CN113320244B - Impact-resistant fiber metal hybrid structure for aviation and manufacturing method thereof - Google Patents

Impact-resistant fiber metal hybrid structure for aviation and manufacturing method thereofDownload PDFInfo

- Publication number

- CN113320244B CN113320244BCN202110637069.5ACN202110637069ACN113320244BCN 113320244 BCN113320244 BCN 113320244BCN 202110637069 ACN202110637069 ACN 202110637069ACN 113320244 BCN113320244 BCN 113320244B

- Authority

- CN

- China

- Prior art keywords

- resin

- titanium alloy

- metal

- manufacturing

- spraying

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 229910052751metalInorganic materials0.000titleclaimsabstractdescription58

- 239000002184metalSubstances0.000titleclaimsabstractdescription55

- 239000000835fiberSubstances0.000titleclaimsabstractdescription22

- 238000004519manufacturing processMethods0.000titleclaimsabstractdescription22

- 238000000034methodMethods0.000claimsabstractdescription50

- 239000011347resinSubstances0.000claimsabstractdescription43

- 229920005989resinPolymers0.000claimsabstractdescription43

- 238000005530etchingMethods0.000claimsabstractdescription35

- 238000005507sprayingMethods0.000claimsabstractdescription34

- 230000008569processEffects0.000claimsabstractdescription22

- 239000003292glueSubstances0.000claimsabstractdescription9

- 230000003647oxidationEffects0.000claimsabstractdescription4

- 238000007254oxidation reactionMethods0.000claimsabstractdescription4

- 229910001069Ti alloyInorganic materials0.000claimsdescription54

- 239000010936titaniumSubstances0.000claimsdescription27

- 239000003960organic solventSubstances0.000claimsdescription16

- YMWUJEATGCHHMB-UHFFFAOYSA-NDichloromethaneChemical groupClCClYMWUJEATGCHHMB-UHFFFAOYSA-N0.000claimsdescription15

- HEDRZPFGACZZDS-UHFFFAOYSA-NChloroformChemical compoundClC(Cl)ClHEDRZPFGACZZDS-UHFFFAOYSA-N0.000claimsdescription14

- 229920000049Carbon (fiber)Polymers0.000claimsdescription9

- 239000004917carbon fiberSubstances0.000claimsdescription9

- VNWKTOKETHGBQD-UHFFFAOYSA-NmethaneChemical compoundCVNWKTOKETHGBQD-UHFFFAOYSA-N0.000claimsdescription9

- 239000003822epoxy resinSubstances0.000claimsdescription7

- 238000000465mouldingMethods0.000claimsdescription7

- 229920000647polyepoxidePolymers0.000claimsdescription7

- 238000005516engineering processMethods0.000claimsdescription6

- 239000003513alkaliSubstances0.000claimsdescription4

- 238000004140cleaningMethods0.000claimsdescription4

- 238000007731hot pressingMethods0.000claimsdescription4

- 229910017855NH 4 FInorganic materials0.000claimsdescription3

- 238000005238degreasingMethods0.000claimsdescription3

- 239000003365glass fiberSubstances0.000claimsdescription3

- 238000000137annealingMethods0.000claimsdescription2

- 238000001035dryingMethods0.000claimsdescription2

- 238000003825pressingMethods0.000claimsdescription2

- 239000002131composite materialSubstances0.000abstractdescription8

- 238000005498polishingMethods0.000abstractdescription2

- 239000010410layerSubstances0.000description27

- 230000006872improvementEffects0.000description11

- 239000000463materialSubstances0.000description11

- 239000007921spraySubstances0.000description9

- 239000000805composite resinSubstances0.000description8

- 239000012790adhesive layerSubstances0.000description7

- 238000010586diagramMethods0.000description5

- 238000000227grindingMethods0.000description5

- 239000002313adhesive filmSubstances0.000description4

- 238000007743anodisingMethods0.000description4

- 230000000694effectsEffects0.000description4

- GRYLNZFGIOXLOG-UHFFFAOYSA-NNitric acidChemical compoundO[N+]([O-])=OGRYLNZFGIOXLOG-UHFFFAOYSA-N0.000description3

- HEMHJVSKTPXQMS-UHFFFAOYSA-MSodium hydroxideChemical compound[OH-].[Na+]HEMHJVSKTPXQMS-UHFFFAOYSA-M0.000description3

- 239000002253acidSubstances0.000description3

- 239000003795chemical substances by applicationSubstances0.000description3

- 230000032798delaminationEffects0.000description3

- 238000009863impact testMethods0.000description3

- 239000002905metal composite materialSubstances0.000description3

- 229910017604nitric acidInorganic materials0.000description3

- 238000002360preparation methodMethods0.000description3

- 239000004094surface-active agentSubstances0.000description3

- DDFHBQSCUXNBSA-UHFFFAOYSA-N5-(5-carboxythiophen-2-yl)thiophene-2-carboxylic acidChemical compoundS1C(C(=O)O)=CC=C1C1=CC=C(C(O)=O)S1DDFHBQSCUXNBSA-UHFFFAOYSA-N0.000description2

- RTAQQCXQSZGOHL-UHFFFAOYSA-NTitaniumChemical compound[Ti]RTAQQCXQSZGOHL-UHFFFAOYSA-N0.000description2

- 239000000853adhesiveSubstances0.000description2

- 230000001070adhesive effectEffects0.000description2

- 239000003792electrolyteSubstances0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 239000004033plasticSubstances0.000description2

- 230000004044responseEffects0.000description2

- 229910052719titaniumInorganic materials0.000description2

- 238000009736wettingMethods0.000description2

- 239000011248coating agentSubstances0.000description1

- 238000000576coating methodMethods0.000description1

- 238000000748compression mouldingMethods0.000description1

- 238000013461designMethods0.000description1

- 239000011229interlayerSubstances0.000description1

- 239000011159matrix materialSubstances0.000description1

- 239000007769metal materialSubstances0.000description1

- 230000035484reaction timeEffects0.000description1

- 238000011160researchMethods0.000description1

- 238000007660shear property testMethods0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B15/00—Layered products comprising a layer of metal

- B32B15/14—Layered products comprising a layer of metal next to a fibrous or filamentary layer

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/06—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the heating method

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/10—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by the pressing technique, e.g. using action of vacuum or fluid pressure

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B37/00—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding

- B32B37/12—Methods or apparatus for laminating, e.g. by curing or by ultrasonic bonding characterised by using adhesives

- B32B37/1284—Application of adhesive

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/0012—Mechanical treatment, e.g. roughening, deforming, stretching

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/0036—Heat treatment

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/16—Drying; Softening; Cleaning

- B32B38/164—Drying

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B5/00—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts

- B32B5/02—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer

- B32B5/12—Layered products characterised by the non- homogeneity or physical structure, i.e. comprising a fibrous, filamentary, particulate or foam layer; Layered products characterised by having a layer differing constitutionally or physically in different parts characterised by structural features of a fibrous or filamentary layer characterised by the relative arrangement of fibres or filaments of different layers, e.g. the fibres or filaments being parallel or perpendicular to each other

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B7/00—Layered products characterised by the relation between layers; Layered products characterised by the relative orientation of features between layers, or by the relative values of a measurable parameter between layers, i.e. products comprising layers having different physical, chemical or physicochemical properties; Layered products characterised by the interconnection of layers

- B32B7/04—Interconnection of layers

- B32B7/12—Interconnection of layers using interposed adhesives or interposed materials with bonding properties

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/0036—Heat treatment

- B32B2038/0048—Annealing, relaxing

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B38/00—Ancillary operations in connection with laminating processes

- B32B38/16—Drying; Softening; Cleaning

- B32B38/164—Drying

- B32B2038/168—Removing solvent

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2262/00—Composition or structural features of fibres which form a fibrous or filamentary layer or are present as additives

- B32B2262/10—Inorganic fibres

- B32B2262/106—Carbon fibres, e.g. graphite fibres

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/50—Properties of the layers or laminate having particular mechanical properties

- B32B2307/56—Damping, energy absorption

- B—PERFORMING OPERATIONS; TRANSPORTING

- B32—LAYERED PRODUCTS

- B32B—LAYERED PRODUCTS, i.e. PRODUCTS BUILT-UP OF STRATA OF FLAT OR NON-FLAT, e.g. CELLULAR OR HONEYCOMB, FORM

- B32B2307/00—Properties of the layers or laminate

- B32B2307/70—Other properties

- B32B2307/718—Weight, e.g. weight per square meter

Landscapes

- Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Thermal Sciences (AREA)

- Fluid Mechanics (AREA)

- Laminated Bodies (AREA)

- ing And Chemical Polishing (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于结构复合材料的生产制造领域,具体面向航空器制造需求的轻质、高强度、耐冲击钛基纤维金属混杂结构件的制造。The invention belongs to the field of production and manufacture of structural composite materials, and is specifically oriented to the manufacture of lightweight, high-strength, impact-resistant titanium-based fiber-metal hybrid structural parts required by aircraft manufacturing.

背景技术Background technique

纤维金属混杂结构是一种将金属与树脂基复合材料按照结构要求混合铺放热压成型的一种复合结构件。该结构最初由荷兰Delft大学的学者提出,通过金属与树脂基复材的界面桥接很好的缓解了金属疲劳裂纹的扩展,同时又兼具较好的损伤容限和较高的强度与模量,使得该结构成为航空航天及车辆轻量化设计的研究方向。The fiber-metal hybrid structure is a kind of composite structure that mixes and lays metal and resin-based composite materials according to the structural requirements and forms them by hot pressing. This structure was originally proposed by scholars from Delft University in the Netherlands. The interface bridging between metal and resin matrix composites can well alleviate the expansion of metal fatigue cracks, and at the same time, it has good damage tolerance and high strength and modulus. , making this structure a research direction for aerospace and vehicle lightweight design.

航空器在服役过程中,冲击损伤是其结构可能出现的损伤形式之一。通常金属材料具有非常好的延展性,在弹塑性变形阶段能吸收大量的能量;而对大多数树脂基复合材料而言,由于材料本身非常脆,且没有明显的塑性变形阶段,因此勉强可见的损伤都能使其结构承载能力大大下降。纤维金属混杂结构由金属和树脂基复合材料复合而成,其抗冲击性能介于这两种材料之间;金属与树脂基复材的胶结强度,以及胶层的厚度,对纤维金属混杂结构抗冲击分层的能力和承载力有很大的关系。当胶层较薄时,对材料表面润湿性要求高,粘接时若润湿不好,容易出现贫胶的区域,使得树脂基复材与金属无法形成有效桥接作用,而当胶膜厚度较厚时,则会影响混杂结构的承载能力。现有的钛合金阳极氧化+胶膜粘接工艺,不仅界面结合力不够强,且胶层较厚导致机械性能不够理想。因此需要进一步提升纤维金属混杂结构的抗冲击性能,需要从金属界面与胶接工艺同时入手。本发明所采用的喷涂+表面刻蚀工艺则能解决以上问题,显著提升纤维金属混杂结构的机械承载能力和抗冲击性能。During the service of an aircraft, impact damage is one of the possible damage forms to its structure. Generally, metal materials have very good ductility and can absorb a large amount of energy in the elastic-plastic deformation stage; for most resin-based composite materials, because the material itself is very brittle and has no obvious plastic deformation stage, it is barely visible. Damage can greatly reduce the bearing capacity of the structure. The fiber-metal hybrid structure is composed of metal and resin-based composite materials, and its impact resistance is between these two materials; the bonding strength of metal and resin-based composite materials, as well as the thickness of the adhesive layer, have a great impact on the resistance of fiber-metal hybrid structures. The ability to impact delamination has a lot to do with bearing capacity. When the adhesive layer is thin, the wettability of the surface of the material is required to be high. If the wetting is not good during bonding, it is easy to have an area with poor adhesive, so that the resin-based composite material and the metal cannot form an effective bridging effect, and when the thickness of the adhesive film When it is thicker, it will affect the bearing capacity of the hybrid structure. The existing titanium alloy anodizing + adhesive film bonding process not only has insufficient interfacial bonding force, but also has a thick adhesive layer resulting in unsatisfactory mechanical properties. Therefore, it is necessary to further improve the impact resistance of the fiber-metal hybrid structure, and it is necessary to start from the metal interface and the bonding process at the same time. The spraying + surface etching process adopted in the present invention can solve the above problems, and significantly improve the mechanical bearing capacity and impact resistance of the fiber-metal hybrid structure.

发明内容Contents of the invention

本发明所要解决的技术问题是,使用新的制造工艺和方法提升金属与树脂界面的结合力,以及在不影响胶接质量的情况下减薄粘接层厚度,从而使纤维金属混杂结构的抗冲击能力和结构承载能力得以提升。The technical problem to be solved by the present invention is to use a new manufacturing process and method to improve the bonding force of the metal-resin interface, and to reduce the thickness of the adhesive layer without affecting the bonding quality, so that the fiber-metal hybrid structure can resist Impact capacity and structural load-carrying capacity are improved.

本发明具体采用的解决方案如下:The solution that the present invention specifically adopts is as follows:

一种航空用耐冲击纤维金属混杂结构的制造方法,其包括如下步骤:A method for manufacturing an impact-resistant fiber-metal hybrid structure for aviation, comprising the steps of:

S1、使用表面刻蚀技术对经过表面清洗的钛合金进行处理,刻蚀之后对金属进行退火处理;S1. Use surface etching technology to process the titanium alloy that has been cleaned on the surface, and anneal the metal after etching;

S2、将溶于有机溶剂中的树脂溶液均匀喷涂于S1处理后的钛合金表面,然后进行干燥处理使有机溶剂充分挥发,得到上胶的钛合金;S2, evenly spraying a resin solution dissolved in an organic solvent on the surface of the titanium alloy treated in S1, and then performing a drying treatment to fully volatilize the organic solvent to obtain a glued titanium alloy;

S3、将所述上胶的钛合金与树脂基纤维预浸料按照预设铺层顺序交替铺放并预压实,形成预压构件,预压构件固化成型后形成纤维金属混杂结构。S3. Alternate laying and pre-compacting the glued titanium alloy and resin-based fiber prepregs according to the preset layering sequence to form a pre-compressed component, and the pre-compressed component is cured and formed to form a fiber-metal hybrid structure.

作为本发明方法的进一步改进,所述表面清洁处理包括金属层表面除油和除氧化膜。As a further improvement of the method of the present invention, the surface cleaning treatment includes degreasing and deoxidizing film on the surface of the metal layer.

作为本发明方法的进一步改进,所述树脂基纤维预浸料为碳纤维预浸料或玻璃纤维预浸料。As a further improvement of the method of the present invention, the resin-based fiber prepreg is carbon fiber prepreg or glass fiber prepreg.

作为本发明方法的进一步改进,所述表面刻蚀技术为碱刻蚀或NH4F溶液刻蚀。As a further improvement of the method of the present invention, the surface etching technique is alkali etching or NH4 F solution etching.

作为本发明方法的进一步改进,所述钛合金表面刻蚀的图案为网状结构或多孔阵列。As a further improvement of the method of the present invention, the pattern etched on the surface of the titanium alloy is a network structure or a porous array.

作为本发明方法的进一步改进,所述有机溶剂为二氯甲烷或氯仿。As a further improvement of the method of the present invention, the organic solvent is dichloromethane or chloroform.

作为本发明方法的进一步改进,所述树脂为环氧树脂。As a further improvement of the method of the present invention, the resin is epoxy resin.

作为本发明方法的进一步改进,所述树脂溶液在钛合金表面的胶层喷涂厚度控制在2~7mg/cm2,喷涂压力控制在2~4bar。As a further improvement of the method of the present invention, the coating thickness of the adhesive layer of the resin solution on the surface of the titanium alloy is controlled at 2-7 mg/cm2 , and the spraying pressure is controlled at 2-4 bar.

作为本发明方法的进一步改进,所述预压构件由M层上胶的钛合金与N层树脂基纤维预浸料按照[Ti/FRP/Ti/FRP/Ti…/FRP/Ti]的铺层顺序铺放并预压实而成,Ti代表钛合金,FRP代表一层或多层树脂基纤维预浸料;M≥2,N≥1。As a further improvement of the method of the present invention, the pre-pressed member is composed of M layers of glued titanium alloy and N layers of resin-based fiber prepreg according to the layup of [Ti/FRP/Ti/FRP/Ti.../FRP/Ti] It is laid sequentially and pre-compacted, Ti stands for titanium alloy, and FRP stands for one or more layers of resin-based fiber prepreg; M≥2, N≥1.

作为本发明方法的进一步改进,所述固化成型的工艺为模压或热压固化,使用设备为热压罐或平板硫化机。As a further improvement of the method of the present invention, the curing molding process is molding or hot pressing curing, and the equipment used is an autoclave or a flat vulcanizer.

另一方面,本发明提供了一种如上述任一方案中的方法制造的航空用耐冲击纤维金属混杂结构。In another aspect, the present invention provides an impact-resistant fiber-metal hybrid structure for aviation manufactured by the method in any of the above solutions.

借由上述方案,本发明至少具有以下优点:一方面,本发明所用金属刻蚀方案能有效提升金属与树脂界面的结合力,具有较好的抗分层性能。另一方面,本发明使用调配的粘接剂进行表面喷涂,不仅能完整覆盖需要粘接的表面,润湿良好,厚度薄且均匀。因此使用喷胶+表面刻蚀工艺制造的纤维金属混杂结构相较传统工艺具有更好的结构强度,更好的耐冲击和抗分层的能力和更高的损伤容限。With the above solution, the present invention has at least the following advantages: On the one hand, the metal etching solution used in the present invention can effectively improve the bonding force between the metal and the resin interface, and has better anti-delamination performance. On the other hand, the present invention uses the prepared adhesive for surface spraying, which not only can completely cover the surface to be bonded, but also has good wetting, thin and uniform thickness. Therefore, the fiber-metal hybrid structure manufactured by the glue spraying + surface etching process has better structural strength, better impact resistance and delamination resistance, and higher damage tolerance than the traditional process.

上述说明仅是本发明技术方案的概述,为了能更清楚的了解本发明的技术手段,并可以依照说明书的内容予以实施,以下为本发明的较佳实施例,并配合附图详细说明如下。The above description is only an overview of the technical solution of the present invention. In order to understand the technical means of the present invention more clearly and implement it according to the content of the specification, the following is a preferred embodiment of the present invention, which is described in detail with accompanying drawings.

附图说明Description of drawings

图1为M=3,N=4时纤维金属混杂层板的结构示意图(左图)和热压罐实物图(右图);Fig. 1 is a schematic diagram of the structure of the fiber-metal hybrid laminate when M=3 and N=4 (left picture) and a physical picture of the autoclave (right picture);

图2为钛合金表面刻蚀后的形貌结构图;Fig. 2 is the morphology and structure diagram after etching on the titanium alloy surface;

图3为不同制造工艺制备的纤维金属混杂结构的层间剪切性能;Figure 3 shows the interlaminar shear properties of fiber-metal hybrid structures prepared by different manufacturing processes;

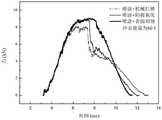

图4为不同工艺制造的纤维金属混杂结构在60J能量冲击下的力学响应;Figure 4 shows the mechanical response of the fiber-metal hybrid structure manufactured by different processes under 60J energy impact;

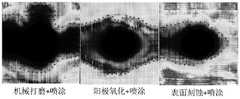

图5为60J低速冲击后样品的超声扫描图(由黑点示出形变区域边界)。Fig. 5 is an ultrasonic scanning image of the sample after 60J low-velocity impact (the boundary of the deformed region is shown by black dots).

具体实施方式detailed description

下面结合附图和实施例,对本发明的具体实施方式作进一步详细描述。以下实施例用于说明本发明,但不用来限制本发明的范围。The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

在本发明中,提供了一种航空用耐冲击纤维金属混杂结构的制造方法,其包括如下步骤:In the present invention, there is provided a method for manufacturing an impact-resistant fiber-metal hybrid structure for aviation, which includes the following steps:

(1)对钛合金进行表面清洁处理,即经过表面除油和除氧化膜后,得到干净的钛表面。(1) Surface cleaning treatment is carried out on the titanium alloy, that is, after surface degreasing and oxidation film removal, a clean titanium surface is obtained.

(2)使用表面刻蚀技术在一定条件下对经过表面清洁处理后的钛合金表面进行刻蚀,刻蚀之后对金属进行退火处理。所用刻蚀技术可以是碱刻蚀或NH4F溶液刻蚀,刻蚀花纹表现为网状结构或多孔阵列,表面刻蚀形成的花纹可以为树脂提供易于结合的界面。(2) Using surface etching technology to etch the surface of the titanium alloy after surface cleaning under certain conditions, and annealing the metal after etching. The etching technique used may be alkali etching or NH4 F solution etching, and the etching pattern shows a network structure or a porous array, and the pattern formed by surface etching can provide an interface that is easy to bond to the resin.

(3)使用有机溶剂,将树脂按照一定比例溶解于有机溶剂当中,形成树脂溶液。所使用的有机溶剂可以为二氯甲烷或氯仿,所用树脂可以为环氧树脂。(3) Using an organic solvent, dissolving the resin in a certain proportion in the organic solvent to form a resin solution. The used organic solvent can be methylene chloride or chloroform, and the used resin can be epoxy resin.

(4)使用喷枪将步骤(3)中的树脂溶液在一定空气压力下均匀喷涂于步骤(2)处理后的钛合金表面。树脂溶液喷涂过程中的参数可根据实际调整,胶层喷涂厚度控制可在2~7mg/cm2,喷涂压力可控制在2~4bar。(4) Use a spray gun to evenly spray the resin solution in step (3) on the surface of the titanium alloy treated in step (2) under a certain air pressure. The parameters in the resin solution spraying process can be adjusted according to the actual situation. The spraying thickness of the adhesive layer can be controlled at 2-7mg/cm2 , and the spraying pressure can be controlled at 2-4bar.

(5)将步骤(4)喷涂后的钛合金放于烘箱中晾干,让有机溶剂充分挥发,得到上胶的的钛合金。(5) Put the titanium alloy sprayed in step (4) in an oven to dry, let the organic solvent fully volatilize, and obtain a glued titanium alloy.

(6)将步骤(5)中的上胶的钛合金与树脂基纤维预浸料按照预设铺层顺序交替铺放并预压实,形成预压构件。铺层顺序可表示为[Ti/FRP/Ti…/FRP/Ti],Ti代表钛合金,FRP代表一层或多层树脂基纤维预浸料。因此,若钛合金层数记为M层,树脂基纤维预浸料层数记为N层,那么需满足M≥2,N≥1。(6) The glued titanium alloy and resin-based fiber prepregs in step (5) are alternately laid and pre-compacted according to the preset lay-up sequence to form a pre-compressed component. The layup sequence can be expressed as [Ti/FRP/Ti.../FRP/Ti], Ti stands for titanium alloy, and FRP stands for one or more layers of resin-based fiber prepreg. Therefore, if the number of titanium alloy layers is recorded as M layers and the number of resin-based fiber prepreg layers is recorded as N layers, then M≥2 and N≥1 must be met.

(7)将步骤(6)中的预压构件固化成型,即得到航空用耐冲击纤维金属混杂结构。固化成型工艺为模压或热压固化,使用设备可以为热压罐或平板硫化机,具体的固化温度和压力可按照所采用的的树脂所需固化温度和压力进行调整。(7) Solidifying and molding the pre-pressed member in step (6) to obtain an impact-resistant fiber-metal hybrid structure for aviation. The curing molding process is mold pressing or hot pressing curing, and the equipment used can be an autoclave or a flat vulcanizing machine. The specific curing temperature and pressure can be adjusted according to the required curing temperature and pressure of the resin used.

在该纤维金属混杂结构种,其结构可以划分为金属层、粘接层和树脂基复合材料层。其中金属层为钛合金本体;树脂基复合材料层为预浸料制造的复合材料,如碳纤维复合材料或玻璃纤维复合材料;粘接层是钛合金与树脂基复合材料粘接形成的富树脂区域。In this fiber-metal hybrid structure, its structure can be divided into metal layer, adhesive layer and resin-based composite material layer. The metal layer is a titanium alloy body; the resin-based composite material layer is a composite material made of prepreg, such as carbon fiber composite material or glass fiber composite material; the bonding layer is a resin-rich area formed by bonding titanium alloy and resin-based composite material .

如图1所示,为了进一步展示本发明的具体技术效果,现通过若干实施例对上述制造方法的具体实现以及得到的纤维金属混杂结构的性能进行详细描述。As shown in FIG. 1 , in order to further demonstrate the specific technical effect of the present invention, the specific implementation of the above-mentioned manufacturing method and the performance of the obtained fiber-metal hybrid structure are now described in detail through several embodiments.

实施例1:Example 1:

一种航空用耐冲击纤维金属混杂结构的制造方法,该方法的步骤如下:A method for manufacturing an impact-resistant fiber-metal hybrid structure for aviation, the steps of the method are as follows:

(1)使用表面活性剂将层状的钛合金表面除油,并使用HF和HNO3混合酸除氧化膜;(1) Use a surfactant to degrease the surface of the layered titanium alloy, and use a mixed acid of HF andHNO3 to remove the oxide film;

(2)使用浓度为1%的氟化铵电解液将钛合金放入电解槽中反应5min,刻蚀完成后取出并清洁表面,之后将钛合金做退火处理;(2) Use an ammonium fluoride electrolyte with a concentration of 1% to put the titanium alloy into the electrolytic cell to react for 5 minutes. After the etching is completed, take it out and clean the surface, and then anneal the titanium alloy;

(3)使用二氯甲烷作为有机溶剂,将带固化剂的环氧树脂胶溶解于二氯甲烷中,质量分数为10%,形成树脂溶液;(3) using dichloromethane as an organic solvent, the epoxy resin glue with curing agent is dissolved in dichloromethane, and the mass fraction is 10%, forming a resin solution;

(4)使用喷枪将步骤(3)中的树脂溶液在2~4bar的空气压力下均匀喷涂于步骤(2)处理后的钛合金表面,胶层喷涂厚度为4.5mg/cm2;(4) Use a spray gun to evenly spray the resin solution in step (3) on the titanium alloy surface after the treatment of step (2) under an air pressure of 2 to 4 bar, and the glue layer spraying thickness is 4.5mg/cm;

(5)将步骤(4)喷涂后的钛合金放于50℃烘箱中40min,让有机溶剂充分挥发,得到上胶的钛合金;(5) Put the titanium alloy sprayed in step (4) in an oven at 50°C for 40 minutes to allow the organic solvent to fully volatilize to obtain a glued titanium alloy;

(6)将步骤(5)中的钛合金与碳纤维预浸料按照[Ti/0/90/Ti/90/0/Ti]的铺层顺序铺放并预压实,具体铺层结构示意图如图1所示,相邻两层钛合金之间分别按照0°和90°铺层角度铺设两层碳纤维预浸料;(6) Lay and pre-compact the titanium alloy and carbon fiber prepreg in step (5) according to the layup sequence of [Ti/0/90/Ti/90/0/Ti]. The specific layup structure diagram is as follows As shown in Figure 1, two layers of carbon fiber prepreg are laid between two adjacent layers of titanium alloy according to the laying angles of 0° and 90°;

(7)将步骤(6)中的预压构件按照树脂所需固化温度和压力放于热压罐中固化成型。(7) Put the pre-pressed component in step (6) into an autoclave for curing and molding according to the required curing temperature and pressure of the resin.

实施例2:Example 2:

一种提高纤维金属层合板层间强度的制备方法,该方法的步骤如下:A preparation method for improving the interlaminar strength of a fiber metal laminate, the steps of the method are as follows:

(1)使用表面活性剂将层状的钛合金表面除油,并使用HF和HNO3混合酸除氧化膜;(1) Use a surfactant to degrease the surface of the layered titanium alloy, and use a mixed acid of HF andHNO3 to remove the oxide film;

(2)使用浓度为2M的NaOH在80℃,30V电压情况下对钛合金表面进行碱刻蚀,反应时间为40min,之后将钛合金做退火处理;(2) Use NaOH with a concentration of 2M to perform alkali etching on the surface of the titanium alloy at 80°C and a voltage of 30V. The reaction time is 40min, and then anneal the titanium alloy;

(3)使用氯仿作为有机溶剂,将带固化剂的环氧树脂胶溶解于氯仿中,质量分数为7%,形成树脂溶液;(3) Using chloroform as an organic solvent, the epoxy resin glue with curing agent is dissolved in chloroform, and the mass fraction is 7%, forming a resin solution;

(4)使用喷枪将步骤(3)中的树脂溶液在2~4bar的空气压力下均匀喷涂于步骤(2)处理后的钛合金表面,胶层喷涂厚度为4.5mg/cm2;(4) Use a spray gun to evenly spray the resin solution in step (3) on the titanium alloy surface after the treatment of step (2) under an air pressure of 2 to 4 bar, and the glue layer spraying thickness is 4.5mg/cm;

(5)将步骤(4)喷涂后的钛合金放于50℃烘箱中40min,让有机溶剂充分挥发,得到上胶的钛合金;(5) Put the titanium alloy sprayed in step (4) in an oven at 50°C for 40 minutes to allow the organic solvent to fully volatilize to obtain a glued titanium alloy;

(6)将步骤(5)中的钛合金与碳纤维预浸料按照[Ti/0/90/Ti/90/0/Ti]的铺层顺序铺放并预压实,具体铺层结构示意图如图1所示,相邻两层钛合金之间分别按照0°和90°铺层角度铺设两层碳纤维预浸料;(6) Lay and pre-compact the titanium alloy and carbon fiber prepreg in step (5) according to the layup sequence of [Ti/0/90/Ti/90/0/Ti]. The specific layup structure diagram is as follows As shown in Figure 1, two layers of carbon fiber prepreg are laid between two adjacent layers of titanium alloy according to the laying angles of 0° and 90°;

(7)将步骤(6)中的预压构件按照树脂所需固化温度和压力放于热压罐中固化成型。(7) Put the pre-pressed component in step (6) into an autoclave for curing and molding according to the required curing temperature and pressure of the resin.

实施例3:Example 3:

一种提高纤维金属层合板层间强度的制备方法,该方法的步骤如下:A preparation method for improving the interlaminar strength of a fiber metal laminate, the steps of the method are as follows:

(1)使用表面活性剂将层状的钛合金表面除油,并使用HF和HNO3混合酸除氧化膜;(1) Use a surfactant to degrease the surface of the layered titanium alloy, and use a mixed acid of HF andHNO3 to remove the oxide film;

(2)使用浓度为1%的氟化铵电解液将钛合金放入电解槽中反应5min,刻蚀完成后取出并清洁表面,之后将钛合金做退火处理;(2) Use an ammonium fluoride electrolyte with a concentration of 1% to put the titanium alloy into the electrolytic cell to react for 5 minutes. After the etching is completed, take it out and clean the surface, and then anneal the titanium alloy;

(3)使用氯仿作为有机溶剂,将带固化剂的环氧树脂胶溶解于氯仿中,质量分数为7%,形成树脂溶液;(3) Using chloroform as an organic solvent, the epoxy resin glue with curing agent is dissolved in chloroform, and the mass fraction is 7%, forming a resin solution;

(4)使用喷枪将步骤(3)中的树脂溶液在2~4bar的空气压力下均匀喷涂于步骤(2)处理后的钛合金表面,胶层喷涂厚度为4.5mg/cm2;(4) Use a spray gun to evenly spray the resin solution in step (3) on the titanium alloy surface after the treatment of step (2) under an air pressure of 2 to 4 bar, and the glue layer spraying thickness is 4.5mg/cm;

(5)将步骤(4)喷涂后的钛合金放于50℃烘箱中40min,让有机溶剂充分挥发,得到上胶的钛合金;(5) Put the titanium alloy sprayed in step (4) in an oven at 50°C for 40 minutes to allow the organic solvent to fully volatilize to obtain a glued titanium alloy;

(6)将步骤(5)中的钛合金与碳纤维预浸料按照[Ti/0/90/Ti/90/0/Ti]的铺层顺序铺放并预压实,具体铺层结构示意图如图1所示,相邻两层钛合金之间分别按照0°和90°铺层角度铺设两层碳纤维预浸料;(6) Lay and pre-compact the titanium alloy and carbon fiber prepreg in step (5) according to the layup sequence of [Ti/0/90/Ti/90/0/Ti]. The specific layup structure diagram is as follows As shown in Figure 1, two layers of carbon fiber prepreg are laid between two adjacent layers of titanium alloy according to the laying angles of 0° and 90°;

(7)将步骤(6)中的预压构件按照树脂所需固化温度和压力放于平板硫化机中模压成型。(7) Put the pre-pressed component in step (6) into a flat vulcanizing machine according to the required curing temperature and pressure of the resin for compression molding.

通过上述三个实施例均通过喷涂+表面刻蚀工艺能制造出具有较高承载能力和较好抗冲击性能的纤维金属混杂结构,下面以实施例1中喷涂+表面刻蚀工艺制备过程为例,展示本发明的具体技术效果。Through the above three examples, the fiber-metal hybrid structure with higher bearing capacity and better impact resistance can be produced by spraying + surface etching process. The preparation process of spraying + surface etching process in Example 1 is taken as an example below. , showing the specific technical effect of the present invention.

在实施例1中,对钛合金表面进行了刻蚀,刻蚀后金属表面形貌如图2所示,金属表面出现相互错层的多孔结构,能够有效的提升与树脂的结合力。实施例1中再将刻蚀后的钛合金,经喷涂工艺上胶,按照[Ti/0/90/Ti/90/0/Ti]的铺层顺序制成混杂结构层板。同时为了对比其他现有技术做法的效果差异,此处还使用胶膜+机械打磨、喷涂+机械打磨、喷涂+阳极氧化三种现有工艺制造相同厚度相同铺层的纤维金属混杂结构,并使用短梁剪切的测试方法对比这些层板的层间承载能力。图3为实施例1以及其他三种不同制造方法下混杂结构层板的层间剪切强度。图中可以看出使用胶膜粘接工艺制造的层板,由于胶膜厚度较厚因此导致承载能力远小于使用喷涂+机械打磨样品的剪切强度;而使用喷涂+表面刻蚀工艺制造的混杂结构层板,比同时使用了喷涂粘接工艺但钛合金使用机械打磨和阳极氧化制备的层板的剪切强度都要高,达到59.5MPa。此项结果说明喷涂+表面刻蚀工艺制造的纤维金属混杂结构在层间承载力方面优于其他制造方案。In Example 1, the surface of the titanium alloy was etched. The surface morphology of the metal after etching is shown in FIG. 2 . There is a porous structure with staggered layers on the metal surface, which can effectively improve the bonding force with the resin. In Example 1, the etched titanium alloy was glued by spraying process, and a hybrid structure laminate was made according to the layering sequence of [Ti/0/90/Ti/90/0/Ti]. At the same time, in order to compare the effect difference of other existing technical methods, three existing processes of film + mechanical grinding, spraying + mechanical grinding, spraying + anodizing are used to manufacture fiber-metal hybrid structures with the same thickness and the same layer, and use The short beam shear test method compares the interlaminar load carrying capacity of these laminates. Fig. 3 shows the interlaminar shear strength of hybrid structure laminates in Example 1 and other three different manufacturing methods. It can be seen from the figure that the laminates manufactured using the adhesive film bonding process, due to the thicker adhesive film, lead to a load-carrying capacity that is much lower than the shear strength of the samples using spraying + mechanical polishing; The shear strength of the structural laminate is 59.5MPa higher than that of the laminate prepared by the spray bonding process but the titanium alloy is mechanically polished and anodized. This result shows that the fiber-metal hybrid structure manufactured by spraying + surface etching process is superior to other manufacturing schemes in terms of interlayer bearing capacity.

为了展示本发明对于纤维金属混杂结构在抗冲击能力方面的优势,分别将喷涂+机械打磨、喷涂+阳极氧化和实施例1中喷涂+表面刻蚀制造的纤维金属混杂结构样品在60J的能量条件下进行低速冲击测试,在冲击过程中结构承载力随冲击时间的响应如图4所示。从图中可以发现喷涂+机械打磨和喷涂+阳极氧化制造的样品在7.7ms时,载荷突降;而实施例1中喷涂+表面刻蚀制造的样品载荷曲线较为均匀对称,没有出现载荷陡降的现象。从图5,三种样品冲击测试后超声波扫描冲击区域的图中可以发现,使用喷涂+机械打磨和喷涂+阳极氧化的样品变形和分层的区域远大于使用喷涂+表面刻蚀技术制造的样品,说明本发明所使用的技术能在冲击测试中更好的保持结构的完整性,损伤容限高,耐冲击性能更加的优异。In order to demonstrate the advantages of the present invention on the impact resistance of the fiber-metal hybrid structure, the fiber-metal hybrid structure samples manufactured by spraying+mechanical grinding, spraying+anodizing and spraying+surface etching in Example 1 were respectively subjected to an energy condition of 60J The low-speed impact test is carried out under the following conditions, and the response of the structural bearing capacity with the impact time during the impact process is shown in Figure 4. It can be seen from the figure that the load of the samples manufactured by spraying + mechanical grinding and spraying + anodic oxidation drops suddenly at 7.7ms; while the load curve of the sample manufactured by spraying + surface etching in Example 1 is relatively uniform and symmetrical, and there is no sudden load drop The phenomenon. From Figure 5, the images of the ultrasonic scanning impact area after the impact test of the three samples, it can be found that the deformed and delaminated areas of the samples using spraying + mechanical grinding and spraying + anodizing are much larger than the samples manufactured using spraying + surface etching technology , indicating that the technology used in the present invention can better maintain the integrity of the structure in the impact test, the damage tolerance is high, and the impact resistance performance is more excellent.

综上,本发明的制造方法使用金属表面刻蚀结合环氧树脂喷涂工艺获得金属与树脂基纤维复合材料牢固轻薄的界面层,不仅使树脂与金属表面充分接触、润湿,而且让界面层厚度均匀轻薄强度高。该方法制造的纤维金属混杂结构件具有较高的抗分层能力和抗冲击能力。In summary, the manufacturing method of the present invention uses metal surface etching combined with epoxy resin spraying process to obtain a firm and thin interface layer between metal and resin-based fiber composite materials, which not only makes the resin and the metal surface fully contact and wet, but also makes the interface layer thicker. Uniform, light and high strength. The fiber-metal hybrid structure manufactured by the method has high delamination resistance and impact resistance.

以上所述仅是本发明的优选实施方式,并不用于限制本发明,应当指出,对于本技术领域的普通技术人员来说,在不脱离本发明技术原理的前提下,还可以做出若干改进和变型,这些改进和变型也应视为本发明的保护范围。The above is only a preferred embodiment of the present invention, and is not intended to limit the present invention. It should be pointed out that for those of ordinary skill in the art, some improvements can also be made without departing from the technical principles of the present invention. and modifications, these improvements and modifications should also be considered as the protection scope of the present invention.

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110637069.5ACN113320244B (en) | 2021-06-08 | 2021-06-08 | Impact-resistant fiber metal hybrid structure for aviation and manufacturing method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110637069.5ACN113320244B (en) | 2021-06-08 | 2021-06-08 | Impact-resistant fiber metal hybrid structure for aviation and manufacturing method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN113320244A CN113320244A (en) | 2021-08-31 |

| CN113320244Btrue CN113320244B (en) | 2023-01-10 |

Family

ID=77420047

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110637069.5AActiveCN113320244B (en) | 2021-06-08 | 2021-06-08 | Impact-resistant fiber metal hybrid structure for aviation and manufacturing method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113320244B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN116262384B (en)* | 2023-02-21 | 2025-07-22 | 哈尔滨工业大学 | Fiber metal laminated plate interface modification method and application |

| CN117507550A (en)* | 2023-11-22 | 2024-02-06 | 浙江大学 | Fiber metal laminated plate capable of improving interlayer shear strength and weather resistance and preparation method thereof |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103029376B (en)* | 2012-12-21 | 2015-12-23 | 官宇寰 | A kind of Metal-fiber composite laminate and manufacture method thereof |

- 2021

- 2021-06-08CNCN202110637069.5Apatent/CN113320244B/enactiveActive

Also Published As

| Publication number | Publication date |

|---|---|

| CN113320244A (en) | 2021-08-31 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US8845910B2 (en) | Aluminum alloy composite and method for joining thereof | |

| CN113320244B (en) | Impact-resistant fiber metal hybrid structure for aviation and manufacturing method thereof | |

| CN101417524B (en) | Method for manufacturing carbon fiber metal composite laminated plate | |

| US10350857B2 (en) | Titanium alloy composite and bonding method thereof | |

| US11618246B2 (en) | Fiber reinforced metal composite and application thereof | |

| CN110116535B (en) | Continuous CF/PEEK thermoplastic composite material and preparation method thereof | |

| CN105538745A (en) | Forming method of aluminum alloy fiber laminate structural part and laminate structural part thereof | |

| CN114103303A (en) | Fiber metal laminate for enhancing composite interface connection and preparation method thereof | |

| CN104191753A (en) | Method for preparing continuous carbon fiber enhanced polyether-ether-ketone matrix fiber metal laminates | |

| CN107283871A (en) | A kind of preparation method of thermoplastic resin matrix's carbon fiber titanium/titanium alloy layer plywood | |

| CN111020685B (en) | Preparation method of fiber metal laminated plate for improving interlayer strength | |

| CN104015917A (en) | Fiber aluminum lithium alloy laminated board used as airplane wall board and production method of laminated board | |

| CN106515188A (en) | Stress releasing forming method of super-hybrid fiber magnesium alloy laminated plate | |

| CN117507550A (en) | Fiber metal laminated plate capable of improving interlayer shear strength and weather resistance and preparation method thereof | |

| CN111231456A (en) | Fiber-metal hybrid composite laminate and preparation method thereof | |

| CN115447173B (en) | A method for preparing an ultrasonic-assisted fiber metal laminate | |

| CN109263184A (en) | A kind of shock proof tencel plymetal and preparation method thereof | |

| CN118322670A (en) | Gradient structure impact-resistant titanium-based fiber metal laminated plate and manufacturing method thereof | |

| CN107234766B (en) | Powder laminating process method for rapidly preparing magnesium-based fiber metal laminate | |

| CN116262384B (en) | Fiber metal laminated plate interface modification method and application | |

| CN111605223A (en) | A kind of high-performance carbon fiber composite material based on discontinuous fiber structure and preparation method thereof | |

| CN116834321A (en) | Technological method for reinforcing bonding of composite material plate ribs | |

| CN112848545A (en) | Impact-resistant design and preparation method of composite laminated plate with embedded thermoplastic film | |

| Kochov et al. | Tensile strength of carbon fiber | |

| CN116811311A (en) | Structural design and forming method for improving interface bonding strength of fiber-metal heterogeneous material |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |