CN114383846B - Bearing composite fault diagnosis method based on fault label information vector - Google Patents

Bearing composite fault diagnosis method based on fault label information vectorDownload PDFInfo

- Publication number

- CN114383846B CN114383846BCN202210010510.1ACN202210010510ACN114383846BCN 114383846 BCN114383846 BCN 114383846BCN 202210010510 ACN202210010510 ACN 202210010510ACN 114383846 BCN114383846 BCN 114383846B

- Authority

- CN

- China

- Prior art keywords

- fault

- composite

- vector

- data

- feature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000013598vectorSubstances0.000titleclaimsabstractdescription291

- 239000002131composite materialSubstances0.000titleclaimsabstractdescription238

- 238000000034methodMethods0.000titleclaimsabstractdescription56

- 238000003745diagnosisMethods0.000titleclaimsabstractdescription48

- 238000000605extractionMethods0.000claimsabstractdescription40

- 238000007781pre-processingMethods0.000claimsabstractdescription15

- 238000013507mappingMethods0.000claimsabstractdescription10

- 238000012549trainingMethods0.000claimsdescription55

- 238000012360testing methodMethods0.000claimsdescription43

- 150000001875compoundsChemical class0.000claimsdescription35

- 238000009826distributionMethods0.000claimsdescription23

- 230000006870functionEffects0.000claimsdescription11

- 238000005070samplingMethods0.000claimsdescription11

- 238000013527convolutional neural networkMethods0.000claimsdescription5

- 230000009466transformationEffects0.000claimsdescription5

- 238000010276constructionMethods0.000claimsdescription4

- 230000008569processEffects0.000claimsdescription3

- 238000013329compoundingMethods0.000claims3

- 238000005096rolling processMethods0.000description9

- 239000000284extractSubstances0.000description8

- 238000010586diagramMethods0.000description3

- 238000011176poolingMethods0.000description3

- 101001121408Homo sapiens L-amino-acid oxidaseProteins0.000description2

- 102100026388L-amino-acid oxidaseHuman genes0.000description2

- 238000004458analytical methodMethods0.000description2

- 230000008878couplingEffects0.000description2

- 238000010168coupling processMethods0.000description2

- 238000005859coupling reactionMethods0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 238000013519translationMethods0.000description2

- ORILYTVJVMAKLC-UHFFFAOYSA-NAdamantaneNatural productsC1C(C2)CC3CC1CC2C3ORILYTVJVMAKLC-UHFFFAOYSA-N0.000description1

- 101000827703Homo sapiens Polyphosphoinositide phosphataseProteins0.000description1

- 102100023591Polyphosphoinositide phosphataseHuman genes0.000description1

- 108010076504Protein Sorting SignalsProteins0.000description1

- 101100012902Saccharomyces cerevisiae (strain ATCC 204508 / S288c) FIG2 geneProteins0.000description1

- 101100233916Saccharomyces cerevisiae (strain ATCC 204508 / S288c) KAR5 geneProteins0.000description1

- 230000002159abnormal effectEffects0.000description1

- 230000001133accelerationEffects0.000description1

- 238000013135deep learningMethods0.000description1

- 230000007547defectEffects0.000description1

- 238000011161developmentMethods0.000description1

- 230000000694effectsEffects0.000description1

- 238000002474experimental methodMethods0.000description1

- 238000010801machine learningMethods0.000description1

- 230000008447perceptionEffects0.000description1

- 230000004044responseEffects0.000description1

- 230000001953sensory effectEffects0.000description1

- 238000011524similarity measureMethods0.000description1

- 230000000087stabilizing effectEffects0.000description1

- 238000006467substitution reactionMethods0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01M—TESTING STATIC OR DYNAMIC BALANCE OF MACHINES OR STRUCTURES; TESTING OF STRUCTURES OR APPARATUS, NOT OTHERWISE PROVIDED FOR

- G01M13/00—Testing of machine parts

- G01M13/04—Bearings

- G01M13/045—Acoustic or vibration analysis

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T90/00—Enabling technologies or technologies with a potential or indirect contribution to GHG emissions mitigation

Landscapes

- Physics & Mathematics (AREA)

- Acoustics & Sound (AREA)

- General Physics & Mathematics (AREA)

- Image Analysis (AREA)

Abstract

Description

Translated fromChinese技术领域Technical Field

本发明涉及轴承的复合故障诊断技术领域,尤其是基于故障标签信息向量的轴承复合故障诊断方法。The present invention relates to the technical field of composite fault diagnosis of bearings, and in particular to a composite fault diagnosis method for bearings based on fault label information vectors.

背景技术Background Art

在轴承故障诊断中,由于不同故障参数的耦合、故障特征的多样性以及可能的故障模式数呈指数增长,复合故障诊断一直是一个难题。In bearing fault diagnosis, compound fault diagnosis has always been a difficult problem due to the coupling of different fault parameters, the diversity of fault characteristics, and the exponential growth of the number of possible fault modes.

传统的复合故障诊断方法主要包括基于定性经验的方法、基于分析模型的方法和基于信号分析的方法。基于定性经验方法利用不完全先验知识描述系统的功能结构,建立定性模型实现推理。基于分析模型的方法通过研究故障状态下动态参数和响应信号之间的内在联系,生成正常和异常操作之间的相关信息。基于信号分析的方法需要在大量原始感知数据的基础上,通过直接推理提取故障特征进行诊断。然而,这些方法需要专家的经验知识和工程经验,难以应用于现实的工业场景。Traditional composite fault diagnosis methods mainly include qualitative experience-based methods, analytical model-based methods, and signal analysis-based methods. Qualitative experience-based methods use incomplete prior knowledge to describe the functional structure of the system and establish qualitative models to achieve reasoning. Analytical model-based methods generate relevant information between normal and abnormal operations by studying the intrinsic connection between dynamic parameters and response signals under fault conditions. Signal analysis-based methods require direct reasoning to extract fault features for diagnosis based on a large amount of original perception data. However, these methods require expert experience and engineering experience and are difficult to apply to real industrial scenarios.

在机械故障诊断领域,机器学习尤其是深度学习的发展已经非常普遍。在此基础上,提出了基于学习模型的方法,用于从原始感官数据中,而不是从专家数据中,自动学习具有代表性的特征和识别复合故障。但是现有的复合故障诊断学习模型的方法通常中基于有监督或半监督学习,对于每一个复合故障的学习都需要足够的有标记或无标记的训练数据。在工业场景中,无论是有标记的还是无标记的复合故障训练数据通常都很难采集,有时甚至无法获取,而单故障样本则很容易获得。In the field of mechanical fault diagnosis, the development of machine learning, especially deep learning, has become very common. On this basis, a learning model-based method is proposed to automatically learn representative features and identify compound faults from raw sensory data rather than from expert data. However, the existing methods of compound fault diagnosis learning models are usually based on supervised or semi-supervised learning, and sufficient labeled or unlabeled training data is required for the learning of each compound fault. In industrial scenarios, both labeled and unlabeled compound fault training data are usually difficult to collect, and sometimes even impossible to obtain, while single fault samples are easy to obtain.

发明内容Summary of the invention

为了克服上述现有技术中的缺陷,本发明提供一种基于故障标签信息向量的轴承复合故障诊断方法,能够使用单故障的样本来识别不可见的复合故障。In order to overcome the defects in the above-mentioned prior art, the present invention provides a bearing composite fault diagnosis method based on fault label information vector, which can use single fault samples to identify invisible composite faults.

为实现上述目的,本发明采用以下技术方案,包括:To achieve the above object, the present invention adopts the following technical solutions, including:

基于故障标签信息向量的轴承复合故障诊断方法,构建零样本学习模型,利用零样本学习模型进行复合故障诊断;所述零样本学习模型包括:数据预处理模块、标签信息定义模块、特征提取模块、生成对抗模块、分类模块;A bearing composite fault diagnosis method based on fault label information vector is constructed, and a zero-sample learning model is used to perform composite fault diagnosis; the zero-sample learning model includes: a data preprocessing module, a label information definition module, a feature extraction module, a generative adversarial module, and a classification module;

所述数据预处理模块用于将原始故障数据φ(t)即一维振动信号转换为二维图像即故障图像q;原始故障数据φ(t)包括:单故障数据φs(t)和复合故障数据φu(t);故障图像q包括单故障图像qs和复合故障图像qu;The data preprocessing module is used to convert the original fault data φ(t), i.e., the one-dimensional vibration signal, into a two-dimensional image, i.e., the fault image q; the original fault data φ(t) includes: single fault data φs (t) and compound fault data φu (t); the fault image q includes a single fault image qs and a compound fault image qu ;

所述标签信息定义模块用于根据原始故障数据构建故障标签信息向量G,包括:单故障标签信息向量Gs和复合故障标签信息向量Gu;The label information definition module is used to construct a fault label information vector G according to the original fault data, including: a single fault label information vector Gs and a composite fault label information vector Gu ;

所述特征提取模块用于对数据预处理模块所转换的故障图像q提取故障特征向量,包括:对单故障图像qs提取单故障特征向量vs,对复合故障图像qu提取复合故障特征向量vu;The feature extraction module is used to extract the fault feature vector from the fault image q converted by the data preprocessing module, including: extracting the single fault feature vectorvs from the single fault imageqs , and extracting the composite fault feature vectorvu from the composite fault imagequ ;

所述生成对抗模块用于学习故障特征空间与故障标签信息空间之间的映射关系;The generative adversarial module is used to learn the mapping relationship between the fault feature space and the fault label information space;

所述分类模块用于根据故障特征空间与故障标签信息空间之间的映射关系,以及根据单故障标签信息向量Gs和复合故障标签信息向量Gu之间的关联关系,并利用复合故障标签信息向量Gu进行复合故障诊断。The classification module is used to perform composite fault diagnosis based on the mapping relationship between the fault feature space and the fault label information space, and the association relationship between the single fault label information vectorGs and the composite fault label information vectorGu , and using the composite fault label information vectorGu .

进一步地,所述数据预处理模块通过小波变换将原始故障数据φ(t)即一维振动信号转换为二维小波图像即故障图像q。Furthermore, the data preprocessing module converts the original fault data φ(t), ie, the one-dimensional vibration signal, into a two-dimensional wavelet image, ie, the fault image q, through wavelet transform.

进一步地,复合故障是由不同的单故障构成的,每个单故障类别对应一个单故障标签信息向量Gs,每个复合故障类别对应一个复合故障标签信息向量Gu;所述标签信息定义模块先根单故障数据φs(t)生成单故障标签信息向量Gs,再根据复合故障所包含的单故障类别,得到复合故障标签信息向量Gu;具体如下所示:Furthermore, a composite fault is composed of different single faults, each single fault category corresponds to a single fault label information vector Gs , and each composite fault category corresponds to a composite fault label information vector Gu ; the label information definition module first generates a single fault label information vector Gs based on the single fault data φs (t), and then obtains a composite fault label information vector Gu according to the single fault categories included in the composite fault; specifically as shown below:

S31,标签信息定义模块利用单故障数据φs(t)提取单故障标签信息向量Gs,单故障标签信息向量Gs的维度均为C×1;其中,第k个单故障类别所对应的单故障标签信息向量即表示第k个单故障类别所对应的单故障标签信息向量中的第c个维度数据,c=1,2,3…C;上标k表示单故障类别序号,k=1,2,3…K,K表示单故障类别的总数量;下标s表示单故障;S31, the label information definition module uses the single fault data φs (t) to extract the single fault label information vector Gs , and the dimension of the single fault label information vector Gs is C×1; wherein the single fault label information vector corresponding to the kth single fault category is Right now Represents the single fault label information vector corresponding to the kth single fault category The c-th dimension data in , c = 1, 2, 3 ... C; the superscript k represents the single fault category number, k = 1, 2, 3 ... K, K represents the total number of single fault categories; the subscript s represents a single fault;

针对第k个单故障类别,选取单故障数据中的连续C个数据点,具体为即表示第k个单故障类别所对应单故障数据中的第c个数据点幅值,c=1,2,3…C;For the kth single fault category, select single fault data There are C consecutive data points in , specifically Right now Represents the single fault data corresponding to the kth single fault category The amplitude of the cth data point in , c = 1, 2, 3...C;

从K个单故障类别所对应的单故障数据中的C个数据点中选取最大值作为阈值μ,即From the single fault data corresponding to K single fault categories The maximum value among the C data points in is selected as the threshold μ, that is,

根据阈值μ将数据点的幅值范围划分为五等份,判断第k个单故障类别的单故障数据中的各个数据点幅值所在的范围区间,从而得到第k个单故障类别的单故障标签信息向量的中各个维度数据的取值为:The amplitude range of the data point is divided into five equal parts according to the threshold μ, and the single fault data of the kth single fault category is determined. The range of the amplitude of each data point in , so as to obtain the single fault label information vector of the kth single fault category Data of each dimension in The value of is:

S32,标签信息定义模块根据复合故障与单故障之间的关联关系,即复合故障是由若干个不同的单故障构成的,结合对应的单故障标签信息向量Gs得到复合故障标签信息向量Gu;复合故障标签信息向量Gu的维度也均为C×1;S32, the label information definition module obtains a composite fault label information vectorGu according to the association relationship between the composite fault and the single fault, that is, the composite fault is composed of several different single faults, combined with the corresponding single fault label information vectorGs ; the dimension of the composite fault label information vectorGu is also C×1;

其中,由类别序号为1,…,J的单故障所构成的复合故障标签信息向量如下所示:Among them, the composite fault label information vector composed of single faults with category numbers 1, ..., J is As shown below:

上标1,…,J是指构成复合故障的单故障的类别序号,J=2,3…,K。The superscripts 1,…,J refer to the category numbers of the single faults that constitute the composite fault, J=2,3…,K.

进一步地,所述特征提取模块的训练方式为:特征提取模块对单故障图像qs,提取单故障特征向量vs,并预测该单故障图像qs的预测故障标签ps;所述特征提取模块根据输入的单故障图像qs的实际故障标签ys和预测故障标签ps之间的分类损失,计算特征提取模块的分类损失,若分类损失满足要求,则特征提取模块训练完成;Furthermore, the training method of the feature extraction module is as follows: the feature extraction module extracts a single fault feature vectorvs for a single fault imageqs , and predicts a predicted fault labelps of the single fault imageqs ; the feature extraction module calculates the classification loss of the feature extraction module according to the classification loss between the actual fault labelys of the input single fault imageqs and the predicted fault labelps , and if the classification loss meets the requirements, the training of the feature extraction module is completed;

训练完成的特征提取模块对单故障图像qs提取单故障特征向量vs,对复合故障图像qu提取复合故障特征向量vu。The trained feature extraction module extracts a single fault feature vectorvs for the single fault imageqs , and extracts a composite fault feature vectorvu for the composite fault imagequ .

进一步地,所述生成对抗模块包括生成器和判别器;所述生成器用于以故障标签信息向量G和高斯噪声z为条件生成故障特征向量所述判别器用于判别生成的故障特征向量和提取的故障特征向量v之间的差异;Furthermore, the generative adversarial module includes a generator and a discriminator; the generator is used to generate a fault feature vector based on the fault label information vector G and Gaussian noise z. The discriminator is used to discriminate the generated fault feature vector The difference between and the extracted fault feature vector v;

所述生成对抗模块的训练方式为:生成器以单故障标签信息向量Gs和高斯噪声z为条件生成单故障特征向量判别器判别生成的单故障特征向量和提取的单故障特征向量vs之间的差异;生成对抗模块根据生成的单故障特征向量和提取的单故障特征向量vs之间的差异计算损失,若损失满足要求,则生成对抗模块训练完成;The training method of the generative adversarial module is as follows: the generator generates a single fault feature vector based on the single fault label information vectorGs and Gaussian noise z. The single fault feature vector generated by the discriminator The difference between the extracted single fault feature vector vss ; the generation adversarial module generates a single fault feature vector based on the generated The loss is calculated by the difference between the extracted single fault feature vectorvs. If the loss meets the requirements, the training of the generative adversarial module is completed;

生成对抗模块训练完成后,所述生成器以各个单故障标签信息向量Gs和高斯噪声z为条件,生成各单故障特征向量以各个复合故障标签信息向量Gu和高斯噪声z为条件,生成各个复合故障特征向量After the training of the generative adversarial module is completed, the generator generates each single fault feature vector based on each single fault label information vectorGs and Gaussian noise z. Each composite fault feature vector is generated based on the composite fault label information vectorGu and Gaussian noise z.

进一步地,所述分类模块进行复合故障诊断的方式如下:Furthermore, the classification module performs compound fault diagnosis in the following manner:

将生成器所生成的各个复合故障特征向量作为复合故障特征空间中的各个中心点,每个中心点均对应一个复合故障类别;Each composite fault feature vector generated by the generator As the center points in the composite fault feature space, each center point corresponds to a composite fault category;

计算特征提取模块所提取的复合故障特征向量vu与各个中心点之间的距离,选择与复合故障特征向量vu距离最小的中心点,距离最小的该中心点所对应的复合故障类别即为该复合故障图像vu的诊断结果。Calculate the distance between the composite fault feature vector vu extracted by the feature extraction module and each center point, select the center point with the smallest distance to the composite fault feature vector vu , and the composite fault category corresponding to the center point with the smallest distance is the diagnosis result of the composite fault image vu .

进一步地,所述零样本学习模型的构建方法,包括以下步骤:Furthermore, the method for constructing the zero-shot learning model comprises the following steps:

S1,数据预处理模块将单故障的原始故障数据即单故障数据φs(t)通过小波变换转换的二维的小波图像即为单故障图像qs;将复合故障的原始故障数据即复合故障数据φu(t)通过小波变换转换的二维的小波图像即为复合故障图像qu;S1, the data preprocessing module transforms the original fault data of a single fault, i.e., the single fault data φs (t), into a two-dimensional wavelet image, i.e., the single fault image qs ; transforms the original fault data of a composite fault, i.e., the composite fault data φu (t), into a two-dimensional wavelet image, i.e., the composite fault imagequ ;

S2,定义零样本模型的训练集Dtrain和测试集Dtest:S2, define the training set Dtrain and test set Dtest of the zero-shot model:

零样本学习模型的训练集Dtrain由单故障类Cs构建,包括单故障数据φs(t)、单故障图像qs、单故障标签ys;所述单故障标签ys是指该单故障的故障类别,每个单故障的故障类别即对应为一个单故障标签ys,且每个单故障标签ys对应一个单故障标签信息向量Gs,下标s表示单故障;所述训练集Dtrain即单故障类Cs中含有K个单故障类别,每个单故障类别均含有N个样本,即N个单故障数据φs(t)和N个单故障图像qs;The training set Dtrain of the zero-shot learning model is constructed by a single fault class Cs , including single fault data φs (t), a single fault image qs , and a single fault label ys ; the single fault label ys refers to the fault category of the single fault, and the fault category of each single fault corresponds to a single fault label ys , and each single fault label ys corresponds to a single fault label information vector Gs , where the subscript s represents a single fault; the training set Dtrain, i.e., the single fault class Cs, contains K single fault categories, and each single fault category contains N samples, i.e., N single fault data φs (t) and N single fault images qs ;

零样本学习模型的测试集Dtest由复合故障类Cu构建,包括复合故障数据φu(t)、复合故障图像qu、复合故障标签yu;复合故障是由若干个不同的单故障构成的,所述复合故障标签yu是指该复合故障的故障类别,即该复合故障所包含的单故障类别,且每个复合故障标签yu对应一个复合故障标签信息向量Gu;下标u表示复合故障;The test set Dtest of the zero-shot learning model is constructed by the composite fault class Cu , including composite fault data φu (t), composite fault image qu , and composite fault label yu ; a composite fault is composed of several different single faults, and the composite fault label yu refers to the fault category of the composite fault, that is, the single fault category contained in the composite fault, and each composite fault label yu corresponds to a composite fault label information vector Gu ; the subscript u represents a composite fault;

S3,标签信息定义模块先利用单故障数据φs(t)提取单故障属性得到单故障标签信息向量Gs,再根据复合故障所包含的单故障类别,得到复合故障语义向量gu;具体如下所示:S3, the label information definition module first uses the single fault data φs (t) to extract the single fault attribute to obtain the single fault label information vector Gs , and then obtains the composite fault semantic vector gu according to the single fault categories contained in the composite fault; specifically as follows:

S31,标签信息定义模块利用单故障数据φs(t)提取单故障标签信息向量Gs,单故障标签信息向量Gs的维度均为C×1;其中,第k个单故障类别所对应的单故障标签信息向量即表示第k个单故障类别所对应的单故障标签信息向量中的第c个维度数据,c表示维度的序号,c=1,2,3…C;上标k表示单故障类别序号,k=1,2,3…K;下标s表示单故障;S31, the label information definition module uses the single fault data φs (t) to extract the single fault label information vector Gs , and the dimension of the single fault label information vector Gs is C×1; wherein the single fault label information vector corresponding to the kth single fault category is Right now Represents the single fault label information vector corresponding to the kth single fault category The c-th dimension data in , c represents the serial number of the dimension, c = 1, 2, 3 ... C; the superscript k represents the serial number of the single fault category, k = 1, 2, 3 ... K; the subscript s represents a single fault;

针对第k个单故障类别,选取单故障数据中的连续C个数据点,具体为即表示第k个单故障类别所对应单故障数据中的第c个数据点幅值,c表示数据点的序号,c=1,2,3…C;For the kth single fault category, select single fault data There are C consecutive data points in , specifically Right now Represents the single fault data corresponding to the kth single fault category The amplitude of the cth data point in , where c represents the sequence number of the data point, c = 1, 2, 3…C;

从第K个单故障类别所对应单故障数据中的C个数据点中选取最大值作为阈值μ,即From the single fault data corresponding to the Kth single fault category The maximum value among the C data points in is selected as the threshold μ, that is,

根据阈值μ将数据点的幅值范围划分为五等份,判断第k个单故障类别的单故障数据中的各个数据点幅值所在的范围区间,从而得到第k个单故障类别的单故障标签信息向量的中各个维度数据的取值为:The amplitude range of the data point is divided into five equal parts according to the threshold μ, and the single fault data of the kth single fault category is determined. The range of the amplitude of each data point in , so as to obtain the single fault label information vector of the kth single fault category Data of each dimension in The value of is:

S32,标签信息定义模块根据复合故障与单故障之间的关联关系,即复合故障是由若干个不同的单故障构成的,结合对应的单故障标签信息向量Gs得到复合故障标签信息向量Gu;复合故障标签信息向量Gu的维度也均为C×1;S32, the label information definition module obtains a composite fault label information vectorGu according to the association relationship between the composite fault and the single fault, that is, the composite fault is composed of several different single faults, combined with the corresponding single fault label information vectorGs ; the dimension of the composite fault label information vectorGu is also C×1;

其中,由类别序号为1,…,J的单故障所构成的复合故障标签信息向量如下所示:Among them, the composite fault label information vector composed of single faults with category numbers 1, ..., J is As shown below:

上标1,…,J是指构成复合故障的单故障的类别序号,J=2,3…,K;The superscript 1, ..., J refers to the category number of the single fault that constitutes the composite fault, J = 2, 3 ..., K;

S4,特征提取模块为利用卷积神经网络建立的特征提取器,S4, the feature extraction module is a feature extractor established using a convolutional neural network.

利用训练集Dtrain对特征提取器进行训练:特征提取器对单故障图像qs,提取单故障特征向量vs,并预测该单故障图像qs的预测故障标签ps;特征提取器根据输入的单故障图像qs的实际故障标签ys和预测故障标签ps之间的分类损失,计算特征提取器的分类损失,若分类损失满足要求,则特征提取器训练完成;The feature extractor is trained using the training set Dtrain : the feature extractor extracts the single fault feature vectorvs for the single fault imageqs , and predicts the predicted fault labelps of the single fault imageqs ; the feature extractor calculates the classification loss of the feature extractor based on the classification loss between the actual fault labelys of the input single fault imageqs and the predicted fault labelps . If the classification loss meets the requirements, the feature extractor training is completed;

特征提取器训练完成后,特征提取器对测试集Dtest中的对复合故障图像qu提取复合故障特征向量vu;After the feature extractor is trained, the feature extractor extracts a composite fault feature vector vu from the composite fault image qu in the test set Dtest ;

S5,生成对抗模块包括生成器和判别器,所述生成器用于以故障标签信息向量G和高斯噪声z为条件生成故障特征向量所述判别器用于判别生成的故障特征向量和提取的故障特征向量v之间的差异;S5, the generation adversarial module includes a generator and a discriminator, wherein the generator is used to generate a fault feature vector based on the fault label information vector G and Gaussian noise z. The discriminator is used to discriminate the generated fault feature vector The difference between and the extracted fault feature vector v;

利用训练集Dtrain对生成对抗模块进行训练,生成器以单故障标签信思向量Gs和高斯噪声z为条件生成单故障特征向量判别器判别生成的单故障特征向量和提取的单故障特征向量vs之间的差异;生成对抗模块根据生成的单故障特征向量和提取的单故障特征向量vs之间的差异计算损失,若损失满足要求,则生成对抗模块训练完成;The training set Dtrain is used to train the generative adversarial module. The generator generates a single fault feature vector based on the single fault label signal vector Gs and Gaussian noise z. The single fault feature vector generated by the discriminator The difference between the extracted single fault feature vector vss ; the generation adversarial module generates a single fault feature vector based on the generated The loss is calculated by the difference between the extracted single fault feature vectorvs. If the loss meets the requirements, the training of the generative adversarial module is completed;

生成对抗模块训练完成后,所述生成器分别以各个复合故障标签信息向量Gu和高斯噪声z为条件,生成各个复合故障特征向量After the training of the generative adversarial module is completed, the generator generates each composite fault feature vector based on each composite fault label information vectorGu and Gaussian noise z.

S6,分类模块对测试集Dtest中的复合故障图像qu进行复合故障诊断测试;S6, the classification module performs a composite fault diagnosis test on the composite fault image qu in the test set Dtest ;

将生成器所生成的各个复合故障特征向量作为复合故障特征空间中的各个中心点,每个中心点均对应一个复合故障类别;Each composite fault feature vector generated by the generator As the center points in the composite fault feature space, each center point corresponds to a composite fault category;

计算特征提取模块针对测试集Dtest中的复合故障图像qu所提取的复合故障特征向量vu与各个中心点之间的距离,选择与复合故障特征向量vu距离最小的中心点,距离最小的该中心点所对应的复合故障类别即为该复合故障图像vu的诊断结果;The feature extraction module calculates the distance between the composite fault feature vector vu extracted from the composite fault image qu in the test set Dtest and each center point, and selects the center point with the smallest distance from the composite fault feature vector vu . The composite fault category corresponding to the center point with the smallest distance is the diagnosis result of the composite fault image vu .

若测试集Dtest中的复合故障图像qu的复合故障标签yu与该复合故障图像vu的诊断结果一致,则表示复合故障诊断正确;否则表示复合故障诊断错误。If the composite fault label yu of the composite fault image qu in the test set Dtest is consistent with the diagnosis result of the composite fault image vu , it means that the composite fault diagnosis is correct; otherwise, it means that the composite fault diagnosis is wrong.

进一步地,步骤S2中,Further, in step S2,

训练集Dtrain和测试集Dtest满足下式中的条件:The training set Dtrain and the test set Dtest satisfy the following conditions:

其中,p(φs(t))、p(φu(t))分别为单故障数据φs(t)、复合故障数据φu(t)的数据分布;I(·)用于计算两个数据分布之间的互信息,I(p(φs(t))、p(φu(t)))即为数据分布p(φs(t))、p(φu(t))之间的互信息;单故障标签ys和复合故障标签yu为不相交。Among them, p(φs (t)) and p(φu (t)) are the data distributions of single fault data φs (t) and compound fault data φu (t), respectively; I(·) is used to calculate the mutual information between two data distributions, and I(p(φs (t)), p(φu (t))) is the mutual information between the data distributions p(φs (t)) and p(φu (t)); the single fault label ys and the compound fault label yu are disjoint.

进一步地,步骤S4中,特征提取器的分类损失L1如下所示:Furthermore, in step S4, the classification loss L1 of the feature extractor is as follows:

其中,ys(i)是该单故障类别中的第i个单故障图像qs(i)的单故障标签,即单故障类别;i表示单故障图像的序号,i=1,2,3…N;ps(i)是特征提取模块针对该单故障类别中的第i个单故障图像qs(i)所预测的预测故障类别。Among them,ys (i) is the single fault label of the i-th single fault imageqs (i) in the single fault category, that is, the single fault category; i represents the sequence number of the single fault image, i=1, 2, 3…N;ps (i) is the predicted fault category predicted by the feature extraction module for the i-th single fault imageqs (i) in the single fault category.

进一步地,步骤S5中,生成对抗模块的损失函数L2如下所示:Furthermore, in step S5, the loss function L2 of the generated adversarial module is as follows:

其中,pr为提取的单故障特征向量vs的数据分布,pg为生成的单故障特征向量的数据分布;Dw(·)为判别器的模型表示,用于判别故障特征向量的真假分数,下标w是判别器Dw(·)的模型参数;Among them, pr is the data distribution of the extracted single fault feature vectorvs, and pg is the generated single fault feature vector The data distribution of; Dw (·) is the model representation of the discriminator, which is used to discriminate the true and false scores of the fault feature vector, and the subscript w is the model parameter of the discriminator Dw (·);

是生成器以单故障标签信息向量Gs和高斯噪声z为条件生成的故障特征向量,为生成器的模型表示,用于生成故障特征向量,下标θ2是别生成器的模型参数;vs是特征提取器提取的单故障特征向量; is the fault feature vector generated by the generator with the single fault label information vectorGs and Gaussian noise z as conditions, is the model representation of the generator, which is used to generate the fault feature vector, and the subscript θ2 is the generator ;vs is the single fault feature vector extracted by the feature extractor;

为梯度惩罚项,是从vs和中均匀采样得到采样单故障特征向量,表示采样单故障特征向量的数据分布,表示对采样单故障特征向量求导,λ为梯度惩罚系数; is the gradient penalty term, is fromvs and The single fault feature vector is obtained by uniform sampling. Represents the sampled single fault feature vector The data distribution, Represents the sampling single fault feature vector Derivative, λ is the gradient penalty coefficient;

为vs和之间的均方误差。 for vss and The mean square error between .

本发明的优点在于:The advantages of the present invention are:

(1)本发明提出了一种基于标签信息向量所构建的零样本模型,该模型通过训练,能够利用单个故障的振动数据识别不可见的复合故障,该模型生成高维复合故障特征进行分类,进一步缓解了枢纽点问题,提高了模型的性能。(1) The present invention proposes a zero-sample model constructed based on a label information vector. The model can be trained to identify invisible composite faults using vibration data of a single fault. The model generates high-dimensional composite fault features for classification, further alleviating the hub problem and improving the performance of the model.

(2)本发明设计了一个新的故障标签信息向量的定义方法,来解决故障标签信息被注释定义的问题,单故障标签信息向量来源于振动信号的峰值。复合故障标签信息向量是基于理论相关性的单故障类别信息向量的组合。因此,在没有复合故障实例的情况下,可以得到复合故障故障标签信息向量集合。该方法不需要专家的先验知识,计算简单,且实验结果验证了该方法的可行性。(2) The present invention designs a new method for defining fault label information vectors to solve the problem of fault label information being annotated and defined. The single fault label information vector is derived from the peak value of the vibration signal. The composite fault label information vector is a combination of single fault category information vectors based on theoretical correlation. Therefore, in the absence of composite fault instances, a composite fault fault label information vector set can be obtained. This method does not require prior knowledge of experts, is simple to calculate, and experimental results verify the feasibility of this method.

(3)本发明针对实际情况下有标记或无标记的复合故障训练数据难以采集的问题,提出了一种基于故障标签信息向量构建的用于复合故障诊断的零样本模型,该模型通过只需使用单故障样本进行训练,即可识别复合故障类别,在实施例的实验数据集上的实验结果表明,该模型在没有复合故障样本的情况下,分类精度显著。(3) In order to solve the problem that labeled or unlabeled compound fault training data is difficult to collect in actual situations, the present invention proposes a zero-sample model for compound fault diagnosis based on the fault label information vector. The model can identify the category of compound faults by training with only a single fault sample. The experimental results on the experimental data set of the embodiment show that the classification accuracy of the model is significant in the absence of compound fault samples.

附图说明BRIEF DESCRIPTION OF THE DRAWINGS

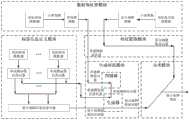

图1为本发明的零样本学习模型的结构图。FIG1 is a structural diagram of a zero-shot learning model of the present invention.

图2为本发明的零样本学习模型的构建流程图。FIG2 is a flowchart of constructing a zero-sample learning model of the present invention.

图3为本实施例的轴承在七个故障状态下的振动信号示意图。FIG3 is a schematic diagram of vibration signals of the bearing of this embodiment under seven fault conditions.

图4为本实施例中基于不同训练样本数量的复合故障分类结果对比图。FIG4 is a comparison diagram of compound fault classification results based on different numbers of training samples in this embodiment.

具体实施方式DETAILED DESCRIPTION

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The following will be combined with the drawings in the embodiments of the present invention to clearly and completely describe the technical solutions in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by ordinary technicians in this field without creative work are within the scope of protection of the present invention.

由图1所示,本发明的一种基于故障标签信息向量的轴承复合故障诊断方法,先利用故障标签信息向量构建零样本模型,再利用零样本模型进行复合故障诊断。As shown in FIG1 , a bearing composite fault diagnosis method based on fault label information vector of the present invention first constructs a zero-sample model using the fault label information vector, and then uses the zero-sample model to perform composite fault diagnosis.

所述零样本模型由如下五个部分组成:数据预处理模块、标签信息定义模块、特征提取模块、生成对抗模块、分类模块。The zero-shot model consists of the following five parts: data preprocessing module, label information definition module, feature extraction module, generative adversarial module, and classification module.

所述数据预处理模块用于将原始故障数据即一维的振动信号通过小波变换转换为二维的小波图像即故障图像;The data preprocessing module is used to convert the original fault data, i.e., the one-dimensional vibration signal, into a two-dimensional wavelet image, i.e., the fault image, through wavelet transformation;

所述标签信息定义模块用于根据原始故障数据构建故障标签信息向量;The label information definition module is used to construct a fault label information vector according to the original fault data;

所述特征提取模块用于对数据预处理模块所转换的故障图像提取故障特征向量;The feature extraction module is used to extract the fault feature vector from the fault image converted by the data preprocessing module;

所述生成对抗模块用于学习故障特征空间与故障标签信息空间之间的映射关系;The generative adversarial module is used to learn the mapping relationship between the fault feature space and the fault label information space;

所述分类模块用于根据故障特征空间与故障标签信息空间之间的映射关系,对故障特征向量进行故障分类;The classification module is used to classify the fault feature vector according to the mapping relationship between the fault feature space and the fault label information space;

所述零样本模型的构建过程如下所示:The construction process of the zero-shot model is as follows:

S1,构建数据预处理模块,所述数据预处理模块用于将原始故障数据φ(t)即一维的振动数据通过小波变换转换为二维的小波图像即故障图像q,具体如下所示:S1, construct a data preprocessing module, which is used to convert the original fault data φ(t), i.e., one-dimensional vibration data, into a two-dimensional wavelet image, i.e., a fault image q, through wavelet transform, as shown below:

从原始故障数据即一维的振动信号中提取有用信息,利用小波变换(WT)方式对振动数据的细节进行分析,小波变换的方式如下式所示:Useful information is extracted from the original fault data, i.e., the one-dimensional vibration signal, and the details of the vibration data are analyzed using the wavelet transform (WT) method. The wavelet transform method is shown in the following formula:

其中,a表示尺度因子,用于小波函数ψ(·)的尺度变换;b表示平移因子,用于小波函数ψ(·)的平移;φ(t)为时域振动信号序列,即原始故障数据;Where a represents the scale factor, which is used for the scale transformation of the wavelet function ψ(·); b represents the translation factor, which is used for the translation of the wavelet function ψ(·); φ(t) is the time domain vibration signal sequence, i.e., the original fault data;

小波函数ψ(·)的定义如下式所示:The definition of the wavelet function ψ(·) is as follows:

本发明利用小波变换将每256个时域数据点转换成64个大小的二维的黑白时频域图像即故障图像,反映振动信号在时域和频域上的特性,小波变换的中间利率为0.8125;The present invention uses wavelet transform to convert every 256 time domain data points into 64 two-dimensional black and white time-frequency domain images, namely fault images, which reflect the characteristics of vibration signals in the time domain and frequency domain. The intermediate rate of wavelet transform is 0.8125.

其中,单故障的原始故障数据即单故障数据φs(t)通过小波变换转换的二维的小波图像即为单故障图像qs;复合故障的原始故障数据即复合故障数据φu(t)通过小波变换转换的二维的小波图像即为复合故障图像qu。The two-dimensional wavelet image of the original fault data of a single fault, i.e., the single fault data φs (t), converted by wavelet transform is the single fault image qs ; the two-dimensional wavelet image of the original fault data of a composite fault, i.e., the composite fault data φu (t), converted by wavelet transform is the composite fault imagequ .

S2,定义零样本模型的训练集Dtrain和测试集Dtest:S2, define the training set Dtrain and test set Dtest of the zero-shot model:

零样本学习模型的训练集Dtrain是由可见的单故障类Cs构建的,包括单故障数据φs(t)、单故障图像qs、单故障标签ys;所述单故障标签ys是指该单故障的故障类别,每个单故障的故障类别即对应为一个单故障标签ys,且每个单故障标签ys对应一个单故障标签信息向量Gs,下标s表示单故障;所述训练集Dtrain即单故障类Cs中含有K个单故障类别,每个单故障类别均含有N个样本,即N个单故障数据φs(t)和N个单故障图像qs;The training set Dtrain of the zero-shot learning model is constructed from the visible single fault class Cs , including single fault data φs (t), single fault image qs , and single fault label ys ; the single fault label ys refers to the fault category of the single fault, and the fault category of each single fault corresponds to a single fault label ys , and each single fault label ys corresponds to a single fault label information vector Gs , and the subscript s represents a single fault; the training set Dtrain, i.e., the single fault class Cs, contains K single fault categories, and each single fault category contains N samples, i.e., N single fault data φs (t) and N single fault images qs ;

零样本学习模型的测试集Dtest是由不可见的复合故障类Cu构建的,包括复合故障数据φu(t)、复合故障图像qu、复合故障标签yu;复合故障是由若干个不同的单故障构成的,所述复合故障标签yu是指该复合故障的故障类别,即该复合故障所包含的单故障类别,且每个复合故障标签yu对应一个复合故障标签信息向量Gu;下标u表示复合故障;The test set Dtest of the zero-shot learning model is constructed by the invisible composite fault class Cu , including composite fault data φu (t), composite fault image qu , and composite fault label yu ; a composite fault is composed of several different single faults, and the composite fault label yu refers to the fault category of the composite fault, that is, the single fault category contained in the composite fault, and each composite fault label yu corresponds to a composite fault label information vector Gu ; the subscript u represents a composite fault;

训练集Dtrain和测试集Dtest满足下式中的条件:The training set Dtrain and the test set Dtest satisfy the following conditions:

其中,p(φs(t))、p(φu(t))分别为单故障数据φs(t)、复合故障数据φu(t)的数据分布;I(·)用于计算两个数据分布之间的互信息,I(p(φs(t))、p(φu(t)))即为数据分布p(φs(t))、p(φu(t))之间的互信息;单故障标签ys和复合故障标签yu为不相交;Gu为复合故障标签信息向量,Gs为单故障标签信息向量,复合故障标签信息向量Gu可通过函数从单故障标签信息向量Gs得到。Where p(φs (t)) and p(φu (t)) are the data distributions of single fault data φs (t) and composite fault data φu (t), respectively. I(·) is used to calculate the mutual information between two data distributions. I(p(φs (t)) and p(φu (t))) are the mutual information between data distributions p(φs (t)) and p(φu (t)). The single fault label ys and the composite fault label yu are disjoint. Gu is the composite fault label information vector, Gs is the single fault label information vector, and the composite fault label information vector Gu can be obtained by the function Obtained from the single fault label information vectorGs .

S3,构建标签信息定义模块,对于故障诊断中的故障标签信息向量,现有的故障标签信息向量的定义方法不能直接使用,本发明中设计了一种新的故障标签信息向量的定义方法,其中,标签信息定义模块先利用单故障的振动信号即单故障数据φs(t)提取单故障属性作为单故障标签信息向量Gs,由于复合故障由不同的单故障构成,因此,标签信息定义模块再根据复合故障所包含的单故障类别,并结合对应的单故障标签信息向量Gs得到复合故障标签信息向量Gu;具体如下所示:S3, construct a label information definition module. For the fault label information vector in fault diagnosis, the existing definition method of the fault label information vector cannot be used directly. The present invention designs a new definition method of the fault label information vector, wherein the label information definition module first uses the vibration signal of the single fault, i.e., the single fault data φs (t), to extract the single fault attribute as the single fault label information vector Gs . Since the composite fault is composed of different single faults, the label information definition module then obtains the composite fault label information vector Gu according to the single fault category contained in the composite fault and in combination with the corresponding single fault label information vector Gs ; specifically as shown below:

S31,标签信息定义模块利用单故障数据φs(t)提取单故障标签信息向量Gs,单故障标签信息向量Gs的维度为C×1;S31, the label information definition module uses the single fault data φs (t) to extract the single fault label information vector Gs , and the dimension of the single fault label information vector Gs is C×1;

其中,第k个单故障类别所对应的单故障标签信息向量即表示第k个单故障类别所对应的单故障标签信息向量中的第c个维度数据,c表示维度的序号,c=1,2,3…C;Among them, the single fault label information vector corresponding to the kth single fault category is Right now Represents the single fault label information vector corresponding to the kth single fault category The c-th dimension data in , where c represents the ordinal number of the dimension, c = 1, 2, 3...C;

针对第k个单故障类别,选取单故障数据中的C个数据点,具体为即表示第k个单故障类别所对应单故障数据中的第c个数据点幅值,上标k表示单故障类别序号,k=1,2,3…K;c表示数据点的序号,c=1,2,3…C,C大于振动信号的周期;下标s表示单故障;For the kth single fault category, select single fault data There are C data points in Right now Represents the single fault data corresponding to the kth single fault category The amplitude of the cth data point in the equation, the superscript k indicates the single fault category number, k = 1, 2, 3 ... K; c indicates the number of the data point, c = 1, 2, 3 ... C, C is greater than the period of the vibration signal; the subscript s indicates a single fault;

从第K个单故障类别所对应单故障数据中的C个数据点中选取最大值作为阈值μ,即From the single fault data corresponding to the Kth single fault category The maximum value among the C data points in is selected as the threshold μ, that is,

根据阈值μ将数据点的幅值范围划分为五等份,判断第k个单故障类别的单故障数据中的各个数据点幅值所在的范围区间,从而得到第k个单故障类别的单故障标签信息向量的中各个维度数据的取值为The amplitude range of the data point is divided into five equal parts according to the threshold μ, and the single fault data of the kth single fault category is determined. The range of the amplitude of each data point in , so as to obtain the single fault label information vector of the kth single fault category Data of each dimension in The value of

通过上述方式,即可得到第k个单故障类别所对应的单故障标签信息向量Through the above method, the single fault label information vector corresponding to the kth single fault category can be obtained:

S32,标签信息定义模块根据复合故障与单故障之间的关联关系,即复合故障是由若干个不同的单故障构成的,结合对应的单故障标签信息向量Gs得到复合故障标签信息向量Gu;复合故障标签信息向量Gu的维度为C×1;S32, the label information definition module obtains a composite fault label information vectorGu according to the association relationship between the composite fault and the single fault, that is, the composite fault is composed of several different single faults, combined with the corresponding single fault label information vectorGs ; the dimension of the composite fault label information vectorGu is C×1;

其中,复合故障标签信息向量Among them, the composite fault label information vector

上标1,…,J是指构成复合故障的单故障的类别序号,J=2,3…,K;The superscript 1, ..., J refers to the category number of the single fault that constitutes the composite fault, J = 2, 3 ..., K;

本实施例中,已知轴承的所有单故障类别,包括内环故障(IF)、滚动体故障(BF)和外环故障(of),对此三种单故障类别进行任意组合,即可得到轴承的所有复合故障类别,得到四种复合故障类别分别为:内圈与滚动体的复合故障(IF&BF)、外圈与滚动体的复合故障(OF&BF)、内圈与外圈的复合故障(IF&OF)、内圈与外圈以及滚动体复合的故障(IF&OF&BF)。In this embodiment, all single fault categories of the bearing are known, including inner ring fault (IF), rolling element fault (BF) and outer ring fault (OF). By arbitrarily combining these three single fault categories, all composite fault categories of the bearing can be obtained, and the four composite fault categories are: composite fault of inner ring and rolling element (IF&BF), composite fault of outer ring and rolling element (OF&BF), composite fault of inner ring and outer ring (IF&OF), and composite fault of inner ring, outer ring and rolling element (IF&OF&BF).

S4,构建特征提取模块,所述特征提取模块用于对故障图像q进行故障特征向量v的提取,具体如下所示:S4, constructing a feature extraction module, wherein the feature extraction module is used to extract a fault feature vector v from the fault image q, as shown below:

利用卷积神经网络(CNN)建立一个特征提取器,对故障图像进行故障特征向量的提取,特征提取器即卷积神经网络的卷积层、池化层、扁平化层和全连接层依次表示为C、P、F、FC,特征提取器的输入层即Input的输入是二维的小波图像即故障图像q,最后一个全连接层的输出即为故障特征向量v;A feature extractor is established using a convolutional neural network (CNN) to extract fault feature vectors from fault images. The feature extractor, i.e., the convolutional layer, pooling layer, flattening layer, and fully connected layer of the convolutional neural network are represented as C, P, F, and FC respectively. The input layer of the feature extractor, i.e., the input of the Input layer, is a two-dimensional wavelet image, i.e., the fault image q. The output of the last fully connected layer is the fault feature vector v.

本发明中,特征提取器的结构和参数如下表1所示:In the present invention, the structure and parameters of the feature extractor are shown in Table 1 below:

表1Table 1

利用训练集Dtrain对特征提取模块进行训练,在特征提取模块训练阶段,特征提取器的输入层输入单故障图像qs,最后一个全连接层的输出单故障特征向量vs,且特征提取器的输出层输出该单故障图像qs的预测故障标签ps;根据该单故障图像qs的实际故障标签ys和预测故障标签ps,计算特征提取模块的分类损失,若分类损失满足要求,则特征提取模块训练完成;The feature extraction module is trained using the training set Dtrain . In the feature extraction module training stage, the input layer of the feature extractor inputs the single fault image qs , the last fully connected layer outputs the single fault feature vectorvs , and the output layer of the feature extractor outputs the predicted fault label ps of the single fault image qs ; the classification loss of the feature extraction module is calculated based on the actual fault label ys and the predicted fault label ps of the single fault image qs . If the classification loss meets the requirements, the feature extraction module training is completed;

针对某个单故障类别,特征提取模块通过优化分类损失函数L1,使得特征提取模块的预测效果更好,分类损失函数L1如下所示:For a single fault category, the feature extraction module optimizes the classification loss function L1 to make the prediction effect of the feature extraction module better. The classification loss function L1 is as follows:

其中,ys(i)是该单故障类别中的第i个单故障图像qs(i)的单故障标签,即单故障类别;i表示单故障图像的序号,i=1,2,3…N;ps(i)是特征提取模块针对该单故障类别中的第i个单故障图像qs(i)所预测的预测故障类别;Wherein,ys (i) is the single fault label of the i-th single fault imageqs (i) in the single fault category, i.e., the single fault category; i represents the sequence number of the single fault image, i=1, 2, 3…N;ps (i) is the predicted fault category predicted by the feature extraction module for the i-th single fault imageqs (i) in the single fault category;

特征提取模块训练阶段,使用反向传播算法对模型参数进行训练,具体使用Adam算法。During the feature extraction module training phase, the model parameters are trained using the back propagation algorithm, specifically the Adam algorithm.

训练完成的特征提取模块对单故障图像qs提取单故障特征向量vs,对复合故障图像qu提取复合故障特征向量vu;The trained feature extraction module extracts a single fault feature vectorvs for the single fault imageqs , and extracts a composite fault feature vectorvu for the composite fault imagequ ;

S5,构建生成对抗模块,所述生成对抗模块包括生成器和判别器;所述生成器用于以故障标签信息向量G和高斯噪声z为条件生成故障特征向量所述判别器用于判别生成的故障特征向量和提取的故障特征向量v之间的差异,从而指导生成器生成高质量的故障特征向量生成器和判别器二者之间相互博弈,生成器生成高质量的故障特征向量让判别器无法判别差异,进而获得稳定的生成器;S5, constructing a generative adversarial module, the generative adversarial module includes a generator and a discriminator; the generator is used to generate a fault feature vector based on the fault label information vector G and Gaussian noise z. The discriminator is used to discriminate the generated fault feature vector The difference between the extracted fault feature vector v and the fault feature vector v is used to guide the generator to generate high-quality fault feature vectors. The generator and the discriminator compete with each other, and the generator generates high-quality fault feature vectors. Make the discriminator unable to distinguish the difference, thereby obtaining a stable generator;

具体如下所示:The details are as follows:

判别器试图让生成的故障特征向量和提取的单故障特征向量v之间的差异LD最大化:The discriminator tries to make the generated fault feature vector The differenceLD between the extracted single fault feature vector v is maximized:

其中,pr为提取的故障特征向量v的数据分布,pg为生成的故障特征向量的数据分布;为生成器的模型表示,用于生成故障特征向量;Dw(·)为判别器的模型表示,用于判别故障特征向量的真假分数,下标w和θ2是生成器和判别器Dw(·)的模型参数;是生成器以故障标签信息向量G和高斯噪声z为条件生成的故障特征向量;v是特征提取器提取的真实故障特征向量。Among them, pr is the data distribution of the extracted fault feature vector v, and pg is the generated fault feature vector Data distribution; is the model representation of the generator, which is used to generate the fault feature vector;Dw (·) is the model representation of the discriminator, which is used to distinguish the true and false scores of the fault feature vector. The subscripts w andθ2 are the generator and the model parameters of the discriminatorDw (·); Is a generator The fault feature vector is generated based on the fault label information vector G and Gaussian noise z; v is the true fault feature vector extracted by the feature extractor.

是指判别特征提取器提取各类故障特征向量所得分数的均值,是指判别生成器生成各类故障特征向量所得分数的均值,用过计算二者之差,使提取的真实的故障特征向量v和生成的故障特征向量尽可能接近,另外,为了确保尽可能接近Dw(v)但不超过Dw(v),本发明还添加了一个稳定梯度的惩罚项,即: It refers to the mean of the scores obtained by the discriminant feature extractor to extract various fault feature vectors. It refers to the mean of the scores of various fault feature vectors generated by the discriminant generator. The difference between the two is calculated to make the extracted real fault feature vector v and the generated fault feature vector As close as possible, in addition, to ensure As close as possible to Dw (v) but not exceeding Dw (v), the present invention also adds a penalty term for stabilizing the gradient, namely:

为从v和中均匀采样得到采样单故障特征向量;表示从数据分布Pr和生成器分布Pg采样的点对之间的直线均匀采样,即采样单故障特征向量的数据分布;表示对采样故障特征向量求导,λ为梯度惩罚系数。 For v and The single fault feature vector is obtained by uniform sampling; Represents the straight line uniform sampling between the point pairs sampled from the data distribution Pr and the generator distribution Pg, that is, sampling the single fault feature vector Data distribution; Represents the sampling fault feature vector Derivative, λ is the gradient penalty coefficient.

本发明中,生成对抗模块的结构如下表2所示:In the present invention, the structure of the generated adversarial module is shown in Table 2 below:

表2Table 2

利用训练集Dtrain对生成对抗模块进行训练,生成器以单故障标签信息向量Gs和高斯噪声z为条件生成单故障特征向量所述判别器用于判别生成的单故障特征向量和提取的单故障特征向量vs之间的差异,从而指导生成器生成高质量的单故障特征向量生成器和判别器二者之间相互博弈,生成器生成高质量的单故障特征向量让判别器无法判别差异,进而获得稳定的生成器,完成生成对抗模块的训练;The training set Dtrain is used to train the generative adversarial module. The generator generates a single fault feature vector based on the single fault label information vector Gs and Gaussian noise z. The discriminator is used to discriminate the generated single fault feature vector The difference between the extracted single fault feature vector vss guides the generator to generate high-quality single fault feature vectors The generator and the discriminator compete with each other, and the generator generates high-quality single-fault feature vectors. Make the discriminator unable to distinguish the difference, thereby obtaining a stable generator and completing the training of the generative adversarial module;

生成对抗模块通过不断优化损失函数L2,获得能够产生高质量单故障特征向量的生成器,损失函数L2如下所示:The generative adversarial module continuously optimizes the loss function L2 to obtain a high-quality single-fault feature vector. The generator of , the loss function L2 is as follows:

其中,pr为提取的单故障特征向量vs的数据分布,pg为生成的单故障特征向量的数据分布;Dw(·)为判别器的模型表示,用于判别故障特征向量的真假分数,下标w是判别器Dw(·)的模型参数;Among them, pr is the data distribution of the extracted single fault feature vectorvs, and pg is the generated single fault feature vector The data distribution of; Dw (·) is the model representation of the discriminator, which is used to discriminate the true and false scores of the fault feature vector, and the subscript w is the model parameter of the discriminator Dw (·);

是生成器以单故障标签信息向量Gs和高斯噪声z为条件生成的故障特征向量,为生成器的模型表示,用于生成故障特征向量,下标θ2是别生成器的模型参数;vs是特征提取器提取的单故障特征向量;。 is the fault feature vector generated by the generator with the single fault label information vectorGs and Gaussian noise z as conditions, is the model representation of the generator, which is used to generate the fault feature vector, and the subscript θ2 is the generator ;vs is the single fault feature vector extracted by the feature extractor;.

为梯度惩罚项,是从vs和中均匀采样得到采样单故障特征向量,表示采样单故障特征向量的数据分布,表示对采样单故障特征向量求导,λ为梯度惩罚系数; is the gradient penalty term, is fromvs and The single fault feature vector is obtained by uniform sampling. Represents the sampled single fault feature vector The data distribution, Represents the sampling single fault feature vector Derivative, λ is the gradient penalty coefficient;

为vs和之间的均方误差;为vs和的范数;|| ||2为范数的表示符号。 for vss and The mean square error between for vss and The norm of ; || ||2 is the symbol representing the norm.

损失函数L2中的第1项和第2项用于解决训练难度大、梯度不稳定的问题,均方误差,用于进一步减小了真实单故障特征向量vs与生成的单故障特征向量之间的距离。The first and second terms in the loss functionL2 are used to solve the problems of high training difficulty and unstable gradient. The mean square error is used to further reduce the difference between the real single fault feature vectorvs and the generated single fault feature vector The distance between.

生成对抗模块训练阶段,使用反向传播算法对模型参数进行训练,具体使用RMSprop算法。During the training phase of the generative adversarial module, the back-propagation algorithm is used to train the model parameters, specifically the RMSprop algorithm.

生成对抗模块训练完成后,所述生成器以各个复合故障标签信息向量Gu和高斯噪声z为条件,生成各个复合故障特征向量After the training of the generative adversarial module is completed, the generator generates each composite fault feature vector based on each composite fault label information vectorGu and Gaussian noise z.

S6,构建分类模块,所述分类模块用于根据故障特征空间与故障标签信息空间之间的映射关系,进行复合故障分类,利用测试集Dtest中的复合故障图像qu进行复合故障诊断测试:S6, construct a classification module, which is used to classify compound faults according to the mapping relationship between the fault feature space and the fault label information space, and perform compound fault diagnosis test using the compound fault image qu in the test set Dtest :

将生成器所生成的各个复合故障特征向量作为复合故障特征空间中的各个中心点,每个中心点均对应一个复合故障类别;Each composite fault feature vector generated by the generator As the center points in the composite fault feature space, each center point corresponds to a composite fault category;

所述分类模块用于计算特征提取模块所提取的复合故障特征向量vu与各个中心点之间的距离,选择与复合故障特征向量vu距离最小的中心点,距离最小的该中心点所对应的复合故障类别即为该复合故障图像vu的预测结果;所述距离是指欧几里得距离;The classification module is used to calculate the distance between the composite fault feature vector vu extracted by the feature extraction module and each center point, and select the center point with the smallest distance from the composite fault feature vector vu . The composite fault category corresponding to the center point with the smallest distance is the prediction result of the composite fault image vu ; the distance refers to the Euclidean distance;

若测试集Dtest中的复合故障图像qu的复合故障标签yu与该复合故障图像vu的诊断结果一致,则表示复合故障诊断正确。If the composite fault labelyu of the composite fault imagequ inthe test set Dtest is consistent with the diagnosis result of the composite fault imagevu , it means that the composite fault diagnosis is correct.

本发明中,利用训练集即单故障集对零样本模型进行训练,利用测试集即复合故障集对零样本模型进行测试,从而验证本发明的零样本模型的复合故障分类的准确性。In the present invention, the zero-sample model is trained using a training set, i.e., a single fault set, and is tested using a test set, i.e., a compound fault set, to verify the accuracy of compound fault classification of the zero-sample model of the present invention.

本实施例中,使用试验台采集故障轴承的振动信号来验证本发明方法的有效性,试验台中,轴承的转速由三相电机通过柔性联轴器控制,在轴承座上安装加速度传感器,采集振动信号,采样频率为51200Hz。In this embodiment, a test bench is used to collect vibration signals of a faulty bearing to verify the effectiveness of the method of the present invention. In the test bench, the rotation speed of the bearing is controlled by a three-phase motor through a flexible coupling, and an acceleration sensor is installed on the bearing seat to collect vibration signals. The sampling frequency is 51200 Hz.

轴承七个故障状态下的振动信号如图3所示。七个故障状态下的振动信号包括:三种单故障的振动信号和四种复合故障的振动信号。三种单故障分别为内环故障(IF)、滚动体故障(BF)、外环故障(OF);四种复合故障分别为:内圈与外圈的复合故障(IF&OF)、内圈与滚动体的复合故障(IF&BF)、外圈与滚动体的复合故障(OF&BF)、内圈与外圈及滚动体的复合故障(IF&OF&BF)。The vibration signals of the bearing under seven fault conditions are shown in Figure 3. The vibration signals under the seven fault conditions include: vibration signals of three single faults and vibration signals of four compound faults. The three single faults are inner ring fault (IF), rolling element fault (BF), and outer ring fault (OF); the four compound faults are: compound fault of inner ring and outer ring (IF&OF), compound fault of inner ring and rolling element (IF&BF), compound fault of outer ring and rolling element (OF&BF), and compound fault of inner ring, outer ring and rolling element (IF&OF&BF).

通过对两组复合故障诊断任务的实验验证了该模型的有效性,具体情况如表3所示,不同训练样本数量的故障分类结果如图4所示,随着训练样本数量的增加,任务A和任务B的分类准确率都有明显提高,当每个单故障类别的训练样本数量为2000时,任务A和任务B的分类平均准确率分别达到77.03%和65.80%。此外,可以观察到任务A的分类精度要高于任务B,原因是任务B与任务A相比,任务B更加复杂和难以分类,任务B多包含一个由三种单故障耦合的复合故障,即多包含了内圈与外圈及滚动体的复合故障数据。The effectiveness of the model was verified by experiments on two groups of composite fault diagnosis tasks. The specific situation is shown in Table 3. The fault classification results with different numbers of training samples are shown in Figure 4. With the increase of the number of training samples, the classification accuracy of Task A and Task B has been significantly improved. When the number of training samples for each single fault category is 2000, the average classification accuracy of Task A and Task B reaches 77.03% and 65.80% respectively. In addition, it can be observed that the classification accuracy of Task A is higher than that of Task B. The reason is that Task B is more complex and difficult to classify than Task A. Task B contains a composite fault coupled by three single faults, that is, it contains composite fault data of the inner ring, outer ring and rolling element.

表3Table 3

本发明针对实际情况下有标记或无标记的复合故障训练数据难以采集的问题,提出了一种基于故障标签信息向量生成的用于复合故障诊断的零样本模型,该模型通过仅需使用单故障样本进行训练,即可识别复合故障类别。本发明设计了一种统一的故障标签信息向量定义方法,来表示单故障和复合故障的故障标签信息向量。本发明的生成对抗模块学习故障特征空间与故障标签信息空间之间的映射关系,然后由生成器通过故障标签信息向量生成故障特征向量。该模型根据真实的故障标签信息向量与生成的故障标签信息向量之间的相似性度量,对复合故障进行分类,在上述实施例的实验数据集上的实验结果表明,该模型在没有复合故障样本的情况下,分类精度显著。In view of the problem that it is difficult to collect labeled or unlabeled compound fault training data in actual situations, the present invention proposes a zero-sample model for compound fault diagnosis based on fault label information vector generation, which can identify compound fault categories by only using single fault samples for training. The present invention designs a unified fault label information vector definition method to represent the fault label information vectors of single faults and compound faults. The generative adversarial module of the present invention learns the mapping relationship between the fault feature space and the fault label information space, and then the generator generates a fault feature vector through the fault label information vector. The model classifies compound faults based on the similarity measure between the real fault label information vector and the generated fault label information vector. The experimental results on the experimental data set of the above embodiment show that the classification accuracy of the model is significant in the absence of compound fault samples.

本发明利用上述零样本学习模型进行轴承复合故障诊断,其方法如下所示:The present invention utilizes the above zero-sample learning model to perform bearing composite fault diagnosis, and the method is as follows:

S201,已知轴承的所有单故障类别,复合故障是由若干个不同的单故障构成的,根据轴承的单故障类别进行组合即可得到所有的复合故障类别;S201, all single fault categories of the bearing are known. A composite fault is composed of several different single faults. All composite fault categories can be obtained by combining the single fault categories of the bearing;

S202,标签向量定义模块先利用单故障的振动信号即单故障数据φs(t)提取单故障属性作为单故障标签信息向量Gs,由于复合故障由不同的单故障构成,因此,标签信息定义模块再根据复合故障所包含的单故障类别,并结合对应的单故障标签信息向量Gs得到复合故障标签信息向量Gu;具体参考步骤S3;S202, the label vector definition module first uses the vibration signal of the single fault, that is, the single fault data φs (t), to extract the single fault attribute as the single fault label information vector Gs . Since the composite fault is composed of different single faults, the label information definition module then obtains the composite fault label information vector Gu according to the single fault category included in the composite fault and the corresponding single fault label information vector Gs ; refer to step S3 for details;

S203,生成对抗模块中的生成器将步骤S202所得到的各个复合故障标签信息向量Gu分别映射到故障特征空间,即生成器分别以步骤S202得到的各个复合故障标签信息向量Gu和高斯噪声z为条件生成各个复合故障特征向量将生成器所生成的各个复合故障特征向量作为复合故障特征空间中的各个中心点,每个中心点对应一个复合故障标签信息向量Gu,且每个复合故障标签信息向量Gu的复合故障类别均为已知,即相当于每个中心点均对应一个复合故障类别;S203, the generator in the generative adversarial module maps each composite fault label information vectorGu obtained in step S202 to the fault feature space, that is, the generator generates each composite fault feature vectorGu obtained in step S202 and Gaussian noise z as conditions. Each composite fault feature vector generated by the generator As each center point in the composite fault feature space, each center point corresponds to a composite fault label information vectorGu , and the composite fault category of each composite fault label information vectorGu is known, that is, each center point corresponds to a composite fault category;

S204,特征提取模块对待预测的复合故障图像qu提取复合故障特征向量vu;S204, a feature extraction module extracts a composite fault feature vector vu from the composite fault image qu to be predicted;

S205,计算所提取的复合故障特征向量vu与复合故障特征空间中的各个中心点之间的距离,选择与复合故障特征向量vu距离最小的中心点,距离最小的该中心点所对应的复合故障类别即为该复合故障图像qu的预测结果。S205, calculate the distance between the extracted composite fault feature vectorvu and each center point in the composite fault feature space, select the center point with the smallest distance to the composite fault feature vectorvu , and the composite fault category corresponding to the center point with the smallest distance is the prediction result of the composite fault imagequ .

以上仅为本发明创造的较佳实施例而已,并不用以限制本发明创造,凡在本发明创造的精神和原则之内所作的任何修改、等同替换和改进等,均应包含在本发明创造的保护范围之内。The above are only preferred embodiments of the present invention and are not intended to limit the present invention. Any modifications, equivalent substitutions and improvements made within the spirit and principles of the present invention should be included in the protection scope of the present invention.

除非特别说明,本发明文本中的以前后顺序出现的各个流程并不必然存在先后的执行顺序。尽管参照前述实施例对本发明进行了详细的说明,本领域的普通技术人员应当理解:其依然可以对前述各实施例所记载的技术方案进行修改,或者对其中部分技术特征进行等同替换;而这些修改或者替换,并不使相应技术方案的本质脱离本发明各实施例技术方案的精神和范围。Unless otherwise specified, the various processes in the text of the present invention that appear in a sequential order do not necessarily have a sequential execution order. Although the present invention has been described in detail with reference to the aforementioned embodiments, a person of ordinary skill in the art should understand that the technical solutions described in the aforementioned embodiments can still be modified, or some of the technical features thereof can be replaced by equivalents; and these modifications or replacements do not deviate the essence of the corresponding technical solutions from the spirit and scope of the technical solutions of the embodiments of the present invention.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210010510.1ACN114383846B (en) | 2022-01-06 | 2022-01-06 | Bearing composite fault diagnosis method based on fault label information vector |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210010510.1ACN114383846B (en) | 2022-01-06 | 2022-01-06 | Bearing composite fault diagnosis method based on fault label information vector |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114383846A CN114383846A (en) | 2022-04-22 |

| CN114383846Btrue CN114383846B (en) | 2023-06-30 |

Family

ID=81199358

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210010510.1AActiveCN114383846B (en) | 2022-01-06 | 2022-01-06 | Bearing composite fault diagnosis method based on fault label information vector |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114383846B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN118427672B (en)* | 2024-07-04 | 2024-11-08 | 广东技术师范大学 | Generalized zero sample bearing composite fault diagnosis method based on multi-label learning |

| CN119272054B (en)* | 2024-10-25 | 2025-09-19 | 天津大学 | Rolling bearing compound fault diagnosis method, device, equipment and storage medium |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109655259A (en)* | 2018-11-23 | 2019-04-19 | 华南理工大学 | Combined failure diagnostic method and device based on depth decoupling convolutional neural networks |

| CN110823574A (en)* | 2019-09-30 | 2020-02-21 | 安徽富煌科技股份有限公司 | A Fault Diagnosis Method Based on Semi-Supervised Learning Deep Adversarial Networks |

| WO2021135630A1 (en)* | 2019-12-31 | 2021-07-08 | 福州大学 | Rolling bearing fault diagnosis method based on grcmse and manifold learning |

| CN113177584A (en)* | 2021-04-19 | 2021-07-27 | 合肥工业大学 | Zero sample learning-based composite fault diagnosis method |

- 2022

- 2022-01-06CNCN202210010510.1Apatent/CN114383846B/enactiveActive

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN109655259A (en)* | 2018-11-23 | 2019-04-19 | 华南理工大学 | Combined failure diagnostic method and device based on depth decoupling convolutional neural networks |

| CN110823574A (en)* | 2019-09-30 | 2020-02-21 | 安徽富煌科技股份有限公司 | A Fault Diagnosis Method Based on Semi-Supervised Learning Deep Adversarial Networks |

| WO2021135630A1 (en)* | 2019-12-31 | 2021-07-08 | 福州大学 | Rolling bearing fault diagnosis method based on grcmse and manifold learning |

| CN113177584A (en)* | 2021-04-19 | 2021-07-27 | 合肥工业大学 | Zero sample learning-based composite fault diagnosis method |

Non-Patent Citations (1)

| Title |

|---|

| 基于多任务深度学习的齿轮箱多故障诊断方法;赵晓平;吴家新;钱承山;张永宏;王丽华;;振动与冲击(第23期);全文* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114383846A (en) | 2022-04-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Li et al. | WavCapsNet: An interpretable intelligent compound fault diagnosis method by backward tracking | |

| CN112763214B (en) | Fault diagnosis method of rolling bearing based on multi-label zero-sample learning | |

| CN113869208B (en) | Rolling bearing fault diagnosis method based on SA-ACWGAN-GP | |

| CN110823574A (en) | A Fault Diagnosis Method Based on Semi-Supervised Learning Deep Adversarial Networks | |

| CN112304614A (en) | End-to-end rolling bearing intelligent fault diagnosis method adopting multi-attention machine system | |

| CN108256556A (en) | Wind-driven generator group wheel box method for diagnosing faults based on depth belief network | |

| CN114383846B (en) | Bearing composite fault diagnosis method based on fault label information vector | |

| CN115563553A (en) | Aviation bearing fault diagnosis method of deep migration map convolution network under fluctuation working condition | |

| CN115753103A (en) | Fault diagnosis method and system based on standard self-learning data enhancement | |

| CN113158984A (en) | Bearing fault diagnosis method based on complex Morlet wavelet and lightweight convolution network | |

| CN113705407A (en) | Time-frequency residual error neural network-based fault diagnosis method for shaft cracks under variable rotating speed | |

| CN114441173A (en) | Rolling bearing fault diagnosis method based on improved deep residual shrinkage network | |

| CN112418175A (en) | Fault diagnosis method, system and storage medium for rolling bearing based on domain migration | |

| CN114383845B (en) | Bearing composite fault diagnosis method based on embedded zero sample learning model | |

| CN113758709A (en) | Rolling bearing fault diagnosis method and system combining edge computing and deep learning | |

| CN119128690A (en) | Bearing fault diagnosis method based on parallel multi-fusion deep learning network model | |

| CN114491823A (en) | Train bearing fault diagnosis method based on improved generation countermeasure network | |

| CN118427610A (en) | GAN data enhanced chain drive bearing fault diagnosis method | |

| CN113505817B (en) | Sample adaptive weighted training method for bearing fault diagnosis model under unbalanced data | |

| CN118427672B (en) | Generalized zero sample bearing composite fault diagnosis method based on multi-label learning | |

| CN115130514A (en) | Construction method and system for health index of engineering equipment | |

| CN119441885A (en) | A method for constructing a generalized fault diagnosis model in a single-source domain under time-varying conditions and its application | |

| Yan et al. | Fault diagnosis of rolling bearing with small samples based on wavelet packet theory and random forest | |

| Hao et al. | New fusion features convolutional neural network with high generalization ability on rolling bearing fault diagnosis | |

| CN115452380A (en) | Bearing fault diagnosis method based on migration component analysis under multi-feature fusion |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |