CN114337467A - Method for adjusting motor rotation speed and computer storage medium - Google Patents

Method for adjusting motor rotation speed and computer storage mediumDownload PDFInfo

- Publication number

- CN114337467A CN114337467ACN202111592532.5ACN202111592532ACN114337467ACN 114337467 ACN114337467 ACN 114337467ACN 202111592532 ACN202111592532 ACN 202111592532ACN 114337467 ACN114337467 ACN 114337467A

- Authority

- CN

- China

- Prior art keywords

- voltage

- threshold value

- speed regulating

- voltage signal

- speed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/72—Electric energy management in electromobility

Landscapes

- Control Of Electric Motors In General (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明总体涉及用于调整电机转速的方法及计算机存储介质。The present invention generally relates to a method and computer storage medium for adjusting the rotational speed of a motor.

背景技术Background technique

通常,电动工具使用者通过调速机构调整电机转速,调速机构的机械移动会带来电信号变化,可以将这种电信号成为调速电压信号。Usually, the user of the electric tool adjusts the motor speed through the speed regulating mechanism, and the mechanical movement of the speed regulating mechanism will bring about changes in the electrical signal, which can be turned into a speed regulating voltage signal.

其中,调速机构具有如下特点:(1)包括机械移动部件和电子部件;(2)调速电压信号受机械、电子部件两者的影响。在电动工具经过长期使用之后,调速机构的机械移动部件和电子部件均会发生老化。这些老化的部件会产生异常的调速电压信号;这些异常的调速电压信号又会导致电机无法满足使用者的期望,从而影响了电动工具整机功能。Among them, the speed regulating mechanism has the following characteristics: (1) It includes mechanical moving parts and electronic components; (2) The speed regulating voltage signal is affected by both mechanical and electronic components. After long-term use of power tools, the mechanical moving parts and electronic parts of the speed control mechanism will age. These aging components will generate abnormal speed regulation voltage signals; these abnormal speed regulation voltage signals will cause the motor to fail to meet the user's expectations, thereby affecting the overall function of the power tool.

发明内容SUMMARY OF THE INVENTION

本发明的实施例提供了一种用于调整电机转速的方法及计算机存储介质,通过对调速电压信号进行实时采样,以基于调速电压信号的最小值和最大值与起点电压初始阈值和终点电压初始阈值之间的关系,自动调整判断阈值,避免了由于调速信号异常而导致的整机失效,有效延长了电动工具的使用寿命。Embodiments of the present invention provide a method and a computer storage medium for adjusting the rotational speed of a motor. By sampling the speed regulation voltage signal in real time, the minimum and maximum values of the speed regulation voltage signal and the initial threshold and end point of the starting voltage are determined based on the minimum and maximum values of the speed regulation voltage signal. The relationship between the initial voltage thresholds, and the judgment thresholds are automatically adjusted to avoid the failure of the whole machine due to abnormal speed control signals, and effectively prolong the service life of the power tool.

本发明的第一实施例提供了一种用于调整电机转速的方法,方法包括:获取用于调速机构的起点电压初始阈值和终点电压初始阈值;获取来自所述调速机构的调速电压信号;根据所述调速电压信号的最小值与所述起点电压初始阈值之间的大小比较关系,确定用于所述调速机构的起点电压更新阈值;根据所述调速电压信号的最大值与所述终点电压初始阈值之间的大小比较关系,确定用于所述调速机构的终点电压更新阈值;以及根据所述起点电压更新阈值和所述终点电压更新阈值,控制所述调速机构调整电机转速。A first embodiment of the present invention provides a method for adjusting the rotational speed of a motor, the method includes: obtaining an initial threshold value of a starting voltage and an initial threshold voltage of an end voltage for a speed regulating mechanism; obtaining a speed regulating voltage from the speed regulating mechanism signal; according to the magnitude comparison relationship between the minimum value of the speed regulating voltage signal and the initial threshold value of the starting point voltage, determine the starting point voltage update threshold value for the speed regulating mechanism; according to the maximum value of the speed regulating voltage signal and the size comparison relationship between the initial threshold value of the end point voltage to determine the end point voltage update threshold value for the speed regulating mechanism; and control the speed regulating mechanism according to the start point voltage update threshold value and the end point voltage update threshold value Adjust the motor speed.

根据本发明的第一实施例提供的方法,根据所述调速电压信号的最小值与所述起点电压初始阈值之间的大小比较关系,确定用于所述调速机构的起点电压更新阈值包括:在所述调速电压信号的最小值小于所述起点电压初始阈值时,将所述起点电压初始阈值作为所述起点电压更新阈值;以及在所述调速电压信号的最小值大于或等于所述起点电压初始阈值时,将所述调速电压信号的最小值作为所述起点电压更新阈值。According to the method provided by the first embodiment of the present invention, according to the magnitude comparison relationship between the minimum value of the speed regulating voltage signal and the initial threshold value of the starting voltage, determining the starting voltage update threshold for the speed regulating mechanism includes: : when the minimum value of the speed regulation voltage signal is less than the initial threshold value of the starting voltage, use the initial threshold value of the starting voltage as the starting voltage update threshold; and when the minimum value of the speed regulating voltage signal is greater than or equal to the When the initial threshold of the starting voltage is set, the minimum value of the speed regulation voltage signal is used as the updated threshold of the starting voltage.

根据本发明的第一实施例提供的方法,根据所述调速电压信号的最大值与所述终点电压初始阈值之间的大小比较关系,确定用于所述调速机构的终点电压更新阈值包括:在所述调速电压信号的最大值大于所述终点电压初始阈值时,将所述终点电压初始阈值作为所述终点电压更新阈值;以及在所述调速电压信号的最大值小于或等于所述终点电压初始阈值时,将所述调速电压信号的最大值作为所述终点电压更新阈值。According to the method provided by the first embodiment of the present invention, according to the magnitude comparison relationship between the maximum value of the speed regulating voltage signal and the initial threshold value of the terminal voltage, determining the update threshold value of the terminal voltage for the speed regulating mechanism includes: : when the maximum value of the speed regulation voltage signal is greater than the initial threshold value of the terminal voltage, use the initial threshold value of the terminal voltage as the update threshold value of the terminal voltage; and when the maximum value of the speed regulation voltage signal is less than or equal to the When the initial threshold value of the end point voltage is set, the maximum value of the speed regulation voltage signal is used as the update threshold value of the end point voltage.

根据本发明的第一实施例提供的方法,还包括:将所述起点电压初始阈值更新为所述起点电压更新阈值,并保存更新后的起点电压初始阈值;将所述终点电压初始阈值更新为所述终点电压更新阈值,并保存更新后的终点电压初始阈值。The method provided according to the first embodiment of the present invention further includes: updating the initial threshold voltage of the starting point to the updating threshold value of the starting point voltage, and saving the updated initial threshold value of the starting point voltage; updating the initial threshold value of the ending point voltage to The endpoint voltage updates the threshold value, and saves the updated initial threshold value of the endpoint voltage.

根据本发明的第一实施例提供的方法,获取来自所述调速机构的调速电压信号包括:获取所述调速机构从初始位置发生位移时的调速电压,以用作所述调速电压信号的最小值。According to the method provided by the first embodiment of the present invention, acquiring the speed regulating voltage signal from the speed regulating mechanism includes: acquiring the speed regulating voltage when the speed regulating mechanism is displaced from an initial position, so as to be used as the speed regulating mechanism The minimum value of the voltage signal.

根据本发明的第一实施例提供的方法,获取来自所述调速机构的调速电压信号还包括:对所述调速机构从初始位置发生位移时的调速电压进行噪声消除处理。According to the method provided by the first embodiment of the present invention, acquiring the speed regulating voltage signal from the speed regulating mechanism further includes: performing noise elimination processing on the speed regulating voltage when the speed regulating mechanism is displaced from the initial position.

根据本发明的第一实施例提供的方法,获取来自所述调速机构的调速电压信号包括:在所述调速电压信号的最小值大于或等于所述起点电压初始阈值之后,获取所述调速电压信号的斜率变化满足预设条件时的调速电压,以用作所述调速电压信号的最大值。According to the method provided by the first embodiment of the present invention, obtaining the speed regulation voltage signal from the speed regulation mechanism includes: after the minimum value of the speed regulation voltage signal is greater than or equal to the initial threshold value of the starting voltage, obtaining the speed regulation voltage signal. The speed regulation voltage when the slope change of the speed regulation voltage signal satisfies the preset condition is used as the maximum value of the speed regulation voltage signal.

根据本发明的第一实施例提供的方法,获取来自所述调速机构的调速电压信号还包括:对所述调速电压信号的斜率变化满足预设条件时的调速电压进行噪声消除处理。According to the method provided by the first embodiment of the present invention, acquiring the speed regulation voltage signal from the speed regulation mechanism further includes: performing noise elimination processing on the speed regulation voltage when the slope change of the speed regulation voltage signal satisfies a preset condition .

根据本发明的第一实施例提供的方法,根据所述调速电压信号的最大值与所述终点电压初始阈值之间的大小比较关系,确定用于所述调速机构的终点电压更新阈值包括:在所述调速电压信号的最大值小于或等于所述终点电压初始阈值的次数超过预设阈值时,将所述调速电压信号的最大值作为所述终点电压更新阈值。According to the method provided by the first embodiment of the present invention, according to the magnitude comparison relationship between the maximum value of the speed regulating voltage signal and the initial threshold value of the terminal voltage, determining the update threshold value of the terminal voltage for the speed regulating mechanism includes: : when the number of times that the maximum value of the speed regulation voltage signal is less than or equal to the initial threshold value of the terminal voltage exceeds a preset threshold, use the maximum value of the speed regulation voltage signal as the update threshold value of the terminal voltage.

本发明的第二实施例提供了一种计算机存储介质,其上存储有指令,所述指令在被一个或多个处理器执行时,使得所述一个或多个处理器执行如第一方面所述的用于调整电机转速的方法。A second embodiment of the present invention provides a computer storage medium having stored thereon instructions that, when executed by one or more processors, cause the one or more processors to perform as described in the first aspect The method described above for adjusting the speed of the motor.

本发明实施例提供的用于调整电机转速的方法及计算机存储介质,能够自动调整判断阈值,防止由于调速电压信号的异常而导致的诸如电机无法关机或电机无法达到最大转速之类的情况,从而延长了电动工具的使用寿命。The method for adjusting the motor speed and the computer storage medium provided by the embodiments of the present invention can automatically adjust the judgment threshold to prevent situations such as the motor cannot be shut down or the motor cannot reach the maximum speed due to an abnormal speed regulation voltage signal. Thereby extending the life of the power tool.

附图说明Description of drawings

为了更清楚地说明本发明实施例的技术方案,下面将对本发明实施例中所需要使用的附图作简单的介绍,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to illustrate the technical solutions of the embodiments of the present invention more clearly, the following briefly introduces the accompanying drawings that need to be used in the embodiments of the present invention. For those of ordinary skill in the art, without creative work, the Additional drawings can be obtained from these drawings.

图1示出了现有技术提供的调整电机转速的方法;Fig. 1 shows the method for adjusting the motor speed provided by the prior art;

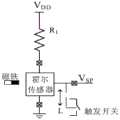

图2示出了本发明一个实施例提供的滑动变阻器类型的调速机构的结构示意图;FIG. 2 shows a schematic structural diagram of a sliding rheostat type speed regulating mechanism provided by an embodiment of the present invention;

图3示出了本发明另一实施例提供的霍尔传感器类型的调速机构的结构示意图;3 shows a schematic structural diagram of a Hall sensor type speed regulating mechanism provided by another embodiment of the present invention;

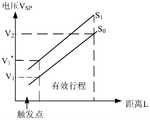

图4示出了调速机构的电压初始阈值与位移距离之间的关系的示意图;Fig. 4 shows the schematic diagram of the relationship between the voltage initial threshold of the speed regulating mechanism and the displacement distance;

图5示出了异常调速电压信号与电压初始阈值之间的关系的示意图;Fig. 5 shows the schematic diagram of the relationship between the abnormal speed regulation voltage signal and the voltage initial threshold;

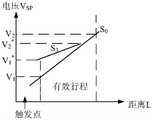

图6示出了异常调速电压信号与电压初始阈值之间的关系的示意图;Fig. 6 shows the schematic diagram of the relationship between the abnormal speed regulation voltage signal and the voltage initial threshold;

图7示出了异常调速电压信号与电压初始阈值之间的关系的示意图;Fig. 7 shows the schematic diagram of the relationship between the abnormal speed regulation voltage signal and the voltage initial threshold;

图8示出了本发明实施例提供的调整电机转速的方法的流程示意图;以及FIG. 8 shows a schematic flowchart of a method for adjusting a rotational speed of a motor provided by an embodiment of the present invention; and

图9示出了本发明实施例提供的调整电机转速的方法的具体流程图。FIG. 9 shows a specific flowchart of a method for adjusting the rotational speed of a motor provided by an embodiment of the present invention.

具体实施方式Detailed ways

下面将详细描述本发明的各个方面的特征和示例性实施例,为了使本发明的目的、技术方案及优点更加清楚明白,以下结合附图及具体实施例,对本发明进行进一步详细描述。应理解,此处所描述的具体实施例仅被配置为解释本发明,并不被配置为限定本发明。对于本领域技术人员来说,本发明可以在不需要这些具体细节中的一些细节的情况下实施。下面对实施例的描述仅仅是为了通过示出本发明的示例来提供对本发明更好的理解。The features and exemplary embodiments of various aspects of the present invention will be described in detail below. In order to make the objectives, technical solutions and advantages of the present invention more clear, the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described herein are only configured to explain the present invention, and are not configured to limit the present invention. It will be apparent to those skilled in the art that the present invention may be practiced without some of these specific details. The following description of the embodiments is only intended to provide a better understanding of the present invention by illustrating examples of the invention.

需要说明的是,在本文中,诸如第一和第二等之类的关系术语仅仅用来将一个实体或者操作与另一个实体或操作区分开来,而不一定要求或者暗示这些实体或操作之间存在任何这种实际的关系或者顺序。而且,术语“包括”、“包含”或者其任何其他变体意在涵盖非排他性的包含,从而使得包括一系列要素的过程、方法、物品或者设备不仅包括那些要素,而且还包括没有明确列出的其他要素,或者是还包括为这种过程、方法、物品或者设备所固有的要素。在没有更多限制的情况下,由语句“包括……”限定的要素,并不排除在包括所述要素的过程、方法、物品或者设备中还存在另外的相同要素。It should be noted that, in this document, relational terms such as first and second are only used to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply any relationship between these entities or operations. any such actual relationship or sequence exists. Moreover, the terms "comprising", "comprising" or any other variation thereof are intended to encompass non-exclusive inclusion such that a process, method, article or device comprising a list of elements includes not only those elements, but also includes not explicitly listed or other elements inherent to such a process, method, article or apparatus. Without further limitation, an element defined by the phrase "comprises" does not preclude the presence of additional identical elements in a process, method, article, or device that includes the element.

现有技术中,随着半导体技术的发展,很多电动工具采用微控制单元(Microcontroller Unit,MCU)来调整电机转速。具体流程如图1所示,图1示出了现有技术提供的调整电机转速的方法,包括如下步骤:S110,调速机构的机械移动;S112,调速机构的机械移动带来了调速电压信号的变化;S114,利用MCU来采样调速电压信号;S116,根据采样得到的调速电压信号的变化,通过MCU来调整执行电路的输出电压;以及S118,基于对输出电压的调整,实现电机转速的变化。In the prior art, with the development of semiconductor technology, many electric tools use a Microcontroller Unit (MCU) to adjust the rotational speed of the motor. The specific process is shown in Figure 1, which shows the method for adjusting the motor speed provided by the prior art, including the following steps: S110, the mechanical movement of the speed regulating mechanism; S112, the mechanical movement of the speed regulating mechanism brings about the speed regulation change of the voltage signal; S114, use the MCU to sample the speed regulation voltage signal; S116, adjust the output voltage of the execution circuit through the MCU according to the change of the speed regulation voltage signal obtained by sampling; and S118, based on the adjustment of the output voltage, realize Changes in motor speed.

然而,由于在电动工具经过长期使用之后,调速机构的机械移动部件和电子部件均会发生老化。这些老化的部件会产生异常的调速电压信号;这些异常的调速电压信号又会导致电机无法满足使用者的期望,从而影响了电动工具整机功能。However, due to the long-term use of the power tool, the mechanical moving parts and electronic parts of the speed control mechanism will age. These aging components will generate abnormal speed regulation voltage signals; these abnormal speed regulation voltage signals will cause the motor to fail to meet the user's expectations, thereby affecting the overall function of the power tool.

为了解决现有技术问题,本发明实施例提供了一种滑动变阻器类型的调速机构以及霍尔传感器类型的调速机构。下面首先对本发明实施例所提供的滑动变阻器类型的调速机构进行介绍。In order to solve the problems of the prior art, the embodiments of the present invention provide a sliding rheostat type speed regulating mechanism and a Hall sensor type speed regulating mechanism. First, the sliding rheostat type speed regulating mechanism provided by the embodiment of the present invention will be introduced below.

作为一个示例,图2示出了本发明一个实施例提供的滑动变阻器类型的调速机构的结构示意图。如图2所示,该滑动变阻器类型的调速机构可以包括电阻R1、滑动变阻器和触发开关,其中,当调速机构从初始位置发生位移后开关被闭合,闭合的开关可以为电机控制电路或MCU电路进行供电,或者唤醒待机状态下的MCU。As an example, FIG. 2 shows a schematic structural diagram of a sliding varistor type speed regulating mechanism provided by an embodiment of the present invention. As shown in FIG. 2 , the sliding rheostat type speed regulating mechanism may include a resistor R1, a sliding rheostat and a trigger switch, wherein, when the speed regulating mechanism is displaced from the initial position, the switch is closed, and the closed switch may be a motor control circuit or a trigger switch. The MCU circuit supplies power, or wakes up the MCU in the standby state.

在一些实施例中,当调速机构发生机械移动时,机械移动杆会同步带动导电刷移动,由于不同的移动位置对应于不同的电阻,因此,经可变电阻分压之后可以得到变化的调制电压信号Vsp。In some embodiments, when the speed regulating mechanism mechanically moves, the mechanical moving rod will synchronously drive the conductive brushes to move. Since different moving positions correspond to different resistances, a variable modulation can be obtained after dividing the voltage by the variable resistance. voltage signal Vsp.

作为一个示例,图3示出了本发明另一实施例提供的霍尔传感器类型的调速机构的结构示意图。如图3所示,该霍尔传感器类型的调速机构可以包括电阻R1、霍尔传感器和触发开关,其中,当调速机构从初始位置发生位移后开关被闭合,闭合的开关可以为电机控制电路或MCU电路进行供电,或者唤醒待机状态下的MCU。As an example, FIG. 3 shows a schematic structural diagram of a Hall sensor type speed regulating mechanism provided by another embodiment of the present invention. As shown in Figure 3, the Hall sensor type speed regulating mechanism may include a resistor R1, a Hall sensor and a trigger switch, wherein, when the speed regulating mechanism is displaced from the initial position, the switch is closed, and the closed switch can be controlled by a motor circuit or MCU circuit to supply power, or wake up the MCU in standby state.

当调速机构发生机械移动时,调速机构的机械移动杆会同步改变永磁铁和霍尔传感器之间的相对位置,从而改变了霍尔传感器处的磁通密度,使得霍尔传感器的输出电压Vsp发生变化。When the speed regulating mechanism moves mechanically, the mechanical moving rod of the speed regulating mechanism will synchronously change the relative position between the permanent magnet and the Hall sensor, thereby changing the magnetic flux density at the Hall sensor, making the output voltage of the Hall sensor Vsp changes.

应注意,在图2和图3所示的实施例中,调速机构的位移距离被表示为L,调速机构的调速电压信号被表示为Vsp,二者之间存在一定的对应关系,例如,图4示出了调速机构的电压初始阈值与位移距离之间的关系的示意图。It should be noted that in the embodiments shown in Figures 2 and 3, the displacement distance of the speed regulating mechanism is denoted as L, and the speed regulating voltage signal of the speed regulating mechanism is denoted as Vsp, there is a certain correspondence between the two, For example, FIG. 4 shows a schematic diagram of the relationship between the initial threshold value of the voltage of the speed regulating mechanism and the displacement distance.

如图4所示,横坐标表示位移距离L,纵坐标表示调速电压信号Vsp,二者之间的对应关系表示为曲线S0,曲线S0通常是单调递增的,为了简单起见,在图4中,曲线S0被示出为一条直线,其中的触发点指的是调速机构从初始位置发生位移后而使得开关被闭合的点。As shown in Figure 4, the abscissa represents the displacement distance L, and the ordinate represents the speed regulation voltage signal Vsp. The corresponding relationship between the two is represented by the curve S0 . The curve S0 is usually monotonically increasing. For simplicity, in Fig. 4, the curve S0 is shown as a straight line, wherein the trigger point refers to the point at which the switch is closed after the speed regulating mechanism is displaced from the initial position.

作为一个示例,当MCU检测到调速电压信号Vsp大于V1时,电机开始工作,将V1称为起点电压初始阈值;当MCU检测到调速电压信号Vsp大于V2时,使得电机处于最高速工况,将V2称为终点电压初始阈值。并且起点电压初始阈值V1和终点电压初始阈值V2之间对应的位移距离可以被认为是调速机构的有效行程。As an example, when the MCU detects that the speed regulation voltage signal Vsp is greater than V1 , the motor starts to work, and V1 is called the initial threshold of the starting voltage; when the MCU detects that the speed regulation voltage signal Vsp is greater than V2 , the motor is in the most In high-speed conditions, V2 is called the initial threshold of the terminal voltage. And the corresponding displacement distance between the initial threshold value V1 of the starting voltage and the initial threshold value V 2of the end voltage can be regarded as the effective stroke of the speed regulating mechanism.

如图4所示,起点电压初始阈值V1对应于距离L1,终点电压初始阈值V2对应于距离L2,从距离L1至距离L2被认为是调速机构的有效行程。As shown in FIG. 4 , the initial threshold voltage V1 of the starting point corresponds to the distance L1 , and the initial threshold voltage V2 of the end point voltage corresponds to the distance L2 . The distance from L1 to the distance L2 is considered as the effective stroke of the speed regulating mechanism.

调速机构常见的老化原因可以如下:(1)在电动工具的使用过程中,整机的振动,会导致调速开关密封结构的老化,并且会导致在环境中产生粉尘,这些粉尘会在电气部件中产生累积,从而引入寄生阻抗;(2)由于调速开关长期的往复运动,会导致接触点阻抗增大;(3)电信号连接线的绝缘皮、焊点等在长期使用过程中会发生阻抗变化,或发生粉尘堆积,从而导致连接阻抗的偏差。上述这些因素都会导致调速电压信号发生偏差,这些偏差可能导致电机无法停机,或者在有效行程内电机无法达到最大设定转速,或者在有效行程内电机既不能停机也无法达到最大设定转速,这将在下面详细介绍。The common reasons for the aging of the speed regulating mechanism can be as follows: (1) During the use of the power tool, the vibration of the whole machine will cause the aging of the sealing structure of the speed regulating switch, and will lead to the generation of dust in the environment. Accumulation occurs in the components, thereby introducing parasitic impedance; (2) due to the long-term reciprocating motion of the speed control switch, the contact point impedance will increase; (3) the insulation and solder joints of the electrical signal connection line will be damaged during long-term use. Impedance change occurs, or dust accumulation occurs, resulting in deviation of connection impedance. The above factors will lead to the deviation of the speed regulation voltage signal. These deviations may cause the motor to fail to stop, or the motor cannot reach the maximum set speed within the effective stroke, or the motor can neither stop nor reach the maximum set speed within the effective stroke. This will be detailed below.

由于调速机构的多样性和故障的多样性,为了便于分析,以下主要调速电压信号的变化特点,将常见的调速电压信号的偏差分为如下几种类型:Due to the diversity of speed control mechanisms and the diversity of faults, in order to facilitate analysis, the following main speed control voltage signal variation characteristics, the common speed control voltage signal deviation is divided into the following types:

首先,图5示出了异常调速电压信号与电压初始阈值(例如,起点电压初始阈值和终点电压初始阈值)之间的关系的示意图。First, FIG. 5 shows a schematic diagram of the relationship between the abnormal speed regulation voltage signal and the voltage initial thresholds (eg, the starting voltage initial threshold and the ending voltage initial threshold).

在图5所示的实施例中,调速电压信号Vsp整体偏高,例如曲线S1沿y轴向上偏离曲线S0,调速电压信号的最小值V1*大于起点电压初始阈值V1。如图4中所描述的,当MCU检测到调速电压信号Vsp大于V1时,电机开始工作,当MCU检测到调速电压信号Vsp大于V2时,使得电机处于最高速工况。在图5所示的实施例中,由于调速电压信号Vsp始终大于V1,例如,调速电压信号的最小值大于V1,因此,MCU判断调速机构没有复位,在这种情况下,电机不会停机,整机表现为无法关机。In the embodiment shown in FIG. 5 , the speed regulation voltage signal Vsp is generally high, for example, the curve S1 deviates from the curve S0 upward along the y-axis, and the minimum value V1 * of the speed regulation voltage signal is greater than the initial threshold value V1 of the starting voltage . As described in Figure 4, when the MCU detects that the speed regulating voltage signal Vsp is greaterthan V1, the motor starts to work, and when the MCU detects that the speed regulating voltage signal Vsp is greaterthan V2, the motor is in the highest speed condition. In the embodiment shown in FIG. 5 , since the speed regulating voltage signal Vsp is always greater than V1 , for example, the minimum value of the speed regulating voltage signal is greater than V1 , the MCU judges that the speed regulating mechanism is not reset, in this case, The motor will not stop, and the whole machine appears to be unable to shut down.

其次,图6示出了异常调速电压信号与电压初始阈值(例如,起点电压初始阈值和终点电压初始阈值)之间的关系的示意图。Next, FIG. 6 shows a schematic diagram of the relationship between the abnormal speed regulation voltage signal and the voltage initial thresholds (eg, the starting voltage initial threshold and the ending voltage initial threshold).

在图6所示的实施例中,调速电压信号Vsp整体偏低,例如曲线S2沿y轴向下偏离曲线S0,调速电压信号的最大值V2*小于终点电压初始阈值V2。如图4中所描述的,当MCU检测到调速电压信号Vsp大于V1时,电机开始工作,当MCU检测到调速电压信号Vsp大于V2时,使得电机处于最高速工况。在图6所示的实施例中,由于调速电压信号Vsp始终小于V2,例如,调速电压信号的最大值小于V2,因此,MCU判断调速机构没有达到最大行程,电机不会工作在最大设定转速,整机表现为在有效行程内,达不到最大设定转速。In the embodiment shown in FIG. 6 , the speed regulation voltage signal Vsp is generally low, for example, the curve S2 deviates from the curve S0 downward along the y-axis, and the maximum value V2 * of the speed regulation voltage signal is less than the initial threshold value V2 of the terminal voltage . As described in Figure 4, when the MCU detects that the speed regulating voltage signal Vsp is greaterthan V1, the motor starts to work, and when the MCU detects that the speed regulating voltage signal Vsp is greaterthan V2, the motor is in the highest speed condition. In the embodiment shown in FIG. 6 , since the speed regulating voltage signal Vsp is always smaller than V2 , for example, the maximum value of the speed regulating voltage signal is less than V2 , the MCU determines that the speed regulating mechanism has not reached the maximum stroke, and the motor will not work At the maximum set speed, the whole machine behaves as if it is within the effective stroke and cannot reach the maximum set speed.

再次,图7示出了异常调速电压信号与电压初始阈值(例如,起点电压初始阈值和终点电压初始阈值)之间的关系的示意图。Again, FIG. 7 shows a schematic diagram of the relationship between the abnormal speed regulation voltage signal and the voltage initial thresholds (eg, the starting voltage initial threshold and the ending voltage initial threshold).

在图7所示的实施例中,调速电压信号Vsp保持单调递增的关系,例如曲线S3沿y轴向上偏离曲线S0,与图6所示的实施例的不同之处在于,图6所示的实施例中的调速电压信号Vsp的最小值和最大值分别大于V1和V2,而图7所示的实施例中的调速电压信号Vsp的最小值大于V1,并且最大值小于V2,整机故障表现为在有效行程内,电机既无法停机,也达不到最大设定转速。In the embodiment shown in FIG. 7 , the speed regulating voltage signal Vsp maintains a monotonically increasing relationship, for example, the curve S3 deviates from the curve S0 upward along the y-axis. The difference from the embodiment shown in FIG. The minimum and maximum values of the speed regulating voltage signal Vsp in the embodiment shown in FIG. 6 are greater than V1 and V2 , respectively, while the minimum value of the speed regulating voltage signal Vsp in the embodiment shown in FIG. 7 is greater than V1 , and If the maximum value is less than V2 , the fault of the whole machine shows that the motor can neither stop nor reach the maximum set speed within the effective stroke.

为了解决如上由于调速信号异常情况而导致的诸如电机无法关机或无法达到最大设定转速之类的情况中的一者或多者,本发明实施例提供了一种调整电机转速的方法,如图8所示,图8示出了本发明实施例提供的调整电机转速的方法的流程示意图,包括:S810,获取用于调速机构的起点电压初始阈值和终点电压初始阈值;S812,获取来自调速机构的调速电压信号;S814,根据调速电压信号的最小值与起点电压初始阈值之间的大小比较关系,确定用于调速机构的起点电压更新阈值;S816,根据调速电压信号的最大值与终点电压初始阈值之间的大小比较关系,确定用于调速机构的终点电压更新阈值;以及S818,根据起点电压更新阈值和终点电压更新阈值,控制调速机构调整电机转速。In order to solve one or more of the above situations such as the failure of the motor to shut down or the inability to reach the maximum set rotation speed due to the abnormal situation of the speed regulation signal, the embodiment of the present invention provides a method for adjusting the rotation speed of the motor, such as As shown in FIG. 8 , FIG. 8 shows a schematic flowchart of a method for adjusting the rotational speed of a motor provided by an embodiment of the present invention, including: S810 , obtaining the initial threshold value of the starting voltage and the initial threshold value of the ending voltage used for the speed regulating mechanism; S812 , obtaining the initial threshold value of the voltage from The speed regulating voltage signal of the speed regulating mechanism; S814, according to the magnitude comparison relationship between the minimum value of the speed regulating voltage signal and the initial threshold value of the starting point voltage, determine the starting point voltage update threshold value for the speed regulating mechanism; S816, according to the speed regulating voltage signal The size comparison relationship between the maximum value of , and the initial threshold value of the terminal voltage, determine the terminal voltage update threshold for the speed regulating mechanism; and S818, control the speed regulating mechanism to adjust the motor speed according to the starting voltage update threshold and the terminal voltage update threshold.

作为一个示例,在S810中,当MCU启动之后,对非易失性存储器(例如,只读存储器(Read-Only Memory,ROM))内的起点电压初始阈值V1和终点电压初始阈值V2和调速信号异常标志位进行读取。As an example, in S810, after the MCU is started, the initial threshold V1 of the start voltage and the initial threshold V2of the end voltage in the non- volatile memory (for example, read-only memory (ROM)) are Read the abnormal flag bit of the speed control signal.

作为一个示例,在S812中,MCU可以对调速机构的调速电压信号进行采样,并判断出调速电压信号的最小值VSP_MIN和最大值VSP_MAX。As an example, in S812, the MCU may sample the speed regulating voltage signal of the speed regulating mechanism, and determine the minimum value VSP_MIN and the maximum value VSP_MAX of the speed regulating voltage signal.

作为一个示例,在S814中,将调速电压信号的最小值VSP_MIN与起点电压初始阈值V1进行比较,确定用于调速机构的起点电压更新阈值。As an example, in S814, the minimum value VSP_MIN of the speed regulating voltage signal is compared with the initial threshold value V1 of the starting voltage to determine the starting voltage updating threshold for the speed regulating mechanism.

具体地,S814可以包括:如果调速电压信号的最小值VSP_MIN小于起点电压初始阈值V1时,则不启动更新程序,程序正常运行,例如将起点电压初始阈值V1作为起点电压更新阈值;如果调速电压信号的最小值VSP_MIN大于或等于起点电压初始阈值V1时,则将调速信号异常标志位进行置位,并进入阈值更新程序,将调速电压信号的最小值VSP_MIN作为起点电压更新阈值,也就是说,将起点电压初始阈值V1更新为调速电压信号的最小值VSP_MIN。Specifically, S814 may include: if the minimum value VSP_MIN of the speed regulation voltage signal is less than the initial threshold voltage V1 of the starting point voltage, the update program is not started, and the program runs normally, for example, the initial threshold value V1 of the starting point voltage is used as the starting point voltage update threshold value; If the minimum value VSP_MIN of the speed regulation voltage signal is greater than or equal to the initial threshold value V1 of the starting voltage, the abnormal flag bit of the speed regulation signal is set, and the threshold value update procedure is entered, and the minimum value VSP_MIN of the speed regulation voltage signal is used as the The threshold value of the starting point voltage is updated, that is, the initial threshold value V1 of the starting point voltage is updated to the minimum value VSP_MIN of the speed regulation voltage signal.

作为一个示例,在S816中,将调速电压信号的最大值VSP_MAX与终点电压初始阈值V2进行比较,确定用于调速机构的终点电压更新阈值。As an example, in S816, the maximum value VSP_MAX of the speed regulation voltage signal is compared with the initial threshold value V2 of the end voltage, to determine the end voltage update threshold for the speed regulation mechanism.

具体地,S816可以包括:如果调速电压信号的最大值VSP_MAX大于终点电压初始阈值V2时,则不启动更新程序,程序正常运行,例如,将终点电压初始阈值V2作为终点电压更新阈值;如果调速电压信号的最大值VSP_MAX小于或等于终点电压初始阈值V2时,则进入阈值更新程序,将调速电压信号的最大值VSP_MAX作为终点电压更新阈值,也就是说,将终点电压初始阈值V2更新为调速电压信号的最大值VSP_MAX。在其他实施例中,当调速电压信号的最大值VSP_MAX小于或等于终点电压初始阈值V2的次数超过预设阈值(例如,N)之后,进入阈值更新程序,将调速电压信号的最大值VSP_MAX作为终点电压更新阈值。Specifically, S816 may include: if the maximum value VSP_MAX of the speed regulation voltage signal is greater than the initial threshold value V2 of the terminal voltage, the update program is not started, and the program runs normally, for example, the initial threshold value V2 of the terminal voltage is used as the terminal voltage update threshold value ; If the maximum value VSP_MAX of the speed regulation voltage signal is less than or equal to the initial threshold value V2 of the end voltage, enter the threshold update procedure, and use the maximum value VSP_MAX of the speed regulation voltage signal as the end voltage update threshold, that is, the end The initial voltage threshold V2 is updated to the maximum value VSP_MAX of the speed regulation voltage signal. In other embodiments, after the number of times that the maximum value VSP_MAX of the speed regulating voltage signal is less than or equal to the initial threshold value V2 of the terminal voltage exceeds a preset threshold (for example, N), a threshold update procedure is entered, and the maximum value of the speed regulating voltage signal is changed to The value VSP_MAX serves as the endpoint voltage update threshold.

在一些实施例中,方法还包括:在将起点电压初始阈值V1更新为起点电压更新阈值之后,将更新后的起点电压初始阈值保存在非易失性存储器中,在将终点电压初始阈值V2更新为终点电压更新阈值之后,将更新后的终点电压初始阈值保存在非易失性存储器中。In some embodiments, the method further includes: after updating the starting voltage initial threshold V1 to the starting voltage updating threshold, saving the updated starting voltage initial threshold in a non-volatile memory, and after updating the starting voltage initial threshold V2 After updating to the update threshold value of the end point voltage, save the updated initial threshold value of the end point voltage in the non-volatile memory.

在一些实施例中,方法还包括:当MCU在此启动之后,读取存储在非易失性存储器中的更新后的起点电压初始阈值和更新后的终点电压初始阈值,并重复以上步骤。In some embodiments, the method further includes: after the MCU is started here, reading the updated initial threshold value of the start voltage and the updated initial threshold value of the end voltage stored in the non-volatile memory, and repeating the above steps.

在一些实施例中,在MCU检测到触发点之后,记录此时的调速电压信号,以用作调速电压信号的最小值VSP_MIN,其中,触发点是调速机构从初始位置发生位移时的点。在其他实施例中,对调速机构从初始位置发生位移时的调速电压进行噪声消除处理,并将经噪声消除处理的调速电压信号作为调速电压信号的最小值VSP_MIN。In some embodiments, after the MCU detects the trigger point, the speed regulation voltage signal at this time is recorded to be used as the minimum value VSP_MIN of the speed regulation voltage signal, wherein the trigger point is when the speed regulation mechanism is displaced from the initial position point. In other embodiments, noise removal processing is performed on the speed control voltage when the speed control mechanism is displaced from the initial position, and the speed control voltage signal after the noise removal process is used as the minimum value VSP_MIN of the speed control voltage signal.

在一些实施例中,在调速信号异常标志位被置位之后,判断调速电压信号的斜率变化与预设条件之间的关系,并对斜率变化满足预设条件时的调速电压信号进行记录,以用作调速电压信号的最大值VSP_MAX。在其他实施例中,对斜率变化满足预设条件时的调速电压信号进行噪声消除处理,并将经噪声消除处理的调速电压信号作为调速电压信号的最大值VSP_MAX。In some embodiments, after the abnormality flag of the speed regulation signal is set, the relationship between the slope change of the speed regulation voltage signal and the preset condition is determined, and the speed regulation voltage signal when the slope change meets the preset condition is evaluated. Recorded to be used as the maximum value VSP_MAX of the speed regulation voltage signal. In other embodiments, noise removal processing is performed on the speed regulation voltage signal when the slope change satisfies a preset condition, and the noise removal processed speed regulation voltage signal is taken as the maximum value VSP_MAX of the speed regulation voltage signal.

上述过程可以采用迭代的方式进行,更新电压判断阈值并对其进行存储。当MCU被复位之后对上一次记录的阈值进行读取,当满足阈值条件时,使得电机正常运行。The above process can be performed in an iterative manner, and the voltage judgment threshold is updated and stored. After the MCU is reset, the threshold value recorded last time is read, and when the threshold value condition is met, the motor runs normally.

图9示出了本发明实施例提供的调整电机转速的方法的具体流程图。如图9所示,该方法可以包括如下步骤:S910,MCU进行初始化;S912,在MCU的初始化之后,对存储在非易失性存储器中的起点电压初始阈值V1、终点电压初始阈值V2和调速信号异常标志位进行读取;S914,对调速电压信号Vsp进行采样;S916,对触发信号是否发生进行检测,如果检测到触发信号,则流程进行到S918,如果未检测到触发信号,则流程进行到S924:S918,在检测到触发信号时,对此时的调速电压信号进行噪声消除处理,以将经噪声消除处理的调速电压信号用作调速电压信号的最小值VSP_MIN;S920,判断调速电压信号的最小值VSP_MIN是否小于起点电压初始阈值V1,如果是,则进行到S922,如果否,则进行到S932;S922,程序正常运行;S932,将调速信号异常标志位进行置位,并进入阈值更新程序,将起点电压初始阈值V1更新为调速电压信号的最小值VSP_MIN;S924,在未检测到触发信号时,判断调速信号异常标志位是否为1,如果是,则流程进行到S926,如果否,则流程进行到S922;S922,如果调速信号异常标志位不为1,则程序正常运行;S926,如果调速信号异常标志位为1,则判断调速电压信号的斜率变化是否满足预设条件,如果是,则流程进行到S928,如果否,则流程进行到S922;S928,在调速电压信号的斜率变化满足预设条件的情况下,对此时的调速电压信号进行噪声消除处理,以将经噪声消除处理的调速信号作为调速电压信号的最大值VSP_MAX;S930,判断调速电压信号的最大值VSP_MAX是否大于终点电压初始阈值V2,如果是,则流程进行到S922,如果否,则流程进行到S932;S932,如果调速电压信号的最大值VSP_MAX小于或等于终点电压初始阈值V2,则进入阈值更新程序,将终点电压初始阈值V2更新为调速电压信号的最大值VSP_MAX。FIG. 9 shows a specific flowchart of a method for adjusting the rotational speed of a motor provided by an embodiment of the present invention. As shown in FIG. 9 , the method may include the following steps: S910, the MCU is initialized; S912, after the initialization of the MCU, the initial threshold value V1 of the starting voltage and the initial threshold value V2 of the end voltage stored in the non-volatile memory are adjusted. Read the abnormal flag bit of the speed regulation signal; S914, sample the speed regulation voltage signal Vsp; S916, detect whether the trigger signal occurs, if a trigger signal is detected, the process proceeds to S918, if no trigger signal is detected. , then the flow goes to S924:S918, when the trigger signal is detected, the noise removal processing is performed on the speed regulation voltage signal at this time, so that the speed regulation voltage signal processed by the noise removal is used as the minimum value V of the speed regulation voltage signalSP_MIN ; S920, judge whether the minimum value VSP_MIN of the speed regulation voltage signal is less than the initial threshold value V1 of the starting voltage, if so, go to S922, if not, go to S932; S922, the program is running normally; S932, speed regulation The signal abnormality flag bit is set, and the threshold value update program is entered, and the initial threshold value V1of the starting voltage is updated to the minimum value VSP_MIN of the speed regulation voltage signal; S924, when the trigger signal is not detected, judge the abnormality flag bit of the speed regulation signal Whether it is 1, if it is, the process goes to S926, if not, the process goes to S922; S922, if the abnormality flag bit of the speed control signal is not 1, the program runs normally; S926, if the abnormality flag bit of the speed control signal is 1, it is judged whether the slope change of the speed regulation voltage signal satisfies the preset condition, if so, the process proceeds to S928, if not, the process proceeds to S922; S928, when the slope change of the speed regulation voltage signal satisfies the preset condition Under the circumstance, noise elimination processing is performed on the speed regulation voltage signal at this time, so that the speed regulation signal processed by noise elimination is used as the maximum value VSP_MAX of the speed regulation voltage signal; S930, it is judged whether the maximum value VSP_MAX of the speed regulation voltage signal is not. is greater than the initial threshold value V2 of the terminal voltage, if yes, the process proceeds to S922, if not, the process proceeds to S932; S932, if the maximum value VSP_MAX of the speed regulation voltage signal is less than or equal to the initial threshold value V2 of the terminal voltage, then enter The threshold value updating procedure updates the initial threshold value V2 of the terminal voltage to the maximum value VSP_MAX of the speed regulation voltage signal.

本发明实施例还提供了一种计算机存储介质,其上存储有指令,这些指令在被一个或多个处理器执行时,使得一个或多个处理器执行如以上所描述的用于调整电机转速的方法。Embodiments of the present invention also provide a computer storage medium storing instructions thereon, and when executed by one or more processors, the instructions cause the one or more processors to execute the above-described method for adjusting the rotational speed of a motor Methods.

综上,本发明实施例提供的调整电机转速的方法及计算机存储介质,可以根据调速电压信号的最小值和最大值与起点电压初始阈值和终点电压初始阈值之间的关系,判断是否需要更新起点电压初始阈值和终点电压初始阈值,从而防止发生诸如电机无法关机和/或电机无法达到最大转速之类的情况。To sum up, the method for adjusting the rotational speed of a motor and the computer storage medium provided by the embodiments of the present invention can determine whether it needs to be updated according to the relationship between the minimum and maximum value of the speed-regulating voltage signal and the initial threshold of the starting voltage and the initial threshold of the ending voltage. Start voltage initial threshold and end voltage initial threshold to prevent situations such as motor not shutting down and/or motor not reaching maximum speed.

通过上述对调速电压信号的异常情况进行分析,并对起点电压初始阈值和终点电压初始阈值进行更新,可以延长调速机构和整机的使用寿命。By analyzing the abnormal situation of the speed regulating voltage signal and updating the initial threshold value of the starting voltage and the initial threshold value of the end voltage, the service life of the speed regulating mechanism and the whole machine can be prolonged.

应注意的是,以上实施例是以电机为例进行说明的,然而,在不脱离本发明的精神和范围的情况下,以上方法同样适用于除电机之外的其他电动工具的调速应用。It should be noted that the above embodiments are described with a motor as an example, however, the above method is also applicable to speed regulation applications of other power tools other than motors without departing from the spirit and scope of the present invention.

需要明确的是,本发明并不局限于上文所描述并在图中示出的特定配置和处理。为了简明起见,这里省略了对已知方法的详细描述。在上述实施例中,描述和示出了若干具体的步骤作为示例。但是,本发明的方法过程并不限于所描述和示出的具体步骤,本领域的技术人员可以在领会本发明的精神后,作出各种改变、修改和添加,或者改变步骤之间的顺序。It is to be understood that the present invention is not limited to the specific arrangements and processes described above and shown in the figures. For the sake of brevity, detailed descriptions of known methods are omitted here. In the above-described embodiments, several specific steps are described and shown as examples. However, the method process of the present invention is not limited to the specific steps described and shown, and those skilled in the art can make various changes, modifications and additions, or change the sequence of steps after comprehending the spirit of the present invention.

以上所述的结构框图中所示的功能块可以实现为硬件、软件、固件或者它们的组合。当以硬件方式实现时,其可以例如是电子电路、专用集成电路(ASIC)、适当的固件、插件、功能卡等等。当以软件方式实现时,本发明的元素是被用于执行所需任务的程序或者代码段。程序或者代码段可以存储在机器可读介质中,或者通过载波中携带的数据信号在传输介质或者通信链路上传送。“机器可读介质”可以包括能够存储或传输信息的任何介质。机器可读介质的例子包括电子电路、半导体存储器设备、ROM、闪存、可擦除ROM(EROM)、软盘、CD-ROM、光盘、硬盘、光纤介质、射频(RF)链路,等等。代码段可以经由诸如因特网、内联网等的计算机网络被下载。The functional blocks shown in the above-described structural block diagrams may be implemented as hardware, software, firmware, or a combination thereof. When implemented in hardware, it may be, for example, an electronic circuit, an application specific integrated circuit (ASIC), suitable firmware, a plug-in, a function card, or the like. When implemented in software, elements of the invention are programs or code segments used to perform the required tasks. The program or code segments may be stored in a machine-readable medium or transmitted over a transmission medium or communication link by a data signal carried in a carrier wave. A "machine-readable medium" may include any medium that can store or transmit information. Examples of machine-readable media include electronic circuits, semiconductor memory devices, ROM, flash memory, erasable ROM (EROM), floppy disks, CD-ROMs, optical disks, hard disks, fiber optic media, radio frequency (RF) links, and the like. The code segments may be downloaded via a computer network such as the Internet, an intranet, or the like.

还需要说明的是,本发明中提及的示例性实施例,基于一系列的步骤或者装置描述一些方法或系统。但是,本发明不局限于上述步骤的顺序,也就是说,可以按照实施例中提及的顺序执行步骤,也可以不同于实施例中的顺序,或者若干步骤同时执行。It should also be noted that the exemplary embodiments mentioned in the present invention describe some methods or systems based on a series of steps or devices. However, the present invention is not limited to the order of the above steps, that is, the steps may be performed in the order mentioned in the embodiments, or may be different from the order in the embodiments, or several steps may be performed simultaneously.

以上所述,仅为本发明的具体实施方式,所属领域的技术人员可以清楚地了解到,为了描述的方便和简洁,上述描述的系统、模块和单元的具体工作过程,可以参考前述方法实施例中的对应过程,在此不再赘述。应理解,本发明的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本发明揭露的技术范围内,可轻易想到各种等效的修改或替换,这些修改或替换都应涵盖在本发明的保护范围之内。The above are only specific implementations of the present invention. Those skilled in the art can clearly understand that, for the convenience and brevity of the description, for the specific working process of the above-described systems, modules and units, reference may be made to the foregoing method embodiments. The corresponding process in , will not be repeated here. It should be understood that the protection scope of the present invention is not limited to this. Any person skilled in the art can easily think of various equivalent modifications or replacements within the technical scope disclosed by the present invention, and these modifications or replacements should all cover within the protection scope of the present invention.

Claims (10)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111592532.5ACN114337467B (en) | 2021-12-23 | 2021-12-23 | Method for adjusting motor rotation speed and computer storage medium |

| TW111105476ATWI784880B (en) | 2021-12-23 | 2022-02-15 | Method and computer storage medium for adjusting motor speed |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111592532.5ACN114337467B (en) | 2021-12-23 | 2021-12-23 | Method for adjusting motor rotation speed and computer storage medium |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114337467Atrue CN114337467A (en) | 2022-04-12 |

| CN114337467B CN114337467B (en) | 2024-01-12 |

Family

ID=81054396

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202111592532.5AActiveCN114337467B (en) | 2021-12-23 | 2021-12-23 | Method for adjusting motor rotation speed and computer storage medium |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN114337467B (en) |

| TW (1) | TWI784880B (en) |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6518719B1 (en)* | 1999-11-16 | 2003-02-11 | Makita Corporation | Power tools with operating speed control circuit |

| US20050002135A1 (en)* | 2003-05-30 | 2005-01-06 | Koichi Kokubo | Pump drive motor control apparatus |

| US20050043873A1 (en)* | 2003-08-21 | 2005-02-24 | Mir Sayeed A. | Current limit for an electric machine |

| US20090295313A1 (en)* | 2008-05-30 | 2009-12-03 | Makita Corporation | Rechargeable power tool, control unit and recording medium |

| JP2011200058A (en)* | 2010-03-23 | 2011-10-06 | Hitachi Automotive Systems Ltd | Driving device for brushless motor |

| US20120262101A1 (en)* | 2011-03-15 | 2012-10-18 | Johnson Controls Technology Company | Control systems and methods for electronically commutated motors |

| JP2014045654A (en)* | 2013-12-12 | 2014-03-13 | Hitachi Automotive Systems Ltd | Drive unit of brushless motor |

| CN106020131A (en)* | 2015-03-31 | 2016-10-12 | 德马吉森精机株式会社 | System and method for fine-tuning speed selection for reducing machine chatter |

| JP2017192207A (en)* | 2016-04-13 | 2017-10-19 | 株式会社日立製作所 | Dynamo-electric machine system and control method of dynamo-electric machine system |

| WO2018102872A1 (en)* | 2016-12-08 | 2018-06-14 | University Of Technology Sydney | Sensorless ac motor controller |

| JP2018182786A (en)* | 2017-04-03 | 2018-11-15 | 株式会社島津製作所 | Motor failure detection device for vacuum pump and vacuum pump system |

| JP2019158315A (en)* | 2018-03-16 | 2019-09-19 | 三菱重工サーマルシステムズ株式会社 | Step-out detection device, duct type air conditioner with the same, step-out detection method and step-out detection program |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| EP2530273B1 (en)* | 2011-06-01 | 2020-04-08 | Joseph Vögele AG | Construction machine with automatic ventilator rotation speed regulator |

| TW201445870A (en)* | 2012-09-21 | 2014-12-01 | Ya De Li Technology Inc | Intelligent motor controller, control method, tag-on circuit and remote control thereof |

| CN111211715B (en)* | 2018-11-22 | 2023-04-25 | 杭州先途电子有限公司 | A motor control method, system, and controller |

| CN112737422B (en)* | 2021-01-20 | 2022-11-29 | 河南城建学院 | A speed control method for motor equipment based on cloud computing |

- 2021

- 2021-12-23CNCN202111592532.5Apatent/CN114337467B/enactiveActive

- 2022

- 2022-02-15TWTW111105476Apatent/TWI784880B/enactive

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US6518719B1 (en)* | 1999-11-16 | 2003-02-11 | Makita Corporation | Power tools with operating speed control circuit |

| US20050002135A1 (en)* | 2003-05-30 | 2005-01-06 | Koichi Kokubo | Pump drive motor control apparatus |

| US20050043873A1 (en)* | 2003-08-21 | 2005-02-24 | Mir Sayeed A. | Current limit for an electric machine |

| US20090295313A1 (en)* | 2008-05-30 | 2009-12-03 | Makita Corporation | Rechargeable power tool, control unit and recording medium |

| JP2011200058A (en)* | 2010-03-23 | 2011-10-06 | Hitachi Automotive Systems Ltd | Driving device for brushless motor |

| US20120262101A1 (en)* | 2011-03-15 | 2012-10-18 | Johnson Controls Technology Company | Control systems and methods for electronically commutated motors |

| JP2014045654A (en)* | 2013-12-12 | 2014-03-13 | Hitachi Automotive Systems Ltd | Drive unit of brushless motor |

| CN106020131A (en)* | 2015-03-31 | 2016-10-12 | 德马吉森精机株式会社 | System and method for fine-tuning speed selection for reducing machine chatter |

| JP2017192207A (en)* | 2016-04-13 | 2017-10-19 | 株式会社日立製作所 | Dynamo-electric machine system and control method of dynamo-electric machine system |

| WO2018102872A1 (en)* | 2016-12-08 | 2018-06-14 | University Of Technology Sydney | Sensorless ac motor controller |

| JP2018182786A (en)* | 2017-04-03 | 2018-11-15 | 株式会社島津製作所 | Motor failure detection device for vacuum pump and vacuum pump system |

| JP2019158315A (en)* | 2018-03-16 | 2019-09-19 | 三菱重工サーマルシステムズ株式会社 | Step-out detection device, duct type air conditioner with the same, step-out detection method and step-out detection program |

Also Published As

| Publication number | Publication date |

|---|---|

| TWI784880B (en) | 2022-11-21 |

| CN114337467B (en) | 2024-01-12 |

| TW202327254A (en) | 2023-07-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Sepe et al. | Fault-tolerant operation of induction motor drives with automatic controller reconfiguration | |

| CN109217758B (en) | Online identification method for rotary transformer zero point, motor controller and storage medium | |

| CN114337467A (en) | Method for adjusting motor rotation speed and computer storage medium | |

| CN115931036B (en) | Magnetic encoder fault detection method and device, electronic equipment and storage medium | |

| US20210315129A1 (en) | Fan control circuit with temperature compensation and method of controlling fan | |

| CN103688228B (en) | Device and method for optimizing output power of solar cell | |

| CN103956940A (en) | Against-wind start control method and device of direct current motor in outdoor unit of air conditioner | |

| US12184216B2 (en) | Parameter control system and motor including the parameter control system | |

| CN112787567B (en) | Control method and system | |

| CN114543341B (en) | Method and device for controlling air deflector, air conditioner and storage medium | |

| CN117639594A (en) | Sensorless control method for asynchronous motor of neural network rotation speed estimator | |

| TWI251397B (en) | Control unit for driving a regulating transistor of a fan arrangement | |

| KR100657489B1 (en) | Method and device for starting determination of motor without sensor | |

| CN110365259B (en) | Back electromotive force sampling circuit and sampling method of permanent magnet synchronous motor | |

| CN100426651C (en) | Motor control device and method | |

| CN118074586A (en) | Method and device for identifying motor rotor positioning angle, motor | |

| CN108631655B (en) | Intelligent power module of motor control device | |

| CN111509665B (en) | Under-voltage protection circuit and method based on temperature and process compensation | |

| CN114094660A (en) | Linear charging system with high-voltage turn-off function | |

| CN113839594A (en) | Identification method and identification device for stator resistance of motor and motor control system | |

| CN113839605A (en) | Motor rotating speed control method and device | |

| Ji et al. | Online q-axis inductance identification of IPM synchronous motor based on relationship between its parameter mismatch and current | |

| CN115185328B (en) | Voltage regulating circuit, electric signal detection circuit and electronic equipment | |

| KR102506215B1 (en) | Apparatus for controlling inverter | |

| CN119695789A (en) | Motor control method, device, motor, storage medium and program product |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| CP03 | Change of name, title or address | ||

| CP03 | Change of name, title or address | Address after:201203 Shanghai Pudong New Area Zhangjiang High-tech Park, No. 168 Huatuo Road, Building 3 Commercial Center Patentee after:Angbao Integrated Circuit Co.,Ltd. Country or region after:China Address before:201203 Shanghai Pudong New Area Zhangjiang High-tech Park, No. 168 Huatuo Road, Building 3 Commercial Center Patentee before:On-Bright Electronics (Shanghai) Co.,Ltd. Country or region before:China |