CN112222676B - Micro-nano powder modified active brazing filler metal and preparation method thereof - Google Patents

Micro-nano powder modified active brazing filler metal and preparation method thereofDownload PDFInfo

- Publication number

- CN112222676B CN112222676BCN202010858316.XACN202010858316ACN112222676BCN 112222676 BCN112222676 BCN 112222676BCN 202010858316 ACN202010858316 ACN 202010858316ACN 112222676 BCN112222676 BCN 112222676B

- Authority

- CN

- China

- Prior art keywords

- micro

- nano powder

- parts

- filler metal

- brazing filler

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 239000011858nanopowderSubstances0.000titleclaimsabstractdescription113

- 238000005219brazingMethods0.000titleclaimsabstractdescription65

- 239000000945fillerSubstances0.000titleclaimsabstractdescription45

- 229910052751metalInorganic materials0.000titleclaimsabstractdescription44

- 239000002184metalSubstances0.000titleclaimsabstractdescription44

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription11

- 238000006263metalation reactionMethods0.000title1

- 229910000679solderInorganic materials0.000claimsabstractdescription66

- 229910045601alloyInorganic materials0.000claimsabstractdescription33

- 239000000956alloySubstances0.000claimsabstractdescription33

- 239000000463materialSubstances0.000claimsabstractdescription17

- 229910017938Cu—Sn—TiInorganic materials0.000claimsabstractdescription11

- 229910000636Ce alloyInorganic materials0.000claimsdescription33

- 239000000843powderSubstances0.000claimsdescription30

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical compound[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000claimsdescription26

- 229910021389grapheneInorganic materials0.000claimsdescription26

- 239000002245particleSubstances0.000claimsdescription25

- 239000002270dispersing agentSubstances0.000claimsdescription23

- 238000000498ball millingMethods0.000claimsdescription17

- 230000002950deficientEffects0.000claimsdescription17

- 239000011259mixed solutionSubstances0.000claimsdescription17

- 238000002156mixingMethods0.000claimsdescription17

- 229910018487Ni—CrInorganic materials0.000claimsdescription16

- CSCPPACGZOOCGX-UHFFFAOYSA-NAcetoneChemical groupCC(C)=OCSCPPACGZOOCGX-UHFFFAOYSA-N0.000claimsdescription14

- 239000000243solutionSubstances0.000claimsdescription13

- 239000003960organic solventSubstances0.000claimsdescription11

- QTBSBXVTEAMEQO-UHFFFAOYSA-NAcetic acidChemical compoundCC(O)=OQTBSBXVTEAMEQO-UHFFFAOYSA-N0.000claimsdescription9

- 239000002904solventSubstances0.000claimsdescription9

- RTZKZFJDLAIYFH-UHFFFAOYSA-NDiethyl etherChemical compoundCCOCCRTZKZFJDLAIYFH-UHFFFAOYSA-N0.000claimsdescription7

- 239000002131composite materialSubstances0.000claimsdescription6

- BDAGIHXWWSANSR-UHFFFAOYSA-Nmethanoic acidNatural productsOC=OBDAGIHXWWSANSR-UHFFFAOYSA-N0.000claimsdescription6

- QKIUAMUSENSFQQ-UHFFFAOYSA-NdimethylazanideChemical groupC[N-]CQKIUAMUSENSFQQ-UHFFFAOYSA-N0.000claimsdescription5

- 229940057995liquid paraffinDrugs0.000claimsdescription5

- 230000007847structural defectEffects0.000claimsdescription5

- 230000007547defectEffects0.000claimsdescription4

- OSWFIVFLDKOXQC-UHFFFAOYSA-N4-(3-methoxyphenyl)anilineChemical compoundCOC1=CC=CC(C=2C=CC(N)=CC=2)=C1OSWFIVFLDKOXQC-UHFFFAOYSA-N0.000claimsdescription3

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000claimsdescription3

- 238000001035dryingMethods0.000claimsdescription3

- 235000019253formic acidNutrition0.000claimsdescription3

- 239000004094surface-active agentSubstances0.000claimsdescription3

- 229910003460diamondInorganic materials0.000abstractdescription50

- 239000010432diamondSubstances0.000abstractdescription50

- 230000003685thermal hair damageEffects0.000abstractdescription8

- 238000012545processingMethods0.000abstractdescription6

- 206010003549astheniaDiseases0.000abstractdescription4

- 229910001092metal group alloyInorganic materials0.000abstract1

- 239000000203mixtureSubstances0.000description8

- 230000000694effectsEffects0.000description7

- 229910010293ceramic materialInorganic materials0.000description6

- 238000000034methodMethods0.000description6

- DBMJMQXJHONAFJ-UHFFFAOYSA-MSodium laurylsulphateChemical compound[Na+].CCCCCCCCCCCCOS([O-])(=O)=ODBMJMQXJHONAFJ-UHFFFAOYSA-M0.000description5

- 238000010586diagramMethods0.000description4

- 238000005553drillingMethods0.000description4

- 238000000227grindingMethods0.000description4

- 238000005054agglomerationMethods0.000description3

- 230000002776aggregationEffects0.000description3

- 238000003754machiningMethods0.000description3

- 238000005457optimizationMethods0.000description3

- XEKOWRVHYACXOJ-UHFFFAOYSA-NEthyl acetateNatural productsCCOC(C)=OXEKOWRVHYACXOJ-UHFFFAOYSA-N0.000description2

- 239000003082abrasive agentSubstances0.000description2

- 235000011054acetic acidNutrition0.000description2

- 230000009286beneficial effectEffects0.000description2

- 239000006185dispersionSubstances0.000description2

- 238000009826distributionMethods0.000description2

- 235000019441ethanolNutrition0.000description2

- 235000019439ethyl acetateNutrition0.000description2

- 150000002739metalsChemical class0.000description2

- 238000012856packingMethods0.000description2

- 230000003068static effectEffects0.000description2

- 238000012876topographyMethods0.000description2

- 230000037303wrinklesEffects0.000description2

- 238000013461designMethods0.000description1

- GVGUFUZHNYFZLC-UHFFFAOYSA-Ndodecyl benzenesulfonate;sodiumChemical compound[Na].CCCCCCCCCCCCOS(=O)(=O)C1=CC=CC=C1GVGUFUZHNYFZLC-UHFFFAOYSA-N0.000description1

- 239000012530fluidSubstances0.000description1

- 238000005087graphitizationMethods0.000description1

- 230000006872improvementEffects0.000description1

- 239000007788liquidSubstances0.000description1

- 238000002844meltingMethods0.000description1

- 230000008018meltingEffects0.000description1

- 230000004048modificationEffects0.000description1

- 238000012986modificationMethods0.000description1

- 230000008569processEffects0.000description1

- 150000003856quaternary ammonium compoundsChemical class0.000description1

- 229940080264sodium dodecylbenzenesulfonateDrugs0.000description1

- 238000001179sorption measurementMethods0.000description1

- 238000003892spreadingMethods0.000description1

- 230000007480spreadingEffects0.000description1

- 239000000126substanceSubstances0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/22—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by the composition or nature of the material

- B23K35/24—Selection of soldering or welding materials proper

- B23K35/30—Selection of soldering or welding materials proper with the principal constituent melting at less than 1550 degrees C

- B23K35/302—Cu as the principal constituent

- B—PERFORMING OPERATIONS; TRANSPORTING

- B23—MACHINE TOOLS; METAL-WORKING NOT OTHERWISE PROVIDED FOR

- B23K—SOLDERING OR UNSOLDERING; WELDING; CLADDING OR PLATING BY SOLDERING OR WELDING; CUTTING BY APPLYING HEAT LOCALLY, e.g. FLAME CUTTING; WORKING BY LASER BEAM

- B23K35/00—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting

- B23K35/22—Rods, electrodes, materials, or media, for use in soldering, welding, or cutting characterised by the composition or nature of the material

- B23K35/36—Selection of non-metallic compositions, e.g. coatings, fluxes; Selection of soldering or welding materials, conjoint with selection of non-metallic compositions, both selections being of interest

- B23K35/362—Selection of compositions of fluxes

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Powder Metallurgy (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于钎焊金刚石工具材料,具体涉及一种微纳米粉体改性活性钎料及其制备方法。The invention belongs to brazing diamond tool materials, in particular to a micro-nano powder modified active brazing filler metal and a preparation method thereof.

背景技术Background technique

钎焊金刚石工具由于活性钎料与金刚石能产生化学冶金反应而具备强的结合力,金刚石出露高度能达到自身高度的50%~70%,因而具有对磨料把持强度高、容屑空间大、磨削效率高、磨削比能低等特点,在难加工材料高效、重负荷加工中已显示出传统金刚石工具无法比拟的优异性能。Brazed diamond tools have strong bonding force due to the chemical metallurgical reaction between active solder and diamond, and the exposed height of diamond can reach 50% to 70% of its own height, so it has high holding strength for abrasives, large chip space, High grinding efficiency and low grinding specific energy have shown excellent performance unmatched by traditional diamond tools in high-efficiency and heavy-duty machining of difficult-to-machine materials.

目前,制备钎焊金刚石工具常用的钎料主要有Ni–Cr合金或Cu–Sn–Ti合金钎料。随着钎焊金刚石工具的逐步推广应用,在使用过程中也暴露出一些问题。例如,Ni–Cr合金高温钎焊会对金刚石造成较大的热损伤,主要表现为金刚石表面发生石墨化、表面呈现较多蚀坑、表面或周围出现微裂纹等。不同粒径的粉体,高温钎焊过程中Cu–Sn–Ti合金钎料较严重流淌导致钎料层厚度不均,钎料层较薄会导致对金刚石磨料把持强度弱,钎料层较厚会导致金刚石磨料被包覆难以出露,这都大大限制了钎焊金刚石工具加工性能的进一步提高。At present, the brazing filler metals commonly used in the preparation of brazed diamond tools are mainly Ni–Cr alloy or Cu–Sn–Ti alloy brazing filler metals. With the gradual popularization and application of brazed diamond tools, some problems are also exposed during use. For example, high-temperature brazing of Ni–Cr alloys will cause great thermal damage to diamond, mainly manifested as graphitization on the surface of diamond, more pits on the surface, and microcracks on the surface or around it. For powders with different particle sizes, the Cu-Sn-Ti alloy solder flows more seriously during the high temperature brazing process, resulting in uneven thickness of the solder layer. The thinner solder layer will lead to weaker holding strength for diamond abrasives and a thicker solder layer. It will cause the diamond abrasive to be coated and difficult to expose, which greatly limits the further improvement of the processing performance of the brazed diamond tool.

发明内容SUMMARY OF THE INVENTION

本发明提供一种微纳米粉体改性活性钎料及其制备方法,其目的是能有效解决上述如Ni–Cr合金高温钎焊对金刚石造成的热损伤、Cu–Sn–Ti合金钎料较严重流淌导致钎料层厚度不均等问题,以提高钎焊金刚石工具的加工效率与使用寿命。The invention provides a micro-nano powder modified active solder and a preparation method thereof, the purpose of which is to effectively solve the above-mentioned thermal damage to diamond caused by high-temperature brazing of Ni-Cr alloy, and the serious problem of Cu-Sn-Ti alloy solder. The flow causes problems such as uneven thickness of the brazing material layer, so as to improve the processing efficiency and service life of the brazed diamond tool.

为达到上述目的,本发明采用如下技术方案:To achieve the above object, the present invention adopts the following technical solutions:

一种微纳米粉体改性活性钎料,按照质量份数计:包括钎料本体80–99份,微纳米粉体1–10份。A micro-nano powder modified active brazing filler metal, calculated in parts by mass: comprises 80-99 parts of a brazing filler metal body and 1-10 parts of a micro-nano powder.

进一步的,钎料本体和微纳米粉体的纯度均大于等于99.9%,钎料本体粒度为50-100目。Further, the purity of the brazing filler metal body and the micro-nano powder is greater than or equal to 99.9%, and the particle size of the brazing filler metal body is 50-100 mesh.

进一步的,微纳米粉体采用缺陷石墨烯时取1–2份;微纳米粉体采用Cu–Ce合金时取5–10份,微纳米粉体采用TiC粉时取4-8份,微纳米粉体采用缺陷石墨烯与Cu–Ce合金两者的复合粉体取1–10份。Further, take 1-2 parts when using defective graphene for micro-nano powder; 5-10 parts when using Cu-Ce alloy for micro-nano powder; 4-8 parts when using TiC powder for micro-nano powder; The powder adopts 1-10 parts of composite powder of defective graphene and Cu-Ce alloy.

进一步的,钎料本体采用Ni–Cr合金钎料或Cu–Sn–Ti合金钎料。Further, the brazing filler metal body adopts Ni-Cr alloy brazing filler metal or Cu-Sn-Ti alloy brazing filler metal.

一种微纳米粉体改性的活性钎料制备方法,包括以下步骤:A preparation method of active solder modified by micro-nano powder, comprising the following steps:

步骤1)、按照质量份数计取钎料本体80–99份和微纳米粉体1–10份;Step 1), count 80-99 parts of the solder body and 1-10 parts of the micro-nano powder according to the mass fraction;

步骤2)、将微纳米粉体进行球磨使其粒径小于20μm;Step 2), ball milling the micro-nano powder to make the particle size less than 20 μm;

步骤3)、采用溶剂将球磨后的微纳米粉体完全分散溶解得到混合液A;Step 3), using a solvent to completely disperse and dissolve the ball-milled micro-nano powder to obtain a mixed solution A;

步骤4)、将混合液A在分散剂溶液中混合均匀,然后加入钎料本体进行充分混合均匀后烘干,即可得到微纳米粉体改性的活性钎料。Step 4), mix the mixed solution A in the dispersant solution uniformly, then add the brazing filler metal body to fully mix uniformly and then dry to obtain the active brazing filler metal modified by micro-nano powder.

进一步的,微纳米粉体采用缺陷石墨烯时取1–2份;微纳米粉体采用Cu–Ce合金时取5–10份,微纳米粉体采用TiC粉时取4-8份,微纳米粉体采用缺陷石墨烯与Cu–Ce合金两者的复合粉体取1–10份;钎料本体采用Ni–Cr合金钎料或Cu–Sn–Ti合金钎料。Further, take 1-2 parts when using defective graphene for micro-nano powder; 5-10 parts when using Cu-Ce alloy for micro-nano powder; 4-8 parts when using TiC powder for micro-nano powder; The powder adopts 1-10 parts of composite powder of defective graphene and Cu-Ce alloy; the solder body adopts Ni-Cr alloy solder or Cu-Sn-Ti alloy solder.

进一步的,微纳米粉体采用缺陷石墨烯时,球磨后使其粒径小于20μm,缺陷石墨烯50%以上面积出现结构缺陷;微纳米粉体采用Cu–Ce合金时,球磨后使其粒径小于10μm;微纳米粉体采用TiC粉时,球磨后使其粒径小于20μm。Further, when the micro-nano powder is made of defective graphene, the particle size is less than 20 μm after ball milling, and more than 50% of the defect graphene has structural defects; when the micro-nano powder is made of Cu-Ce alloy, the particle size is reduced after ball milling. Less than 10μm; when the micro-nano powder is TiC powder, the particle size is less than 20μm after ball milling.

进一步的,步骤3)中,溶剂采用二甲基酰胺或液体石蜡,溶剂与微纳米粉体的重量比例为1:(10–50)。Further, in step 3), the solvent is dimethylamide or liquid paraffin, and the weight ratio of the solvent to the micro-nano powder is 1:(10-50).

进一步的,步骤4)中,分散剂溶液采用分散剂和有机溶剂的混合液;分散剂采用表面活性剂,分散剂与微纳米粉体的重量比例为1:(5–10),有机溶剂为丙酮、酒精、甲酸、乙酸或乙醚,有机溶剂与微纳米粉体的重量比例为1:(0.4–0.8)。Further, in step 4), the dispersant solution adopts a mixed solution of a dispersant and an organic solvent; the dispersant adopts a surfactant, the weight ratio of the dispersant to the micro-nano powder is 1:(5-10), and the organic solvent is Acetone, alcohol, formic acid, acetic acid or ether, and the weight ratio of organic solvent to micro-nano powder is 1:(0.4–0.8).

进一步的,步骤4)中,将混合液A与分散剂溶液在混料机中混合均匀,混料机转速为50~150r/min,混料时间0.5~2h,球料比为1:(10–20),球和粉料总体积不超过混料罐体积的50%。Further, in step 4), the mixed solution A and the dispersant solution are uniformly mixed in a mixer, the speed of the mixer is 50~150r/min, the mixing time is 0.5~2h, and the ratio of ball to material is 1:(10 –20), the total volume of balls and powder does not exceed 50% of the volume of the mixing tank.

与现有技术相比,本发明具有以下有益的技术效果:Compared with the prior art, the present invention has the following beneficial technical effects:

本发明一种微纳米粉体改性活性钎料,按照质量份数计包括钎料本体80–99份,微纳米粉体1–10份,微纳米粉体均匀吸附在钎料表面,用微纳米粉体改性的活性钎料制备的金刚石工具,其表面金刚石蚀坑数量、金刚石表面或周围的微裂纹数量大大减少,钎料合金层强度损失小,金刚石的力学性能提高8%以上,工具的加工性能得到提升,能够避免高温钎焊对金刚石造成的热损伤、Cu–Sn–Ti合金钎料较严重流淌导致钎料层厚度不均等问题,以提高钎焊金刚石工具的加工效率与使用寿命。The present invention is a micro-nano powder modified active solder, which comprises 80-99 parts of the solder body and 1-10 parts of the micro-nano powder in parts by mass, the micro-nano powder is uniformly adsorbed on the surface of the solder, and the The number of diamond pits on the surface and the number of micro-cracks on the diamond surface or around the diamond tool prepared by the nano-powder modified active solder are greatly reduced, the strength loss of the solder alloy layer is small, and the mechanical properties of the diamond are improved by more than 8%. The processing performance of the brazed diamond tool has been improved, which can avoid the thermal damage to the diamond caused by high-temperature brazing, and the serious flow of the Cu-Sn-Ti alloy brazing material causes the uneven thickness of the brazing material layer, so as to improve the processing efficiency and service life of the brazed diamond tool. .

进一步的,微纳米粉体粒径小于20μm,有利于微纳米粉体均匀吸附在钎料表面。Further, the particle size of the micro-nano powder is less than 20 μm, which is conducive to the uniform adsorption of the micro-nano powder on the surface of the solder.

进一步的,采用微纳米粉体改性的活性钎料制备的Cu基钎焊金刚石工具,其表面各处的钎料层厚度较均匀,钎料层对金刚石磨料的把持强度较高,金刚石磨料能出露,并增强了钎料层的耐磨性,工具的加工性能得到提升。Further, the Cu-based brazing diamond tool prepared by using the active solder modified by micro-nano powder has a relatively uniform thickness of the solder layer on the surface, and the solder layer has a high holding strength to the diamond abrasive, and the diamond abrasive can be used. It is exposed, and the wear resistance of the brazing material layer is enhanced, and the machining performance of the tool is improved.

本发明一种微纳米粉体改性的活性钎料制备方法,按照质量份数计取钎料本体80–99份和微纳米粉体1–10份;采用溶剂将粒径小于20μm的微纳米粉体完全分散溶解得到混合液A,防止微纳米粉体团聚,然后利用分散剂溶液对微纳米粉体进一步分散,然后加入钎料本体进行充分混合,采用球磨后的微纳米粉体先分散防止其团聚,再通过分散液进一步分散能够与钎料本体充分融合,有利于微纳米粉体在钎料本体表面团聚,本发明钎料本体和微纳米粉体添加比例通过物理数学建模方法精准获取,能够针对活性钎料熔化炉冷后形成合金的韧性、强度和耐磨性要求在给定的高温钎焊条件下获得微纳米粉体的最佳添加比例,得到符合要求的微纳米粉体改性的活性钎料,增加堆积密度有利于改善微纳米粉体分布均匀性,根据本发明制备得到的材料表面金刚石蚀坑数量、金刚石表面或周围的微裂纹数量大大减少,钎料合金层强度损失小,金刚石的力学性能提高8%以上,工具的加工性能得到提升The invention provides a method for preparing active solder modified by micro-nano powder. According to the parts by mass, 80-99 parts of the solder body and 1-10 parts of the micro-nano powder are taken; The powder is completely dispersed and dissolved to obtain the mixed solution A to prevent the agglomeration of the micro-nano powder, and then the micro-nano powder is further dispersed by the dispersant solution, and then the solder body is added to fully mix, and the ball-milled micro-nano powder is first dispersed to prevent Its agglomeration and further dispersion through the dispersion liquid can be fully integrated with the solder body, which is conducive to the agglomeration of the micro-nano powder on the surface of the solder body. , according to the toughness, strength and wear resistance requirements of the alloy formed after the active brazing filler metal is melted and cooled in the furnace, the optimal addition ratio of the micro-nano powder can be obtained under the given high temperature brazing conditions, and the modified micro-nano powder that meets the requirements can be obtained. The increase of the bulk density is conducive to improving the uniformity of the distribution of the micro-nano powder. The number of diamond pits on the surface of the material prepared according to the present invention, the number of microcracks on the diamond surface or around it is greatly reduced, and the strength of the solder alloy layer is lost. Small, the mechanical properties of diamond are improved by more than 8%, and the machining performance of tools is improved

附图说明Description of drawings

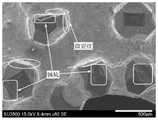

图1为本发明实施例中微纳米粉体改性的活性钎料示意图。FIG. 1 is a schematic diagram of an active solder modified by micro-nano powder in an embodiment of the present invention.

图2为本发明实施例中微纳米粉体改性的活性钎料形貌图。FIG. 2 is a topography diagram of the active solder modified by micro-nano powder in the embodiment of the present invention.

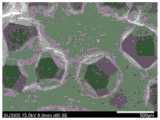

图3为现有Ni–Cr合金钎焊金刚石钻头示意图。Figure 3 is a schematic diagram of an existing Ni-Cr alloy brazed diamond drill bit.

图4为本发明实施例中改性Ni基活性钎料钎焊钻头形貌图。4 is a topography diagram of a modified Ni-based active solder brazing drill bit in an embodiment of the present invention.

其中,1、钎料;2、微纳米粉体。Among them, 1. solder; 2. micro-nano powder.

具体实施方式Detailed ways

下面结合附图对本发明做进一步详细描述:Below in conjunction with accompanying drawing, the present invention is described in further detail:

一种微纳米粉体改性活性钎料,包括钎料本体和微纳米粉体,按照质量份数计:包括钎料本体80–99份,微纳米粉体1–10份。A micro-nano powder modified active brazing filler metal comprises a brazing filler metal body and a micro-nano powder body, and in parts by mass: comprises 80-99 parts of the brazing filler metal body and 1-10 parts of the micro-nano powder.

钎料本体和微纳米粉体的纯度均大于等于99.9%,钎料本体粒度为50-100目,微纳米粉体粒径小于20μm;微纳米粉体均匀吸附在钎料表面。The purity of the solder body and the micro-nano powder is greater than or equal to 99.9%, the particle size of the solder body is 50-100 mesh, and the particle size of the micro-nano powder is less than 20 μm; the micro-nano powder is uniformly adsorbed on the surface of the solder.

所述钎料本体采用Ni–Cr合金钎料或Cu–Sn–Ti合金钎料,所述微纳米粉体采用缺陷石墨烯与Cu–Ce合金两者的复合粉体、缺陷石墨烯、Cu–Ce合金或TiC粉;The brazing filler metal body adopts Ni-Cr alloy brazing filler metal or Cu-Sn-Ti alloy brazing filler metal, and the micro-nano powder adopts composite powder of both defective graphene and Cu-Ce alloy, defective graphene, Cu- Ce alloy or TiC powder;

一种微纳米粉体改性的活性钎料制备方法,包括以下步骤:A preparation method of active solder modified by micro-nano powder, comprising the following steps:

步骤1)、按照质量份数计取钎料本体80–99份和微纳米粉体1–10份;Step 1), count 80-99 parts of the solder body and 1-10 parts of the micro-nano powder according to the mass fraction;

微纳米粉体采用缺陷石墨烯时取1–2份;微纳米粉体采用Cu–Ce合金时取5–10份,微纳米粉体采用TiC粉时取4-8份,微纳米粉体采用缺陷石墨烯与Cu–Ce合金两者的复合粉体取1–10份;钎料本体采用Ni–Cr合金钎料或Cu–Sn–Ti合金钎料;When using defective graphene for micro-nano powder, take 1-2 parts; when using Cu-Ce alloy for micro-nano powder, take 5-10 parts; when using TiC powder for micro-nano powder, take 4-8 parts; The composite powder of defective graphene and Cu-Ce alloy is taken as 1-10 parts; the solder body adopts Ni-Cr alloy solder or Cu-Sn-Ti alloy solder;

步骤2)、将微纳米粉体进行球磨使其粒径小于20μm;Step 2), ball milling the micro-nano powder to make the particle size less than 20 μm;

具体的,微纳米粉体采用缺陷石墨烯时,球磨后使其粒径小于20μm,缺陷石墨烯50%以上面积出现结构缺陷;微纳米粉体采用Cu–Ce合金时,球磨后使其粒径小于10μm;微纳米粉体采用TiC粉时,球磨后使其粒径小于20μm。Specifically, when the micro-nano powder is made of defective graphene, the particle size is less than 20 μm after ball milling, and more than 50% of the defective graphene has structural defects; when the micro-nano powder is made of Cu-Ce alloy, the particle size is reduced by ball milling. Less than 10μm; when the micro-nano powder is TiC powder, the particle size is less than 20μm after ball milling.

步骤3)、采用溶剂将球磨后的微纳米粉体完全分散溶解得到混合液A;Step 3), using a solvent to completely disperse and dissolve the ball-milled micro-nano powder to obtain a mixed solution A;

步骤4)、将混合液A在分散剂溶液中混合均匀,然后加入钎料本体进行充分混合均匀后烘干,即可得到微纳米粉体改性的活性钎料。Step 4), mix the mixed solution A in the dispersant solution uniformly, then add the brazing filler metal body to fully mix uniformly and then dry to obtain the active brazing filler metal modified by micro-nano powder.

具体的,本申请采用多层石墨烯经过振动球磨得到缺陷石墨烯;Specifically, the present application adopts multilayer graphene to obtain defective graphene through vibration ball milling;

采用振动球磨机对多层石墨烯或Cu–Ce合金进行球磨,振动球磨机振动频率为10-60Hz,工作振幅2-10mm,球磨机转速为20~80r/min,振动球磨时间1~6h,球料比为1:(0.5–2),球和粉料(多层石墨烯或Cu–Ce合金)总体积不超过球磨罐体积的85%,球磨罐和球均采用耐磨陶瓷材质。使用电镜观察经过振动球磨制的多层石墨烯或者Cu–Ce合金粉,经过球磨的多层石墨烯的结构缺陷(如褶皱、皱折)和Cu–Ce合金粒径大小;得到粒径小于20μm、50%以上面积出现结构缺陷即为缺陷石墨烯;Cu–Ce合金粒径小于10μm。将多层石墨烯进行研磨目的是增加其缺陷数量;将Cu–Ce合金进行研磨目的是减小其粒径。The multi-layer graphene or Cu-Ce alloy is ball-milled by a vibration ball mill. The vibration frequency of the vibration ball mill is 10-60Hz, the working amplitude is 2-10mm, the speed of the ball mill is 20-80r/min, the vibration ball milling time is 1-6h, and the ball-to-material ratio is 1:(0.5–2), the total volume of balls and powder (multilayer graphene or Cu–Ce alloy) does not exceed 85% of the volume of the ball mill jar, and both the ball mill jar and the ball are made of wear-resistant ceramic materials. Using electron microscope to observe the multi-layer graphene or Cu-Ce alloy powder produced by vibrating ball milling, the structural defects (such as wrinkles, wrinkles) of ball-milled multi-layer graphene and the particle size of Cu-Ce alloy; the particle size is less than 20μm , The structural defects in more than 50% of the area are defective graphene; the particle size of the Cu–Ce alloy is less than 10 μm. The purpose of grinding multi-layer graphene is to increase the number of defects; the purpose of grinding Cu-Ce alloy is to reduce its particle size.

步骤3)中,溶剂采用二甲基酰胺(DMF)或液体石蜡,溶剂与微纳米粉体的重量比例为1:(10–50)。In step 3), the solvent is dimethylamide (DMF) or liquid paraffin, and the weight ratio of the solvent to the micro-nano powder is 1:(10-50).

步骤4)中,分散剂溶液采用分散剂和有机溶剂的混合液;In step 4), the dispersant solution adopts the mixed solution of dispersant and organic solvent;

分散剂采用表面活性剂,具体为十二烷基硫酸钠、十二烷基苯磺酸钠或季铵化物,分散剂与微纳米粉体的重量比例为1:(5–10),有机溶剂为丙酮、酒精、甲酸、乙酸或乙醚,有机溶剂与微纳米粉体的重量比例为1:(0.4–0.8)。The dispersant adopts surfactant, specifically sodium dodecyl sulfate, sodium dodecylbenzenesulfonate or quaternary ammonium compound, the weight ratio of dispersant and micro-nano powder is 1:(5-10), organic solvent It is acetone, alcohol, formic acid, acetic acid or ether, and the weight ratio of organic solvent to micro-nano powder is 1:(0.4–0.8).

步骤4)中,将混合液A与分散剂溶液在混料机中混合均匀,混料机转速为50~150r/min,混料时间0.5~2h,球料比为1:(10–20),球和粉料总体积不超过混料罐体积的50%,混料罐采用耐磨陶瓷材质。In step 4), the mixed solution A and the dispersant solution are mixed evenly in a mixer, the speed of the mixer is 50-150r/min, the mixing time is 0.5-2h, and the ratio of ball to material is 1:(10-20) , The total volume of balls and powder does not exceed 50% of the volume of the mixing tank, and the mixing tank is made of wear-resistant ceramic material.

本发明微纳米粉体改性的活性钎料添加比例通过以下优化方法计算得到:The addition ratio of the active solder modified by the micro-nano powder of the present invention is calculated by the following optimization method:

对微纳米粉体改性的活性钎料进行布料后其形貌可视为二维平面密堆积(当Ni–Cr合金钎料粒度为50目左右时)或空间密堆积(当Ni–Cr合金钎料粒度为100目左右时),其特性采用堆积密度来表示,增加堆积密度有利于改善微纳米粉体分布均匀性;本发明微纳米粉体添加比例的优化方法采用物理数学建模方法,即以微纳米粉体改性的活性钎料堆积密度最高作为微纳米粉体添加比例优化的目标函数,根据微纳米粉体和钎料本体的实际粒径大小,建立如下数学关系式:The morphology of the micro-nano powder modified active solder can be regarded as two-dimensional plane close packing (when the particle size of the Ni–Cr alloy solder is about 50 mesh) or space close packing (when the Ni–Cr alloy is about 50 mesh). When the particle size of the brazing filler metal is about 100 mesh), its characteristics are represented by the bulk density, and increasing the bulk density is beneficial to improve the uniformity of the distribution of the micro-nano powder; the optimization method for the addition ratio of the micro-nano powder in the present invention adopts the physical and mathematical modeling method, That is, the highest bulk density of active solder modified by micro-nano powder is used as the objective function for the optimization of the addition ratio of micro-nano powder. According to the actual particle size of the micro-nano powder and the solder body, the following mathematical relationship is established:

其中,为微纳米粉体改性活性钎料在考虑松动效应和楔入效应后的堆积密度,为微纳米粉体在考虑松动效应和楔入效应后的体积分数,与微纳米粉体添加比例直接相关;a为松动效应系数,b为楔入效应系数,为微纳米粉体的堆积密度,为钎料本体的堆积密度,y1为微纳米粉体的体积分数,y2为钎料本体的体积分数。in, After considering the loosening effect and wedging effect, the bulk density of the active solder modified by the micro-nano powder, is the volume fraction of the micro-nano powder after considering the loosening effect and the wedging effect, which is directly related to the addition ratio of the micro-nano powder; a is the loosening effect coefficient, b is the wedging effect coefficient, is the bulk density of the micro-nano powder, is the bulk density of the solder body, y1 is the volume fraction of the micro-nano powder, and y2 is the volume fraction of the solder body.

同时,以添加的微纳米粉体不影响活性钎料流动铺展性能作为约束条件,根据活性钎料熔化后流动主要驱动力与其粘性剪切力的关系,建立如下约束函数:At the same time, with the added micro-nano powder not affecting the flow and spreading performance of the active solder as a constraint, according to the relationship between the main driving force of the active solder after melting and its viscous shear force, the following constraint function is established:

其中,μ为与微纳米粉体添加比例相关的流体动力粘度,T为温度,为表面张力温度系数,u为x方向动量,v为y方向动量,τ为流体单位面积上微纳米粉体对钎料的摩擦阻力,du/dy为速度梯度。Among them, μ is the hydrodynamic viscosity related to the addition ratio of micro-nano powder, T is the temperature, is the temperature coefficient of surface tension, u is the momentum in the x direction, v is the momentum in the y direction, τ is the frictional resistance of the micro-nano powder to the solder on the unit area of the fluid, and du/dy is the velocity gradient.

同时联解上述式(1)和式(2)求得和针对活性钎料熔化炉冷后形成合金的韧性、强度和耐磨性要求在给定的高温钎焊条件下获得微纳米粉体的最佳添加比例。Simultaneously solve the above equations (1) and (2) to obtain and According to the toughness, strength and wear resistance of the alloy formed after the active brazing filler metal is melted and cooled in the furnace, the optimal addition ratio of micro-nano powder can be obtained under the given high temperature brazing conditions.

实施例1:Example 1:

步骤1)、按照质量份数计取Ni–Cr合金钎料90份和Cu–Ce合金8份;Step 1), count 90 parts of Ni-Cr alloy brazing filler metal and 8 parts of Cu-Ce alloy according to the mass fraction;

步骤2)、将Cu–Ce合金进行球磨使其粒径小于20μm,振动球磨机振动频率为30Hz,工作振幅7mm,球磨机转速为30r/min,振动球磨时间3h,球料比为1:1,球和粉料总体积为球磨罐体积的80%,球磨罐和球均采用耐磨陶瓷材质;Step 2), the Cu-Ce alloy is ball-milled to make the particle size less than 20 μm, the vibration frequency of the vibration ball mill is 30Hz, the working amplitude is 7mm, the ball mill rotation speed is 30r/min, the vibration ball milling time is 3h, the ball-to-material ratio is 1:1, and the ball The total volume of powder and powder is 80% of the volume of the ball mill jar, and the ball mill jar and balls are made of wear-resistant ceramic materials;

步骤3)、采用二甲基酰胺将球磨后的Cu–Ce合金完全分散溶解得到混合液A,二甲基酰胺与Cu–Ce合金的重量比例为1:10;Step 3), using dimethylamide to completely disperse and dissolve the ball-milled Cu-Ce alloy to obtain mixed solution A, and the weight ratio of dimethylamide and Cu-Ce alloy is 1:10;

步骤4)、将混合液A在分散剂溶液中混合均匀,然后加入Ni–Cr合金钎料进行充分混合均匀后烘干,即可得到微纳米粉体改性的活性钎料;分散剂溶液中分散剂为十二烷基硫酸钠,十二烷基硫酸钠与Cu–Ce合金的重量比例为1:5,有机溶剂为丙酮,丙酮与Cu–Ce合金的重量比例为1:0.5;混料机转速为100r/min,混料时间1h,球料比为1:10,球和粉料总体积为混料罐体积的50%,混料罐采用耐磨陶瓷材质。实施例1中制成的微纳米粉体改性的Ni基活性钎料,如图1所示;其对钎焊金刚石造成的热损伤较少,采用该Ni基活性钎料制备的钎焊金刚石钻头表面金刚石蚀坑数量、金刚石表面或周围的微裂纹数量大大减少(参阅图2、图3和图4),钎焊金刚石的静抗压强度提高9%,冲击韧性提高7.9%,钻削寿命提高45%,钻削效率提高25.7%。Step 4), mix the mixed solution A in the dispersant solution uniformly, then add the Ni-Cr alloy brazing filler metal for full mixing and drying, and then obtain the active brazing filler metal modified by micro-nano powder; The dispersant is sodium dodecyl sulfate, the weight ratio of sodium dodecyl sulfate and Cu-Ce alloy is 1:5, the organic solvent is acetone, and the weight ratio of acetone and Cu-Ce alloy is 1:0.5; The rotating speed of the machine is 100r/min, the mixing time is 1h, the ratio of ball to material is 1:10, the total volume of ball and powder is 50% of the volume of the mixing tank, and the mixing tank is made of wear-resistant ceramic material. The micro-nano powder-modified Ni-based active solder prepared in Example 1 is shown in Figure 1; it causes less thermal damage to the brazed diamond, and the brazed diamond prepared by using the Ni-based active solder The number of diamond pits on the surface of the drill bit and the number of microcracks on or around the diamond surface are greatly reduced (see Figure 2, Figure 3 and Figure 4), the static compressive strength of brazed diamond is increased by 9%, the impact toughness is increased by 7.9%, and the drilling life 45% increase, drilling efficiency increased by 25.7%.

实施例2:Example 2:

步骤1)、按照质量份数计取Ni–Cr合金钎料80份和Cu–Ce合金10份;Step 1), count 80 parts of Ni-Cr alloy brazing filler metal and 10 parts of Cu-Ce alloy according to parts by mass;

步骤2)、将Cu–Ce合金进行球磨,振动球磨机振动频率为10Hz,工作振幅10mm,球磨机转速为20r/min,振动球磨时间6h,球料比为1:2,球和粉料总体积为球磨罐体积的75%,球磨罐和球均采用耐磨陶瓷材质;Step 2), the Cu-Ce alloy is ball-milled, the vibration frequency of the vibration ball mill is 10Hz, the working amplitude is 10mm, the ball mill rotation speed is 20r/min, the vibration ball milling time is 6h, the ball-to-material ratio is 1:2, and the total volume of the ball and powder is 75% of the volume of the ball mill, the ball mill and balls are made of wear-resistant ceramic materials;

步骤3)、采用液体石蜡将球磨后的Cu–Ce合金完全分散溶解得到混合液A,液体石蜡与Cu–Ce合金的重量比例为1:10;Step 3), using liquid paraffin to completely disperse and dissolve the ball-milled Cu-Ce alloy to obtain a mixed solution A, and the weight ratio of the liquid paraffin to the Cu-Ce alloy is 1:10;

步骤4)、将混合液A在分散剂溶液中混合均匀,然后加入Ni–Cr合金钎料进行充分混合均匀后烘干,即可得到微纳米粉体改性的活性钎料;分散剂溶液中分散剂为十二烷基硫酸钠,十二烷基硫酸钠与Cu–Ce合金的重量比例为1:5,有机溶剂为丙酮,丙酮与Cu–Ce合金的重量比例为1:0.5;混料机转速为100r/min,混料时间1h,球料比为1:10,球和粉料总体积为混料罐体积的50%,混料罐采用耐磨陶瓷材质。Step 4), mix the mixed solution A in the dispersant solution uniformly, then add the Ni-Cr alloy brazing filler metal for full mixing and drying, and then obtain the active brazing filler metal modified by micro-nano powder; The dispersant is sodium dodecyl sulfate, the weight ratio of sodium dodecyl sulfate and Cu-Ce alloy is 1:5, the organic solvent is acetone, and the weight ratio of acetone and Cu-Ce alloy is 1:0.5; The rotating speed of the machine is 100r/min, the mixing time is 1h, the ratio of ball to material is 1:10, the total volume of ball and powder is 50% of the volume of the mixing tank, and the mixing tank is made of wear-resistant ceramic material.

实施例2中制成的微纳米粉体改性的Ni基活性钎料,其对钎焊金刚石造成的热损伤同样较少,采用Ni基活性钎料制备的钎焊金刚石钻头表面金刚石蚀坑数量、金刚石表面或周围的微裂纹数量大大减少,钎焊金刚石的静抗压强度提高8.6%,冲击韧性提高8.1%,钻削寿命提高44%,钻削效率提高24.2%。The micro-nano powder-modified Ni-based active solder prepared in Example 2 has less thermal damage to the brazed diamond, and the number of diamond pits on the surface of the brazed diamond drill bit prepared by the Ni-based active solder The number of microcracks on or around the diamond surface is greatly reduced, the static compressive strength of brazed diamond is increased by 8.6%, the impact toughness is increased by 8.1%, the drilling life is increased by 44%, and the drilling efficiency is increased by 24.2%.

与上述实施例中其余步骤相同,采用不同组分及配比制备得到的微纳米粉体改性的活性钎料以及采用其制备的钎焊金刚石工具性能如表1所示:Identical to the remaining steps in the above-described embodiment, the micro-nano powder-modified active solder prepared by different components and proportions and the brazing diamond tool properties prepared by using it are shown in Table 1:

表1不同组分下钎焊金刚石工具性能Table 1 Properties of brazed diamond tools with different compositions

由以上实施例可知,本申请制备的微纳米粉体改性的活性钎料能减少高温钎焊对金刚石造成的热损伤,同时具有钎料合金层强度损失小等特点,适合于制作高性能金刚石工具。It can be seen from the above examples that the micro-nano powder-modified active solder prepared by the present application can reduce the thermal damage caused by high-temperature brazing to diamond, and at the same time has the characteristics of small strength loss of the solder alloy layer, and is suitable for making high-performance diamond. tool.

上述仅为本发明的具体实施方式,但本发明的设计构思并不局限于此,凡利用此构思对本发明进行非实质性的改动,均应属于侵犯本发明保护范围的行为。The above are only specific embodiments of the present invention, but the design concept of the present invention is not limited to this, and any non-substantial modification of the present invention by using this concept should be regarded as an act of infringing the protection scope of the present invention.

Claims (5)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010858316.XACN112222676B (en) | 2020-08-24 | 2020-08-24 | Micro-nano powder modified active brazing filler metal and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010858316.XACN112222676B (en) | 2020-08-24 | 2020-08-24 | Micro-nano powder modified active brazing filler metal and preparation method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN112222676A CN112222676A (en) | 2021-01-15 |

| CN112222676Btrue CN112222676B (en) | 2022-02-22 |

Family

ID=74116556

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010858316.XAActiveCN112222676B (en) | 2020-08-24 | 2020-08-24 | Micro-nano powder modified active brazing filler metal and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112222676B (en) |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1411945A (en)* | 2002-08-29 | 2003-04-23 | 胡仁良 | Braze filler metal copper base alloy powder for diamond braze welding and its preparation method |

| CN101579735A (en)* | 2009-06-25 | 2009-11-18 | 宋建华 | Self-fluxing solid material of diamond high-temperature alloy |

| CN101890593A (en)* | 2010-07-23 | 2010-11-24 | 安泰科技股份有限公司 | Nickel-based brazing material for brazed diamond tool and preparation method thereof |

| CN104607823A (en)* | 2014-12-12 | 2015-05-13 | 南京大学 | Manufacturing method of spherical self-fluxing alloy solder |

| CN104668807A (en)* | 2015-01-21 | 2015-06-03 | 南京大学 | Spherical low-melting-point brazing filler metal powder manufacturing method |

| CN104907732A (en)* | 2015-06-18 | 2015-09-16 | 鄂州市金刚石技术研发中心 | Prealloy powder used for laser welding diamond saw blade transition layer and preparation method |

| CN106238962A (en)* | 2016-08-30 | 2016-12-21 | 郑州机械研究所 | A kind of active solder alloy |

| CN109465568A (en)* | 2018-12-29 | 2019-03-15 | 郑州机械研究所有限公司 | A copper-based active solder for brazing of diamond grinding tools |

| CN110303269A (en)* | 2019-07-02 | 2019-10-08 | 华侨大学 | Sn-Cu-Ti Alloy Solder for Low Temperature Brazing of Diamond and Its Application |

| CN110640351A (en)* | 2019-09-25 | 2020-01-03 | 河南机电职业学院 | Micro-nano particle reinforced high-indium copper-based active solder and preparation method thereof |

| CN111299905A (en)* | 2020-03-20 | 2020-06-19 | 安徽工业大学 | Composite brazing filler metal containing WC and ZrC simultaneously, preparation method thereof and brazing method |

| CN111390426A (en)* | 2020-03-20 | 2020-07-10 | 安徽工业大学 | Composite brazing filler metal for brazing superhard abrasive material, preparation method of composite brazing filler metal and brazing method |

- 2020

- 2020-08-24CNCN202010858316.XApatent/CN112222676B/enactiveActive

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1411945A (en)* | 2002-08-29 | 2003-04-23 | 胡仁良 | Braze filler metal copper base alloy powder for diamond braze welding and its preparation method |

| CN101579735A (en)* | 2009-06-25 | 2009-11-18 | 宋建华 | Self-fluxing solid material of diamond high-temperature alloy |

| CN101890593A (en)* | 2010-07-23 | 2010-11-24 | 安泰科技股份有限公司 | Nickel-based brazing material for brazed diamond tool and preparation method thereof |

| CN104607823A (en)* | 2014-12-12 | 2015-05-13 | 南京大学 | Manufacturing method of spherical self-fluxing alloy solder |

| CN104668807A (en)* | 2015-01-21 | 2015-06-03 | 南京大学 | Spherical low-melting-point brazing filler metal powder manufacturing method |

| CN104907732A (en)* | 2015-06-18 | 2015-09-16 | 鄂州市金刚石技术研发中心 | Prealloy powder used for laser welding diamond saw blade transition layer and preparation method |

| CN106238962A (en)* | 2016-08-30 | 2016-12-21 | 郑州机械研究所 | A kind of active solder alloy |

| CN109465568A (en)* | 2018-12-29 | 2019-03-15 | 郑州机械研究所有限公司 | A copper-based active solder for brazing of diamond grinding tools |

| CN110303269A (en)* | 2019-07-02 | 2019-10-08 | 华侨大学 | Sn-Cu-Ti Alloy Solder for Low Temperature Brazing of Diamond and Its Application |

| CN110640351A (en)* | 2019-09-25 | 2020-01-03 | 河南机电职业学院 | Micro-nano particle reinforced high-indium copper-based active solder and preparation method thereof |

| CN111299905A (en)* | 2020-03-20 | 2020-06-19 | 安徽工业大学 | Composite brazing filler metal containing WC and ZrC simultaneously, preparation method thereof and brazing method |

| CN111390426A (en)* | 2020-03-20 | 2020-07-10 | 安徽工业大学 | Composite brazing filler metal for brazing superhard abrasive material, preparation method of composite brazing filler metal and brazing method |

Also Published As

| Publication number | Publication date |

|---|---|

| CN112222676A (en) | 2021-01-15 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN108213771B (en) | Composite brazing filler metal for brazing silicon carbide ceramic in vacuum and brazing process thereof | |

| CN113182632B (en) | Method for connecting C/C composite material by adopting high-entropy alloy brazing | |

| CN107760933A (en) | A kind of 3D printing strengthens Al alloy powder and preparation method thereof with in-situ nano complex phase ceramic | |

| Zhang et al. | Ultrasonic-accelerated metallurgical reaction of Sn/Ni composite solder: Principle, kinetics, microstructure, and joint properties | |

| CN112609115B (en) | Diamond/copper heat sink material for electronic packaging and preparation method thereof | |

| WO2021164613A1 (en) | Multi-grade micro-nano mixed metal paste and preparation method therefor | |

| CN101905387B (en) | Preparation method of nanometer Ag enhancing low-temperature lead-free compound soldering paste | |

| CN105624505A (en) | Metal based superhard composite and preparation method thereof | |

| Hu et al. | Effect of SiC reinforcement on the reliability of Ag nanoparticle paste for high-temperature applications | |

| CN112222676B (en) | Micro-nano powder modified active brazing filler metal and preparation method thereof | |

| CN116329812A (en) | A kind of preparation method of yttrium tungstate reinforced AgCuSnTi-based composite solder | |

| CN111961926A (en) | 3D printed nanoparticle reinforced aluminum-based composite powder and preparation method thereof | |

| CN109482863B (en) | Mixed powder for diamond saw blade | |

| CN113787192B (en) | A kind of preparation method of W-Cu composite plate with Cu phase in finger-like gradient distribution | |

| Zhao et al. | Effects of nanoparticles on properties and interface reaction of Sn solder for microelectronic packaging | |

| CN117921252A (en) | A nickel-based alloy powder solder for surface repair of nickel-based high-temperature alloys | |

| CN108608345B (en) | A kind of Cr-containing low-temperature brazing diamond and its brazing alloy | |

| CN118123323A (en) | Brazing material and preparation method thereof | |

| CN114192738B (en) | Aluminosilicate binder for casting and preparation method thereof | |

| CN113102915B (en) | A copper-based solder that can precisely control the amount of flux and has a good effect on brazing seam protection | |

| CN116623179A (en) | Vacuum infiltration sintering method of self-adaptive gradient blade tip wear-resistant sealing coating | |

| CN115319085A (en) | Method for preparing copper-based diamond composite material based on powder stirring friction processing | |

| CN112936121B (en) | Superabrasive grinding wheel working layer and preparation method thereof, superabrasive grinding wheel | |

| CN114921784A (en) | A kind of preparation method of high-quality radiation-resistant tungsten alloy coating | |

| CN105609426B (en) | A kind of nano pulp preparation method free of cleaning for low-temperature welding |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |