CN113295597B - Test device and test method for ballast particle characteristics under simulated cyclic load - Google Patents

Test device and test method for ballast particle characteristics under simulated cyclic loadDownload PDFInfo

- Publication number

- CN113295597B CN113295597BCN202110652373.7ACN202110652373ACN113295597BCN 113295597 BCN113295597 BCN 113295597BCN 202110652373 ACN202110652373 ACN 202110652373ACN 113295597 BCN113295597 BCN 113295597B

- Authority

- CN

- China

- Prior art keywords

- test

- loading

- aluminum alloy

- alloy plate

- water

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000012360testing methodMethods0.000titleclaimsabstractdescription116

- 239000002245particleSubstances0.000titleclaimsabstractdescription52

- 125000004122cyclic groupChemical group0.000titleclaimsabstractdescription31

- 238000010998test methodMethods0.000titleclaimsabstractdescription15

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription124

- 238000011068loading methodMethods0.000claimsabstractdescription95

- 230000009471actionEffects0.000claimsabstractdescription11

- 229910000838Al alloyInorganic materials0.000claimsdescription64

- 239000011148porous materialSubstances0.000claimsdescription21

- 238000006073displacement reactionMethods0.000claimsdescription19

- 239000007788liquidSubstances0.000claimsdescription17

- 239000012530fluidSubstances0.000claimsdescription15

- 239000003921oilSubstances0.000claimsdescription14

- 238000000034methodMethods0.000claimsdescription13

- 238000002360preparation methodMethods0.000claimsdescription13

- 238000007789sealingMethods0.000claimsdescription12

- 238000005056compactionMethods0.000claimsdescription9

- 230000008569processEffects0.000claimsdescription8

- 238000003756stirringMethods0.000claimsdescription8

- VVQNEPGJFQJSBK-UHFFFAOYSA-NMethyl methacrylateChemical compoundCOC(=O)C(C)=CVVQNEPGJFQJSBK-UHFFFAOYSA-N0.000claimsdescription7

- 229920005372Plexiglas®Polymers0.000claimsdescription7

- 239000004746geotextileSubstances0.000claimsdescription6

- 239000000463materialSubstances0.000claimsdescription6

- 230000007246mechanismEffects0.000claimsdescription5

- 238000011049fillingMethods0.000claimsdescription4

- 238000005259measurementMethods0.000claimsdescription4

- 239000002689soilSubstances0.000claimsdescription4

- 229940099259vaselineDrugs0.000claimsdescription4

- 239000010720hydraulic oilSubstances0.000claimsdescription3

- 230000002093peripheral effectEffects0.000claimsdescription3

- 238000005204segregationMethods0.000claimsdescription3

- 238000004891communicationMethods0.000claimsdescription2

- 239000004810polytetrafluoroethyleneSubstances0.000claims1

- 229920001343polytetrafluoroethylenePolymers0.000claims1

- 230000008878couplingEffects0.000abstractdescription7

- 238000010168coupling processMethods0.000abstractdescription7

- 238000005859coupling reactionMethods0.000abstractdescription7

- 239000000945fillerSubstances0.000abstractdescription5

- 238000011160researchMethods0.000abstractdescription5

- 230000009286beneficial effectEffects0.000abstractdescription3

- 238000004088simulationMethods0.000abstractdescription3

- 238000010586diagramMethods0.000description7

- 229910045601alloyInorganic materials0.000description2

- 239000000956alloySubstances0.000description2

- 239000010419fine particleSubstances0.000description2

- 229910000831SteelInorganic materials0.000description1

- 239000004809TeflonSubstances0.000description1

- 229920006362Teflon®Polymers0.000description1

- 230000008859changeEffects0.000description1

- 230000019771cognitionEffects0.000description1

- 238000013461designMethods0.000description1

- 238000001914filtrationMethods0.000description1

- 230000006870functionEffects0.000description1

- 230000003068static effectEffects0.000description1

- 239000010959steelSubstances0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N15/00—Investigating characteristics of particles; Investigating permeability, pore-volume or surface-area of porous materials

- G01N15/08—Investigating permeability, pore-volume, or surface area of porous materials

- G01N15/082—Investigating permeability by forcing a fluid through a sample

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N3/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N3/32—Investigating strength properties of solid materials by application of mechanical stress by applying repeated or pulsating forces

- G01N3/36—Investigating strength properties of solid materials by application of mechanical stress by applying repeated or pulsating forces generated by pneumatic or hydraulic means

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2203/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N2203/0001—Type of application of the stress

- G01N2203/0005—Repeated or cyclic

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2203/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N2203/0014—Type of force applied

- G01N2203/0016—Tensile or compressive

- G01N2203/0019—Compressive

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2203/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N2203/003—Generation of the force

- G01N2203/0042—Pneumatic or hydraulic means

- G01N2203/0048—Hydraulic means

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N2203/00—Investigating strength properties of solid materials by application of mechanical stress

- G01N2203/02—Details not specific for a particular testing method

- G01N2203/022—Environment of the test

- G01N2203/023—Pressure

Landscapes

- Chemical & Material Sciences (AREA)

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Dispersion Chemistry (AREA)

- Investigating Strength Of Materials By Application Of Mechanical Stress (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于铁路轨道安全技术领域,尤其涉及模拟循环荷载作用下底砟颗粒特性试验装置及试验方法。The invention belongs to the technical field of railway track safety, and in particular relates to a test device and a test method for the characteristics of bottom ballast particles under the action of simulated cyclic loads.

背景技术Background technique

铁路为了轨道安全性需要,一般需要在底层铺设铁路底砟层,铁路底砟层兼具持力层、排水层以及过滤层等多重功能,是有砟轨道的重要结构组成部分。In order to meet the requirements of track safety, the railway generally needs to lay a railway bottom ballast layer on the bottom layer. The railway bottom ballast layer has multiple functions such as a bearing layer, a drainage layer and a filter layer, and is an important structural part of the ballast track.

在现有技术中,底砟颗粒在列车荷载下产生破碎、粉化,或受到外部细小颗粒的侵入(如地基细粒土填料在水的软化下形成粘滞流体,在列车荷载的驱动下侵入底砟层),进而导致底砟脏污现象,脏污底砟的孔隙填充细小颗粒,严重影响其承载能力以及排水和过滤性能,目前有关循环荷载作用下底砟填料内部粘滞流特性以及底砟颗粒水—力耦合特性的研究往往难以同时实现循环荷载施加以及水压力渗流的试验,因此亟需设计一个能够实现循环荷载作用下底砟颗粒粘滞流特性与水—力耦合特性的试验装置,而基于该试验装置的试验方法也是实现对铁路底砟颗粒特性研究的方向。In the prior art, the bottom ballast particles are broken and pulverized under the train load, or are invaded by external fine particles (for example, the foundation fine-grained soil filler forms a viscous fluid under the softening of water, and intrusion is driven by the train load). The bottom ballast layer), which leads to the phenomenon of bottom ballast fouling. The pores of the dirty bottom ballast are filled with fine particles, which seriously affects its bearing capacity, drainage and filtration performance. The research on the water-mechanical coupling characteristics of ballast particles is often difficult to realize the test of cyclic load application and water pressure seepage at the same time. Therefore, it is urgent to design a test device that can realize the viscous flow characteristics and water-mechanical coupling characteristics of bottom ballast particles under cyclic loading. , and the test method based on this test device is also the direction to realize the research on the characteristics of railway bottom ballast particles.

发明内容SUMMARY OF THE INVENTION

本发明的目的在于:为了解决有关循环荷载作用下底砟填料内部粘滞流特性以及底砟颗粒水—力耦合特性的研究往往难以同时实现循环荷载施加以及水压力渗流的试验的问题,而提出的模拟循环荷载作用下底砟颗粒特性试验装置及试验方法。The purpose of the present invention is: in order to solve the problem that it is often difficult to realize the test of cyclic load application and water pressure seepage at the same time in the research on the internal viscous flow characteristics of the bottom ballast filler and the water-mechanical coupling characteristics of the bottom ballast particles under the action of cyclic load, and proposes A test device and test method for the characteristics of ballast particles under simulated cyclic loading.

为了实现上述目的,本发明采用了如下技术方案:In order to achieve the above object, the present invention adopts the following technical solutions:

一种模拟循环荷载作用下底砟颗粒特性试验装置,包括收集箱,所述收集箱一侧通过管路连通有试验模型系统,所述试验模型系统顶部固定安装有轴向加载装置,所述试验模型系统一侧连通有水位控制系统,且轴向加载装置和试验模型系统一侧连通有数据采集系统;A test device for simulating the characteristics of bottom ballast particles under the action of cyclic loads, including a collection box, one side of the collection box is connected with a test model system through a pipeline, and an axial loading device is fixedly installed on the top of the test model system. One side of the model system is connected with a water level control system, and one side of the axial loading device and the test model system is connected with a data acquisition system;

所述轴向加载装置包括加载横梁,所述加载横梁两侧均设有加载架立柱,且两侧加载架立柱底端之间固定连接有加载底座,所述加载底座与外部测试面固定放置,所述加载横梁内滑动连接有加载杆,所述加载杆底端固定连接有荷重传感器,所述荷重传感器底端与底部测试样品相贴合,所述加载杆一侧固定连接有位移传感器,所述荷重传感器和位移传感器均与数据采集系统通讯连接。The axial loading device includes a loading beam, both sides of the loading beam are provided with loading frame columns, and a loading base is fixedly connected between the bottom ends of the loading frame columns on both sides, and the loading base is fixedly placed with the external test surface, The loading beam is slidably connected with a loading rod, the bottom end of the loading rod is fixedly connected with a load sensor, the bottom end of the load sensor is attached to the bottom test sample, and one side of the loading rod is fixedly connected with a displacement sensor, so Both the load sensor and the displacement sensor are connected in communication with the data acquisition system.

作为上述技术方案的进一步描述:As a further description of the above technical solution:

所述试验模型系统包括试样筒,所述试样筒内滑动连接有加载板,所述加载板顶部与荷重传感器底部相贴合,所述加载板顶部贴合有上部铝合金板,所述上部铝合金板通过导向螺栓连接有导向柱,所述试样筒侧壁开孔安装有孔隙水压力传感器和动土压力传感器,所述上部铝合金板底部贴合有下部铝合金板,且上部铝合金板和下部铝合金板四角处均通过支撑杆连接有底座,且支撑杆位于试样筒周侧,且支撑杆顶端通过螺栓与上部铝合金板限位,所述底座一侧固定安装有进水阀门,且进水阀门与水位控制系统相连通,且底座上表面开设有进水阀门相连通的开口,且底座下部四角处均设有支座,所述上部铝合金板顶部嵌设有出水阀门,且出水阀门与收集箱相连通;The test model system includes a sample cylinder, a loading plate is slidably connected in the sample cylinder, the top of the loading plate is attached to the bottom of the load cell, and the upper aluminum alloy plate is attached to the top of the loading plate. The upper aluminum alloy plate is connected with a guide column through guide bolts, the pore water pressure sensor and the earth pressure sensor are installed in the side wall of the sample cylinder, the bottom of the upper aluminum alloy plate is attached with the lower aluminum alloy plate, and the upper aluminum alloy plate is attached to the bottom of the upper aluminum alloy plate. The four corners of the alloy plate and the lower aluminum alloy plate are connected with a base through support rods, and the support rod is located on the peripheral side of the sample cylinder, and the top of the support rod is limited by bolts with the upper aluminum alloy plate, and a feeder is fixedly installed on one side of the base. Water valve, and the water inlet valve is connected with the water level control system, and the upper surface of the base is provided with an opening that communicates with the water inlet valve, and the four corners of the lower part of the base are provided with supports, and the top of the upper aluminum alloy plate is embedded with water outlet valve, and the outlet valve is connected with the collection tank;

所述水位控制系统包括水箱,所述水箱下部一侧出水口与试验模型系统进水口通过软管相连接,且出水口与进水口之间安装有流量传感器,所述水箱上部通过管路与外部水源相连,且水箱通过上部进气阀门连接有空气压缩机,所述空气压缩机一侧设有压力控制器。The water level control system includes a water tank, the water outlet on the lower part of the water tank is connected with the water inlet of the test model system through a hose, and a flow sensor is installed between the water outlet and the water inlet, and the upper part of the water tank is connected to the outside through a pipeline. The water source is connected, and the water tank is connected with an air compressor through the upper air inlet valve, and a pressure controller is provided on one side of the air compressor.

作为上述技术方案的进一步描述:As a further description of the above technical solution:

所述数据采集系统用于采集试验过程中荷重传感器、位移传感器、孔隙水压力传感器、动土压力传感器以及流量传感器采集到的物理信号转换为数字信号并保存,且数据采集系统通过测试端显示屏幕进行数据显示同时保存。The data acquisition system is used to convert the physical signals collected by the load sensor, displacement sensor, pore water pressure sensor, earth pressure sensor and flow sensor into digital signals and save them during the test process. The data display is saved at the same time.

作为上述技术方案的进一步描述:As a further description of the above technical solution:

所述加载杆一侧固定连接有轴向作动器,所述轴向作动器一侧连通有油压控制器,所述油压控制器底部连通有油源,且油源内填充有液压油,且加载杆与加载横梁之间套设有加载套,且加载套嵌设于加载横梁顶部。One side of the loading rod is fixedly connected with an axial actuator, one side of the axial actuator is connected with an oil pressure controller, and the bottom of the oil pressure controller is connected with an oil source, and the oil source is filled with hydraulic oil , and a loading sleeve is sleeved between the loading rod and the loading beam, and the loading sleeve is embedded at the top of the loading beam.

作为上述技术方案的进一步描述:As a further description of the above technical solution:

所述下部铝合金板内腔套设有密封圈,所述密封圈外侧壁与试样筒内侧壁一侧顶部相贴合,且密封圈内腔直径与下铝合金板的直径相等,所述密封圈为聚四氟乙烯弹力垫圈。The inner cavity of the lower aluminum alloy plate is sleeved with a sealing ring, the outer side wall of the sealing ring is in contact with the top of one side of the inner side wall of the sample cylinder, and the diameter of the inner cavity of the sealing ring is equal to the diameter of the lower aluminum alloy plate. The sealing ring is a Teflon elastic washer.

作为上述技术方案的进一步描述:As a further description of the above technical solution:

所述上部铝合金板和下部铝合金板的横截面形状均为矩形,且上部铝合金板和下部铝合金板内部开口横截面形状为圆形,且上部铝合金板的厚度大于下部铝合金板的厚度。The cross-sectional shapes of the upper aluminum alloy plate and the lower aluminum alloy plate are both rectangular, and the cross-sectional shapes of the internal openings of the upper aluminum alloy plate and the lower aluminum alloy plate are circular, and the thickness of the upper aluminum alloy plate is larger than that of the lower aluminum alloy plate. thickness of.

作为上述技术方案的进一步描述:As a further description of the above technical solution:

所述水箱为有机玻璃筒,且水箱内设有搅拌机构,且搅拌机构通过驱动电机进行转动,且驱动电机固定安装在水箱内腔一侧。The water tank is a plexiglass cylinder, and a stirring mechanism is arranged in the water tank, and the stirring mechanism is rotated by a driving motor, and the driving motor is fixedly installed on one side of the inner cavity of the water tank.

作为上述技术方案的进一步描述:As a further description of the above technical solution:

所述试样筒为高强度透明有机玻璃筒。The sample tube is a high-strength transparent plexiglass tube.

作为上述技术方案的进一步描述:As a further description of the above technical solution:

所述底座下部四角处均设有支座,且支座横截面形状为矩形。The four corners of the lower part of the base are provided with supports, and the cross-sectional shape of the supports is rectangular.

一种模型循环荷载的底砟颗粒特性试验方法,具体包括以下步骤:A test method for the characteristics of bottom ballast particles under model cyclic loading, which specifically includes the following steps:

S1、试验装置检测准备,试验进行前需要对整个试验装置的完备性和密封性状况进行检查,对测试装置的荷重传感器、位移传感器、孔隙水压力传感器、动土压力传感器以及流量传感器进行校准,试验前需要对试验所用底砟材料的基本力学性质以及颗粒级配进行测定;S1. Test preparation of the test device. Before the test is carried out, the completeness and tightness of the entire test device need to be checked, and the load sensor, displacement sensor, pore water pressure sensor, earth pressure sensor and flow sensor of the test device should be calibrated and tested. The basic mechanical properties and particle gradation of the sub-ballast materials used in the test need to be determined beforehand;

S2、试验条件预备,试样制备之前需要在试验模型系统的底座上部铺设两层透水土工布,并打开底座处的进水阀门,使试样筒内部液面漫过土工布上表面,以排出进水管内部的空气,待底座进水口不再有气泡冒出,关闭进水阀门,在试样筒的内壁均匀涂抹凡士林,凡士林不仅可以减小土体与内壁之间的摩擦力,还可以避免产生集中渗流;S2. Test conditions are prepared. Before sample preparation, it is necessary to lay two layers of permeable geotextiles on the upper part of the base of the test model system, and open the water inlet valve at the base, so that the liquid level inside the sample cylinder overflows the upper surface of the geotextile to drain When the air inside the water inlet pipe no longer has bubbles emerging from the water inlet of the base, close the water inlet valve, and apply Vaseline evenly on the inner wall of the sample tube. Vaseline can not only reduce the friction between the soil and the inner wall, but also avoid produce concentrated seepage;

S3、试样装填准备,试样采用分层夯实法进行制备,夯实过程中尽量控制每一层落锤的高度基本一致,夯实的次数基本相同,夯实的次数根据同一批次试样夯实的次数确定;S3. Sample filling preparation. The sample is prepared by layered compaction method. During the compaction process, try to control the height of the drop weight of each layer to be basically the same. The number of compaction is basically the same. Sure;

S4、试样制备完成后安装好加载板、下部铝合金板和上部铝合金板部分,并且在下部铝合金板和上部铝合金板通过导向杆进行导向装配;S4. After the sample preparation is completed, the loading plate, the lower aluminum alloy plate and the upper aluminum alloy plate are installed, and the lower aluminum alloy plate and the upper aluminum alloy plate are guided and assembled by guide rods;

S5、水箱内部装一定量粘滞流体后,打开下部搅拌装置以防止流体离析,关闭进水阀门,打开水箱的进气阀门,按照设定的压力值对水箱内部的流体进行加压,待压力值稳定后打开试验模型系统的进水阀门,同时,按照设定的动荷载幅值以及动荷载频率开始对试样进行动荷载施加;S5. After a certain amount of viscous fluid is installed in the water tank, open the lower stirring device to prevent fluid segregation, close the water inlet valve, open the air inlet valve of the water tank, pressurize the fluid inside the water tank according to the set pressure value, wait for the pressure After the value is stable, open the water inlet valve of the test model system, and at the same time, start to apply dynamic load to the sample according to the set dynamic load amplitude and dynamic load frequency;

S6、采集数据,试验过程中数据采集系统通过对荷重传感器、位移传感器、孔隙水压力传感器、动土压力传感器以及流量传感器数据的收集实时记录并保存试验过程中的轴向力、轴向变形、动孔隙水压力、动土压力和流量数据;S6. Collect data. During the test, the data acquisition system records and saves the axial force, axial deformation, dynamic force and dynamic force during the test in real time by collecting the data of the load sensor, displacement sensor, pore water pressure sensor, earth pressure sensor and flow sensor. Pore water pressure, earth pressure and flow data;

S7、采集液体,试验过程中每次间隔一段时间收集流出液体,将液体装于瓶中,编号并记录好采集的时间信息,后期对液体的性质进行分析;S7. Collect the liquid, collect the outflow liquid every time during the test, put the liquid in a bottle, number and record the collected time information, and analyze the properties of the liquid later;

S8、结束测定,试验结束后将试样分层取出,测定每一层底砟材料的颗粒级配,与试验前颗粒级配进行对比分析。S8. End the measurement. After the test, the sample is taken out in layers, and the particle gradation of each layer of bottom ballast material is measured, and the particle gradation before the test is compared and analyzed.

综上所述,由于采用了上述技术方案,本发明的有益效果是:To sum up, due to the adoption of the above-mentioned technical solutions, the beneficial effects of the present invention are:

1、本发明中,通过设计的试验装置,通过水位控制装置可以实现复杂粘滞流的模拟,利用空气压缩机与压力控制器可以模拟不同压力下的粘滞流动,水箱与模型筒之间的流量计可以实现试验过程中流量的测量,通过试验模型系统可以实现底砟颗粒内部粘滞流特性以及底砟颗粒水—力耦合特性的研究,通过轴向加载装置实现列车荷载的模拟,从而能够利用该试验装置研究底砟填料内粘滞流动特性以及循环荷载作用下底砟颗粒水—力耦合特性,实现对底砟颗粒在脏污现象下特性的研究,有利于提高对底砟颗粒水力学特性的认知。1. In the present invention, the simulation of complex viscous flow can be realized through the designed test device and the water level control device, and the viscous flow under different pressures can be simulated by the air compressor and the pressure controller. The flowmeter can realize the measurement of the flow during the test. Through the test model system, the internal viscous flow characteristics of the bottom ballast particles and the water-mechanical coupling characteristics of the bottom ballast particles can be studied. The axial loading device can be used to simulate the train load, so that the The test device is used to study the viscous flow characteristics of the bottom ballast filler and the water-mechanical coupling characteristics of the bottom ballast particles under the action of cyclic loading, so as to realize the research on the characteristics of the bottom ballast particles under the fouling phenomenon, which is beneficial to improve the hydraulics of the bottom ballast particles. cognition of characteristics.

2、本发明中,通过设计的试验模型系统,通过在试验模型系统内填筑底砟颗粒,其下部进水管允许水箱内的粘滞流体进入试样内,在循环荷载以及粘滞流体压力驱动下沿着底砟颗粒孔隙向上流动,从上部出水管流出至收集箱中。模型筒侧壁开孔安装动孔隙水压力传感器,填料内部预先埋设动土压力传感器,试验过程中可以对不同部位的动孔隙水压力、动土压力进行测量。2. In the present invention, through the designed test model system, by filling the bottom ballast particles in the test model system, the lower water inlet pipe allows the viscous fluid in the water tank to enter the sample, and is driven by the cyclic load and the pressure of the viscous fluid. The bottom flows upward along the pores of the bottom ballast particles, and flows out from the upper outlet pipe to the collection box. The dynamic pore water pressure sensor is installed in the side wall of the model cylinder, and the dynamic earth pressure sensor is pre-buried inside the filler. During the test, the dynamic pore water pressure and dynamic earth pressure of different parts can be measured.

3、本发明中,通过设计的轴向加载装置,可以进行不同列车轴重即动应力幅值、列车运行速度即动应力频率以及不同列车运行次数即加载次数的模拟,轴向加载系统安装荷载传感器以及位移位移传感器,可以对底砟颗粒在试验过程中受到的轴向力以及产生的轴向位移进行测量,有效提高颗粒测试的模拟准度。3. In the present invention, through the designed axial loading device, it is possible to simulate different train axle loads, namely dynamic stress amplitude, train running speed, namely dynamic stress frequency, and different train running times, namely loading times. The axial loading system installs the load. The sensor and displacement sensor can measure the axial force and the generated axial displacement of the bottom ballast particles during the test, which can effectively improve the simulation accuracy of the particle test.

4、本发明中,通过收集箱对流出试验模型系统的粘滞流体进行收集,后期可以对粘滞流体特性进行测定,通过数据采集分析系统可以实现粘滞流流量,底砟颗粒内部不同位置处孔隙水压力、动土压力,试样所受的轴向力以及产生的轴向位移数据的实时采集与记录。4. In the present invention, the viscous fluid flowing out of the test model system is collected by the collection box, the characteristics of the viscous fluid can be measured later, and the viscous flow can be realized through the data acquisition and analysis system. Real-time collection and recording of pore water pressure, dynamic earth pressure, axial force on the sample and the generated axial displacement data.

附图说明Description of drawings

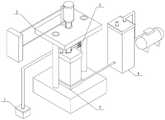

图1为本发明提出的模拟循环荷载作用下底砟颗粒特性试验装置及试验方法的立体结构示意图;Fig. 1 is the three-dimensional structure schematic diagram of the test device and test method of ballast particle characteristics under simulated cyclic load proposed by the present invention;

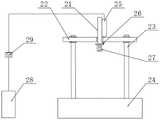

图2为本发明提出的模拟循环荷载作用下底砟颗粒特性试验装置及试验方法的正视剖面结构示意图;Fig. 2 is the front view sectional structure schematic diagram of the test device and test method of ballast particle characteristics under simulated cyclic load action proposed by the present invention;

图3为本发明提出的模拟循环荷载作用下底砟颗粒特性试验装置及试验方法的轴向加载装置结构示意图;3 is a schematic structural diagram of the axial loading device of the test device and the test method for the characteristics of ballast particles under simulated cyclic loading proposed by the present invention;

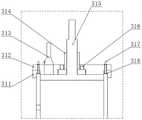

图4为本发明提出的模拟循环荷载作用下底砟颗粒特性试验装置及试验方法的试验模型系统结构示意图;4 is a schematic structural diagram of a test model system of a test device and a test method for simulating the characteristics of ballast particles under the action of a cyclic load proposed by the present invention;

图5为本发明提出的模拟循环荷载作用下底砟颗粒特性试验装置及试验方法的试验模型系统上部铝合金板部分结构示意图;5 is a schematic structural diagram of the upper part of the aluminum alloy plate of the test model system of the test device and test method for simulating the characteristics of ballast particles under the action of cyclic loads proposed by the present invention;

图6为本发明提出的模拟循环荷载作用下底砟颗粒特性试验装置及试验方法的试验模型系统底座部分结构示意图;6 is a schematic structural diagram of the base part of the test model system of the test device and test method for simulating the characteristics of ballast particles under the action of cyclic loads proposed by the present invention;

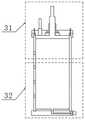

图7为本发明提出的模拟循环荷载作用下底砟颗粒特性试验装置及试验方法的水位控制系统结构示意图。FIG. 7 is a schematic structural diagram of the water level control system of the test device and test method for the characteristics of ballast particles under simulated cyclic loads proposed by the present invention.

图例说明:illustration:

1、收集箱;2、轴向加载装置;21、加载杆;22、加载横梁;23、加载架立柱;24、加载底座;25、轴向作动器;26、位移传感器;27、荷重传感器;28、油源;29、油压控制器;3、试验模型系统;311、下部铝合金板;312、上部铝合金板;313、出水阀门;314、导向柱;315、加载板;316、导向螺栓;317、支撑杆;318、密封圈;321、动土压力传感器;322、试样筒;323、底座;324、支座;325、孔隙水压力传感器;326、进水阀门;4、水位控制系统;41、流量传感器;42、水箱;43、压力控制器;44、空气压缩机;5、数据采集系统。1. Collection box; 2. Axial loading device; 21. Loading rod; 22. Loading beam; 23. Loading frame column; 24. Loading base; 25. Axial actuator; 26. Displacement sensor; 27. Load sensor ; 28, oil source; 29, oil pressure controller; 3, test model system; 311, lower aluminum alloy plate; 312, upper aluminum alloy plate; 313, water outlet valve; 314, guide column; 315, loading plate; 316, Guide bolt; 317, support rod; 318, sealing ring; 321, earth pressure sensor; 322, sample cylinder; 323, base; 324, support; 325, pore water pressure sensor; 326, water inlet valve; 4, water level Control system; 41, flow sensor; 42, water tank; 43, pressure controller; 44, air compressor; 5, data acquisition system.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有作出创造性劳动前提下所获得的所有其它实施例,都属于本发明保护的范围。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

请参阅图1-7,本发明提供一种技术方案:一种模拟循环荷载作用下底砟颗粒特性试验装置,包括收集箱1,所述收集箱1一侧连通有试验模型系统3,所述试验模型系统3顶部连接有轴向加载装置2,所述试验模型系统3一侧连通有水位控制系统4,且轴向加载装置2和试验模型系统3一侧连通有数据采集系统5;1-7, the present invention provides a technical solution: a test device for simulating the characteristics of bottom ballast particles under the action of cyclic loads, comprising a

所述轴向加载装置2包括加载横梁22,所述加载横梁22两侧均通过加载架立柱23固定连接有加载底座24,所述加载横梁22内滑动连接有加载杆21,所述油压控制器29底部连通有油源28,所述加载杆21底端固定连接有荷重传感器27,所述加载杆21一侧固定连接有位移传感器26;The

所述试验模型系统3包括试样筒322,所述试样筒322内滑动连接有加载板315,所述加载板315顶部与荷重传感器27底部相贴合,所述加载板315顶部贴合有上部铝合金板312,所述上部铝合金板312通过导向螺栓316连接有导向柱314,所述试样筒322侧壁开孔安装有孔隙水压力传感器325和动土压力传感器321,所述上部铝合金板312底部贴合有下部铝合金板311,且上部铝合金板312和下部铝合金板311四角处均通过支撑杆317连接有底座323,且支撑杆317位于试样筒322周侧,且支撑杆317顶端通过螺栓与上部铝合金板312限位,所述底座323一侧固定安装有进水阀门326,且进水阀门326与水位控制系统4相连通,且底座323上表面开设有进水阀门326相连通的开口,且底座323下部四角处均设有支座324,所述上部铝合金板312顶部嵌设有出水阀门313,且出水阀门313与收集箱1相连通。The

所述水位控制系统4包括水箱42,所述水箱42下部一侧出水口与试验模型系统3进水口通过软管相连接,且出水口与进水口之间安装有流量传感器41,所述水箱42上部通过管路与外部水源相连,且水箱42通过上部进气阀门连接有空气压缩机44,所述空气压缩机44一侧设有压力控制器43,所述加载杆21一侧固定连接有轴向作动器25,所述轴向作动器25一侧连通有油压控制器29,所述下部铝合金板311通过密封圈318套设在试样筒322外部,且密封圈318内腔直径与下铝合金板的直径相等,所述上部铝合金板312和下部铝合金板311的横截面形状均为矩形,且上部铝合金板312和下部铝合金板311内部开口横截面形状为圆形,所述水箱42为有机玻璃筒,且水箱42内设有搅拌机构,所述试样筒322为高强度透明有机玻璃筒,所述底座323下部四角处均设有支座324,且支座324横截面形状为矩形。The water

实施方式具体为:收集箱1为PVC水箱42,主要收集试验过程中从试验模型系统3出水阀门313流出的液体,方便后续对流出液体的性质进行测定,加载立柱上连接加载横梁22,加载横梁22的高度可调节,以适应不同高度的试样,通过油压控制器29控制油源28可以提供可靠的液压动力,再通过轴向作动器25实现不同形式静和动荷载的输出,荷重传感器27可以精确测量输出荷载的量级,位移传感器26可以测量加载过程中产生的轴向位移,加载板315由高强度钢材制成,可以将动荷载均匀施加在试样上,上部铝合金板312在试样制备过程中可以拆卸,下部铝合金板311与试样筒322连接处设置密封圈318,部铝合金板与导向柱314通过螺栓连接,试样筒322为高强度透明有机玻璃,试样筒322侧壁开孔安装有孔隙水压力传感器325以及动土压力传感器321,水箱42中的水通过进水阀门326以及底座323上表面开口流入试样内部,水箱42下部的出水口与试验模型系统3的进水口通过PVC软管相连,并在两者之间安装流量传感器41,通过PVC软管提高拉扯适配性。The specific embodiment is as follows: the

所述数据采集系统5用于采集试验过程中荷重传感器27、位移传感器26、孔隙水压力传感器325、动土压力传感器321以及流量传感器41采集到的物理信号转换为数字信号并保存。The

一种模型循环荷载的底砟颗粒特性试验方法,具体包括以下步骤:A test method for the characteristics of bottom ballast particles under model cyclic loading, which specifically includes the following steps:

S1、试验装置检测准备,试验进行前需要对整个试验装置的完备性和密封性状况进行检查,对测试装置的荷重传感器27、位移传感器26、孔隙水压力传感器325、动土压力传感器321以及流量传感器41进行校准,试验前需要对试验所用底砟材料的基本力学性质以及颗粒级配进行测定;S1. Test preparation of the test device. Before the test, the completeness and tightness of the entire test device need to be checked, and the

S2、试验条件预备,试样制备之前需要在试验模型系统3的底座323上部铺设两层透水土工布,并打开底座323处的进水阀门326,使试样筒322内部液面漫过土工布上表面,以排出进水管内部的空气,待底座323进水口不再有气泡冒出,关闭进水阀门326,在试样筒322的内壁均匀涂抹凡士林,凡士林不仅可以减小土体与内壁之间的摩擦力,还可以避免产生集中渗流;S2. The test conditions are prepared. Before the sample preparation, two layers of permeable geotextiles need to be laid on the upper part of the

S3、试样装填准备,试样采用分层夯实法进行制备,夯实过程中尽量控制每一层落锤的高度基本一致,夯实的次数基本相同,夯实的次数根据同一批次试样夯实的次数确定;S3. Sample filling preparation. The sample is prepared by layered compaction method. During the compaction process, try to control the height of the drop weight of each layer to be basically the same. The number of compaction is basically the same. Sure;

S4、试样制备完成后安装好加载板315、下部铝合金板311和上部铝合金板312部分,并且在下部铝合金板311和上部铝合金板312通过导向杆314进行导向装配;S4. After the sample preparation is completed, the

S5、水箱42内部装一定量粘滞流体后,打开下部搅拌装置以防止流体离析,关闭进水阀门326,打开水箱42的进气阀门,按照设定的压力值对水箱42内部的流体进行加压,待压力值稳定后打开试验模型系统3的进水阀门326,同时,按照设定的动荷载幅值以及动荷载频率开始对试样进行动荷载施加;S5. After a certain amount of viscous fluid is installed in the

S6、采集数据,试验过程中数据采集系统5通过对荷重传感器27、位移传感器26、孔隙水压力传感器325、动土压力传感器321以及流量传感器41数据的收集实时记录并保存试验过程中的轴向力、轴向变形、动孔隙水压力、动土压力和流量数据;S6. Collect data. During the test, the

S7、采集液体,试验过程中每次间隔一段时间收集流出液体,将液体装于瓶中,编号并记录好采集的时间信息,后期对液体的性质进行分析;S7. Collect the liquid, collect the outflow liquid every time during the test, put the liquid in a bottle, number and record the collected time information, and analyze the properties of the liquid later;

S8、结束测定,试验结束后将试样分层取出,测定每一层底砟材料的颗粒级配,与试验前颗粒级配进行对比分析。S8. End the measurement. After the test, the sample is taken out in layers, and the particle gradation of each layer of bottom ballast material is measured, and the particle gradation before the test is compared and analyzed.

以上所述,仅为本发明较佳的具体实施方式,但本发明的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本发明揭露的技术范围内,根据本发明的技术方案及其发明构思加以等同替换或改变,都应涵盖在本发明的保护范围之内。The above description is only a preferred embodiment of the present invention, but the protection scope of the present invention is not limited to this. The equivalent replacement or change of the inventive concept thereof shall be included within the protection scope of the present invention.

Claims (9)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110652373.7ACN113295597B (en) | 2021-06-11 | 2021-06-11 | Test device and test method for ballast particle characteristics under simulated cyclic load |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110652373.7ACN113295597B (en) | 2021-06-11 | 2021-06-11 | Test device and test method for ballast particle characteristics under simulated cyclic load |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN113295597A CN113295597A (en) | 2021-08-24 |

| CN113295597Btrue CN113295597B (en) | 2022-04-26 |

Family

ID=77328001

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110652373.7AActiveCN113295597B (en) | 2021-06-11 | 2021-06-11 | Test device and test method for ballast particle characteristics under simulated cyclic load |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113295597B (en) |

Families Citing this family (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114324076B (en)* | 2022-03-10 | 2022-05-31 | 西南交通大学 | A particle migration measurement device for graded crushed stone permeable base |

| CN114935524A (en)* | 2022-05-20 | 2022-08-23 | 广西交通职业技术学院 | A test method for the maximum compression ratio and maximum forming density of stone filling |

| CN114878313A (en)* | 2022-05-31 | 2022-08-09 | 西安建筑科技大学 | Broken stone and aggregate repeated load test device and method under combined action of water permeability and load |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103217348A (en)* | 2013-04-12 | 2013-07-24 | 同济大学 | Testing device for simulating mechanical behaviors of gravel soil subgrade under reciprocating traffic moving load |

| CN103760045A (en)* | 2014-01-15 | 2014-04-30 | 湖南省交通科学研究院 | Simulated experiment device for dynamic damages of roadbeds and road surfaces under highway traffic loads |

| CN107576562A (en)* | 2017-10-19 | 2018-01-12 | 南京泰克奥科技有限公司 | A kind of multi- scenarios method true triaxial test system and its test method |

| CN108051308A (en)* | 2017-12-29 | 2018-05-18 | 成都东华卓越科技有限公司 | Sound state triaxial test system |

| CN109374855A (en)* | 2018-09-20 | 2019-02-22 | 中南大学 | A test device and test method for simulating the phenomenon of muddying and muddying of railway subgrade |

| CN110006793A (en)* | 2019-05-08 | 2019-07-12 | 中南大学 | Test device and method for studying the kinematic properties of granular materials under vibration loading |

| CN110006764A (en)* | 2019-05-13 | 2019-07-12 | 安徽建筑大学 | Geotechnical and underground engineering model test traffic dynamic load simulation device and test method |

- 2021

- 2021-06-11CNCN202110652373.7Apatent/CN113295597B/enactiveActive

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103217348A (en)* | 2013-04-12 | 2013-07-24 | 同济大学 | Testing device for simulating mechanical behaviors of gravel soil subgrade under reciprocating traffic moving load |

| CN103760045A (en)* | 2014-01-15 | 2014-04-30 | 湖南省交通科学研究院 | Simulated experiment device for dynamic damages of roadbeds and road surfaces under highway traffic loads |

| CN107576562A (en)* | 2017-10-19 | 2018-01-12 | 南京泰克奥科技有限公司 | A kind of multi- scenarios method true triaxial test system and its test method |

| CN108051308A (en)* | 2017-12-29 | 2018-05-18 | 成都东华卓越科技有限公司 | Sound state triaxial test system |

| CN109374855A (en)* | 2018-09-20 | 2019-02-22 | 中南大学 | A test device and test method for simulating the phenomenon of muddying and muddying of railway subgrade |

| CN110006793A (en)* | 2019-05-08 | 2019-07-12 | 中南大学 | Test device and method for studying the kinematic properties of granular materials under vibration loading |

| CN110006764A (en)* | 2019-05-13 | 2019-07-12 | 安徽建筑大学 | Geotechnical and underground engineering model test traffic dynamic load simulation device and test method |

Non-Patent Citations (2)

| Title |

|---|

| 粗粒土路基循环荷载试验及累积变形模型研究;龙尧 等;《振动与冲击》;20171231;第36卷(第16期);第43-46页、第72页* |

| 高速铁路路基模型列车振动荷载模拟;王启云 等;《振动与冲击》;20131231;第32卷(第6期);第128-133页、第1587页* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN113295597A (en) | 2021-08-24 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN113295597B (en) | Test device and test method for ballast particle characteristics under simulated cyclic load | |

| CN105486840B (en) | A kind of consolidation infiltration Collaborative experiment device | |

| CN110849790B (en) | A constant water head static load pile-supported roadbed seepage erosion test device | |

| CN101915718A (en) | Consolidation and penetration test device and test method of multifunctional soil | |

| CN110208123A (en) | A kind of laboratory testing rig measuring soil sample seepage inflow erosion characteristic under pressure in situ | |

| CN107290501B (en) | Experimental device and method for seepage instability and water inrush of filling medium in fractured-fault-type geological structure | |

| CN112540010B (en) | Triaxial test device and test method for soil stress path piping | |

| CN115112531B (en) | A multifunctional penetration piping test device and method | |

| CN109374855A (en) | A test device and test method for simulating the phenomenon of muddying and muddying of railway subgrade | |

| CN109001098A (en) | A kind of instantaneous Penetration Signature tester of soil and soil infiltration characteristics calculation method | |

| CN105862933B (en) | The foundation model experimental rig of dynamic artesian water effect | |

| CN105716958B (en) | Simulate the foundation model experimental rig of artesian head lifting | |

| CN104819925A (en) | Comprehensive test equipment for observing permeation and settlement of accumulated gravel soil | |

| CN113218841A (en) | Device and method for testing reverse filtration characteristic of geotextile | |

| CN110409400A (en) | A test device and test method for measuring the temporal and spatial evolution characteristics of mud turbidity | |

| CN103293286B (en) | Soil body phase transformation-Ben structure Coupling Rule test proving installation and method | |

| CN105672378B (en) | Simulate the excavation of foundation pit model test apparatus of artesian head lifting | |

| CN205484324U (en) | Concrete joint experimental apparatus of infiltration | |

| CN117074270A (en) | Test method for low-stress soft soil consolidation | |

| CN205506572U (en) | Ground model test device that simulation artesian head goes up and down | |

| CN115078219A (en) | Multifunctional test device for studying water migration in soil | |

| CN205712215U (en) | The excavation of foundation pit model test apparatus of simulation artesian head lifting | |

| US20250290840A1 (en) | Seepage erosion test system | |

| CN113640210A (en) | A test device for the ability of a geomembrane anti-seepage structure to adapt to the deformation of a dam body or a dam foundation | |

| CN205720219U (en) | Phreatic table and artesian head work in coordination with the excavation of foundation pit model test apparatus of lifting |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |