CN114323405A - Cadmium phosphide (Cd3P2) is applied to the pressure calibration in the high pressure device of the large cavity press - Google Patents

Cadmium phosphide (Cd3P2) is applied to the pressure calibration in the high pressure device of the large cavity pressDownload PDFInfo

- Publication number

- CN114323405A CN114323405ACN202011055458.9ACN202011055458ACN114323405ACN 114323405 ACN114323405 ACN 114323405ACN 202011055458 ACN202011055458 ACN 202011055458ACN 114323405 ACN114323405 ACN 114323405A

- Authority

- CN

- China

- Prior art keywords

- pressure

- pyrophyllite

- cavity

- press

- copper sheet

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Landscapes

- Investigating Or Analyzing Materials By The Use Of Electric Means (AREA)

- Investigating Strength Of Materials By Application Of Mechanical Stress (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及首次将Cd3P2应用于大腔体压机高压装置压力标定。具体涉及在铋(Bi)、铊(Tl)、钡(Ba)等传统标压物质的基础上,新增Cd3P2作为标压物质,并利用其在高压下发生相变时电阻率突变对腔体压力进行标定,属于高压实验技术领域。The invention relates to the first application of Cd3 P2 to the pressure calibration of a high-pressure device of a large-cavity press. Specifically, on the basis of traditional standard pressure substances such as bismuth (Bi), thallium (Tl), and barium (Ba), Cd3 P2 is added as a standard pressure substance, and its resistivity is abruptly changed when it undergoes a phase transition under high pressure. The calibration of the cavity pressure belongs to the technical field of high pressure experiments.

背景技术Background technique

作为决定物质存在状态和结构变化的基本热力学参数,压力(P)在诱导物质结构和性质的改变上具有不同于温度(T)和化学组分的特殊能力。1935年,随着Bridgman压机的发明,高压技术逐渐出现在人们的视野之中。近百年来,高压实验技术快速发展是加深和扩大高压科学与技术应用的基础,已成为实现高压极端物理条件处理材料的主要方法。多面顶大腔体压机高压装置主要分为拉杆式、滑块式、铰链式。其中铰链式六面顶大腔体压机是我国自主研发的一种结构紧凑、运行成本低、自对中性好、易于维护、样品尺寸大、压力温度场相对均匀可控的高压设备。由于其具有的诸多技术优点,国产铰链式六面顶压机现已广泛应用于国内外科研领域的科学研究和生产领域的超硬材料的合成及其他相关领域取得了一系列突破进展,成为科研与生产的主流高压装置之一。As a basic thermodynamic parameter that determines the existence state and structural changes of substances, pressure (P) has a special ability different from temperature (T) and chemical composition in inducing changes in the structure and properties of substances. In 1935, with the invention of the Bridgman press, high pressure technology gradually appeared in people's field of vision. In the past 100 years, the rapid development of high-pressure experimental technology is the basis for deepening and expanding the application of high-pressure science and technology, and has become the main method to achieve high-pressure extreme physical conditions for processing materials. The high-pressure device of the multi-sided top and large cavity press is mainly divided into pull rod type, slider type and hinge type. Among them, the hinged six-sided top large cavity press is a high-pressure equipment independently developed by my country with compact structure, low operating cost, good self-centering, easy maintenance, large sample size, and relatively uniform and controllable pressure and temperature fields. Due to its many technical advantages, the domestic hinged six-sided top press has been widely used in the synthesis of superhard materials in the field of scientific research and production at home and abroad and has made a series of breakthroughs in other related fields. One of the mainstream high-voltage devices with production.

在高压环境下通常伴随着物质结构、电学性质、磁学性质、光学性质等物性变化。因此,在高压实验中常常通过间接测量物质的物性变化来标定高压腔体内部的压力,常用的压力标定方法有物质相变压力标定法、状态方程压力标定法和光谱压力标定法。压力的标定在高压科学与技术领域实则为压强的标定,其目的在于建立大腔体压机油压加载与腔体中压强的对应关系。本专利采用国产六面顶铰链式压机作为高压产生装置,对于国产六面顶铰链式压机一级腔体压力的标定,常利用物质在高压下的相变点进行标定。通常将已知的相变压力的物质放置于高压装置的压腔内,然后对该物质的某一物性随压力变化情况进行原位观测来判断是否发生相变或者其他物性的改变。如果发生相变,那么就可以判断当前高压腔体中的压力为该物质的相变压力值,从而得到腔体压力随油压加载的对应关系。1952年由Bridgman提出的Bridgman基准便是利用物质在高压极端物理条件下相变时电阻率突变现象来标定物质所处环境的压力值,该方法已广泛的应用于常温下包括六面顶铰链式压机在内的大腔体压机高压装置腔体压力的标定。In a high-voltage environment, it is usually accompanied by changes in physical properties such as material structure, electrical properties, magnetic properties, and optical properties. Therefore, in high-pressure experiments, the pressure inside the high-pressure cavity is often calibrated by indirectly measuring the physical properties of the material. The commonly used pressure calibration methods include the material phase transition pressure calibration method, the state equation pressure calibration method and the spectral pressure calibration method. The calibration of pressure is actually the calibration of pressure in the field of high-pressure science and technology, and its purpose is to establish the corresponding relationship between the oil pressure loading of the large-cavity compressor and the pressure in the cavity. This patent uses a domestic six-sided top hinged press as a high-pressure generating device. For the calibration of the primary cavity pressure of the domestic six-sided top hinged press, the phase transition point of the substance under high pressure is often used for calibration. Usually, a substance with a known phase transition pressure is placed in the pressure chamber of a high-pressure device, and then a certain physical property of the substance is observed in-situ with the pressure change to determine whether a phase transition or other physical property changes have occurred. If a phase change occurs, it can be determined that the current pressure in the high-pressure chamber is the phase change pressure value of the substance, so as to obtain the corresponding relationship between the chamber pressure and the oil pressure loading. The Bridgman benchmark proposed by Bridgman in 1952 is to calibrate the pressure value of the environment where the material is located by using the resistivity mutation phenomenon when the material undergoes phase transition under high pressure extreme physical conditions. The calibration of the cavity pressure of the high pressure device of the large cavity press including the press.

发明内容SUMMARY OF THE INVENTION

本发明目的在于新增标压物质磷化镉(Cd3P2)使腔体压力与油压加载之间关系曲线的准确性提升,能够更精准的对高压装置中腔内压力进行标定。2008年,F.S. Yel’kin等人研究了Cd3P2在高温高压下的相变,该研究表明Cd3P2在常温下的高压相变压力点为4.0GPa(F.S. Yel’kin, et al. "Phase transitions in Cd3P2 at high pressures andhigh temperatures." Journal of Alloys & Compounds 450.1-2(2008):79-85.)。在此研究基础上,我们利用Cd3P2在常温下4.0GPa电阻率发生突变这一电学特性,将其应用在大腔体压机高压装置的压力标定之中,本发明采用国产链铰式六面顶大腔体压机作为高压产生装置。本发明中首次利用Cd3P2进行国产铰链式六面顶压机一级压腔压力标定,对于腔体压力与油压加载之间对应关系的准确性作出了进一步校准。The purpose of the invention is to add a standard pressure substance cadmium phosphide (Cd3 P2 ) to improve the accuracy of the relationship curve between cavity pressure and oil pressure loading, and to more accurately calibrate the pressure in the cavity of the high-pressure device. In 2008, FS Yel'kin et al. studied the phase transition of Cd3 P2 at high temperature and high pressure, which showed that the high pressure phase transition pressure point of Cd3 P2 at room temperature was 4.0GPa (FS Yel'kin, et al. . "Phase transitions in Cd3 P2 at high pressures and high temperatures." Journal of Alloys & Compounds 450.1-2(2008):79-85.). On the basis of this research, we use the electrical property of Cd3 P2 to change its resistivity to 4.0GPa at room temperature, and apply it in the pressure calibration of the high-pressure device of the large-cavity press. The present invention adopts the domestic hinge type. The six-sided top large-cavity press is used as a high-pressure generating device. In the present invention, Cd3 P2 is used for the first time to calibrate the pressure of the primary pressure cavity of the domestic hinged six-sided top press, and further calibration is made for the accuracy of the corresponding relationship between the cavity pressure and the oil pressure loading.

本发明涉及的磷化镉(Cd3P2)应用于大腔体压机高压装置压力标定主要包括以下步骤:The application of the cadmium phosphide (Cd3 P2 ) to the pressure calibration of the high-pressure device of the large-cavity press mainly includes the following steps:

第一步:挑选品质较高,较为致密的叶腊石实心块(32.5mm×32.5mm×32.5mm),质量约为90.6g;Step 1: Select a solid block of pyrophyllite (32.5mm×32.5mm×32.5mm) with higher quality and denser, with a mass of about 90.6g;

第二步:将挑选好的叶腊石切去约1/3体积,同时保证剩余叶腊石高度大于16.25mm;Step 2: Cut off about 1/3 of the selected pyrophyllite, and ensure that the height of the remaining pyrophyllite is greater than 16.25mm;

第三步:把切好的叶腊石用车床加工成两个表面平滑的叶腊石块(32.5mm×32.5mm×16.25mm),即将其组合成边长为32.5mm的正方体叶腊石块;Step 3: Use a lathe to process the cut pyrophyllite into two smooth-surfaced pyrophyllite blocks (32.5mm×32.5mm×16.25mm), that is, combine them into a cube pyrophyllite block with a side length of 32.5mm;

第四步:选择某一个表面较为平整的叶腊石块,沿着某一条对角线的方向,在中心处用小刀划一条深约2mm,长度约为8mm的小槽,将重量约为0.2g的Cd3P2粉末填入槽内;Step 4: Select a pyrophyllite block with a relatively flat surface, along a diagonal direction, use a knife to make a small groove about 2mm deep and about 8mm long in the center, and cut a small groove with a weight of about 0.2g. Cd3 P2 powder is filled into the groove;

第五步:将经砂纸打磨后光亮的导电性能好的铜片剪成L型,其中部尖锐处与Cd3P2粉末接触导通,并固定好铜片,然后剪去超出叶腊石部分的铜片,并留出2-3mm的部分折叠后用于锤面的电路导通即可;Step 5: Cut the bright copper sheet with good electrical conductivity after sanding into an L shape, the sharp part of which is in contact with the Cd3 P2 powder, and fix the copper sheet, and then cut off the copper beyond the pyrophyllite part. 2-3mm part is folded and used for the circuit of the hammer face to be turned on;

第六步:将另外一半叶腊石盖上,用重物静置压实2小时,以保证填充粉末的致密性。采用四线法,将恒流源和多通道记录仪引入到压机的前、后、左、右四个顶锤,将油压信号接到多通道记录仪,在恒流源两端并联一个阻值为1KΩ的电阻。实验开始前设置好升压速率和时间,实验开始后保证恒流源电流稳定的前提下,记录油压曲线和选择好电压测试的量程并记录下电压取值的变化。Step 6: Cover the other half of the pyrophyllite, and let it stand and compact with a heavy object for 2 hours to ensure the compactness of the filling powder. Using the four-wire method, the constant current source and the multi-channel recorder are introduced into the front, rear, left and right top hammers of the press, the oil pressure signal is connected to the multi-channel recorder, and a parallel connection between the two ends of the constant current source A resistor with a resistance value of 1KΩ. Set the boost rate and time before the start of the experiment. After the start of the experiment, under the premise of ensuring the stability of the constant current source current, record the oil pressure curve, select the range of the voltage test, and record the change of the voltage value.

本发明所述方法第一步中选择的高品质叶腊石实心块,其主要成分为Al2Si4O10(OH)2,并且在高温下分解的最终产物为SiO2、Al2O3。所挑选的叶腊石实心块密度约为2.64g/cm3。The high-quality pyrophyllite solid block selected in the first step of the method of the present invention is mainly composed of Al2 Si4 O10 (OH)2 , and the final products decomposed at high temperature are SiO2 and Al2 O3 . The selected solid block of pyrophyllite had a density of about 2.64 g/cm3 .

本发明所述方法第二步中用钢锯切去叶腊石正方块的1/3,尽可能使被切面无较大倾斜,以方便加工。In the second step of the method of the present invention, a hacksaw is used to cut off 1/3 of the square of the pyrophyllite, so that the cut surface is not greatly inclined as much as possible, so as to facilitate processing.

本发明所述方法第三步中用车床加工叶腊石时,在保证平面平整的同时,尽可能保证叶腊石的高度在16.25(±0.1)mm,即两个块组合起来加工成边长为32.5mm的正方体叶腊石块。In the third step of the method of the present invention, when using a lathe to process the pyrophyllite, while ensuring the flatness of the plane, the height of the pyrophyllite should be ensured as much as possible to be 16.25 (±0.1) mm, that is, the two blocks are combined and processed into a side length of 32.5mm. Cube pyrophyllite blocks.

本发明所述方法第四步中在叶腊石中心处划槽的目的在于减小粉末在被压缩过程中产生的流变对电学信号探测的影响。划槽的深度和长度以及取粉量为大概范围取值,具体的实验可灵活实施。The purpose of making grooves at the center of the pyrophyllite in the fourth step of the method of the present invention is to reduce the influence of the rheology of the powder during the compression process on the detection of electrical signals. The depth and length of the grooves and the amount of powder taken are approximate values, and specific experiments can be flexibly implemented.

本发明所述方法第五步中将铜片打磨光亮的目的在于磨去被氧化的氧化铜薄膜,提高铜片的导电性能。L型铜片的尖锐处一定要和粉末较好贴合以为了能够与中部标压物质导通,在沿着对角线方向固定好铜片之后,用万用表的测量电阻的档位确保电路的连通性。切忌将两个L型的铜片顶端相靠太近,以免出现电路短路的问题。The purpose of polishing the copper sheet in the fifth step of the method of the present invention is to polish off the oxidized copper oxide film and improve the electrical conductivity of the copper sheet. The sharp part of the L-shaped copper sheet must be in good contact with the powder in order to be able to conduct with the central pressure material. After fixing the copper sheet along the diagonal direction, use the multimeter to measure the resistance gear to ensure the circuit. Connectivity. Do not place the tops of the two L-shaped copper sheets too close together to avoid short circuit problems.

本发明所述方法第六步中采用四线法布置电路,四线法有利于降低接触电阻,能够使实验所需要采集的电学信号更加清晰。保证恒流源在实验全程中的电流值稳定,多通道记录仪记录原位压力加载过程中的压机油压和线路中的电压信号。In the sixth step of the method of the present invention, a four-wire method is used to arrange the circuit, and the four-wire method is beneficial to reduce the contact resistance, and can make the electrical signal to be collected in the experiment clearer. To ensure that the current value of the constant current source is stable during the whole experiment, the multi-channel recorder records the oil pressure of the compressor and the voltage signal in the line during the in-situ pressure loading process.

有益效果beneficial effect

(1)本发明是首次以磷化镉(Cd3P2)作为新的标压物质,本发明在铋(Bi)、铊(Tl)、钡(Ba)等传统标压物质的基础上新增了可用于大腔体压机高压装置压力标定的物质。磷化镉化学性能稳定,相变时电阻变化明显,测量压力准确。同时没有像铊材料的剧毒和钡材料的极易氧化,是大腔体压机压力标定的一种比较理想的标压物质。(1) The present invention uses cadmium phosphide (Cd3 P2 ) as a new standard pressure substance for the first time. The present invention is based on traditional standard pressure substances such as bismuth (Bi), thallium (Tl) and barium (Ba). Added substances that can be used for pressure calibration of high-pressure devices of large-cavity presses. The chemical properties of cadmium phosphide are stable, the resistance changes obviously during the phase transition, and the measurement pressure is accurate. At the same time, it does not have the high toxicity of thallium material and the easy oxidation of barium material. It is an ideal standard pressure material for the pressure calibration of large cavity presses.

(2)本发明将磷化镉(Cd3P2)应用于大腔体压机高压装置压力标定,进一步校准了标压曲线,有利于提高腔体压力与油压加载的关系曲线的准确性。(2) The present invention applies cadmium phosphide (Cd3 P2 ) to the pressure calibration of the high-pressure device of the large-cavity press, and further calibrates the standard pressure curve, which is beneficial to improve the accuracy of the relationship curve between the cavity pressure and the oil pressure loading .

(3)本发明不仅只适用于六面顶铰链式压机,对于两面顶,四面顶,八面顶等其他大腔体高压装置均可以用于压力标定,具体设备其电学信号的采集方式不同,需要具体装置具体分析。本发明仅以国产六面顶铰链式压机作为高压产生装置,旨在新增标压物质磷化镉(Cd3P2)并且可用于高压设备腔体压力的标定。(3) The present invention is not only applicable to the six-sided top hinged press, but can also be used for pressure calibration for other large-cavity high-pressure devices such as two-sided tops, four-sided tops, and eight-sided tops, and the collection methods of electrical signals for specific equipment are different. , requires a specific device-specific analysis. The invention only uses a domestic six-sided top hinged press as a high-pressure generating device, and aims to add a standard pressure substance cadmium phosphide (Cd3 P2 ) and can be used for the calibration of the cavity pressure of high-pressure equipment.

附图说明Description of drawings

图1:实施例一所述组装的高压原位电阻测量电路示意图。FIG. 1 is a schematic diagram of the high-voltage in-situ resistance measurement circuit assembled according to the first embodiment.

图2:实施例二所述初始标压物质磷化镉(Cd3P2)的XRD图谱。Figure 2: The XRD pattern of the initial standard pressure substance cadmium phosphide (Cd3 P2 ) described in Example 2.

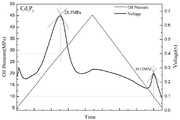

图3:实施例三所述多通道记录仪采集的电压信号变化图。Fig. 3: Variation diagram of the voltage signal collected by the multi-channel recorder according to the third embodiment.

图4:实施例三所述常用于大腔体压机高压装置压力标定材料的相变压力点。Figure 4: The phase change pressure point of the pressure calibration material commonly used in the high pressure device of the large cavity press according to the third embodiment.

图5:实施例四所述新增入磷化镉(Cd3P2)后的标压曲线与传统标压曲线的对比图。Figure 5: The comparison diagram of the standard pressure curve after adding cadmium phosphide (Cd3 P2 ) according to the fourth embodiment and the traditional standard pressure curve.

具体实施方式Detailed ways

实施例一:Example 1:

(1)选取品质较高,较为致密的叶腊石实心块(32.5mm×32.5mm×32.5mm),将挑选好的叶腊石用钢锯切去约1/3,同时保证剩余叶腊石高度大于16.25mm;(1) Select a solid block of pyrophyllite (32.5mm×32.5mm×32.5mm) with higher quality and denser, and cut about 1/3 of the selected pyrophyllite with a hacksaw, while ensuring that the height of the remaining pyrophyllite is greater than 16.25mm;

(2)将切好的叶腊石用车床加工成两个表面平滑的叶腊石块(32.5mm×32.5mm×16.25mm),控制其组合成边长为32.5mm的正方体叶腊石块,误差范围在±0.1mm以内;(2) Use a lathe to process the cut pyrophyllite into two smooth-surfaced pyrophyllite blocks (32.5mm×32.5mm×16.25mm), and control them to form a cube with a side length of 32.5mm. The error range is ±0.1mm within;

(3)选择某一个表面较为平整的叶腊石块,沿着某一条对角线的方向,在中心处用小刀划一条深约2mm,长度约为8mm的小槽,将重量约为0.2g的Cd3P2粉末填入槽内;将经砂纸打磨后光亮的导电性能好的铜片剪成L型,其中部尖锐处与Cd3P2粉末接触导通,并固定好铜片,剪去超出叶腊石部分的铜片,并留出2-3mm的部分折叠后与锤面接触使得电路导通;然后把另外一个叶腊石块盖上,用重物静置压实2小时;采用四线法,将恒流源和多通道记录仪分别引入到六面顶压机的前、后、左、右四个顶锤,在恒流源两端并联一个阻值为1KΩ的电阻,并将油压信号接到多通道记录仪;(3) Select a pyrophyllite block with a relatively flat surface, and along a diagonal direction, use a knife to make a small groove about 2mm deep and about 8mm long in the center, and cut the Cd with a weight of about 0.2g.3 P2 powder is filled into the groove; cut the bright copper sheet with good conductivity after sanding into L shape, the sharp part of the middle part is in contact with the Cd3 P2 powder, and the copper sheet is fixed, and the excess is cut off. The copper sheet of the pyrophyllite part, and leave a 2-3mm part to be folded and contacted with the hammer surface to make the circuit conduct; then cover the other pyrophyllite block, and use a heavy object to stand and compact for 2 hours; using the four-wire method, the The constant current source and the multi-channel recorder are respectively introduced into the front, rear, left and right top hammers of the six-sided top press. A resistor with a resistance value of 1KΩ is connected in parallel at both ends of the constant current source, and the oil pressure signal is connected to to a multi-channel recorder;

(4)实验开始前设置升降压速率为5-45MPa/20min,保证恒流源电流稳定,选择适当电压测试的量程;实验开始时,对压机六个油缸进行充液,当油压升至5MPa时开始记录油压信号和电压信号,当油压升至45MPa时点击压力跳步开始泄压,待油压泄至5MPa时停止记录取出读卡器分析电压信号的变化曲线;(4) Before the start of the experiment, set the step-up and pressure-down rate to 5-45MPa/20min to ensure the stability of the constant current source current, and select the appropriate voltage test range; When the oil pressure reaches 5MPa, start to record the oil pressure signal and voltage signal. When the oil pressure rises to 45MPa, click the pressure jump to start the pressure relief. When the oil pressure is released to 5MPa, stop recording and take out the card reader to analyze the change curve of the voltage signal;

(5)用多通道读取软件将文件转换成Excel格式,然后用Origin绘图,观测电压信号即电阻的突变。实验结果:在对应油压加载为28.2MPa时,电压信号发生明显变化,出现曲线拐点,说明该油压值对应于腔体压力4.0GPa;最后将Bi、Tl、Cd3P2、Ba的相变压力点通过Origin拟合得到了油压加载与腔体压力的关系图,即得到标压曲线。(5) Use the multi-channel reading software to convert the file into Excel format, and then use Origin to draw the graph to observe the voltage signal, that is, the mutation of the resistance. Experimental results: when the corresponding oil pressure loading is 28.2MPa, the voltage signal changes significantly, and the curve inflection point appears, indicating that the oil pressure value corresponds to the cavity pressure 4.0GPa; finally, the phases of Bi, Tl, Cd3 P2 , Ba The relationship between the oil pressure loading and the cavity pressure is obtained by Origin fitting at the variable pressure point, that is, the standard pressure curve is obtained.

实施例二:Embodiment 2:

(1)选取品质较高,较为致密的叶腊石实心块(32.5mm×32.5mm×32.5mm),将挑选好的叶腊石用钢锯切去约1/3,同时保证剩余叶腊石高度大于16.25mm;(1) Select a solid block of pyrophyllite (32.5mm×32.5mm×32.5mm) with higher quality and denser, and cut about 1/3 of the selected pyrophyllite with a hacksaw, while ensuring that the height of the remaining pyrophyllite is greater than 16.25mm;

(2)将切好的叶腊石用车床加工成两个表面平滑的叶腊石块(32.5mm×32.5mm×16.25mm),控制其组合成边长为32.5mm的正方体叶腊石块,误差范围在±0.1mm以内;(2) Use a lathe to process the cut pyrophyllite into two smooth-surfaced pyrophyllite blocks (32.5mm×32.5mm×16.25mm), and control them to form a cube with a side length of 32.5mm. The error range is ±0.1mm within;

(3)选择某一个表面较为平整的叶腊石块,沿着某一条对角线的方向,在中心处用小刀划一条深约2mm,长度约为8mm的小槽,将重量约为0.2g的Cd3P2粉末填入槽内;将经砂纸打磨后光亮的导电性能好的铜片剪成L型,其中部尖锐处与Cd3P2粉末接触导通,并固定好铜片,剪去超出叶腊石部分的铜片,并留出2-3mm的部分折叠后与锤面接触使得电路导通;然后把另外一个叶腊石块盖上,用重物静置压实2小时;采用四线法,将恒流源和多通道记录仪分别引入到六面顶压机的前、后、左、右四个顶锤,在恒流源两端并联一个阻值为1KΩ的电阻,并将油压信号接到多通道记录仪;(3) Select a pyrophyllite block with a relatively flat surface, and along a diagonal direction, use a knife to make a small groove about 2mm deep and about 8mm long in the center, and cut the Cd with a weight of about 0.2g.3 P2 powder is filled into the groove; cut the bright copper sheet with good conductivity after sanding into L shape, the sharp part of the middle part is in contact with the Cd3 P2 powder, and the copper sheet is fixed, and the excess is cut off. The copper sheet of the pyrophyllite part, and leave a 2-3mm part to be folded and contacted with the hammer surface to make the circuit conduct; then cover the other pyrophyllite block, and use a heavy object to stand and compact for 2 hours; using the four-wire method, the The constant current source and the multi-channel recorder are respectively introduced into the front, rear, left and right top hammers of the six-sided top press. A resistor with a resistance value of 1KΩ is connected in parallel at both ends of the constant current source, and the oil pressure signal is connected to to a multi-channel recorder;

(4)实验开始前设置升降压速率为5-45MPa/20min,保证恒流源电流稳定,选择适当电压测试的量程;实验开始时,对压机六个油缸进行充液,当油压升至5MPa时开始记录油压信号和电压信号,当油压升至45MPa时点击压力跳步开始泄压,待油压泄至5MPa时停止记录取出读卡器分析电压信号的变化曲线;(4) Before the start of the experiment, set the step-up and pressure-down rate to 5-45MPa/20min to ensure the stability of the constant current source current, and select the appropriate voltage test range; When the oil pressure reaches 5MPa, start to record the oil pressure signal and voltage signal. When the oil pressure rises to 45MPa, click the pressure jump to start the pressure relief. When the oil pressure is released to 5MPa, stop recording and take out the card reader to analyze the change curve of the voltage signal;

(5)用多通道读取软件将文件转换成Excel格式,然后用Origin绘图,观测电压信号即电阻的突变。实验结果:在对应油压加载为29.3MPa时,电压信号发生明显变化,电压曲线出现拐点,说明该油压值对应于腔体压力4.0GPa。最后将Bi、Tl、Cd3P2、Ba的相变压力点通过Origin拟合得到了油压加载与腔体压力的关系图,即得到标压曲线。(5) Use the multi-channel reading software to convert the file into Excel format, and then use Origin to draw the graph to observe the voltage signal, that is, the mutation of the resistance. Experimental results: When the corresponding oil pressure loading is 29.3MPa, the voltage signal changes significantly, and the voltage curve has an inflection point, indicating that the oil pressure value corresponds to the cavity pressure 4.0GPa. Finally, the phase transition pressure points of Bi, Tl, Cd3 P2 and Ba are fitted by Origin to obtain the relationship between oil pressure loading and cavity pressure, that is, the standard pressure curve is obtained.

实施例三:Embodiment three:

(1)选取品质较高,较为致密的叶腊石实心块(32.5mm×32.5mm×32.5mm),将挑选好的叶腊石用钢锯切去约1/3,同时保证剩余叶腊石高度大于16.25mm;(1) Select a solid block of pyrophyllite (32.5mm×32.5mm×32.5mm) with higher quality and denser, and cut about 1/3 of the selected pyrophyllite with a hacksaw, while ensuring that the height of the remaining pyrophyllite is greater than 16.25mm;

(2)将切好的叶腊石用车床加工成两个表面平滑的叶腊石块(32.5mm×32.5mm×16.25mm),控制其组合成边长为32.5mm的正方体叶腊石块,误差范围在±0.1mm以内;(2) Use a lathe to process the cut pyrophyllite into two smooth-surfaced pyrophyllite blocks (32.5mm×32.5mm×16.25mm), and control them to form a cube with a side length of 32.5mm. The error range is ±0.1mm within;

(3)选择某一个表面较为平整的叶腊石块,沿着某一条对角线的方向,在中心处用小刀划一条深约2mm,长度约为8mm的小槽,将重量约为0.2g的Cd3P2粉末填入槽内;将经砂纸打磨后光亮的导电性能好的铜片剪成L型,其中部尖锐处与Cd3P2粉末接触导通,并固定好铜片,剪去超出叶腊石部分的铜片,并留出2-3mm的部分折叠后用于与锤面接触使得电路导通;然后把另外一个叶腊石块盖上,用重物静置压实2小时;采用四线法,将恒流源和多通道记录仪分别引入到六面顶压机的前、后、左、右四个顶锤,在恒流源两端并联一个阻值为1KΩ的电阻,并将油压信号接到多通道记录仪;(3) Select a pyrophyllite block with a relatively flat surface, and along a diagonal direction, use a knife to make a small groove about 2mm deep and about 8mm long in the center, and cut the Cd with a weight of about 0.2g.3 P2 powder is filled into the groove; cut the bright copper sheet with good conductivity after sanding into L shape, the sharp part of the middle part is in contact with the Cd3 P2 powder, and the copper sheet is fixed, and the excess is cut off. The copper sheet of the pyrophyllite part, and leave a 2-3mm part folded for contact with the hammer surface to make the circuit conduct; then cover the other pyrophyllite block, and use a heavy object to stand and compact for 2 hours; use the four-wire method , introduce the constant current source and the multi-channel recorder into the front, rear, left and right top hammers of the six-sided top press respectively, connect a resistor with a resistance value of 1KΩ in parallel at both ends of the constant current source, and connect the oil pressure The signal is connected to the multi-channel recorder;

(4)实验开始前设置升降压速率为5-45MPa/30min,保证恒流源电流稳定,选择适当电压测试的量程;实验开始时,对压机六个油缸进行充液,当油压升至5MPa时开始记录油压信号和电压信号,当油压升至45MPa是点击压力跳步开始泄压,待油压泄至5MPa时停止记录取出读卡器分析电压信号的变化曲线;(4) Before the start of the experiment, set the step-up and pressure-down rate to 5-45MPa/30min to ensure the stability of the constant current source current, and select the appropriate voltage test range; When the oil pressure reaches 5MPa, it starts to record the oil pressure signal and the voltage signal. When the oil pressure rises to 45MPa, click the pressure jump to start the pressure relief. When the oil pressure is released to 5MPa, stop recording and take out the card reader to analyze the change curve of the voltage signal;

(5)用多通道读取软件将文件转换成Excel格式,然后用Origin绘图,观测电压信号即电阻的突变。实验结果:在对应油压28.3MPa时,电压信号发生明显变化,电压曲线出现拐点,说明该油压值对应于腔体压力4.0GPa。最后将Bi、Tl、Cd3P2、Ba的相变压力点通过Origin拟合得到了油压加载与腔体压力的关系图,即得到标压曲线。(5) Use the multi-channel reading software to convert the file into Excel format, and then use Origin to draw the graph to observe the voltage signal, that is, the mutation of the resistance. Experimental results: When the corresponding oil pressure is 28.3MPa, the voltage signal changes significantly, and the voltage curve has an inflection point, indicating that the oil pressure value corresponds to the cavity pressure 4.0GPa. Finally, the phase transition pressure points of Bi, Tl, Cd3 P2 and Ba are fitted by Origin to obtain the relationship between oil pressure loading and cavity pressure, that is, the standard pressure curve is obtained.

实施例四:Embodiment 4:

(1)选取品质较高,较为致密的叶腊石实心块(32.5mm×32.5mm×32.5mm),将挑选好的叶腊石用钢锯切去约1/3,同时保证剩余叶腊石高度大于16.25mm;(1) Select a solid block of pyrophyllite (32.5mm×32.5mm×32.5mm) with higher quality and denser, and cut about 1/3 of the selected pyrophyllite with a hacksaw, while ensuring that the height of the remaining pyrophyllite is greater than 16.25mm;

(2)将切好的叶腊石用车床加工成两个表面平滑的叶腊石块(32.5mm×32.5mm×16.25mm),控制其组合成边长为32.5mm的正方体叶腊石块,误差范围在±0.1mm以内;(2) Use a lathe to process the cut pyrophyllite into two smooth-surfaced pyrophyllite blocks (32.5mm×32.5mm×16.25mm), and control them to form a cube with a side length of 32.5mm. The error range is ±0.1mm within;

(3)选择某一个表面较为平整的叶腊石块,沿着某一条对角线的方向,在中心处用小刀划一条深约2mm,长度约为8mm的小槽,将重量约为0.2g的Cd3P2粉末填入槽内;将经砂纸打磨后光亮的导电性能好的铜片剪成L型,其中部尖锐处与Cd3P2粉末接触导通,并固定好铜片,剪去超出叶腊石部分的铜片,并留出2-3mm的部分折叠后与锤面接触使得电路导通;然后把另外一个叶腊石块盖上,用重物静置压实2小时;采用四线法,将恒流源和多通道记录仪分别引入到六面顶压机的前、后、左、右四个顶锤,在恒流源两端并联一个阻值为1KΩ的电阻,并将油压信号接到多通道记录仪;(3) Select a pyrophyllite block with a relatively flat surface, and along a diagonal direction, use a knife to make a small groove about 2mm deep and about 8mm long in the center, and cut the Cd with a weight of about 0.2g.3 P2 powder is filled into the groove; cut the bright copper sheet with good conductivity after sanding into L shape, the sharp part of the middle part is in contact with the Cd3 P2 powder, and the copper sheet is fixed, and the excess is cut off. The copper sheet of the pyrophyllite part, and leave a 2-3mm part to be folded and contacted with the hammer surface to make the circuit conduct; then cover the other pyrophyllite block, and use a heavy object to stand and compact for 2 hours; using the four-wire method, the The constant current source and the multi-channel recorder are respectively introduced into the front, rear, left and right top hammers of the six-sided top press. A resistor with a resistance value of 1KΩ is connected in parallel at both ends of the constant current source, and the oil pressure signal is connected to to a multi-channel recorder;

(4)实验开始前设置升降压速率为5-45MPa/30min,保证恒流源电流稳定,选择适当电压测试的量程;实验开始时,对压机六个油缸进行充液,当油压升至5MPa时开始记录油压信号和电压信号,当油压升至45MPa是点击压力跳步开始泄压,待油压泄至5MPa时停止记录取出读卡器分析电压信号的变化曲线;(4) Before the start of the experiment, set the step-up and pressure-down rate to 5-45MPa/30min to ensure the stability of the constant current source current, and select the appropriate voltage test range; When the oil pressure reaches 5MPa, it starts to record the oil pressure signal and the voltage signal. When the oil pressure rises to 45MPa, click the pressure jump to start the pressure relief. When the oil pressure is released to 5MPa, stop recording and take out the card reader to analyze the change curve of the voltage signal;

(5)用多通道读取软件将文件转换成Excel格式,然后用Origin绘图,观测电压信号即电阻的突变。实验结果:在对应油压29.5MPa时,电压信号发生明显变化,电压曲线出现拐点,说明该油压值对应于腔体压力4.0GPa。最后将Bi、Tl、Cd3P2、Ba的相变压力点通过Origin拟合得到了油压加载与腔体压力的关系图,即得到标压曲线。(5) Use the multi-channel reading software to convert the file into Excel format, and then use Origin to draw the graph to observe the voltage signal, that is, the mutation of the resistance. Experimental results: When the corresponding oil pressure is 29.5MPa, the voltage signal changes significantly, and the voltage curve has an inflection point, indicating that the oil pressure value corresponds to the cavity pressure 4.0GPa. Finally, the phase transition pressure points of Bi, Tl, Cd3 P2 and Ba are fitted by Origin to obtain the relationship between oil pressure loading and cavity pressure, that is, the standard pressure curve is obtained.

本发明的实验结果由于每一次实验组装的细微差异导致电压突变点对应的油压误差在1.3MPa以内,属于大腔体压机高压装置油压加载的允许误差范围,经多次重复实验证明了磷化镉(Cd3P2)作为压力标定物质的可行性。所列举的工艺参数(例如叶腊石质量、标压物质用量、升压速率、划槽深度与长度、并联电阻阻值、铜片长度等)上下区间值都能实现本发明,再此不一一列举实施例。以上所述仅为本发明的优选实施例而已,用以说明本发明的技术方案,并不用以限制本发明,在本发明的启示下,有关技术领域的人员在不脱离本发明的遵旨和权利要求的情况下,还可以做出各种改变、修饰、替换、组合和简化,这些均属于本发明的保护范畴。In the experimental results of the present invention, the oil pressure error corresponding to the voltage mutation point is within 1.3MPa due to the slight difference of each experimental assembly, which belongs to the allowable error range of oil pressure loading of the high-pressure device of the large-cavity press. Repeated experiments have proved that Feasibility of cadmium phosphide (Cd3 P2 ) as a pressure calibration substance. The enumerated process parameters (such as pyrophyllite quality, amount of standard pressure substance, boost rate, depth and length of grooves, resistance value of parallel resistance, length of copper sheet, etc.) can realize the present invention, and they will not be listed one by one. Example. The above descriptions are only preferred embodiments of the present invention, and are used to illustrate the technical solutions of the present invention, but not to limit the present invention. In the case of the claims, various changes, modifications, substitutions, combinations and simplifications can also be made, which all belong to the protection scope of the present invention.

Claims (7)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011055458.9ACN114323405B (en) | 2020-09-30 | 2020-09-30 | Cadmium Phosphide (Cd3P2) Applied to Calibration of Cavity Pressure in High Pressure Device of Large Cavity Press |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011055458.9ACN114323405B (en) | 2020-09-30 | 2020-09-30 | Cadmium Phosphide (Cd3P2) Applied to Calibration of Cavity Pressure in High Pressure Device of Large Cavity Press |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN114323405Atrue CN114323405A (en) | 2022-04-12 |

| CN114323405B CN114323405B (en) | 2023-05-19 |

Family

ID=81011941

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011055458.9AActiveCN114323405B (en) | 2020-09-30 | 2020-09-30 | Cadmium Phosphide (Cd3P2) Applied to Calibration of Cavity Pressure in High Pressure Device of Large Cavity Press |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN114323405B (en) |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103529299A (en)* | 2013-09-30 | 2014-01-22 | 东北大学 | Four-line measuring method used for studying piezoresistive characteristics of conducting polymer composite materials |

| CN103943968A (en)* | 2014-04-28 | 2014-07-23 | 浙江大学 | Perfect matching wave absorbing layer composed of sub-wavelength resonance units and active circuits |

| US20170020402A1 (en)* | 2015-05-04 | 2017-01-26 | The Board Of Trustees Of The University Of Illinois | Implantable and bioresorbable sensors |

| CN108389893A (en)* | 2011-12-01 | 2018-08-10 | 伊利诺伊大学评议会 | It is designed to undergo the transient state device of programmable transformation |

| CN109975338A (en)* | 2019-04-01 | 2019-07-05 | 四川大学 | A Type 2-8 High Pressure Loading Device for In Situ Neutron Diffraction |

| CN111025055A (en)* | 2019-12-04 | 2020-04-17 | 四川大学 | Conductive medium and assembly part for high-stress and large-deformation environment and application of conductive medium and assembly part |

- 2020

- 2020-09-30CNCN202011055458.9Apatent/CN114323405B/enactiveActive

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108389893A (en)* | 2011-12-01 | 2018-08-10 | 伊利诺伊大学评议会 | It is designed to undergo the transient state device of programmable transformation |

| CN103529299A (en)* | 2013-09-30 | 2014-01-22 | 东北大学 | Four-line measuring method used for studying piezoresistive characteristics of conducting polymer composite materials |

| CN103943968A (en)* | 2014-04-28 | 2014-07-23 | 浙江大学 | Perfect matching wave absorbing layer composed of sub-wavelength resonance units and active circuits |

| US20170020402A1 (en)* | 2015-05-04 | 2017-01-26 | The Board Of Trustees Of The University Of Illinois | Implantable and bioresorbable sensors |

| CN109975338A (en)* | 2019-04-01 | 2019-07-05 | 四川大学 | A Type 2-8 High Pressure Loading Device for In Situ Neutron Diffraction |

| CN111025055A (en)* | 2019-12-04 | 2020-04-17 | 四川大学 | Conductive medium and assembly part for high-stress and large-deformation environment and application of conductive medium and assembly part |

Non-Patent Citations (6)

| Title |

|---|

| HAIKUO WANG,ET AL.: "A hybrid pressure cell of pyrophyllite and magnesium oxide to extend the pressure range for large volume cubic presses", 《HIGH PRESSURE RESEARCH: AN INTERNATIONAL JOURNAL》* |

| PEI WANG,ET AL.: "Cadmium phosphide,Cd7P10,prepared at high pressures", 《HIGH PRESSURE RESEARCH》* |

| XIAOZHIYAN,ET AL.: "Compressibility determination by electrical resistance measurement:a universal method for both crystalline and amorphous solids", 《HIGH PRESSURE RESEARCH:AN INTERNATIONAL JOURNAL》* |

| 张书霞等: "一种压力标定所用铋丝的制备新方法", 《超硬材料工程》* |

| 王海阔等: "基于国产铰链式六面顶压机的大腔体静高压技术研究进展", 《高压物理学报》* |

| 袁朝圣: "压力标定设计性实验的研究与开发", 《大学物理实验》* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN114323405B (en) | 2023-05-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US9423370B2 (en) | Use of capacitance to analyze polycrystalline diamond | |

| TW479004B (en) | Ceramic slurry composition and methods for producing ceramic green sheet and multilayer ceramic electronic device | |

| JPH0316723B2 (en) | ||

| EP2631637A2 (en) | Use of capacitance and eddy currents to analyze polycrystalline diamond | |

| CN109665857B (en) | A preparation method of iron tetroxide with porous honeycomb structure based on photocuring 3D printing forming technology | |

| CN101823877A (en) | Low-temperature co-fired ceramic medium material and preparation method thereof | |

| CN114323405A (en) | Cadmium phosphide (Cd3P2) is applied to the pressure calibration in the high pressure device of the large cavity press | |

| US20140253149A1 (en) | Non-Destructive Leaching Depth Measurement Using Capacitance Spectroscopy | |

| Dunn et al. | Electrical behavior of sulfur up to 600 kbar—metallic state | |

| Allen et al. | The kinetics of low-temperature oxygen migration in ZrWMoO 8 | |

| US3212851A (en) | Boron nitride having a new structure | |

| Jaramillo et al. | Four-probe electrical measurements with a liquid pressure medium in a diamond anvil cell | |

| CN112782211A (en) | Water phase change detection method | |

| CN103540806A (en) | A novel composite material Al-Y2W3O12 and its preparation method | |

| Barzilovich et al. | The influence of the fractional composition of a filler on thermal conductivity of a polymer composition | |

| CN101823876A (en) | Ceramic material for temperature stabilization type multilayer ceramic capacitor and preparation method thereof | |

| CN109206133A (en) | A kind of ultra-low loss tantalum system huge dielectric constant dielectric material and preparation method thereof | |

| CN219957422U (en) | Jig for MLCC slurry shrinkage test | |

| Baranowski et al. | High-pressure phase diagram of silver mercury iodide (Ag 2 HgI 4) | |

| CN223122106U (en) | Putty dynamic anti-cracking performance detection device | |

| CN110220448A (en) | Device for rapidly and nondestructively detecting cobalt removal depth of polycrystalline diamond compact | |

| JPS59100853A (en) | Oxygen sensor manufacturing method | |

| CN222761509U (en) | A magnetic-proof aluminum alloy caliper structure | |

| CN119650291A (en) | A method for preparing a wireless charging coil and a wireless charger | |

| Mothersole et al. | The determination of the characteristic temperatures of silver, aluminium and lead by x-ray diffraction |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |