CN113431535B - Method for carbon sequestration by using in-situ pyrolyzed organic ore bed - Google Patents

Method for carbon sequestration by using in-situ pyrolyzed organic ore bedDownload PDFInfo

- Publication number

- CN113431535B CN113431535BCN202110920648.0ACN202110920648ACN113431535BCN 113431535 BCN113431535 BCN 113431535BCN 202110920648 ACN202110920648 ACN 202110920648ACN 113431535 BCN113431535 BCN 113431535B

- Authority

- CN

- China

- Prior art keywords

- well

- situ

- temperature

- pressure

- injection

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000011065in-situ storageMethods0.000titleclaimsabstractdescription32

- 229910052799carbonInorganic materials0.000titleclaimsabstractdescription24

- 238000000034methodMethods0.000titleclaimsabstractdescription24

- 230000009919sequestrationEffects0.000titleclaimsabstractdescription24

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical compound[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000titleclaimsabstractdescription23

- CURLTUGMZLYLDI-UHFFFAOYSA-NCarbon dioxideChemical compoundO=C=OCURLTUGMZLYLDI-UHFFFAOYSA-N0.000claimsabstractdescription74

- 229910002092carbon dioxideInorganic materials0.000claimsabstractdescription39

- 239000001569carbon dioxideSubstances0.000claimsabstractdescription37

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription32

- 238000000197pyrolysisMethods0.000claimsabstractdescription25

- 229910001425magnesium ionInorganic materials0.000claimsabstractdescription16

- 229910052500inorganic mineralInorganic materials0.000claimsabstractdescription13

- 239000011707mineralSubstances0.000claimsabstractdescription13

- OYPRJOBELJOOCE-UHFFFAOYSA-NCalciumChemical compound[Ca]OYPRJOBELJOOCE-UHFFFAOYSA-N0.000claimsabstractdescription12

- JLVVSXFLKOJNIY-UHFFFAOYSA-NMagnesium ionChemical compound[Mg+2]JLVVSXFLKOJNIY-UHFFFAOYSA-N0.000claimsabstractdescription12

- 239000011575calciumSubstances0.000claimsabstractdescription12

- 229910001424calcium ionInorganic materials0.000claimsabstractdescription12

- 238000006243chemical reactionMethods0.000claimsabstractdescription7

- 238000002347injectionMethods0.000claimsdescription36

- 239000007924injectionSubstances0.000claimsdescription36

- 239000012530fluidSubstances0.000claimsdescription14

- 238000004519manufacturing processMethods0.000claimsdescription12

- 239000000243solutionSubstances0.000claimsdescription11

- 239000007788liquidSubstances0.000claimsdescription5

- IJGRMHOSHXDMSA-UHFFFAOYSA-NAtomic nitrogenChemical compoundN#NIJGRMHOSHXDMSA-UHFFFAOYSA-N0.000claimsdescription4

- ZFXVRMSLJDYJCH-UHFFFAOYSA-Ncalcium magnesiumChemical compound[Mg].[Ca]ZFXVRMSLJDYJCH-UHFFFAOYSA-N0.000claimsdescription4

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000claimsdescription2

- 230000015572biosynthetic processEffects0.000claimsdescription2

- 229910052757nitrogenInorganic materials0.000claimsdescription2

- 239000001301oxygenSubstances0.000claimsdescription2

- 229910052760oxygenInorganic materials0.000claimsdescription2

- 238000012544monitoring processMethods0.000claims2

- 238000011084recoveryMethods0.000claims1

- 238000003860storageMethods0.000abstractdescription5

- 239000000126substanceSubstances0.000abstractdescription3

- 229910021645metal ionInorganic materials0.000abstractdescription2

- 239000011148porous materialSubstances0.000abstractdescription2

- 230000009977dual effectEffects0.000abstract1

- 230000002093peripheral effectEffects0.000description26

- 239000007789gasSubstances0.000description9

- 238000005065miningMethods0.000description5

- 238000006073displacement reactionMethods0.000description4

- 230000009286beneficial effectEffects0.000description2

- 238000009933burialMethods0.000description2

- 230000007423decreaseEffects0.000description2

- 238000010586diagramMethods0.000description2

- 239000004058oil shaleSubstances0.000description2

- 239000011435rockSubstances0.000description2

- 239000003245coalSubstances0.000description1

- 230000007812deficiencyEffects0.000description1

- 230000007613environmental effectEffects0.000description1

- 239000002803fossil fuelSubstances0.000description1

- 239000005431greenhouse gasSubstances0.000description1

- 230000014759maintenance of locationEffects0.000description1

- 230000000717retained effectEffects0.000description1

- 238000006467substitution reactionMethods0.000description1

- 231100000331toxicToxicity0.000description1

- 230000002588toxic effectEffects0.000description1

- 239000002918waste heatSubstances0.000description1

Images

Classifications

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B43/00—Methods or apparatus for obtaining oil, gas, water, soluble or meltable materials or a slurry of minerals from wells

- E21B43/16—Enhanced recovery methods for obtaining hydrocarbons

- E21B43/164—Injecting CO2 or carbonated water

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B43/00—Methods or apparatus for obtaining oil, gas, water, soluble or meltable materials or a slurry of minerals from wells

- E21B43/16—Enhanced recovery methods for obtaining hydrocarbons

- E21B43/20—Displacing by water

- E—FIXED CONSTRUCTIONS

- E21—EARTH OR ROCK DRILLING; MINING

- E21B—EARTH OR ROCK DRILLING; OBTAINING OIL, GAS, WATER, SOLUBLE OR MELTABLE MATERIALS OR A SLURRY OF MINERALS FROM WELLS

- E21B43/00—Methods or apparatus for obtaining oil, gas, water, soluble or meltable materials or a slurry of minerals from wells

- E21B43/30—Specific pattern of wells, e.g. optimising the spacing of wells

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02P—CLIMATE CHANGE MITIGATION TECHNOLOGIES IN THE PRODUCTION OR PROCESSING OF GOODS

- Y02P90/00—Enabling technologies with a potential contribution to greenhouse gas [GHG] emissions mitigation

- Y02P90/70—Combining sequestration of CO2 and exploitation of hydrocarbons by injecting CO2 or carbonated water in oil wells

Landscapes

- Geology (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Mining & Mineral Resources (AREA)

- Environmental & Geological Engineering (AREA)

- Fluid Mechanics (AREA)

- Physics & Mathematics (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Geochemistry & Mineralogy (AREA)

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Physical Or Chemical Processes And Apparatus (AREA)

- Treating Waste Gases (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及二氧化碳地质封存和捕捉技术领域,具体为一种利用原位热解后的有机矿层进行碳封存的方法。The invention relates to the technical field of carbon dioxide geological sequestration and capture, in particular to a method for carbon sequestration by using an organic mineral layer after in-situ pyrolysis.

背景技术Background technique

煤炭等化石能源燃料的燃烧会产生大量的二氧化碳温室气体以及其它有毒有害气体,造成十分严峻的环境和生态问题。将大气中的二氧化碳高效永久封存在地下是“双碳”背景和要求下行之有效的方法。通过原位注热开采的方式可将地下的有机岩石热解形成油气产物排采到地面,而热解后的矿层依然留存于地下,起到支撑覆岩和控制地表变形的作用。充分利用巨大储量的地下资源进行碳捕捉和封存可以大量减少大气中二氧化碳的含量。The burning of fossil fuels such as coal will produce a large amount of carbon dioxide, greenhouse gas and other toxic and harmful gases, causing very serious environmental and ecological problems. Efficiently and permanently sequestering atmospheric carbon dioxide underground is an effective approach to the "two-carbon" background and requirements. Through in-situ heat injection mining, the underground organic rock can be pyrolyzed to form oil and gas products, and the oil and gas products can be discharged to the surface, while the ore bed after pyrolysis still remains underground, which plays the role of supporting the overlying rock and controlling the surface deformation. Leveraging vast underground resources for carbon capture and sequestration can substantially reduce atmospheric carbon dioxide levels.

发明内容SUMMARY OF THE INVENTION

本发明克服了现有技术的不足,提出一种利用原位热解后的有机矿层进行碳封存的方法;是一种在有机矿层原位高效热解的基础上,充分利用热解后矿层内部大量的孔裂隙空间进行碳的物理封存,以及利用热解后矿层内部大量的游离金属离子进行碳的化学封存,从而对二氧化碳进行高效稳定封存的方法。解决目前二氧化碳排放过量的问题,使之可以高效稳定封存在地下。The invention overcomes the deficiencies of the prior art, and proposes a method for carbon sequestration by using the organic ore layer after in-situ pyrolysis; it is a method based on the in-situ efficient pyrolysis of the organic ore layer, and fully utilizes the interior of the ore layer after pyrolysis. A large number of pores and fissures are used for physical storage of carbon, and a large number of free metal ions in the ore layer after pyrolysis are used for chemical storage of carbon, so as to efficiently and stably store carbon dioxide. Solve the current problem of excessive carbon dioxide emissions, so that it can be efficiently and stably stored underground.

为了达到上述目的,本发明是通过如下技术方案实现的。In order to achieve the above objects, the present invention is achieved through the following technical solutions.

一种利用原位热解后的有机矿层进行碳封存的方法,包括以下步骤:A method for carbon sequestration using an organic mineral layer after in-situ pyrolysis, comprising the following steps:

a)从地面至地下的有机矿层之间设置有注入井和开采井;在原位热解有机矿层完成后,在注入井或开采井中注入常温水,常温水经过高温矿层换热,换热过程中矿层内形成滞留水用于溶解钙镁离子。a) There are injection wells and mining wells between the organic ore layers from the ground to the underground; after the in-situ pyrolysis of the organic ore layers is completed, normal temperature water is injected into the injection wells or mining wells, and the normal temperature water passes through the high temperature ore layers for heat exchange, and the process of heat exchange Retained water is formed in the middle ore layer for dissolving calcium and magnesium ions.

b)关闭开采井,向注入井注入CO2,使CO2和钙镁离子溶液充分发生化学反应。b) Close the production well and inject CO2 into the injection well, so that the CO2 and the calcium and magnesium ion solution fully react chemically.

c)开启开采井,向注入井注入高温流体,监测各个井筒内的温度,当矿层温度达到常温时,关闭开采井,向注入井中注入高压CO2,使多孔高渗透矿层内部充满液态二氧化碳;所述高温流体的温度为150-200℃;所述高压CO2的压力高于地层压力。c) Open the mining well, inject high-temperature fluid into the injection well, monitor the temperature in each wellbore, when the temperature of the ore layer reaches normal temperature, close the mining well, and inject high-pressure CO2 into the injection well, so that the porous high-permeability ore layer is filled with liquid carbon dioxide; The temperature of the high temperature fluid is 150-200°C; the pressure of the high pressure CO2 is higher than the formation pressure.

d)封固所有井管,使得二氧化碳封存在地下。d) Seal all well pipes so that carbon dioxide is sequestered in the ground.

优选的,步骤b中,当排采口监测水蒸汽的温度<150℃时关闭开采井。Preferably, in step b, the production well is closed when the temperature of the monitored water vapor at the discharge outlet is less than 150°C.

优选的,步骤b中,注入井中注入的CO2压力为0.5MPa~1MPa。Preferably, in step b, the pressure of CO2 injected into the injection well is 0.5 MPa to 1 MPa.

优选的,所述的高温流体是高温空气、高温氮气、高温氧气其中一种或任意组合。Preferably, the high temperature fluid is one or any combination of high temperature air, high temperature nitrogen, and high temperature oxygen.

优选的,重复步骤b中所述的向注入井注入CO2,直到开采井的压力不再变化,以使二氧化碳和钙镁离子溶液的化学反应完全。Preferably, the injection of CO2 into the injection well described in step b is repeated until the pressure of the production well no longer changes, so that the chemical reaction between the carbon dioxide and the calcium-magnesium ion solution is completed.

优选的,步骤c中,当开采井井口不再有水蒸汽排出时,停止高温流体的注入工作。Preferably, in step c, when no water vapor is discharged from the wellhead of the production well, the injection of the high-temperature fluid is stopped.

优选的,步骤d中,通过高压注浆方式封固所有井管。Preferably, in step d, all well pipes are sealed by high pressure grouting.

优选的,注浆压力高于高压CO2的注入压力。Preferably, the grouting pressure is higher than the injection pressure of high pressure CO2 .

优选的,所述注入井位于中心,围绕注入井外围开设若干开采井。Preferably, the injection well is located in the center, and several production wells are opened around the periphery of the injection well.

优选的,原位热解后的有机矿层的深度≥300m。Preferably, the depth of the organic mineral layer after in-situ pyrolysis is greater than or equal to 300m.

本发明相对于现有技术所产生的有益效果为:The beneficial effects that the present invention produces relative to the prior art are:

1、在原位热解后的矿层中注入水既能利用矿层的余热,高效回收能量,而且可以使得矿层内部的钙镁离子溶解到水中,为二氧化碳与钙镁离子的反应提供良好条件。1. Injecting water into the ore layer after in-situ pyrolysis can not only utilize the waste heat of the ore layer, recover energy efficiently, but also dissolve the calcium and magnesium ions inside the ore layer into the water, providing good conditions for the reaction of carbon dioxide and calcium and magnesium ions.

2、300m以下深度的矿层所受压力超过了7.5MPa,这样可以保证封存在矿层内部的常温二氧化碳为液态。2. The pressure of the ore seam below 300m exceeds 7.5MPa, which can ensure that the normal temperature carbon dioxide sealed in the ore seam is liquid.

3、充分利用原位热解后无法回收的矿层进行碳封存,可以极大降低大气中的二氧化碳含量。3. Make full use of the unrecoverable mineral layers after in-situ pyrolysis for carbon sequestration, which can greatly reduce the carbon dioxide content in the atmosphere.

附图说明Description of drawings

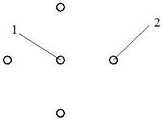

图1是实施例1和2中原位热解有机矿层的群井布置方式示意图;Fig. 1 is a schematic diagram of the arrangement of wells in groups of in-situ pyrolysis organic ore layers in Examples 1 and 2;

图2是实施例1和2中间井和外围井之间原位热解后的矿层剖面示意图;Fig. 2 is the ore bed sectional schematic diagram after the in-situ pyrolysis between the middle well and the peripheral well of

图中,1为中间井;2为外围井;3为原位热解后的矿层。In the figure, 1 is the middle well; 2 is the peripheral well; 3 is the ore bed after in-situ pyrolysis.

具体实施方式Detailed ways

为了使本发明所要解决的技术问题、技术方案及有益效果更加清楚明白,结合实施例和附图,对本发明进行进一步详细说明。应当理解,此处所描述的具体实施例仅仅用以解释本发明,并不用于限定本发明。下面结合实施例及附图详细说明本发明的技术方案,但保护范围不被此限制。In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail with reference to the embodiments and the accompanying drawings. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention. The technical solutions of the present invention will be described in detail below with reference to the embodiments and the accompanying drawings, but the protection scope is not limited by this.

实施例1Example 1

当油页岩矿层的厚度在5m,埋深为300m。一种利用原位热解后的有机矿层进行碳封存的方法,其具体步骤如下:When the thickness of the oil shale layer is 5m, the burial depth is 300m. A method for carbon sequestration using an organic mineral layer after in-situ pyrolysis, the specific steps of which are as follows:

(1)在原位热解有机矿层工作完成后,在中间井1中注入常温水,其余的外围井2排采,常温水经过高温矿层换热后温度迅速升高形成水蒸汽,在外围井2的排采口监测水蒸汽的温度变化。(1) After the in-situ pyrolysis of the organic ore layer is completed, normal temperature water is injected into the

(2)在常温水换热过程中矿层内部会形成大量的滞留水,可以充分溶解钙镁离子,当排采后监测到的水蒸汽温度达到150℃时关闭外围井2,在中间井1中注入0.5MPa的二氧化碳,监测外围井2底部的压力变化;待外围井2底部的压力与二氧化碳注入压力相同时,停止注气工作,使得二氧化碳和钙镁离子溶液充分发生化学反应。(2) During the process of water heat exchange at room temperature, a large amount of stagnant water will be formed inside the ore layer, which can fully dissolve calcium and magnesium ions. When the temperature of the water vapor monitored after drainage reaches 150 °C, the

(3)当外围井2的压力降低到常压状态,继续通过中间井1注入一定压力的二氧化碳,同样当外围井2底部的压力与二氧化碳注入压力相同时,停止注气;一直重复步骤(2)的工作,直到外围井2的压力不再变化,说明二氧化碳和钙镁离子溶液的化学反应已经完全。(3) When the pressure of the

(4)开启外围井2,在中间井1中注入150℃的高温压缩空气,在外围井2井口监测水蒸汽排量,随着水蒸汽排量的减少适当降低注入高温流体的温度,当外围井2井口不再有水蒸汽排出时,停止高温流体的注入工作。(4) Open the

(5)监测各个井筒内的温度,当矿层温度达到常温时,关闭外围井2,在中间井1中注入7.5MPa的二氧化碳,监测外围井2底部的压力变化;待外围井2底部的压力开始增大时,停止注气工作,使多孔高渗透矿层内部充满液态二氧化碳。(5) Monitor the temperature in each wellbore. When the temperature of the ore bed reaches normal temperature, close the

(6)通过高压注浆方式封固所有井管,注浆压力设置为8.0MPa,使得二氧化碳永久稳定的封存在地下。(6) All well pipes are sealed by high-pressure grouting, and the grouting pressure is set to 8.0MPa, so that carbon dioxide is permanently and stably sealed underground.

实施例2Example 2

当油页岩矿层的厚度在10m,埋深为600m。一种利用原位热解后的有机矿层进行碳封存的方法,其具体步骤如下:When the thickness of the oil shale layer is 10m, the burial depth is 600m. A method for carbon sequestration using an organic mineral layer after in-situ pyrolysis, the specific steps of which are as follows:

(1)在原位热解有机矿层工作完成后,在外围井2中注入常温水,中间井1排采,常温水经过高温矿层换热后温度迅速升高形成水蒸汽,在排采口监测水蒸汽的温度变化。(1) After the in-situ pyrolysis of the organic ore layer is completed, normal temperature water is injected into the

(2)在常温水换热过程中矿层内部会形成大量的滞留水,可以充分溶解钙镁离子,当排采后监测到的水蒸汽温度达到150℃时关闭外围井2,在中间井1中注入1.0MPa的二氧化碳,监测外围井2的压力变化;待外围井2底部的压力与二氧化碳注入压力相同时,停止注气工作,使得二氧化碳和钙镁离子溶液充分发生化学反应。(2) During the process of water heat exchange at room temperature, a large amount of stagnant water will be formed inside the ore layer, which can fully dissolve calcium and magnesium ions. When the temperature of the water vapor monitored after drainage reaches 150 °C, the

(3)当外围井2的压力降低到常压状态,继续通过中间井1注入一定压力的二氧化碳,同样当外围井2底部的压力与二氧化碳注入压力相同时,停止注气;一直重复步骤(2)的工作,直到外围井2的压力不再变化,说明二氧化碳和钙镁离子溶液的化学反应已经完全。(3) When the pressure of the

(4)开启外围井2,在中间井1中注入200℃的高温压缩空气,在外围井2井口监测水蒸汽排量,随着水蒸汽排量的减少适当降低注入高温流体的温度,当外围井2井口不再有水蒸汽排出时,停止高温流体的注入工作。(4) Open the

(5)监测各个井筒内的温度,当矿层温度达到常温时,关闭外围井2,在中间井1中注入15.0MPa的二氧化碳,监测外围井2底部的压力变化;待外围井2底部的压力开始增大时,停止注气工作,使多孔高渗透矿层内部充满液态二氧化碳。(5) Monitor the temperature in each wellbore. When the temperature of the ore layer reaches normal temperature, close the

(6)通过高压注浆方式封固所有井管,注浆压力设置为16.0MPa,使得二氧化碳永久稳定的封存在地下。(6) All well pipes are sealed by high-pressure grouting, and the grouting pressure is set to 16.0MPa, so that carbon dioxide is permanently and stably stored underground.

以上内容是结合具体的优选实施方式对本发明所做的进一步详细说明,不能认定本发明的具体实施方式仅限于此,对于本发明所属技术领域的普通技术人员来说,在不脱离本发明的前提下,还可以做出若干简单的推演或替换,都应当视为属于本发明由所提交的权利要求书确定专利保护范围。The above content is a further detailed description of the present invention in conjunction with the specific preferred embodiments, and it cannot be considered that the specific embodiments of the present invention are limited to this. Below, some simple deductions or substitutions can also be made, all of which should be regarded as belonging to the invention and the scope of patent protection determined by the submitted claims.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110920648.0ACN113431535B (en) | 2021-08-11 | 2021-08-11 | Method for carbon sequestration by using in-situ pyrolyzed organic ore bed |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110920648.0ACN113431535B (en) | 2021-08-11 | 2021-08-11 | Method for carbon sequestration by using in-situ pyrolyzed organic ore bed |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN113431535A CN113431535A (en) | 2021-09-24 |

| CN113431535Btrue CN113431535B (en) | 2022-04-15 |

Family

ID=77797545

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110920648.0AActiveCN113431535B (en) | 2021-08-11 | 2021-08-11 | Method for carbon sequestration by using in-situ pyrolyzed organic ore bed |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113431535B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113931605B (en)* | 2021-11-05 | 2022-08-02 | 西安科技大学 | A method for CO2 capture and storage after deep underground coal gasification |

| CN117052366B (en)* | 2023-10-11 | 2023-12-22 | 太原理工大学 | Method for in-situ exploitation and energy efficient utilization of deep organic rock ore layer |

| CN117819119B (en)* | 2024-03-06 | 2024-05-10 | 太原理工大学 | Continuous integrated device and method for trapping, sealing and separating underground rock stratum of flue gas |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103278615A (en)* | 2013-05-15 | 2013-09-04 | 太原理工大学 | Test method for geological storage of carbon dioxide coal seams |

| CN106761585A (en)* | 2017-02-25 | 2017-05-31 | 太原理工大学 | A kind of Abandoned golfs coal bed gas limit pumping method |

Family Cites Families (13)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20040200618A1 (en)* | 2002-12-04 | 2004-10-14 | Piekenbrock Eugene J. | Method of sequestering carbon dioxide while producing natural gas |

| WO2010039818A2 (en)* | 2008-10-02 | 2010-04-08 | American Shale Oil, Llc | Carbon sequestration in depleted oil shale deposits |

| US8616279B2 (en)* | 2009-02-23 | 2013-12-31 | Exxonmobil Upstream Research Company | Water treatment following shale oil production by in situ heating |

| EP2406562B1 (en)* | 2009-03-13 | 2014-12-17 | Regents of the University of Minnesota | Carbon dioxide-based geothermal energy generation systems and methods related thereto |

| WO2011050385A1 (en)* | 2009-10-27 | 2011-05-05 | Walter Doyle | Method of sequestration of carbon dioxide |

| CN102425870A (en)* | 2011-12-26 | 2012-04-25 | 中国科学院地质与地球物理研究所 | An integrated method for improving geothermal recharge rate and CO2 geological storage |

| CN103670338B (en)* | 2012-09-21 | 2016-06-15 | 新奥气化采煤有限公司 | A kind of coal bed gas and coal mining method altogether |

| CN103603639B (en)* | 2013-11-23 | 2016-01-20 | 中国地质大学(武汉) | A kind of exploitation of earth formation deep height bittern water and heat utilization system |

| CN106437653B (en)* | 2016-09-27 | 2018-07-20 | 大连理工大学 | A kind of hydrate exploitation and the carbon dioxide sequestration integrated processes of note quick lime and carbon dioxide process |

| CN106854984B (en)* | 2016-11-17 | 2019-03-05 | 大连理工大学 | A kind of gas hydrates method of replacing of combination injection hot sea water enhancing methane exploitation and carbon dioxide sequestration |

| US10569956B1 (en)* | 2018-08-14 | 2020-02-25 | Marvin S Keshner | Sequestration of carbon dioxide into underground structures |

| CN211847165U (en)* | 2020-03-24 | 2020-11-03 | 兰州理工大学 | A carbon dioxide formation storage system |

| CN113101789B (en)* | 2021-04-27 | 2022-04-19 | 珞珈环讯环境科技(北京)有限公司 | Method and structure for sealing carbon dioxide by utilizing open pit and mining method |

- 2021

- 2021-08-11CNCN202110920648.0Apatent/CN113431535B/enactiveActive

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103278615A (en)* | 2013-05-15 | 2013-09-04 | 太原理工大学 | Test method for geological storage of carbon dioxide coal seams |

| CN106761585A (en)* | 2017-02-25 | 2017-05-31 | 太原理工大学 | A kind of Abandoned golfs coal bed gas limit pumping method |

Also Published As

| Publication number | Publication date |

|---|---|

| CN113431535A (en) | 2021-09-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN113431535B (en) | Method for carbon sequestration by using in-situ pyrolyzed organic ore bed | |

| CN108868706B (en) | A method of directional drilling supercritical carbon dioxide fracturing replacement to recover natural gas hydrate | |

| CN112878978B (en) | A supercritical water fracturing enhanced hydrogen production method for underground coal gasification | |

| CN114575800B (en) | A method for in-situ deep in-situ supercritical storage of flue gas | |

| CN104790915B (en) | Coal bed methane recovery method | |

| CN114876437B (en) | Coal seam in-situ hydrogen production method by utilizing supercritical water | |

| CN114876438A (en) | Coal mining method for in-situ hydrogen production of filling coal | |

| CN115478815B (en) | Sea area high-temperature and high-pressure reservoir natural gas hydrate exploitation method, system and application | |

| CN106522914A (en) | Underground gasifier quenching and burnt-out area restoration treatment method for coal underground gasification process | |

| CN118148568B (en) | Method for integrally sealing carbon dioxide and displacing and exploiting hydrate by ocean | |

| CN103498652A (en) | Method and device for exploiting natural gas hydrate in frozen soil area through injection of high-temperature steam | |

| CN103573233A (en) | Method and device for exploiting natural gas hydrate in cryolithozone | |

| CN1508387A (en) | Coalbed Gas Thermal Exploitation Method | |

| CN100351491C (en) | Thermal recovery method for coal seam gas | |

| CN116066052A (en) | A method of side-pillar filling-in-situ gasification synergistic re-mining of residual coal pillars in residual mining area | |

| DK202101178A1 (en) | System and method for providing a hydrogen (h2) composition | |

| CN117823112B (en) | In-situ coal supercritical water gasification hydrogen production different-layer mining method and device | |

| CN113803048A (en) | Coal in-situ separation mining method based on pyrolysis | |

| CN117489319B (en) | A method for thermal insulation of coal seams during in-situ coal gasification | |

| CN117052366B (en) | Method for in-situ exploitation and energy efficient utilization of deep organic rock ore layer | |

| CN115492557B (en) | Deep non-recoverable coal seam CO 2 Sealing and storing device and method for extracting coalbed methane under negative pressure | |

| CN112761589B (en) | A CO2-enhanced gas layer recovery method of deep low-permeability coal seam | |

| CN116042277A (en) | CO in coal gasification products 2 Is a method for trapping and circulating sealing | |

| CN114856499A (en) | Method for improving yield of coal-bed gas well by generating carbon dioxide through in-situ oxidation | |

| CN117287175B (en) | A method for in-situ high-efficiency dissolution and displacement mining of bauxite under coal |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |