CN113547955B - Battery charging control method, device, battery management system and medium - Google Patents

Battery charging control method, device, battery management system and mediumDownload PDFInfo

- Publication number

- CN113547955B CN113547955BCN202010328925.4ACN202010328925ACN113547955BCN 113547955 BCN113547955 BCN 113547955BCN 202010328925 ACN202010328925 ACN 202010328925ACN 113547955 BCN113547955 BCN 113547955B

- Authority

- CN

- China

- Prior art keywords

- battery

- charging

- value

- capacity

- parameter

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L53/00—Methods of charging batteries, specially adapted for electric vehicles; Charging stations or on-board charging equipment therefor; Exchange of energy storage elements in electric vehicles

- B60L53/60—Monitoring or controlling charging stations

- B60L53/62—Monitoring or controlling charging stations in response to charging parameters, e.g. current, voltage or electrical charge

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L3/00—Electric devices on electrically-propelled vehicles for safety purposes; Monitoring operating variables, e.g. speed, deceleration or energy consumption

- B60L3/12—Recording operating variables ; Monitoring of operating variables

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L53/00—Methods of charging batteries, specially adapted for electric vehicles; Charging stations or on-board charging equipment therefor; Exchange of energy storage elements in electric vehicles

- B60L53/60—Monitoring or controlling charging stations

- B60L53/66—Data transfer between charging stations and vehicles

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L58/00—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles

- B60L58/10—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries

- B60L58/12—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries responding to state of charge [SoC]

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L58/00—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles

- B60L58/10—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries

- B60L58/12—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries responding to state of charge [SoC]

- B60L58/15—Preventing overcharging

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L58/00—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles

- B60L58/10—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries

- B60L58/16—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries responding to battery ageing, e.g. to the number of charging cycles or the state of health [SoH]

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/42—Methods or arrangements for servicing or maintenance of secondary cells or secondary half-cells

- H01M10/425—Structural combination with electronic components, e.g. electronic circuits integrated to the outside of the casing

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/42—Methods or arrangements for servicing or maintenance of secondary cells or secondary half-cells

- H01M10/44—Methods for charging or discharging

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/42—Methods or arrangements for servicing or maintenance of secondary cells or secondary half-cells

- H01M10/44—Methods for charging or discharging

- H01M10/443—Methods for charging or discharging in response to temperature

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/42—Methods or arrangements for servicing or maintenance of secondary cells or secondary half-cells

- H01M10/48—Accumulators combined with arrangements for measuring, testing or indicating the condition of cells, e.g. the level or density of the electrolyte

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/42—Methods or arrangements for servicing or maintenance of secondary cells or secondary half-cells

- H01M10/48—Accumulators combined with arrangements for measuring, testing or indicating the condition of cells, e.g. the level or density of the electrolyte

- H01M10/486—Accumulators combined with arrangements for measuring, testing or indicating the condition of cells, e.g. the level or density of the electrolyte for measuring temperature

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/0047—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries with monitoring or indicating devices or circuits

- H02J7/0048—Detection of remaining charge capacity or state of charge [SOC]

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/0047—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries with monitoring or indicating devices or circuits

- H02J7/005—Detection of state of health [SOH]

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/007—Regulation of charging or discharging current or voltage

- H02J7/00712—Regulation of charging or discharging current or voltage the cycle being controlled or terminated in response to electric parameters

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/007—Regulation of charging or discharging current or voltage

- H02J7/00712—Regulation of charging or discharging current or voltage the cycle being controlled or terminated in response to electric parameters

- H02J7/007182—Regulation of charging or discharging current or voltage the cycle being controlled or terminated in response to electric parameters in response to battery voltage

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/007—Regulation of charging or discharging current or voltage

- H02J7/007188—Regulation of charging or discharging current or voltage the charge cycle being controlled or terminated in response to non-electric parameters

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J7/00—Circuit arrangements for charging or depolarising batteries or for supplying loads from batteries

- H02J7/007—Regulation of charging or discharging current or voltage

- H02J7/007188—Regulation of charging or discharging current or voltage the charge cycle being controlled or terminated in response to non-electric parameters

- H02J7/007192—Regulation of charging or discharging current or voltage the charge cycle being controlled or terminated in response to non-electric parameters in response to temperature

- H02J7/007194—Regulation of charging or discharging current or voltage the charge cycle being controlled or terminated in response to non-electric parameters in response to temperature of the battery

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L2240/00—Control parameters of input or output; Target parameters

- B60L2240/40—Drive Train control parameters

- B60L2240/54—Drive Train control parameters related to batteries

- B60L2240/545—Temperature

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60Y—INDEXING SCHEME RELATING TO ASPECTS CROSS-CUTTING VEHICLE TECHNOLOGY

- B60Y2200/00—Type of vehicle

- B60Y2200/90—Vehicles comprising electric prime movers

- B60Y2200/91—Electric vehicles

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M10/00—Secondary cells; Manufacture thereof

- H01M10/42—Methods or arrangements for servicing or maintenance of secondary cells or secondary half-cells

- H01M10/425—Structural combination with electronic components, e.g. electronic circuits integrated to the outside of the casing

- H01M2010/4271—Battery management systems including electronic circuits, e.g. control of current or voltage to keep battery in healthy state, cell balancing

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M2220/00—Batteries for particular applications

- H01M2220/20—Batteries in motive systems, e.g. vehicle, ship, plane

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02J—CIRCUIT ARRANGEMENTS OR SYSTEMS FOR SUPPLYING OR DISTRIBUTING ELECTRIC POWER; SYSTEMS FOR STORING ELECTRIC ENERGY

- H02J2310/00—The network for supplying or distributing electric power characterised by its spatial reach or by the load

- H02J2310/40—The network being an on-board power network, i.e. within a vehicle

- H02J2310/48—The network being an on-board power network, i.e. within a vehicle for electric vehicles [EV] or hybrid vehicles [HEV]

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/70—Energy storage systems for electromobility, e.g. batteries

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/7072—Electromobility specific charging systems or methods for batteries, ultracapacitors, supercapacitors or double-layer capacitors

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Manufacturing & Machinery (AREA)

- General Chemical & Material Sciences (AREA)

- Electrochemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Chemical & Material Sciences (AREA)

- Health & Medical Sciences (AREA)

- Medical Informatics (AREA)

- General Health & Medical Sciences (AREA)

- Microelectronics & Electronic Packaging (AREA)

- Secondary Cells (AREA)

- Charge And Discharge Circuits For Batteries Or The Like (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及新能源领域,尤其涉及一种电池的充电控制方法、装置、电池管理系统和介质。The invention relates to the field of new energy, in particular to a battery charging control method, device, battery management system and medium.

背景技术Background technique

锂离子电池由于其高能量密度和循环性能等优点,被广泛应用于电动汽车等领域。然而,锂离子电池在不同的充电或放电工况下,具有不同的老化速率。Lithium-ion batteries are widely used in fields such as electric vehicles due to their high energy density and cycle performance. However, lithium-ion batteries have different aging rates under different charging or discharging conditions.

在充电过程中,锂离子电池负极电位下降。若负极局部电位持续过低,则很可能导致锂离子在负极表面获取电子后无法及时扩散嵌入负极,造成负极锂枝晶,甚至刺穿隔膜造成内短路,引发电池老化加剧甚至导致安全问题。During the charging process, the potential of the negative electrode of the lithium-ion battery drops. If the local potential of the negative electrode continues to be too low, it is likely that lithium ions cannot diffuse and embed in the negative electrode in time after acquiring electrons on the surface of the negative electrode, resulting in lithium dendrites on the negative electrode, and even piercing the separator to cause an internal short circuit, causing battery aging and even safety problems.

当电池长期使用达到质保甚至设计寿命后,电池参数在严重老化后发生变异,例如阻抗增加,锂离子损失等,导致电池发生析锂以及热失控等安全风险。因此,急需提供一种充电方法以提高电池使用的安全性。When the battery has been used for a long time to reach the warranty or even the design life, the battery parameters will change after severe aging, such as increased impedance, loss of lithium ions, etc., leading to safety risks such as lithium deposition and thermal runaway in the battery. Therefore, it is urgent to provide a charging method to improve the safety of battery use.

发明内容Contents of the invention

本发明实施例提供一种电池的充电控制方法、装置、电池管理系统和介质,提高了电池使用的安全性。Embodiments of the present invention provide a battery charging control method, device, battery management system and medium, which improve the safety of battery use.

第一方面,本发明实施例提供一种电池的充电控制方法,包括:In a first aspect, an embodiment of the present invention provides a battery charging control method, including:

基于接收的充电请求,获取电池的充电参数的阈值和初始值;充电参数的阈值是基于电池的实际容量值和所在的电动汽车的累计行驶里程确定的;Based on the received charging request, the threshold and initial value of the charging parameter of the battery are obtained; the threshold of the charging parameter is determined based on the actual capacity value of the battery and the cumulative mileage of the electric vehicle where it is located;

若充电参数的初始值小于充电参数的阈值,发送对电池进行充电的控制命令,以对电池进行充电;If the initial value of the charging parameter is less than the threshold value of the charging parameter, send a control command for charging the battery to charge the battery;

在电池的充电过程中,实时获取电池的充电参数的数值;During the charging process of the battery, the value of the charging parameter of the battery is obtained in real time;

若获取的电池的充电参数的数值大于或等于充电参数的阈值,则发送停止对电池充电的控制命令,以停止充电。If the acquired value of the charging parameter of the battery is greater than or equal to the threshold value of the charging parameter, a control command to stop charging the battery is sent to stop charging.

第二方面,本发明实施例提供一种电池的充电控制装置,包括:In a second aspect, an embodiment of the present invention provides a charging control device for a battery, including:

第一获取模块,用于基于接收的充电请求,获取电池的充电参数的阈值和初始值;充电参数的阈值是基于电池的实际容量值和所在的电动汽车的累计行驶里程确定的;The first acquisition module is used to acquire the threshold and initial value of the charging parameter of the battery based on the received charging request; the threshold of the charging parameter is determined based on the actual capacity value of the battery and the accumulated mileage of the electric vehicle where it is located;

第一控制命令发送模块,用于若充电参数的初始值小于充电参数的阈值,发送对电池进行充电的控制命令,以对电池进行充电;The first control command sending module is used to send a control command to charge the battery if the initial value of the charging parameter is less than the threshold of the charging parameter, so as to charge the battery;

第二获取模块,用于在电池的充电过程中,实时获取电池的充电参数的数值;The second obtaining module is used to obtain the value of the charging parameter of the battery in real time during the charging process of the battery;

第二控制命令发送模块,用于若获取的电池的充电参数的数值大于或等于充电参数的阈值,则发送停止对电池充电的控制命令,以停止充电。The second control command sending module is configured to send a control command to stop charging the battery if the obtained value of the charging parameter of the battery is greater than or equal to the threshold of the charging parameter, so as to stop charging.

第三方面,本发明实施例提供一种电池管理系统,包括:处理器以及存储有计算机程序指令的存储器;In a third aspect, an embodiment of the present invention provides a battery management system, including: a processor and a memory storing computer program instructions;

处理器执行计算机程序指令时实现如本发明实施例提供的电池的充电控制方法。When the processor executes the computer program instructions, the battery charging control method provided by the embodiment of the present invention is realized.

第四方面,本发明实施例提供一种计算机存储介质,计算机存储介质上存储有计算机程序指令,计算机程序指令被处理器执行时实现如本发明实施例提供的电池的充电控制方法。In a fourth aspect, an embodiment of the present invention provides a computer storage medium, on which computer program instructions are stored, and when the computer program instructions are executed by a processor, the battery charging control method provided by the embodiment of the present invention is implemented.

本发明实施例提供的电池的充电控制方法、装置、电池管理系统和介质,根据电池的实际容量值和电池所在的电动汽车的累计行驶里程动态确定电池的充电参数的阈值,以实现依据电池的老化状态来动态计算充电参数的阈值。在对电池充电的过程中,若获取的电池的充电参数的数值大于最新计算的充电参数的阈值时,则停止对电池充电。通过考虑电池的老化状态来确定电池的充电参数的阈值,可以防止在电池老化状态时出现过充或热失控等情况,提高了电池使用的安全性。The battery charging control method, device, battery management system and medium provided by the embodiments of the present invention dynamically determine the threshold value of the charging parameter of the battery according to the actual capacity value of the battery and the accumulated mileage of the electric vehicle in which the battery is located, so as to realize the charging according to the battery. Aging state to dynamically calculate thresholds of charging parameters. During the process of charging the battery, if the acquired value of the charging parameter of the battery is greater than the newly calculated threshold value of the charging parameter, the charging of the battery is stopped. By considering the aging state of the battery to determine the threshold value of the charging parameter of the battery, it is possible to prevent overcharging or thermal runaway when the battery is aging, and improve the safety of the battery.

附图说明Description of drawings

为了更清楚地说明本发明实施例的技术方案,下面将对本发明实施例中所需要使用的附图作简单地介绍,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to more clearly illustrate the technical solutions of the embodiments of the present invention, the following will briefly introduce the accompanying drawings that need to be used in the embodiments of the present invention. Additional figures can be derived from these figures.

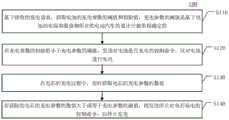

图1示出本发明实施例提供的电池的充电控制方法的流程示意图;FIG. 1 shows a schematic flowchart of a battery charging control method provided by an embodiment of the present invention;

图2示出本发明实施例提供的电池的充电控制装置的结构示意图;Fig. 2 shows a schematic structural diagram of a charging control device for a battery provided by an embodiment of the present invention;

图3示出本发明实施例提供的电池管理系统的结构示意图。Fig. 3 shows a schematic structural diagram of a battery management system provided by an embodiment of the present invention.

具体实施方式Detailed ways

下面将详细描述本发明的各个方面的特征和示例性实施例,为了使本发明的目的、技术方案及优点更加清楚明白,以下结合附图及实施例,对本发明进行进一步详细描述。应理解,此处所描述的具体实施例仅被配置为解释本发明,并不被配置为限定本发明。对于本领域技术人员来说,本发明可以在不需要这些具体细节中的一些细节的情况下实施。下面对实施例的描述仅仅是为了通过示出本发明的示例来提供对本发明更好的理解。The characteristics and exemplary embodiments of various aspects of the present invention will be described in detail below. In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only configured to explain the present invention, not to limit the present invention. It will be apparent to one skilled in the art that the present invention may be practiced without some of these specific details. The following description of the embodiments is only to provide a better understanding of the present invention by showing examples of the present invention.

需要说明的是,在本文中,诸如第一和第二等之类的关系术语仅仅用来将一个实体或者操作与另一个实体或操作区分开来,而不一定要求或者暗示这些实体或操作之间存在任何这种的关系或者顺序。而且,术语“包括”、“包含”或者其任何其他变体意在涵盖非排他性的包含,从而使得包括一系列要素的过程、方法、物品或者设备不仅包括那些要素,而且还包括没有明确列出的其他要素,或者是还包括为这种过程、方法、物品或者设备所固有的要素。在没有更多限制的情况下,由语句“包括……”限定的要素,并不排除在包括所述要素的过程、方法、物品或者设备中还存在另外的相同要素。It should be noted that in this article, relational terms such as first and second are only used to distinguish one entity or operation from another entity or operation, and do not necessarily require or imply that there is a relationship between these entities or operations. Any such relationship or order exists between them. Furthermore, the term "comprises", "comprises" or any other variation thereof is intended to cover a non-exclusive inclusion such that a process, method, article, or apparatus comprising a set of elements includes not only those elements, but also includes elements not expressly listed. other elements of or also include elements inherent in such a process, method, article, or device. Without further limitations, an element defined by the statement "comprising..." does not exclude the presence of additional same elements in the process, method, article or device comprising said element.

目前在对电池的充电过程中,通常根据充电参数是否达到一个预设的固定上限,来判断是否停止对电池充电。在电动汽车处于超期服役的情况下,若仍利用充电参数的固定上限来判断是否停止对电池充电,则会导致电池存在过充或热失控等安全风险。At present, in the process of charging the battery, it is usually judged whether to stop charging the battery according to whether the charging parameter reaches a preset fixed upper limit. When the electric vehicle is in service for an extended period, if the fixed upper limit of charging parameters is still used to judge whether to stop charging the battery, it will lead to safety risks such as overcharging or thermal runaway of the battery.

基于此,本发明实施例提供一种电池的充电控制方法,根据电池的实际容量值和电池所在的电动汽车的累计行驶里程动态确定电池的充电参数的阈值,以实现依据电池的老化状态来动态计算充电参数的阈值。在对电池充电的过程中,若获取的电池的充电参数的数值大于最新计算的充电参数的阈值时,则停止对电池充电。通过考虑电池的老化状态来确定电池的充电参数的阈值,可以防止在电池老化状态时出现过充或热失控等情况,提高了电池使用的安全性。Based on this, an embodiment of the present invention provides a battery charging control method, which dynamically determines the threshold value of the charging parameter of the battery according to the actual capacity value of the battery and the cumulative mileage of the electric vehicle where the battery is located, so as to realize dynamic charging according to the aging state of the battery. Calculate thresholds for charging parameters. During the process of charging the battery, if the acquired value of the charging parameter of the battery is greater than the newly calculated threshold value of the charging parameter, the charging of the battery is stopped. By considering the aging state of the battery to determine the threshold value of the charging parameter of the battery, it is possible to prevent overcharging or thermal runaway when the battery is aging, and improve the safety of the battery.

图1示出本发明实施例提供的电池的充电控制方法100的流程示意图。如图1所示,电池的充电控制方法100包括以下步骤:FIG. 1 shows a schematic flowchart of a battery

S110,基于接收的充电请求,获取电池的充电参数的阈值和初始值。充电参数的阈值是基于电池的实际容量值和电池所在的电动汽车的累计行驶里程确定的。S110. Based on the received charging request, acquire a threshold value and an initial value of a charging parameter of the battery. The threshold value of the charging parameter is determined based on the actual capacity value of the battery and the accumulated mileage of the electric vehicle where the battery is located.

在本发明的一些实施例中,电池的实际容量值是一个用来表征电池的老化状态的一个参数。在一些实施例中,电池的实际容量值可以基于电池的累计充/放电容量值确定。In some embodiments of the present invention, the actual capacity value of the battery is a parameter used to characterize the aging state of the battery. In some embodiments, the actual capacity value of the battery may be determined based on the cumulative charge/discharge capacity value of the battery.

作为一个示例,电池的累计充/放电容量值可以为以下任意一个值:累计的电池每次充电时的充电容量值和电池的回充容量的和值、累计的电池每次放电时的放电容量值、累计的电池每次充电时的充电容量值和累计的电池每次放电时的放电容量值的和值。As an example, the accumulative charge/discharge capacity value of the battery can be any one of the following values: the sum of the accumulative charge capacity value and the recharge capacity of the battery each time the accumulative battery is charged, the accumulative discharge capacity of the battery each time it is discharged value, the sum of the accumulated charging capacity value for each battery charge and the accumulated discharge capacity value for each battery discharge.

其中,电池的充电容量是指在规定条件下测得的电池充入的容量值,电池的放电容量是指在规定条件下测得的电池输出的容量值。Wherein, the charging capacity of the battery refers to the capacity value of the battery charged under the specified conditions, and the discharge capacity of the battery refers to the capacity value of the battery output measured under the specified conditions.

在本发明的一些实施例中,为了提高对电池的累计充/放电容量值累计的准确性,电池的累计充/放电容量值还可以为以下任意一个值:累计的电芯的经折算后的充电容量值、累计的电芯的经折算后的放电容量值、累计的电芯的经折算后的充电容量值和累计的电芯的经折算后的放电容量值的和值。In some embodiments of the present invention, in order to improve the accumulative accuracy of the accumulative charge/discharge capacity value of the battery, the accumulative charge/discharge capacity value of the battery can also be any of the following values: The charge capacity value, the accumulated converted discharge capacity value of the batteries, the sum of the accumulated converted charge capacity values of the batteries and the accumulated converted discharge capacity values of the batteries.

其中,电池的充电温度对应的折算系数基于电池的充电温度和预设的温度与折算系数的对应关系确定,电池的放电温度对应的折算系数基于电池的放电温度和预设的温度与折算系数的对应关系确定。Wherein, the conversion coefficient corresponding to the charging temperature of the battery is determined based on the corresponding relationship between the charging temperature of the battery and the preset temperature and the conversion coefficient, and the conversion coefficient corresponding to the discharging temperature of the battery is determined based on the discharge temperature of the battery and the preset temperature and the conversion coefficient. Correspondence is confirmed.

也就是说,在电池的每次充电过程中获取电池的充电温度。然后将电池的充电温度与预设的温度与折算系数的对应关系中的温度进行匹配,并将该对应关系中与电池的充电温度匹配的温度所对应的折算系数作为电池的充电温度对应的折算系数。That is, the charging temperature of the battery is acquired during each charging process of the battery. Then match the charging temperature of the battery with the temperature in the correspondence relationship between the preset temperature and the conversion coefficient, and use the conversion coefficient corresponding to the temperature matching the charging temperature of the battery in the correspondence relationship as the conversion corresponding to the charging temperature of the battery coefficient.

相类似的,在电池的每次放电过程中获取电池的放电温度。然后将电池的放电温度与预设的温度与折算系数的对应关系中的温度进行匹配,并将该对应关系中与电池的放电温度匹配的温度所对应的折算系数作为电池的放电温度对应的折算系数。Similarly, the discharge temperature of the battery is obtained during each discharge of the battery. Then match the discharge temperature of the battery with the temperature in the correspondence relationship between the preset temperature and the conversion coefficient, and use the conversion coefficient corresponding to the temperature matching the discharge temperature of the battery in the correspondence relationship as the conversion corresponding to the discharge temperature of the battery coefficient.

由于电池的放电温度会影响电池的放电容量,电池的充电温度会影响电池的充电容量,为了提高对电池的累计充/放电容量值累计的准确性,可以利用电池的经温度折算后的充电容量和/或放电容量来计算电池的累计充/放电容量值。Because the discharge temperature of the battery will affect the discharge capacity of the battery, and the charging temperature of the battery will affect the charging capacity of the battery. In order to improve the accuracy of the accumulative charge/discharge capacity value of the battery, the charge capacity converted by the temperature of the battery can be used and/or discharge capacity to calculate the cumulative charge/discharge capacity value of the battery.

作为一个具体示例,电池管理系统可以基于预先标定的充/放电容量与实际容量的对应关系,以及获取的电池的累计充/放电容量值确定电池的实际容量值。As a specific example, the battery management system may determine the actual capacity value of the battery based on the pre-calibrated correspondence between the charging/discharging capacity and the actual capacity, and the acquired accumulative charging/discharging capacity value of the battery.

需要说明的是,预先标定的充/放电容量与实际容量的对应关系中充/放电容量的统计方式与电池的累计充/放电容量值的统计方式相同。It should be noted that the statistical method of the charging/discharging capacity in the corresponding relationship between the pre-calibrated charging/discharging capacity and the actual capacity is the same as the statistical method of the cumulative charging/discharging capacity value of the battery.

作为一个示例,若电池的累计充/放电容量值为累计的电池每次充电时的充电容量和回充容量的和值,则预先标定的充/放电容量与实际容量的对应关系为充电容量与实际容量的对应关系。As an example, if the accumulative charge/discharge capacity value of the battery is the sum of the accumulative charge capacity and recharge capacity for each charge of the battery, the corresponding relationship between the pre-calibrated charge/discharge capacity and the actual capacity is the charge capacity vs. The corresponding relationship of actual capacity.

若电池的累计充/放电容量值为累计的电池每次放电时的放电容量,则预先标定的充/放电容量与实际容量的对应关系为放电容量与实际容量的对应关系。If the accumulative charge/discharge capacity value of the battery is the accumulative discharge capacity of each discharge of the battery, the corresponding relationship between the pre-calibrated charge/discharge capacity and the actual capacity is the corresponding relationship between the discharge capacity and the actual capacity.

若电池的累计充/放电容量值为累计的电池每次放电时的放电容量值和累计的电池每次充电时的充电容量值的和值,则预先标定的充/放电容量与实际容量的对应关系为充放电容量与实际容量的对应关系。If the accumulative charge/discharge capacity value of the battery is the sum of the accumulative discharge capacity value for each discharge of the battery and the accumulative charge capacity value for each charge of the battery, the correspondence between the pre-calibrated charge/discharge capacity and the actual capacity The relationship is the corresponding relationship between the charge and discharge capacity and the actual capacity.

表1示出本发明一实施例提供的预先标定的充/放电容量与实际容量的对应关系的示意图。Table 1 shows a schematic diagram of the corresponding relationship between the pre-calibrated charge/discharge capacity and the actual capacity provided by an embodiment of the present invention.

表1Table 1

其中,Ai为不同的充/放电容量值,Di为不同的实际容量值,i为大于等于1且小于等于4的整数。需要说明的是,表1中关于充/放电容量的个数仅是示意,对于第一对应关系中充/放电容量的个数可根据实际需求进行调整。Wherein, Ai is a different charge/discharge capacity value, Di is a different actual capacity value, and i is an integer greater than or equal to 1 and less than or equal to 4. It should be noted that the number of charging/discharging capacities in Table 1 is only indicative, and the number of charging/discharging capacities in the first correspondence can be adjusted according to actual needs.

在预先标定的充/放电容量与实际容量的对应关系中,随着充/放电容量的增加,即随着电池的充放电次数的增加,实际容量呈现出递减趋势。对于表1中的对应关系可以根据历史记录的充/放电容量数据和实际容量值预先进行线下标定。In the corresponding relationship between the pre-calibrated charge/discharge capacity and the actual capacity, as the charge/discharge capacity increases, that is, as the number of charge and discharge of the battery increases, the actual capacity presents a decreasing trend. For the corresponding relationship in Table 1, offline calibration can be performed in advance according to the historically recorded charge/discharge capacity data and actual capacity value.

在本发明的实施例中,当电池管理系统获取电池的累计充/放电容量值之后,将电池的累计充/放电容量值与预先标定的充/放电容量与实际容量的对应关系中的每个充/放电容量进行匹配,得到在该对应关系中与电池的累计充/放电容量值匹配的充/放电容量,并将该充/放电容量对应的实际容量作为电池的实际容量值。In the embodiment of the present invention, after the battery management system acquires the accumulative charge/discharge capacity value of the battery, each The charging/discharging capacity is matched to obtain the charging/discharging capacity matching the accumulative charging/discharging capacity value of the battery in the corresponding relationship, and the actual capacity corresponding to the charging/discharging capacity is taken as the actual capacity value of the battery.

通过利用预设的充/放电容量与实际容量的对应关系可以快速地得到电池的实际容量值,提高了对充电参数的阈值的计算效率。The actual capacity value of the battery can be quickly obtained by utilizing the correspondence relationship between the preset charging/discharging capacity and the actual capacity, which improves the calculation efficiency of the threshold value of the charging parameter.

需要说明的是,当电池的累计充/放电容量值是利用经温度折算后的充电容量和/或放电容量进行计算的情况下,预先标定的充/放电容量与实际容量的对应关系中的充/放电容量也是经温度折算后的容量。It should be noted that when the cumulative charge/discharge capacity value of the battery is calculated by using the charge capacity and/or discharge capacity converted by temperature, the charge/discharge capacity in the corresponding relationship between the pre-calibrated charge/discharge capacity and the actual capacity /Discharge capacity is also the capacity converted by temperature.

在本发明的一些实施例中,电池的实际容量值也可以基于电动汽车的累计行驶里程以及预设的行驶里程和容量的第二对应关系确定。例如,电池管理系统先将电动汽车的累计行驶里程与预设的第二对应关系中的每个行驶里程进行匹配,得到在该第二对应关系中与电动汽车的累计行驶里程匹配的行驶里程。然后电池管理系统将在预设的第二对应关系中与电动汽车的累计行驶里程匹配的行驶里程对应的容量作为电池的实际容量值。对于电池的实际容量的具体获取方法,在此并不限定。In some embodiments of the present invention, the actual capacity value of the battery may also be determined based on the accumulated mileage of the electric vehicle and the second correspondence between the preset mileage and capacity. For example, the battery management system first matches the accumulative mileage of the electric vehicle with each mileage in the preset second correspondence to obtain the mileage matching the accumulative mileage of the electric vehicle in the second correspondence. Then the battery management system takes the capacity corresponding to the mileage matching the accumulative mileage of the electric vehicle in the second preset correspondence relationship as the actual capacity value of the battery. The specific method for obtaining the actual capacity of the battery is not limited here.

在本发明的实施例中,电池的充电控制方法可以应用于电池管理系统。若电动汽车需要充电,则需要先将电动汽车与充电桩连接。当充电桩与电动汽车连接之后,充电桩会向电池管理系统发送充电请求,以请求对电动汽车中的电池组进行充电。In the embodiment of the present invention, the battery charging control method can be applied to a battery management system. If the electric vehicle needs to be charged, the electric vehicle needs to be connected to the charging pile first. When the charging pile is connected to the electric vehicle, the charging pile will send a charging request to the battery management system to request to charge the battery pack in the electric vehicle.

电池管理系统接收到充电请求之后,获取电池的充电参数的阈值和初始值。After receiving the charging request, the battery management system acquires the threshold value and the initial value of the charging parameter of the battery.

在本发明的实施例中,电池的充电参数的初始值是指电池管理系统接收到充电请求之后第一次获取的电池的充电参数的数值。In the embodiment of the present invention, the initial value of the charging parameter of the battery refers to the value of the charging parameter of the battery acquired for the first time after the battery management system receives the charging request.

在本发明的实施例中,充电参数可以为充电荷电状态(State of Charge,SOC)和充电电压中的至少一种。需要说明的是,电池的充电电压是指采集的电池两端电压的压差。电池的充电SOC是由电池管理系统中的SOC计算模块实时计算的,具体计算方法在此不限定。In an embodiment of the present invention, the charging parameter may be at least one of a charging state of charge (State of Charge, SOC) and a charging voltage. It should be noted that the charging voltage of the battery refers to the collected voltage difference between the two terminals of the battery. The charging SOC of the battery is calculated in real time by the SOC calculation module in the battery management system, and the specific calculation method is not limited here.

在本发明的实施例中,考虑到随着电动汽车的使用时间的增加,电池的老化状态在不断变化,因此充电参数的阈值是由电池管理系统实时计算的。作为一个示例,电池管理系统每隔预设时间间隔计算一次充电参数的阈值。当电池管理系统接收到充电请求后,则获取最新计算的充电参数的阈值。In the embodiment of the present invention, considering that the aging state of the battery is constantly changing with the increase of the use time of the electric vehicle, the threshold value of the charging parameter is calculated in real time by the battery management system. As an example, the battery management system calculates the threshold value of the charging parameter every preset time interval. When the battery management system receives the charging request, it acquires the latest calculated threshold value of the charging parameter.

S120,若充电参数的初始值小于充电参数的阈值,发送对电池进行充电的控制命令,以对电池进行充电。S120, if the initial value of the charging parameter is less than the threshold of the charging parameter, send a control command for charging the battery, so as to charge the battery.

在本发明的实施例中,若充电参数的初始值大于或等于充电参数的阈值,则电池管理系统向充电桩发送不充电的控制指令,以提高电池的使用安全性,防止产生过充或热失控等问题。In the embodiment of the present invention, if the initial value of the charging parameter is greater than or equal to the threshold value of the charging parameter, the battery management system sends a control command of not charging to the charging pile to improve the safety of the battery and prevent overcharging or overheating. issues such as loss of control.

若充电参数的初始值小于充电参数的阈值,则代表可以对电池进行充电,则电池管理系统向充电桩发送对电池充电的控制指令。充电桩接收到对电池进行充电的控制指令后,对电池开始充电。If the initial value of the charging parameter is less than the threshold value of the charging parameter, it means that the battery can be charged, and the battery management system sends a control command for charging the battery to the charging pile. After the charging pile receives the control command to charge the battery, it starts charging the battery.

S130,在电池的充电过程中,实时获取电池的充电参数的数值。S130, during the charging process of the battery, acquire the value of the charging parameter of the battery in real time.

S140,若获取的电池的充电参数的数值大于或等于充电参数的阈值,则发送停止对电池充电的控制命令,以停止充电。S140, if the acquired value of the charging parameter of the battery is greater than or equal to the threshold of the charging parameter, send a control command to stop charging the battery, so as to stop charging.

在电池的充电过程中,电池管理系统实时获取充电参数的数值,每获取一个电池的充电参数的数值,则判断获取的电池的充电参数的数值是否大于或等于充电参数的阈值。During the charging process of the battery, the battery management system obtains the value of the charging parameter in real time, and each time the value of the charging parameter of a battery is obtained, it judges whether the value of the obtained charging parameter of the battery is greater than or equal to the threshold value of the charging parameter.

若获取的电池的充电参数的数值小于充电参数的阈值,则电池管理系统不动作,充电桩可以继续对电池进行充电。If the acquired value of the charging parameter of the battery is less than the threshold value of the charging parameter, the battery management system does not operate, and the charging pile can continue to charge the battery.

若获取的电池的充电参数的数值大于或等于充电参数的阈值,则电池管理系统向充电桩发送停止对电池充电的控制指令。充电桩接收到电池管理系统发送的停止对电池充电的控制指令之后,则停止对电池进行充电。If the acquired value of the charging parameter of the battery is greater than or equal to the threshold value of the charging parameter, the battery management system sends a control command to the charging pile to stop charging the battery. After the charging pile receives the control instruction to stop charging the battery sent by the battery management system, it stops charging the battery.

在本发明的实施例中,通过根据电池的老化状态,即电池的实际容量值和电池所在的电动汽车的累计行驶里程,动态确定电池的充电参数的阈值,而不是固定充电参数的上限,充分考虑了电池目前的老化状态,可以提高电池使用的安全性。In the embodiment of the present invention, by dynamically determining the threshold value of the charging parameter of the battery, instead of fixing the upper limit of the charging parameter, it is sufficient Taking into account the current aging state of the battery, the safety of battery use can be improved.

值得一提的是,在一些实施例中,随着电池的老化状态的严重程度的增加,可以通过减小充电参数的阈值,以减少电池的充入容量,实现延长电池的安全寿命,提高电池的使用安全性。也就是说,随着电池的实际容量值和电动汽车的行驶里程的增加,逐渐降低充电参数的阈值。It is worth mentioning that in some embodiments, as the severity of the aging state of the battery increases, the charging capacity of the battery can be reduced by reducing the threshold value of the charging parameter, so as to prolong the safe life of the battery and improve the battery life. safety of use. That is to say, as the actual capacity value of the battery and the mileage of the electric vehicle increase, the threshold value of the charging parameter is gradually reduced.

在本发明的实施例中,在S110之前,电池管理系统在实时计算充电参数的阈值。下面详细介绍电池的充电参数的阈值的具体计算方法。In the embodiment of the present invention, before S110, the battery management system calculates the threshold value of the charging parameter in real time. The specific calculation method of the threshold value of the charging parameter of the battery will be described in detail below.

在本发明的实施例中,在S110之前包括:In an embodiment of the present invention, before S110 includes:

S101,基于电池的实际容量值和累计行驶里程,确定电池的可充入容量上限值。S101. Based on the actual capacity value of the battery and the accumulated mileage, determine the upper limit value of the chargeable capacity of the battery.

在本发明的一些实施例中,S101包括以下步骤:In some embodiments of the present invention, S101 includes the following steps:

A1,基于电池的实际容量值、累计行驶里程以及预设的第三对应关系,确定电池的可充入容量上限值。其中,所述第三对应关系为第一容量与第二参数的对应关系,所述第二参数包括第二容量和行驶里程。A1, based on the actual capacity value of the battery, the cumulative mileage and the third preset corresponding relationship, determine the upper limit of the rechargeable capacity of the battery. Wherein, the third correspondence is the correspondence between the first capacity and the second parameter, and the second parameter includes the second capacity and the mileage.

在本发明的实施例中,电池管理系统将电池的实际容量值与预设的第三对应关系中的每个第二容量进行匹配,得到在该对应关系中与电池的实际容量值匹配的第二容量。In the embodiment of the present invention, the battery management system matches the actual capacity value of the battery with each second capacity in the preset third correspondence relationship, and obtains the second capacity value matched with the actual capacity value of the battery in the correspondence relationship. Two capacity.

电池管理系统将电动汽车的累计行驶里程与预设的第三对应关系中的每个行驶里程进行匹配,得到在该对应关系中与电动汽车的累计行驶里程匹配的行驶里程。The battery management system matches the accumulative mileage of the electric vehicle with each mileage in the preset third correspondence to obtain the mileage matching the accumulative mileage of the electric vehicle in the correspondence.

最后,电池管理系统将在第三对应关系中与电池的实际容量值匹配的第二容量和与电动汽车的累计行驶里程匹配的行驶里程共同对应的第一容量,作为电池的可充入容量上限值。Finally, the battery management system uses the second capacity that matches the actual capacity of the battery in the third correspondence and the first capacity that matches the accumulated mileage of the electric vehicle as the chargeable capacity of the battery. limit.

在预设的第三对应关系中,在第二容量一定的情况下,若行驶里程越高,对应的第一容量越小。在第三对应关系中,在行驶里程一定的情况下,则若第二容量越低,对应的第一容量越小。也就是说,随着电池老化状态逐步严重,则可以降低电池的可充入容量上限值,从而实现避免对电池进行过充,提高了电池的使用的安全性。In the preset third corresponding relationship, when the second capacity is constant, the higher the driving mileage, the smaller the corresponding first capacity. In the third corresponding relationship, when the mileage is constant, the lower the second capacity, the smaller the corresponding first capacity. That is to say, as the aging state of the battery becomes serious, the upper limit of the chargeable capacity of the battery can be lowered, so as to avoid overcharging of the battery and improve the safety of the battery.

在本发明的一些实施例中,考虑到电池的规格可能有所不同,为了提高本发明实施例提供的电池的充电控制方法的适用性,S101包括以下步骤:In some embodiments of the present invention, considering that the specifications of the batteries may be different, in order to improve the applicability of the battery charging control method provided in the embodiments of the present invention, S101 includes the following steps:

A2,基于电池的实际容量值,确定电池的实际健康度(State Of Health,SOH)SOH。A2. Determine the actual state of health (State Of Health, SOH) SOH of the battery based on the actual capacity value of the battery.

在本发明的实施例中,基于电池的实际容量值和电池的标称容量可以得到电池的实际SOH。电池的实际容量值与电池的标称容量的比值即为电池的实际SOH。In the embodiment of the present invention, the actual SOH of the battery can be obtained based on the actual capacity value of the battery and the nominal capacity of the battery. The ratio of the actual capacity value of the battery to the nominal capacity of the battery is the actual SOH of the battery.

A3,根据实际SOH和累计行驶里程,确定电池的可充入容量上限值。A3, according to the actual SOH and accumulated mileage, determine the upper limit of the battery's rechargeable capacity.

在本发明的一些实施例中,可根据电池的实际SOH、电动汽车的行驶里程以及预设第四对应关系,确定电池的可充入容量上限值。其中,第四对应关系为容量与第三参数的对应关系,所述第三参数包括行驶里程和SOH。表2示出本发明一实施例提供的预设的第四对应关系,即容量与行驶里程c和SOH的对应关系的示意图。In some embodiments of the present invention, the upper limit of the chargeable capacity of the battery can be determined according to the actual SOH of the battery, the mileage of the electric vehicle and the preset fourth corresponding relationship. Wherein, the fourth corresponding relationship is the corresponding relationship between the capacity and the third parameter, and the third parameter includes the driving mileage and the SOH. Table 2 shows a schematic diagram of the preset fourth corresponding relationship provided by an embodiment of the present invention, that is, the corresponding relationship between capacity, mileage c and SOH.

表2Table 2

其中,对于容量与行驶里程c和SOH的对应关系可以通过线下标定测试获得。如表2所示,表2中的第1行中的每个数值或数值范围代表不同的行驶里程,表2中的第1列中的Bt代表不同的SOH。其中,t为大于等于1且小于等于4的整数。Ejk代表一个容量值,j为大于等于0的整数,k为大于等于1的整数。即对于任意一个SOH,以及任意一个c,两者对应一个容量值。需要说明的是,表2中关于SOH的个数和行驶里程的个数仅是示意,对于第四对应关系中SOH的个数和行驶里程的个数可根据实际需求进行调整。Among them, the corresponding relationship between capacity and mileage c and SOH can be obtained through offline calibration test. As shown in Table 2, each value or value range in the first row of Table 2 represents a different mileage, and Bt in the first column of Table 2 represents a different SOH. Wherein, t is an integer greater than or equal to 1 and less than or equal to 4. Ejk represents a capacity value, j is an integer greater than or equal to 0, and k is an integer greater than or equal to 1. That is, for any SOH and any c, the two correspond to a capacity value. It should be noted that the number of SOHs and the number of mileages in Table 2 are only indicative, and the number of SOHs and mileages in the fourth correspondence can be adjusted according to actual needs.

在预设的第四对应关系中,在SOH一定的情况下,则若行驶里程越高,对应的容量值越小。在预设的第四对应关系中,在行驶里程一定的情况下,则若SOH越低,对应的容量值越小。也就是说,随着电池老化状态逐步严重,则可以降低电池的可充入容量上限值,从而实现避免对电池进行过充,提高了电池的使用的安全性。In the preset fourth correspondence relationship, when the SOH is constant, the higher the mileage, the smaller the corresponding capacity value. In the preset fourth corresponding relationship, when the mileage is constant, the lower the SOH, the smaller the corresponding capacity value. That is to say, as the aging state of the battery becomes serious, the upper limit of the chargeable capacity of the battery can be lowered, so as to avoid overcharging of the battery and improve the safety of the battery.

在另一些实施例中,在预设的第四对应关系中,行驶里程c也可以对应一个里程段。In some other embodiments, in the preset fourth corresponding relationship, the driving mileage c may also correspond to a mileage segment.

在本发明的实施例中,将获取的实际SOH与表2中的第四对应关系中的每个SOH进行匹配,找到该对应关系中与电池的实际SOH匹配的SOH。作为一个示例,若电池的实际SOH与对应关系中的某个SOH之间的差值的绝对值小于等于预设SOH差值阈值,则可以认为电池的实际SOH与对应关系中的该SOH相匹配。In an embodiment of the present invention, the obtained actual SOH is matched with each SOH in the fourth correspondence in Table 2, and the SOH in the correspondence that matches the actual SOH of the battery is found. As an example, if the absolute value of the difference between the actual SOH of the battery and a certain SOH in the corresponding relationship is less than or equal to the preset SOH difference threshold, it can be considered that the actual SOH of the battery matches the SOH in the corresponding relationship .

然后,将获取的电动汽车累计行驶里程与表2中的第四对应关系中的每个行驶里程进行匹配。Then, match the acquired accumulative mileage of the electric vehicle with each mileage in the fourth correspondence in Table 2.

在一个示例中,若表2中的第四对应关系中的每个行驶里程为一个里程段,则电动汽车的累计行驶里程落入的里程段作为与其匹配的行驶里程。如表2所示,若S1为10000km,在电动汽车累计行驶里程为5000km的情况下,则在表2中与电动汽车累计行驶里程匹配的行驶里程为小于S1的里程段。In an example, if each mileage in the fourth correspondence in Table 2 is a mileage segment, the mileage segment in which the accumulated mileage of the electric vehicle falls is taken as the matching mileage. As shown in Table 2, if S1 is 10,000 km, and the accumulative mileage of the electric vehicle is 5,000 km, then the mileage matching the accumulative mileage of the electric vehicle in Table 2 is a mileage segment that is less than S1.

在另一个示例中,若表2中的第四对应关系中的每个行驶里程为一个具体的里程值,则将该对应关系中与电动汽车的累计行驶里程的差值的绝对值小于预设里程差值阈值的行驶里程,作为与电动汽车的累计行驶里程匹配的行驶里程。In another example, if each mileage in the fourth correspondence in Table 2 is a specific mileage value, then the absolute value of the difference between the correspondence and the cumulative mileage of the electric vehicle is less than the preset The mileage of the mileage difference threshold is used as the mileage matching the accumulated mileage of the electric vehicle.

在又一个示例中,若表2中的第四对应关系中的每个行驶里程为一个具体的里程值,则将该对应关系中与电动汽车的累计行驶里程相邻最近的前后两个里程值,作为与电动汽车的累计匹配的行驶里程。例如,若S2为20000km,S3为30000km,在电动汽车累计行驶里程为25000km的情况下,则S2和S3为与电动汽车的累计行驶里程匹配的里程。In yet another example, if each mileage in the fourth corresponding relationship in Table 2 is a specific mileage value, then the two mileage values closest to the accumulated mileage of the electric vehicle in the corresponding relationship , as the accumulative mileage matched with the EV. For example, if S2 is 20,000 km, S3 is 30,000 km, and the accumulative mileage of the electric vehicle is 25,000 km, then S2 and S3 are the mileage matching the accumulative mileage of the electric vehicle.

最后,基于表2中的第四对应关系中与电池的实际SOH匹配的SOH以及与电动汽车的累计行驶里程匹配的行驶里程共同对应的容量值,得出电池的可充入容量上限值。Finally, based on the capacity value corresponding to the SOH that matches the actual SOH of the battery and the mileage that matches the cumulative mileage of the electric vehicle in the fourth correspondence in Table 2, the upper limit of the battery’s rechargeable capacity is obtained.

在本发明的一些实施例中,若与电动汽车的累计行驶里程匹配的里程为一个行驶里程值或一个行驶里程段,则将与电动汽车的累计行驶里程匹配的里程和与电池的实际SOH匹配的SOH共同对应的容量值作为电池的可充入容量上限值。In some embodiments of the present invention, if the mileage matched with the accumulative mileage of the electric vehicle is a mileage value or a mileage section, the mileage matched with the accumulated mileage of the electric vehicle is matched with the actual SOH of the battery The capacity value corresponding to the SOH of the battery is used as the upper limit value of the rechargeable capacity of the battery.

在本发明的一些实施例中,若与电动汽车的累计行驶里程匹配的里程为与该里程值相邻最近的前后两个里程值,则基于这两个里程值以及这两个里程值分别和与电池的实际SOH匹配的SOH共同对应的两个容量值,计算电池的可充入容量上限值。In some embodiments of the present invention, if the mileage matched with the accumulative mileage of the electric vehicle is the two mileage values adjacent to and closest to the mileage value, then based on these two mileage values and the two mileage values respectively and The two capacity values corresponding to the SOH that matches the actual SOH of the battery are used to calculate the upper limit of the rechargeable capacity of the battery.

作为一个示例,若电动汽车的累计行驶里程S0大于S2且小于S3,则与电动汽车的累计行驶里程S0匹配的行驶里程为S2和S3。若在表2中与电池的实际SOH匹配的SOH为90%。则在表2中S2和90%共同对应的容量值为E23,在表2中S3和90%共同对应的容量值为E33。则基于下述公式可以计算电池的可充入容量上限值C0:As an example, if the accumulated mileage S0 of the electric vehicle is greater than S2 and smaller than S3, the mileages matching the accumulated mileage S0 of the electric vehicle are S2 and S3. If the SOH matching the actual SOH of the battery in Table 2 is 90%. Then in Table 2, the capacity value corresponding to S2 and 90% is E23, and in Table 2, the capacity value corresponding to S3 and 90% is E33. Then the upper limit value C0 of the rechargeable capacity of the battery can be calculated based on the following formula:

需要说明的是,在预设的第一容量与第二容量和行驶里程的对应关系中,行驶里程可以为一个值,也可以为一个里程段。若与电动汽车的累计行驶里程匹配的里程为与该里程值相邻最近的前后两个里程值,则基于这两个里程值以及这两个里程值分别和与电池的实际容量值匹配的第二容量共同对应的两个第一容量值,计算电池的可充入容量上限值。具体计算方法,可参考公式(1),在此不再赘述。It should be noted that, in the preset correspondence relationship between the first capacity, the second capacity and the driving mileage, the driving mileage may be a value or a mileage segment. If the mileage matching the accumulative mileage of the electric vehicle is the two mileage values that are closest to the mileage value, then based on these two mileage values and the first two mileage values that match the actual capacity value of the battery, The two first capacity values corresponding to the two capacities are used to calculate the upper limit value of the rechargeable capacity of the battery. For the specific calculation method, refer to the formula (1), which will not be repeated here.

S103,基于电池的实际容量值和电池的可充入容量上限值,确定电池的充电参数的阈值。S103. Based on the actual capacity value of the battery and the upper limit value of the chargeable capacity of the battery, determine a threshold value of a charging parameter of the battery.

在本发明的一些实施例中,充电参数为充电SOC,则相应地,充电参数的阈值包括充电SOC阈值。In some embodiments of the present invention, the charging parameter is a charging SOC, and accordingly, the threshold of the charging parameter includes a charging SOC threshold.

其中,S103包括:Among them, S103 includes:

S1301,将可充入容量上限值与实际容量值的比值,作为电池的充电SOC阈值。S1301. Use the ratio of the upper limit value of the rechargeable capacity to the actual capacity value as the charging SOC threshold of the battery.

在获取的电池的充电SOC大于或等于充电SOC阈值的情况下,则发送停止对电池充电的控制命令,以停止对电池进行充电,提高电池的安全性。When the obtained charging SOC of the battery is greater than or equal to the charging SOC threshold, a control command to stop charging the battery is sent to stop charging the battery and improve the safety of the battery.

在本发明的一些实施例中,充电SOC的阈值的范围为[30%,100%]。In some embodiments of the present invention, the range of the charging SOC threshold is [30%, 100%].

在本发明的另一些实施例中,充电参数为充电电压,则相应地,充电参数的阈值包括充电电压阈值。In other embodiments of the present invention, the charging parameter is a charging voltage, and accordingly, the threshold of the charging parameter includes a charging voltage threshold.

在这种情况下,步骤S103不仅包括S1301,还包括S1303。In this case, step S103 includes not only S1301 but also S1303.

S1303,基于充电SOC阈值、获取的电池的当前温度以及第一对应关系,确定电池的充电电压阈值。其中,第一对应关系为电压与第一参数的对应关系,第一参数包括温度和SOC。S1303. Determine a charging voltage threshold of the battery based on the charging SOC threshold, the acquired current temperature of the battery, and the first corresponding relationship. Wherein, the first correspondence is a correspondence between voltage and a first parameter, and the first parameter includes temperature and SOC.

其中,第一对应关系可以通过电池在正常充电时线下标定测试获得。Wherein, the first corresponding relationship can be obtained through an offline calibration test when the battery is charged normally.

作为一个示例,表3示出本发明一实施例提供的预设的第一对应关系的示意图。As an example, Table 3 shows a schematic diagram of a preset first correspondence provided by an embodiment of the present invention.

表3table 3

如表3所示,表3中的第1行中的Cq为不同的SOC,q为大于等于1且小于等于4的整数。表3中的第1列中的Tp代表不同的温度,p为大于等于1且小于等于5的整数。。表3中的Ah代表不同的电压值,h为大于等于1的整数。对于任意一个SOC,以及任意一个温度,两者对应一个电压值。需要说明的是,表3中关于SOC的个数和温度的个数仅是示意,对于第一对应关系中SOC的个数和温度的个数可根据实际需求进行调整。As shown in Table 3, Cq in the first row of Table 3 are different SOCs, and q is an integer greater than or equal to 1 and less than or equal to 4. Tp in the first column in Table 3 represents different temperatures, and p is an integer greater than or equal to 1 and less than or equal to 5. . Ah in Table 3 represents different voltage values, and h is an integer greater than or equal to 1. For any SOC and any temperature, the two correspond to a voltage value. It should be noted that the number of SOCs and the number of temperatures in Table 3 are only indicative, and the number of SOCs and temperatures in the first correspondence can be adjusted according to actual needs.

在第一对应关系中,若温度一定,随着SOC的降低,电压呈现逐步降低趋势,从而实现随着老化程度的严重,降低电池的充电截止电压,以提高电池的使用安全性。In the first corresponding relationship, if the temperature is constant, the voltage will gradually decrease as the SOC decreases, so as to realize the reduction of the charge cut-off voltage of the battery as the aging degree is serious, so as to improve the use safety of the battery.

作为一个示例,若电池为高镍三元锂离子电池正极材料(NCM)电池,则表3中每个电压值的范围均位于[3.6V,4.3V]。As an example, if the battery is a high-nickel ternary lithium-ion battery cathode material (NCM) battery, the range of each voltage value in Table 3 is located at [3.6V, 4.3V].

当获取电池的充电SOC阈值之后,将该充电SOC阈值与表3中的对应关系中的每个SOC进行匹配,查找到表3的对应关系中与充电SOC阈值匹配的SOC。作为一个示例,在预设的第一对应关系中,与充电SOC阈值的差值的绝对值小于等于预设SOC阈值的SOC可以为与充电SOC阈值匹配的SOC。After the charging SOC threshold of the battery is obtained, the charging SOC threshold is matched with each SOC in the corresponding relationship in Table 3, and the SOC matching the charging SOC threshold in the corresponding relationship in Table 3 is found. As an example, in the preset first corresponding relationship, the SOC whose absolute value of the difference from the charging SOC threshold is less than or equal to the preset SOC threshold may be the SOC matching the charging SOC threshold.

当获取电池的当前温度之后,将电池的当前温度与标3中的对应关系中的每个温度进行匹配,查找到表3中的对应关系中与电池的当前温度匹配的温度。作为一个示例,在预设的第一对应关系中,与电池的当前温度的差值小于等于预设温度阈值的温度即可以为与电池的当前温度匹配的温度。After the current temperature of the battery is obtained, match the current temperature of the battery with each temperature in the corresponding relationship in Table 3, and find the temperature matching the current temperature of the battery in the corresponding relationship in Table 3. As an example, in the preset first corresponding relationship, the temperature whose difference with the current temperature of the battery is less than or equal to the preset temperature threshold may be the temperature matching the current temperature of the battery.

接着,将表3中与电池的当前温度匹配的温度和与充电SOC阈值匹配的SOC共同对应的电压值作为电池的充电截止电压。Next, the voltage value corresponding to the temperature matching the current temperature of the battery and the SOC matching the charging SOC threshold in Table 3 is taken as the charging cut-off voltage of the battery.

在获取的电池的充电电压大于或等于充电电压阈值的情况下,则发送停止对电池充电的控制命令,以提高电池的使用安全性,提高电池的使用寿命。When the obtained charging voltage of the battery is greater than or equal to the charging voltage threshold, a control command to stop charging the battery is sent, so as to improve the use safety of the battery and increase the service life of the battery.

在本发明的又一些实施例中,充电参数包括充电电压和充电SOC,则相应地,充电参数的阈值包括充电SOC阈值和充电电压阈值。In some other embodiments of the present invention, the charging parameters include a charging voltage and a charging SOC, and correspondingly, the thresholds of the charging parameters include a charging SOC threshold and a charging voltage threshold.

在这种情况下,S103也包括S1031~S1303,具体实现方式可参见上述叙述,在此不再赘述。In this case, S103 also includes S1031-S1303, and the specific implementation manner may refer to the above description, which will not be repeated here.

在此种应用场景下,在获取的电池的充电电压大于或等于充电电压阈值,且获取的充电SOC大于或等于充电SOC阈值的情况下,则发送停止对电池充电的控制命令,以提高电池的使用安全性,提高电池的使用寿命。In this application scenario, when the obtained charging voltage of the battery is greater than or equal to the charging voltage threshold, and the obtained charging SOC is greater than or equal to the charging SOC threshold, a control command to stop charging the battery is sent to improve the battery’s It is safe to use and improves the service life of the battery.

下面以标称容量为100Ah,质保为3年30万公里运营车质保的电池为例,介绍本发明实施例提供的电池的充电控制方法的具体实现过程。Taking a battery with a nominal capacity of 100Ah and a warranty of 3 years and 300,000 kilometers for operating vehicles as an example, the specific implementation process of the battery charging control method provided by the embodiment of the present invention will be introduced below.

若统计电池从出厂至今的累计充电容量为150000Ah,则根据预设的充电容量与实际容量的对应关系,可以确定电池的实际容量值为70Ah。基于电池的实际容量值和电池的标称容量,可以得出电池的实际SOH为70%。If the cumulative charging capacity of the battery from the factory to the present is 150000Ah, then according to the correspondence between the preset charging capacity and the actual capacity, the actual capacity of the battery can be determined to be 70Ah. Based on the actual capacity value of the battery and the nominal capacity of the battery, it can be concluded that the actual SOH of the battery is 70%.

若电动汽车的累计行驶里程为35万公里,根据预设的容量值与行驶里程和SOH的对应关系,可以确定电池的可充入容量上限值为55Ah。If the accumulative mileage of the electric vehicle is 350,000 kilometers, according to the corresponding relationship between the preset capacity value and the mileage and SOH, the upper limit of the rechargeable capacity of the battery can be determined to be 55Ah.

基于电池的实际SOH和电池的可充入容量上限值可以计算出电池的充电SOC阈值=55Ah/70Ah=78.6%。Based on the actual SOH of the battery and the upper limit of the chargeable capacity of the battery, the charging SOC threshold of the battery=55Ah/70Ah=78.6% can be calculated.

进一步的,根据电池的充电SOC阈值和电池的当前温度,以及预设的第一对应关系,可以确定电池的充电电压阈值为3.9V。Further, according to the charging SOC threshold of the battery, the current temperature of the battery, and the first preset corresponding relationship, it can be determined that the charging voltage threshold of the battery is 3.9V.

在电池的充电过程中,若SOC模块计算得到的SOC达到充电SOC阈值78.6%,和/或在电池的电压达到3.9V,则停止对电池充电。During the charging process of the battery, if the SOC calculated by the SOC module reaches 78.6% of the charging SOC threshold, and/or when the voltage of the battery reaches 3.9V, the charging of the battery is stopped.

在本发明实施例中,从电池出厂开始至电池的最终寿命期间,随着电池的老化状态逐渐严重,为了提高电池的使用安全性,电池的充电SOC阈值呈现逐渐降低的趋势,电池的充电截止电压也呈现逐渐降低的趋势。In the embodiment of the present invention, from the time the battery leaves the factory to the final life of the battery, as the aging state of the battery is gradually serious, in order to improve the safety of the battery, the charging SOC threshold of the battery shows a trend of gradually decreasing, and the charging of the battery is cut off. The voltage also showed a gradually decreasing trend.

图2示出了根据本发明一实施例提供的电池的充电控制装置的结构示意图。如图2所示,电池的充电控制装置200包括:Fig. 2 shows a schematic structural diagram of a charging control device for a battery provided according to an embodiment of the present invention. As shown in Figure 2, the battery

第一获取模块210,用于基于接收的充电请求,获取电池的充电参数的阈值和初始值。充电参数的阈值是基于电池的实际容量值和所在的电动汽车的累计行驶里程确定的。The first obtaining

第一控制命令发送模块220,用于若充电参数的初始值小于充电参数的阈值,发送对电池进行充电的控制命令,以对电池进行充电。The first control

第二获取模块230,用于在电池的充电过程中,实时获取电池的充电参数的数值。The second obtaining

第二控制命令发送模块240,用于若获取的电池的充电参数的数值大于充电参数的阈值,则发送停止对电池充电的控制命令,以停止充电。The second control

在本发明的实施例中,电池的充电控制装置200还包括:In an embodiment of the present invention, the charging

可充入容量上限值确定模块,用于基于电池的实际容量值和累计行驶里程,确定电池的可充入容量上限值。The upper limit value determination module of the chargeable capacity is used for determining the upper limit value of the chargeable capacity of the battery based on the actual capacity value of the battery and the accumulated mileage.

充电参数阈值确定模块,用于基于实际容量值和可充入容量上限值,确定充电参数的阈值。The charging parameter threshold determination module is used to determine the charging parameter threshold based on the actual capacity value and the upper limit value of the rechargeable capacity.

在本发明的实施例中,充电参数为充电荷电状态SOC,相应地,充电参数的阈值包括充电SOC阈值,则充电参数阈值确定模块,用于:将可充入容量上限值与实际容量值的比值,作为电池的充电SOC阈值。In an embodiment of the present invention, the charging parameter is the charging state of charge SOC, correspondingly, the threshold of the charging parameter includes the charging SOC threshold, and the charging parameter threshold determination module is used to: compare the upper limit value of the rechargeable capacity with the actual capacity The ratio of the values is used as the charging SOC threshold of the battery.

在本发明的实施例中,充电参数为充电电压,相应地,充电参数的阈值包括充电电压阈值,则充电参数阈值确定模块,用于:In an embodiment of the present invention, the charging parameter is a charging voltage. Correspondingly, the threshold of the charging parameter includes a charging voltage threshold, and the charging parameter threshold determining module is configured to:

将可充入容量上限值与实际容量值的比值,作为电池的充电SOC阈值;The ratio of the upper limit value of the rechargeable capacity to the actual capacity value is used as the charging SOC threshold of the battery;

基于充电SOC阈值、获取的电池的当前温度以及预设的第一对应关系,确定电池的充电电压阈值。Based on the charging SOC threshold, the acquired current temperature of the battery and the preset first corresponding relationship, the charging voltage threshold of the battery is determined.

其中,第一对应关系为电压与第一参数的对应关系,第一参数包括温度和SOC。Wherein, the first correspondence is a correspondence between voltage and a first parameter, and the first parameter includes temperature and SOC.

在本发明的实施例中,充电参数包括充电电压和充电SOC,相应地,充电参数的阈值包括充电SOC阈值和充电电压阈值,则充电参数阈值确定模块,用于:In an embodiment of the present invention, the charging parameter includes a charging voltage and a charging SOC, and correspondingly, the threshold of the charging parameter includes a charging SOC threshold and a charging voltage threshold, and the charging parameter threshold determination module is configured to:

将可充入容量上限值与实际容量值的比值,作为电池的充电SOC阈值;The ratio of the upper limit value of the rechargeable capacity to the actual capacity value is used as the charging SOC threshold of the battery;

基于充电SOC阈值、获取的电池的当前温度以及预设的第一对应关系,确定电池的充电电压阈值。Based on the charging SOC threshold, the acquired current temperature of the battery and the preset first corresponding relationship, the charging voltage threshold of the battery is determined.

其中,第一对应关系为电压与第一参数的对应关系,第一参数包括温度和SOC。Wherein, the first correspondence is a correspondence between voltage and a first parameter, and the first parameter includes temperature and SOC.

在本发明的实施例中,实际容量值基于电池的累计充/放电容量值确定。In an embodiment of the present invention, the actual capacity value is determined based on the accumulated charge/discharge capacity value of the battery.

其中,电池的累计充/放电容量值为以下任意一个值:Among them, the accumulative charge/discharge capacity value of the battery is any one of the following values:

累计的电池的经折算后的充电容量值、放电容量值、充电容量值和放电容量值的和值;The accumulated battery's converted charge capacity value, discharge capacity value, and the sum of charge capacity value and discharge capacity value;

其中,电池的经折算后的充电容量值为电池的充电容量值与电池的充电温度对应的折算系数的乘积,电池的经折算后的放电容量值为电池的放电容量值与电池的放电温度对应的折算系数的乘积;Wherein, the converted charging capacity value of the battery is the product of the charging capacity value of the battery and the conversion coefficient corresponding to the charging temperature of the battery, and the converted discharging capacity value of the battery is corresponding to the discharging capacity value of the battery and the discharging temperature of the battery The product of the conversion factor;

其中,电池的充电温度对应的折算系数基于电池的充电温度和预设的温度与折算系数的对应关系确定,电池的放电温度对应的折算系数基于电池的放电温度和预设的温度与折算系数的对应关系确定。Wherein, the conversion coefficient corresponding to the charging temperature of the battery is determined based on the corresponding relationship between the charging temperature of the battery and the preset temperature and the conversion coefficient, and the conversion coefficient corresponding to the discharging temperature of the battery is determined based on the discharge temperature of the battery and the preset temperature and the conversion coefficient. Correspondence is confirmed.

在本发明的实施例中,实际容量值基于累计行驶里程以及预设的第二对应关系确定。其中,第二对应关系为行驶里程和容量的对应关系。In an embodiment of the present invention, the actual capacity value is determined based on the accumulated driving mileage and the second preset corresponding relationship. Wherein, the second corresponding relationship is the corresponding relationship between driving mileage and capacity.

在本发明的实施例中,可充入容量上限值确定模块,用于:In an embodiment of the present invention, a capacity upper limit determination module may be charged for:

基于电池的实际容量值、累计行驶里程以及预设的第三对应关系,确定电池的可充入容量上限值。其中,第三对应关系为第一容量与第二参数的对应关系,第二参数包括第二容量和行驶里程。Based on the actual capacity value of the battery, the accumulated mileage and the third preset corresponding relationship, the upper limit of the rechargeable capacity of the battery is determined. Wherein, the third correspondence is the correspondence between the first capacity and the second parameter, and the second parameter includes the second capacity and the mileage.

在本发明的实施例中,可充入容量上限值确定模块,包括:In an embodiment of the present invention, the capacity upper limit determination module that can be charged includes:

实际SOH确定单元,用于基于电池的实际容量值,确定电池的实际健康度SOH。The actual SOH determination unit is configured to determine the actual SOH of the battery based on the actual capacity value of the battery.

可充入容量上限值确定单元,用于根据实际SOH和累计行驶里程,确定电池的可充入容量上限值。A rechargeable capacity upper limit determination unit is used to determine the rechargeable capacity upper limit of the battery according to the actual SOH and the accumulated mileage.

在本发明的实施例中,可充入容量上限值确定单元,用于:In an embodiment of the present invention, a capacity upper limit determination unit may be charged for:

根据实际SOH、累计行驶里程以及预设的第四对应关系,确定电池的可充入容量上限值。其中,第四对应关系为容量与第三参数的对应关系,第三参数包括行驶里程和SOH。The upper limit of the rechargeable capacity of the battery is determined according to the actual SOH, the accumulated mileage and the fourth preset corresponding relationship. Wherein, the fourth corresponding relationship is the corresponding relationship between the capacity and the third parameter, and the third parameter includes the driving mileage and the SOH.

在本发明的实施例中,根据电池的实际容量值和电池所在的电动汽车的累计行驶里程动态确定电池的充电参数的阈值,以实现依据电池的老化状态来动态计算充电参数的阈值。在对电池充电的过程中,若获取的电池的充电参数的数值大于根据最新计算的充电参数的阈值时,则停止对电池充电。通过考虑电池的老化状态来确定电池的充电参数的阈值,提高了电池使用的安全性。In the embodiment of the present invention, the threshold value of the charging parameter of the battery is dynamically determined according to the actual capacity value of the battery and the cumulative mileage of the electric vehicle where the battery is located, so as to realize the dynamic calculation of the threshold value of the charging parameter according to the aging state of the battery. During the process of charging the battery, if the acquired value of the charging parameter of the battery is greater than the threshold value based on the newly calculated charging parameter, then the charging of the battery is stopped. By considering the aging state of the battery to determine the threshold value of the charging parameter of the battery, the safety of battery use is improved.

根据本发明实施例的电池的充电控制装置的其他细节与以上结合图1描述的根据本发明实施例的方法类似,在此不再赘述。Other details of the battery charging control device according to the embodiment of the present invention are similar to the method according to the embodiment of the present invention described above in conjunction with FIG. 1 , and will not be repeated here.

结合图1至图2描述的根据本发明实施例的电池的充电控制方法和装置可以由电池的电池管理系统来实现。图3是示出根据发明实施例的电池管理系统的硬件结构300示意图。The charging control method and device for a battery described in conjunction with FIGS. 1 to 2 according to the embodiments of the present invention may be implemented by a battery management system for a battery. Fig. 3 is a schematic diagram showing a

如图3所示,本实施例中的电池管理系统300包括:处理器301、存储器302、通信接口303和总线310,其中,处理器301、存储器302、通信接口303通过总线310连接并完成相互间的通信。As shown in FIG. 3, the

具体地,上述处理器301可以包括中央处理器(CPU),或者特定集成电路(ASIC),或者可以被配置成实施本发明实施例的一个或多个集成电路。Specifically, the above-mentioned processor 301 may include a central processing unit (CPU), or an specific integrated circuit (ASIC), or may be configured to implement one or more integrated circuits in the embodiments of the present invention.

存储器302可以包括用于数据或指令的大容量存储器。举例来说而非限制,存储器302可包括HDD、软盘驱动器、闪存、光盘、磁光盘、磁带或通用串行总线(USB)驱动器或者两个或更多个以上这些的组合。在合适的情况下,存储器302可包括可移除或不可移除(或固定)的介质。在合适的情况下,存储器302可在电池管理系统300的内部或外部。在特定实施例中,存储器302是非易失性固态存储器。在特定实施例中,存储器302包括只读存储器(ROM)。在合适的情况下,该ROM可以是掩模编程的ROM、可编程ROM(PROM)、可擦除PROM(EPROM)、电可擦除PROM(EEPROM)、电可改写ROM(EAROM)或闪存或者两个或更多个以上这些的组合。Memory 302 may include mass storage for data or instructions. By way of example and not limitation, memory 302 may include a HDD, a floppy disk drive, flash memory, an optical disk, a magneto-optical disk, magnetic tape, or a universal serial bus (USB) drive, or a combination of two or more of these. Storage 302 may include removable or non-removable (or fixed) media, where appropriate. Memory 302 may be internal or external to

通信接口303,主要用于实现本发明实施例中各模块、装置、单元和/或设备之间的通信。The communication interface 303 is mainly used to implement communication between various modules, devices, units and/or devices in the embodiments of the present invention.

总线310包括硬件、软件或两者,将电池管理系统300的部件彼此耦接在一起。举例来说而非限制,总线可包括加速图形端口(AGP)或其他图形总线、增强工业标准架构(EISA)总线、前端总线(FSB)、超传输(HT)互连、工业标准架构(ISA)总线、无限带宽互连、低引脚数(LPC)总线、存储器总线、微信道架构(MCA)总线、外围组件互连(PCI)总线、PCI-Express(PCI-X)总线、串行高级技术附件(SATA)总线、视频电子标准协会局部(VLB)总线或其他合适的总线或者两个或更多个以上这些的组合。在合适的情况下,总线310可包括一个或多个总线。尽管本发明实施例描述和示出了特定的总线,但本发明考虑任何合适的总线或互连。The bus 310 includes hardware, software, or both, and couples the components of the

也就是说,图3所示的电池管理系统300可以被实现为包括:处理器301、存储器302、通信接口303和总线310。处理器301、存储器302和通信接口303通过总线310连接并完成相互间的通信。存储器302用于存储程序代码;处理器301通过读取存储器302中存储的可执行程序代码来运行与可执行程序代码对应的程序,以用于执行本发明任一实施例中的电池的充电控制方法,从而实现结合图1至图2描述的电池的充电控制方法和装置。That is to say, the

本发明实施例还提供一种计算机存储介质,该计算机存储介质上存储有计算机程序指令;该计算机程序指令被处理器执行时实现本发明实施例提供的电池的充电控制方法。The embodiment of the present invention also provides a computer storage medium, on which computer program instructions are stored; when the computer program instructions are executed by a processor, the battery charging control method provided by the embodiment of the present invention is implemented.