CN114307535A - System and method for directly capturing carbon dioxide by continuous air - Google Patents

System and method for directly capturing carbon dioxide by continuous airDownload PDFInfo

- Publication number

- CN114307535A CN114307535ACN202210122916.9ACN202210122916ACN114307535ACN 114307535 ACN114307535 ACN 114307535ACN 202210122916 ACN202210122916 ACN 202210122916ACN 114307535 ACN114307535 ACN 114307535A

- Authority

- CN

- China

- Prior art keywords

- adsorbent

- carbon dioxide

- air

- desorption

- adsorption

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01D—SEPARATION

- B01D53/00—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols

- B01D53/02—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols by adsorption, e.g. preparative gas chromatography

- B01D53/04—Separation of gases or vapours; Recovering vapours of volatile solvents from gases; Chemical or biological purification of waste gases, e.g. engine exhaust gases, smoke, fumes, flue gases, aerosols by adsorption, e.g. preparative gas chromatography with stationary adsorbents

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02C—CAPTURE, STORAGE, SEQUESTRATION OR DISPOSAL OF GREENHOUSE GASES [GHG]

- Y02C20/00—Capture or disposal of greenhouse gases

- Y02C20/40—Capture or disposal of greenhouse gases of CO2

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Analytical Chemistry (AREA)

- General Chemical & Material Sciences (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Solid-Sorbent Or Filter-Aiding Compositions (AREA)

- Treating Waste Gases (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于空气直接捕集二氧化碳技术领域,具体涉及一种连续空气直接捕集二氧化碳系统及方法。The invention belongs to the technical field of direct air capture of carbon dioxide, and in particular relates to a continuous air capture carbon dioxide system and method.

背景技术Background technique

1999年,美国阿拉莫斯国家实验室(Los Alamos National Laboratory)的Lackner为缓解气候变化提出了直接空气碳捕集技术(direct air capture,DAC)的概念。经过多年的研究,科研人员提出了很多DAC的方法和材料。目前,DAC技术已经被认为是可行的CO2减排技术之一。空气中的CO2通过吸附剂进行捕集,完成捕集后的吸附剂通过改变压力或温度进行吸附剂再生,再生后的吸附剂循环用于CO2捕集,而纯CO2则被储存起来。In 1999, Lackner of Los Alamos National Laboratory proposed the concept of direct air carbon capture (DAC) for mitigating climate change. After years of research, researchers have proposed many DAC methods and materials. At present, DAC technology has been considered as one of the feasible CO2 emission reduction technologies. TheCO2 in the air is captured by the adsorbent, the adsorbent after the capture is regenerated by changing the pressure or temperature, the regenerated adsorbent is recycled forCO2 capture, and the pureCO2 is stored .

在过去的半个多世纪,人类活动导致全球CO2排放量逐年增加。大气中的CO2浓度由1960年的310ppm左右急剧增加到2019年的410ppm,目前每年全球CO2排放量都超过了350亿吨。作为负碳排放技术研究热点,直接空气碳捕集技术2019年入选《麻省理工科技评论》的全球十大突破性技术之一。随着碳中和目标的提出,全产业链减碳已经成为共识,直接空气碳捕集技术亟需进一步发展。Over the past half century, human activities have led to an annual increase in globalCO2 emissions. The CO2 concentration in the atmosphere has increased sharply from about 310 ppm in 1960 to 410 ppm in 2019, and the current annual global CO2 emission exceeds 35 billion tons. As a research hotspot of negative carbon emission technology, direct air carbon capture technology was selected as one of the top ten breakthrough technologies in the world by MIT Technology Review in 2019. With the proposed carbon neutrality goal, carbon reduction in the entire industry chain has become a consensus, and direct air carbon capture technology needs to be further developed.

DAC技术与CCS(carbon capture and storage碳捕集与封存)技术的区别如表1所示。The difference between DAC technology and CCS (carbon capture and storage) technology is shown in Table 1.

表1DAC与CCS技术的区别Table 1 Differences between DAC and CCS technology

与CCS技术不同,DAC的技术特点是:Different from CCS technology, the technical characteristics of DAC are:

(1)可用于捕集分散排放源CO2;(1) It can be used to capture CO2 from scattered emission sources;

(2)安装地点选取相对灵活,可以选择在可再生能源丰富、且距离碳储存利用位置较近的地点,以降低捕集能耗和运输成本;(2) The installation location is relatively flexible, and the location that is rich in renewable energy and close to the carbon storage and utilization location can be selected to reduce the capture energy consumption and transportation cost;

(3)无须考虑NOx和SO2等气体杂质的影响。直接空气碳捕集技术的主要难点在于空气中CO2分压低(40Pa)、浓度低(400ppm),CO2吸附/再生效率低,再生能耗和成本高。(3) The influence of gas impurities such as NOx and SO2 need not be considered. The main difficulties of direct air carbon capture technology are the low partial pressure (40Pa) and low concentration (400ppm) ofCO2 in the air, lowCO2 adsorption/regeneration efficiency, and high regeneration energy consumption and cost.

当前,采用物理吸附法的DAC技术,通常接触器都是矩形塔设备,接触器内嵌的胺吸附剂附着在多孔的、蜂窝的陶瓷块上用以吸附CO2。吸附完成后使用低温蒸汽(85~100℃)对CO2进行脱附收集。Global Thermostat公司宣称其使用的氨基聚合物吸附剂将整个系统的循环时间缩短到30分钟以下,这基本上代表了行业领先水平。这一类DAC技术存在的一大难题就是吸附/再生过程的不可连续性,影响了整体效率的提升。Currently, in the DAC technology using physical adsorption method, the contactor is usually a rectangular tower device, and the amine adsorbent embedded in the contactor is attached to a porous, honeycomb ceramic block to adsorb CO2 . After the adsorption is completed, CO2 is desorbed and collected by using low-temperature steam (85-100 °C). Global Thermostat claims that its use of aminopolymer adsorbents reduces the cycle time of the entire system to less than 30 minutes, which is basically an industry-leading level. A major problem of this type of DAC technology is the discontinuity of the adsorption/regeneration process, which affects the improvement of the overall efficiency.

发明内容SUMMARY OF THE INVENTION

本发明的目的在于提供了一种连续空气直接捕集二氧化碳系统及方法,通过将吸附、解吸附、再生等过程分步开展,可以实现空气直接捕集二氧化碳全过程的连续化运行,大大提高了系统利用效率。The purpose of the present invention is to provide a system and method for the direct capture of carbon dioxide by continuous air. System utilization efficiency.

本发明采用如下技术方案来实现的:The present invention adopts following technical scheme to realize:

一种连续空气直接捕集二氧化碳系统,包括吸附剂料仓、吸附装置、解吸附装置、吸附剂再生装置和吸附剂返料装置;A continuous air direct capture carbon dioxide system, comprising an adsorbent silo, an adsorption device, a desorption device, an adsorbent regeneration device and an adsorbent return device;

吸附剂料仓的出口连接至吸附装置的进口,吸附装置的出口连接至解吸附装置的进口,解吸附装置的出口连接至吸附剂再生装置的进口,吸附剂再生装置的出口连接至吸附剂返料装置的进口,吸附剂返料装置的出口连接至吸附剂料仓的进口。The outlet of the adsorbent silo is connected to the inlet of the adsorption device, the outlet of the adsorption device is connected to the inlet of the desorption device, the outlet of the desorption device is connected to the inlet of the adsorbent regeneration device, and the outlet of the adsorbent regeneration device is connected to the adsorbent return. The inlet of the sorbent material device, and the outlet of the sorbent return device is connected to the inlet of the sorbent silo.

本发明进一步的改进在于,吸附剂料仓用于存放颗粒状二氧化碳吸附剂材料。A further improvement of the present invention is that the adsorbent silo is used to store particulate carbon dioxide adsorbent material.

本发明进一步的改进在于,吸附剂料仓用于存放块状二氧化碳吸附剂材料。A further improvement of the present invention is that the adsorbent silo is used to store the bulk carbon dioxide adsorbent material.

本发明进一步的改进在于,吸附装置包括用于空气与吸附剂材料充分接触的吸附器,吸附器的底部开设有空气进口,顶部开设有空气出口,且空气出口处设置有引风机,吸附器的底部出料口处设置有第一卸料阀和第一吸附剂输送机设备。A further improvement of the present invention lies in that the adsorption device includes an adsorber for fully contacting the air with the adsorbent material, the bottom of the adsorber is provided with an air inlet, the top is provided with an air outlet, and an induced draft fan is arranged at the air outlet, and the adsorber is provided with an air inlet. The discharge port at the bottom is provided with a first discharge valve and a first adsorbent conveyor device.

本发明进一步的改进在于,吸附装置设置有两套。A further improvement of the present invention is that there are two sets of adsorption devices.

本发明进一步的改进在于,解吸附装置包括通过加热使吸附剂材料释放二氧化碳的解吸附器,解吸附器的周向上设置有加热器,解吸附器的顶部设置有进料口和CO2出口,进料口与第一吸附剂输送机设备的出口连接,解吸附器的底部出料口处设置有第二卸料阀和第二吸附剂输送机设备。A further improvement of the present invention is that the desorption device includes a desorber that releases carbon dioxide from the adsorbent material by heating, a heater is provided on the circumference of the desorber, and a feed port and a CO2 outlet are provided on the top of the desorber, The feed port is connected with the outlet of the first adsorbent conveyor equipment, and the bottom discharge port of the desorber is provided with a second discharge valve and a second adsorbent conveyor equipment.

本发明进一步的改进在于,吸附剂再生装置包括解吸后吸附剂降温的再生器,再生器的进料口与第二吸附剂输送机设备的出口连接。A further improvement of the present invention is that the adsorbent regeneration device includes a regenerator for cooling the adsorbent after desorption, and the feed port of the regenerator is connected to the outlet of the second adsorbent conveyor device.

本发明进一步的改进在于,吸附剂返料装置包括与再生器的出料口连接的第三吸附剂输送机设备,第三吸附剂输送机设备的出口与返料器的进口连接,返料器的出口与吸附剂料仓的进口连接。A further improvement of the present invention is that the adsorbent returning device includes a third adsorbent conveyor device connected to the discharge port of the regenerator, and the outlet of the third adsorbent conveyor device is connected to the inlet of the reverter, and the regenerator The outlet is connected to the inlet of the adsorbent silo.

一种连续空气直接捕集二氧化碳方法,该方法基于所述的一种连续空气直接捕集二氧化碳系统,包括:A method for directly capturing carbon dioxide by continuous air, the method is based on the described system for directly capturing carbon dioxide by air, comprising:

空气直接捕集二氧化碳吸附过程,引风机启动,空气通过管道被抽入吸附装置,空气在吸附装置内与自上而下的颗粒状或块状二氧化碳吸附剂材料逆向直接接触,空气中的二氧化碳被吸附剂材料捕集吸附,被吸附后的空气流出吸附装置,而逐渐吸附饱和的吸附剂材料通过第一卸料阀落入第一吸附剂输送机设备,送入解吸附过程;The air directly captures the carbon dioxide adsorption process, the induced draft fan is started, and the air is drawn into the adsorption device through the pipeline. The adsorbent material is captured and adsorbed, the adsorbed air flows out of the adsorption device, and the adsorbent material that is gradually adsorbed and saturated falls into the first adsorbent conveyor equipment through the first discharge valve, and is sent to the desorption process;

空气直接捕集二氧化碳解吸附过程,吸附饱和的吸附剂材料落入解吸附装置,在解吸附器内与蒸汽加热器间接接触,蒸汽释放热量后变成冷凝水排出系统,吸附剂材料温度升高到50~85℃,吸附剂材料温度升高伴随着二氧化碳的解吸释放,释放的二氧化碳被捕集下来,而解吸升温的吸附剂材料通过第二卸料阀落入第二吸附剂输送机设备,送入再生过程;The air directly captures the carbon dioxide desorption process, the adsorbent material saturated with adsorption falls into the desorption device, and indirectly contacts with the steam heater in the desorber. After the steam releases heat, it becomes condensed water and is discharged from the system, and the temperature of the adsorbent material increases. When the temperature of the adsorbent material rises to 50 to 85°C, the temperature of the adsorbent material increases along with the desorption and release of carbon dioxide. The released carbon dioxide is captured, and the desorbed and heated adsorbent material falls into the second adsorbent conveyor equipment through the second discharge valve. into the regeneration process;

空气直接捕集二氧化碳再生过程,解吸后升温的吸附剂材料落入再生装置,在再生器内与吸附装置排出的吸附后的空气逆向直接接触,通过空气冷却吸附剂材料,完成降温再生过程,被加热后的空气直接排空,而冷却后的吸附剂材料进入返料过程;The air directly captures the carbon dioxide regeneration process, the adsorbent material heated up after desorption falls into the regeneration device, and is in direct contact with the adsorbed air discharged from the adsorption device in the regenerator, and the adsorbent material is cooled by the air to complete the cooling regeneration process. The heated air is directly evacuated, and the cooled adsorbent material enters the return process;

空气直接捕集二氧化碳返料过程,冷却后的吸附剂材料通过第三吸附剂输送机设备和返料器,重新被送入吸附剂料仓,完成整个过程。The air directly captures carbon dioxide and returns the material, and the cooled adsorbent material is sent back to the adsorbent silo through the third adsorbent conveyor equipment and the return material to complete the whole process.

本发明至少具有如下有益的技术效果:The present invention at least has the following beneficial technical effects:

本发明提出的一种针对颗粒状或块状吸附剂材料的连续空气直接捕集二氧化碳系统及方法,吸附剂从料仓中送入吸附装置内,在吸附装置内自上而下流动的过程中与空气充分接触,吸附并捕集空气中的二氧化碳,在吸附装置尾端逐渐吸附至饱和,然后通过卸料阀、输送机送入解吸附装置中,吸附剂在解吸附装置中被蒸汽加热升温,释放所吸附的二氧化碳,吸附剂在解吸附装置尾端逐渐完成解吸附过程,然后通过卸料阀、输送机送入再生装置中,吸附剂在再生装置中被空气直接冷却降温逐渐完成再生过程,然后通过输送机、返料装置送回吸附剂料仓,完成循环过程,本系统可连续运行,完全实现空气直接捕集二氧化碳全过程的连续性,大大提高捕集过程效率,从而降低捕集能耗与成本。The present invention proposes a continuous air carbon dioxide capture system and method for granular or bulk adsorbent materials. The adsorbent is fed into the adsorption device from the silo, and in the process of flowing from top to bottom in the adsorption device Fully contact with air, adsorb and capture carbon dioxide in the air, gradually adsorb to saturation at the end of the adsorption device, and then send it to the desorption device through the discharge valve and conveyor, and the adsorbent is heated by steam in the desorption device. , release the adsorbed carbon dioxide, the adsorbent gradually completes the desorption process at the end of the desorption device, and then is sent to the regeneration device through the discharge valve and conveyor, and the adsorbent is directly cooled by the air in the regeneration device to gradually complete the regeneration process. , and then sent back to the adsorbent silo through the conveyor and the return device to complete the cycle process. The system can run continuously, fully realize the continuity of the whole process of direct air capture of carbon dioxide, greatly improve the efficiency of the capture process, and reduce the capture rate. Energy consumption and cost.

附图说明Description of drawings

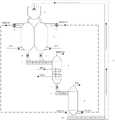

图1为本发明一种连续空气直接捕集二氧化碳系统的结构示意图。FIG. 1 is a schematic structural diagram of a continuous air direct capture carbon dioxide system of the present invention.

附图标记说明:Description of reference numbers:

1-吸附剂料仓,2-引风机,3-吸附器,4-第一卸料阀,5-第一吸附剂输送机设备,6-解吸附器,7-第二卸料阀,8-第二吸附剂输送机设备,9-再生器,10-第三吸附剂输送机设备,11-返料器。1- Adsorbent silo, 2- Induced fan, 3- Adsorber, 4- First discharge valve, 5- First adsorbent conveyor equipment, 6- Desorber, 7- Second discharge valve, 8 - Second sorbent conveyor equipment, 9 - Regenerator, 10 - Third sorbent conveyor equipment, 11 - Return feeder.

具体实施方式Detailed ways

下面将参照附图更详细地描述本公开的示例性实施例。虽然附图中显示了本公开的示例性实施例,然而应当理解,可以以各种形式实现本公开而不应被这里阐述的实施例所限制。相反,提供这些实施例是为了能够更透彻地理解本公开,并且能够将本公开的范围完整的传达给本领域的技术人员。需要说明的是,在不冲突的情况下,本发明中的实施例及实施例中的特征可以相互组合。下面将参考附图并结合实施例来详细说明本发明。Exemplary embodiments of the present disclosure will be described in more detail below with reference to the accompanying drawings. While exemplary embodiments of the present disclosure are shown in the drawings, it should be understood that the present disclosure may be embodied in various forms and should not be limited by the embodiments set forth herein. Rather, these embodiments are provided so that the present disclosure will be more thoroughly understood, and will fully convey the scope of the present disclosure to those skilled in the art. It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict. The present invention will be described in detail below with reference to the accompanying drawings and in conjunction with the embodiments.

本发明提出的一种连续空气直接捕集二氧化碳系统,包括吸附剂料仓1、吸附装置、解吸附装置、吸附剂再生装置和吸附剂返料装置;吸附剂料仓1的出口连接至吸附装置的进口,吸附装置的出口连接至解吸附装置的进口,解吸附装置的出口连接至吸附剂再生装置的进口,吸附剂再生装置的出口连接至吸附剂返料装置的进口,吸附剂返料装置的出口连接至吸附剂料仓1的进口。A continuous air direct capture carbon dioxide system proposed by the present invention includes an

其中吸附剂料仓1用于存放颗粒状或块状二氧化碳吸附剂材料,如固态胺类吸附剂、物理吸附剂等。The

具体的,吸附装置包括用于空气与吸附剂材料充分接触的吸附器3,吸附器3的底部开设有空气进口,顶部开设有空气出口,且空气出口处设置有引风机2,吸附器3的底部出料口处设置有第一卸料阀4和第一吸附剂输送机设备5。且吸附装置设置有两套。Specifically, the adsorption device includes an

解吸附装置包括通过加热使吸附剂材料释放二氧化碳的解吸附器6,解吸附器6的周向上设置有加热器,解吸附器6的顶部设置有进料口和CO2出口,进料口与第一吸附剂输送机设备5的出口连接,解吸附器6的底部出料口处设置有第二卸料阀7和第二吸附剂输送机设备8。The desorption device includes a

吸附剂再生装置包括解吸后吸附剂降温的再生器9,再生器9的进料口与第二吸附剂输送机设备8的出口连接。The adsorbent regeneration device includes a

吸附剂返料装置包括与再生器9的出料口连接的第三吸附剂输送机设备,第三吸附剂输送机设备10的出口与返料器11的进口连接,返料器11的出口与吸附剂料仓1的进口连接。The adsorbent returning device includes a third adsorbent conveyor device connected to the outlet of the

本发明提供的一种连续空气直接捕集二氧化碳方法,包括:A method for directly capturing carbon dioxide with continuous air provided by the present invention comprises:

空气直接捕集二氧化碳吸附过程,引风机2启动,空气通过管道被抽入吸附装置,空气在吸附装置内与自上而下的颗粒状或块状二氧化碳吸附剂材料逆向直接接触,空气中的二氧化碳被吸附剂材料捕集吸附,被吸附后的空气流出吸附装置,而逐渐吸附饱和的吸附剂材料通过第一卸料阀4落入第一吸附剂输送机设备5,送入解吸附过程;The air directly captures the carbon dioxide adsorption process, the induced

空气直接捕集二氧化碳解吸附过程,吸附饱和的吸附剂材料落入解吸附装置,在解吸附器6内与蒸汽加热器间接接触,蒸汽释放热量后变成冷凝水排出系统,吸附剂材料温度升高到50~85℃,吸附剂材料温度升高伴随着二氧化碳的解吸释放,释放的二氧化碳被捕集下来,而解吸升温的吸附剂材料通过第二卸料阀7落入第二吸附剂输送机设备8,送入再生过程;The air directly captures the carbon dioxide desorption process, and the adsorbent material saturated with adsorption falls into the desorption device, and indirectly contacts with the steam heater in the

空气直接捕集二氧化碳再生过程,解吸后升温的吸附剂材料落入再生装置,在再生器9内与吸附装置排出的吸附后的空气逆向直接接触,通过空气冷却吸附剂材料,完成降温再生过程,被加热后的空气直接排空,而冷却后的吸附剂材料进入返料过程;The air directly captures the carbon dioxide regeneration process, the adsorbent material heated up after desorption falls into the regeneration device, and directly contacts with the adsorbed air discharged from the adsorption device in the

空气直接捕集二氧化碳返料过程,冷却后的吸附剂材料通过第三吸附剂输送机设备10和返料器11,重新被送入吸附剂料仓1,完成整个过程。The air directly captures carbon dioxide and returns the material, and the cooled adsorbent material is sent back to the

虽然,上文中已经用一般性说明及具体实施方案对本发明作了详尽的描述,但在本发明基础上,可以对之作一些修改或改进,这对本领域技术人员而言是显而易见的。因此,在不偏离本发明精神的基础上所做的这些修改或改进,均属于本发明要求保护的范围。Although the present invention has been described in detail above with general description and specific embodiments, some modifications or improvements can be made on the basis of the present invention, which will be obvious to those skilled in the art. Therefore, these modifications or improvements made without departing from the spirit of the present invention fall within the scope of the claimed protection of the present invention.

Claims (9)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210122916.9ACN114307535A (en) | 2022-02-09 | 2022-02-09 | System and method for directly capturing carbon dioxide by continuous air |

| PCT/CN2022/136017WO2023151355A1 (en) | 2022-02-09 | 2022-12-01 | System and method for continuously capturing carbon dioxide by means of direct air capture |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210122916.9ACN114307535A (en) | 2022-02-09 | 2022-02-09 | System and method for directly capturing carbon dioxide by continuous air |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114307535Atrue CN114307535A (en) | 2022-04-12 |

Family

ID=81031124

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210122916.9APendingCN114307535A (en) | 2022-02-09 | 2022-02-09 | System and method for directly capturing carbon dioxide by continuous air |

Country Status (2)

| Country | Link |

|---|---|

| CN (1) | CN114307535A (en) |

| WO (1) | WO2023151355A1 (en) |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114939323A (en)* | 2022-04-20 | 2022-08-26 | 西安热工研究院有限公司 | Low-energy-consumption air direct carbon capture system |

| CN115040972A (en)* | 2022-04-21 | 2022-09-13 | 山东保蓝环保工程有限公司 | Multidimensional normal-pressure purification equipment for carbon dioxide |

| CN115569501A (en)* | 2022-08-05 | 2023-01-06 | 北京德润晨环保科技有限公司 | Carbon dioxide capture and desorption device |

| CN116212592A (en)* | 2023-04-12 | 2023-06-06 | 西安热工研究院有限公司 | Carbon dioxide air direct-capturing coupling photocatalytic reduction system |

| WO2023151355A1 (en)* | 2022-02-09 | 2023-08-17 | 西安热工研究院有限公司 | System and method for continuously capturing carbon dioxide by means of direct air capture |

| WO2023246097A1 (en)* | 2022-06-22 | 2023-12-28 | 中国华能集团清洁能源技术研究院有限公司 | Direct air capturing method of carbon dioxide |

| CN119819116A (en)* | 2025-03-17 | 2025-04-15 | 成都锐思环保技术股份有限公司 | Circulating type hydrogen purification system and method |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101822929A (en)* | 2010-02-02 | 2010-09-08 | 华东理工大学 | Method for capturing carbon dioxide by utilizing electrical desorption technology |

| CN104162341A (en)* | 2014-08-14 | 2014-11-26 | 清华大学 | Device and method for removing CO2 from smoke by using solid amine adsorbent |

| CN207667379U (en)* | 2017-11-21 | 2018-07-31 | 国电科学技术研究院 | It is suitble to the activated coke system of garbage-incineration smoke purifying |

| CN113813746A (en)* | 2021-10-22 | 2021-12-21 | 北京德润晨环保科技有限公司 | Device and method for directly capturing carbon dioxide from air |

| CN216537693U (en)* | 2022-02-09 | 2022-05-17 | 西安热工研究院有限公司 | A continuous air direct capture carbon dioxide system |

Family Cites Families (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN102728334B (en)* | 2012-07-12 | 2014-10-29 | 北京国电清新环保技术股份有限公司 | System and process method for desorption, activation and regeneration of granular adsorbing agent |

| WO2016185387A1 (en)* | 2015-05-19 | 2016-11-24 | Reliance Industries Limited | A process for capturing carbon-dioxide from a gas stream |

| CN108636059B (en)* | 2018-05-03 | 2020-06-05 | 太原理工大学 | Integrated device and method for capturing and regenerating carbon dioxide |

| EP3842123B1 (en)* | 2019-12-24 | 2024-01-03 | Arçelik Anonim Sirketi | An air purifier |

| CN113694688B (en)* | 2021-08-30 | 2023-09-08 | 北京德润晨环保科技有限公司 | A device and method for solid amine absorption, capture and desorption of carbon dioxide |

| CN114307535A (en)* | 2022-02-09 | 2022-04-12 | 西安热工研究院有限公司 | System and method for directly capturing carbon dioxide by continuous air |

- 2022

- 2022-02-09CNCN202210122916.9Apatent/CN114307535A/enactivePending

- 2022-12-01WOPCT/CN2022/136017patent/WO2023151355A1/ennot_activeCeased

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101822929A (en)* | 2010-02-02 | 2010-09-08 | 华东理工大学 | Method for capturing carbon dioxide by utilizing electrical desorption technology |

| CN104162341A (en)* | 2014-08-14 | 2014-11-26 | 清华大学 | Device and method for removing CO2 from smoke by using solid amine adsorbent |

| CN207667379U (en)* | 2017-11-21 | 2018-07-31 | 国电科学技术研究院 | It is suitble to the activated coke system of garbage-incineration smoke purifying |

| CN113813746A (en)* | 2021-10-22 | 2021-12-21 | 北京德润晨环保科技有限公司 | Device and method for directly capturing carbon dioxide from air |

| CN216537693U (en)* | 2022-02-09 | 2022-05-17 | 西安热工研究院有限公司 | A continuous air direct capture carbon dioxide system |

Non-Patent Citations (2)

| Title |

|---|

| 张龙等: "《绿色化学》", 31 July 2014, 华中科技大学出版社, pages: 203* |

| 王丽萍: "《大气污染控制工程》", 30 August 2002, 煤炭工业出版社, pages: 164* |

Cited By (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2023151355A1 (en)* | 2022-02-09 | 2023-08-17 | 西安热工研究院有限公司 | System and method for continuously capturing carbon dioxide by means of direct air capture |

| CN114939323A (en)* | 2022-04-20 | 2022-08-26 | 西安热工研究院有限公司 | Low-energy-consumption air direct carbon capture system |

| CN115040972A (en)* | 2022-04-21 | 2022-09-13 | 山东保蓝环保工程有限公司 | Multidimensional normal-pressure purification equipment for carbon dioxide |

| WO2023246097A1 (en)* | 2022-06-22 | 2023-12-28 | 中国华能集团清洁能源技术研究院有限公司 | Direct air capturing method of carbon dioxide |

| CN115569501A (en)* | 2022-08-05 | 2023-01-06 | 北京德润晨环保科技有限公司 | Carbon dioxide capture and desorption device |

| CN116212592A (en)* | 2023-04-12 | 2023-06-06 | 西安热工研究院有限公司 | Carbon dioxide air direct-capturing coupling photocatalytic reduction system |

| CN119819116A (en)* | 2025-03-17 | 2025-04-15 | 成都锐思环保技术股份有限公司 | Circulating type hydrogen purification system and method |

| CN119819116B (en)* | 2025-03-17 | 2025-07-11 | 成都锐思环保技术股份有限公司 | Circulating type hydrogen purification system and method |

Also Published As

| Publication number | Publication date |

|---|---|

| WO2023151355A1 (en) | 2023-08-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN114307535A (en) | System and method for directly capturing carbon dioxide by continuous air | |

| CN101745288B (en) | Method for vacuum pressure and temperature varying coupling adsorbing and trapping carbon dioxide in flue gas | |

| CN101274193B (en) | System for purifying flue gas and recovering sulfur and technique | |

| CN103657381B (en) | Flue gas pretreatment and carbon dioxide collecting, purifying and recycling device | |

| CN104162341A (en) | Device and method for removing CO2 from smoke by using solid amine adsorbent | |

| CN101314102A (en) | Carbon dioxide capture method and device in flue gas of coal-fired power plant | |

| CN114307534A (en) | Experimental research system and method for directly capturing carbon dioxide by air | |

| TW201241366A (en) | Apparatus and system for NOx reduction in wet flue gas | |

| CN216537693U (en) | A continuous air direct capture carbon dioxide system | |

| CN112263890A (en) | Flue gas waste heat utilization type carbon capture method and system | |

| CN118251265A (en) | Utilization of carbon dioxide from ambient air | |

| CN116059784A (en) | Method and system for capturing carbon dioxide in flue gas by pressure swing adsorption | |

| CN106039929A (en) | Circular demercuration and mercury recycling system and method for renewable adsorbent | |

| CN113813744B (en) | Promote CO in coal fired boiler flue gas 2 System and method for capture economics | |

| CN105032113B (en) | Process for capturing carbon dioxide in flue gas based on wet reclamation technology | |

| CN106902617A (en) | A kind of high concentration VOC air purifying recovering apparatus and method | |

| CN102266702A (en) | Method for capturing ammonia in industrial waste gas and equipment and application thereof | |

| CN206082073U (en) | System for adsorbent circulation demercuration of can regenerating is retrieved with mercury | |

| KR102055976B1 (en) | A single compression system and process for capturing carbon dioxide | |

| WO2025092856A1 (en) | Fixed-bed flue gas purification system and control method therefor | |

| CN116764399A (en) | Flue gas adsorption dehydration system and process | |

| CN210332252U (en) | To CO in cement kiln tail flue gas2Trapping, concentrating and utilizing system | |

| CN216537692U (en) | Experimental research system for directly capturing carbon dioxide from air | |

| CN104984628A (en) | Organic waste gas adsorption recovery process | |

| CN103157346A (en) | Coupling method and system for low-temperature methanol washing and CO2 capture |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20220412 | |

| RJ01 | Rejection of invention patent application after publication |