CN112297965A - Automobile seat position sensor - Google Patents

Automobile seat position sensorDownload PDFInfo

- Publication number

- CN112297965A CN112297965ACN202011323382.3ACN202011323382ACN112297965ACN 112297965 ACN112297965 ACN 112297965ACN 202011323382 ACN202011323382 ACN 202011323382ACN 112297965 ACN112297965 ACN 112297965A

- Authority

- CN

- China

- Prior art keywords

- gear

- shell

- pcb

- intermediate transmission

- meshed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 230000005540biological transmissionEffects0.000claimsabstractdescription18

- 238000006243chemical reactionMethods0.000claimsabstractdescription5

- 108090000565Capsid ProteinsProteins0.000claims1

- 238000009434installationMethods0.000claims1

- XOMKZKJEJBZBJJ-UHFFFAOYSA-N1,2-dichloro-3-phenylbenzeneChemical compoundClC1=CC=CC(C=2C=CC=CC=2)=C1ClXOMKZKJEJBZBJJ-UHFFFAOYSA-N0.000description6

- 210000000078clawAnatomy0.000description2

- 238000006073displacement reactionMethods0.000description2

- 206010063385IntellectualisationDiseases0.000description1

- 238000010276constructionMethods0.000description1

- 238000010586diagramMethods0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60N—SEATS SPECIALLY ADAPTED FOR VEHICLES; VEHICLE PASSENGER ACCOMMODATION NOT OTHERWISE PROVIDED FOR

- B60N2/00—Seats specially adapted for vehicles; Arrangement or mounting of seats in vehicles

- B60N2/02—Seats specially adapted for vehicles; Arrangement or mounting of seats in vehicles the seat or part thereof being movable, e.g. adjustable

- B60N2/0224—Non-manual adjustments, e.g. with electrical operation

- B60N2/0244—Non-manual adjustments, e.g. with electrical operation with logic circuits

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60N—SEATS SPECIALLY ADAPTED FOR VEHICLES; VEHICLE PASSENGER ACCOMMODATION NOT OTHERWISE PROVIDED FOR

- B60N2/00—Seats specially adapted for vehicles; Arrangement or mounting of seats in vehicles

- B60N2/02—Seats specially adapted for vehicles; Arrangement or mounting of seats in vehicles the seat or part thereof being movable, e.g. adjustable

- B60N2/0224—Non-manual adjustments, e.g. with electrical operation

- B60N2/0244—Non-manual adjustments, e.g. with electrical operation with logic circuits

- B60N2/0268—Non-manual adjustments, e.g. with electrical operation with logic circuits using sensors or detectors for adapting the seat or seat part, e.g. to the position of an occupant

Landscapes

- Engineering & Computer Science (AREA)

- Aviation & Aerospace Engineering (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Seats For Vehicles (AREA)

- Measurement Of Length, Angles, Or The Like Using Electric Or Magnetic Means (AREA)

Abstract

Description

Technical Field

The invention relates to the technical field of automobile sensors, in particular to an automobile seat position sensor.

Background

With the development of the automobile industry and the continuous improvement of the electronization degree thereof, automobiles gradually go to automation and intellectualization so as to provide better riding experience for drivers. For a driver, the comfort of the seat is a very intuitive factor influencing the experience of the vehicle, and the adjustment of the position of the seat can provide a comfortable human posture which is convenient for operation or rest for the driver. The traditional seat needs to be adjusted manually, so that the seat is very inconvenient to use, and in the modern automobile seat, the use of the Hall sensor and the motor enables a driver to easily realize automatic control and adjustment of the position of the seat. However, the existing hall sensor design still has the following disadvantages: 1. the structure is complex and the cost is high; 2. poor accuracy, only identifying whether the seat is in the 1/3 or 2/3 position; 3. hysteresis exists and in severe cases errors of several millimeters may occur.

Disclosure of Invention

The present invention is directed to provide a vehicle seat position sensor having a compact structure, high output accuracy and stable signal, which overcomes the above-mentioned disadvantages of the prior art.

In order to achieve the purpose, the invention adopts the technical scheme that: a car seat position sensor comprises a shell, a gear reduction mechanism, a magnet, a Hall chip and a PCB, wherein the gear reduction mechanism, the magnet, the Hall chip and the PCB are arranged in the shell; the gear reduction mechanism is composed of an input gear, an intermediate transmission gear and an output gear, wherein the input gear and the intermediate transmission gear are duplicate gears and are respectively arranged on corresponding shaft positions of the front shell through respective gear shafts, a large gear in the input gear is exposed at the notch and is meshed with a gear on the automobile seat, a small gear is meshed with a large gear in the intermediate transmission gear, the output gear and the input gear are coaxially arranged and are arranged behind the input gear and are meshed with a small gear in the intermediate transmission gear; the Hall chip is welded on a PCB printed with a conversion circuit, the PCB is fixed on the inner side surface of the rear shell through bolts, and three signal output lines are also welded on the PCB; the magnet is fixed on the output gear, and faces the Hall chip in a short distance without contacting each other.

The sensor has simple and compact structure, changes the magnetic field by driving the magnet to rotate through the gear reduction mechanism during working, has very low magnetic hysteresis, high output precision and stable signal, can identify the absolute position information of the automobile seat, has the maximum stroke of 500mm, and is suitable for different automobile seat platforms.

Drawings

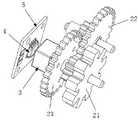

FIG. 1 is a schematic diagram of the construction of a sensor of the present invention;

fig. 2 is a schematic view of the internal structure of the sensor of the present invention.

In the figure: 1-a housing; 11-a front housing; 12-a rear housing; 13-a bolt; 14-a fastener; 15-notch; 16-a locating post; 17-claw hook; 2-a gear reduction mechanism; 21-input gear; 22-intermediate transmission gear; 23-an output gear; 3-a magnet; 4-Hall chip; 5-a PCB board; 6-signal output line.

Detailed Description

The invention will be further described in detail with reference to examples of embodiments shown in the drawings to which, however, the invention is not restricted.

As shown in fig. 1 and 2, the car seat position sensor provided by the invention comprises ahousing 1, agear reduction mechanism 2 arranged in thehousing 1, a magnet 3, ahall chip 4 and aPCB 5, wherein thehousing 1 is formed by assembling afront housing 11 and arear housing 12, thefront housing 11 and therear housing 12 are fixed bybolts 13 and bucklingpieces 14 which can be buckled and separated with each other, the upper part of the end surface of thefront housing 11 is provided with anotch 15, and a plurality ofpositioning columns 16 andclaws 17 of a barb structure are arranged on the end surface avoiding thenotch 15 at intervals and are used for positioning and mounting with a car seat; thegear reduction mechanism 2 is composed of aninput gear 21, anintermediate transmission gear 22 and anoutput gear 23, wherein theinput gear 21 and theintermediate transmission gear 22 are duplicate gears which are respectively arranged on corresponding axial positions of thefront shell 11 through respective gear shafts, a large gear in theinput gear 21 is exposed at thenotch 15 and is meshed with a gear (not shown) on the automobile seat, a small gear is meshed with a large gear in theintermediate transmission gear 22, and theoutput gear 23 and theinput gear 21 are coaxially arranged and are arranged behind theinput gear 21 and are meshed with a small gear in theintermediate transmission gear 22; theHall chip 4 is welded on aPCB 5 printed with a conversion circuit, thePCB 5 is fixed on the inner side surface of therear shell 12 through bolts, and threesignal output lines 6 are also welded on thePCB 5; the magnet 3 is fixed on theoutput gear 23 and faces thehall chip 4 at a short distance without contacting each other.

When the invention is used, the invention is fixedly arranged on an automobile seat through aclaw 17 on ashell 1, when the position of the seat is adjusted (manually adjusted or adjusted by a motor), a gear arranged on the seat rotates along with the seat and simultaneously transmits power to a gearspeed reducing mechanism 2 in a sensor, power is transmitted to anoutput gear 23 through anintermediate transmission gear 22 by aninput gear 21, theoutput gear 23 drives a magnet 3 to rotate, so that a magnetic field is changed, aHall chip 4 senses the change of the magnetic field and simultaneously transmits an electromagnetic signal to aPCB 5, a conversion circuit on thePCB 5 converts the electromagnetic signal into a corresponding linear displacement signal and outputs the linear displacement signal to an automobile ECU through asignal output line 6, and the ECU identifies the position of the automobile seat.

The sensor has simple and compact structure, the magnet 3 is driven to rotate by thegear reduction mechanism 2, the hysteresis is very low during working, the output precision is high, the signal is stable, the absolute position information of the automobile seat can be identified, the maximum stroke is 500mm, and the sensor is suitable for different automobile seat platforms.

Claims (3)

1. The utility model provides a car seat position sensor, includes the shell, sets up gear reduction mechanism, magnet, hall chip and the PCB board in the shell, its characterized in that: the shell is formed by assembling a front shell and a rear shell, and a notch is formed in the upper part of the end face of the front shell; the gear reduction mechanism is composed of an input gear, an intermediate transmission gear and an output gear, wherein the input gear and the intermediate transmission gear are duplicate gears and are respectively arranged on corresponding shaft positions of the front shell through respective gear shafts, a large gear in the input gear is exposed at the notch and is meshed with a gear on the automobile seat, a small gear is meshed with a large gear in the intermediate transmission gear, the output gear and the input gear are coaxially arranged and are arranged behind the input gear and are meshed with a small gear in the intermediate transmission gear; the Hall chip is welded on a PCB printed with a conversion circuit, the PCB is fixed on the inner side surface of the rear shell through bolts, and three signal output lines are also welded on the PCB; the magnet is fixed on the output gear, and faces the Hall chip in a short distance without contacting each other.

2. The vehicle seat position sensor according to claim 1, wherein: the front shell and the rear shell are fixed through bolts and buckling pieces capable of being buckled and separated mutually.

3. The vehicle seat position sensor according to claim 1, wherein: the procapsid is equipped with the jack catch of a plurality of reference columns and overhead kick structure on the terminal surface of avoiding the breach at the interval for fix a position the installation with car seat.

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011323382.3ACN112297965A (en) | 2020-11-23 | 2020-11-23 | Automobile seat position sensor |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011323382.3ACN112297965A (en) | 2020-11-23 | 2020-11-23 | Automobile seat position sensor |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112297965Atrue CN112297965A (en) | 2021-02-02 |

Family

ID=74335262

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011323382.3APendingCN112297965A (en) | 2020-11-23 | 2020-11-23 | Automobile seat position sensor |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112297965A (en) |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20030080734A1 (en)* | 2001-10-10 | 2003-05-01 | Kayvan Hedayat | Non-contact absolute position sensor |

| CN2700167Y (en)* | 2004-04-05 | 2005-05-18 | 浙江胜华波汽车电器有限公司 | Motor gear reducing arrangement for adjusting automobile seat back |

| CN201188569Y (en)* | 2008-05-12 | 2009-01-28 | 浙江省东阳市诚基电机有限公司 | Angle-modulation electric machine of vehicle seat convenient to feedback control |

| CN201690320U (en)* | 2010-04-07 | 2010-12-29 | 南京龙泰航空电子科技有限公司 | Small digital servo of metal middle cover based on electromagnetic transduction technology |

| CN102425642A (en)* | 2011-12-12 | 2012-04-25 | 陈晓 | Automatic gear box |

| CN106132768A (en)* | 2014-03-26 | 2016-11-16 | 佛吉亚汽车座椅有限责任公司 | Seat |

| CN209336339U (en)* | 2018-12-29 | 2019-09-03 | 深圳市慧乐智能科技有限公司 | A kind of mechanical pencil |

| CN209764003U (en)* | 2019-06-25 | 2019-12-10 | 湖南湘瑞智能工控设备有限公司 | Transmission structure of double-Hall long angle detection sensor |

| CN211875037U (en)* | 2020-03-20 | 2020-11-06 | 宁夏众信机械设备制造有限公司 | Power takeoff of automobile transmission part |

- 2020

- 2020-11-23CNCN202011323382.3Apatent/CN112297965A/enactivePending

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20030080734A1 (en)* | 2001-10-10 | 2003-05-01 | Kayvan Hedayat | Non-contact absolute position sensor |

| CN2700167Y (en)* | 2004-04-05 | 2005-05-18 | 浙江胜华波汽车电器有限公司 | Motor gear reducing arrangement for adjusting automobile seat back |

| CN201188569Y (en)* | 2008-05-12 | 2009-01-28 | 浙江省东阳市诚基电机有限公司 | Angle-modulation electric machine of vehicle seat convenient to feedback control |

| CN201690320U (en)* | 2010-04-07 | 2010-12-29 | 南京龙泰航空电子科技有限公司 | Small digital servo of metal middle cover based on electromagnetic transduction technology |

| CN102425642A (en)* | 2011-12-12 | 2012-04-25 | 陈晓 | Automatic gear box |

| CN106132768A (en)* | 2014-03-26 | 2016-11-16 | 佛吉亚汽车座椅有限责任公司 | Seat |

| CN209336339U (en)* | 2018-12-29 | 2019-09-03 | 深圳市慧乐智能科技有限公司 | A kind of mechanical pencil |

| CN209764003U (en)* | 2019-06-25 | 2019-12-10 | 湖南湘瑞智能工控设备有限公司 | Transmission structure of double-Hall long angle detection sensor |

| CN211875037U (en)* | 2020-03-20 | 2020-11-06 | 宁夏众信机械设备制造有限公司 | Power takeoff of automobile transmission part |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN205469271U (en) | EPS is with integration rotation direction sensor | |

| CN106687359B (en) | Wheel steering system transmission device | |

| CN101318518A (en) | Coach steering system | |

| CN203867715U (en) | Electronic throttle valve installed on engine intake manifold | |

| CN208651604U (en) | A kind of monostable knob selector | |

| CN211145319U (en) | Gear shifting fork driving mechanism for compact two-gear reduction gearbox | |

| CN112297965A (en) | Automobile seat position sensor | |

| CN202243633U (en) | Electric steering device with automatic aligning function for automobile | |

| CN108533745B (en) | Actuating mechanism for automatically switching gear of transfer case | |

| CN107339162A (en) | A kind of control system of electronic throttle valve for university student's equation motorcycle race | |

| CN219015512U (en) | EPS torque sensor based on gear structure | |

| CN218267197U (en) | Gear recognition device of pure electric cargo-carrying instructional car | |

| CN2630076Y (en) | Automobile booster steering gear | |

| CN207393334U (en) | A kind of control system of electronic throttle valve for university student's equation motorcycle race | |

| CN2890847Y (en) | Hall component type sensor for automobile electric steering | |

| CN212447770U (en) | Electric circulating ball steering gear assembly for medium truck commercial vehicle | |

| CN203064019U (en) | Electric power steering device used for automobile | |

| CN1587758A (en) | Electric gearshift of automatic mechanic speed variator | |

| CN101371063B (en) | Semi-automatic gearbox for vehicle | |

| CN209870118U (en) | Hanging type electronic accelerator pedal assembly | |

| CN212708952U (en) | Electronic accelerator pedal | |

| CN201333936Y (en) | Heavy-duty car transmission case postposition single-stage power takeoff device | |

| CN221838871U (en) | Electronically controlled shift actuator | |

| CN220430276U (en) | Steering gear and transmission mechanism thereof | |

| CN219339551U (en) | Electric recirculating ball steering gear for vehicle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| CB03 | Change of inventor or designer information | Inventor after:Li Cheng Inventor after:Mao Shiwen Inventor after:Chen Changlin Inventor after:Yu Shuqiao Inventor after:He Xiaodan Inventor before:Mao Shiwen Inventor before:Chen Changlin Inventor before:Yu Shuqiao | |

| CB03 | Change of inventor or designer information | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20210202 | |

| RJ01 | Rejection of invention patent application after publication |