CN114302852A - Laminated article carrier and blank therefor - Google Patents

Laminated article carrier and blank thereforDownload PDFInfo

- Publication number

- CN114302852A CN114302852ACN202080062827.9ACN202080062827ACN114302852ACN 114302852 ACN114302852 ACN 114302852ACN 202080062827 ACN202080062827 ACN 202080062827ACN 114302852 ACN114302852 ACN 114302852A

- Authority

- CN

- China

- Prior art keywords

- layer

- article carrier

- layers

- bonded

- paperboard

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/40—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material comprising a plurality of articles held together only partially by packaging elements formed by folding a blank or several blanks

- B65D71/42—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material comprising a plurality of articles held together only partially by packaging elements formed by folding a blank or several blanks formed by folding a single blank into a single layer element

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/02—Arrangements of flexible binders

- B65D71/04—Arrangements of flexible binders with protecting or supporting elements arranged between binder and articles or materials, e.g. for preventing chafing of binder

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D71/00—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material

- B65D71/50—Bundles of articles held together by packaging elements for convenience of storage or transport, e.g. portable segregating carrier for plural receptacles such as beer cans or pop bottles; Bales of material comprising a plurality of articles held together only partially by packaging elements formed otherwise than by folding a blank

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D2301/00—Details of blanks

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Packages (AREA)

- Wrappers (AREA)

- Cartons (AREA)

- Making Paper Articles (AREA)

- Wrapping Of Specific Fragile Articles (AREA)

- Laminated Bodies (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及物品承载器和用于形成物品承载器的坯件。更具体地但非排他地,本发明涉及一种顶部夹持或顶部接合式样的承载器,该承载器具有用于将物品接收和保持在其中的一个或多个孔口。The present invention relates to article carriers and blanks for forming article carriers. More specifically, but not exclusively, the present invention relates to a top clamp or top engage style carrier having one or more apertures for receiving and retaining items therein.

背景技术Background technique

在包装领域中,已知提供用于携带多个物品的纸板箱。纸板箱在本领域中是众所周知的,并且对于使得消费者能够运输、存储和接近一组物品以供消费是有用的。出于成本和环境的考虑,这样的纸板箱或承载器需要由尽可能少的材料形成并且对形成其的材料造成尽可能少的损耗。进一步的考虑是纸板箱的强度及其对保持和运输大重量物品的适用性。期望纸板箱的内容物在纸板箱内是固定的。In the field of packaging, it is known to provide cartons for carrying a plurality of items. Cartons are well known in the art and are useful for enabling consumers to transport, store and access a collection of items for consumption. For cost and environmental reasons, such a carton or carrier needs to be formed from as little material as possible and incur as little loss as possible to the material from which it is formed. A further consideration is the strength of the carton and its suitability for holding and transporting heavy items. It is desirable that the contents of the carton be fixed within the carton.

提供顶部夹持的物品承载器是众所周知的,其中在承载器的面板中形成孔口,接片可绕所述孔口限定。这些接片可移位出所述面板的平面。当物品被接收在孔口中时,所述接片大致绕物品的凸缘或唇缘来接合物品。Item carriers that provide a top grip are well known in which apertures are formed in the panels of the carrier around which tabs can be defined. These tabs can be displaced out of the plane of the panel. The tabs engage the article generally around a flange or lip of the article when the article is received in the aperture.

本发明寻求提供通常由纸板等形成的纸板箱领域方面的改进。The present invention seeks to provide improvements in the field of cartons typically formed from paperboard and the like.

发明内容SUMMARY OF THE INVENTION

本发明的第一方面提供了一种形成顶部接合的物品承载器的方法,该方法包括:A first aspect of the present invention provides a method of forming a top-engaged article carrier, the method comprising:

提供第一纸板基材;providing a first cardboard substrate;

提供第二纸板基材;providing a second cardboard substrate;

将粘合剂处理均匀地施加到第一纸板基材的整个第一表面;uniformly applying the adhesive treatment to the entire first surface of the first paperboard substrate;

将第二纸板基材的表面固定到第一纸板基材的第一表面以形成层压纸板结构;securing the surface of the second paperboard substrate to the first surface of the first paperboard substrate to form a laminated paperboard structure;

从层压纸板结构切割一个或多个坯件。One or more blanks are cut from the laminated cardboard structure.

可选地,从层压纸板结构切割一个或多个坯件包括从层压纸板结构切割一个或多个顶部接合装置,每个顶部接合装置具有顶部接收开口。Optionally, cutting the one or more blanks from the laminated paperboard structure includes cutting one or more top engaging means from the laminated paperboard structure, each top engaging means having a top receiving opening.

可选地,该方法包括:Optionally, the method includes:

将坯件应用于一个或多个物品以形成包装;applying the blank to one or more articles to form a package;

将所述一个或多个顶部接合装置与所述一个或多个物品中的相应一个接合。The one or more top engaging devices are engaged with a corresponding one of the one or more articles.

可选地,所述一个或多个顶部接合装置各自包括至少一个齿,所述至少一个齿包括均匀地结合的多层层压结构,并且其中,将所述一个或多个顶部接合装置与所述一个或多个物品中的相应一个接合包括:Optionally, the one or more top engaging devices each include at least one tooth comprising a uniformly bonded multilayer laminate structure, and wherein the one or more top engaging devices are coupled to the The engagement of a respective one of the one or more items includes:

将所述至少一个齿的边缘与所述一个或多个物品中的所述相应一个的凸缘接合。The edge of the at least one tooth is engaged with the flange of the corresponding one of the one or more items.

本发明的第二方面提供了一种用于包装至少一个物品的顶部接合的物品承载器。物品承载器包括主面板,该主面板包括具有顶部接收开口的至少一个顶部接合装置。主面板包括由均匀地结合在一起的两层或更多层基材形成的层压结构。A second aspect of the present invention provides a top-engaged article carrier for packaging at least one article. The article carrier includes a main panel including at least one top engagement device having a top receiving opening. The primary panel includes a laminate structure formed from two or more layers of substrates uniformly bonded together.

可选地,顶部接合装置包括用于接合物品的一个或多个齿,所述一个或多个齿包括均匀地结合在一起的两层或更多层基材。Optionally, the top engaging means includes one or more teeth for engaging the article, the one or more teeth including two or more layers of substrates uniformly bonded together.

可选地,两层或更多层基材中的每一层包括至少一个未涂覆侧。Optionally, each of the two or more layers of substrate includes at least one uncoated side.

可选地,两层或更多层基材中的每一层包括涂覆侧,并且其中,第一层的涂覆侧结合到第二层的涂覆侧。Optionally, each of the two or more layers of the substrate includes a coated side, and wherein the coated side of the first layer is bonded to the coated side of the second layer.

可选地,两层或更多层基材中的每一层包括与涂覆侧相对的未涂覆侧。Optionally, each of the two or more layers of the substrate includes an uncoated side opposite the coated side.

可选地,两层或更多层基材中的每一层包括未涂覆侧,并且其中,第一层的未涂覆侧结合到第二层的未涂覆侧。Optionally, each of the two or more layers of the substrate includes an uncoated side, and wherein the uncoated side of the first layer is bonded to the uncoated side of the second layer.

可选地,两层或更多层基材中的每一层包括与未涂覆侧相对的涂覆侧。Optionally, each of the two or more layers of the substrate includes a coated side opposite the uncoated side.

可选地,两层或更多层基材中的每一层包括与第一未涂覆侧相对的第二未涂覆侧。Optionally, each of the two or more layers of substrate includes a second uncoated side opposite the first uncoated side.

可选地,两层或更多层基材中的每一层包括未涂覆侧,并且其中,第一层的未涂覆侧结合到第二层的未涂覆侧。Optionally, each of the two or more layers of the substrate includes an uncoated side, and wherein the uncoated side of the first layer is bonded to the uncoated side of the second layer.

可选地,层压结构包括:Optionally, the laminate structure includes:

第一层,其具有涂覆侧以及与该涂覆侧相对的未涂覆侧;以及a first layer having a coated side and an uncoated side opposite the coated side; and

第二层,其具有未涂覆侧;a second layer having an uncoated side;

其中,第一层的未涂覆侧结合到第二层的未涂覆侧。Therein, the uncoated side of the first layer is bonded to the uncoated side of the second layer.

可选地,基材是纸板材料。Optionally, the substrate is a cardboard material.

本发明的第三方面提供了一种用于形成顶部接合的物品承载器的坯件。坯件包括主面板,该主面板包括具有至少一个顶部接收开口的至少一个顶部接合装置。主面板包括由均匀地结合在一起的两层或更多层基材形成的层压结构。A third aspect of the present invention provides a blank for forming a top-engaged article carrier. The blank includes a main panel including at least one top engagement means having at least one top receiving opening. The primary panel includes a laminate structure formed from two or more layers of substrates uniformly bonded together.

本发明的第四方面提供了一种用于包装至少一个物品的物品承载器。物品承载器包括主面板,该主面板包括具有至少一个物品接收开口的至少一个物品保持装置。主面板包括由均匀地结合在一起的两层或更多层纸板材料形成的层压结构。A fourth aspect of the present invention provides an article carrier for packaging at least one article. The article carrier includes a main panel including at least one article holder having at least one article receiving opening. The primary panel includes a laminate structure formed from two or more layers of cardboard material uniformly bonded together.

本发明的第五方面提供了一种用于形成物品承载器的层压纸板结构,该层压纸板结构包括两层或更多层纸板基材,该两层或更多层纸板基材包括具有第一表面的第一层和包括第二表面的第二层。第二表面设置成与第一表面相邻并均匀地结合到第一表面。A fifth aspect of the present invention provides a laminated paperboard structure for forming an article carrier, the laminated paperboard structure comprising two or more layers of paperboard substrate comprising a A first layer of the first surface and a second layer comprising the second surface. The second surface is disposed adjacent to and uniformly bonded to the first surface.

在本申请的范围内,设想或预期在前面的段落、权利要求和/或下面的描述和附图中阐述的各个方面、实施例、示例、特征和替代方案可独立地或以其任何组合的方式来考虑或采用。It is contemplated or contemplated that the various aspects, embodiments, examples, features and alternatives set forth in the preceding paragraphs, claims and/or the following description and drawings may be independently or in any combination thereof within the scope of this application. way to be considered or adopted.

结合或关于一个实施例所描述的特征或元件适用于所有实施例,除非存在特征的不相容。来自一个实施例的一个或多个特征或元件可结合到本文中所公开的任何其他实施例中或与其组合,可包括从所述一个实施例中提取的所述特征或元件以补充或代替所述其他实施例的一个或多个特征或元件。Features or elements described in connection with or in relation to one embodiment apply to all embodiments unless there is an incompatibility of features. One or more features or elements from one embodiment may be incorporated into or in combination with any other embodiment disclosed herein, and said features or elements extracted from said one embodiment may be included in addition to or in place of all other embodiments disclosed herein. describe one or more features or elements of other embodiments.

本文中所公开的实施例的特征或特征的组合可孤立于该实施例的其他特征来提取。替代地,可从实施例省略该实施例的特征或特征的组合。Features or combinations of features of an embodiment disclosed herein may be extracted in isolation from other features of the embodiment. Alternatively, a feature or combination of features of the embodiment may be omitted from the embodiment.

附图说明Description of drawings

现在将参考附图描述本发明的示例性实施例,其中:Exemplary embodiments of the present invention will now be described with reference to the accompanying drawings, in which:

图1是多个连接的坯件的俯视平面图,每个坯件能够形成根据第一实施例的承载器;1 is a top plan view of a plurality of connected blanks, each blank capable of forming a carrier according to a first embodiment;

图2是图1的坯件中的一个的俯视平面图;Figure 2 is a top plan view of one of the blanks of Figure 1;

图3是由图2的坯件形成的承载器的俯视透视图;Figure 3 is a top perspective view of a carrier formed from the blank of Figure 2;

图4是多个连接的坯件的俯视平面图,每个坯件能够形成根据第二实施例的承载器;以及4 is a top plan view of a plurality of connected blanks, each blank capable of forming a carrier according to the second embodiment; and

图5A至图5E是根据本公开的各种实施例的由纸板基材形成的多个结构的示意性图示。5A-5E are schematic illustrations of various structures formed from paperboard substrates in accordance with various embodiments of the present disclosure.

具体实施方式Detailed ways

本文中公开了包装、坯件和承载器的具体实施例的详细描述。将理解,所公开的实施例仅仅是能够实施本发明的某些方面的方式的示例,而并不表示可体现本发明的所有方式的详尽列表。如本文中所使用的,词语“示例性”在广泛意义上被使用以指代用作图示、样本、模型或样式的实施例。实际上,将理解,可以以各种和替代形式来体现本文中所描述的包装、坯件和承载器。诸图未必按比例绘制,并且一些特征可能被夸大或最小化以示出特定部件的细节。众所周知的部件、材料或方法未必很详细地描述,以便避免模糊本公开。本文中所公开的任何具体结构和功能细节将不解释为限制性的,而是仅仅作为权利要求的基础和作为教导本领域技术人员以各种方式采用本发明的代表性基础。Detailed descriptions of specific embodiments of packages, blanks and carriers are disclosed herein. It will be appreciated that the disclosed embodiments are merely illustrative of the ways in which certain aspects of the invention can be implemented, and do not represent an exhaustive list of all ways in which the invention can be embodied. As used herein, the word "exemplary" is used in a broad sense to refer to an embodiment serving as an illustration, sample, model, or style. Indeed, it will be appreciated that the packages, blanks and carriers described herein may be embodied in various and alternative forms. The figures are not necessarily to scale and some features may be exaggerated or minimized to show details of particular components. Well-known components, materials, or methods are not necessarily described in great detail in order to avoid obscuring the disclosure. Any specific structural and functional details disclosed herein are not to be interpreted as limiting, but merely as a basis for the claims and as a representative basis for teaching one skilled in the art to variously employ the present invention.

参考图1,示出了多个连接的坯件10A、10B、10C、10D、10D、10E、10F的平面图;图2中示出了能够形成纸板箱或承载器90(如图3中所示)的单独的坯件10,该纸板箱或承载器用于容纳和携带一组主要产品,诸如但不限于瓶或罐,下文中称为物品B,如图3中所示。坯件10形成用于包装至少一个主要产品容器或包装的二次包装。图4中示出了替代性坯件110。Referring to FIG. 1, a plan view of a plurality of

在本文中所详述的实施例中,出于图示本发明的各种特征的非限制性目的,术语“纸板箱”和“承载器”指代用于接合和携带物品(诸如,主要产品容器)的容器。预期本发明的教导能够应用于各种产品容器,这些产品容器可以是或可以不是逐渐变细的和/或圆柱形的。示例性容器包括瓶(例如,金属瓶、玻璃瓶或塑料瓶)、罐(例如,铝罐)、锡器、袋子、小包等等。In the embodiments detailed herein, for the non-limiting purpose of illustrating various features of the present invention, the terms "carton" and "carrier" refer to the terms "carton" and "carrier" for engaging and carrying items such as primary product containers ) container. It is contemplated that the teachings of the present invention can be applied to a variety of product containers, which may or may not be tapered and/or cylindrical. Exemplary containers include bottles (eg, metal, glass, or plastic bottles), cans (eg, aluminum cans), tins, bags, sachets, and the like.

坯件10、110由合适基材的片材形成。将理解,如本文中所使用的,术语“合适基材”包括各种各样的可折叠片材材料,诸如纸板、瓦楞纸板、硬纸板、塑料、其组合等等。应认识到,在适当的情况下,可采用一个或其他数量的坯件,例如以提供下文更详细地描述的承载器结构。The

本文中所描述的包装结构或纸板箱可由片材材料(诸如,纸板)形成,该片材材料可由多种材料制成或涂覆有多种材料以增加其强度。这样的片材材料的示例是由WestRockCompany制造的抗撕裂NATRALOCK®纸板。应注意,抗撕裂材料可由多于一层提供,以有助于改进包装的抗撕裂性。通常,片材材料的一个表面可具有与另一表面不同的特性。例如,片材材料的从已完成包装面向外的表面可特别光滑,并且可具有涂层(诸如,粘土涂层或其他表面处理)以提供良好的印刷适性。另一方面,片材材料的面向内的表面可设置有涂层、层、处理或以其他方式做好准备,以提供诸如抗撕裂性、良好的胶粘性、热封性或其他期望的功能性能中的一者或多者的性能。The packaging structures or cartons described herein may be formed from a sheet material, such as cardboard, which may be made from or coated with a variety of materials to increase its strength. An example of such a sheet material is tear-resistant NATRALOCK® paperboard manufactured by WestRock Company. It should be noted that the tear resistant material may be provided by more than one layer to help improve the tear resistance of the package. Typically, one surface of the sheet material may have different properties than the other surface. For example, the surface of the sheet material facing outward from the finished package may be particularly smooth and may have a coating such as a clay coating or other surface treatment to provide good printability. On the other hand, the inward facing surface of the sheet material may be provided with a coating, layer, treatment, or otherwise prepared to provide, for example, tear resistance, good adhesion, heat sealability, or other desired The performance of one or more of the functional performances.

在所图示的实施例中,坯件10被构造成形成用于包装示例性物品B的示例性布置的纸板箱或承载器90。在图1、图2和图3中所图示的实施例中,布置是2 × 2矩阵或阵列;在所图示的实施例中,提供两排各两个物品,并且物品B是饮料罐。在图4中所图示的实施例中,布置是3 × 2矩阵或阵列;在所图示的实施例中,提供三排各两个物品,并且物品B是饮料罐。替代地,坯件10、110能够被构造成形成用于包装其他类型、数量和大小的物品和/或用于以不同的布置或构型来包装物品的承载器。In the illustrated embodiment, the blank 10 is configured to form an exemplary arrangement of carton or

参考图1,示出了多个连接的坯件(总体上由附图标记1指代),具体地,存在以3 ×2矩阵或阵列布置的六个坯件10A、10B、10C、10D、10E、10F。每个坯件10A、10B、10C、10D、10E、10F包括用于形成承载器90(见图3)的顶壁或接合面板的主面板12。每个坯件10A、10B、10C、10D、10E、10F通过易断连接部14连接到至少两个相邻坯件10A、10B、10C、10D、10E、10F。Referring to Figure 1, a plurality of connected blanks (generally designated by reference numeral 1) are shown, in particular, there are six

主面板12包括至少一个物品保持结构RT1、RT2、RT3、RT4,见图2。在图1和图2的实施例中,主面板12包括多个物品保持结构RT1、RT2、RT3、RT4,具体地以2 × 2矩阵或阵列布置的四个物品保持结构RT1、RT2、RT3、RT4。物品保持结构RT1、RT2、RT3、RT4中的每一个包括孔口A1、A2、A3、A4。The

物品保持结构RT1、RT2、RT3、RT4中的每一个在构造上基本上相似,且因此将参考第二物品保持结构RT2进行详细描述。Each of the article holding structures RT1 , RT2 , RT3 , RT4 is substantially similar in construction and thus will be described in detail with reference to the second article holding structure RT2 .

第二物品保持结构RT2包括部分地由孔口A2限定的物品接收开口。The second article retention structure RT2 includes an article receiving opening partially defined by the aperture A2.

第二物品保持结构RT2包括第一段和第二段。第一段S1限定第一弧S1,且第二段限定第二弧S2。The second article retention structure RT2 includes a first segment and a second segment. The first segment S1 defines a first arc S1 and the second segment defines a second arc S2.

第一段可以是‘有齿的’,第二段可以是‘无齿的’。也就是说,在孔口A2的由第一段S1限定的周边区域中,孔口A2包括绕第一弧S1设置的多个齿。孔口A2的由第二段限定的周边区域(第二弧S2)没有齿。在图2中所图示的实施例中,第二段包括弓形边缘,该弓形边缘具有成对间隔开的缓解凹口C8、C9。The first segment can be 'toothed' and the second segment can be 'toothless'. That is, in the peripheral area of the aperture A2 defined by the first segment S1, the aperture A2 includes a plurality of teeth arranged around the first arc S1. The peripheral area (second arc S2 ) of orifice A2 defined by the second segment has no teeth. In the embodiment illustrated in Figure 2, the second segment includes an arcuate edge with pairs of spaced relief notches C8, C9.

‘有齿的’区域包括绕孔口A2形成在主面板12中的多个齿或接片。The 'toothed' area includes a plurality of teeth or tabs formed in the

每个齿包括接合边缘或齿边缘31。每个齿边缘31的形状可以是线性的,或者可以是弓形的。齿边缘31可由圆的弧或一部分限定。孔口A2包括可近似或限定具有中心的假想圆的周边。Each tooth includes an engagement edge or

主面板12的包围孔口A2的“有齿的”区域可包括呈凹部或凹口形式的切除口C1、C2、C3、C4、C5、C6、C7。切除口C1、C2、C3、C4、C5、C6、C7基本上是“U”形的,在其他实施例中,切除口C1、C2、C3、C4、C5、C6、C7可替代地被成形为诸如但不限于“V”形的。切除口C1、C2、C3、C4、C5、C6、C7从假想圆NC径向向外延伸。The "toothed" area of the

齿或接片中的每一个至少部分地由成对切除口C1、C2、C3、C4、C5、C6、C7限定。切除口C1、C2、C3、C4、C5、C6、C7可形成径向地延伸远离假想圆的中心的缓解元件。Each of the teeth or tabs is at least partially defined by a pair of cutouts C1, C2, C3, C4, C5, C6, C7. The cut-outs C1, C2, C3, C4, C5, C6, C7 may form relief elements that extend radially away from the center of the imaginary circle.

主面板12的包围孔口A2的无齿的或不含齿的区域S2包括接合边缘或自由边缘37(本文中也称为连续支撑边缘)。接合边缘37的形状是曲线或弓形。The toothless or toothless area S2 of the

主面板12的包围孔口A2的无齿的或不含齿的区域可被限定在对着约180°角度的弧中或占据该弧,在其他实施例中,该角度可小于180°,例如但不限于170°。The toothless or toothless area of the

以这种方式,孔口A2的基本上一半的周边包括齿或接片。In this way, substantially half of the perimeter of orifice A2 includes teeth or tabs.

第二物品保持结构RT2包括两个相邻设置的缓解元件C1、C7,接合边缘37被限定在这两个缓解元件之间。接合边缘37可被一个或多个缓解元件C8、C9中断。在所图示的实施例中,接合边缘37被两个缓解元件C8、C9中断。The second article retention structure RT2 comprises two adjacently arranged relief elements C1, C7 between which an

可选地,主面板12可包括手柄结构H。手柄结构H可包括手柄开口。手柄开口被限定在主面板12中,并且位于居中设置在第一对物品保持结构RT1、RT2和第二对物品保持结构RT3、RT4之间的区域中。手柄开口可至少部分地由缓冲接片16限定,该缓冲接片通过折线15铰接到主面板12。Optionally, the

可选地,主面板12的侧边缘可布置成曲线或波浪形状。以这种方式,第一坯件10可布置成与第二坯件10成嵌套布置。波浪形状规定第一和第二坯件10一起限定的宽度小于单独的坯件10的最大宽度的两倍。这可通过减少生产给定数量的坯件10所需的基材量而具有经济和环境益处。Alternatively, the side edges of the

主面板12至少包括纸板基材。纸板基材的材料可选自任何常规的纸板,例如,重量范围从大约10 pt. (0.010”/~0.25 mm)往上、优选地从大约16 pt. (0.016”/~0.41 mm)至大约28 pt. (0.028”/~0.7 mm)。纸板基材可以是漂白的或未漂白的纸板。纸板可在至少一个侧上涂覆有经选择以实现与印刷方法和纸板组合物相容的常规涂层。The

这样的基材的示例是由WestRock®公司制造的28点(pt.)SBS纸板(在一侧上涂覆的固体漂白硫酸盐纸板,商品名PrintKote®)、未漂白未涂覆的牛皮纸(UUK)或CNK®纸板(Coated Natural Kraft®—在一侧上具有粘土涂层的未漂白牛皮纸板,商品名CarrierKoteTM)。Examples of such substrates are 28 point (pt.) SBS paperboard (solid bleached sulfate paperboard coated on one side, trade name PrintKote®), unbleached uncoated kraft paper (UUK ) or CNK® board (Coated Natural Kraft®—unbleached kraft board with a clay coating on one side, trade name CarrierKoteTM).

在所图示的实施例中,主面板12由两层纸板基材形成,这两层结合在一起以形成层压纸板材料。粘合剂处理或胶水可在两层纸板基材之间形成胶水层。图5A至图5E图示了用于形成物品承载器90的层压纸板材料的各种实施例。In the illustrated embodiment, the

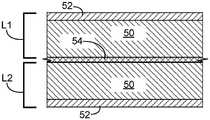

图5A示出了包括层压纸板结构的实施例,该层压纸板结构包括在纤维层50的一侧上具有涂层52的第一层L1纸板。第一层L1纸板结合到在纤维层50的一侧上具有涂层52的第二层L2纸板。第一层L1的未涂覆侧(纤维层50)结合到第二层L2的未涂覆侧(纤维层50);粘合剂处理或胶水在其间形成胶水或粘合剂层54。图5A的层压结构可以是抗卷曲的,卷曲是由于例如但不限于纤维层的水分吸着(吸收或吸附)和/或解吸所致。层压纸板结构包括在相对表面上的涂层,这些涂层可抑制纤维层的水分吸着和/或解吸。FIG. 5A shows an embodiment comprising a laminated paperboard structure comprising a first layer of L1 paperboard having a

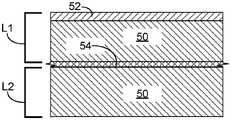

图5B示出了包括层压纸板结构的实施例,该层压纸板结构包括在纤维层50的一侧上具有涂层52的第一层L1纸板。第一层L1纸板结合到在纤维层50的一侧上具有涂层52的第二层L2纸板。第一层L1的涂覆侧结合到第二层L2的涂覆侧;粘合剂处理或胶水在其间形成胶水或粘合剂层54。FIG. 5B shows an embodiment comprising a laminated paperboard structure comprising a first layer of L1 paperboard having a

图5C示出了包括层压纸板结构的实施例,该层压纸板结构包括在纤维层50的一侧上具有涂层52的第一层L1纸板。第一层L1纸板结合到在纤维层50的一侧上具有涂层52的第二层L2纸板。第一层L1的未涂覆侧(纤维层50)结合到第二层L2的涂覆侧;粘合剂处理或胶水在其间形成胶水或粘合剂层54。FIG. 5C shows an embodiment comprising a laminated paperboard structure comprising a first layer of L1 paperboard having a

图5D示出了包括层压纸板结构的实施例,该层压纸板结构包括在纤维层50的一侧上具有涂层52的第一层L1纸板。第一层L1纸板结合到具有纤维层50的第二层L2未涂覆纸板。第一层L1的未涂覆侧(纤维层50)结合到第二层L2的未涂覆侧中的一个;粘合剂处理或胶水在其间形成胶水或粘合剂层54。FIG. 5D shows an embodiment comprising a laminated paperboard structure comprising a first layer of L1 paperboard having a

图5E示出了包括层压纸板结构的实施例,该层压纸板结构包括具有纤维层50的第一层L1未涂覆纸板。第一层L1纸板结合到具有纤维层50的第二层L2未涂覆纸板。第一层L1的未涂覆侧中的一个结合到第二层L2的未涂覆侧中的一个;粘合剂处理或胶水在其间形成胶水或粘合剂层54。FIG. 5E shows an embodiment comprising a laminated paperboard structure comprising a first layer L1 of uncoated paperboard with a

在一个示例中,28 pt CBS或CNK纸板的第一片材结合到28 pt CBS或CNK纸板的第二片材。这产生了厚度为大约0.056”(约1.4 mm)的基材,该基材在其相对面上具有涂层。这样的基材的优点是在不包括聚合物材料或塑料材料的情况下增加了强度,这样的基材可提供环境益处并且更容易回收。在其他实施例中,一层材料或一片材材料的涂覆侧结合到另一层材料或另一片材材料的未涂覆侧。在替代性实施例中,一层材料或一片材材料的涂覆侧结合到另一层材料或另一片材材料的涂覆侧。In one example, a first sheet of 28 pt CBS or CNK paperboard is bonded to a second sheet of 28 pt CBS or CNK paperboard. This results in a substrate having a thickness of approximately 0.056" (approximately 1.4 mm) with a coating on its opposite side. The advantage of such a substrate is the added benefit of not including polymeric or plastic materials. strength, such substrates can provide environmental benefits and are easier to recycle. In other embodiments, the coated side of one layer or sheet of material is bonded to the uncoated side of another layer or sheet of material In an alternative embodiment, the coated side of one layer or sheet of material is bonded to the coated side of another layer or sheet of material.

将理解,经选择以用于结合在一起的纸板基材的厚度或卡尺厚度(caliper)(密度或重量)可具有不同的厚度或重量。还将理解,经选择的纸板基材的厚度或卡尺厚度(密度或重量)可以是基于物品承载器旨在支撑的重量或负荷来选择的,例如用于包装更大体积/更重饮料罐,或者更大数量的饮料罐的物品承载器可由更厚的(或重量更重的)纸板基材形成。类似地,当物品承载器旨在支撑更大的负荷时,物品承载器可由结合在一起的纸板基材的更大数量的层(layers/plies)形成。It will be appreciated that the thickness or caliper (density or weight) of the paperboard substrates selected for bonding together can have different thicknesses or weights. It will also be appreciated that the thickness or caliper thickness (density or weight) of the cardboard substrate selected may be selected based on the weight or load that the article carrier is intended to support, such as for packaging larger volume/heavier beverage cans, Or an item carrier for a larger number of beverage cans may be formed from a thicker (or heavier weight) cardboard substrate. Similarly, when the article carrier is intended to support larger loads, the article carrier may be formed from a larger number of layers/plies of cardboard substrates bonded together.

胶水层可由对纸板具有良好亲和力的任何粘合剂形成,诸如水性胶(例如,白色工艺胶、黄色木胶和聚醋酸乙烯酯—PVA胶)。The glue layer can be formed from any adhesive that has a good affinity for paperboard, such as water-based glues (eg, white craft glue, yellow wood glue, and polyvinyl acetate-PVA glue).

纸板的两个或更多个片材被层压在一起形成层压纸板,且然后可将层压纸板模切成承载器坯件10,诸如,图1的承载器坯件。Two or more sheets of paperboard are laminated together to form a laminated paperboard, and the laminated paperboard can then be die cut into a

在一些实施例中,坯件和物品承载器由纸板原料的可商购的两个或更多个片材或卷材形成,所述片材或卷材结合在一起以形成层压结构。所设想的是,层压结构由已在造纸厂中干燥的纸板原料形成,该纸板原料还可在结合在一起之前经受一种或多种干端处理,诸如但不限于轧光和/或用涂层修整。In some embodiments, the blank and article carrier are formed from two or more commercially available sheets or rolls of paperboard stock that are bonded together to form a laminate structure. It is envisaged that the laminate structure is formed from paperboard stock that has been dried in the paper mill, which may also be subjected to one or more dry end treatments such as, but not limited to, calendering and/or prior to joining together. Coating trim.

在一些实施例中,可处理或调节纸板基材的待结合到另一纸板基材的表面以改进结合力,诸如但不限于,通过穿孔或以其他方式中断该表面,例如利用部分深度切口中断该表面。In some embodiments, the surface of a paperboard substrate to be bonded to another paperboard substrate may be treated or conditioned to improve the bond, such as, but not limited to, by perforating or otherwise interrupting the surface, for example by interrupting with partial depth cuts the surface.

顶部接合承载器90包括均匀地结合的层。在顶部接合承载器90包括接合齿的那些实施例中,每个齿具有均匀地结合的纸板层。这比具有多个纸板层且这些纸板层具有非胶合结构的物品承载器、以及比具有后胶合结构(其中纸板层在纸板的每个层被模切之后被粘附)的物品承载器有利。在这样的后胶合物品承载器中,因为每个层已经被模切,所以这些层通过点状胶合粘附在一起且因此承载器不具有均匀地胶合的层。在承载器包括接合齿的情况下,这些齿不包括均匀地胶合的层并且可由未结合的层形成。The

在一些实施例中,至少一个抗撕裂层可设置在第一层基材和第二层基材之间,这样的基材可通过结合材料的两个片材形成,其中的至少一个片材包括层压到其的抗撕裂层。这可具有增加基材强度的优点。In some embodiments, at least one tear resistant layer may be disposed between the first layer of substrate and the second layer of substrate, such substrate may be formed by joining two sheets of material, at least one of the sheets Includes tear resistant layer laminated to it. This can have the advantage of increasing the strength of the substrate.

主面板12可包括层压到纸板层的抗撕裂层。可选地,它包括在纸板基材和抗撕裂层之间的粘合剂层。抗撕裂层可设置在纸板基材的未涂覆侧之上,并且可由聚合物材料形成并固定到基材。抗撕裂层将韧性赋予层压结构。合适的抗撕裂材料可包括但不限于抗撕裂层压片材材料,例如NATRALOCK®,其可包括一层n轴取向的膜,例如,MYLAR®,其是双轴取向聚酯、取向尼龙、交叉层压聚烯烃或高密度聚烯烃。这些材料的取向和交叉层压结构促成了抗撕裂特性。而且,抗撕裂性可归因于抗撕裂材料的化学性质,抗撕裂材料诸如挤出茂金属催化聚乙烯(mPE)。The

替代地,抗撕裂层可以是线性低密度聚乙烯(LLDPE)层。在使用线性低密度聚乙烯(LLDPE)或mPE的实施例中,不必要结合粘合剂层。也可使用具有高水平抗撕裂性的其他合适材料。Alternatively, the tear resistant layer may be a linear low density polyethylene (LLDPE) layer. In embodiments using linear low density polyethylene (LLDPE) or mPE, it is not necessary to bond the adhesive layer. Other suitable materials with high levels of tear resistance can also be used.

粘合剂层可由聚烯烃材料形成,诸如低密度聚乙烯(LDPE)。粘合剂层可放置在基材和抗撕裂层之间以将抗撕裂层固定到基材。The adhesive layer may be formed of a polyolefin material, such as low density polyethylene (LDPE). An adhesive layer can be placed between the substrate and the tear resistant layer to secure the tear resistant layer to the substrate.

转向由坯件10构造承载器90,可将坯件10应用于一组物品B。将坯件10相对于该组物品B降低。使坯件10的物品保持结构RT1、RT2、RT3、RT4中的每一个与该组中的相应物品B对准。物品B的部分穿过主面板12。主面板12的绕物品保持结构RT1、RT2、RT3、RT4中的每一个的有齿区域可被折叠出主面板12的平面。Turning to constructing

主面板12的每个有齿区域可绕物品中的一个(该物品被接收在物品保持结构RT1、RT2、RT3、RT4中的相应一个中)折叠;坯件10可绕物品B变形,例如但不限于物品B的肩部部分,在物品B是罐的情况下,肩部部分可由颈缩部提供。Each toothed area of the

主面板12的齿的接合边缘31和不含齿的区域的接合边缘37在突起下面接合。该突起可绕物品B的物品B(其可设有凸缘)的颈部或凸边定位。当物品B是罐时,该突起可由罐的端缝提供。在其他实施例中,该突起可由物品B的脊部或底切成形部提供,或者由物品B的端部封闭件提供,例如但不限于冠形瓶塞或封闭件。以这种方式,接合边缘31、37夹持或保持物品B并防止或抑制物品B无意地与主面板12分开。图3中示出了已组装的承载器90。The engaging edges 31 of the teeth of the

齿包括均匀地结合在一起的两层基材,这两层基材提供物品B的牢固接合。The teeth comprise two layers of substrates uniformly bonded together that provide a secure engagement of the article B.

承载器90的另一可选特征是主面板12由不与承载器90的其他部分连接的周边限定。也就是说,承载器90没有连接到其他面板,例如但不限于绕物品组的侧部延伸的侧壁面板或端壁面板。主面板12的周边因此整体由自由边缘、切割边缘或未铰接边缘限定。Another optional feature of the

承载器90的另一可选特征是主面板12由包括凸弯曲边缘和凹弯曲边缘的周边限定,其中,凸弯曲边缘的曲率半径基本上等于凹弯曲边缘的曲率半径,因此允许两个类似的坯件10放置成嵌套或镶嵌布置。Another optional feature of the

在一些实施例中,将多个坯件1同时应用于第一组物品B。第一组物品B可划分成多个第二组物品B。因此,每个第二组物品B由第一组物品B的子集形成。在图1中所图示的实施例中,第一组物品B包括以4 × 6矩阵或阵列布置的二十四个物品,并且每个单独的坯件10A、10B、10C、10D、10E、10F容纳呈2 × 2矩阵或阵列的四个物品。In some embodiments, multiple blanks 1 are applied to the first set of articles B simultaneously. The first group of articles B may be divided into a plurality of second groups of articles B. Thus, each second set of items B is formed from a subset of the first set of items B. In the embodiment illustrated in FIG. 1 , the first set of articles B includes twenty-four articles arranged in a 4×6 matrix or array, and each individual blank 10A, 10B, 10C, 10D, 10E, 10F holds four items in a 2 x 2 matrix or array.

单独的坯件10A、10B、10C、10D、10E、10F之间的易断连接部14可在将所述多个坯件1应用于第一组物品B时分开。替代地,易断连接部14可保持完整,单独的坯件10A、10B、10C、10D、10E、10F可在销售或分销点与其他坯件分开。The

现在参考图4,示出了本公开的附加实施例。在第二所图示的实施例中,在可能的情况下已使用相似的数字来表示相似的部分,只不过添加了前缀“100”以指示这些特征属于第二实施例。该附加实施例与第一实施例共享许多共同的特征,且因此将仅详细描述与图1至图3中所图示的实施例的差异。Referring now to FIG. 4, additional embodiments of the present disclosure are shown. In the second illustrated embodiment, like numerals have been used where possible to refer to like parts, but with the addition of the prefix "100" to indicate that these features pertain to the second embodiment. This additional embodiment shares many common features with the first embodiment, and therefore only the differences from the embodiment illustrated in FIGS. 1-3 will be described in detail.

图4图示了第二实施例并且示出了总体上由附图标记101指代的多个连接的坯件,具体地,存在以2 × 2矩阵或阵列布置的四个坯件110A、110B、110C、110D。每个坯件110A、110B、110C、110D包括用于形成承载器(未示出)的顶壁或接合面板的主面板112。每个坯件110A、110B、110C、110D通过易断连接部114连接到两个相邻坯件110A、110B、110C、110D。Figure 4 illustrates the second embodiment and shows a plurality of connected blanks generally designated by

每个坯件110A、110B、110C、110D的主面板112包括至少一个物品保持结构RT1、RT2、RT3、RT4、RT5、RT6。主面板112包括多个物品保持结构RT1、RT2、RT3、RT4、RT5、RT6,具体地以3 × 2矩阵或阵列布置的六个物品保持结构RT1、RT2、RT3、RT4、RT5、RT6。物品保持结构RT1、RT2、RT3、RT4、RT5、RT6中的每一个包括孔口A1、A2、A3、A4、A5、A6。The

物品保持结构RT1、RT2、RT5、RT6(也称为最末端的物品保持结构RT1、RT2、RT5、RT6)中的每一个在构造上基本上类似于图1和图2的实施例的物品保持结构RT1、RT2、RT3、RT4。这些物品保持结构包括绕孔口A1、A2、A5、A6的周边设置的六个齿。物品保持结构RT1、RT2、RT5、RT6设置在主面板112的角部中。Each of the item retention structures RT1, RT2, RT5, RT6 (also referred to as the endmost item retention structures RT1, RT2, RT5, RT6) is substantially similar in construction to the item retention of the embodiment of FIGS. 1 and 2 Structure RT1, RT2, RT3, RT4. These article retention structures include six teeth arranged around the perimeter of the apertures A1, A2, A5, A6. The article holding structures RT1 , RT2 , RT5 , RT6 are provided in the corners of the

物品保持结构RT3、RT4(也称为中间物品保持结构RT3、RT4)设置在主面板112上的中间、在第一对最末端的物品保持结构RT1、RT2和第二对最末端的物品保持结构RT5、RT6之间。Item retention structures RT3, RT4 (also referred to as intermediate item retention structures RT3, RT4) are disposed on the

中间物品保持结构RT3、RT4包括三个齿,每个齿部分地由成对缓解元件C限定。每个齿包括接合边缘131、132、133。齿的接合边缘131、132、133占据孔口A3、A4的周边的一部分。该部分限定了具有中心的假想圆的第一弧,该弧所对着的角度可小于120°,该角度可大于60°并且可为约90°。第一弧被限定在两个缓解元件之间。The intermediate article holding structures RT3, RT4 comprise three teeth, each tooth being partially defined by a pair of relief elements C. Each tooth includes an

保持结构RT3、RT4包括无齿的或不含齿的部分。不含齿的部分限定与第一弧互补的第二弧。不含齿的区域包括接合边缘137。The retention structures RT3, RT4 comprise toothless or toothless portions. The tooth-free portion defines a second arc complementary to the first arc. The tooth-free area includes the

可选地,主面板112可包括手柄结构H1、H2。手柄结构H1、H2可包括至少部分地由第一手柄孔口形成的第一开口。第一手柄孔口从主面板112冲压而成,并且位于居中设置在第一对物品保持结构RT1、RT2和第二对物品保持结构RT3、RT4之间的区域中。第一开口可部分地由第一缓冲接片限定,该第一缓冲接片通过折线铰接到主面板112。第一手柄孔口可以是基本上新月形或“C”形的。手柄结构H1、H2可包括至少部分地由第二手柄孔口形成的第二开口。第二手柄孔口从主面板112冲压而成,并且位于居中设置在第二对物品保持结构RT3、RT4和第三对物品保持结构RT5、RT6之间的区域中。第二开口可部分地由第二缓冲接片限定,该第二缓冲接片通过折线铰接到主面板112。第二手柄孔口可以是基本上新月形或“C”形的。第一开口和第二开口可以以彼此相对的方式布置,使得第一缓冲瓣片和第二缓冲瓣片以彼此相对的方式铰接到主面板112。Optionally, the

本公开提供了一种顶部接合类型的承载器,其具有形成在层压基材中的物品保持结构或物品顶部接合装置,该层压基材由均匀地结合在一起的两层或更多层纸板基材形成。层压基材是在从其上模切坯件之前形成的。The present disclosure provides a top-bonded-type carrier having an article retention structure or article top-bonding device formed in a laminated substrate consisting of two or more layers uniformly bonded together Cardboard substrates are formed. Laminate substrates are formed before blanks are die cut therefrom.

层压基材可由纸板的两个或更多个片材或卷材形成,其中的至少一个片材或卷材预印有图形或其他标记。所述两个或更多个片材或卷材在对层中的一个印刷之后被层压。以这种方式,形成了在至少一侧上具有印刷的图形或其他标记的层压基材。然后,切割已印刷的层压基材以形成承载器坯件。在层压基材由纸板的卷材形成的一些实施例中,可在切割承载器坯件之前将层压基材切割成片材。在层压基材由纸板的卷材形成的其他实施例中,不必要将层压基材切割成片材,可使用在线(inline)模切装置直接从层压基材切割承载器坯件。The laminated substrate may be formed from two or more sheets or rolls of paperboard, at least one of which is pre-printed with graphics or other indicia. The two or more sheets or webs are laminated after printing one of the layers. In this manner, a laminated substrate having printed graphics or other indicia on at least one side is formed. The printed laminate substrate is then cut to form carrier blanks. In some embodiments where the laminated substrate is formed from a roll of paperboard, the laminated substrate may be cut into sheets prior to cutting the carrier blank. In other embodiments where the laminate substrate is formed from a roll of paperboard, it is not necessary to cut the laminate substrate into sheets, and an inline die cutting device can be used to cut the carrier blank directly from the laminate substrate.

层压基材可由将未印刷纸板的两个或更多个片材或卷材结合在一起而形成。一旦层压基材形成,至少一侧就可印刷有图形或其他标记。以这种方式,形成了在至少一侧上具有印刷的图形或其他标记的层压基材。然后,切割已印刷的层压基材以形成承载器坯件。在层压基材由纸板的卷材形成的实施例中,层压基材可被在线印刷,或者可被切割成片材,然后对片材进行印刷。Laminated substrates may be formed by joining together two or more sheets or rolls of unprinted paperboard. Once the laminated substrate is formed, at least one side can be printed with graphics or other indicia. In this manner, a laminated substrate having printed graphics or other indicia on at least one side is formed. The printed laminate substrate is then cut to form carrier blanks. In embodiments where the laminate substrate is formed from a roll of paperboard, the laminate substrate can be printed in-line, or can be cut into sheets and then printed on the sheets.

将认识到,如本文中所使用的,方向参考(诸如,“顶部”、“底部”、“基底”、“前部”、“后部”、“端部”、“侧部”、“内”、“外”、“上部”和“下部”)未必将相应面板限制到这样的取向,而是可能仅用来使这些面板彼此区分开。It will be appreciated that, as used herein, directional references (such as "top", "bottom", "base", "front", "rear", "end", "side", "inside" ", "outer", "upper" and "lower") do not necessarily limit the respective panels to such orientations, but may merely serve to distinguish the panels from one another.

如本文中所使用的,术语“铰接连接部”和“折线”指代限定坯件的铰接特征、促进坯件的多个部分相对于彼此折叠、或以其他方式指示坯件的最佳面板折叠位置的各种各样的线。对“铰接连接部”的任何引用不应被解释为必定是指仅单条折线;实际上,铰接连接部能够由两条或更多条折线形成,其中,两条或更多条折线中的每一条的形状可以是直线的/线性的抑或弯曲的/曲线的。当线性的折线形成铰接连接部时,它们可设置成彼此平行或相对于彼此略微成角度。当曲线的折线形成铰接连接部时,它们可彼此相交以在被这些曲线的折线包围的区域内限定成形的面板。这样的铰接连接部的典型示例可包括成对拱形或弓形的折线,该对折线在两个点处相交,使得它们在其间限定椭圆形面板。铰接连接部可由一条或多条线性的折线以及一条或多条曲线的折线形成。这样的铰接连接部的典型示例可包括线性的折线和拱形或弓形的折线的组合,这些折线在两个点处相交,使得它们在其间限定半月形面板。As used herein, the terms "hinge connection" and "fold line" refer to hinge features that define the blank, facilitate the folding of portions of the blank relative to each other, or otherwise indicate optimal panel folding of the blank Various lines of location. Any reference to "a hinged connection" should not be construed as necessarily referring to only a single polyline; in fact, a hinged connection can be formed from two or more polylines, wherein each of the two or more polylines The shape of a strip can be straight/linear or curved/curved. When linear fold lines form hinged connections, they may be arranged parallel to each other or slightly angled relative to each other. When the fold lines of the curves form hinged connections, they may intersect with each other to define a shaped panel in the area enclosed by the fold lines of the curves. Typical examples of such hinged connections may include pairs of arcuate or arcuate fold lines that meet at two points such that they define an oval panel therebetween. The hinged connection may be formed by one or more linear polylines and one or more curvilinear polylines. Typical examples of such hinged connections may include a combination of linear fold lines and arcuate or arcuate fold lines that intersect at two points such that they define a meniscus panel therebetween.

如本文中所使用的,术语“折线”可指代以下各者中的一者:刻痕线、压纹线、凹入线、一行穿孔、一行短狭缝、一行半切口、单个半切口、中断的切割线、一行对准的狭缝、一行刻痕及上述选项的任何组合。As used herein, the term "crease line" may refer to one of the following: a score line, an embossed line, a debossed line, a row of perforations, a row of short slits, a row of half-cuts, a single half-cut, Interrupted cut lines, one row of aligned slits, one row of nicks, and any combination of the above options.

应理解,铰接连接部和折线能够各自包括形成于坯件的基材中的元件,包括穿孔、一行穿孔、一行短狭缝、一行半切口、单个半切口、切割线、中断的切割线、狭缝、刻痕、压纹线、凹入线、其任何组合等等。这些元件能够被确定尺寸并布置成提供期望的功能。例如,一行穿孔能够被确定尺寸或设计有薄弱度以限定折线和/或分割线。该行穿孔能够被设计成促进折叠且抵抗断裂,促进折叠且促进通过更多的努力使其断裂,或促进通过很少的努力使其断裂。It will be appreciated that the hinged connection and the fold line can each include elements formed in the substrate of the blank, including perforations, a row of perforations, a row of short slits, a row of half-cuts, single half-cuts, cut lines, interrupted cut lines, slits Seams, scores, embossed lines, indented lines, any combination thereof, and the like. These elements can be sized and arranged to provide the desired functionality. For example, a row of perforations can be sized or designed with weakness to define fold lines and/or dividing lines. The row of perforations can be designed to promote folding and resist breaking, promote folding and facilitate breaking with more effort, or facilitate breaking with little effort.

如本文中所使用的短语“与……对齐”指代在竖立的纸板箱中的两个或更多个元件(诸如,形成于两个叠置面板中的第一个中的孔口、以及形成于两个叠置面板中的第二个中的第二孔口)的对准。彼此对齐的那些元件可沿叠置面板的厚度方向彼此对准。例如,当第一面板中的孔口与第二面板(其放置成与第一面板成叠置布置)中的第二孔口“对齐”时,该孔口的边缘可沿着第二孔口的边缘的至少一部分延伸,且可沿第一面板和第二面板的厚度方向与第二孔口对准。The phrase "aligned with" as used herein refers to two or more elements in an erected carton (such as an aperture formed in a first of two stacked panels, and alignment of a second aperture formed in the second of the two stacked panels). Those elements that are aligned with each other may be aligned with each other in the thickness direction of the stacked panels. For example, when an aperture in a first panel is "aligned" with a second aperture in a second panel (which is placed in an overlapping arrangement with the first panel), the edge of the aperture may follow the second aperture At least a portion of the edge of the fin extends and can be aligned with the second aperture in the thickness direction of the first panel and the second panel.

Claims (18)

Translated fromChineseApplications Claiming Priority (3)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| US201962871333P | 2019-07-08 | 2019-07-08 | |

| US62/871333 | 2019-07-08 | ||

| PCT/US2020/034191WO2021006963A1 (en) | 2019-07-08 | 2020-05-22 | Laminated article carrier and blank therfor |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN114302852Atrue CN114302852A (en) | 2022-04-08 |

Family

ID=71078621

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202080062827.9APendingCN114302852A (en) | 2019-07-08 | 2020-05-22 | Laminated article carrier and blank therefor |

Country Status (11)

| Country | Link |

|---|---|

| US (1) | US20220242637A1 (en) |

| EP (1) | EP3997008A1 (en) |

| JP (2) | JP2022540225A (en) |

| KR (1) | KR20220030286A (en) |

| CN (1) | CN114302852A (en) |

| AU (1) | AU2020311834A1 (en) |

| BR (1) | BR112022000421A2 (en) |

| CA (1) | CA3146415A1 (en) |

| CL (1) | CL2022000046A1 (en) |

| MX (1) | MX2022000401A (en) |

| WO (1) | WO2021006963A1 (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| USD996227S1 (en)* | 2021-08-20 | 2023-08-22 | Fishbone Packaging Inc. | Container carrier |

| KR20240134872A (en)* | 2022-01-09 | 2024-09-10 | 웨스트락 패키징 시스템스, 엘엘씨 | Goods carrier and blank therefor |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB8925557D0 (en)* | 1989-11-11 | 1990-01-04 | Mead Corp | Top gripping article carrier |

| US5186321A (en)* | 1992-02-24 | 1993-02-16 | Fadus Richard F | Biodegradable multi-container carrier |

| US20040097157A1 (en)* | 2002-11-20 | 2004-05-20 | Cosentino Steven R | Thermal bondable film for insulation facing, and method for making the same |

| CN101815656A (en)* | 2007-08-15 | 2010-08-25 | 米德韦斯特瓦科包装系统有限责任公司 | Carton and carton blank |

| CN102725206A (en)* | 2009-12-18 | 2012-10-10 | 印刷包装国际公司 | Package for containers |

| CN103748155A (en)* | 2011-06-10 | 2014-04-23 | 梅尔-梅能纸箱公司 | Process for producing coated coating material and coating material with at least one barrier layer for hydrophobic compounds |

| CN109328171A (en)* | 2016-05-02 | 2019-02-12 | 维实洛克包装系统有限公司 | blanks for forming article carriers |

Family Cites Families (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS461050Y1 (en)* | 1966-03-04 | 1971-01-14 | ||

| US4190149A (en)* | 1979-02-12 | 1980-02-26 | The Mead Corporation | Article carrier and blank therefor |

| US5366791A (en)* | 1990-07-06 | 1994-11-22 | Paramount Packaging Corporation | Thermoformable laminate material with registered print and method of making the same |

| US5487464A (en)* | 1993-12-20 | 1996-01-30 | Imperial Packaging, Inc. | Paperboard carrier with container release provision |

| US5415278A (en)* | 1994-02-03 | 1995-05-16 | Riverwood International Corporation | Clip-type can carrier |

| US5472137A (en)* | 1994-07-11 | 1995-12-05 | Illinois Tool Works Inc. | Sift proof carton and method of making |

| US5474172A (en)* | 1994-08-02 | 1995-12-12 | International Paper | Paperboard bottle carrier with handle |

| US5553704A (en)* | 1994-10-11 | 1996-09-10 | International Paper | Stackable can carrier |

| US5551566A (en)* | 1995-04-06 | 1996-09-03 | Riverwood International Corporation | Can clip carrier |

| US5573111A (en)* | 1995-06-13 | 1996-11-12 | International Paper | Paperboard bottle carrier |

| US20040007480A1 (en)* | 2002-07-15 | 2004-01-15 | Pattee Daniel P. | Flexible carrier sheet for supporting and carrying such as returnable bottles and cans |

| ES2323109B1 (en)* | 2007-01-25 | 2010-02-12 | Graphic Packaging International, Inc. | "PACKING FOR CONTAINERS". |

| US20180362234A1 (en)* | 2014-01-07 | 2018-12-20 | Fishbone Packaging, Inc. | Container carrying device |

| CA2984682A1 (en)* | 2017-02-03 | 2018-08-03 | Westrock Packaging Systems, Llc | Carton and blank therefor |

| US11124341B2 (en)* | 2017-10-19 | 2021-09-21 | Tommy L. Patton | Plastic bottle retaining apparatus and advertising platform |

- 2020

- 2020-05-22CNCN202080062827.9Apatent/CN114302852A/enactivePending

- 2020-05-22USUS17/625,760patent/US20220242637A1/enactivePending

- 2020-05-22WOPCT/US2020/034191patent/WO2021006963A1/ennot_activeCeased

- 2020-05-22JPJP2022501300Apatent/JP2022540225A/enactivePending

- 2020-05-22EPEP20732045.8Apatent/EP3997008A1/ennot_activeWithdrawn

- 2020-05-22BRBR112022000421Apatent/BR112022000421A2/ennot_activeApplication Discontinuation

- 2020-05-22KRKR1020227003930Apatent/KR20220030286A/ennot_activeCeased

- 2020-05-22CACA3146415Apatent/CA3146415A1/enactivePending

- 2020-05-22MXMX2022000401Apatent/MX2022000401A/enunknown

- 2020-05-22AUAU2020311834Apatent/AU2020311834A1/enactivePending

- 2022

- 2022-01-07CLCL2022000046Apatent/CL2022000046A1/enunknown

- 2024

- 2024-11-29JPJP2024209018Apatent/JP2025026487A/enactivePending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| GB8925557D0 (en)* | 1989-11-11 | 1990-01-04 | Mead Corp | Top gripping article carrier |

| US5186321A (en)* | 1992-02-24 | 1993-02-16 | Fadus Richard F | Biodegradable multi-container carrier |

| US20040097157A1 (en)* | 2002-11-20 | 2004-05-20 | Cosentino Steven R | Thermal bondable film for insulation facing, and method for making the same |

| CN101815656A (en)* | 2007-08-15 | 2010-08-25 | 米德韦斯特瓦科包装系统有限责任公司 | Carton and carton blank |

| CN102725206A (en)* | 2009-12-18 | 2012-10-10 | 印刷包装国际公司 | Package for containers |

| CN103748155A (en)* | 2011-06-10 | 2014-04-23 | 梅尔-梅能纸箱公司 | Process for producing coated coating material and coating material with at least one barrier layer for hydrophobic compounds |

| CN109328171A (en)* | 2016-05-02 | 2019-02-12 | 维实洛克包装系统有限公司 | blanks for forming article carriers |

Non-Patent Citations (2)

| Title |

|---|

| 刘舜雄: "印后加工", 28 February 2010, pages: 69* |

| 李永强: "印后装订操作教程", 31 January 2011, pages: 183* |

Also Published As

| Publication number | Publication date |

|---|---|

| BR112022000421A2 (en) | 2022-03-03 |

| WO2021006963A1 (en) | 2021-01-14 |

| EP3997008A1 (en) | 2022-05-18 |

| AU2020311834A1 (en) | 2022-02-10 |

| CA3146415A1 (en) | 2021-01-14 |

| KR20220030286A (en) | 2022-03-10 |

| CL2022000046A1 (en) | 2023-01-20 |

| JP2025026487A (en) | 2025-02-21 |

| JP2022540225A (en) | 2022-09-14 |

| US20220242637A1 (en) | 2022-08-04 |

| MX2022000401A (en) | 2022-05-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US12179983B2 (en) | Article carrier and blank therefor | |

| US20220371800A1 (en) | Article top engaging device, article carrier and blank therefor | |

| JP2022145699A (en) | Blank for forming article carrier | |

| KR20230044258A (en) | Article carriers and blanks therefor | |

| KR20230095063A (en) | Article carriers and blanks therefor | |

| JP2025026487A (en) | Laminated article carriers and blanks therefor | |

| US20230257177A1 (en) | Article carrier and blank therefor | |

| WO2020023257A1 (en) | Carton and blank therefor | |

| US20240391669A1 (en) | Article carrier and blank therefor | |

| JP2024512746A (en) | Goods carriers and blanks for them | |

| US20220396406A1 (en) | Article carrier and blank therefor | |

| US20220258943A1 (en) | Article top engaging device, article carrier and blank therfor | |

| US12258190B2 (en) | Article carrier and blank therfor | |

| US20250153914A1 (en) | Article carrier and blank therfor |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20220408 |