CN113150560B - pH colorimetric sensing membrane, preparation method and application thereof - Google Patents

pH colorimetric sensing membrane, preparation method and application thereofDownload PDFInfo

- Publication number

- CN113150560B CN113150560BCN202110125241.9ACN202110125241ACN113150560BCN 113150560 BCN113150560 BCN 113150560BCN 202110125241 ACN202110125241 ACN 202110125241ACN 113150560 BCN113150560 BCN 113150560B

- Authority

- CN

- China

- Prior art keywords

- film

- solution

- alizarin

- antibacterial

- forming

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription47

- 239000012528membraneSubstances0.000titleclaimsabstractdescription20

- RGCKGOZRHPZPFP-UHFFFAOYSA-NalizarinChemical compoundC1=CC=C2C(=O)C3=C(O)C(O)=CC=C3C(=O)C2=C1RGCKGOZRHPZPFP-UHFFFAOYSA-N0.000claimsabstractdescription108

- 235000013305foodNutrition0.000claimsabstractdescription18

- 239000004014plasticizerSubstances0.000claimsabstractdescription18

- 235000013372meatNutrition0.000claimsabstractdescription12

- 239000000758substrateSubstances0.000claimsabstractdescription11

- 239000002994raw materialSubstances0.000claimsabstractdescription9

- 239000000243solutionSubstances0.000claimsdescription91

- 230000000844anti-bacterial effectEffects0.000claimsdescription44

- 108010010803GelatinProteins0.000claimsdescription34

- 229920000159gelatinPolymers0.000claimsdescription34

- 239000008273gelatinSubstances0.000claimsdescription34

- 235000019322gelatineNutrition0.000claimsdescription34

- 235000011852gelatine dessertsNutrition0.000claimsdescription34

- PEDCQBHIVMGVHV-UHFFFAOYSA-Nglycerol groupChemical groupOCC(O)COPEDCQBHIVMGVHV-UHFFFAOYSA-N0.000claimsdescription25

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000claimsdescription22

- 239000011259mixed solutionSubstances0.000claimsdescription21

- 239000000203mixtureSubstances0.000claimsdescription19

- 239000007788liquidSubstances0.000claimsdescription17

- 239000002105nanoparticleSubstances0.000claimsdescription16

- 229910021642ultra pure waterInorganic materials0.000claimsdescription12

- 239000012498ultrapure waterSubstances0.000claimsdescription12

- 238000002156mixingMethods0.000claimsdescription11

- 239000000839emulsionSubstances0.000claimsdescription8

- 244000178870Lavandula angustifoliaSpecies0.000claimsdescription7

- 235000010663Lavandula angustifoliaNutrition0.000claimsdescription7

- 239000001102lavandula veraSubstances0.000claimsdescription7

- 235000018219lavenderNutrition0.000claimsdescription7

- 239000000341volatile oilSubstances0.000claimsdescription7

- 238000000034methodMethods0.000claimsdescription6

- 238000007872degassingMethods0.000claimsdescription5

- 239000011159matrix materialSubstances0.000claimsdescription4

- 230000015572biosynthetic processEffects0.000claimsdescription3

- 238000004737colorimetric analysisMethods0.000claimsdescription2

- 239000012530fluidSubstances0.000claimsdescription2

- 229920006280packaging filmPolymers0.000claimsdescription2

- 239000012785packaging filmSubstances0.000claimsdescription2

- 230000008859changeEffects0.000abstractdescription9

- 238000012544monitoring processMethods0.000abstractdescription6

- 150000001412aminesChemical class0.000abstractdescription4

- 230000000035biogenic effectEffects0.000abstractdescription3

- 238000004519manufacturing processMethods0.000abstractdescription3

- 235000013622meat productNutrition0.000abstractdescription3

- 244000005700microbiomeSpecies0.000abstractdescription3

- 230000006866deteriorationEffects0.000abstractdescription2

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterChemical compoundOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description20

- 108010025899gelatin filmProteins0.000description17

- 238000002834transmittanceMethods0.000description10

- 238000003756stirringMethods0.000description9

- 230000000694effectsEffects0.000description8

- 238000002441X-ray diffractionMethods0.000description7

- 235000011187glycerolNutrition0.000description7

- QTBSBXVTEAMEQO-UHFFFAOYSA-NAcetic acidChemical compoundCC(O)=OQTBSBXVTEAMEQO-UHFFFAOYSA-N0.000description6

- QGZKDVFQNNGYKY-UHFFFAOYSA-NAmmoniaChemical compoundNQGZKDVFQNNGYKY-UHFFFAOYSA-N0.000description6

- 230000004888barrier functionEffects0.000description6

- 230000005540biological transmissionEffects0.000description6

- 238000001878scanning electron micrographMethods0.000description6

- 230000001954sterilising effectEffects0.000description6

- 238000004659sterilization and disinfectionMethods0.000description6

- 241000588724Escherichia coliSpecies0.000description5

- 241000191967Staphylococcus aureusSpecies0.000description5

- 238000012360testing methodMethods0.000description5

- CSCPPACGZOOCGX-UHFFFAOYSA-NAcetoneChemical compoundCC(C)=OCSCPPACGZOOCGX-UHFFFAOYSA-N0.000description4

- IJGRMHOSHXDMSA-UHFFFAOYSA-NAtomic nitrogenChemical compoundN#NIJGRMHOSHXDMSA-UHFFFAOYSA-N0.000description4

- 230000002401inhibitory effectEffects0.000description4

- 230000002147killing effectEffects0.000description4

- 239000007864aqueous solutionSubstances0.000description3

- 239000000463materialSubstances0.000description3

- 238000004806packaging method and processMethods0.000description3

- 239000000126substanceSubstances0.000description3

- ROSDSFDQCJNGOL-UHFFFAOYSA-NDimethylamineChemical compoundCNCROSDSFDQCJNGOL-UHFFFAOYSA-N0.000description2

- VVQNEPGJFQJSBK-UHFFFAOYSA-NMethyl methacrylateChemical compoundCOC(=O)C(C)=CVVQNEPGJFQJSBK-UHFFFAOYSA-N0.000description2

- 229920005372Plexiglas®Polymers0.000description2

- 230000009471actionEffects0.000description2

- 229910021529ammoniaInorganic materials0.000description2

- 238000011161developmentMethods0.000description2

- 238000007689inspectionMethods0.000description2

- 229910052757nitrogenInorganic materials0.000description2

- 235000015277porkNutrition0.000description2

- 230000008569processEffects0.000description2

- GETQZCLCWQTVFV-UHFFFAOYSA-NtrimethylamineChemical compoundCN(C)CGETQZCLCWQTVFV-UHFFFAOYSA-N0.000description2

- NLXLAEXVIDQMFP-UHFFFAOYSA-NAmmonium chlorideSubstances[NH4+].[Cl-]NLXLAEXVIDQMFP-UHFFFAOYSA-N0.000description1

- VHUUQVKOLVNVRT-UHFFFAOYSA-NAmmonium hydroxideChemical compound[NH4+].[OH-]VHUUQVKOLVNVRT-UHFFFAOYSA-N0.000description1

- 241000894006BacteriaSpecies0.000description1

- 102000004190EnzymesHuman genes0.000description1

- 108090000790EnzymesProteins0.000description1

- SXRSQZLOMIGNAQ-UHFFFAOYSA-NGlutaraldehydeChemical compoundO=CCCCC=OSXRSQZLOMIGNAQ-UHFFFAOYSA-N0.000description1

- 239000002313adhesive filmSubstances0.000description1

- 235000011114ammonium hydroxideNutrition0.000description1

- 230000009286beneficial effectEffects0.000description1

- 238000000354decomposition reactionMethods0.000description1

- 230000007423decreaseEffects0.000description1

- 230000007547defectEffects0.000description1

- 230000007812deficiencyEffects0.000description1

- 238000004807desolvationMethods0.000description1

- 238000010586diagramMethods0.000description1

- 238000011156evaluationMethods0.000description1

- 238000002474experimental methodMethods0.000description1

- 239000002360explosiveSubstances0.000description1

- 238000009920food preservationMethods0.000description1

- 239000010794food wasteSubstances0.000description1

- 239000003292glueSubstances0.000description1

- 238000010438heat treatmentMethods0.000description1

- 230000000813microbial effectEffects0.000description1

- QJGQUHMNIGDVPM-UHFFFAOYSA-Nnitrogen groupChemical group[N]QJGQUHMNIGDVPM-UHFFFAOYSA-N0.000description1

- 231100000252nontoxicToxicity0.000description1

- 230000003000nontoxic effectEffects0.000description1

- 231100000956nontoxicityToxicity0.000description1

- 235000021485packed foodNutrition0.000description1

- 239000002245particleSubstances0.000description1

- 239000007793ph indicatorSubstances0.000description1

- 238000004321preservationMethods0.000description1

- 108090000623proteins and genesProteins0.000description1

- 102000004169proteins and genesHuman genes0.000description1

- 230000002441reversible effectEffects0.000description1

- 230000001953sensory effectEffects0.000description1

- 238000003860storageMethods0.000description1

- 239000006228supernatantSubstances0.000description1

- 230000007704transitionEffects0.000description1

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/18—Manufacture of films or sheets

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D65/00—Wrappers or flexible covers; Packaging materials of special type or form

- B65D65/38—Packaging materials of special type or form

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D81/00—Containers, packaging elements, or packages, for contents presenting particular transport or storage problems, or adapted to be used for non-packaging purposes after removal of contents

- B65D81/24—Adaptations for preventing deterioration or decay of contents; Applications to the container or packaging material of food preservatives, fungicides, pesticides or animal repellants

- B65D81/28—Applications of food preservatives, fungicides, pesticides or animal repellants

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2389/00—Characterised by the use of proteins; Derivatives thereof

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2489/00—Characterised by the use of proteins; Derivatives thereof

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2491/00—Characterised by the use of oils, fats or waxes; Derivatives thereof

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/04—Oxygen-containing compounds

- C08K5/05—Alcohols; Metal alcoholates

- C08K5/053—Polyhydroxylic alcohols

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/04—Oxygen-containing compounds

- C08K5/13—Phenols; Phenolates

- C08K5/132—Phenols containing keto groups, e.g. benzophenones

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Mechanical Engineering (AREA)

- Food Science & Technology (AREA)

- Medicinal Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Life Sciences & Earth Sciences (AREA)

- Health & Medical Sciences (AREA)

- Pest Control & Pesticides (AREA)

- Materials Engineering (AREA)

- Investigating Or Analysing Materials By The Use Of Chemical Reactions (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于食品工程技术领域,具体涉及一种pH比色传感膜、制备方法及其应用。The invention belongs to the technical field of food engineering, and particularly relates to a pH colorimetric sensing film, a preparation method and an application thereof.

背景技术Background technique

食物垃圾的爆炸性增长和食品安全问题一直是社会各界持续关注的焦点科学问题之一,猪肉是我国消费量最大的食用肉类,鲜肉保鲜及包装储存是肉品工业的发展方向之一。肉类新鲜度是指动物性食品由于酶和细菌的作用,在腐败过程中,使蛋白质分解而产生氨以及胺类等碱性含氮物质,例如氨气,二甲胺和三甲胺等,据挥发性盐基总氮是肉食品新鲜度最重要的理化指标,也是肉品检验的须测项目。挥发性盐基氮与动物性食品腐败变质之间有明确的对应关系,它是食品卫生检验标准的一项重要指标,特别是对于鲜肉和肉制品。尽管有很多理化实验方法和感官评价法能够判断猪肉的新鲜度,但传统方法存在操作复杂、耗时耗力、对实验人员技术要求高等局限。The explosive growth of food waste and food safety issues have always been one of the focal scientific issues of continuous attention from all walks of life. Pork is the most consumed edible meat in my country. Fresh meat preservation and packaging storage are one of the development directions of the meat industry. Meat freshness refers to the decomposition of protein in animal food due to the action of enzymes and bacteria to produce ammonia and amines and other alkaline nitrogen-containing substances, such as ammonia, dimethylamine and trimethylamine. Volatile base total nitrogen is the most important physical and chemical index of meat freshness, and it is also a test item for meat inspection. There is a clear correspondence between volatile base nitrogen and animal food spoilage, and it is an important indicator of food hygiene inspection standards, especially for fresh meat and meat products. Although there are many physical and chemical experimental methods and sensory evaluation methods to judge the freshness of pork, the traditional methods have the limitations of complicated operation, time-consuming and labor-intensive, and high technical requirements for experimenters.

发明内容SUMMARY OF THE INVENTION

针对现有技术中的缺陷和不足,本发明采用的一种pH比色传感膜、制备方法及其应用,根据酸碱条件而变化,pH比色传感膜从低pH值的黄色变为高pH值的紫色,并且在反复的pH变化下,颜色变化会再次重现;同时由于肉制品变质时,微生物生长增加和生物胺的产生使得其酸碱环境发生变化,pH比色传感膜在食品肉类的新鲜度监测中显示出巨大的潜在用途,整体具有使用便捷、安全、无毒、可降解、可食用、食品pH监测潜力等优势。In view of the defects and deficiencies in the prior art, a pH colorimetric sensing film, a preparation method and an application thereof adopted in the present invention change according to the acid-base conditions, and the pH colorimetric sensing film changes from yellow at low pH value to High pH purple color, and under repeated pH changes, the color change will reproduce again; at the same time, due to the deterioration of meat products, the increase in microbial growth and the production of biogenic amines make the acid-base environment change, pH colorimetric sensing membrane It has shown a huge potential use in the freshness monitoring of food meat, and has the advantages of convenient use, safety, non-toxicity, degradability, edible, and potential for food pH monitoring.

为达到上述技术效果,本发明采取的技术方案为:In order to achieve above-mentioned technical effect, the technical scheme adopted in the present invention is:

一种pH比色传感膜,原料包括成膜基体和增塑剂,原料包括成膜基体、增塑剂和茜素溶液。A pH colorimetric sensing film, the raw materials include a film-forming substrate and a plasticizer, and the raw materials include a film-forming substrate, a plasticizer and an alizarin solution.

进一步的,原料还包括抗菌溶液,茜素溶液和抗菌溶液混合制得混合溶液,混合溶液中茜素溶液和抗菌溶液的组分分别为50%—100%和50%—0,且抗菌溶液的组分不为0。Further, the raw materials also include an antibacterial solution, and the alizarin solution and the antibacterial solution are mixed to obtain a mixed solution. The components of the alizarin solution and the antibacterial solution in the mixed solution are 50%-100% and 50%-0 respectively, and the antibacterial solution is component is not 0.

优选的,茜素溶液是由体积比为1:(9-10)的茜素乳液和超纯水混合制得;茜素乳液是由固液比为(2—6):1g/L的茜素和乙醇混合制得。Preferably, the alizarin solution is prepared by mixing alizarin emulsion with a volume ratio of 1:(9-10) and ultrapure water; the alizarin emulsion is prepared from alizarin with a solid-liquid ratio of (2-6):1g/L prepared by mixing ethanol and ethanol.

优选的,抗菌溶液是由体积比为4:(45—47)的薰衣草精油与明胶纳米颗粒溶液混合制得;明胶纳米颗粒溶液是由质量比为1:(499—500)的明胶纳米颗粒和超纯水混合制得。Preferably, the antibacterial solution is prepared by mixing lavender essential oil with a gelatin nanoparticle solution in a volume ratio of 4:(45-47); the gelatin nanoparticle solution is prepared by mixing the gelatin nanoparticles and Mixed with ultrapure water.

优选的,pH比色传感膜是在混合溶液或茜素溶液中添加40g/L的成膜基体和10g/L的增塑剂,于45±1℃的条件下混合脱气得到成膜液,再将成膜液铺展至厚度为4±0.5mm,并于温度为23±0.5℃、湿度为50±3%以及成膜时间为24-48h成膜后制得。Preferably, the pH colorimetric sensing film is obtained by adding 40 g/L of film-forming substrate and 10 g/L of plasticizer to the mixed solution or alizarin solution, and mixing and degassing at 45±1 °C to obtain the film-forming liquid , and then spread the film-forming liquid to a thickness of 4±0.5mm, and prepare the film after forming the film at a temperature of 23±0.5° C., a humidity of 50±3% and a film-forming time of 24-48h.

优选的,成膜基体为明胶,增塑剂为甘油。Preferably, the film-forming matrix is gelatin, and the plasticizer is glycerol.

一种本发明公开的pH比色传感膜的制备方法,包括如下步骤:A preparation method of a pH colorimetric sensing membrane disclosed in the present invention comprises the following steps:

步骤1,茜素溶液的制备:将固液比为(2—6):1g/L的茜素和乙醇混合得到茜素乳液,再将茜素乳液和超纯水以体积比为1:(9-10)混合制得茜素溶液;Step 1, the preparation of alizarin solution: the solid-liquid ratio is (2-6): 1g/L of alizarin and ethanol are mixed to obtain alizarin emulsion, and then the alizarin emulsion and ultrapure water are 1:( 9-10) mix to obtain Alizarin solution;

步骤2,成膜液的制备:在步骤1的得到的茜素溶液中添加40g/L的成膜基体和10g/L的增塑剂,于45±1℃的条件下混合脱气得到成膜液;Step 2, preparation of film-forming solution: add 40g/L of film-forming substrate and 10g/L of plasticizer to the alizarin solution obtained in step 1, mix and degas at 45±1°C to obtain film-forming liquid;

步骤3,将步骤2得到的成膜液铺展至厚度为4±0.5mm,并于温度为 23±0.5℃、湿度为50±3%以及成膜时间为24-48h成膜后得到pH比色传感膜。

进一步的,还包括如下步骤:Further, it also includes the following steps:

步骤4,抗菌溶液的制备:将质量比为1:(499—500)的明胶纳米颗粒和超纯水混合得到明胶纳米颗粒溶液,再将体积比为4:(45—47)的薰衣草精油与明胶纳米颗粒溶液混合得到抗菌溶液;

步骤5,混合溶液的制备:将步骤1的得到的茜素溶液和步骤4的得到的抗菌溶液混合得到混合溶液,混合溶液中茜素溶液和抗菌溶液的组分分别为50%—100%和50%—0,且抗菌溶液的组分不为0;

步骤6,抗菌成膜液的制备:在步骤5的得到的混合溶液中添加40g/L 的成膜基体和10g/L的增塑剂,于45±1℃的条件下混合脱气得到抗菌成膜液;Step 6, preparation of antibacterial film-forming solution: add 40g/L of film-forming substrate and 10g/L of plasticizer to the mixed solution obtained in

步骤7,将步骤6得到的抗菌成膜液铺展至厚度为4±0.5mm,并于温度为23±0.5℃、湿度为50±3%以及成膜时间为24-48h成膜后得到pH比色传感膜。Step 7, spread the antibacterial film-forming liquid obtained in step 6 to a thickness of 4±0.5mm, and obtain the pH ratio after film formation at a temperature of 23±0.5° C., a humidity of 50±3% and a film-forming time of 24-48h. Color sensing film.

优选的,成膜基体为明胶,增塑剂为甘油。Preferably, the film-forming matrix is gelatin, and the plasticizer is glycerol.

一种本发明公开的pH比色传感膜用作肉类食品包装膜的应用。An application of the pH colorimetric sensing film disclosed in the present invention as a meat food packaging film.

由于采用上述技术方案,具有以下有益效果:Due to the adoption of the above technical solution, the following beneficial effects are obtained:

(1)本发明的pH比色传感膜、制备方法及其应用,根据酸碱条件而变化,传感膜从低pH值的黄色变为高pH值的紫色;同时由于肉制品变质时, 微生物生长增加和生物胺的产生使得其酸碱环境发生变化,pH比色传感膜在食品肉类的新鲜度监测中显示出巨大的潜在用途。(1) The pH colorimetric sensing film of the present invention, the preparation method and the application thereof change according to the acid-base conditions, and the sensing film changes from yellow with low pH value to purple with high pH value; The increased growth of microorganisms and the production of biogenic amines change their acid-base environment, and pH colorimetric sensing membranes show great potential for monitoring the freshness of food and meat.

(2)本发明的pH比色传感膜、制备方法及其应用,从低pH值的黄色变为高pH值的紫色,并且在反复的pH变化下,颜色变化会再次重现,增加了pH比色传感膜指示食品新鲜度的实用性。(2) The pH colorimetric sensing membrane, preparation method and application of the present invention change from yellow at low pH to purple at high pH, and under repeated pH changes, the color change will reproduce again, increasing the The utility of pH colorimetric sensing membranes to indicate food freshness.

(3)本发明的pH比色传感膜、制备方法及其应用,具有良好的抗菌性能,能阻止外界微生物与食品接触,抑制食品腐烂,从而达到食品保鲜及延长货架期的效果。(3) The pH colorimetric sensing film, preparation method and application of the present invention have good antibacterial properties, can prevent external microorganisms from contacting food, inhibit food rot, thereby achieving the effects of food preservation and shelf life extension.

(4)本发明的pH比色传感膜、制备方法及其应用,其原料来源广泛,同时茜素为绿色天然、无毒无害原料;整体具有使用便捷、安全、无毒、可降解、可食用、食品pH监测潜力等优势。(4) The pH colorimetric sensing film, preparation method and application thereof of the present invention have a wide range of raw material sources, and at the same time alizarin is a green, natural, non-toxic and harmless raw material; Edible, food pH monitoring potential and other advantages.

附图说明Description of drawings

图1为传统胶膜和本发明pH比色传感膜的SEM图;Fig. 1 is the SEM image of traditional glue film and pH colorimetric sensing film of the present invention;

(其中,图1a为实施例1制备的传统胶膜的SEM图;图1b为实施例 2制备的pH比色传感膜的SEM图;图1c为实施例3制备的pH比色传感膜的SEM图;图1d为实施例4制备的pH比色传感膜的SEM图;图1e为实施例5制备的pH比色传感膜的SEM图)(wherein, Fig. 1a is the SEM image of the traditional adhesive film prepared in Example 1; Fig. 1b is the SEM image of the pH colorimetric sensing film prepared in Example 2; Fig. 1c is the pH colorimetric sensing film prepared in Example 3 SEM image; Figure 1d is the SEM image of the pH colorimetric sensing film prepared in Example 4; Figure 1e is the SEM image of the pH colorimetric sensing film prepared in Example 5)

图2为实施例1-5的XRD对比图;Fig. 2 is the XRD contrast chart of embodiment 1-5;

图3为实施例1-5的拉伸应力应变曲线对比图;Fig. 3 is the tensile stress-strain curve comparison diagram of embodiment 1-5;

图4为实施例1-5的拉伸强度和断裂伸长率对比图,其中,图中不同字母表示差异显著(P≤0.05);Figure 4 is a comparison chart of tensile strength and elongation at break of Examples 1-5, wherein different letters in the figure indicate significant differences (P≤0.05);

图5为实施例1-5的厚度对比图,其中,图中不同字母表示差异显著 (P≤0.05);Fig. 5 is the thickness comparison chart of embodiment 1-5, wherein, different letters in the figure represent significant difference (P≤0.05);

图6为实施例1-5的透光率对比图;Fig. 6 is the light transmittance comparison chart of embodiment 1-5;

图7为实施例1-5的水蒸气透过率对比图,其中,图中不同字母表示差异显著(P≤0.05);Fig. 7 is the water vapor transmission rate comparison chart of embodiment 1-5, wherein, different letters in the figure indicate significant difference (P≤0.05);

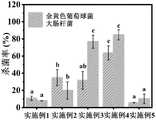

图8为实施例1-5的杀菌率对比图,不同字母表示差异显著 (P≤0.05);Fig. 8 is the sterilization rate comparison chart of embodiment 1-5, and different letters indicate significant difference (P≤0.05);

以下结合说明书附图和具体实施方式对本发明做具体说明。The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

具体实施方式Detailed ways

本实施例的茜素、薰衣草精油、明胶和甘油均为现有材料,其中,茜素和薰衣草精油均从上海麦克林生化有限公司购买,明胶从成都科龙化工有限公司购买,甘油从中国成都市新都市木兰镇工业开发区购买。Alizarin, lavender essential oil, gelatin and glycerin in the present embodiment are all existing materials, wherein, alizarin and lavender essential oil are purchased from Shanghai McLean Biochemical Co., Ltd., gelatin is purchased from Chengdu Kelong Chemical Co., Ltd., and glycerin is purchased from Chengdu, China Purchased from the Industrial Development Zone of Mulan Town, a new city in the city.

本实施例的明胶纳米颗粒为市面上任一采购的现有材料,也可采用现有的两步脱溶法制备得到,具体为:将明胶1.25g溶解于25ml超纯水中,在45℃下连续搅拌加热得到明胶溶液。随后,加入25mL丙酮,脱溶,沉淀高分子量明胶,丢弃上清液。然后在剩余溶液中加入25mL超纯水,调整溶液pH为12。紧接着滴加75ml丙酮搅拌10mi n,加入戊二醛(250μL,25%) 交联颗粒,不断搅拌16h。将得到的溶液进行浓缩和冻干,得到明胶纳米颗粒。The gelatin nanoparticles in this embodiment are any existing materials purchased on the market, and can also be prepared by the existing two-step desolvation method. The gelatin solution was obtained with continuous stirring and heating. Subsequently, 25 mL of acetone was added, desolubilized, high molecular weight gelatin was precipitated, and the supernatant was discarded. Then 25 mL of ultrapure water was added to the remaining solution to adjust the pH of the solution to 12. Then, 75 ml of acetone was added dropwise and stirred for 10 min, and glutaraldehyde (250 μL, 25%) was added to cross-link the particles, and the mixture was continuously stirred for 16 h. The resulting solution was concentrated and lyophilized to obtain gelatin nanoparticles.

实施例1Example 1

本实施例为传统纯明胶膜的制备方法,包括如下步骤:The present embodiment is the preparation method of traditional pure gelatin film, comprising the following steps:

(1)纯明胶膜成膜液的制备:称量0.4g明胶,将其加入到10mL超纯水中,于45℃恒温水浴中磁力搅拌直至明胶完全溶解,添加0.1g甘油作为增塑剂,将上述成膜溶液在恒温水浴条件下继续搅拌至混合均匀,超声脱气15mi n后得到均匀的纯明胶膜成膜液。(1) Preparation of pure gelatin film-forming liquid: Weigh 0.4g of gelatin, add it to 10mL of ultrapure water, stir magnetically in a constant temperature water bath at 45°C until the gelatin is completely dissolved, add 0.1g of glycerol as a plasticizer, The above-mentioned film-forming solution was continuously stirred under the condition of a constant temperature water bath until it was evenly mixed, and after ultrasonic degassing for 15 min, a uniform pure gelatin film-forming solution was obtained.

(2)纯明胶膜的制备:量取10mL所述成膜液浇注铺展到有机玻璃成膜模具中(120mm×80mm×4mm),成膜温度为23±0.5℃,湿度为50±3%,成膜时间为24-48h,然后手动揭下即得纯明胶膜。(2) Preparation of pure gelatin film: Measure 10mL of the film-forming solution, pour and spread it into a plexiglass film-forming mold (120mm×80mm×4mm), the film-forming temperature is 23±0.5°C, and the humidity is 50±3%, The film-forming time is 24-48h, and then the pure gelatin film is obtained by manually peeling it off.

对制备的纯明胶膜的表面进行了SEM测定,结果如图1a所示。The surface of the prepared pure gelatin film was measured by SEM, and the results are shown in Fig. 1a.

对本实施例制备的纯明胶膜的XRD、拉伸应力应变曲线、拉伸强度和断裂伸长率、厚度、透光率、水蒸气透过率以及杀菌率进行了测定,结果依次由图2-图8所示。The XRD, tensile stress-strain curve, tensile strength, elongation at break, thickness, light transmittance, water vapor transmission rate and sterilization rate of the pure gelatin film prepared in this example were measured, and the results are shown in Figure 2- shown in Figure 8.

通过X射线衍射(XRD)对纯明胶膜内物质结构进行分析;拉伸应力应变曲线、拉伸强度和断裂伸长率、厚度表征纯明胶膜的物理机械性能,拉伸应力应变曲线形状反应纯明胶膜在外力作用下的形变过程,拉伸强度体现了纯明胶膜在断裂点时所能承受的最大抗张应力,断裂伸长率表征了纯明胶膜的弹性性能;透光率、水蒸气透过率表征薄膜对光线和水蒸气的阻隔性能。纯明胶膜抗菌性能通过对大肠杆菌和金黄色葡萄球菌的抑制和杀灭效果进行了测定。The material structure in the pure gelatin film was analyzed by X-ray diffraction (XRD); the tensile stress-strain curve, tensile strength, elongation at break, and thickness characterize the physical and mechanical properties of the pure gelatin film, and the shape of the tensile stress-strain curve reflects pure The deformation process of the gelatin film under the action of external force, the tensile strength reflects the maximum tensile stress that the pure gelatin film can bear at the breaking point, and the elongation at break characterizes the elastic properties of the pure gelatin film; light transmittance, water vapor The transmittance characterizes the barrier properties of the film to light and water vapor. The antibacterial properties of pure gelatin films were determined by their inhibitory and killing effects on Escherichia coli and Staphylococcus aureus.

本实施例的纯明胶膜表面光滑,截面无空隙,这导致其韧性和弹性较差,质感偏硬不适合食品包装。纯明胶膜厚度较薄,透光率、水蒸气透过率高,但是对光线和水蒸气阻隔效果差,基本没有抗菌效果,也无PH指示作用。The pure gelatin film of this embodiment has a smooth surface and no voids in the cross-section, which results in poor toughness and elasticity, and a hard texture, which is not suitable for food packaging. The thickness of pure gelatin film is thin, and the light transmittance and water vapor transmittance are high, but the barrier effect on light and water vapor is poor, and there is basically no antibacterial effect and no PH indication effect.

实施例2Example 2

本实施例为pH比色传感膜的制备方法,包括如下步骤:The present embodiment is a preparation method of a pH colorimetric sensing film, comprising the following steps:

步骤1,茜素溶液的制备:称量30mg的茜素于10mL的试管中,加入 5mL的乙醇溶解,再量取茜素乙醇溶液1mL,将其加入到9mL超纯水溶液中,磁力搅拌至均匀得到浓度为6mg/mL的茜素溶液。Step 1, preparation of alizarin solution: weigh 30 mg of alizarin into a 10 mL test tube, add 5 mL of ethanol to dissolve, and then measure 1 mL of alizarin ethanol solution, add it to 9 mL of ultrapure aqueous solution, and stir magnetically until uniform A solution of alizarin with a concentration of 6 mg/mL was obtained.

步骤2,抗菌溶液的制备:将0.5wt%明胶纳米颗粒与8%的薰衣草精油混合,得到明胶纳米粒子稳定的抗菌溶液。Step 2, preparation of antibacterial solution: mixing 0.5wt% gelatin nanoparticles with 8% lavender essential oil to obtain a gelatin nanoparticle stable antibacterial solution.

步骤3,混合溶液的制备:将步骤1得到的浓度为6mg/mL的茜素溶液与步骤2得到的抗菌溶液按照体积比1:1混合,得到混合溶液。

步骤4,抗菌成膜液的制备:称量0.4g明胶,将其加入到10mL步骤3 得到的混合溶液中,于45℃恒温水浴中磁力搅拌直至明胶完全溶解,添加 0.1g甘油作为增塑剂,并在45℃的恒温水浴条件下继续搅拌至混合均匀,超声脱气15mi n后得到均匀的抗菌成膜液。

步骤5,pH比色传感薄膜的制备:量取10mL步骤4得到的抗菌成膜液浇注铺展到有机玻璃成膜模具中(120mm×80mm×4mm),在成膜温度为23 ±0.5℃、湿度为50±3%以及成膜时间为24-48h成膜,然后手动揭下得到 pH比色传感薄膜。

对制备的pH比色传感膜的表面进行了SEM测定,结果如图1b所示。The surface of the prepared pH colorimetric sensing film was measured by SEM, and the results are shown in Figure 1b.

对本实施例制备的纯明胶膜的XRD、拉伸应力应变曲线、拉伸强度和断裂伸长率、厚度、透光率、水蒸气透过率以及杀菌率进行了测定,结果依次由图2-图8所示。The XRD, tensile stress-strain curve, tensile strength, elongation at break, thickness, light transmittance, water vapor transmission rate and sterilization rate of the pure gelatin film prepared in this example were measured, and the results are shown in Figure 2- shown in Figure 8.

与实施例1相比,实施例2得到的pH比色传感膜表面和截面无很大差别,但是由于抗菌溶液的加入,拉伸强度下降,断裂伸长率上升,传感膜韧性好,质感柔软。厚度也随茜素和抗菌溶液加入而增加,传感膜对光线和水蒸气的阻隔性能有所提升。抗菌溶液赋予传感膜一定的抑制大肠杆菌和金黄色葡萄球菌生长的的性能,也有明显的PH指示作用。Compared with Example 1, the pH colorimetric sensing film obtained in Example 2 has no great difference in surface and cross-section, but due to the addition of the antibacterial solution, the tensile strength decreases, the elongation at break increases, and the sensing film has good toughness. Soft texture. The thickness also increased with the addition of alizarin and antibacterial solution, and the barrier properties of the sensing film against light and water vapor were improved. The antibacterial solution endows the sensing membrane with a certain ability to inhibit the growth of Escherichia coli and Staphylococcus aureus, and also has an obvious pH indicator effect.

实施例3Example 3

本实施例为pH比色传感膜的制备方法,包括如下步骤:The present embodiment is a preparation method of a pH colorimetric sensing film, comprising the following steps:

步骤1,茜素溶液的制备:称量20mg的茜素于10mL的试管中,加入 5mL的乙醇溶解,再量取茜素乙醇溶液1mL,将其加入到9mL超纯水溶液中,磁力搅拌至均匀得到浓度为4mg/mL的茜素溶液。Step 1, preparation of alizarin solution: weigh 20 mg of alizarin into a 10 mL test tube, add 5 mL of ethanol to dissolve, then measure 1 mL of alizarin ethanol solution, add it to 9 mL of ultrapure aqueous solution, and stir magnetically until uniform A solution of alizarin with a concentration of 4 mg/mL was obtained.

步骤2,抗菌溶液的制备与实施例2的步骤2一致。Step 2, the preparation of the antibacterial solution is the same as that of Step 2 of Example 2.

步骤3,混合溶液的制备:将步骤1得到的浓度为4mg/mL的茜素溶液与步骤2得到的抗菌溶液按照体积比1:1混合,得到混合溶液。

步骤4,抗菌成膜液成膜液的制备与实施例2的步骤4一致。

步骤5,pH比色传感薄膜的制备与实施例2的步骤5一致。In

对制备的pH比色传感膜的表面进行了SEM测定,结果如图1c所示。The surface of the prepared pH colorimetric sensing film was measured by SEM, and the results are shown in Figure 1c.

对本实施例制备的纯明胶膜的XRD、拉伸应力应变曲线、拉伸强度和断裂伸长率、厚度、透光率、水蒸气透过率以及杀菌率进行了测定,结果依次由图2-图8所示。The XRD, tensile stress-strain curve, tensile strength, elongation at break, thickness, light transmittance, water vapor transmission rate and sterilization rate of the pure gelatin film prepared in this example were measured, and the results are shown in Figure 2- shown in Figure 8.

与实施例1相比,实施例3得到的pH比色传感膜表面光滑,截面呈现网状结构,这可能是导致断裂伸长率进一步上升的原因,使得传感膜的韧性和弹性大大提升,质感变柔软,适合食品包装。与实施例1,实施例3得到的pH比色传感膜厚度有所增加,传感膜对光线和水蒸气的阻隔性能有所提升。实施例3得到的pH比色传感膜对大肠杆菌和金黄色葡萄球菌有较强的抑制和杀灭作用,也有明显的PH指示作用。Compared with Example 1, the pH colorimetric sensing film obtained in Example 3 has a smooth surface and a network structure in cross section, which may be the reason for the further increase in elongation at break, which greatly improves the toughness and elasticity of the sensing film. , the texture becomes soft, suitable for food packaging. Compared with Example 1, the thickness of the pH colorimetric sensing film obtained in Example 3 is increased, and the barrier performance of the sensing film to light and water vapor is improved. The pH colorimetric sensing membrane obtained in Example 3 has strong inhibitory and killing effects on Escherichia coli and Staphylococcus aureus, and also has an obvious pH indication effect.

实施例4Example 4

本实施例为pH比色传感膜的制备方法,包括如下步骤:The present embodiment is a preparation method of a pH colorimetric sensing film, comprising the following steps:

步骤1,茜素溶液的制备:称量10mg的茜素于10mL的试管中,加入 5mL的乙醇溶解,再量取茜素乙醇溶液1mL,将其加入到9mL超纯水溶液中,磁力搅拌至均匀得到浓度为2mg/mL的茜素溶液。Step 1, preparation of alizarin solution: weigh 10 mg of alizarin into a 10 mL test tube, add 5 mL of ethanol to dissolve, then measure 1 mL of alizarin ethanol solution, add it to 9 mL of ultrapure aqueous solution, and stir magnetically until uniform A solution of alizarin with a concentration of 2 mg/mL was obtained.

步骤2,抗菌溶液的制备与实施例2的步骤2一致。Step 2, the preparation of the antibacterial solution is the same as that of Step 2 of Example 2.

步骤3,混合溶液的制备:将步骤1得到的浓度为2mg/mL的茜素溶液与步骤2得到的抗菌溶液按照体积比1:1混合,得到混合溶液。

步骤4,抗菌成膜液的制备与实施例2的步骤4一致。In

步骤5,pH比色传感薄膜的制备与实施例2的步骤5一致。In

对制备的pH比色传感膜的表面进行了SEM测定,结果如图1d所示。The surface of the prepared pH colorimetric sensing film was measured by SEM, and the results are shown in Figure 1d.

对本实施例制备的纯明胶膜的XRD、拉伸应力应变曲线、拉伸强度和断裂伸长率、厚度、透光率、水蒸气透过率以及杀菌率进行了测定,结果依次由图2-图8所示。The XRD, tensile stress-strain curve, tensile strength, elongation at break, thickness, light transmittance, water vapor transmission rate and sterilization rate of the pure gelatin film prepared in this example were measured, and the results are shown in Figure 2- shown in Figure 8.

与实施例1相比,实施例4得到的pH比色传感膜表面光滑,截面呈现规则的网状结构,这导致断裂伸长率上升到最大,传感膜的韧性和弹性进一步提升,质感更柔软,适合包装食品。与实施例1相比,实施例4得到的pH比色传感膜厚度有所增加,传感膜对光线和水蒸气的阻隔性能有所提升。实施例4得到的pH比色传感膜对大肠杆菌和金黄色葡萄球菌有很强的抑制和杀灭作用,也有明显的PH指示作用。Compared with Example 1, the pH colorimetric sensing film obtained in Example 4 has a smooth surface and a regular network structure in cross-section, which leads to the maximum elongation at break, the toughness and elasticity of the sensing film are further improved, and the texture is improved. Softer and suitable for packaged food. Compared with Example 1, the thickness of the pH colorimetric sensing film obtained in Example 4 is increased, and the barrier performance of the sensing film to light and water vapor is improved. The pH colorimetric sensing membrane obtained in Example 4 has a strong inhibitory and killing effect on Escherichia coli and Staphylococcus aureus, and also has an obvious pH indication effect.

实施例5Example 5

本实施例为pH比色传感膜的制备方法,包括如下步骤:The present embodiment is a preparation method of a pH colorimetric sensing film, comprising the following steps:

步骤1,茜素溶液的制备与实施例2的步骤1一致。Step 1, the preparation of alizarin solution is the same as step 1 of Example 2.

步骤2,成膜液的制备:称量0.4g明胶,将其加入到10mL步骤1得到的茜素溶液中,于45℃恒温水浴中磁力搅拌直至明胶完全溶解,添加0.1g 甘油作为增塑剂,并在45℃的恒温水浴条件下继续搅拌至混合均匀,超声脱气15mi n后得到均匀的成膜液。Step 2, preparation of film-forming solution: weigh 0.4 g of gelatin, add it to 10 mL of the alizarin solution obtained in step 1, stir magnetically in a constant temperature water bath at 45°C until the gelatin is completely dissolved, and add 0.1 g of glycerol as a plasticizer , and continue to stir in a constant temperature water bath at 45°C until the mixture is uniform, and a uniform film-forming solution is obtained after ultrasonic degassing for 15 min.

步骤5,pH比色传感薄膜的制备与实施例2的步骤5一致。In

对制备的pH比色传感膜的表面进行了SEM测定,结果如图1e所示。The surface of the prepared pH colorimetric sensing film was measured by SEM, and the results are shown in Figure 1e.

对本实施例制备的纯明胶膜的XRD、拉伸应力应变曲线、拉伸强度和断裂伸长率、厚度、透光率、水蒸气透过率以及杀菌率进行了测定,结果依次由图2-图8所示。The XRD, tensile stress-strain curve, tensile strength, elongation at break, thickness, light transmittance, water vapor transmission rate and sterilization rate of the pure gelatin film prepared in this example were measured, and the results are shown in Figure 2- shown in Figure 8.

与实施例1相比,实施例5得到的pH比色传感膜表面光滑,截面与实施例1相似,断裂伸长率和拉伸强度最小,传感膜的韧性和强度较差,质感较硬,同时其厚度有所增加,传感膜对光线和水蒸气的阻隔性能有所提升。实施例5得到的pH比色传感膜对大肠杆菌和金黄色葡萄球菌基本没有抑制和杀灭作用,但是有明显的PH指示作用。Compared with Example 1, the pH colorimetric sensing film obtained in Example 5 has a smooth surface, a cross section similar to that of Example 1, the elongation at break and tensile strength are the smallest, the toughness and strength of the sensing film are poor, and the texture is better. At the same time, its thickness has been increased, and the barrier performance of the sensing film to light and water vapor has been improved. The pH colorimetric sensing membrane obtained in Example 5 basically has no inhibitory or killing effect on Escherichia coli and Staphylococcus aureus, but has obvious pH indicating effect.

实施例6Example 6

将实施例1制得的纯明胶膜和实施例3和4制得的pH比色传感膜放置不同pH值条件下,其颜色变化如表1所示。本发明制得的pH比色传感膜在pH分别为2、5、6、7、9、11的环境下呈现由黄色到紫色颜色转变。The pure gelatin membrane prepared in Example 1 and the pH colorimetric sensing membrane prepared in Examples 3 and 4 were placed under different pH conditions, and the color changes were shown in Table 1. The pH colorimetric sensing membrane prepared by the invention exhibits a color transition from yellow to purple under the environment of

其中,表1中的L代表明暗度容(黑白),a*代表红绿色,b*代表黄蓝色,△E总色差的大小;数值以平均值±标准差表示,同一行后面不同字母的值差异显著(p≤0.05)。Among them, L in Table 1 represents the light and shade capacity (black and white), a* represents red and green, b* represents yellow and blue, and the size of the total color difference of △E; The values were significantly different (p≤0.05).

其中,本实施例对纯明胶膜/或pH比色传感膜的颜色变化测定,是通过分光测色仪测得;分光测色仪为杭州彩谱科技有限公司购得,型号为 CS-820。Among them, the color change of pure gelatin film/or pH colorimetric sensing film in this embodiment is measured by a spectrophotometer; the spectrophotometer is purchased from Hangzhou Caipu Technology Co., Ltd., and the model is CS-820 .

表1Table 1

将实施例4制得的pH比色传感膜在25℃下悬挂在装有80mL氨溶液 (0.8M)的锥形瓶中10分钟,或将pH比色传感膜暴露于氨气中10分钟,;再在25℃下将pH比色传感膜悬挂在乙酸溶液(99.7%)中10分钟,。上述过程重复3次以测试指示剂膜在不同pH值下的可逆性,其结果如表1 所示(当pH比色传感膜暴露于氨气中呈现紫色,当pH比色传感膜暴露于乙酸中呈现黄色),本发明制得的pH比色传感膜在不同酸碱环境下的颜色指示具有可逆性。The pH colorimetric sensing film prepared in Example 4 was suspended in a conical flask containing 80 mL of ammonia solution (0.8M) at 25°C for 10 minutes, or the pH colorimetric sensing film was exposed to ammonia gas for 10 minutes. The pH colorimetric sensing membrane was suspended in acetic acid solution (99.7%) for 10 minutes at 25°C. The above process was repeated three times to test the reversibility of the indicator film at different pH values, and the results are shown in Table 1 (when the pH colorimetric sensing film was exposed to ammonia gas, it appeared purple, and when the pH colorimetric sensing film was exposed to yellow in acetic acid), the color indication of the pH colorimetric sensing membrane prepared by the present invention is reversible in different acid-base environments.

表2Table 2

Claims (6)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110125241.9ACN113150560B (en) | 2021-01-29 | 2021-01-29 | pH colorimetric sensing membrane, preparation method and application thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110125241.9ACN113150560B (en) | 2021-01-29 | 2021-01-29 | pH colorimetric sensing membrane, preparation method and application thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN113150560A CN113150560A (en) | 2021-07-23 |

| CN113150560Btrue CN113150560B (en) | 2022-09-20 |

Family

ID=76879102

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110125241.9AActiveCN113150560B (en) | 2021-01-29 | 2021-01-29 | pH colorimetric sensing membrane, preparation method and application thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113150560B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115308199A (en)* | 2022-09-07 | 2022-11-08 | 集美大学 | A composite material, colorimetric film and preparation thereof for meat freshness monitoring |

| CN119101289A (en)* | 2024-09-29 | 2024-12-10 | 临沂中科芯华新材料科技有限公司 | A kind of pha plastic food antibacterial material and preparation method thereof |

Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103113603A (en)* | 2013-03-05 | 2013-05-22 | 中国农业大学 | Edible packaging film capable of indicating food rancidity and preparation method thereof |

| CN106706612A (en)* | 2015-11-12 | 2017-05-24 | 中国科学院大连化学物理研究所 | Method for improving sensitivity of gas colorimetric sensor for detecting acid /alkaline gas |

- 2021

- 2021-01-29CNCN202110125241.9Apatent/CN113150560B/enactiveActive

Patent Citations (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103113603A (en)* | 2013-03-05 | 2013-05-22 | 中国农业大学 | Edible packaging film capable of indicating food rancidity and preparation method thereof |

| CN106706612A (en)* | 2015-11-12 | 2017-05-24 | 中国科学院大连化学物理研究所 | Method for improving sensitivity of gas colorimetric sensor for detecting acid /alkaline gas |

Non-Patent Citations (4)

| Title |

|---|

| Parya Ezati等.pH-responsive chitosan-based film incorporated with alizarin for intelligent packaging applications.《Food Hydrocolloids》.2019,第102卷* |

| pH-responsive chitosan-based film incorporated with alizarin for intelligent packaging applications;Parya Ezati等;《Food Hydrocolloids》;20191230;第102卷;第1-10页* |

| 可食性明胶复合膜及其在食品包装上的应用研究进展;胡熠等;《食品工业科技》;20170623;第38卷(第20期);第341-346页* |

| 水溶性可食酸碱指示膜的初步研究;高泽宇等;《农产品加工》;20190115(第1期);第52-54页* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN113150560A (en) | 2021-07-23 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| Majdinasab et al. | Development of a novel colorimetric sensor based on alginate beads for monitoring rainbow trout spoilage | |

| Galus et al. | Optical, mechanical, and moisture sorption properties of whey protein edible films | |

| EP3428222B1 (en) | Method for use in preparing intelligent chromogenic antibacterial anti-oxidation protective film | |

| CN112920468A (en) | Anthocyanin-based freshness indication label and preparation method thereof | |

| CN113150560B (en) | pH colorimetric sensing membrane, preparation method and application thereof | |

| CN108586828A (en) | A kind of edible compound fresh-keeping film and its preparation method and application | |

| CN111607114B (en) | Preparation method of green degradable multifunctional collagen-based nanocomposite membrane | |

| CN116023716B (en) | A layer-by-layer nanoparticle-filled preservation-indicating composite film, preparation method and application | |

| CN113402734B (en) | Preparation method and application of hydrogel for indicating freshness of chilled meat | |

| CN105694320B (en) | A kind of Extracts from Plant Recourses antimicrobial preservative film and preparation method and application | |

| CN112646219A (en) | Preparation method of chondroitin sulfate-anthocyanin sensitization type food freshness indicating membrane | |

| CN106867038A (en) | A kind of anti-bacterial packaging film and preparation method thereof | |

| CN111234325A (en) | Preparation method of food packaging film and milk packaging structure | |

| CN114957751A (en) | Preparation method of edible tannin crosslinked tensile composite coating | |

| CN111537479B (en) | Preparation method of freshness indicating film based on ratio type fluorescent material | |

| CN110272628B (en) | Anticorrosion and antioxidant multi-effect type active nano preservative film for chilled fresh meat and preparation method thereof | |

| CN102250368A (en) | Edible collagen-based food packaging film and preparation method thereof | |

| CN114573846B (en) | Preparation method of soybean protein antibacterial biological film with high mechanical strength | |

| CN115340712A (en) | A functional edible composite film based on pullulan and its preparation method | |

| CN106380620A (en) | Preparation method of chitosan/ionic liquid composite membrane | |

| CN107151338A (en) | A kind of anthocyanidin strengthens the preparation method of modified protein edible film | |

| CN111702999A (en) | A kind of convenient poultry meat, fish and shrimp freshness intelligent indicator film based on betalain and preparation method thereof | |

| CN115449171B (en) | Preparation method of high-strength high-toughness starch-based pH response type intelligent indication film | |

| CN1760247A (en) | Food wrap film of collagen and preparation method | |

| CN115353653B (en) | A kind of preparation method of food preservation film |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |