真拣货物品任务,得出仿真输出结果。In

在上述过程的步骤702中,具体按照如下过程提供仿真模型系统:In

第一步骤,添加物品货架:根据所述仓储物流方案布局设置货架层高、列宽、以及层数列数,货架数量;The first step is to add item shelves: according to the layout of the storage logistics plan, set the shelf height, column width, number of layers and columns, and the number of shelves;

第二步骤,根据所述仓储物流方案布局添加拣选坐标网,设置转弯、直线、方向等参数;The second step is to add a picking coordinate network according to the layout of the warehousing and logistics plan, and set parameters such as turning, straight line, and direction;

第三步骤,设置储区及分割物理区域;The third step is to set up the storage area and divide the physical area;

第四步骤,添加每个虚拟实体包括接收拣选业务信息,发送当前位置以及物品容器信息,再次接收拣选业务信息,拣货完成满箱指令等事件时需要执行的各种信息;The fourth step, adding each virtual entity includes receiving the picking business information, sending the current location and item container information, receiving the picking business information again, and various information that needs to be executed when the picking completes the full box instruction and other events;

第五步骤,仿真模型系统中设置每个虚拟实体的运行参数,包括拣货装载时间,行走最大速度,加速度,减速度或/和卸载货物时间等参数;In the fifth step, the operation parameters of each virtual entity are set in the simulation model system, including parameters such as picking and loading time, maximum walking speed, acceleration, deceleration or/and time for unloading goods;

第六步骤,添加修改拣选仿真模型的接口;The sixth step is to add an interface for modifying the picking simulation model;

第七步骤,添加仿真输出结果显示界面,以方便观察仿真模型系统的运行情况和任务完成情况。In the seventh step, an interface for displaying the simulation output results is added to facilitate the observation of the operation of the simulation model system and the completion of tasks.

在第六步骤中,添加修改拣选模型的接口可以包括:拣选人员数参数化、行走速度参数化、货架属性参数化,添加仿真模型运行控制按键,包括应用按键以及开始暂停停止按键,通过对按键的响应对仿真模型系统进行提供。当对某一参数修改时,点击应用按键即可完成仿真模型系统参数的更新实现。In the sixth step, the interface for adding and modifying the picking model may include: parameterization of the number of picking personnel, parameterization of walking speed, parameterization of shelf attributes, adding simulation model operation control buttons, including application buttons and start, pause and stop buttons, The responses are provided to the simulation model system. When modifying a parameter, click the Apply button to complete the update of the simulation model system parameters.

在第七步骤中,该仿真输出结果包括以下一种或多种:首次作业位置是否和实际一致;拣选轨迹是否和实际一致;当拣选人员发生变动时,再次分配的作业位置是否和实际一致;以及作业效率是否和实际一致等等。In the seventh step, the simulation output results include one or more of the following: whether the first working position is consistent with the actual; whether the picking track is consistent with the actual; when the picking personnel changes, whether the re-assigned working position is consistent with the actual; And whether the work efficiency is consistent with the actual, etc.

在上述过程的步骤705中,具体包括:提供的仿真模型系统中的仿真涉及的规划系统参数是否设置正确,物品订单完成状态、拣选业务的处理能力是否达到预期,如果不满足,则反查所设置的仿真涉及的规划系统参数,重新运行所提供的仿真模型系统,按照上述过程重新执行,并对得到的仿真输出结果及实际输出结果进行分析,通过这样的反复迭代最终得到满足期望的拣选业务的物流方案。In

按照图7所述的过程执行,得到了图8所示的实施规划的拣选业务的物流方案的仿真输出结果示意图,图中是以仓库当前物品容量与实施所述物流方案的时间值之间的对应关系。在可选的实施例中,仿真输出结果还可以以图标的形式展示,比如采用曲线图或柱形图等。Executed according to the process shown in FIG. 7 , a schematic diagram of the simulation output result of the logistics scheme for implementing the planned picking business shown in FIG. 8 is obtained. Correspondence. In an optional embodiment, the simulation output result may also be displayed in the form of an icon, such as a curve graph or a bar graph.

作为具体的示例,拣选业务的执行时间可以包括如图8所示的各个时间节点。其中PersonNum是当前拣选人员的人数,status标识任务状态,1表示拣选任务未拉下,2表示当前拣选的任务,3表示拣选完成的任务,PersonDis是拣选行走距离。对于未拉下任务,Queue1表示已进入订单池但未被拉下的订单数量;对于当前拣选任务,Queue2表示已经从订单池拉下的订单数量;对于拣选完成任务,Queue3表示已经从订单池拉下并且完成拣货动动作订单数量。在这里,由于对于整个仓库的拣选任务,后一拣选任务的输入是基于前一拣选物品任务的完成,所以在仿真模型系统中添加的拣选任务的行走距离和当前拣选人员的人数,基于此得到比较全面的分析结果,确定仓储物流方案的优化方向。As a specific example, the execution time of the picking service may include various time nodes as shown in FIG. 8 . Among them, PersonNum is the current number of picking personnel, status identifies the task status, 1 indicates that the picking task is not pulled down, 2 indicates the currently picked task, 3 indicates the picking completed task, and PersonDis is the picking distance. For tasks that have not been pulled down, Queue1 indicates the number of orders that have entered the order pool but have not been pulled; for the current picking task, Queue2 indicates the number of orders that have been pulled from the order pool; for picking completed tasks, Queue3 indicates that it has been pulled from the order pool. Place and complete the picking motion order quantity. Here, for the picking task of the entire warehouse, the input of the subsequent picking task is based on the completion of the previous picking item task, so the walking distance of the picking task and the number of current picking personnel added in the simulation model system are based on this. Based on the comprehensive analysis results, determine the optimization direction of the warehousing logistics plan.

可以看出,影响仓储物流方案的拣选业务的拣选效率的原因是单次拣选物品数量和拣选人员行走距离,这与物品订单的结构及WMS所采用的下拉算法相关联。其中物品订单的结构属于规划层面要解决的问题,下拉算法,是采用何种方式拆解及融合物品订单,并下发相应的拣选任务信息;行走距离,可以通过仿真模型系统中的仿真涉及的规划系统参数进行设置。It can be seen that the reason that affects the picking efficiency of the picking business of the warehousing logistics solution is the number of items picked in a single time and the walking distance of the pickers, which is related to the structure of the item order and the drop-down algorithm adopted by the WMS. The structure of the item order is a problem to be solved at the planning level. The pull-down algorithm is how to disassemble and integrate the item order, and issue the corresponding picking task information; the walking distance can be determined by the simulation in the simulation model system. Planning system parameters to set.

在本发明实施例中,所述实施规划的仓储物流方案的仿真模型系统包括了仿真涉及的规划系统参数,该参数可以通过提供设置界面进行直接设置,如图9所示,图9为本发明实施例提供的仿真模型系统中的仿真涉及的规划系统参数的设置界面示意图。In the embodiment of the present invention, the simulation model system for implementing the planned warehousing logistics scheme includes the planning system parameters involved in the simulation, and the parameters can be directly set by providing a setting interface, as shown in FIG. 9 , which is the present invention A schematic diagram of a setting interface of planning system parameters involved in the simulation in the simulation model system provided by the embodiment.

图10为本发明实施例提供的一种仓储物流方案的规划系统结构示意图,包括:设置单元、信息交互单元、仿真单元及结果输出单元,其中,10 is a schematic structural diagram of a planning system for a warehousing and logistics solution provided by an embodiment of the present invention, including: a setting unit, an information interaction unit, a simulation unit, and a result output unit, wherein,

该设置单元,用于提供实施规划的仓储物流方案的仿真模型系统;提供实现规划的仓储物流方案的终端设备,以使该终端设备根据接收WMS的物流任务信息,按照该规划的仓储物流方案执行,得到实际执行输出结果;The setting unit is used to provide a simulation model system for implementing the planned warehousing and logistics scheme; provide terminal equipment for realizing the planned warehousing and logistics scheme, so that the terminal equipment can execute the planned warehousing and logistics scheme according to the logistics task information received from the WMS. , get the actual execution output result;

该信息交互单元,用于接收该WMS的物流任务信息及接收该终端设备的实际执行输出结果;The information exchange unit is used to receive the logistics task information of the WMS and receive the actual execution output result of the terminal device;

该仿真单元,用于基于该仿真模型系统根据所述物流任务信息仿真运行所述规划的仓储物流方案,得到仿真输出结果;The simulation unit is used to simulate and run the planned warehouse logistics scheme according to the logistics task information based on the simulation model system, and obtain a simulation output result;

该结果输出单元,用于根据该仿真输出结果与该实际执行输出结果,进行拟真度验证,得到拟真度验证结果;The result output unit is configured to perform fidelity verification according to the simulation output result and the actual execution output result, and obtain a fidelity verification result;

在该系统中,还包括修正单元,用于根据所得到的拟真度验证结果对该规划的仓储物流方案修正,迭代进行上述过程,直到得到的拟真度验证结果达到所设定的拟真度阈值为止。In the system, a correction unit is also included for correcting the planned warehousing logistics scheme according to the obtained fidelity verification result, and the above process is iteratively performed until the obtained fidelity verification result reaches the set fidelity up to the threshold.

可以看出,上述系统可以实现基于与WMS之间的通信交互信息,对仓储物流方案进行规划。It can be seen that the above system can realize the planning of the warehousing and logistics scheme based on the communication and exchange of information with the WMS.

图11为本发明实施例提供的实现仓储物流方案规划的终端设备或服务器的计算机系统的结构示意图,如图所示,包括多个终端设备S110、服务器S111及云网络S112,及终端设备S110与服务器S111通过云网络S112进行通信交互,云网络S112是终端设备S110与服务器S111之间的通信交互的介质,其中,FIG. 11 is a schematic structural diagram of a computer system of a terminal device or server for implementing warehousing and logistics plan planning according to an embodiment of the present invention. As shown in the figure, it includes a plurality of terminal devices S110, a server S111 and a cloud network S112, and the terminal devices S110 and S110 The server S111 communicates and interacts through the cloud network S112, and the cloud network S112 is a medium for communication and interaction between the terminal device S110 and the server S111, wherein,

多个终端设备S110分别实施规划的仓储物流方案的仿真终端、WMS及终端装置终端等,通过云网络S112和服务器S111进行通信交互,从而实现物流任务信息的发送或接收。A plurality of terminal devices S110 respectively implement simulation terminals, WMS and terminal device terminals of the planned warehousing logistics scheme, and communicate and interact with the server S111 through the cloud network S112, thereby realizing the sending or receiving of logistics task information.

本申请实施例还提供一种计算机可读介质,所述计算机可读存储介质存储指令,所述指令在由处理器执行时可执行如上所述的一种仓储物流方案的规划方法中的执行步骤。实际应用中,所述的计算机可读介质可以是上述实施例中描述的设备/装置/系统中所包含的,也可以是单独存在,而未装配入该设备/装置/系统中。上述计算机可读存储介质承载有一个或者多个程序,当上述一个或多个程序被执行时,可以实现上述各实施例描述的所述的一种仓储物流方案的规划方法。根据本申请公开的实施例,计算机可读存储介质可以是非易失性的计算机可读存储介质,例如可以包括但不限于:便携式计算机磁盘、硬盘、随机访问存储器(RAM)、只读存储器(ROM)、可擦式可编程只读存储器(EPROM或闪存)、便携式紧凑磁盘只读存储器(CD-ROM)、光存储器件、磁存储器件,或者上述的任意合适的组合,但不用于限制本申请保护的范围。在本申请公开的实施例中,计算机可读存储介质可以是任何包含或存储程序的有形介质,该程序可以被指令执行系统、装置或者器件使用或者与其结合使用。Embodiments of the present application further provide a computer-readable medium, where the computer-readable storage medium stores instructions, and when executed by a processor, the instructions can perform the execution steps in the above-mentioned planning method for a warehouse logistics scheme . In practical applications, the computer-readable medium may be included in the device/apparatus/system described in the above embodiments, or may exist alone without being assembled into the apparatus/apparatus/system. The above-mentioned computer-readable storage medium carries one or more programs, and when the above-mentioned one or more programs are executed, the method for planning a warehouse logistics scheme described in the above-mentioned embodiments can be implemented. According to the embodiments disclosed in the present application, the computer-readable storage medium may be a non-volatile computer-readable storage medium, such as, but not limited to, portable computer disks, hard disks, random access memory (RAM), read only memory (ROM) ), erasable programmable read-only memory (EPROM or flash memory), portable compact disk read-only memory (CD-ROM), optical storage devices, magnetic storage devices, or any suitable combination of the above, but are not intended to limit this application scope of protection. In the embodiments disclosed in this application, a computer-readable storage medium may be any tangible medium that contains or stores a program that can be used by or in conjunction with an instruction execution system, apparatus, or device.

本发明实施例还提供一种电子设备,其中可以集成本申请实施例实现方法的装置。The embodiments of the present invention further provide an electronic device, in which the apparatus for implementing the methods in the embodiments of the present application can be integrated.

具体来讲:Specifically:

该电子设备可以包括一个或一个以上处理核心的处理器、一个或一个以上计算机可读存储介质的存储器以及存储在存储器上并可在处理器上运行的计算机程序。在执行所述存储器的程序时,可以实现上述的一种仓储物流方案的规划方法。The electronic device may include a processor of one or more processing cores, memory of one or more computer-readable storage media, and a computer program stored on the memory and executable on the processor. When the program of the memory is executed, the above-mentioned planning method of a warehouse logistics scheme can be realized.

具体的,实际应用中,该电子设备还可以包括电源、输入单元、以及输出单元等部件。本领域技术人员可以理解,本发明实施例中的电子设备的结构并不构成对该电子设备的限定,可以包括比图示更多或更少的部件,或者组合某些部件,或者不同的部件布置。Specifically, in practical applications, the electronic device may further include components such as a power supply, an input unit, and an output unit. Those skilled in the art can understand that the structure of the electronic device in the embodiment of the present invention does not constitute a limitation on the electronic device, and may include more or less components than the one shown, or combine some components, or different components layout.

其中:in:

处理器是该电子设备的控制中心,利用各种接口和线路连接整个电子设备的各个部分,通过运行或执行存储在存储器内的软件程序和/或模块,以及调用存储在存储器内的数据,执行服务器的各种功能和处理数据,从而对该电子设备进行整体监控。The processor is the control center of the electronic device, and uses various interfaces and lines to connect various parts of the entire electronic device, and executes by running or executing the software programs and/or modules stored in the memory and calling the data stored in the memory. Various functions of the server and processing data to monitor the electronic equipment as a whole.

存储器可用于存储软件程序以及模块,即上述计算机可读存储介质。处理器通过运行存储在存储器的软件程序以及模块,从而执行各种功能应用以及数据处理。存储器可主要包括存储程序区和存储数据区,其中,存储程序区可存储操作系统、至少一个功能所需的应用程序等;存储数据区可存储根据服务器的使用所创建的数据等。此外,存储器可以包括高速随机存取存储器,还可以包括非易失性存储器,例如至少一个磁盘存储器件、闪存器件、或其他易失性固态存储器件。相应地,存储器还可以包括存储器控制器,以提供处理器对存储器的访问。The memory can be used to store software programs and modules, ie, the above-mentioned computer-readable storage medium. The processor executes various functional applications and data processing by running software programs and modules stored in the memory. The memory may mainly include a stored program area and a stored data area, wherein the stored program area may store an operating system, an application program required for at least one function, and the like; the storage data area may store data created according to the use of the server, and the like. Additionally, the memory may include high-speed random access memory, and may also include non-volatile memory, such as at least one magnetic disk storage device, flash memory device, or other volatile solid state storage device. Accordingly, the memory may also include a memory controller to provide processor access to the memory.

该电子设备还包括给各个部件供电的电源,可以通过电源管理系统与处理器逻辑相连,从而通过电源管理系统实现管理充电、放电、以及功耗管理等功能。电源还可以包括一个或一个以上的直流或交流电源、再充电系统、电源故障检测电路、电源转换器或者逆变器、电源状态指示器等任意组件。The electronic device also includes a power supply for supplying power to each component, and can be logically connected to the processor through the power management system, so that functions such as charging, discharging, and power consumption management are implemented through the power management system. The power source may also include one or more DC or AC power sources, recharging systems, power failure detection circuits, power converters or inverters, power status indicators, and any other components.

该电子设备还可包括输入单元,该输入单元可用于接收输入的数字或字符信息,以及产生与用户设置以及功能控制有关的键盘、鼠标、操作杆、光学或者轨迹球信号输入。The electronic device may also include an input unit operable to receive input numerical or character information and generate keyboard, mouse, joystick, optical or trackball signal input related to user settings and function control.

该电子设备还可以包括输出单元,该输出单元可以用于显示由用户输入的信息或提供给用户的信息以及各种图像用户接口,这些图形用户接口可以由图形、文本、图标、视频和其任意组合来构成。The electronic device may further include an output unit, which may be used to display information input by the user or information provided to the user and various graphical user interfaces, which may be composed of graphics, text, icons, videos, and any other composition to form.

本申请附图中的流程图和框图,示出了按照本申请公开的各种实施例的系统、方法和计算机程序产品的可能实现的体系架构、功能和操作。在这点上,流程图或框图中的每个方框可以代表一个模块、程序段、或者代码的一部分,上述模块、程序段、或代码的一部分包含一个或多个用于实现规定的逻辑功能的可执行指令。也应该注意,在有些作为替换的实现中,方框中所标注的功能也可以以不同附图中所标准的顺序发生。例如,两个连接地表示的方框实际上可以基本并行地执行,它们有时也可以按照相反的顺序执行,这依所涉及的功能而定。也要注意的是,框图或流程图中的每个方框、以及框图或者流程图中的方框的组合,可以用执行规定的功能或操作的专用的基于硬件的系统来实现,或者可以用专用硬件与计算机指令的组合来实现。The flowchart and block diagrams in the figures of the present application illustrate the architecture, functionality, and operation of possible implementations of systems, methods and computer program products according to various embodiments disclosed herein. In this regard, each block in the flowchart or block diagrams may represent a module, segment, or portion of code that contains one or more functions for implementing the specified logical function(s) executable instructions. It should also be noted that, in some alternative implementations, the functions noted in the blocks may occur out of the order noted in the different figures. For example, two blocks shown in connection may, in fact, be executed substantially concurrently, or the blocks may sometimes be executed in the reverse order, depending upon the functionality involved. It is also noted that each block of the block diagrams or flowchart illustrations, and combinations of blocks in the block diagrams or flowchart illustrations, can be implemented in special purpose hardware-based systems that perform the specified functions or operations, or can be implemented using A combination of dedicated hardware and computer instructions is implemented.

本领域技术人员可以理解,本公开的各个实施例和/或权利要求中记载的特征可以进行多种组合和/或结合,即使这样的组合或结合没有明确记载于本申请中。特别地,在不脱离本申请精神和教导的情况下,本申请的各个实施例和/或权利要求中记载的特征可以进行多种组合和/或结合,所有这些组合和/或结合均落入本申请公开的范围。Those skilled in the art will appreciate that various combinations and/or combinations of features recited in various embodiments of the present disclosure and/or claims are possible, even if such combinations or combinations are not explicitly described in this application. In particular, various combinations and/or combinations of the features recited in the various embodiments of the present application and/or the claims may be made without departing from the spirit and teachings of the present application, all such combinations and/or combinations falling within Scope of this disclosure.

本文中应用了具体实施例对本发明的原理及实施方式进行了阐述,以上实施例的说明只是用于帮助理解本发明的方法及其核心思路,并不用于限制本申请。对于本领域的技术人员来说,可以依据本发明的思路、精神和原则,在具体实施方式及应用范围上进行改变,其所做的任何修改、等同替换、改进等,均应包含在本申请保护的范围之内。The principles and implementations of the present invention are described herein by using specific embodiments. The descriptions of the above embodiments are only used to help understand the method and the core idea of the present invention, and are not intended to limit the application. For those skilled in the art, changes can be made in the specific embodiments and application scope according to the idea, spirit and principles of the present invention, and any modifications, equivalent replacements, improvements, etc. made by them should be included in this application. within the scope of protection.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210086766.0ACN114418504A (en) | 2022-01-25 | 2022-01-25 | Planning method and system for warehouse logistics scheme |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210086766.0ACN114418504A (en) | 2022-01-25 | 2022-01-25 | Planning method and system for warehouse logistics scheme |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114418504Atrue CN114418504A (en) | 2022-04-29 |

Family

ID=81276741

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210086766.0APendingCN114418504A (en) | 2022-01-25 | 2022-01-25 | Planning method and system for warehouse logistics scheme |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114418504A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116468346A (en)* | 2023-04-14 | 2023-07-21 | 上海多维明软信息技术有限公司 | Intelligent logistics control method and system |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110147069A (en)* | 2019-04-28 | 2019-08-20 | 武汉理工大学 | A digital twin-based real-time port monitoring system and its working method |

| CN111680893A (en)* | 2020-05-25 | 2020-09-18 | 北京科技大学 | A digital twin system and scheduling method of multi-self-addressing robot picking system |

| CN112084646A (en)* | 2020-09-03 | 2020-12-15 | 江西农业大学 | A Modular Product Customization Method Based on Digital Twin |

| CN112906299A (en)* | 2021-02-05 | 2021-06-04 | 北京交通大学 | Data calculation method and system for digital twin simulation of urban rail power supply system |

| CN113222310A (en)* | 2020-02-04 | 2021-08-06 | 北京京东振世信息技术有限公司 | Goods picking productivity scheduling method and device |

| US20210374659A1 (en)* | 2020-05-27 | 2021-12-02 | Vimaan Robotics, Inc. | Real Time Event Tracking and Digitization for Warehouse Inventory Management |

| US20210405173A1 (en)* | 2019-07-08 | 2021-12-30 | Strong Force Vcn Portfolio 2019, Llc | Systems and methods for detecting occupancy using radio signals |

| CN113868898A (en)* | 2021-11-29 | 2021-12-31 | 联想新视界(北京)科技有限公司 | Data processing method and device based on digital twin model |

- 2022

- 2022-01-25CNCN202210086766.0Apatent/CN114418504A/enactivePending

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110147069A (en)* | 2019-04-28 | 2019-08-20 | 武汉理工大学 | A digital twin-based real-time port monitoring system and its working method |

| US20210405173A1 (en)* | 2019-07-08 | 2021-12-30 | Strong Force Vcn Portfolio 2019, Llc | Systems and methods for detecting occupancy using radio signals |

| CN113222310A (en)* | 2020-02-04 | 2021-08-06 | 北京京东振世信息技术有限公司 | Goods picking productivity scheduling method and device |

| CN111680893A (en)* | 2020-05-25 | 2020-09-18 | 北京科技大学 | A digital twin system and scheduling method of multi-self-addressing robot picking system |

| US20210374659A1 (en)* | 2020-05-27 | 2021-12-02 | Vimaan Robotics, Inc. | Real Time Event Tracking and Digitization for Warehouse Inventory Management |

| CN112084646A (en)* | 2020-09-03 | 2020-12-15 | 江西农业大学 | A Modular Product Customization Method Based on Digital Twin |

| CN112906299A (en)* | 2021-02-05 | 2021-06-04 | 北京交通大学 | Data calculation method and system for digital twin simulation of urban rail power supply system |

| CN113868898A (en)* | 2021-11-29 | 2021-12-31 | 联想新视界(北京)科技有限公司 | Data processing method and device based on digital twin model |

Non-Patent Citations (2)

| Title |

|---|

| BUCKOVÁ, M ET AL.: ""Designing of logistics systems with using of computer simulation and emulation"", 《13TH INTERNATIONAL SCIENTIFIC CONFERENCE ON SUSTAINABLE, MODERN AND SAFE TRANSPORT (TRANSCOM 2019)》, vol. 40, 24 September 2020 (2020-09-24), pages 978 - 985* |

| 何黎明等: "《中国物流技术发展报告》", 30 April 2021, 北京:中国财富出版社有限公司, pages: 44* |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116468346A (en)* | 2023-04-14 | 2023-07-21 | 上海多维明软信息技术有限公司 | Intelligent logistics control method and system |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| USRE44188E1 (en) | System and method for dynamically simulating process and value stream maps | |

| CN114580695A (en) | Multi-vehicle task allocation and path optimization simulation platform and implementation method thereof | |

| US10810542B2 (en) | Systems and methods for fulfilment design and optimization | |

| CN109408996B (en) | Interaction method, device and system for intelligent equipment control and storage medium | |

| CN115724113B (en) | Goods picking method, device, electronic device and readable storage medium | |

| CN113743876A (en) | Digital twin unmanned warehouse management system for nuclear power equipment | |

| US20220351133A1 (en) | Modeling dynamic material flow in generative design using topological maps | |

| CN105467997A (en) | Storage robot path program method based on linear temporal logic theory | |

| JP7416597B2 (en) | Information processing device and information processing method | |

| CN109839927B (en) | Method and device for robot path planning | |

| WO2007067892A2 (en) | System and method for dynamically simulating value stream and network maps | |

| CN112101841A (en) | Logistics path planning method, device, equipment and storage medium | |

| CN116702454A (en) | Modeling method, device, electronic equipment and storage medium for logistics layout | |

| Shang et al. | Spatial scheduling optimization algorithm for block assembly in shipbuilding | |

| CN112068455A (en) | Task simulation method, system, device, electronic equipment and readable storage medium | |

| CN104573184A (en) | Method and device for constructing high-speed train product meta-model | |

| CN114418504A (en) | Planning method and system for warehouse logistics scheme | |

| Verriet et al. | Warehouse simulation through model configuration | |

| Turgay | Agent-based FMS control | |

| CN109784593A (en) | Production capacity equalization processing method and device for multistoried storehouse | |

| CN111217095B (en) | Hanging operation state simulation demonstration method and device | |

| Li et al. | Research on the task assignment problem of warehouse robots in the smart warehouse | |

| JP2021022016A (en) | Shipping operation support system, method thereof, and computer program | |

| CN117764253A (en) | Design execution device and design execution method | |

| CN116703104A (en) | Material box robot order picking method and device based on decision-making big model |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |