CN114323933A - Testing system and method based on mechanical characteristics of contact surface of high polymer and concrete - Google Patents

Testing system and method based on mechanical characteristics of contact surface of high polymer and concreteDownload PDFInfo

- Publication number

- CN114323933A CN114323933ACN202111411031.2ACN202111411031ACN114323933ACN 114323933 ACN114323933 ACN 114323933ACN 202111411031 ACN202111411031 ACN 202111411031ACN 114323933 ACN114323933 ACN 114323933A

- Authority

- CN

- China

- Prior art keywords

- concrete

- contact surface

- sample

- grouting

- testing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N3/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N3/08—Investigating strength properties of solid materials by application of mechanical stress by applying steady tensile or compressive forces

- G01N3/10—Investigating strength properties of solid materials by application of mechanical stress by applying steady tensile or compressive forces generated by pneumatic or hydraulic pressure

- G01N3/12—Pressure testing

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2203/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N2203/0014—Type of force applied

- G01N2203/0016—Tensile or compressive

- G01N2203/0019—Compressive

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2203/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N2203/0058—Kind of property studied

- G01N2203/0069—Fatigue, creep, strain-stress relations or elastic constants

- G01N2203/0075—Strain-stress relations or elastic constants

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2203/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N2203/02—Details not specific for a particular testing method

- G01N2203/026—Specifications of the specimen

- G01N2203/0298—Manufacturing or preparing specimens

Landscapes

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Investigating Strength Of Materials By Application Of Mechanical Stress (AREA)

- Sampling And Sample Adjustment (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及力学测量仪器领域,尤其涉及一种基于高聚物与混凝土接触面力学特性测试系统及方法。The invention relates to the field of mechanical measuring instruments, in particular to a system and method for testing mechanical properties of a contact surface between a polymer and concrete.

背景技术Background technique

高聚物注浆技术指在压力作用下将双组份原材料注入岩土体裂隙内,原材料经过化学反应后生成固体介质,从而达到抬升上部结构、充填空洞裂隙和防渗堵漏的目的。高聚物注浆技术在交通、水利和市政等基础工程设施非开挖快速修复中取得了成功应用。在实际工程中,高聚物注浆试样通常和路基、管道、堤坝等既有工程体紧密贴合,出现了高聚物材料与混凝土接触面这一工程问题。Polymer grouting technology refers to the injection of two-component raw materials into the cracks of rock and soil under pressure, and the raw materials undergo chemical reaction to generate solid media, so as to achieve the purpose of lifting the upper structure, filling voids and cracks, and preventing seepage and plugging. Polymer grouting technology has been successfully applied in the rapid repair of infrastructure such as transportation, water conservancy and municipal facilities without excavation. In practical engineering, polymer grouting samples are usually closely attached to existing engineering bodies such as roadbeds, pipelines, and dams, and the engineering problem of the contact surface between polymer materials and concrete appears.

目前科研人员主要是采用直剪法研究高聚物与混凝土接触面的力学特性,现有的方法或装置难以获得接触面的变形特征,且试样的制备和力学测试过程是分开进行的,接触面易受到扰动。现有专利CN201920166352.2公开了一种交通荷载作用下埋地管道力学响应试验装置,通过更换填土类型、改变压实度、调节变径板、顶推不同长度抽屉式脱空箱、滚动反力架和作动器、改变填土高度、改变含水率的方式考量土质、压实度、管径、脱空长度、交通荷载作用位置、埋深、含水量对埋地管道力学响应的影响,为交通荷载作用下正常和脱空埋地管道受力机理研究和高聚物修复管底脱空效果评价提供可靠的数据依据,可见,其针对的是管道在交通载荷作用下的数据参数变化情况,并未对管道与混凝土接触面进行分析,进而亟需一种可以用于研究高聚物与混凝土接触面的力学特性的装置。At present, researchers mainly use the direct shear method to study the mechanical properties of the contact surface between polymer and concrete. It is difficult to obtain the deformation characteristics of the contact surface with the existing method or device, and the preparation of the sample and the mechanical testing process are carried out separately. face is easily disturbed. The existing patent CN201920166352.2 discloses a mechanical response test device for buried pipelines under the action of traffic loads. The force frame and actuator, the method of changing the fill height and the water content consider the influence of soil quality, compaction, pipe diameter, void length, traffic load action position, burial depth, and water content on the mechanical response of buried pipelines. It provides a reliable data basis for the study of the stress mechanism of the normal and empty buried pipelines under the action of traffic loads and the evaluation of the emptying effect of the polymer repair pipe bottom. It can be seen that it is aimed at the changes of the data parameters of the pipeline under the action of traffic loads. , the interface between the pipe and the concrete is not analyzed, and there is an urgent need for a device that can be used to study the mechanical properties of the interface between the polymer and the concrete.

发明内容SUMMARY OF THE INVENTION

本发明的主要目的在于提出一种基于高聚物与混凝土接触面力学特性测试系统及方法,旨在解决现有技术中难以获取高聚物与混凝土接触面的力学特性的技术问题。The main purpose of the present invention is to propose a system and method for testing the mechanical properties of the contact surface between polymer and concrete, aiming to solve the technical problem that it is difficult to obtain the mechanical properties of the contact surface between polymer and concrete in the prior art.

为实现上述目的,本发明提供一种基于高聚物与混凝土接触面力学特性测试系统,包括制样测试一体装置和采集机构;In order to achieve the above object, the present invention provides a mechanical property testing system based on the contact surface between polymer and concrete, including a sample preparation and testing integrated device and a collection mechanism;

所述制样测试一体装置包括可调节的试验箱本体和压力控制结构;The integrated device for sample preparation and testing includes an adjustable test box body and a pressure control structure;

所述试验箱体包括用于放置预制混凝土的两个第一腔体和位于所述两个第一腔体之间的第二腔体,所述第二腔体用于放置待试验注浆试样;The test box includes two first cavities for placing precast concrete and a second cavity between the two first cavities, and the second cavity is used for placing the grouting test to be tested. Sample;

所述压力控制结构用于对放置在两个第一腔体中的混凝土施加相对作用力;the pressure control structure is used to exert a relative force on the concrete placed in the two first cavities;

所述采集机构用于实时采集所述待试验注浆试样在相对作用力下的变形数据。The acquisition mechanism is used for real-time acquisition of deformation data of the grouting sample to be tested under the relative force.

可选地,所述第二腔体包括两个活动式挡板和一个活动式底板。Optionally, the second cavity includes two movable baffles and a movable bottom plate.

可选地,所述试验箱本体还包括可移动密封盖,所述可移动密封盖覆盖在所述两个第一腔体和第二腔体上方,所述可移动密封盖表面设置有注浆孔。Optionally, the test box body further includes a movable sealing cover, the movable sealing cover is covered above the two first cavities and the second cavity, and the surface of the movable sealing cover is provided with grouting. hole.

可选地,所述可移动密封盖表面还设置有观测孔。Optionally, an observation hole is also provided on the surface of the movable sealing cover.

可选地,所述压力控制结构还包括至少两根贯通所述试验箱本体的贯通式螺栓,各贯通式螺栓平行于两个第一腔体中的混凝土所受的的相对作用力方向,且位于所述两个第一腔体和第二腔体外侧。Optionally, the pressure control structure further includes at least two through-bolts penetrating the test box body, each through-bolt is parallel to the direction of the relative force on the concrete in the two first cavities, and located outside the two first cavities and the second cavity.

可选地,处于同一水平的两个贯通式螺栓与所述试验箱本体的侧表面之间设置有垫片,各垫片下方设置有压力感应器。Optionally, gaskets are arranged between the two through-bolts at the same level and the side surface of the test box body, and a pressure sensor is arranged under each gasket.

可选地,所述制样测试一体装置还包括刚性垫片,所述刚性垫片放置在固化的注浆试样的上表面。Optionally, the integrated device for sample preparation and testing further includes a rigid gasket, and the rigid gasket is placed on the upper surface of the cured grouting sample.

此外,为实现上述目的,本发明还提供一种基于高聚物与混凝土接触面力学特性测试方法,采用上述任一项所述的基于高聚物与混凝土接触面力学特性测试系统,所述方法包括以下步骤:In addition, in order to achieve the above object, the present invention also provides a method for testing the mechanical properties of the contact surface based on polymers and concrete, using any of the above-mentioned testing systems based on the mechanical properties of the contact surface between polymers and concrete, the method Include the following steps:

在固化的注浆试样与两个预制混凝土的接触面喷涂目标物质,所述固化的注浆试样位于所述两个预制混凝土之间;The target substance is sprayed on the contact surface of the cured grouting sample and the two precast concretes, and the cured grouting sample is located between the two precast concretes;

对所述两个预制混凝土侧表面施加相对作用力,以使所述固化的注浆试样在相对作用力下发生形变;applying a relative force to the two precast concrete side surfaces to deform the cured grouting sample under the relative force;

实时采集所述固化的注浆试样在相对作用力下的变形数据。The deformation data of the solidified grouting sample under the relative force is collected in real time.

可选地,所述在固化的注浆试样与两个预制混凝土的接触面喷涂目标物质的步骤之前,包括:Optionally, before the step of spraying the target substance on the contact surfaces of the cured grouting sample and the two precast concretes, it includes:

在制样测试一体装置的两个间隔的第一腔体中分别放入预制混凝土;Put precast concrete into the two spaced first cavities of the integrated sample preparation and testing device respectively;

在所述制样测试一体装置上方盖上密封盖,所述密封盖贯通设置有注浆孔;A sealing cover is covered above the integrated device for sample preparation and testing, and a grouting hole is provided through the sealing cover;

通过所述注浆孔向所述两个第一腔体之间的第二腔体注射注浆试样,直至注浆试样达到预设重量。The grouting sample is injected into the second cavity between the two first cavities through the grouting hole until the grouting sample reaches a preset weight.

可选地,所述对所述两个预制混凝土侧表面施加相对作用力的同时,还包括:Optionally, while applying a relative force to the two precast concrete side surfaces, it also includes:

对固化的注浆试样上表面施加作用力。A force is applied to the upper surface of the cured grout specimen.

本发明提出的一种基于高聚物与混凝土接触面力学特性测试系统,包括制样测试一体装置和采集机构;所述制样测试一体装置包括可调节的试验箱本体和压力控制结构;所述试验箱体包括用于放置预制混凝土的两个第一腔体和位于所述两个第一腔体之间的第二腔体,所述第二腔体用于放置待试验注浆试样;所述压力控制结构用于对放置在两个第一腔体中的混凝土施加相对作用力;所述采集机构用于实时采集所述待试验注浆试样在相对作用力下的变形数据。该测试系统的兼具制备试验试样和力学测试试验试样一体化,进而提高了试验试样测试的数据准确率,以及为定量评价高聚物注浆修复效果的提供了夯实的理论基础。A mechanical property testing system based on the contact surface between polymers and concrete proposed by the present invention includes a sample preparation and testing integrated device and a collection mechanism; the sample preparation and testing integrated device includes an adjustable test box body and a pressure control structure; the The test box includes two first cavities for placing precast concrete and a second cavity between the two first cavities, where the second cavities are used for placing grouting samples to be tested; The pressure control structure is used to apply a relative force to the concrete placed in the two first cavities; the acquisition mechanism is used to collect the deformation data of the grouting sample to be tested under the relative force in real time. The test system integrates the preparation test sample and the mechanical test test sample, thereby improving the data accuracy of the test sample test, and providing a solid theoretical basis for quantitatively evaluating the repair effect of polymer grouting.

附图说明Description of drawings

为了更清楚地说明本发明实施例或现有技术中的技术方案,下面将对实施例或现有技术描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图仅仅是本发明的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图示出的结构获得其他的附图。In order to illustrate the embodiments of the present invention or the technical solutions in the prior art more clearly, the following briefly introduces the accompanying drawings that are used in the description of the embodiments or the prior art. Obviously, the drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained according to the structures shown in these drawings without creative efforts.

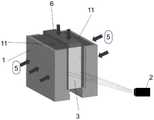

图1为本发明基于高聚物与混凝土接触面力学特性测试系统一实施例的效果示意图;1 is a schematic diagram of the effect of an embodiment of the present invention based on the testing system for mechanical properties of the contact surface between polymers and concrete;

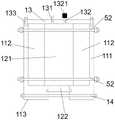

图2为图1所示实施例中试验箱本体的俯视简图;Figure 2 is a schematic top view of the test box body in the embodiment shown in Figure 1;

图3为图1所示实施例中试验箱本体的后视图;Fig. 3 is the rear view of the test box body in the embodiment shown in Fig. 1;

图4为图1所示实施例中试验箱本体的右视图;Fig. 4 is the right side view of the test box body in the embodiment shown in Fig. 1;

图5为图1所示实施例中试验箱本体的底部俯视图;Fig. 5 is the bottom plan view of the test box body in the embodiment shown in Fig. 1;

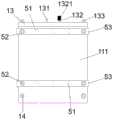

图6为图1所示实施例中试验箱本体的密封盖的俯视图;Fig. 6 is the top view of the sealing cover of the test box body in the embodiment shown in Fig. 1;

图7为本发明基于高聚物与混凝土接触面力学特性测试方法一实施例的流程示意图。FIG. 7 is a schematic flowchart of an embodiment of a method for testing mechanical properties of a contact surface between polymers and concrete according to the present invention.

本发明目的的实现、功能特点及优点将结合实施例,参照附图做进一步说明。The realization, functional characteristics and advantages of the present invention will be further described with reference to the accompanying drawings in conjunction with the embodiments.

附图标号说明:Description of reference numbers:

具体实施方式Detailed ways

应当理解,此处所描述的具体实施例仅仅用以解释本发明,并不用于限定本发明。It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明的一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有作出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

需要说明,本发明实施例中所有方向性指示(诸如上、下、左、右、前、后......)仅用于解释在某一特定姿态(如附图所示)下各部件之间的相对位置关系、运动情况等,如果该特定姿态发生改变时,则该方向性指示也相应地随之改变。It should be noted that all directional indications (such as up, down, left, right, front, back...) in the embodiments of the present invention are only used to explain the The relative positional relationship between the components, the movement situation, etc., if the specific posture changes, the directional indication also changes accordingly.

另外,在本发明中涉及“第一”、“第二”等的描述仅用于描述目的,而不能理解为指示或暗示其相对重要性或者隐含指明所指示的技术特征的数量。由此,限定有“第一”、“第二”的特征可以明示或者隐含地包括至少一个该特征。另外,各个实施例之间的技术方案可以相互结合,但是必须是以本领域普通技术人员能够实现为基础,当技术方案的结合出现相互矛盾或无法实现时应当认为这种技术方案的结合不存在,也不在本发明要求的保护范围之内。In addition, the descriptions involving "first", "second", etc. in the present invention are only for descriptive purposes, and should not be understood as indicating or implying their relative importance or implying the number of indicated technical features. Thus, a feature delimited with "first", "second" may expressly or implicitly include at least one of that feature. In addition, the technical solutions between the various embodiments can be combined with each other, but must be based on the realization by those of ordinary skill in the art. When the combination of technical solutions is contradictory or cannot be realized, it should be considered that the combination of such technical solutions does not exist. , is not within the scope of protection required by the present invention.

参见图1至图6,本发明提供提供一种基于高聚物与混凝土接触面力学特性测试系统,包括制样测试一体装置和采集机构2;所述制样测试一体装置包括可调节的试验箱本体1和压力控制结构5;所述试验箱本体1包括用于放置预制混凝土4的两个第一腔体11和位于所述两个第一腔体之间的第二腔体12,所述第二腔体12用于放置待试验注浆试样3;所述压力控制结构5用于对放置在两个第一腔体11中的混凝土4施加相对作用力;所述采集机构2用于实时采集所述待试验注浆试样3在相对作用力下的变形数据。Referring to FIGS. 1 to 6 , the present invention provides a mechanical property testing system based on the contact surface between polymers and concrete, including a sample preparation and testing integrated device and a

具体地,注浆试样3一般为高聚物,如图3至5所示,所述试验箱本体1包括两组侧挡板111、两块前/后挡板112、底板113、两个活动式挡板122和一个活动式底121板拼接形成的容纳腔体,所述容纳腔体分为两个第一腔体11和一个第二腔体12,其中两组侧挡板111、两块前/后挡板112和底板113形成两个第一腔体11,以及由两个活动式挡板122和一个活动式底板121形成的第二腔体12将两个第一腔体11隔开。此外,所述两个第一腔体11的尺寸可以设置相同,也可以不同。Specifically, the

进一步地,所述底板113还贯通设置有辅助结构14,所述辅助结构14两端通过固定件与底板113的侧表面固定,所述辅助结构14起到加强固定试验箱本体1稳固性。其中所述固定件多采用螺栓与螺母进行匹配固定。Further, the

进一步地,如图2所示,所述两个活动式挡板122不接触且间隔预设距离,两个活动式挡板122的间隔距离与放入第一腔体11中的混凝土4长度相匹配。优选地,所述两个活动式挡板122平行设置,进而可以得到规整的固化试样。在制备试样时,需要将两个活动式挡板122、一个活动式底板121与第一腔体11中放置的混凝土围成第二腔体12,以方便在第二腔体12中注入待试验注浆材料;并在制备完成后,将两个活动式挡板122、一个活动式底板121拆除,并露出高聚物-混凝土接触面,以备后续测试使用。Further, as shown in FIG. 2 , the two

进一步地,如图3至4所示,所述试验箱本体1还包括可移动密封盖13,所述可移动密封盖13覆盖在所述两个第一腔体11和第二腔体12上方,且所述可移动密封盖13通过固定件133分别与两个侧挡板111进行固定,固定件133多采用螺栓与螺母进行固定。密封盖13的设置,使得在制备试样时可以避免外界环境对制备的影响,进而提高后续测试的准确性。Further, as shown in FIGS. 3 to 4 , the

进一步地,如图6所示,所述可移动密封盖13表面设置有注浆孔131。Further, as shown in FIG. 6 , a

进一步地,所述可移动密封盖13表面还设置有观测孔132。Further, an

具体地,所述注浆孔131和观测孔132贯通所述可移动密封盖13且与第二腔体12连通,观测孔132可以有利于在制备试样的过程中排出多余的空气,以及实时确定注浆孔131中注射浆料量的情况。此外,所述观测孔132出口还设置有关闭阀门1321。Specifically, the

进一步地,如图3所示,所述压力控制结构5还包括至少两根贯通所述试验箱本体1的贯通式螺栓52,各贯通式螺栓52平行于两个第一腔体11中的混凝土所受的相对作用力方向,且位于所述两个第一腔体11和第二腔体12外侧。具体地,所述各贯通式螺栓52贯通所述试验箱本体1并通过相应的固定件与试验箱本体1的两个侧挡板111固定,且位于放置预制混凝土4和高聚物试样3的外侧,进而方便对预制混凝土4和高聚物试样3施加可调节的作用力。其中所述固定件多采用螺栓与螺母进行匹配固定。Further, as shown in FIG. 3 , the

进一步地,处于同一水平的两个贯通式螺栓52与所述试验箱本体1的侧表面之间设置有垫片53,各垫片下方设置有压力感应器51。具体地,底板53为矩形结构,且底板的长度大于或等于所述侧挡板111的宽度,并且在各垫片53下方设置有多个压力传感器51,如图4所示,单个垫片53连接着两根相互平行的贯通式螺栓52,以及单块垫片53下方设置有3个压力传感器51,以及在侧挡板111上设置有两块垫片。该垫片53的设置,可以实现通过螺母连接两个处于同一水平的贯通式螺栓52,进而在一定程度上起到均匀受力的效果。一般地,在测试时,将制样测试一体装置放置在电液伺服试验机上,并通过逐渐拧紧贯通式螺栓52实现对预制混凝土4和高聚物试样3的接触面施加法向荷载至预设要求,并通过压力传感器51对法向应力进行实时监测。Further,

进一步地,所述制样测试一体装置还包括刚性垫片6,所述刚性垫片6放置在固化的注浆试样3的上表面。具体地,在测试过程中,除了需要采集二维的相对作用力,还要根据实际需求设置施加在试样上表面的压力,进而通过设置刚性垫片6,使得固化的注浆试样3均匀受力。Further, the integrated device for sample preparation and testing further includes a

此外,为实现上述目的,本发明还提供一种混凝土接触面力学特性测试方法,采用上述任一项所述的混凝土接触面力学特性测试系统,所述方法包括以下步骤:In addition, in order to achieve the above purpose, the present invention also provides a method for testing the mechanical properties of a concrete contact surface, using any of the above-mentioned concrete contact surface mechanical properties testing system, and the method includes the following steps:

步骤S1,在固化的注浆试样与两个预制混凝土4的接触面喷涂目标物质,所述固化的注浆试样3位于所述两个预制混凝土4之间;Step S1, spraying the target substance on the contact surface of the cured grouting sample and the two

具体地,将注浆试样3与两个预制混凝土4接触面上均匀喷涂散斑后将整体装置移至电液伺服试验机进行测试。Specifically, after uniformly spraying speckles on the contact surfaces of the

步骤S2,对所述两个预制混凝土4侧表面施加相对作用力,以使所述固化的注浆试样在相对作用力下发生形变;Step S2, applying a relative force to the side surfaces of the two

步骤S3,实时采集所述固化的注浆试样3在相对作用力下的变形数据。In step S3, the deformation data of the solidified

具体地,通过设置的压力传感器51对所述两个预制混凝土4侧表面所受的法向应力进行实时监测,并且,在所述步骤S2的同时,还通过设置在固化的注浆试样3上表面的刚性垫片6施加向下的作用力。进而借助试验机和刚性垫片6向固化的注浆试样试样施加荷载,并借助于采集机构2对接触面的三维应变数据进行实时采集,接触面的黏结强度t通过如下公式计算:Specifically, the normal stress on the side surfaces of the two

其中,F为试样破坏时的荷载,L为接触面边长;m为刚性垫片质量;g为重力加速度;Among them, F is the load when the sample fails, L is the side length of the contact surface; m is the mass of the rigid gasket; g is the acceleration of gravity;

具体地,所述采集机构2为DIC高清数字照相变形量测系统。Specifically, the

进一步地,所述在固化的注浆试样与两个预制混凝土的接触面喷涂目标物质的步骤之前,还包括:Further, before the step of spraying the target substance on the contact surfaces of the cured grouting sample and the two precast concretes, it also includes:

步骤S5,在制样测试一体装置的两个间隔的第一腔体11中分别放入预制混凝土4;Step S5, put the

步骤S6,在所述制样测试一体装置上方盖上密封盖13,所述密封盖13贯通设置有注浆孔131;Step S6, cover the sealing

步骤S7,通过所述注浆孔131向所述两个第一腔体11之间的第二腔体12注射注浆试样,直至注浆试样达到预设重量。Step S7, inject the grouting sample into the

具体地,通过注浆孔131向两块混凝土4中间位置注射高聚物注浆试样3原材料,当有原材料从观测孔132溢出时关闭阀门1321,继续注射高聚物原材料至预设重量。Specifically, inject the raw material of the

本实施例的测试方法采用兼具制备试验试样和力学测试试验试样一体化,一方面保障了试样的制备过程及力学试验过程是连续进行的,避免试样移动过程中接触面受到外界扰动,另一方面,可以实现对接触面的三维应变场的实时监测与采集。此外,可以通过向注浆区域内预先充满水,来模拟有水条件下的高聚物注浆过程,研究接触面含水率对其力学特性的影响规律。The test method of this embodiment adopts the integration of both the preparation test sample and the mechanical test test sample. On the one hand, it ensures that the preparation process of the sample and the mechanical test process are carried out continuously, and avoids the contact surface being affected by the external environment during the movement of the sample. The disturbance, on the other hand, can realize the real-time monitoring and acquisition of the three-dimensional strain field of the contact surface. In addition, the polymer grouting process under water conditions can be simulated by filling the grouting area with water in advance, and the influence of the moisture content of the contact surface on its mechanical properties can be studied.

需要说明的是,在本文中,术语“包括”、“包含”或者其任何其他变体意在涵盖非排他性的包含,从而使得包括一系列要素的过程、方法、物品或者系统不仅包括那些要素,而且还包括没有明确列出的其他要素,或者是还包括为这种过程、方法、物品或者系统所固有的要素。在没有更多限制的情况下,由语句“包括一个......”限定的要素,并不排除在包括该要素的过程、方法、物品或者系统中还存在另外的相同要素。上述本发明实施例序号仅仅为了描述,不代表实施例的优劣。It should be noted that, herein, the terms "comprising", "comprising" or any other variation thereof are intended to encompass non-exclusive inclusion, such that a process, method, article or system comprising a series of elements includes not only those elements, It also includes other elements not expressly listed or inherent to such a process, method, article or system. Without further limitation, an element qualified by the phrase "comprising a..." does not preclude the presence of additional identical elements in the process, method, article or system that includes the element. The above-mentioned serial numbers of the embodiments of the present invention are only for description, and do not represent the advantages or disadvantages of the embodiments.

以上仅为本发明的优选实施例,并非因此限制本发明的专利范围,凡是利用本发明说明书及附图内容所作的等效结构或等效流程变换,或直接或间接运用在其他相关的技术领域,均同理包括在本发明的专利保护范围内。The above are only preferred embodiments of the present invention, and are not intended to limit the scope of the present invention. Any equivalent structure or equivalent process transformation made by using the contents of the description and drawings of the present invention, or directly or indirectly applied in other related technical fields , are similarly included in the scope of patent protection of the present invention.

Claims (10)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111411031.2ACN114323933A (en) | 2021-11-25 | 2021-11-25 | Testing system and method based on mechanical characteristics of contact surface of high polymer and concrete |

| KR1020220078518AKR102826001B1 (en) | 2021-11-25 | 2022-06-27 | Testing system and method based on mechanical properties of polymer-concrete interface |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202111411031.2ACN114323933A (en) | 2021-11-25 | 2021-11-25 | Testing system and method based on mechanical characteristics of contact surface of high polymer and concrete |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114323933Atrue CN114323933A (en) | 2022-04-12 |

Family

ID=81047503

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202111411031.2APendingCN114323933A (en) | 2021-11-25 | 2021-11-25 | Testing system and method based on mechanical characteristics of contact surface of high polymer and concrete |

Country Status (2)

| Country | Link |

|---|---|

| KR (1) | KR102826001B1 (en) |

| CN (1) | CN114323933A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115290405A (en)* | 2022-05-30 | 2022-11-04 | 郑州大学 | Sample preparation device and method for mud-skin-containing high polymer solidified soil and concrete shear sample |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN119715660B (en)* | 2024-12-02 | 2025-09-26 | 郑州大学 | A real-time testing device for frost heave force and deformation of cylindrical concrete specimens under freeze-thaw-load coupling |

| CN119321987B (en)* | 2024-12-19 | 2025-04-11 | 江西省骏杰鞋材有限责任公司 | Performance data evaluation method for sole rubber material |

Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20030071109A (en)* | 2002-02-27 | 2003-09-03 | 윤경구 | An apparatus and method for measurement of adhesion strength of concrete by a uniaxial tension |

| CN101074912A (en)* | 2007-06-06 | 2007-11-21 | 河海大学 | Apparatus and method for testing cement concrete penetration performance under loading action |

| CN103674708A (en)* | 2013-12-27 | 2014-03-26 | 大连大学 | Multi-factor coupling concrete durability study experiment loading device |

| CN203587484U (en)* | 2013-11-19 | 2014-05-07 | 河海大学 | Mechanical fixing device for measuring adhesive property between steel bar and concrete |

| CN111829923A (en)* | 2020-07-14 | 2020-10-27 | 郑州大学 | Polyurethane rheological property testing device and method |

| CN112461685A (en)* | 2020-12-24 | 2021-03-09 | 长沙理工大学 | Experimental test method for shear strength of CA mortar and concrete bonding contact surface |

| US20210164875A1 (en)* | 2019-12-02 | 2021-06-03 | Restone As | Bond strength testing |

| CN113029819A (en)* | 2021-03-19 | 2021-06-25 | 三峡大学 | Sample preparation and test integrated shearing device and method suitable for self-expanding medium |

| CN113324852A (en)* | 2021-04-27 | 2021-08-31 | 东南大学 | Interface bonding static and dynamic performance test device and test method |

| CN113504095A (en)* | 2021-07-08 | 2021-10-15 | 河南神火煤电股份有限公司 | Method for testing cementing strength of extremely soft mudstone crack grouting interface |

Family Cites Families (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH08198654A (en)* | 1995-01-19 | 1996-08-06 | Asahi Denka Kogyo Kk | Quick-hardening cement-epoxy composition |

| JP6439210B2 (en)* | 2015-02-26 | 2018-12-19 | 清水建設株式会社 | Water retention performance test body for materials having water retention capacity, method for producing the same, and water retention performance test method |

| CN212540073U (en)* | 2020-08-10 | 2021-02-12 | 中铁第四勘察设计院集团有限公司 | Concrete water permeability test device |

| CN113607640B (en)* | 2021-07-21 | 2022-06-21 | 清华大学 | Test analysis method and device for macroscopic occlusal force of steel pipe concrete interface |

- 2021

- 2021-11-25CNCN202111411031.2Apatent/CN114323933A/enactivePending

- 2022

- 2022-06-27KRKR1020220078518Apatent/KR102826001B1/enactiveActive

Patent Citations (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20030071109A (en)* | 2002-02-27 | 2003-09-03 | 윤경구 | An apparatus and method for measurement of adhesion strength of concrete by a uniaxial tension |

| CN101074912A (en)* | 2007-06-06 | 2007-11-21 | 河海大学 | Apparatus and method for testing cement concrete penetration performance under loading action |

| CN203587484U (en)* | 2013-11-19 | 2014-05-07 | 河海大学 | Mechanical fixing device for measuring adhesive property between steel bar and concrete |

| CN103674708A (en)* | 2013-12-27 | 2014-03-26 | 大连大学 | Multi-factor coupling concrete durability study experiment loading device |

| US20210164875A1 (en)* | 2019-12-02 | 2021-06-03 | Restone As | Bond strength testing |

| CN111829923A (en)* | 2020-07-14 | 2020-10-27 | 郑州大学 | Polyurethane rheological property testing device and method |

| CN112461685A (en)* | 2020-12-24 | 2021-03-09 | 长沙理工大学 | Experimental test method for shear strength of CA mortar and concrete bonding contact surface |

| CN113029819A (en)* | 2021-03-19 | 2021-06-25 | 三峡大学 | Sample preparation and test integrated shearing device and method suitable for self-expanding medium |

| CN113324852A (en)* | 2021-04-27 | 2021-08-31 | 东南大学 | Interface bonding static and dynamic performance test device and test method |

| CN113504095A (en)* | 2021-07-08 | 2021-10-15 | 河南神火煤电股份有限公司 | Method for testing cementing strength of extremely soft mudstone crack grouting interface |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115290405A (en)* | 2022-05-30 | 2022-11-04 | 郑州大学 | Sample preparation device and method for mud-skin-containing high polymer solidified soil and concrete shear sample |

Also Published As

| Publication number | Publication date |

|---|---|

| KR20230077624A (en) | 2023-06-01 |

| KR102826001B1 (en) | 2025-06-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN114323933A (en) | Testing system and method based on mechanical characteristics of contact surface of high polymer and concrete | |

| CN103995097B (en) | A kind of test method and device of simulating jacking construction initiation stratum deformation | |

| CN109868849B (en) | A visual test device for pile-soil interaction and its test method | |

| CN105675395B (en) | Ground anchor solid interface stress transfer mechanism pilot system and test method | |

| Gallage et al. | Response of a plastic pipe buried in expansive clay | |

| Tang et al. | Investigations of seismic response to an irregular-section subway station structure located in a soft clay site | |

| CN107478812B (en) | Visualization device and use method for the expansion process of rock and soil mass expansive cement slurry | |

| CN109001098B (en) | A kind of soil instantaneous permeability characteristic tester and soil permeability characteristic calculation method | |

| CN106759547B (en) | Integral bridge abutment, pile foundation and soil interaction quasi-static test measuring device and its installation method | |

| CN104153404A (en) | Testing device and testing method of pile composite foundation combined with broken stone hardcore foundation | |

| CN112649304B (en) | Load performance test system and test method for assembled reinforced retaining wall | |

| Sadeghi et al. | A vacuum-refilled tensiometer for deep monitoring of in-situ pore water pressure | |

| CN109469124B (en) | Layered pile foundation test device and test method adopting double air pressure films for vertical loading | |

| CN109797786A (en) | Excavation of foundation pit model test apparatus and application method based on earth's surface water penetration | |

| CN111413485A (en) | Small hole expansion test device and method | |

| CN107179391A (en) | A kind of experimental rig that Under-cross tunnel shallow layer grouting is buried for an ultra shallow | |

| CN110849729B (en) | Active and passive soil pressure model test device for limited cohesive soil behind foundation pit flexible retaining wall | |

| CN106814017A (en) | Nano sol reinforces the permeability and modulus at rapid deformation relation test device and method of sand | |

| CN209798849U (en) | Layered pile foundation test device with vertical loading of double air pressure film | |

| Wang et al. | Relationship between grain crushing and excess pore pressure generation by sandy soils in ring-shear tests | |

| CN117388082B (en) | Forward-pulling type tunnel anchor indoor test model and test method | |

| CN118566468A (en) | A method for predicting water inrush in fractured rock mass under earthquake-pulsating flow coupling | |

| CN211401942U (en) | Finite cohesive soil active and passive soil pressure model test device behind foundation pit flexible retaining wall | |

| CN106284274B (en) | For measuring the method for Reinforced Foundation soil body bearer properties under different loads | |

| CN120404360B (en) | Determination method for lateral expansion coefficient of expansive soil |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |