CN113128555B - A method for abnormal detection of train brake pad components - Google Patents

A method for abnormal detection of train brake pad componentsDownload PDFInfo

- Publication number

- CN113128555B CN113128555BCN202110258195.XACN202110258195ACN113128555BCN 113128555 BCN113128555 BCN 113128555BCN 202110258195 ACN202110258195 ACN 202110258195ACN 113128555 BCN113128555 BCN 113128555B

- Authority

- CN

- China

- Prior art keywords

- detection

- brake pad

- model

- abnormal

- cnn

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F18/00—Pattern recognition

- G06F18/20—Analysing

- G06F18/21—Design or setup of recognition systems or techniques; Extraction of features in feature space; Blind source separation

- G06F18/214—Generating training patterns; Bootstrap methods, e.g. bagging or boosting

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06N—COMPUTING ARRANGEMENTS BASED ON SPECIFIC COMPUTATIONAL MODELS

- G06N3/00—Computing arrangements based on biological models

- G06N3/02—Neural networks

- G06N3/04—Architecture, e.g. interconnection topology

- G06N3/045—Combinations of networks

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06V—IMAGE OR VIDEO RECOGNITION OR UNDERSTANDING

- G06V10/00—Arrangements for image or video recognition or understanding

- G06V10/20—Image preprocessing

- G06V10/22—Image preprocessing by selection of a specific region containing or referencing a pattern; Locating or processing of specific regions to guide the detection or recognition

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06V—IMAGE OR VIDEO RECOGNITION OR UNDERSTANDING

- G06V10/00—Arrangements for image or video recognition or understanding

- G06V10/70—Arrangements for image or video recognition or understanding using pattern recognition or machine learning

- G06V10/74—Image or video pattern matching; Proximity measures in feature spaces

- G06V10/75—Organisation of the matching processes, e.g. simultaneous or sequential comparisons of image or video features; Coarse-fine approaches, e.g. multi-scale approaches; using context analysis; Selection of dictionaries

- G06V10/751—Comparing pixel values or logical combinations thereof, or feature values having positional relevance, e.g. template matching

Landscapes

- Engineering & Computer Science (AREA)

- Theoretical Computer Science (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Computer Vision & Pattern Recognition (AREA)

- Evolutionary Computation (AREA)

- Artificial Intelligence (AREA)

- Data Mining & Analysis (AREA)

- General Health & Medical Sciences (AREA)

- Multimedia (AREA)

- Software Systems (AREA)

- General Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- Health & Medical Sciences (AREA)

- Computing Systems (AREA)

- Biophysics (AREA)

- Computational Linguistics (AREA)

- Bioinformatics & Computational Biology (AREA)

- Molecular Biology (AREA)

- Biomedical Technology (AREA)

- Mathematical Physics (AREA)

- Evolutionary Biology (AREA)

- Databases & Information Systems (AREA)

- Medical Informatics (AREA)

- Bioinformatics & Cheminformatics (AREA)

- Image Analysis (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及列车部件异常检测领域,具体涉及一种用于列车闸片部件异常检测的方法。The invention relates to the field of abnormality detection of train components, in particular to a method for abnormality detection of train brake pad components.

背景技术Background technique

随着我国经济快速发展,中国内地轨道里程稳居世界第一。不论是速度还是效率,都取得了巨大的进步。而在列车的维护上,传统的人工检测依然占据绝大部分。传统故障检测中,检修人员工作环境恶劣、列车数量众多,需要大量人力物力,效率低可靠性差等,这与当今不断自动化、智能化的时代格格不入。迫切需要一门高效率、高准确率同时低成本的技术来对列车故障进行自动检测,保障列车的安全运营。得益于机器学习和深度学习的发展,基于计算机视觉的异常检测拥有了落地的可能。With the rapid development of my country's economy, the track mileage in mainland China ranks first in the world. Huge progress has been made in both speed and efficiency. In the maintenance of trains, traditional manual inspection still accounts for the vast majority. In traditional fault detection, the working environment of maintenance personnel is harsh, the number of trains is large, a lot of manpower and material resources are required, and the efficiency is low and reliability is poor. There is an urgent need for a high-efficiency, high-accuracy and low-cost technology to automatically detect train faults and ensure the safe operation of trains. Thanks to the development of machine learning and deep learning, anomaly detection based on computer vision has the possibility of landing.

目前计算机视觉的主要落地的应用在于人脸识别、对象分类等领域。对于故障诊断方面,主流的研究方向主要有三个:(1)模板匹配法,通过待测图片与标准模板之间近似度来判断是否存在异常,该方法极易受到成像环境以及污渍等干扰,有着苛刻的适用范围。(2)基于统计学的机器学习法,是通过对样本进行特征提取后根据特征分布进行分类。其关键在于特征提取的算法,需要根据不同的目标设计不同的算法,鲁棒性较差。同时当检测对象处于较复杂的环境时,容易受到环境影响,因此可靠性难以得到保障。针对小缺陷,其整体的特征差异可能难以达到阈值,对应用目标有较大约束。(3)基于深度学习的缺陷检测,该模型需要大量的数据集对神经网络进行训练,需要对每一类的异常进行学习才能得到较好的网络权重,深度学习模型的神经网络能够有效抑制光照条件、污渍等环境对检测结果的影响。然而在实际工程项目中,正负样本比例差距巨大,负样本较少,因此往往无法训练出效果满意的模型。At present, the main application of computer vision is in the fields of face recognition and object classification. For fault diagnosis, there are three main research directions: (1) Template matching method, which judges whether there is an abnormality by the similarity between the image to be tested and the standard template. This method is easily disturbed by the imaging environment and stains. Harsh scope of application. (2) The machine learning method based on statistics is to classify the samples according to the feature distribution after feature extraction. The key lies in the algorithm of feature extraction, which needs to design different algorithms according to different goals, and the robustness is poor. At the same time, when the detection object is in a complex environment, it is easily affected by the environment, so the reliability is difficult to be guaranteed. For small defects, the overall feature difference may be difficult to reach the threshold, which imposes great constraints on the application target. (3) Defect detection based on deep learning. This model requires a large number of datasets to train the neural network. It is necessary to learn each type of anomaly to obtain better network weights. The neural network of the deep learning model can effectively suppress the illumination. The influence of conditions, stains and other environments on the test results. However, in actual engineering projects, there is a huge gap between the proportion of positive and negative samples, and there are few negative samples, so it is often impossible to train models with satisfactory results.

从上诉背景中可以清晰地得到利用计算机视觉进行故障诊断必须要解决的四个关键点是:(1)算法模型必须能够有效抑制环境因素的干扰,如光照、污渍等,具有强鲁棒性。(2)算法模型需要在少量负样本的情况下,能够训练出效果满意的模型,才具有工程可行性。(3)算法模型必须具备高精度、低误检以及零漏报率,这是代替人工检修保障列车安全行驶的重点。(4)高效率,列车检修的时间只能是运营空期,在这个空期内需要完成对整个列车的检查与维修。From the background of the appeal, it can be clearly obtained that the four key points that must be solved by using computer vision for fault diagnosis are: (1) The algorithm model must be able to effectively suppress the interference of environmental factors, such as light, stains, etc., and has strong robustness. (2) The algorithm model needs to be able to train a model with satisfactory effect in the case of a small number of negative samples, so as to have engineering feasibility. (3) The algorithm model must have high precision, low false detection and zero false negative rate, which is the key point to replace manual maintenance to ensure the safe running of trains. (4) High efficiency, the time for train maintenance can only be during the operation period, during which the inspection and maintenance of the entire train needs to be completed.

因此,亟需一种检测效率高,同时需要算法模型在短时间内准确完成项点的检测方法。Therefore, there is an urgent need for a detection method with high detection efficiency and an algorithm model that accurately completes the item point detection in a short time.

发明内容SUMMARY OF THE INVENTION

为解决现有技术中存在的问题,本发明提供了一种用于列车闸片部件异常检测的方法,能快速完成列车闸片部件的异常检测,高准确率,能够在负样本不足,正负样本不均衡时完成部件的异常检测,解决了上述背景技术中提到的问题。In order to solve the problems existing in the prior art, the present invention provides a method for abnormal detection of train brake pad components, which can quickly complete the abnormal detection of train brake pad components, has high accuracy, When the sample is not balanced, the abnormality detection of the component is completed, which solves the problems mentioned in the above background art.

为实现上述目的,本发明提供如下技术方案:一种用于列车闸片部件异常检测的方法,模型检测步骤如下:In order to achieve the above purpose, the present invention provides the following technical solutions: a method for abnormal detection of train brake pad components, the model detection steps are as follows:

步骤一、将数据采集设备采集到的闸片数据进行图像预处理,符合模型输入格式;Step 1. Perform image preprocessing on the brake pad data collected by the data acquisition device to conform to the model input format;

步骤二、利用YoloV4-tiny目标检测模型加载训练好的权重文件,对闸片图片进行钩子部件定位以及销子部件的异常检测,YoloV4-tiny目标检测模型对销子进行一步到位检测并输出检测结果;Step 2. Use the YoloV4-tiny target detection model to load the trained weight file, perform hook component positioning and pin component anomaly detection on the brake plate image, and the YoloV4-tiny target detection model performs one-step detection on the pins and outputs the detection results ;

步骤三、同时利用YoloV4-tiny目标检测模型对钩子部件定位,将钩子部件区域截出,再使用改进的OC-CNN异常检测网络对钩子截图进行检测;Step 3. At the same time, use the YoloV4-tiny target detection model to locate the hook component, cut out the hook component area, and then use the improved OC-CNN anomaly detection network to detect the hook screenshot;

步骤四、通过OC-CNN检测钩子截图得到异常分数,判断钩子是否存在异常并输出检测结果;Step 4. Obtain the abnormal score through the OC-CNN detection hook screenshot, determine whether the hook is abnormal and output the detection result;

步骤五、综合YoloV4-tiny以及改进OC-CNN的检测结果,得到整个闸片的详细异常信息。Step 5. Synthesize the detection results of YoloV4-tiny and improved OC-CNN to obtain detailed abnormal information of the entire brake pad.

优选的,在模型检测之前还有个模型训练的步骤,所述模型训练步骤如下:Preferably, there is a model training step before the model detection, and the model training steps are as follows:

步骤S1、通过数据采集设备取得列车闸片部件的图片;Step S1, obtaining pictures of train brake pad components through data acquisition equipment;

步骤S2、采用Labelimg打标签软件对采集到的闸片图片进行打标签,制成VOC格式的数据集;Step S2, using Labelimg labeling software to label the collected brake piece pictures to make a data set in VOC format;

步骤S3、构建闸片异常检测模型的训练集与测试集,经过训练后得到YoloV4-tiny权重文件;所述训练集中包括1300张正样本闸片图片和938张异常的闸片图片;所述测试集中包括1338张闸片图片;Step S3, construct the training set and test set of the brake pad abnormality detection model, and obtain the YoloV4-tiny weight file after training; the training set includes 1300 positive sample brake pad pictures and 938 abnormal brake pad pictures; the test The collection includes 1338 pictures of brake pads;

步骤S4、通过训练好的YoloV4-ting模型检测正样本闸片图片,通过网络的定位截取,获得1000张正常状态下的钩子截图,然后再额外加入70张钩子异常的截图图片,制成OC-CNN网络数据集,最后完成对OC-CNN进行的训练。Step S4: Detect the positive sample gate pictures through the trained YoloV4-ting model, and obtain 1,000 screenshots of hooks in normal state through the positioning and interception of the network, and then add 70 additional screenshots of abnormal hooks to make OC- CNN network dataset, and finally complete the training of OC-CNN.

优选的,所述步骤一中的图像预处理是将图片格式处理成PIL.Image,通道数为3,确保符合模型输入格式。Preferably, the image preprocessing in the first step is to process the image format into PIL.Image, and the number of channels is 3 to ensure that it conforms to the model input format.

优选的,所述步骤四中的得到的异常分数若高于0.25,则判断钩子部件正常;若低于0.25,则判断钩子部件异常。Preferably, if the abnormal score obtained in the fourth step is higher than 0.25, it is determined that the hook component is normal; if it is lower than 0.25, it is determined that the hook component is abnormal.

优选的,所述改进的OC-CNN异常检测网络是指引入负样本进行监督学习的OC-CNN。Preferably, the improved OC-CNN anomaly detection network refers to an OC-CNN that introduces negative samples for supervised learning.

优选的,所述步骤S3中的异常闸片图片包括销子缺失、钩子缺失或钩子变形。Preferably, the abnormal brake piece picture in the step S3 includes missing pins, missing hooks or deformed hooks.

优选的,所述步骤S3中的异常的闸片图片是通过PS或数据增强处理得到的。Preferably, the abnormal gate picture in the step S3 is obtained through PS or data enhancement processing.

优选的,所述检测方法中模型检测速度在CPU运行下达到0.2张/s,能够实现对闸片异常进行实时的检测。Preferably, in the detection method, the model detection speed reaches 0.2 sheets/s under the operation of the CPU, which can realize real-time detection of the abnormality of the brake pads.

本发明的有益效果是:The beneficial effects of the present invention are:

1)本发明利用YoloV4-tiny+OC-CNN的异常检测模型,在CPU运行下能达到0.2张/s,能够实现对闸片异常进行实时的检测,检测速度快,检测效率高。1) The present invention utilizes the abnormal detection model of YoloV4-tiny+OC-CNN, which can reach 0.2 sheets/s under CPU operation, and can realize real-time detection of brake pad abnormality, with fast detection speed and high detection efficiency.

2)本发明对普通OC-CNN异常检测网络进行改进,从只用正样本进行训练改进为正样本训练的同时利用少量的负样本进行微调,减少对负样本依赖,提高模型在工程项目中的可行性,提高网络对异常特征的敏感性,降低误报的同时提高了准确度和鲁棒性。2) The present invention improves the ordinary OC-CNN anomaly detection network, from only using positive samples for training to positive sample training, while using a small number of negative samples for fine-tuning, reducing the dependence on negative samples, and improving the model's performance in engineering projects. Feasibility, improve the sensitivity of the network to abnormal features, reduce false positives and improve accuracy and robustness.

3)本发明利用One-stage目标检测模型YoloV4-tiny,实现对钩子部件快速定位截取同时对变化差异较大的销子进行一步到位异常检测,钩子实现定位截取,有效避免待测图片其他部分特征对OC-CNN异常检测的影响。3) The present invention utilizes the One-stage target detection model YoloV4-tiny to realize the rapid positioning and interception of the hook parts and simultaneously perform one-step abnormal detection on the pins with large variation differences, and the hooks realize the positioning and interception, effectively avoiding the characteristics of other parts of the picture to be tested. Impact on OC-CNN anomaly detection.

4)本发明将YoloV4-tiny目标检测模型与改进版OC-CNN相结合,构成闸片异常检测模型,充分发挥两种网络各自优势,有效消除因数据采集环境如:光照、雨水以及污渍等带来的影响,保证了检测的准确率,本发明相比于利用传统的基于模板匹配以及简单特征比对的部件故障检测,利用YoloV4-tiny+OC-CNN异常检测模型对于实际情况下的光照,污渍干扰等情况具有更高的鲁棒性,准确率更高,能在无漏报的情况下拥有很低的误报率<10%。能够让检测人员脱离列车低的恶劣工作环境,减少维修人员工作量。对于减少人力物力投入,保证列车运行安全具有重大意义。4) The present invention combines the YoloV4-tiny target detection model with the improved version of OC-CNN to form a brake pad abnormality detection model, giving full play to the respective advantages of the two networks, and effectively eliminating the problems caused by the data collection environment such as light, rain and stains. Compared with the traditional component fault detection based on template matching and simple feature comparison, the present invention uses the YoloV4-tiny+OC-CNN anomaly detection model for the illumination in the actual situation, Stain interference and other situations have higher robustness and higher accuracy, and can have a very low false positive rate <10% without false negatives. It can let the inspectors get out of the harsh working environment of the low train and reduce the workload of maintenance personnel. It is of great significance to reduce the input of manpower and material resources and ensure the safety of train operation.

附图说明Description of drawings

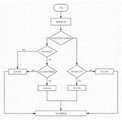

图1为本发明检测流程图;Fig. 1 is the detection flow chart of the present invention;

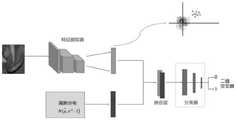

图2为本发明YoloV4-tiny网络结构图;Fig. 2 is the YoloV4-tiny network structure diagram of the present invention;

图3为本发明改进OC-CNN网络结构图;Fig. 3 is the improved OC-CNN network structure diagram of the present invention;

图4为本发明正常与异常样本示意图。FIG. 4 is a schematic diagram of normal and abnormal samples of the present invention.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动前提下所获得的所有其他实施例,都属于本发明保护的范围。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative efforts shall fall within the protection scope of the present invention.

请参阅图1-4,如图1所示,图1是基于YoloV4-tiny目标检测模型以及改进OC-CNN异常检测网络的列车闸片部件异常检测流程图。其中模型训练过程如下:Please refer to Figure 1-4, as shown in Figure 1, Figure 1 is a flowchart of the abnormal detection of train brake pad components based on the YoloV4-tiny target detection model and the improved OC-CNN abnormal detection network. The model training process is as follows:

第一步,利用部件图片信息采集设备取得列车闸片部件的图片,得到闸片部件的图像;The first step is to use the component picture information collection equipment to obtain the pictures of the train brake pad components, and obtain the images of the brake pad components;

第二步,利用Labelimg打标签软件对采集到的闸片图片进行打标签,制成VOC格式的数据集;The second step is to use Labelimg labeling software to label the collected gate pictures to make a data set in VOC format;

第三步,通过PS以及数据增强做出938张异常的闸片图片(销子缺失,钩子缺失,钩子变形)与1300张正样本作为闸片异常模型的训练集,另有1338张图片作为模型测试集,经过训练后得到YoloV4-tiny权重文件;In the third step, through PS and data enhancement, 938 abnormal brake pictures (missing pins, missing hooks, and deformed hooks) and 1300 positive samples are used as the training set of the abnormal brake model, and another 1338 pictures are used as the model. Test set, YoloV4-tiny weight file is obtained after training;

第四步,利用训练好的YoloV4-ting模型检测正样本,通过网络的定位截取,获得1000张正常状态下的钩子截图,在此基础上,额外加入70张钩子异常的截图图片,制成OC-CNN网络数据集,最后完成对OC-CNN进行训练;The fourth step is to use the trained YoloV4-ting model to detect positive samples, and to obtain 1000 screenshots of hooks in normal state through network positioning and interception. On this basis, additional 70 screenshots of abnormal hooks are added to make OC -CNN network data set, and finally complete the training of OC-CNN;

模型测试过程如下:The model testing process is as follows:

第一步,将巡检机器人采集到的闸片数据进行图像预处理,采集到的闸片数据为灰度图,通道数为2,格式为.jpg格式,不符合YoloV4-Tiny检测模型输入格式,预处理就是通过cv2.cvtColor以及Image.fromarray函数将图片转化为3通道,PIL.Image格式,满足模型输入格式;The first step is to perform image preprocessing on the gate data collected by the inspection robot. The collected gate data is a grayscale image, the number of channels is 2, and the format is .jpg format, which does not conform to the input format of the YoloV4-Tiny detection model. , the preprocessing is to convert the image into 3-channel, PIL.Image format through the cv2.cvtColor and Image.fromarray functions, which satisfies the model input format;

第二步,利用YoloV4-tiny目标检测模型加载训练好的YoloV4-tiny权重文件,YoloV4-tiny网络结构如图2所示,对闸片图片进行钩子部件定位以及销子部件的异常检测,YoloV4-tiny目标检测模型对销子进行一步到位检测,输出检测结果;The second step is to use the YoloV4-tiny target detection model to load the trained YoloV4-tiny weight file. The YoloV4-tiny network structure is shown in Figure 2. The brake picture is used for hook component positioning and pin component anomaly detection. YoloV4- The tiny target detection model detects the pins in one step and outputs the detection results;

第三步,利用YoloV4-tiny目标检测模型对钩子部件定位,将钩子部件区域截出,再将利用改进OC-CNN异常检测网络对钩子截图进行检测,OC-CNN网络结构如图3所示;The third step is to use the YoloV4-tiny target detection model to locate the hook component, cut out the hook component area, and then use the improved OC-CNN anomaly detection network to detect the hook screenshot. The OC-CNN network structure is shown in Figure 3;

第四步,通过OC-CNN检测钩子截图得到的异常分数,判断是否存在异常。异常分数高于0.25则钩子部件正常,反之异常;The fourth step is to judge whether there is an abnormality through the abnormal score obtained by the OC-CNN detection hook screenshot. If the abnormal score is higher than 0.25, the hook component is normal, otherwise it is abnormal;

第五步,综合YoloV4-tiny以及改进OC-CNN的检测结果,得到整个闸片的详细异常信息。The fifth step is to synthesize the detection results of YoloV4-tiny and the improved OC-CNN to obtain detailed abnormal information of the entire brake pad.

本发明首先利用数据采集设备如工业数字相机(CCD)对待检修的列车进行部件图像采集;将采集到的图片数据传输带服务器,通过部署在服务器中的闸片异常检测模型对闸片部件图片进行检测,再把检测结果输出并反映给检修人员,最后检修人员根据异常信息进行定点维修。The present invention firstly uses data acquisition equipment such as an industrial digital camera (CCD) to collect component images of the train to be overhauled; the collected picture data is transmitted to a server, and the brake piece component pictures are processed by a brake piece abnormality detection model deployed in the server. Then, the inspection results are output and reflected to the maintenance personnel, and finally the maintenance personnel carry out fixed-point maintenance according to the abnormal information.

由于项点中,销子丢失的异常特征比较明显,利用目标检测模型可以准确判断销子是否异常,而钩子部分,丢失和缺损时,正常与异常样本如图4所示,YoloV4-tiny特征提取网络提取的异常特征与正常样本特征在分布上处于难分区域,差异难以找到合适分界,无法使用目标检测网络一步到位进行检测,因此钩子部分需要采用额外网络模型进行检测。对于闸片部分异常检测的步骤是,首先采用YoloV4-tiny目标检测模型对销子进行一步到位检测,完成其定位以及异常检测,同时YoloV4-tiny对钩子进行定位,将其所属区域进行裁切,利用改进后的引入负样本监督学习的异常检测网络OC-CNN对YoloV4-tiny裁切所得图片进行检测,通过OC-CNN检测所得异常分数值判断钩子部件的异常情况。引入负样本进行监督学习的OC-CNN相较于原始版本只采用正样本进行训练的OC-CNN网络,对于异常情况判断更准确、敏感度更高,在准确性和鲁棒性均有明显提升。YoloV4-tiny与OC-CNN组成一个完整的闸片异常检测模型,能够快速,准确,高效完成闸片的异常检测。Because the abnormal features of missing pins are obvious in the item points, the target detection model can accurately determine whether the pins are abnormal, and the normal and abnormal samples of the hook part, when missing and missing, are shown in Figure 4. YoloV4-tiny feature extraction The abnormal features extracted by the network and the normal sample features are in a difficult distribution area, and it is difficult to find a suitable boundary for the difference, and the target detection network cannot be used for one-step detection. Therefore, the hook part needs to be detected by an additional network model. For the abnormal detection of the brake pad, the first step is to use the YoloV4-tiny target detection model to detect the pin in one step to complete its positioning and abnormal detection. At the same time, YoloV4-tiny locates the hook and cuts the area to which it belongs. The image cropped by YoloV4-tiny is detected by the improved anomaly detection network OC-CNN that introduces negative sample supervised learning, and the abnormality of the hook component is judged by the abnormal score value detected by OC-CNN. Compared with the original version of the OC-CNN network that only uses positive samples for training, the OC-CNN that introduces negative samples for supervised learning is more accurate in judging abnormal situations, with higher sensitivity, and has significantly improved accuracy and robustness. . YoloV4-tiny and OC-CNN form a complete brake pad abnormality detection model, which can quickly, accurately and efficiently complete the brake pad abnormality detection.

尽管参照前述实施例对本发明进行了详细的说明,对于本领域的技术人员来说,其依然可以对前述各实施例所记载的技术方案进行修改,或者对其中部分技术特征进行等同替换,凡在本发明的精神和原则之内,所作的任何修改、等同替换、改进等,均应包含在本发明的保护范围之内。Although the present invention has been described in detail with reference to the foregoing embodiments, for those skilled in the art, it is still possible to modify the technical solutions described in the foregoing embodiments, or perform equivalent replacements for some of the technical features. Any modification, equivalent replacement, improvement, etc. made within the spirit and principle of the present invention shall be included within the protection scope of the present invention.

Claims (6)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110258195.XACN113128555B (en) | 2021-03-09 | 2021-03-09 | A method for abnormal detection of train brake pad components |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202110258195.XACN113128555B (en) | 2021-03-09 | 2021-03-09 | A method for abnormal detection of train brake pad components |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN113128555A CN113128555A (en) | 2021-07-16 |

| CN113128555Btrue CN113128555B (en) | 2022-05-31 |

Family

ID=76772949

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202110258195.XAActiveCN113128555B (en) | 2021-03-09 | 2021-03-09 | A method for abnormal detection of train brake pad components |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN113128555B (en) |

Families Citing this family (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113688171B (en)* | 2021-08-24 | 2022-05-10 | 北京工商大学 | A method and system for train braking fault detection based on graph convolutional neural network |

| CN113822867A (en)* | 2021-09-24 | 2021-12-21 | 东莞市诺丽电子科技有限公司 | Train appearance abnormity detection method and train appearance abnormity detection system |

| CN116071423A (en)* | 2023-02-09 | 2023-05-05 | 哈尔滨市科佳通用机电股份有限公司 | A method, system and medium for positioning components of a railway freight car brake regulator |

| CN118506299B (en)* | 2024-07-17 | 2024-09-20 | 中数智科(杭州)科技有限公司 | Rail train body abnormality detection method, device and storage medium |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108152059A (en)* | 2017-12-20 | 2018-06-12 | 西南交通大学 | High-speed train bogie fault detection method based on Fusion |

| CN109685131A (en)* | 2018-12-20 | 2019-04-26 | 斑马网络技术有限公司 | Automobile vehicle device system exception recognition methods and device |

| CN110395402A (en)* | 2019-06-26 | 2019-11-01 | 北京晶品特装科技有限责任公司 | The low disturbance unmanned aerial vehicle ejecting frame separating mechanism of one kind and separation method |

| CN110530639A (en)* | 2019-10-08 | 2019-12-03 | 五邑大学 | A kind of bullet train axle box bearing failure diagnostic method |

| CN110929577A (en)* | 2019-10-23 | 2020-03-27 | 桂林电子科技大学 | An improved target recognition method based on YOLOv3 lightweight framework |

| CN111239158A (en)* | 2020-03-13 | 2020-06-05 | 苏州鑫睿益荣信息技术有限公司 | Automobile instrument panel detection system and detection method based on machine vision |

| CN111337789A (en)* | 2019-10-23 | 2020-06-26 | 西安科技大学 | Method and system for detecting faulty electrical components in high-voltage transmission lines |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US11507064B2 (en)* | 2016-05-09 | 2022-11-22 | Strong Force Iot Portfolio 2016, Llc | Methods and systems for industrial internet of things data collection in downstream oil and gas environment |

- 2021

- 2021-03-09CNCN202110258195.XApatent/CN113128555B/enactiveActive

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN108152059A (en)* | 2017-12-20 | 2018-06-12 | 西南交通大学 | High-speed train bogie fault detection method based on Fusion |

| CN109685131A (en)* | 2018-12-20 | 2019-04-26 | 斑马网络技术有限公司 | Automobile vehicle device system exception recognition methods and device |

| CN110395402A (en)* | 2019-06-26 | 2019-11-01 | 北京晶品特装科技有限责任公司 | The low disturbance unmanned aerial vehicle ejecting frame separating mechanism of one kind and separation method |

| CN110530639A (en)* | 2019-10-08 | 2019-12-03 | 五邑大学 | A kind of bullet train axle box bearing failure diagnostic method |

| CN110929577A (en)* | 2019-10-23 | 2020-03-27 | 桂林电子科技大学 | An improved target recognition method based on YOLOv3 lightweight framework |

| CN111337789A (en)* | 2019-10-23 | 2020-06-26 | 西安科技大学 | Method and system for detecting faulty electrical components in high-voltage transmission lines |

| CN111239158A (en)* | 2020-03-13 | 2020-06-05 | 苏州鑫睿益荣信息技术有限公司 | Automobile instrument panel detection system and detection method based on machine vision |

Non-Patent Citations (4)

| Title |

|---|

| A DEEP LEARNING APPROACH TO TARGET RECOGNITION IN SIDE-SCAN SONAR IMAGERY;Dylan Einsidler等;《IEEE》;20190110;第1-4页* |

| Defect Detection of Axle Box Cover Device Fixing Bolts in Metro Based on Convolutional Neural Network;Yao Yang等;《IEEE》;20200729;7054-7059页* |

| YOLOv3算法在闸片丢失及装反检测设备中的应用;张甬成;《铁道车辆》;20201130;第58卷(第11期);第31-34页* |

| 基于EEMD的高速列车横向减振器故障的排列熵特征分析;吴志丹 等;《计算机科学》;20160531;第304-307页* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN113128555A (en) | 2021-07-16 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN113128555B (en) | A method for abnormal detection of train brake pad components | |

| CN112581463A (en) | Image defect detection method and device, electronic equipment, storage medium and product | |

| CN117392042A (en) | Defect detection method, defect detection apparatus, and storage medium | |

| CN111650204A (en) | Method and system for fault detection of transmission line fittings based on cascade target detection | |

| CN114677362B (en) | Surface defect detection method based on improved YOLOv5 | |

| CN106980922A (en) | A kind of power transmission and transformation equipment state evaluation method based on big data | |

| CN108074231A (en) | Magnetic sheet surface defect detection method based on convolutional neural network | |

| CN111080598A (en) | Bolt and nut missing detection method for coupler yoke key safety crane | |

| CN109726730B (en) | Automatic optical inspection image classification method, system and computer readable medium | |

| CN115995056A (en) | A method for automatic identification of bridge defects based on deep learning | |

| CN113139572B (en) | An image-based fault detection method for train air springs | |

| CN110186375A (en) | Intelligent high-speed rail white body assemble welding feature detection device and detection method | |

| CN111652295A (en) | A fault identification method for the fall-off of the joist of the coupler pin joist of a railway freight car | |

| CN114757925A (en) | Method and system for defect detection of non-contact high-voltage circuit breaker | |

| CN112465784B (en) | Metro clamp appearance abnormality detection method | |

| CN111899216A (en) | A kind of abnormal detection method of high-speed rail catenary insulator fasteners | |

| CN102621154A (en) | Method and device for automatically detecting cloth defects on line based on improved differential box multi-fractal algorithm | |

| You | PCB defect detection based on generative adversarial network | |

| CN115471476A (en) | A component defect detection method, device, equipment and medium | |

| CN116152674A (en) | Dam unmanned aerial vehicle image crack intelligent recognition method based on improved U-Net model | |

| CN117314829A (en) | Industrial part quality inspection method and system based on computer vision | |

| CN118822996A (en) | Welding quality inspection method for assembled bridges based on MIU-Transformer | |

| CN119379692A (en) | An intelligent TFT display defect recognition system based on machine vision | |

| CN110245582A (en) | A method for identifying single-class components in bitmaps based on deep learning | |

| CN115082650A (en) | Implementation method of automatic pipeline defect labeling tool based on convolutional neural network |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |