CN113527895B - Degradable super-tough silk protein-based material and preparation method and application thereof - Google Patents

Degradable super-tough silk protein-based material and preparation method and application thereofDownload PDFInfo

- Publication number

- CN113527895B CN113527895BCN202110891655.2ACN202110891655ACN113527895BCN 113527895 BCN113527895 BCN 113527895BCN 202110891655 ACN202110891655 ACN 202110891655ACN 113527895 BCN113527895 BCN 113527895B

- Authority

- CN

- China

- Prior art keywords

- super

- based material

- silk protein

- solution

- plasticizer

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/16—Halogen-containing compounds

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/18—Manufacture of films or sheets

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/04—Oxygen-containing compounds

- C08K5/05—Alcohols; Metal alcoholates

- C08K5/053—Polyhydroxylic alcohols

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F1/00—General methods for the manufacture of artificial filaments or the like

- D01F1/02—Addition of substances to the spinning solution or to the melt

- D01F1/10—Other agents for modifying properties

- D—TEXTILES; PAPER

- D01—NATURAL OR MAN-MADE THREADS OR FIBRES; SPINNING

- D01F—CHEMICAL FEATURES IN THE MANUFACTURE OF ARTIFICIAL FILAMENTS, THREADS, FIBRES, BRISTLES OR RIBBONS; APPARATUS SPECIALLY ADAPTED FOR THE MANUFACTURE OF CARBON FILAMENTS

- D01F4/00—Monocomponent artificial filaments or the like of proteins; Manufacture thereof

- D01F4/02—Monocomponent artificial filaments or the like of proteins; Manufacture thereof from fibroin

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2389/00—Characterised by the use of proteins; Derivatives thereof

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K3/00—Use of inorganic substances as compounding ingredients

- C08K3/16—Halogen-containing compounds

- C08K2003/162—Calcium, strontium or barium halides, e.g. calcium, strontium or barium chloride

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Health & Medical Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Medicinal Chemistry (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Textile Engineering (AREA)

- General Chemical & Material Sciences (AREA)

- Materials Engineering (AREA)

- Manufacture Of Macromolecular Shaped Articles (AREA)

- Materials For Medical Uses (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及丝蛋白基材料,具体涉及一种可降解超韧丝蛋白材料、其制备方法及其应用。The invention relates to a silk protein-based material, in particular to a degradable super tough silk protein material, a preparation method and application thereof.

背景技术Background technique

丝蛋白是一种从天然蚕茧中提取的蛋白基生物高分子,具有优异的力学性能、生物相容性和生物降解性。近年来,丝蛋白基材料在组织工程、生物电子、再生医学等生物医学领域中应用广泛。例如,丝蛋白薄膜可以作为制备生物传感器的基底;丝蛋白海绵可以作为组织工程支架;丝蛋白纳米小球可以作为药物传输和释放的载体;丝蛋白块材可以被加工成可植入的骨钉等。通常,丝蛋白可以通过溶解再生的方法从天然蚕茧中提取得到,这一制备途径绿色环保,具有很好的实际应用价值。Silk protein is a protein-based biopolymer extracted from natural silkworm cocoons with excellent mechanical properties, biocompatibility and biodegradability. In recent years, silk protein-based materials have been widely used in biomedical fields such as tissue engineering, bioelectronics, and regenerative medicine. For example, silk protein films can be used as substrates for the preparation of biosensors; silk protein sponges can be used as scaffolds for tissue engineering; silk protein nanospheres can be used as carriers for drug delivery and release; silk protein blocks can be processed into implantable bone nails Wait. Generally, silk protein can be extracted from natural silkworm cocoons by the method of dissolution and regeneration. This preparation method is environmentally friendly and has good practical application value.

基于丝蛋白制备得到的丝蛋白基材料被广泛应用于表皮伤口修复、角膜再生、鼓膜修复、组织工程支架、柔性生物电子器件等生物医学领域,具有很好的应用前景。一般来说,丝蛋白基材料是通过溶液加工的方法制备而成。为了调控丝蛋白基材料的物理化学性质,特别是力学性能和生物降解性,一些后处理方法(如水退火、醇处理等)被采用。另外,为了增加丝蛋白基材料的力学性能(如可拉伸性和韧性),一些小分子(如甘油等)可作为增塑剂被添加入丝蛋白溶液(S.Lu et al.Biomacromolecules 2010,11,143-150;J.E.Brownet al.Biomacromolecules 2016,17,3911-3921)。以甘油为例,甘油的加入使得丝蛋白分子链的流动性增加,提升了丝蛋白薄膜的柔韧性。同时,甘油的加入会诱导丝蛋白分子形成β-折叠结构,进一步形成结晶区,从而导致丝蛋白基材料的降解性降低,限制了其在可降解柔性器件领域的研究和应用。Silk protein-based materials prepared based on silk protein are widely used in epidermal wound repair, corneal regeneration, tympanic membrane repair, tissue engineering scaffolds, flexible bioelectronic devices and other biomedical fields, and have good application prospects. Generally, silk protein-based materials are prepared by solution-processing methods. In order to modulate the physicochemical properties of silk protein-based materials, especially the mechanical properties and biodegradability, some post-treatment methods (such as water annealing, alcohol treatment, etc.) are employed. In addition, in order to increase the mechanical properties (such as stretchability and toughness) of silk protein-based materials, some small molecules (such as glycerol, etc.) can be added into silk protein solutions as plasticizers (S.Lu et al.Biomacromolecules 2010, 11, 143-150; J.E. Brownet al. Biomacromolecules 2016, 17, 3911-3921). Taking glycerol as an example, the addition of glycerol increases the fluidity of the silk protein molecular chain and improves the flexibility of the silk protein film. At the same time, the addition of glycerol will induce the silk protein molecules to form a β-sheet structure and further form a crystalline region, resulting in a decrease in the degradability of silk protein-based materials, limiting its research and application in the field of degradable flexible devices.

除了增塑剂外,一些金属阳离子(如钾、钙等)可以与丝蛋白分子发生相互作用,形成离子对或配位作用,从而影响丝蛋白的分子结构和在材料制备成型过程中的链聚集态。例如,相关研究表明钙离子可以与丝蛋白中带负电荷的氨基酸残基(如谷氨酸和天冬氨酸)相互作用,阻碍普遍存在的疏水相互作用并调节丝素蛋白的自组装过程(P.Dubey etal.Biomacromolecules 2015,16,3936-3944)。In addition to plasticizers, some metal cations (such as potassium, calcium, etc.) can interact with silk protein molecules to form ion pairs or coordination, thereby affecting the molecular structure of silk protein and chain aggregation during the material preparation and molding process. state. For example, related studies have shown that calcium ions can interact with negatively charged amino acid residues (such as glutamic acid and aspartic acid) in silk proteins, hindering ubiquitous hydrophobic interactions and regulating the self-assembly process of silk fibroin ( P. Dubey et al. Biomacromolecules 2015, 16, 3936-3944).

制备具有可降解超韧丝蛋白基材料对促进丝蛋白材料在更多领域,特别是生物医学领域应用具有重要的意义,也是研究重点。虽然通过前期相关研究已取得了一些进展,但是,直至目前,仍缺少非常有效易行的加工制备方法。因此,探索丝蛋白在加工过程中的结构和聚集态调控方法,开发新型可降解超韧丝蛋白基材料的制备方法是当前的迫切需求。The preparation of degradable super-strand fibroin-based materials is of great significance for promoting the application of silk fibroin materials in more fields, especially in the field of biomedicine, and is also a research focus. Although some progress has been made through previous related research, until now, there is still a lack of very effective and easy processing and preparation methods. Therefore, it is an urgent need to explore the regulation of the structure and aggregation state of silk protein during processing and to develop a new method for the preparation of degradable super-tough silk protein-based materials.

发明内容SUMMARY OF THE INVENTION

本发明的目的是提供一种可降解超韧丝蛋基材料及其制备方法,通过改变原料的混合比例,实现丝蛋白基材料的水溶性、力学性能和可降解性精确调控。The purpose of the present invention is to provide a degradable super tough silk egg-based material and a preparation method thereof. By changing the mixing ratio of the raw materials, the water-solubility, mechanical properties and degradability of the silk protein-based material can be precisely regulated.

一方面,本发明提供一种超韧丝蛋白基材料,其包含增塑剂、盐及丝蛋白,其中,所述塑化剂为选自甘油、山梨醇、聚乙二醇中的一种或多种,以及所述盐为选自氯化钙、氯化锂、溴化锂中的一种或多种。In one aspect, the present invention provides a super tenacity fibroin-based material, which comprises a plasticizer, a salt and silk protein, wherein the plasticizer is one selected from glycerol, sorbitol, and polyethylene glycol or multiple, and the salt is one or more selected from calcium chloride, lithium chloride, and lithium bromide.

在一些实施方式中,在超韧丝蛋白基材料中,丝蛋白:增塑剂:盐的重量比可以为1:(0.15-0.3):(0.05-0.15),例如为1:(0.25-0.28):(0.05-0.07),或者1:(0.27-0.29):(0.13-0.15)。In some embodiments, in the superfibroin-based material, the silk protein:plasticizer:salt weight ratio may be 1:(0.15-0.3):(0.05-0.15), eg, 1:(0.25-0.28 ):(0.05-0.07), or 1:(0.27-0.29):(0.13-0.15).

通过调节丝蛋白、塑化剂和盐三者的质量比例,可以调控制备材料的性质和性能。例如,当盐的比例大于等于10%时,所制备的材料具有优异的水溶性和可降解性。当塑化剂比例大于等于20%时,所制备的材料具有优异的韧性和可拉伸性。本发明通过调节混合溶液中丝蛋白、塑化剂和盐的比例,可以调节所制备得到的丝蛋白基材料的韧性和水溶性、力学性能和可降解性,从而为获得具有期望性能的丝蛋白基材料提供了简便可靠的方法。By adjusting the mass ratio of silk protein, plasticizer and salt, the properties and performance of the prepared materials can be regulated. For example, when the proportion of the salt is greater than or equal to 10%, the prepared material has excellent water solubility and degradability. When the proportion of plasticizer is greater than or equal to 20%, the prepared material has excellent toughness and stretchability. The present invention can adjust the toughness, water solubility, mechanical properties and degradability of the prepared silk protein-based material by adjusting the ratio of silk protein, plasticizer and salt in the mixed solution, so as to obtain silk protein with desired properties. The base material provides an easy and reliable method.

在根据本发明的超韧丝蛋白基材料中,增塑剂、盐及丝蛋白三者均匀混合,优选以分子水平均匀混合。In the super tough silk protein-based material according to the present invention, the plasticizer, the salt and the silk protein are uniformly mixed, preferably at the molecular level.

根据需要,所述超韧丝蛋白基材料中还可以包含功能分子或材料,如药物、抗体、生长因子、无机纳米材料、染料、有机分子等。一般而言,基于超韧丝蛋白基材料的总重,这些成分的含量可以为0-50重量%,例如可添加20%碳纳米管。According to needs, the super fibroin-based material may also contain functional molecules or materials, such as drugs, antibodies, growth factors, inorganic nanomaterials, dyes, organic molecules, and the like. In general, the content of these components may be 0-50 wt% based on the total weight of the superfibroin-based material, for example, 20% carbon nanotubes may be added.

在一些实施方式中,所述超韧丝蛋白基材料由增塑剂、盐及丝蛋白组成。In some embodiments, the superfibroin-based material consists of a plasticizer, a salt, and silk protein.

在一些实施方式中,所述增塑剂为甘油,所述盐为氯化钙。在一些实施方式中,以100重量%的超韧丝蛋白基材料干重计,甘油的质量分数为15-20%,例如15.5%,16%,16.5%,17%,17.5%,18%,18.5%,19%,19.5%等,氯化钙的质量分数为5-10%,例如5.5%,6%,6.5%,7%,7.5%,8%,8.5%,9%,9.5%等。在一些实施方式中,以100重量%的超韧丝蛋白基材料干重计,甘油的质量分数为20%,氯化钙的质量分数为10%。在另一些实施方式中,以100重量%的超韧丝蛋白基材料干重计,甘油的质量分数为20%,氯化钙的质量分数为5%。In some embodiments, the plasticizer is glycerin and the salt is calcium chloride. In some embodiments, the mass fraction of glycerol is 15-20%, such as 15.5%, 16%, 16.5%, 17%, 17.5%, 18%, based on the dry weight of 100% by weight of the superfibroin-based material, 18.5%, 19%, 19.5%, etc., the mass fraction of calcium chloride is 5-10%, such as 5.5%, 6%, 6.5%, 7%, 7.5%, 8%, 8.5%, 9%, 9.5%, etc. . In some embodiments, the mass fraction of glycerol is 20% and the mass fraction of calcium chloride is 10% based on the dry weight of 100% by weight of the super tenacin-based material. In other embodiments, the mass fraction of glycerol is 20% and the mass fraction of calcium chloride is 5% based on the dry weight of 100% by weight of the super fibronectin-based material.

在一些实施方式中,所述超韧丝蛋白基材料可以呈膜状、片材、海绵、粉末、纤维、凝胶等形式,但不限于此。In some embodiments, the superfibroin-based material may be in the form of films, sheets, sponges, powders, fibers, gels, etc., but is not limited thereto.

对根据本发明的超韧丝蛋白基材料的制备方法没有特别限制,只要能够实现各组分的均匀混合,优选分子水平均匀混合即可,例如可以通过溶液混合,在溶剂存在下研磨,熔融混合、捏合等。There is no particular limitation on the preparation method of the super tenacin-based material according to the present invention, as long as uniform mixing of each component can be achieved, preferably uniform mixing at the molecular level, such as solution mixing, grinding in the presence of a solvent, and melt mixing. , kneading, etc.

另一方面,本发明提供一种制备上述超韧丝蛋白基材料的方法,所述方法包括以下步骤:On the other hand, the present invention provides a method for preparing the above-mentioned super tenacin-based material, the method comprising the following steps:

(1)制备丝蛋白水溶液;(1) prepare silk protein aqueous solution;

(2)制备塑化剂水溶液;(2) prepare an aqueous solution of plasticizer;

(3)制备盐的水溶液;(3) prepare the aqueous solution of salt;

(4)将上述丝蛋白水溶液、塑化剂水溶液和盐的水溶液混合得到混合均匀的溶液;(4) mixing the above-mentioned silk protein aqueous solution, plasticizer aqueous solution and salt aqueous solution to obtain a uniformly mixed solution;

(5)将得到的溶液干燥得到所述超韧丝蛋白基材料。(5) drying the obtained solution to obtain the super-strassin-based material.

在一些实施方式中,所述超韧丝蛋白基材料为薄膜形式。例如,所述薄膜可以通过溶液浇筑的方法制成,但不限于此。例如,将步骤(4)得到的混合溶液转移至预制模具中,干燥后即得到所述改性丝蛋白薄膜,干燥温度为0-90℃,时间为3-48小时。干燥可以在常压或真空中进行。In some embodiments, the super tenacin-based material is in the form of a thin film. For example, the film can be made by solution casting, but not limited thereto. For example, the mixed solution obtained in step (4) is transferred to a prefabricated mold, and the modified silk protein film is obtained after drying. The drying temperature is 0-90° C. and the drying time is 3-48 hours. Drying can be carried out at atmospheric pressure or under vacuum.

在一些实施方式中,所述超韧丝蛋白基材料为海绵形式。例如,所述海绵通过冷冻干燥的方式制成,但不限于此。优选地,冷冻干燥的温度为-50~-110℃。In some embodiments, the super tenacin-based material is in the form of a sponge. For example, the sponge is made by freeze-drying, but not limited thereto. Preferably, the temperature of freeze-drying is -50~-110°C.

在一些实施方式中,所述超韧丝蛋白基材料为粉末形式。例如,所述海绵通过喷雾干燥的方式制成,但不限于此。In some embodiments, the superfibroin-based material is in powder form. For example, the sponge is made by spray drying, but not limited thereto.

在一些实施方式中,所述超韧丝蛋白基材料为凝胶形式。例如,所述凝胶可以通过将溶液浓缩后再通过物理或化学交联的方法制成。例如,浓缩温度为5-60℃,浓缩时间为1-60小时,物理交联包括调节pH至低于5、通电、加入醇等有机溶剂等,化学交联包括酶交联,但不限于此。In some embodiments, the super-strassin-based material is in the form of a gel. For example, the gel can be made by concentrating the solution followed by physical or chemical cross-linking. For example, the concentration temperature is 5-60°C, the concentration time is 1-60 hours, the physical cross-linking includes adjusting the pH to less than 5, electrification, adding organic solvents such as alcohol, etc., and the chemical cross-linking includes enzymatic cross-linking, but not limited to this .

在一些实施方式中,所述超韧丝蛋白基材料为片材或块材形式。例如将所述溶液通过干燥、固化制成片材或块材形式,优选地,干燥温度为5-150℃。In some embodiments, the super fibroin-based material is in the form of a sheet or block. For example, the solution is dried and cured into a sheet or block form, preferably, the drying temperature is 5-150°C.

在一些实施方式中,所述超韧丝蛋白基材料为纤维形式。例如,所述纤维可以通过将溶液浓缩后再将所得浓缩液通过干法纺丝、湿法纺丝、静电纺丝等纺丝方法制成纤维,但不限于此。In some embodiments, the superstrandin-based material is in the form of fibers. For example, the fibers can be made into fibers by concentrating the solution and then subjecting the obtained concentrated solution to spinning methods such as dry spinning, wet spinning, electrospinning, etc., but not limited thereto.

在一些实施方式中,步骤(1)包括:将破碎好的蚕茧加入到沸腾的碳酸钠溶液中并保持进行脱胶,将脱胶后的蚕丝漂洗并干燥。然后将干燥后的脱胶蚕丝加入到溴化锂水溶液中,溶解。待蚕丝纤维全部溶解后将溶液进行透析纯化,得到丝蛋白水溶液并置于冰箱保存。通过取一定量丝蛋白水溶液进行干燥可以测量其浓度。In some embodiments, step (1) includes: adding the broken cocoons to a boiling sodium carbonate solution and keeping it for degumming, rinsing and drying the degummed silk. Then, the dried degummed silk is added to the lithium bromide aqueous solution to dissolve. After all the silk fibers are dissolved, the solution is dialyzed and purified to obtain an aqueous solution of silk protein and stored in a refrigerator. Its concentration can be measured by taking a certain amount of silk protein aqueous solution and drying it.

在一些实施方式中,在步骤(1)中,碳酸钠溶液的浓度为0.01-0.05mol/L,脱胶处理时间为5-180分钟。In some embodiments, in step (1), the concentration of the sodium carbonate solution is 0.01-0.05mol/L, and the degumming treatment time is 5-180 minutes.

在一些实施方式中,在步骤(1)中,溴化锂水溶液的浓度为9.3mol/L,溶解在60℃下持续4小时。In some embodiments, in step (1), the concentration of the lithium bromide aqueous solution is 9.3 mol/L, and the solution is dissolved at 60° C. for 4 hours.

在一些实施方式中,在步骤(2)中,塑化剂溶液的浓度为10-1000mg/mL,例如为100mg/mL。In some embodiments, in step (2), the concentration of the plasticizer solution is 10-1000 mg/mL, eg, 100 mg/mL.

在一些实施方式中,在步骤(3)中,盐溶液的浓度为0.01-5mol/L,例如为1mol/L。In some embodiments, in step (3), the concentration of the salt solution is 0.01-5 mol/L, for example, 1 mol/L.

在一些实施方式中,在最终制备的材料中,塑化剂占体系中除水外所有物质的质量分数可以为10-30%,例如为15-20%。In some embodiments, in the final prepared material, the mass fraction of the plasticizer in all substances in the system except water may be 10-30%, for example, 15-20%.

在一些实施方式中,在最终制备的材料中,盐占体系中除水外所有物质的质量分数可以为2-20%,例如为5-10%。In some embodiments, in the final prepared material, the mass fraction of salt in all substances in the system except water may be 2-20%, for example, 5-10%.

再一方面,本发明提供上述超韧丝蛋白基材料作为生物工程材料的应用,其中,所述生物工程材料可选自表皮伤口修复材料、角膜再生材料、鼓膜修复材料、组织再生支架材料、包装材料以及柔性生物电子器件等。In yet another aspect, the present invention provides the application of the above-mentioned super tenasin-based material as a bioengineering material, wherein the bioengineering material can be selected from epidermal wound repair materials, corneal regeneration materials, tympanic membrane repair materials, tissue regeneration scaffold materials, packaging materials, etc. materials and flexible bioelectronic devices.

有益效果beneficial effect

本发明所述的超韧丝蛋白基材料的制备方法具有以下优点:The preparation method of the super tenacin-based material of the present invention has the following advantages:

(1)本发明所述的制备方法中需要的丝蛋白溶液直接从天然蚕茧制备得到,原料来源广泛,便宜易得并且产量可控;所添加的试剂,塑化剂和盐通常为常见工业原料,价格低廉。该调控方法操作简单易行,并且不影响丝蛋白基材料的生物相容性,为扩大丝蛋白基材料在生物医学领域的应用提供了有效的途径。(1) The silk protein solution required in the preparation method of the present invention is directly prepared from natural silk cocoons, and the raw material sources are wide, cheap and easy to obtain, and the output is controllable; the added reagents, plasticizers and salts are usually common industrial raw materials , the price is low. The control method is simple and easy to operate, and does not affect the biocompatibility of the silk protein-based material, which provides an effective way for expanding the application of the silk protein-based material in the biomedical field.

(2)本发明的调控方法得到的丝蛋白薄膜的力学性能和降解性能够通过塑化剂和盐的加入比例进行精确调控。从分子层面上分析,添加塑化剂可以增加丝蛋白分子的链运动,调控其玻璃化转变温度,以及调控材料的结晶程度,从而在宏观上增强材料的可拉伸性和韧性。盐中的离子,尤其是金属离子可以与丝蛋白分子中的带负电的基团形成离子对,从而调控丝蛋白分子的链聚集态,并且影响丝蛋白分子的结晶行为,从而在宏观上调控材料的水溶性和可降解性。通过将塑化剂调控和盐调控相结合,可以制备得到可降解的超韧丝蛋白基材料,并且可以实现对材料力学性能和降解性能的精确调控。(2) The mechanical properties and degradability of the silk protein film obtained by the regulation method of the present invention can be precisely regulated by the addition ratio of plasticizer and salt. At the molecular level, adding plasticizers can increase the chain motion of silk protein molecules, regulate its glass transition temperature, and regulate the degree of crystallization of the material, thereby enhancing the stretchability and toughness of the material at a macroscopic level. Ions in salts, especially metal ions, can form ion pairs with negatively charged groups in silk protein molecules, thereby regulating the chain aggregation state of silk protein molecules, and affecting the crystallization behavior of silk protein molecules, thereby macroscopically regulating materials. water solubility and degradability. By combining plasticizer regulation and salt regulation, a degradable super-fibroin-based material can be prepared, and the precise regulation of the mechanical properties and degradation properties of the material can be achieved.

(3)本发明实现了一种可以同时对丝蛋白基材料力学性能和降解性能进行精确调控的方法,并制备得到了具有优异降解性的超韧丝蛋白基材料,极大地促进了丝蛋白基材料在生物医学领域的应用潜力,例如可以制备具有优异性能的可降解组织工程支架和植入介入器件,柔性电子器件基底等。(3) The present invention realizes a method that can precisely control the mechanical properties and degradation properties of silk protein-based materials at the same time, and prepares super tough silk protein-based materials with excellent degradability, which greatly promotes silk protein-based materials. The application potential of materials in the biomedical field, such as the preparation of degradable tissue engineering scaffolds and implantable interventional devices with excellent properties, flexible electronic device substrates, etc.

附图说明Description of drawings

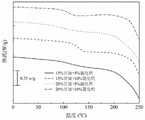

图1是本发明实施例1中制备得到的可降解超韧丝蛋白薄膜的照片。Fig. 1 is a photo of the degradable super fibroin film prepared in Example 1 of the present invention.

图2是本发明实施例1-4中制备得到的可降解超韧丝蛋白薄膜的红外吸收光谱图。2 is an infrared absorption spectrum diagram of the degradable super tenasin films prepared in Examples 1-4 of the present invention.

图3是本发明实施例1-4中制备得到的可降解超韧丝蛋白薄膜的差示扫描量热法表征图。3 is a differential scanning calorimetry characterization diagram of the degradable super tenasin films prepared in Examples 1-4 of the present invention.

图4是本发明实施例1-4中制备得到的可降解超韧丝蛋白薄膜的力学性能表征图,A是表征各薄膜的断裂伸长率及断裂强度的图,B是表征各薄膜的杨氏模量的图。Figure 4 is a graph showing the mechanical properties of the degradable super tenasin films prepared in Examples 1-4 of the present invention, A is a graph characterizing the elongation at break and breaking strength of each film, B is a graph that characterizes each film Plot of the modulus.

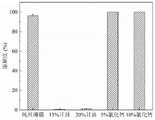

图5是本发明实施例1-4中制备得到的可降解超韧丝蛋白薄膜的水溶性表征图。FIG. 5 is a water solubility characterization diagram of the degradable super tenasin films prepared in Examples 1-4 of the present invention.

图6是本发明实施例3中制备得到的可降解超韧丝蛋白薄膜在不同酶作用下的降解表征图。FIG. 6 is a graph showing the degradation characterization of the degradable super tenasin film prepared in Example 3 of the present invention under the action of different enzymes.

图7是实施例5中制备的高浓度丝蛋白/甘油/氯化钙浓缩液的照片。7 is a photograph of the high-concentration silk protein/glycerol/calcium chloride concentrate prepared in Example 5. FIG.

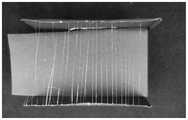

图8是利用实施例5中制备的高浓度丝蛋白/甘油/氯化钙浓缩液进行干法纺丝所得到的纤维的照片。8 is a photograph of fibers obtained by dry spinning using the high-concentration silk protein/glycerol/calcium chloride concentrate prepared in Example 5. FIG.

图9是示出实施例6中制备的纤维的力学性能测试结果的图。FIG. 9 is a graph showing the test results of mechanical properties of the fibers prepared in Example 6. FIG.

图10是本发明对比例1-5中制备得到的丝蛋白薄膜的红外吸收光谱图。10 is an infrared absorption spectrum diagram of the silk protein films prepared in Comparative Examples 1-5 of the present invention.

图11是本发明对比例1-5中制备得到的丝蛋白薄膜的差示扫描量热法表征图。Figure 11 is a differential scanning calorimetry characterization diagram of the silk protein films prepared in Comparative Examples 1-5 of the present invention.

图12是本发明对比例1-5中制备得到的丝蛋白薄膜的机械性能表征图,A是表征各薄膜的断裂伸长率及断裂强度的图,B是表征各薄膜的杨氏模量的图。Figure 12 is a graph showing the mechanical properties of the silk protein films prepared in Comparative Examples 1-5 of the present invention, A is a graph that characterizes the elongation at break and breaking strength of each film, and B is a graph that characterizes the Young's modulus of each film. picture.

图13是本发明对比例1-5中制备得到的丝蛋白薄膜的水溶性表征图。Figure 13 is a graph showing the water solubility of the silk protein films prepared in Comparative Examples 1-5 of the present invention.

具体实施方式Detailed ways

本发明所述的调控方法通过下面实施例作进一步详细的说明。实施例仅用于解释而不以任何方式限制本发明。The control method of the present invention is further described in detail by the following examples. The examples are for illustration only and do not limit the invention in any way.

实施例1-4Examples 1-4

根据以下方法制备可降解超韧丝蛋白薄膜:Degradable super tenacin films were prepared according to the following method:

(1)如表1中,分别配置丝蛋白溶液、甘油溶液、氯化钙溶液,配置完毕后将上述各溶液按照表1中的体积混合均匀。取3.5mL混合溶液浇筑于直径为6mm的培养皿中,使溶液完全覆盖陪培养皿表面。(1) As in Table 1, prepare silk protein solution, glycerol solution, and calcium chloride solution respectively, and mix the above solutions according to the volume in Table 1 after the configuration is completed. Take 3.5mL of the mixed solution and pour it into a petri dish with a diameter of 6mm, so that the solution completely covers the surface of the petri dish.

(2)将浇筑了混合溶液的培养皿敞口置于室温下干燥12小时,然后将干燥后的培养皿置于真空干燥箱在室温下继续干燥2-4小时,制备得到各丝蛋白薄膜(15%甘油+5%氯化钙;15%甘油+10%氯化钙;20%甘油+5%氯化钙;20%甘油+10%氯化钙)。(2) placing the open mouth of the culture dish on which the mixed solution was poured to be dried at room temperature for 12 hours, and then placing the dried culture dish in a vacuum drying oven to continue drying at room temperature for 2-4 hours to prepare each silk protein film ( 15% glycerol + 5% calcium chloride; 15% glycerol + 10% calcium chloride; 20% glycerol + 5% calcium chloride; 20% glycerol + 10% calcium chloride).

制备得到的丝蛋白薄膜(20%甘油+10%氯化钙)的照片如图1中所示。The photo of the prepared silk protein film (20% glycerol + 10% calcium chloride) is shown in FIG. 1 .

表1Table 1

在以上表1中,*表示占体系中除水以外所有物质总质量的质量分数。In Table 1 above, * represents the mass fraction of the total mass of all substances in the system except water.

对比例1-5Comparative Examples 1-5

为了与本发明制备的可降解超韧丝蛋白薄膜的性能形成对比,按照以下方法制备未使用塑化剂和盐改性的丝蛋白薄膜以及使用单一塑化剂或单一盐改性的丝蛋白薄膜:In order to compare with the performance of the degradable super fibroin film prepared by the present invention, the silk protein film not modified with plasticizer and salt and the silk protein film modified with single plasticizer or single salt were prepared according to the following methods :

(1)如表2中,分别配置丝蛋白溶液、甘油溶液、氯化钙溶液,配置完毕后将上述各溶液按照表2中的体积混合均匀。分别取3.5mL混合溶液浇筑于直径为6mm的培养皿中,使溶液完全覆盖培养皿表面。(1) As in Table 2, configure silk protein solution, glycerol solution, and calcium chloride solution respectively, and mix the above solutions according to the volume in Table 2 after the configuration is completed. Take 3.5 mL of the mixed solution and pour it into a petri dish with a diameter of 6 mm, so that the solution completely covers the surface of the petri dish.

(2)将浇筑了混合溶液的培养皿敞口置于室温下干燥12小时,然后将干燥后的培养皿置于真空干燥箱在室温下继续干燥2-4小时,制备得到各丝蛋白薄膜(纯丝薄膜;15%甘油;20%甘油;5%氯化钙;10%氯化钙)。(2) placing the open mouth of the culture dish on which the mixed solution was poured to be dried at room temperature for 12 hours, and then placing the dried culture dish in a vacuum drying oven to continue drying at room temperature for 2-4 hours to prepare each silk protein film ( Pure silk film; 15% glycerol; 20% glycerol; 5% calcium chloride; 10% calcium chloride).

表2Table 2

在以上表2中,*表示占体系中除水以外所有物质总质量的质量分数。In Table 2 above, * represents the mass fraction of the total mass of all substances in the system except water.

测试实施例1:Test Example 1:

实施例1-4及对比例1-5中制备的改性丝蛋白薄膜使用配备衰减全反射附件的红外光谱仪对来进行红外吸收光谱表征。将薄膜样品置于金刚石平板的凹槽内采集信号,对于每个样品均扫描64次,分辨率为4cm-1,波数范围为400cm-1到4000cm-1。红外吸收光谱图如图2和10所示。The modified silk protein films prepared in Examples 1-4 and Comparative Examples 1-5 were characterized by infrared absorption spectroscopy using an infrared spectrometer pair equipped with an attenuated total reflection accessory. The thin film samples were placed in the grooves of the diamond plate to collect signals, and each sample was scanned 64 times with a resolution of 4 cm-1 and a wavenumber range of 400 cm-1 to 4000 cm-1 . Infrared absorption spectra are shown in Figures 2 and 10.

测试实施例2:Test Example 2:

实施例1-4及对比例1-5的热性能通过差示扫描量热法来表征。将样品切成小片后装入40μL的铝坩埚中,每个样品的重量均为3-7mg。差示扫描量热法测量程序由两次扫描组成,加热速率为20℃/min。第一次扫描从20加热到200℃以去除薄膜中的游离水,第二次扫描从-30加热到270℃以测量不同薄膜的玻璃化转变温度。差示扫描量热法表征结果如图3和11所示。The thermal properties of Examples 1-4 and Comparative Examples 1-5 were characterized by differential scanning calorimetry. The samples were cut into small pieces and loaded into 40 μL aluminum crucibles, each weighing 3-7 mg. The differential scanning calorimetry measurement procedure consisted of two scans with a heating rate of 20°C/min. The first scan was heated from 20 to 200 °C to remove free water in the films, and the second scan was heated from −30 to 270 °C to measure the glass transition temperature of the different films. Differential scanning calorimetry characterization results are shown in Figures 3 and 11.

测试实施例3:Test Example 3:

实施例1-4及对比例1-5的机械性能通过配备50N称重传感器的万能力学试验机来测试。根据ASTM标准将样品切成哑铃形条,然后将薄膜加载到机器的夹具上。对于每个测试,所有样品的拉伸速率为20mm/min,直到样品断裂后停止拉伸,每组薄膜至少测试4个重复样。每个样品的横截面积通过膜厚乘以其标距宽度来计算。拉伸应力和应变分别基于原始横截面积和长度来计算。杨氏模量、断裂伸长率和断裂强度由拉伸应力和应变确定,根据横截面积和长度变化绘制。机械性能表征结果如图4和12所示。The mechanical properties of Examples 1-4 and Comparative Examples 1-5 were tested by a universal chemical testing machine equipped with a 50N load cell. The samples were cut into dumbbell-shaped strips according to ASTM standards, and the film was loaded onto the machine's grips. For each test, all samples were stretched at a rate of 20 mm/min until the stretch stopped after the sample broke, and at least 4 replicates were tested for each set of films. The cross-sectional area of each sample was calculated by multiplying the film thickness by its gauge width. Tensile stress and strain are calculated based on the original cross-sectional area and length, respectively. Young's modulus, elongation at break and strength at break are determined from tensile stress and strain, plotted against changes in cross-sectional area and length. The mechanical property characterization results are shown in Figures 4 and 12.

测试实施例4:Test Example 4:

实施例1-4及对比例1-5的水溶性通过紫外分光光度法来测试。将不同组的样品剪成10mm×10mm的方块,分别浸泡在20mL的去离子水中。24小时后,分别取所有样品的上清液,在280nm下测量溶液的紫外吸光度,通过不同的吸光度可以确定样品溶解在水中的丝蛋白含量,最终计算出不同样品的水溶性。水溶性测试结果如图5和13所示。The water solubility of Examples 1-4 and Comparative Examples 1-5 was tested by UV spectrophotometry. The samples of different groups were cut into squares of 10 mm × 10 mm and immersed in 20 mL of deionized water respectively. After 24 hours, the supernatants of all samples were taken, and the UV absorbance of the solution was measured at 280 nm. The content of silk protein dissolved in water can be determined by different absorbances, and the water solubility of different samples was finally calculated. The water solubility test results are shown in Figures 5 and 13.

测试实施例5:Test Example 5:

实施例3得到的薄膜的降解性能通过在不同酶溶液(蛋白酶ⅩⅣ,胶原酶和α-糜蛋白酶)中的降解表现来表征。将样品剪成10mm×10mm的方块,分别浸泡在2mL的不同种酶溶液内。分别在第1天和第3天称量剩余的样品质量,可计算样品在不同酶溶液中的降解率。酶降解测试结果如图6所示。The degradation properties of the films obtained in Example 3 were characterized by their degradation performance in different enzyme solutions (Protease XIV, collagenase and α-chymotrypsin). The samples were cut into 10mm×10mm squares and immersed in 2mL of different enzyme solutions respectively. The remaining sample mass was weighed on

结果分析:从图2和图3中的数据,可以看出,随着添加甘油比例的上升,可降解超韧丝蛋白薄膜中的β-折叠含量也随之上升,并且丝蛋白分子的玻璃化转变温度降低。Analysis of the results: From the data in Figure 2 and Figure 3, it can be seen that with the increase of the proportion of glycerol added, the β-sheet content in the degradable super tenacity fibroin film also increases, and the vitrification of silk protein molecules increases. The transition temperature decreases.

从图4中的数据可以看出,随着添加甘油和氯化钙比例的上升,可降解超韧丝蛋白薄膜的断裂伸长率(可拉伸性)随之增加。From the data in Figure 4, it can be seen that the elongation at break (stretchability) of the degradable super tenacity fibroin film increases with the increase of the ratio of glycerol and calcium chloride added.

从图5中的数据可以看出,当氯化钙比例达到或大于10%时,可降解超韧丝蛋白薄膜的水溶性增加。From the data in Figure 5, it can be seen that when the ratio of calcium chloride reaches or exceeds 10%, the water solubility of the degradable superfibroin film increases.

从图6中的数据可以看出,所制备得到的可降解超韧丝蛋白薄膜具有很好的酶降解性。It can be seen from the data in Fig. 6 that the prepared degradable super tenasin film has good enzymatic degradation.

另外,从图4的A和图12的A可以看出,与实施例1-4中制备的可降解超韧丝蛋白薄膜相比,未使用塑化剂和盐改性的丝蛋白薄膜具有较差的可拉伸性。In addition, it can be seen from A of FIG. 4 and A of FIG. 12 that compared with the degradable super tenacity fibroin films prepared in Examples 1-4, the silk fibroin films without plasticizer and salt modification have better Poor stretchability.

从图4和12以及图5和13可以看出,与实施例1-4中制备的可降解超韧丝蛋白薄膜相比,仅使用塑化剂改性的丝蛋白薄膜具有较差的水溶性和韧性。It can be seen from Figures 4 and 12 and Figures 5 and 13 that, compared with the degradable super tenacity fibroin films prepared in Examples 1-4, the silk fibroin films modified only with plasticizers have poor water solubility and toughness.

从图4和12可以看出,与实施例1-4中制备的可降解超韧丝蛋白薄膜相比,仅使用盐改性的丝蛋白薄膜具有较差的可拉伸性。It can be seen from Figures 4 and 12 that, compared with the degradable super tenacity fibroin films prepared in Examples 1-4, the fibroin films modified only with salt have poor stretchability.

通过以上该数据证明通过甘油和氯化钙的协同调节作用,可以制备得到具有力学性能可调的可降解超韧丝蛋白薄膜,特别当添加甘油比例为20%,氯化钙比例为10%时,可以制备得到一种新型的具有优良水溶性的超韧丝蛋白薄膜,该薄膜在未来可植入医疗器件等领域具有很好的应用前景。The above data proves that through the synergistic regulation effect of glycerol and calcium chloride, degradable super tenacity fibroin films with adjustable mechanical properties can be prepared, especially when the proportion of glycerol is 20% and the proportion of calcium chloride is 10%. , a new type of super tenasin film with excellent water solubility can be prepared, which has good application prospects in the fields of implantable medical devices in the future.

实施例5Example 5

将实施例3中所配置得到的低浓度丝蛋白/甘油/氯化钙混合水溶液进行浓缩以制备得到高浓度混合丝蛋白水溶液。经浓缩后的丝蛋白水溶液溶液进行离心提纯后可以在低温下稳定保存,浓度为40%。图7为高浓度丝蛋白/甘油/氯化钙浓缩液的图。The low-concentration silk protein/glycerol/calcium chloride mixed aqueous solution prepared in Example 3 was concentrated to prepare a high-concentration mixed silk protein aqueous solution. The concentrated silk protein aqueous solution can be stably stored at low temperature after being purified by centrifugation, and the concentration is 40%. Figure 7 is a graph of a high concentration silk protein/glycerol/calcium chloride concentrate.

实施例6Example 6

将实施例5中得到的高浓度丝蛋白/甘油/氯化钙浓缩液加入5mL注射器进行干法纺丝,注射器端口与不锈钢针头相连,针头直径为0.6mm。通过注射泵控制溶液流速,速度为40μL/h。收集装置直径为12mm,转速为140rpm。针尖到收集装置之间的距离为150mm。实验过程中温度为27℃,湿度为40%。最终制得纤维直径为7.0±1.4μm。图8为利用高浓度丝蛋白/甘油/氯化钙浓缩液进行干法纺丝所得到的纤维图,所得纤维的力学性能测试曲线如图9所示,结果显示所制备的纤维具有很强的韧性。The high-concentration silk protein/glycerol/calcium chloride concentrate obtained in Example 5 was added to a 5 mL syringe for dry spinning, and the syringe port was connected to a stainless steel needle with a diameter of 0.6 mm. The solution flow rate was controlled by a syringe pump at a rate of 40 μL/h. The collecting device has a diameter of 12 mm and a rotational speed of 140 rpm. The distance from the needle tip to the collection device was 150 mm. During the experiment, the temperature was 27°C and the humidity was 40%. The final fiber diameter was 7.0±1.4 μm. Figure 8 is a diagram of the fiber obtained by dry spinning using high-concentration silk protein/glycerol/calcium chloride concentrate. The mechanical property test curve of the obtained fiber is shown in Figure 9. The results show that the prepared fiber has a strong toughness.

Claims (15)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110891655.2ACN113527895B (en) | 2021-08-04 | 2021-08-04 | Degradable super-tough silk protein-based material and preparation method and application thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110891655.2ACN113527895B (en) | 2021-08-04 | 2021-08-04 | Degradable super-tough silk protein-based material and preparation method and application thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN113527895A CN113527895A (en) | 2021-10-22 |

| CN113527895Btrue CN113527895B (en) | 2022-07-29 |

Family

ID=78090369

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110891655.2AActiveCN113527895B (en) | 2021-08-04 | 2021-08-04 | Degradable super-tough silk protein-based material and preparation method and application thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113527895B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115845115A (en)* | 2023-03-03 | 2023-03-28 | 西湖大学 | Silk protein-based double-layer material and preparation method and application thereof |

| CN116350848A (en)* | 2023-03-31 | 2023-06-30 | 鹏拓生物科技(杭州)有限公司 | Silk protein film, preparation and use methods and application |

| CN116925396A (en)* | 2023-07-19 | 2023-10-24 | 西湖大学 | Silk protein-based ink and its application in 3D printing to prepare tissue engineering scaffolds |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2005103158A1 (en)* | 2004-04-20 | 2008-03-13 | 日本新薬株式会社 | Silk fibroin film |

| CN101857729A (en)* | 2010-06-02 | 2010-10-13 | 苏州大学 | A kind of insoluble silk fibroin porous material and preparation method thereof |

| CN101967282A (en)* | 2010-09-21 | 2011-02-09 | 苏州大学 | Sparingly water-soluble transparent silk fibroin film and preparation method thereof |

| CN102271724A (en)* | 2008-10-09 | 2011-12-07 | 塔夫茨大学信托人 | Modified silk film containing glycerin |

| CN103289107A (en)* | 2013-05-28 | 2013-09-11 | 苏州丝美特生物技术有限公司 | Preparation method and application of injectable silk fibroin in-situ gel |

| CN103554520A (en)* | 2013-11-15 | 2014-02-05 | 苏州大学 | Ion-induced method for preparing tussah silk fibroin nanoparticles |

| CN105885070A (en)* | 2016-05-04 | 2016-08-24 | 南京师范大学 | Preparation method of regenerated silk fibroin membrane |

| AU2017243878A1 (en)* | 2016-03-31 | 2018-09-27 | Deakin University | Improved silk fibroin glycerol membranes |

| JP2019031605A (en)* | 2017-08-07 | 2019-02-28 | 株式会社日本触媒 | Fibroin composition |

| CN109851842A (en)* | 2019-01-31 | 2019-06-07 | 南通纺织丝绸产业技术研究院 | High-intensitive fibroin albumen aeroge and preparation method thereof |

| CN111635565A (en)* | 2020-06-03 | 2020-09-08 | 杭州电子科技大学 | A kind of fibroin functional layer for improving allergy of mask and preparation method thereof |

| CN112194904A (en)* | 2020-08-31 | 2021-01-08 | 盐城工学院 | Preparation method of fibroin glass |

| CN112266490A (en)* | 2020-10-29 | 2021-01-26 | 之江实验室 | Method for preparing fibroin film by wet film coating method |

| CN112940293A (en)* | 2021-02-25 | 2021-06-11 | 中国科学院上海微系统与信息技术研究所 | Preparation method of hydrogel based on biological protein |

Family Cites Families (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN106317906A (en)* | 2015-06-19 | 2017-01-11 | 大连瑞贤达塑胶有限公司 | Production method of gelatin protein-based degradable plastic film |

| WO2018081805A1 (en)* | 2016-10-31 | 2018-05-03 | Sofregen Medical, Inc. | Compositions comprising low molecular weight silk fibroin fragments and plasticizers |

- 2021

- 2021-08-04CNCN202110891655.2Apatent/CN113527895B/enactiveActive

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPWO2005103158A1 (en)* | 2004-04-20 | 2008-03-13 | 日本新薬株式会社 | Silk fibroin film |

| CN102271724A (en)* | 2008-10-09 | 2011-12-07 | 塔夫茨大学信托人 | Modified silk film containing glycerin |

| CN101857729A (en)* | 2010-06-02 | 2010-10-13 | 苏州大学 | A kind of insoluble silk fibroin porous material and preparation method thereof |

| CN101967282A (en)* | 2010-09-21 | 2011-02-09 | 苏州大学 | Sparingly water-soluble transparent silk fibroin film and preparation method thereof |

| CN103289107A (en)* | 2013-05-28 | 2013-09-11 | 苏州丝美特生物技术有限公司 | Preparation method and application of injectable silk fibroin in-situ gel |

| CN103554520A (en)* | 2013-11-15 | 2014-02-05 | 苏州大学 | Ion-induced method for preparing tussah silk fibroin nanoparticles |

| AU2017243878A1 (en)* | 2016-03-31 | 2018-09-27 | Deakin University | Improved silk fibroin glycerol membranes |

| CN105885070A (en)* | 2016-05-04 | 2016-08-24 | 南京师范大学 | Preparation method of regenerated silk fibroin membrane |

| JP2019031605A (en)* | 2017-08-07 | 2019-02-28 | 株式会社日本触媒 | Fibroin composition |

| CN109851842A (en)* | 2019-01-31 | 2019-06-07 | 南通纺织丝绸产业技术研究院 | High-intensitive fibroin albumen aeroge and preparation method thereof |

| CN111635565A (en)* | 2020-06-03 | 2020-09-08 | 杭州电子科技大学 | A kind of fibroin functional layer for improving allergy of mask and preparation method thereof |

| CN112194904A (en)* | 2020-08-31 | 2021-01-08 | 盐城工学院 | Preparation method of fibroin glass |

| CN112266490A (en)* | 2020-10-29 | 2021-01-26 | 之江实验室 | Method for preparing fibroin film by wet film coating method |

| CN112940293A (en)* | 2021-02-25 | 2021-06-11 | 中国科学院上海微系统与信息技术研究所 | Preparation method of hydrogel based on biological protein |

Non-Patent Citations (1)

| Title |

|---|

| 甘油对丝素蛋白膜水溶性和结构的影响;罗敏清等;《高等学校化学学报》;20111010(第10期);全文* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN113527895A (en) | 2021-10-22 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN113527895B (en) | Degradable super-tough silk protein-based material and preparation method and application thereof | |

| CN105237925B (en) | Nanometer bacteria cellulose polyvinyl alcohol polyglycol porous composite aquogel | |

| Shang et al. | Physical properties of silk fibroin/cellulose blend films regenerated from the hydrophilic ionic liquid | |

| Lu et al. | Water-insoluble silk films with silk I structure | |

| Shen et al. | Dissolution behavior of silk fibroin in a low concentration CaCl2-methanol solvent: From morphology to nanostructure | |

| CN112759774B (en) | Mechanically-enhanced gelatin frozen hydrogel and preparation method and application thereof | |

| JP5968447B2 (en) | Chitosan and / or chitin complex with enhanced physical properties and uses thereof | |

| EP3112396A1 (en) | Preparation method and use of sericin hydrogel | |

| Ribeiro et al. | The role of dialysis and freezing on structural conformation, thermal properties and morphology of silk fibroin hydrogels | |

| Putthanarat et al. | Effect of processing temperature on the morphology of silk membranes | |

| CN110041536B (en) | Functional sericin hydrogel and preparation method and application thereof | |

| Ming et al. | Novel two-step method to form silk fibroin fibrous hydrogel | |

| CN110818921A (en) | Rapidly-curable double-crosslinked hydrogel and preparation method and application thereof | |

| Cai et al. | Ultrasound regulated flexible protein materials: Fabrication, structure and physical-biological properties | |

| CN110343169A (en) | A kind of modified I-type collagen and method of modifying and collagen gel using modification I-type collagen preparation | |

| CN114835920B (en) | Recombinant collagen-polyglutamate hydrogel and preparation method thereof | |

| CN105797216A (en) | Method for preparing porous material from silk fibroin and carboxymethyl chitosan | |

| Wang et al. | Flexible silk fibroin films modified by genipin and glycerol | |

| Luo et al. | Preparation and properties of nanometer silk fibroin peptide/polyvinyl alcohol blend films for cell growth | |

| TWI538935B (en) | Composite material | |

| CN113244454A (en) | Collagen-reinforced scaffold based on cellulose nanowhiskers and preparation method thereof | |

| Yang et al. | Modification of collagen-chitosan membrane by oxidation sodium alginate and in vivo/in vitro evaluation for wound dressing application | |

| CN103861149A (en) | Durably-transparent silk fibroin film and preparation method thereof | |

| CN110698694A (en) | High mechanical strength sericin hydrogel and its preparation method and application | |

| Yoshioka et al. | Fabrication scheme for obtaining transparent, flexible, and water-insoluble silk films from apparently dissolved silk-gland fibroin of Bombyx mori silkworm |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |