CN114373935A - Negative electrode binder for lithium battery, negative electrode, and lithium battery - Google Patents

Negative electrode binder for lithium battery, negative electrode, and lithium batteryDownload PDFInfo

- Publication number

- CN114373935A CN114373935ACN202210112703.8ACN202210112703ACN114373935ACN 114373935 ACN114373935 ACN 114373935ACN 202210112703 ACN202210112703 ACN 202210112703ACN 114373935 ACN114373935 ACN 114373935A

- Authority

- CN

- China

- Prior art keywords

- negative electrode

- lithium battery

- block

- flexible

- rigid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/62—Selection of inactive substances as ingredients for active masses, e.g. binders, fillers

- H01M4/621—Binders

- H01M4/622—Binders being polymers

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/05—Accumulators with non-aqueous electrolyte

- H01M10/052—Li-accumulators

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M4/13—Electrodes for accumulators with non-aqueous electrolyte, e.g. for lithium-accumulators; Processes of manufacture thereof

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/02—Electrodes composed of, or comprising, active material

- H01M2004/026—Electrodes composed of, or comprising, active material characterised by the polarity

- H01M2004/027—Negative electrodes

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/10—Energy storage using batteries

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Electrochemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Manufacturing & Machinery (AREA)

- Materials Engineering (AREA)

- Battery Electrode And Active Subsutance (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及锂电池负极技术领域,特别涉及一种锂电池负极粘合剂、负极和锂电池。The invention relates to the technical field of lithium battery negative electrodes, in particular to a lithium battery negative electrode binder, a negative electrode and a lithium battery.

背景技术Background technique

作为最常用的锂电池负极粘合剂材料,CMC-SBR水性复合体系粘合剂已在过去的数十年里得到了长足的研究,但与此同时,这一体系的性能也已触达上限,几乎无法进一步突破,因此难以满足锂电池各项性能快速发展的需要。CMC-SBR粘合剂的主要缺陷在于粘接能力不足,对活性物质的分散、粘接性差,且该粘合剂整体韧性差,机械强度不高,干燥后的胶膜易脆断;因而导致:(1)极片的剥离强度不高,易掉粉;(2)极片耐开裂性不佳,当极片的涂覆厚度增加时,易在干燥过程中开裂;(3)浆料稳定性差,易沉降。As the most commonly used negative electrode binder material for lithium batteries, CMC-SBR water-based composite system binder has been extensively studied in the past few decades, but at the same time, the performance of this system has also reached the upper limit , it is almost impossible to make further breakthroughs, so it is difficult to meet the needs of the rapid development of various properties of lithium batteries. The main defects of CMC-SBR adhesives are insufficient adhesion, poor dispersion and adhesion to active substances, and the overall toughness of the adhesive is poor, the mechanical strength is not high, and the dried film is easily brittle; thus resulting in : (1) The peel strength of the pole piece is not high, and the powder is easy to fall off; (2) The crack resistance of the pole piece is not good. When the coating thickness of the pole piece increases, it is easy to crack during the drying process; (3) The slurry is stable Poor sex, easy to settle.

为克服上述缺陷,近年来,人们提出了多种替代CMC-SBR体系的方案,如聚丙烯酸体系、聚丙烯腈体系、聚乙烯醇体系、聚酰亚胺体系等,均在锂电池负极粘合剂领域得到了广泛而充分的研究。然而这些体系虽然能够提升负极的某些性能,但同时也引入了新的问题,例如聚丙烯酸体系和聚丙烯腈体系刚性过强、聚乙烯醇体系热性能和力学性能不佳、聚酰亚胺体系工艺复杂等,尚难以广泛应用,因此目前负极粘合剂领域,仍以CMC-SBR体系为主流。In order to overcome the above defects, in recent years, people have proposed a variety of alternatives to CMC-SBR systems, such as polyacrylic acid system, polyacrylonitrile system, polyvinyl alcohol system, polyimide system, etc., all of which are bonded to the negative electrode of lithium batteries. The field of pharmaceuticals has been extensively and well researched. However, although these systems can improve some properties of the negative electrode, they also introduce new problems, such as excessive rigidity of polyacrylic acid system and polyacrylonitrile system, poor thermal and mechanical properties of polyvinyl alcohol system, polyimide The complex process of the system makes it difficult to be widely used. Therefore, the CMC-SBR system is still the mainstream in the field of negative electrode binders.

发明内容SUMMARY OF THE INVENTION

本发明提供了一种锂电池负极粘合剂、负极和锂电池,以解决现有技术中负极极片剥离强度不高、耐开裂性不佳、负极浆料稳定性差的技术问题。The invention provides a lithium battery negative electrode binder, a negative electrode and a lithium battery, so as to solve the technical problems of low peeling strength of negative electrode pole pieces, poor cracking resistance and poor stability of negative electrode slurry in the prior art.

为达到上述目的,本发明的技术方案是这样实现的:In order to achieve the above object, the technical scheme of the present invention is achieved in this way:

本发明提供了一种锂电池负极粘合剂,包括嵌段共聚物,所述嵌段共聚物包括刚性嵌段A和柔性嵌段B,其结构为其中,n、m均为正整数,且n≤m;所述刚性嵌段A为网状交联结构,所述柔性嵌段B为线性结构,所述嵌段共聚物的分子量为104~107。The present invention provides a lithium battery negative electrode binder, comprising a block copolymer, wherein the block copolymer comprises a rigid block A and a flexible block B, and its structure is Wherein, n and m are both positive integers, and n≤m; the rigid block A is a network cross-linked structure, the flexible block B is a linear structure, and the molecular weight of the block copolymer is 104 - 107 .

进一步地,每个所述刚性嵌段A与一个或多个所述柔性嵌段B相连,和/或,每个所述刚性嵌段A与一个或多个所述刚性嵌段A相连;每个所述柔性嵌段B与一个或多个所述刚性嵌段A相连,和/或,每个所述柔性嵌段B与一个或多个所述柔性嵌段B相连。Further, each of the rigid blocks A is connected with one or more of the flexible blocks B, and/or, each of the rigid blocks A is connected with one or more of the rigid blocks A; each Each of the flexible blocks B is connected to one or more of the rigid blocks A, and/or each of the flexible blocks B is connected to one or more of the flexible blocks B.

进一步地,1≤n≤103,10≤m≤104。Further, 1≤n≤103 , 10≤m≤104 .

进一步地,所述刚性嵌段A的结构式为:Further, the structural formula of the rigid block A is:

其中,a、b、c、d分别为1~5之间的整数;R1、R2、R3、R4分别包括一环状结构,所述环状结构包括烃基与第一基团,所述第一基团包括羰基、酯键、酰胺键、醚键中的一种或多种基团。Wherein, a, b, c, and d are integers between 1 and 5, respectively; R1 , R2 , R3 , and R4 respectively include a cyclic structure, and the cyclic structure includes a hydrocarbon group and a first group, The first group includes one or more groups of carbonyl, ester bond, amide bond, and ether bond.

进一步地,所述柔性嵌段B的结构式为:Further, the structural formula of the flexible block B is:

其中,R5包括羟基、羧基、酯键、酰胺键、醚键中的一种或多种基团;R6、R7分别包括一线性结构,所述线性结构包括烃基和第二基团,所述第二基团包括羰基、酯键、酰胺键、腈基、醚键中的一种或多种基团。Wherein, R5 includes one or more groups in hydroxyl, carboxyl, ester bond, amide bond, ether bond; R6 and R7 respectively include a linear structure, and the linear structure includes a hydrocarbon group and a second group, The second group includes one or more groups of carbonyl group, ester bond, amide bond, nitrile group and ether bond.

根据本发明的第二方面,还提供了一种锂电池负极,包括涂覆有负极浆料的极片,所述负极浆料的原料包括上述的锂电池负极粘合剂。According to a second aspect of the present invention, a lithium battery negative electrode is also provided, comprising a pole piece coated with a negative electrode slurry, and the raw material of the negative electrode slurry includes the above-mentioned lithium battery negative electrode binder.

根据本发明的第三方面,还提供了一种锂电池,所述锂电池包括上述的锂电池负极。According to a third aspect of the present invention, there is also provided a lithium battery, the lithium battery comprising the above-mentioned negative electrode of the lithium battery.

本发明提供的锂电池负极粘合剂,通过分子链结构设计,将刚性且富含极性基团的网状交联结构与柔性的长链线性基团通过化学键连接,并使其有效排列,得到了一种“刚柔并济”的锂电池负极粘合剂;其中,刚性结构一方面赋予粘合剂较高的力学强度,另一方面其极性基团对极片中的活性物质具有较强的作用力,再一方面该结构的立体网状形态使之能够有效地“托举”活性物质粉末;柔性结构则赋予粘合剂良好的柔韧性,使之不易脆断。因而,使用本发明锂电池负极粘合剂制备锂电池负极时,一方面有利于制备高固含量且不易沉降的负极浆料,另一方面制得的负极极片剥离强度高,且烘烤、弯折时不易开裂。因此,该粘合剂能够有效提升锂电池的能量密度。The lithium battery negative electrode binder provided by the present invention connects the rigid and polar group-rich network cross-linked structure with the flexible long-chain linear groups through chemical bonds through the molecular chain structure design, and makes them effectively arranged, A "rigid and flexible" negative electrode binder for lithium batteries is obtained; on the one hand, the rigid structure endows the binder with high mechanical strength, and on the other hand, its polar groups have a positive effect on the active material in the pole piece. On the other hand, the three-dimensional network shape of the structure enables it to effectively "lift" the active substance powder; the flexible structure gives the adhesive good flexibility, making it not easy to break. Therefore, when using the lithium battery negative electrode binder of the present invention to prepare a lithium battery negative electrode, on the one hand, it is beneficial to prepare a negative electrode slurry with a high solid content and is not easy to settle; Not easy to crack when bent. Therefore, the binder can effectively improve the energy density of lithium batteries.

附图说明Description of drawings

图1为本发明实施例提供的锂电池负极粘合剂分子链“网-线结构”设计概念图;FIG. 1 is a conceptual diagram of the design of the “net-wire structure” of the molecular chain of the negative electrode binder of a lithium battery provided by an embodiment of the present invention;

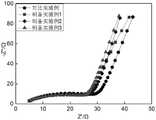

图2为实施例1~3的锂电池负极粘合剂、对比例CMC-SBR粘合剂所制作的电池的EIS曲线;Fig. 2 is the EIS curve of the battery made by the lithium battery negative electrode binder of Examples 1-3 and the comparative example CMC-SBR binder;

图3为实施例1负极粘合剂的分子量分布曲线;Fig. 3 is the molecular weight distribution curve of the negative electrode binder of Example 1;

图4为实施例1负极粘合剂的DSC曲线;Fig. 4 is the DSC curve of the negative electrode binder of Example 1;

图5为实施例1负极粘合剂的TGA曲线。5 is the TGA curve of the negative electrode binder in Example 1.

具体实施方式Detailed ways

应用广泛的锂电池负极粘合剂材料即CMC-SBR水性复合体系粘合剂,存在负极极片剥离强度不高、耐开裂性不佳、负极浆料稳定性差的技术问题。经研究发现,CMC-SBR是一种简单的共混结构,两种组分的分子链之间仅存在相互穿插,并未形成有效结合与排列,因此难以有效发挥两种组分各自的优势,即SBR本身良好的柔韧性及CMC的极性基团对极片活性物质的作用力均未得到充分的发挥,因而在宏观上,CMC-SBR复合粘合剂的胶膜表现出质地硬而脆、力学强度低、粘接力不佳等特性。The widely used negative electrode binder material for lithium batteries, namely the CMC-SBR water-based composite system binder, has the technical problems of low peel strength of negative electrode pieces, poor crack resistance, and poor stability of negative electrode slurry. The research found that CMC-SBR is a simple blend structure, the molecular chains of the two components only interpenetrate each other, and no effective combination and arrangement are formed, so it is difficult to effectively play the respective advantages of the two components. That is to say, the good flexibility of SBR itself and the force of the polar groups of CMC on the active material of the pole pieces have not been fully exerted, so macroscopically, the film of the CMC-SBR composite adhesive shows a hard and brittle texture. , low mechanical strength, poor adhesion and other characteristics.

本申请实施例的第一方面,提供了一种锂电池负极粘合剂,包括嵌段共聚物,嵌段共聚物包括刚性嵌段A和柔性嵌段B,其结构为其中,n、m均为正整数,且n≤m;刚性嵌段A形成网状交联结构,柔性嵌段B形成线性结构,嵌段共聚物的分子量为104~107。The first aspect of the embodiments of the present application provides a lithium battery negative electrode binder, which includes a block copolymer, and the block copolymer includes a rigid block A and a flexible block B, and its structure is Wherein, n and m are both positive integers, and n≤m; the rigid block A forms a network cross-linked structure, the flexible block B forms a linear structure, and the molecular weight of the block copolymer is 104 -107 .

本申请通过研究,设计了一种分子链为“网-线结构”的负极粘合剂,设计概念图参照图1。其中,“网”部分为富含极性基团的交联结构,代表刚性嵌段A,“线”部分为线性长链结构,代表柔性嵌段B,“网”和“线”通过化学键连接,最终得到一个如同多个“蜘蛛网”相互连接形成的立体分子结构。图1仅用于示意分子链结构的设计概念,并非用于表示特定构型的分子链。Through research in this application, a negative electrode binder with a molecular chain of "net-wire structure" has been designed, and the conceptual diagram of the design is shown in FIG. 1 . Among them, the "net" part is a cross-linked structure rich in polar groups, representing rigid block A, the "wire" part is a linear long-chain structure, representing flexible block B, and the "net" and "wire" are connected by chemical bonds , and finally get a three-dimensional molecular structure formed by interconnecting multiple "spider webs". Figure 1 is only used to illustrate the design concept of the molecular chain structure, and is not used to represent the molecular chain of a specific configuration.

本申请实施例通过分子结构设计,得到了一种以富含极性基团的网状交联结构和柔性的长链线性结构为主体的嵌段共聚物,两种结构通过化学键连接,且有效排列,使两者的性能优势得到充分发挥,兼具高粘接强度、高力学强度和高韧性等特点。本申请实施例的锂电池负极粘合剂非常适合负极极片厚涂覆的情形。Through molecular structure design in the examples of the present application, a block copolymer is obtained which is mainly composed of a network cross-linked structure rich in polar groups and a flexible long-chain linear structure. The two structures are connected by chemical bonds, and effectively Arrangement, the performance advantages of the two can be fully exerted, and they have the characteristics of high bonding strength, high mechanical strength and high toughness. The lithium battery negative electrode binder of the embodiments of the present application is very suitable for the situation of thick coating of the negative electrode pole piece.

本申请实施例提供的锂电池负极粘合剂,通过分子链结构设计,将刚性且富含极性基团的网状交联结构与柔性的长链线性基团通过化学键连接,并使其有效排列,得到了一种“刚柔并济”的锂电池负极粘合剂;其中,刚性结构一方面赋予粘合剂较高的力学强度,另一方面其极性基团对极片中的活性物质具有较强的作用力,再一方面该结构的立体网状形态使之能够有效地“托举”活性物质粉末;柔性结构则赋予粘合剂良好的柔韧性,使之不易脆断。因而,使用本申请实施例的锂电池负极粘合剂制备锂电池负极时,一方面有利于制备高固含量且不易沉降的负极浆料,另一方面制得的负极极片剥离强度高,且烘烤、弯折时不易开裂。因此,该粘合剂能够有效提升锂电池的能量密度。The negative electrode binder for lithium batteries provided in the examples of this application, through the design of the molecular chain structure, connects the rigid and polar group-rich network cross-linked structure with the flexible long-chain linear groups through chemical bonds, and makes it effective Arranged to obtain a "rigid and flexible" negative electrode binder for lithium batteries; on the one hand, the rigid structure endows the binder with high mechanical strength, and on the other hand, its polar groups affect the activity of the pole pieces. The substance has a strong force. On the other hand, the three-dimensional network shape of the structure enables it to effectively "lift" the active substance powder; the flexible structure gives the adhesive good flexibility, making it not easy to break. Therefore, when using the lithium battery negative electrode binder of the embodiment of the present application to prepare a lithium battery negative electrode, on the one hand, it is beneficial to prepare a negative electrode slurry with high solid content and is not easy to settle, on the other hand, the obtained negative electrode pole piece has high peeling strength, and It is not easy to crack when baking and bending. Therefore, the binder can effectively improve the energy density of lithium batteries.

一些实施例中,每个刚性嵌段A与一个或多个柔性嵌段B相连,和/或,每个刚性嵌段A与一个或多个刚性嵌段A相连;每个柔性嵌段B与一个或多个刚性嵌段A相连,和/或,每个柔性嵌段B与一个或多个柔性嵌段B相连。一些实施例中,1≤n≤103,10≤m≤104。In some embodiments, each rigid block A is connected to one or more flexible blocks B, and/or, each rigid block A is connected to one or more rigid blocks A; each flexible block B is connected to One or more rigid blocks A are attached, and/or each flexible block B is attached to one or more flexible blocks B. In some embodiments, 1≤n≤103 and 10≤m≤104 .

可以理解地,刚性嵌段A与柔性嵌段B通过化学键连接,作为非限定的实例,可以通过碳碳单键、醚键、酰胺键、酯键中的一种或多种方式。It can be understood that the rigid block A and the flexible block B are connected by chemical bonds, as non-limiting examples, one or more of carbon-carbon single bonds, ether bonds, amide bonds, and ester bonds can be used.

一些实施例中,刚性嵌段A的结构式为:In some embodiments, the structural formula of rigid block A is:

其中,a、b、c、d分别为1~5之间的整数;R1、R2、R3、R4分别包括一环状结构,环状结构包括烃基与第一基团,第一基团包括羰基、酯键、酰胺键、醚键中的一种或多种基团。其中,R1、R2、R3、R4之间有化学键连接或者没有化学键连接,为便于理解,在结构式中用虚线表示;作为非限定性的实例,当R1、R2、R3、R4之间有化学键相连时,化学键可以是碳碳单键、醚键、酰胺键、酯键中的一种或多种。Wherein, a, b, c, and d are integers between 1 and 5 respectively; R1 , R2 , R3 , and R4 respectively include a cyclic structure, and the cyclic structure includes a hydrocarbon group and a first group, and the first The group includes one or more of carbonyl, ester bond, amide bond, ether bond. Wherein, R1 , R2 , R3 , and R4 are connected by chemical bonds or without chemical bonds, and are represented by dotted lines in the structural formula for ease of understanding; as a non-limiting example, when R1 , R2 , R3 When there is a chemical bond between , R4, the chemical bond can be one or more of carbon- carbon single bond, ether bond, amide bond, ester bond.

一些实施例中,柔性嵌段B的结构式为:In some embodiments, the structural formula of flexible block B is:

其中,R5包括羟基、羧基、酯键、酰胺键、醚键中的一种或多种基团;R6、R7分别包括一线性结构,线性结构包括烃基和第二基团,第二基团包括羰基、酯键、酰胺键、腈基、醚键中的一种或多种基团。Wherein, R5 includes one or more groups in hydroxyl, carboxyl, ester bond, amide bond, ether bond; R6 , R7 respectively include a linear structure, the linear structure includes a hydrocarbon group and a second group, the second The group includes one or more of carbonyl group, ester bond, amide bond, nitrile group and ether bond.

为便于理解,这里需要进行非限定性说明的是,上述的基团的具体结构如表1所示。For ease of understanding, it is necessary to make a non-limiting description here that the specific structures of the above-mentioned groups are shown in Table 1.

表1基团的具体结构说明The specific structure description of the group in Table 1

可以理解地,刚性嵌段A与柔性嵌段B通过化学键连接,化学键一端连接基团R1、R2、R3、R4中的任意一个,另一端则连接R6、R7中的任意一个。为便于理解,提供以下结构式以展示一种刚性嵌段A与柔性嵌段B非限定性的连接方式实例,其中p、q均为正整数。It can be understood that the rigid block A and the flexible block B are connected by a chemical bond, one end of the chemical bond is connected to any one of the groups R1 , R2 , R3 and R4 , and the other end is connected to any one of R6 and R7 . One. For ease of understanding, the following structural formula is provided to illustrate a non-limiting example of the connection manner of rigid block A and flexible block B, wherein p and q are both positive integers.

显而易见的是,以上结构仅展示了一个刚性嵌段A和一个柔性嵌段B的连接。本领域技术人员不难发现,在其他实施例中,每个刚性嵌段A都可以和一个或多个柔性嵌段B相连,和/或,每个刚性嵌段A与一个或多个刚性嵌段A相连。而每个柔性嵌段B都可以和一个或多个刚性嵌段A相连,和/或,每个柔性嵌段B与一个或多个柔性嵌段B相连。为有效形成上述的“网-线结构”,显然,分子链中刚性嵌段A的数量n不会多于柔性嵌段B的数量m,即n≤m。It is obvious that the above structure only shows the connection of one rigid block A and one flexible block B. Those skilled in the art can easily find that, in other embodiments, each rigid block A may be connected with one or more flexible blocks B, and/or each rigid block A may be connected with one or more rigid blocks Section A is connected. And each flexible block B can be connected with one or more rigid blocks A, and/or each flexible block B can be connected with one or more flexible blocks B. In order to effectively form the above-mentioned "net-wire structure", obviously, the number n of rigid blocks A in the molecular chain should not be more than the number m of flexible blocks B, that is, n≤m.

本申请实施例的锂电池负极粘合剂的制备方法,以制备上述的锂电池负极粘合剂,包括以下步骤:将原料A与原料B通过自由基聚合的方式,原料A包括刚性嵌段A,原料B包括柔性嵌段B,选择间歇法或者半连续法进行聚合反应,即可得到锂电池负极粘合剂。The preparation method of the lithium battery negative electrode binder according to the embodiment of the present application, in order to prepare the above-mentioned lithium battery negative electrode binder, includes the following steps: the raw material A and the raw material B are subjected to radical polymerization, and the raw material A includes a rigid block A. , the raw material B includes the flexible block B, and the batch method or the semi-continuous method is selected to carry out the polymerization reaction, and the negative electrode binder of the lithium battery can be obtained.

本申请实施例的第二方面,还提供了一种锂电池负极,包括涂覆有负极浆料的极片,负极浆料的原料包括上述的锂电池负极粘合剂。In a second aspect of the embodiments of the present application, a lithium battery negative electrode is further provided, including a pole piece coated with a negative electrode slurry, and the raw material of the negative electrode slurry includes the above-mentioned lithium battery negative electrode binder.

具体地,作为非限定性实例,上述锂电池负极极片的制备方法为:将活性物质、溶剂、助剂及上述的锂电池负极粘合剂混合,得到负极浆料;将负极浆料涂覆在集流体上;将涂覆有负极浆料的集流体烘干,即可得到负极极片。其中,活性物质包括石墨、硅碳、纯硅中的一种或多种。溶剂包括水和/或有机溶剂。助剂包括分散剂、增稠剂、润湿剂、导电剂、消泡剂中的一种或多种。Specifically, as a non-limiting example, the preparation method of the above-mentioned lithium battery negative pole piece is as follows: mixing active materials, solvents, additives and the above-mentioned lithium battery negative electrode binder to obtain a negative electrode slurry; coating the negative electrode slurry On the current collector; drying the current collector coated with the negative electrode slurry, the negative electrode pole piece can be obtained. Wherein, the active material includes one or more of graphite, silicon carbon, and pure silicon. Solvents include water and/or organic solvents. Adjuvants include one or more of dispersing agents, thickening agents, wetting agents, conductive agents, and defoaming agents.

本申请实施例的第三方面,还提供了一种锂电池,锂电池包括上述的锂电池负极。In a third aspect of the embodiments of the present application, a lithium battery is further provided, and the lithium battery includes the above-mentioned negative electrode of the lithium battery.

以下各实施例中所用试剂均为市售。The reagents used in the following examples are all commercially available.

实施例1Example 1

一种锂电池负极粘合剂,包括嵌段共聚物,嵌段共聚物包括刚性嵌段A和柔性嵌段B,刚性嵌段A的结构式为:A lithium battery negative electrode adhesive, comprising a block copolymer, the block copolymer comprises a rigid block A and a flexible block B, and the structural formula of the rigid block A is:

柔性嵌段B的结构式为:The structural formula of flexible block B is:

其中,p、q皆为正整数。 Among them, p and q are both positive integers.

聚合方法选择自由基聚合,聚合工艺选择间歇法或者半连续法。The polymerization method selects free radical polymerization, and the polymerization process selects batch method or semi-continuous method.

实施例2Example 2

一种锂电池负极粘合剂,包括嵌段共聚物,嵌段共聚物包括刚性嵌段A和柔性嵌段B,刚性嵌段A的结构式为:A lithium battery negative electrode adhesive, comprising a block copolymer, the block copolymer comprises a rigid block A and a flexible block B, and the structural formula of the rigid block A is:

柔性嵌段B的结构式为:The structural formula of flexible block B is:

其中,p、q皆为正整数。 Among them, p and q are both positive integers.

聚合方法选择自由基聚合,聚合工艺选择间歇法或者半连续法。The polymerization method selects free radical polymerization, and the polymerization process selects batch method or semi-continuous method.

实施例3Example 3

一种锂电池负极粘合剂,包括嵌段共聚物,嵌段共聚物包括刚性嵌段A和柔性嵌段B,刚性嵌段A的结构式为:A lithium battery negative electrode adhesive, comprising a block copolymer, the block copolymer comprises a rigid block A and a flexible block B, and the structural formula of the rigid block A is:

柔性嵌段B的结构式为:The structural formula of flexible block B is:

其中,p、q皆为正整数。 Among them, p and q are both positive integers.

聚合方法选择自由基聚合,聚合工艺选择间歇法或者半连续法。The polymerization method selects free radical polymerization, and the polymerization process selects batch method or semi-continuous method.

利用实施例1~3的锂电池负极粘合剂、市售的CMC-SBR粘合剂分别制备锂电池负极。制备方法为:分别以实施例1~3的锂电池负极粘合剂或者市售的CMC-SBR粘合剂为粘合剂原料,以铜箔为集流体,石墨为活性物质,乙炔黑为导电剂,并辅以必要的溶剂和助剂,分别制备固含量为56%的负极浆料,并制备面密度为18mg/cm2的负极极片,然后进行测试。使用上述的负极极片分别制作扣式电池并进行测试。Lithium battery negative electrodes were prepared by using the lithium battery negative electrode binders and commercially available CMC-SBR binders in Examples 1 to 3, respectively. The preparation method is as follows: respectively use the lithium battery negative electrode binder of Examples 1 to 3 or the commercially available CMC-SBR binder as the binder raw material, use copper foil as the current collector, graphite as the active material, and acetylene black as the conductive material. The negative electrode slurry with a solid content of 56% and a negative electrode sheet with an areal density of 18 mg/cm2 were prepared, and then tested. Button cells were fabricated and tested using the above-mentioned negative pole pieces.

实施例1负极粘合剂的分子量分布曲线参照图3。实施例1负极粘合剂的DSC曲线参照图4,由图4可知,该粘合剂在在-37.5℃处表现出玻璃化转变行为,是柔性嵌段B的特征;刚性嵌段A的玻璃化转变行为则未在测试温度范围内观察到,说明高于200℃。实施例1负极粘合剂的TGA曲线参照图5。由图5可知,该粘合剂在测试温度达到300℃左右时,才开始表现出较为显著的热失重行为。Refer to FIG. 3 for the molecular weight distribution curve of the negative electrode binder in Example 1. Referring to Figure 4 for the DSC curve of the negative electrode binder in Example 1, it can be seen from Figure 4 that the binder exhibits glass transition behavior at -37.5°C, which is the characteristic of the flexible block B; the glass of the rigid block A The transformation behavior was not observed in the test temperature range, indicating that it was higher than 200 °C. Refer to FIG. 5 for the TGA curve of the negative electrode binder in Example 1. It can be seen from Fig. 5 that the adhesive begins to show significant thermal weight loss behavior when the test temperature reaches about 300°C.

负极浆料测试结果参照表2,其中,电池阻抗结果参照图2。图2展示了实施例1~3的锂电池负极粘合剂、对比例CMC-SBR粘合剂所制作的电池的EIS曲线。由图2可知,实施例1~3对应的电池的阻抗低于对比例对应电池的阻抗。Refer to Table 2 for the test results of the negative electrode slurry, and refer to FIG. 2 for the battery impedance results. FIG. 2 shows the EIS curves of batteries made from the negative electrode binders of lithium batteries of Examples 1 to 3 and the CMC-SBR binder of Comparative Example. It can be seen from FIG. 2 that the impedances of the batteries corresponding to Examples 1 to 3 are lower than those of the batteries corresponding to the comparative example.

表2负极浆料测试结果Table 2 Test results of negative electrode slurry

对所公开的实施例的上述说明,使本领域专业技术人员能够实现或使用本发明。对这些实施例的多种修改对本领域的专业技术人员来说将是显而易见的,本文中所定义的一般原理可以在不脱离本发明的精神或范围的情况下,在其他实施例中实现。因此,本发明将不会被限制于本文所示的这些实施例,而是要符合与本文所公开的原理和新颖特点相一致的最宽的范围。The above description of the disclosed embodiments enables any person skilled in the art to make or use the present invention. Various modifications to these embodiments will be readily apparent to those skilled in the art, and the generic principles defined herein may be implemented in other embodiments without departing from the spirit or scope of the invention. Thus, the present invention is not intended to be limited to the embodiments shown herein, but is to be accorded the widest scope consistent with the principles and novel features disclosed herein.

以上所述,仅为本发明的具体实施方式,但本发明的保护范围并不同限于此,任何熟悉本技术领域的技术人员在本发明揭露的技术范围内,可轻易想到变化或替换,都应涵盖在本发明的保护范围之内。并且,本发明各个实施方式之间的技术方案可以相互结合,但是必须是以本领域普通技术人员能够实现为基础,当技术方案的结合出现相互矛盾或无法实现时应当认为这种技术方案的结合不存在,也不在本发明要求的保护范围之内。因此,本发明的保护范围应以所述权利要求的保护范围为准。The above are only specific embodiments of the present invention, but the protection scope of the present invention is not limited to this. Any person skilled in the art can easily think of changes or substitutions within the technical scope disclosed by the present invention. Included within the scope of protection of the present invention. In addition, the technical solutions between the various embodiments of the present invention can be combined with each other, but must be based on the realization by those of ordinary skill in the art. When the combination of technical solutions is contradictory or cannot be achieved, it should be considered that the combination of technical solutions does not exist and is not within the scope of protection claimed by the present invention. Therefore, the protection scope of the present invention should be based on the protection scope of the claims.

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210112703.8ACN114373935B (en) | 2022-01-29 | 2022-01-29 | Negative electrode binder for lithium battery, negative electrode, and lithium battery |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210112703.8ACN114373935B (en) | 2022-01-29 | 2022-01-29 | Negative electrode binder for lithium battery, negative electrode, and lithium battery |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114373935Atrue CN114373935A (en) | 2022-04-19 |

| CN114373935B CN114373935B (en) | 2023-01-31 |

Family

ID=81145351

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210112703.8AActiveCN114373935B (en) | 2022-01-29 | 2022-01-29 | Negative electrode binder for lithium battery, negative electrode, and lithium battery |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114373935B (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114773599A (en)* | 2022-04-29 | 2022-07-22 | 北京宇程科技有限公司 | Block type polyamic acid solution, block type polyimide adhesive, preparation method and application thereof |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20100280561A1 (en)* | 2007-04-19 | 2010-11-04 | University Of Massachusetts Medical School | Thermal-Responsive Polymer Networks, Compositions, And Methods And Applications Related Thereto |

| US20120052305A1 (en)* | 2010-09-01 | 2012-03-01 | The Boeing Company | Composite structures using interpenetrating polymer network adhesives |

| US20150141544A1 (en)* | 2012-02-03 | 2015-05-21 | U.S. Government as represented by the Administrator of the National Aeronautics and Spac | Porous cross-linked polyimide networks |

| CN107556450A (en)* | 2016-06-30 | 2018-01-09 | 翁秋梅 | A kind of dynamic aggregation thing and application with hybrid cross-linked network |

| CN109206826A (en)* | 2017-06-30 | 2019-01-15 | 翁秋梅 | A kind of physics split-phase dynamic aggregation object and its application |

- 2022

- 2022-01-29CNCN202210112703.8Apatent/CN114373935B/enactiveActive

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20100280561A1 (en)* | 2007-04-19 | 2010-11-04 | University Of Massachusetts Medical School | Thermal-Responsive Polymer Networks, Compositions, And Methods And Applications Related Thereto |

| US20120052305A1 (en)* | 2010-09-01 | 2012-03-01 | The Boeing Company | Composite structures using interpenetrating polymer network adhesives |

| US20150141544A1 (en)* | 2012-02-03 | 2015-05-21 | U.S. Government as represented by the Administrator of the National Aeronautics and Spac | Porous cross-linked polyimide networks |

| CN107556450A (en)* | 2016-06-30 | 2018-01-09 | 翁秋梅 | A kind of dynamic aggregation thing and application with hybrid cross-linked network |

| CN109206826A (en)* | 2017-06-30 | 2019-01-15 | 翁秋梅 | A kind of physics split-phase dynamic aggregation object and its application |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114773599A (en)* | 2022-04-29 | 2022-07-22 | 北京宇程科技有限公司 | Block type polyamic acid solution, block type polyimide adhesive, preparation method and application thereof |

| CN114773599B (en)* | 2022-04-29 | 2024-05-03 | 北京宇程科技有限公司 | Block type polyamide acid solution, block type polyimide adhesive, preparation method and application thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114373935B (en) | 2023-01-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN105229832B (en) | Binder composition for secondary battery, slurry composition for secondary battery electrode, negative electrode for secondary battery, and secondary battery | |

| CN115000407B (en) | Silicon-based negative electrode plate and preparation method and application thereof | |

| WO2019242318A1 (en) | Waterborne binder, preparation method therefor and use thereof | |

| CN111712952B (en) | Slurry composition for lithium ion secondary batteries and electrode for lithium ion secondary batteries | |

| WO2018000578A1 (en) | Multi-functional modified polyvinyl alcohol-based water-borne adhesive for lithium ion battery and application thereof in electrochemical energy storage device | |

| CN114830380B (en) | Binder composition for non-aqueous secondary battery electrode, slurry composition for non-aqueous secondary battery electrode, electrode for non-aqueous secondary battery, and non-aqueous secondary battery | |

| CN114864870A (en) | A negative pole piece and a lithium ion battery including the same | |

| CN107710468A (en) | Composition for electrochemical element electrode, electrode for electrochemical element, electrochemical element, and method for producing composition for electrochemical element electrode | |

| CN109957361B (en) | Aqueous binder and secondary battery | |

| CN110511377A (en) | Electrode binder and preparation method thereof, negative electrode of lithium ion battery and lithium ion battery | |

| CN115881966A (en) | Conductive adhesive, preparation method thereof, current collector, electrode and battery | |

| WO2023232162A1 (en) | Binder and preparation method therefor, electrode plate and secondary battery | |

| CN114373935B (en) | Negative electrode binder for lithium battery, negative electrode, and lithium battery | |

| CN112467086A (en) | Preparation method of silicon-based negative electrode material based on polyamide-acid-based electrode binder | |

| CN115275096A (en) | Self-repairing flexible electrode, preparation method thereof and lithium-sulfur battery | |

| CN118271630A (en) | Self-repairing polyimide and application thereof in lithium ion battery | |

| CN113839037A (en) | Conductive agent, electrode paste, electrode sheet and battery | |

| CN115176360A (en) | Binder for secondary battery | |

| CN110690412A (en) | A kind of ternary lithium ion battery positive electrode sheet and its preparation method and battery | |

| CN117678084A (en) | Water-based adhesive compositions and their applications | |

| TW201024365A (en) | Composite substrate for counter electrode of dye-sensitized solar cell | |

| CN119709061A (en) | Side coating binder for lithium ion battery, preparation method thereof and side coating slurry | |

| CN113880976B (en) | Application of Alternating Copolymer of Ethylene Maleic Anhydride and Its Hydrolyzate in Preparation of Silicon Negative Electrode Material | |

| CN118109144A (en) | Special carbon nano tube-based water-based conductive adhesive for silicon-based negative electrode and preparation method thereof | |

| CN115939398A (en) | Conductive adhesive, preparation method and application thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |