CN112197662B - A device for preventing blast holes from freezing - Google Patents

A device for preventing blast holes from freezingDownload PDFInfo

- Publication number

- CN112197662B CN112197662BCN202011120376.8ACN202011120376ACN112197662BCN 112197662 BCN112197662 BCN 112197662BCN 202011120376 ACN202011120376 ACN 202011120376ACN 112197662 BCN112197662 BCN 112197662B

- Authority

- CN

- China

- Prior art keywords

- hole

- barrel

- blast hole

- closed barrel

- closed

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42D—BLASTING

- F42D5/00—Safety arrangements

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42D—BLASTING

- F42D1/00—Blasting methods or apparatus, e.g. loading or tamping

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F42—AMMUNITION; BLASTING

- F42D—BLASTING

- F42D1/00—Blasting methods or apparatus, e.g. loading or tamping

- F42D1/08—Tamping methods; Methods for loading boreholes with explosives; Apparatus therefor

- F42D1/18—Plugs for boreholes

Landscapes

- Engineering & Computer Science (AREA)

- General Engineering & Computer Science (AREA)

- Life Sciences & Earth Sciences (AREA)

- General Life Sciences & Earth Sciences (AREA)

- Drilling And Exploitation, And Mining Machines And Methods (AREA)

- Pipe Accessories (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于工程爆破施工技术领域,具体地说主要涉及高原高寒地区爆破施工防止炮孔冻冰的器材。The invention belongs to the technical field of engineering blasting construction, and in particular mainly relates to equipment for preventing freezing of blastholes during blasting construction in plateau alpine regions.

背景技术Background technique

我国的多年冻土面积占国土面积的22.3%,在世界上占第三位,其中高海拔多年冻土的面积则居世界之最。根据国家政策我国建设重点正逐步向西部转移,在甘、清、新、藏、宁等广大地区的季节性冻土和多年冻土将逐步成为建设施工的重点。许多工程如房屋和道路地基开挖、矿产资源的开发、油田管路的铺设、水利水电工程以及军事工程的施工建设等都会面临冰冻、缺氧、环境保护等问题。在高原高寒地区,钻孔爆破法是矿岩、冻土开挖的主要施工方法。在爆破施工中经常会遇到炮孔内冻冰的问题,冻冰的位置有的从孔口开始向下延伸一段距离、有的在孔底、有的整个炮孔全部冻冰,冻冰致使炮孔孔径变细、深度变浅、有时使炮孔全部堵死,施工人员无法正常装填炸药。因此施工人员必须采取措施除去结冰,才能正常作业,这样不仅延长了工人在高原缺氧环境下的工作时间、增加劳动强度,而且增加企业生产成本、影响爆破效果、增大爆破风险,甚至对生态环境造成破坏。高原‘一快二低’(温度变化快、含氧低、气压低)的特殊环境使得高原施工不同于平原地区,时间就是工人的健康、是生态环境的保障、是企业的效益。my country's permafrost area accounts for 22.3% of the country's land area, ranking third in the world, and the area of high-altitude permafrost ranks the largest in the world. According to national policies, the focus of my country's construction is gradually shifting to the west. Seasonal frozen soil and permafrost in vast areas such as Gansu, Qing, Xin, Tibet, and Ningxia will gradually become the focus of construction. Many projects, such as excavation of housing and road foundations, development of mineral resources, laying of oilfield pipelines, water conservancy and hydropower projects, and construction of military projects, will face problems such as freezing, lack of oxygen, and environmental protection. In the plateau alpine region, the drilling and blasting method is the main construction method for mining rock and frozen soil. In the blasting construction, the problem of freezing ice in the blast hole is often encountered. Some of the frozen ice positions extend downward from the hole for a certain distance, some are at the bottom of the hole, and some of the entire blast hole is completely frozen. The hole diameter of the blast hole becomes thinner and the depth becomes shallower, and sometimes the blast hole is completely blocked, and the construction workers cannot normally load explosives. Therefore, the construction workers must take measures to remove the icing before they can work normally. This not only prolongs the working hours of the workers in the hypoxic environment on the plateau, increases the labor intensity, but also increases the production cost of the enterprise, affects the blasting effect, increases the blasting risk, and even affects damage to the ecological environment. The special environment of "one fast and two low" (fast temperature changes, low oxygen content, and low air pressure) on the plateau makes construction on the plateau different from that in plain areas. Time is the health of workers, the guarantee of the ecological environment, and the benefit of enterprises.

多年来,川藏线的修建、青藏铁路的建设以及新疆高寒地区水库大坝的修建、西藏矿产资源的开发,为高原高寒爆破施工积累了很多经验,对于炮孔冻冰的问题也提出了一些解决措施:1.采用PPR管悬吊于炮孔孔口部位,然后用装有煤灰的袋子覆盖;2.减少穿孔数量,确定合理的爆破规模;3.使用钻机二次透孔;4.用钢管套在木棍上,前端打磨锋利,人工凿冰;5.遵循快速施工的原则,减小装药间隔时间、钻完孔后尽快装药;6.加热融冰。但是上述措施仍然难于从根本上解决问题:方法1在孔口位置仍然有冻冰存在;方法2是被动施工方法,并没有解决冻冰问题,而且限制了工程进度;方法3是去除冻冰的方法,但将增加钻孔成本;方法4也是去除冻冰的方法,但将极大地增加工人的劳动量;方法5也是被动施工方法,同样没有从根本上解决炮孔冻冰的问题;方法6对于大量冻冰炮孔实施难度大,而且会带来新的排水问题。可见,上述方法并不能从根本上有效地解决高原高寒地区炮孔冻冰的技术问题。Over the years, the construction of the Sichuan-Tibet line, the construction of the Qinghai-Tibet Railway, the construction of reservoirs and dams in the alpine regions of Xinjiang, and the development of mineral resources in Tibet have accumulated a lot of experience for blasting construction in the plateau and alpine regions. Solutions: 1. Use PPR pipes to suspend the hole at the blast hole, and then cover it with a bag filled with coal ash; 2. Reduce the number of perforations and determine a reasonable blasting scale; 3. Use a drilling rig for secondary penetration; 4. Use a steel pipe to cover the wooden stick, sharpen the front end, and manually chisel the ice; 5. Follow the principle of rapid construction, reduce the charge interval time, and charge the charge as soon as possible after drilling the hole; 6. Heat to melt the ice. However, the above measures are still difficult to fundamentally solve the problem:

发明内容Contents of the invention

为了从根本上有效地解决多年来高原高寒地区炮孔冻冰的技术难题,本发明提出了一种防止炮孔冻冰的装置,能够阻止地表水从孔口流到炮孔中,能够阻止外部空气进入到炮孔中,也能够阻止岩体孔隙水、层流水进入到炮孔中,炮孔内没有了水自然无法冻冰,因此本发明能够从源头上解决炮孔冻冰的难题。In order to fundamentally and effectively solve the technical problem of blast hole freezing in plateau alpine areas for many years, the present invention proposes a device for preventing blast hole freezing, which can prevent surface water from flowing into the blast hole and prevent external The air entering the blast hole can also prevent rock mass pore water and laminar water from entering the blast hole. Without water in the blast hole, it is impossible to freeze ice. Therefore, the present invention can solve the problem of blast hole freezing from the source.

本发明解决其技术问题所采用的技术方案是:该装置由九部分组成,第一部分是封闭桶,材质为具有良好弹性性能的橡胶,圆柱形,其直径小于炮孔直径,为炮孔直径的1/3-1/2,可根据炮孔直径的实际大小调整,其长度比炮孔长度大,一般大50cm即可,底部封闭上部开口,作用是放入炮孔内,充气体积膨胀后紧密贴合在炮孔底部和周壁、填满孔口从而达到对炮孔全方位封闭的目的;第二部分是充气软管,为耐高压高强度软管,长度与封闭桶等长,直径为2cm,置于封闭桶内部,作用是将高压气体导向封闭桶底部;第三部分是阻尼器,形状为实心圆环体,材质为橡胶,内径大于充气软管外径,紧紧套在封闭桶底部导向平衡铅块上方,作用是限制封闭桶在充气时的自由膨胀,确保封闭桶先从底部膨胀,进而逐渐向上膨胀;第四部分是导向平衡铅块,圆柱形,中间有一圆柱形空孔,空孔内嵌套一内径为2cm的铁质圆管,铅块底部有五条半圆形导气凹槽联通中间空孔,总质量为5kg,作用是使封闭桶能方便地顺直放入炮孔底部,也起到为充气软管出气端导气的作用,使高压气体先到达封闭桶底部;第五部分是充气接头,作用是将充气软管和高压气源相联结;第六部分是磁吸接头,形状为一端带有向外凸出的环形外沿的圆管,外径为2cm,材质为磁铁,作用是将充气软管和导向平衡铅块相连,磁性材质便于封闭桶充气体积膨胀时磁吸接头与导向平衡铅块的分离;第七部分是安全绳,作用是在封闭桶提出炮孔时起到辅助提拉的作用;第八部分是束紧袋,圆筒形,在封闭桶沿径向折叠后套在封闭桶外部,使封闭桶所占体积更小更规整,便于装入炮孔内部,沿束紧袋纵向全长设置有一条断口线,作用是便于束紧袋在封闭桶膨胀时沿断口线断开脱落;第九部分是封口砂袋,为内部装有钻孔岩屑的塑料编织袋,作用是待封闭桶充气膨胀超过孔口一段距离时压住孔口,使封闭桶紧密贴合在炮孔孔口部位。由于影响炮孔冻冰的因素比较多,如高原高寒地区温差大、温度变化快空气在炮孔内形成冷凝水,岩体内含有孔隙水渗入炮孔,岩体节理裂隙发育形成水流通道通向炮孔,个别岩体含有层流水进入炮孔,降水从孔口流入炮孔,空气窜入头排炮孔裂隙形成的冷凝水等,这些因素都可能造成炮孔内冻冰。冻冰的部位和程度也都不同,有的在孔口部位,有的在孔底,有的沿着炮孔全长冻冰,使孔径变细,孔深变浅,甚至整个炮孔全部被冻冰填满,致使炸药无法装填。每个爆区几十个甚至几百个炮孔的情况都各不相同。但不管是哪一种情况,受何种因素影响,冻冰的根本原因都是水或空气首先进入到炮孔中,因此,本发明技术方案解决问题的原理是每个炮孔钻完后立即用本装置对该炮孔进行全封闭处理,使外部水源及空气无法进入到炮孔中。由于橡胶材料具有良好的弹性性能,封闭桶充气后体积膨胀,在阻尼器的限制下首先在底部膨胀,膨胀至炮孔周壁后便紧密地贴合在炮孔周壁上,同时受炮孔周壁的限制停止径向膨胀,此时继续充气,内部气体压力增大便推动阻尼器向上运动,封闭桶体积又开始膨胀至炮孔周壁,这样封闭桶不断地自下而上地膨胀,同时自下而上地将炮孔内的空气或者积水排除至孔外,最后紧密地贴合在孔底及整个炮孔周壁,在封口砂袋的压力作用下封闭桶紧密封住孔口,从而实现了对整个炮孔的全封闭,使孔外降水、岩体孔隙水、层流水、外部空气等无法进入到炮孔中,炮孔内没有水便无法结冰,从根本上解决了炮孔冻冰的技术难题。另外封闭桶回收后还可折叠或者卷起来以备重复使用。The technical solution adopted by the present invention to solve its technical problems is: the device is composed of nine parts, the first part is a closed barrel, the material is rubber with good elastic properties, cylindrical, and its diameter is less than the diameter of the blasthole, which is the diameter of the blasthole. 1/3-1/2, can be adjusted according to the actual diameter of the blast hole, its length is larger than the blast hole length, generally 50cm larger, the bottom seals the upper opening, the function is to put it into the blast hole, and the inflated volume expands tightly Attached to the bottom and surrounding wall of the blast hole, filling the hole so as to achieve the purpose of all-round sealing of the blast hole; the second part is the inflatable hose, which is a high-pressure resistant high-strength hose with a length equal to that of the closed barrel and a diameter of 2cm , placed inside the closed barrel, the function is to guide the high-pressure gas to the bottom of the closed barrel; the third part is the damper, which is a solid torus, made of rubber, with an inner diameter larger than the outer diameter of the inflatable hose, and tightly sleeved at the bottom of the closed barrel The function of guiding the balance lead block is to limit the free expansion of the closed barrel when it is inflated, to ensure that the closed barrel expands from the bottom first, and then gradually expands upward; the fourth part is the lead balance lead block, which is cylindrical and has a cylindrical hole in the middle. An iron round pipe with an inner diameter of 2cm is nested in the empty hole. There are five semicircular air guiding grooves at the bottom of the lead block to communicate with the middle empty hole, with a total mass of 5kg. The bottom of the hole also plays the role of guiding air for the outlet end of the inflatable hose, so that the high-pressure gas reaches the bottom of the closed barrel first; the fifth part is the inflatable joint, which is used to connect the inflatable hose with the high-pressure gas source; the sixth part is Magnetic connector, shaped like a round tube with a protruding ring-shaped outer edge at one end, with an outer diameter of 2cm, made of a magnet, used to connect the inflation hose with the guide balance lead weight, the magnetic material is convenient for closing the inflation volume of the barrel The separation of the magnetic suction joint and the guide balance lead weight during expansion; the seventh part is a safety rope, which is used to assist in lifting when the closed barrel is lifted out of the blast hole; the eighth part is a tightening bag, cylindrical, in the The closed barrel is folded radially and placed outside the closed barrel to make the volume occupied by the closed barrel smaller and more regular, which is convenient for loading into the blasthole. When the closed barrel expands, it breaks and falls off along the fracture line; the ninth part is the sealing sand bag, which is a plastic woven bag with drilling cuttings inside, and its function is to press the orifice when the closed barrel is inflated to exceed a certain distance from the orifice , so that the closed barrel fits tightly on the blast hole orifice. Because there are many factors that affect the freezing of blastholes, such as large temperature differences and rapid temperature changes in plateau alpine regions, air forms condensed water in blastholes, pore water in the rock body penetrates into blastholes, and rock mass joints and fissures develop to form water flow channels leading to Blast hole, individual rock mass contains laminar water entering the blast hole, precipitation flows into the blast hole from the orifice, and air enters the condensed water formed in the cracks of the first row of blast holes, etc. These factors may cause ice in the blast hole. The location and degree of freezing ice are also different. Some are at the mouth of the hole, some are at the bottom of the hole, and some are frozen along the entire length of the blast hole, making the hole diameter thinner, the hole depth shallower, and even the entire blast hole is completely covered. Filled with ice, making it impossible to reload the explosives. The situation of dozens or even hundreds of blast holes in each blast area is different. But no matter what kind of situation, affected by what factors, the root cause of freezing is that water or air first enters the blast hole. Therefore, the principle of the technical solution of the present invention is to immediately The device is used to fully seal the blast hole so that external water and air cannot enter the blast hole. Due to the good elastic properties of the rubber material, the volume of the closed barrel expands after inflation, and under the restriction of the damper, it first expands at the bottom, and after expanding to the surrounding wall of the blasthole, it is closely attached to the surrounding wall of the blasthole, and at the same time, it is affected by the surrounding wall of the blasthole. The radial expansion is limited and stopped. At this time, continue to inflate, and the internal gas pressure increases to push the damper upward, and the volume of the closed barrel begins to expand to the surrounding wall of the blast hole, so that the closed barrel continues to expand from bottom to top, and at the same time The air or accumulated water in the blast hole is exhausted to the outside of the hole, and finally it is tightly attached to the bottom of the hole and the entire wall of the blast hole. The complete sealing of the blast hole prevents precipitation outside the hole, rock mass pore water, laminar water, and external air from entering the blast hole. If there is no water in the blast hole, it cannot freeze, which fundamentally solves the technology of blast hole freezing. problem. In addition, the closed barrel can be folded or rolled up for reuse after recycling.

本发明的有益效果是,在无需测定、分析高原高寒环境下各种影响因素及其指标的情况下,直接对炮孔进行全方位地封闭处理,有效地阻断了造成炮孔冻冰的水源,从根本上解决了炮孔冻冰的问题,其结构简单、操作快捷、工人劳动量小、强度低,并且成本低廉、利于推广。The beneficial effect of the present invention is that without the need to measure and analyze various influencing factors and their indicators in the plateau alpine environment, the blast hole is directly sealed in all directions, effectively blocking the water source that causes the blast hole to freeze , fundamentally solves the problem of blast hole freezing, and has the advantages of simple structure, fast operation, small labor load, low strength, low cost and favorable promotion.

附图说明Description of drawings

下面结合附图和实施例对本发明进一步说明。The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

图1是本发明的结构组成示意图。Fig. 1 is a schematic diagram of the structure and composition of the present invention.

图2是阻尼器结构示意图。Figure 2 is a schematic diagram of the structure of the damper.

图3是导向平衡铅块结构细节示意图。Fig. 3 is a schematic diagram of the structural details of the guide balance lead block.

图4是磁吸接头结构细节示意图。Fig. 4 is a schematic diagram of the structural details of the magnetic suction joint.

图5是束紧袋断口线结构示意图。Fig. 5 is a schematic diagram of the structure of the fracture line of the tightening bag.

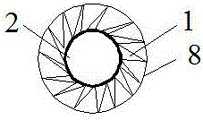

图6是本发明在折叠状态横断面示意图。Fig. 6 is a schematic cross-sectional view of the present invention in a folded state.

图7是本发明防止冻冰原理及效果示意图。Fig. 7 is a schematic diagram of the principle and effect of preventing freezing in the present invention.

图中1.封闭桶,2.充气软管,3.阻尼器,4.导向平衡铅块,5.充气接头,6.磁吸接头,7.安全绳,8.束紧袋,9.封口砂袋,10.炮孔,11.环形外沿,12.铁质圆管,13.导气凹槽,14.地表水,15.岩体裂隙水,16.岩体渗流水,17.断口线。In the figure 1. Closed barrel, 2. Inflatable hose, 3. Damper, 4. Guide balance lead weight, 5. Inflatable joint, 6. Magnetic joint, 7. Safety rope, 8. Tie bag, 9. Seal Sand bag, 10. Blasting hole, 11. Ring outer edge, 12. Iron circular pipe, 13. Air guide groove, 14. Surface water, 15. Rock mass fissure water, 16. Rock mass seepage water, 17. Fracture Wire.

具体实施方式detailed description

在图1中,用三颗螺栓将导向平衡铅块(4)和安全绳(7)的一端安装固定在封闭桶(1)内底部位置,充气软管(2)安装在封闭桶(1)内部,充气软管(2)一端连接充气接头(5),另一端连接磁吸接头(6),磁吸接头(6)与导向平衡铅块(4)相连接,束紧袋(8)沿全长套在封闭桶(1)外部,阻尼器(3)安装在束紧袋(8)外部紧挨导向平衡铅块(4)并在其上方位置。In Figure 1, use three bolts to install and fix one end of the guide balance lead weight (4) and the safety rope (7) at the bottom of the closed bucket (1), and the inflation hose (2) is installed in the closed bucket (1) Inside, one end of the inflation hose (2) is connected to the inflation connector (5), and the other end is connected to the magnetic connector (6). The full length is set on the outside of the closed bucket (1), and the damper (3) is installed on the outside of the tightening bag (8) close to the guide balance lead weight (4) and at the position above it.

在图3中,导气凹槽(13)安装方向向下,即与封闭桶(1)底相接触。In Fig. 3, the installation direction of the air guide groove (13) is downward, that is, it is in contact with the bottom of the closed barrel (1).

在图4中,环形外沿(11)安装时位于内侧,即充气软管(2)一侧,主要起限位作用,防止充气软管(2)过度穿过导向平衡铅块(4)。In Fig. 4, the annular outer edge (11) is located on the inner side during installation, that is, on the side of the inflation hose (2), and mainly acts as a limiter to prevent the inflation hose (2) from excessively passing through the guide balance lead weight (4).

在图5中,断口线(17)连接部分和断开部分连续密集交错设置。In Fig. 5, the connection part and the disconnection part of the fracture line (17) are continuously and closely interlaced.

在图6中,封闭桶(1)在未充气时为折叠状态,束紧袋(8)将封闭桶(1)紧紧包裹住,可以减小封闭桶(1)在装入时与孔壁的摩擦,同时使阻尼器(3)在充气时的运动阻力更均匀,也方便储运。In Fig. 6, the closed barrel (1) is in a folded state when it is not inflated, and the tightening bag (8) wraps the closed barrel (1) tightly, which can reduce the contact between the closed barrel (1) and the hole wall when it is loaded. At the same time, the movement resistance of the damper (3) when inflated is more uniform, and it is also convenient for storage and transportation.

使用时,将本装置轻轻顺直放进待封闭炮孔(10)内,封闭桶(1)底部到达孔底后,将充气接头(5)与高压充气设备连接,开始匀速充气,充气软管(2)首先将高压气体导向封闭桶(1)底部,在阻尼器(3)的限制下封闭桶(1)体积首先在底部膨胀变大,膨胀至炮孔(10)周壁后便紧密地贴合在炮孔(10)周壁上,同时受炮孔(10)周壁的限制停止径向膨胀,此时继续充气,内部气体压力增大便推动阻尼器(3)向上运动,封闭桶(1)体积又开始膨胀至炮孔(10)周壁。这样封闭桶(1)体积不断地自下而上地膨胀增大,同时自下而上地将炮孔(10)内的空气或者积水排除至孔外,最后紧密地贴合在孔底及整个炮孔(10)周壁。待封闭桶(1)膨胀至超出炮孔(10)孔口5-10cm后停止充气,用卡钳夹紧,对折后再次用卡钳夹紧,然后用装有钻孔岩屑的封口砂袋(9)压在炮孔(10)孔口封闭桶(1)上端,即完成炮孔(10)的全封闭处理。待装药时,移除封口砂袋(9),松开卡钳,气体排出后封闭桶(1)收缩恢复到初始的状态,借助安全绳(7)的辅助作用将其从炮孔(10)中提出即可进行装药作业。When in use, put the device gently and straightly into the blast hole (10) to be sealed. After the bottom of the closed barrel (1) reaches the bottom of the hole, connect the inflation joint (5) to the high-pressure inflation device, and start to inflate at a constant speed. The tube (2) first guides the high-pressure gas to the bottom of the closed barrel (1), and under the restriction of the damper (3), the volume of the closed barrel (1) first expands at the bottom, and after expanding to the surrounding wall of the blast hole (10), it is tightly sealed It fits on the surrounding wall of the blasthole (10), and at the same time, it is restricted by the surrounding wall of the blasthole (10) to stop radial expansion. At this time, continue to inflate, and the internal gas pressure increases to push the damper (3) to move upward, closing the barrel (1) Volume begins to expand to blasthole (10) peripheral wall again. In this way, the volume of the closed barrel (1) expands continuously from bottom to top, and at the same time, the air or accumulated water in the blast hole (10) is removed from the bottom to the top of the hole, and finally it is tightly attached to the bottom of the hole and the bottom of the hole. Whole blasthole (10) peripheral wall. Stop inflating after the closed barrel (1) expands to 5-10cm beyond the blast hole (10), clamp it with calipers, fold it in half and clamp it again with calipers, and then use the sealing sand bag (9 ) is pressed on the upper end of the blasthole (10) orifice sealing barrel (1), that is, the full sealing process of the blasthole (10) is completed. When charging, remove the sealed sand bag (9), loosen the caliper, and after the gas is discharged, the closed barrel (1) shrinks back to its original state, and with the help of the safety rope (7), remove it from the blasthole (10) Proposed in the charging operation can be carried out.

在图7中,封闭桶(1)将炮孔(10)暴露的空间全部填满封闭后,炮孔(10)空间以外的地表水(14)、岩体裂隙水(15)、岩体渗流水(16)等水源和空气都无法进入到其内部,没有了水自然无法冻冰,这样从根本上解决了高原高寒地区炮孔冻冰的技术难题。In Fig. 7, after the closed barrel (1) completely fills and seals the exposed space of the blast hole (10), the surface water (14), rock mass fissure water (15), and rock mass seepage outside the blast hole (10) space Water (16) and other water sources and air cannot enter its interior, and the ice cannot be frozen naturally without water, which fundamentally solves the technical problem of freezing ice in blastholes in plateau alpine regions.

以某高原高海拔地区海拔约5270米处的露天爆破施工为例,其具体工况为:爆区岩体节理裂隙较发育,岩石普氏系数f=6-10,使用潜孔钻机钻孔,孔径120mm,孔深14.5m,孔距6米,排距4.5米,三角形布孔,填塞高度4.5-5米,使用高原型乳化炸药,普通塑料导爆管毫秒延期雷管,平均炸药单耗0.40kg/m3左右。冻冰情况为,经过一天或几天将整个爆区所有炮孔钻完后,待装药时孔内便出现冻冰现象,有的孔口结冰孔径变细,有的整个炮孔全部冻冰,严重时几乎整个爆区钻孔都出现冻冰。以此工程说明本发明的应用效果:Taking the open-pit blasting construction at an altitude of about 5,270 meters in a plateau high-altitude area as an example, the specific working conditions are: the rock mass joints and fissures in the blasting area are relatively developed, and the rock's Platts coefficient is f=6-10. The hole diameter is 120mm, the hole depth is 14.5m, the hole distance is 6 meters, the row distance is 4.5 meters, the holes are arranged in a triangle, the filling height is 4.5-5 meters, the plateau type emulsion explosive is used, the ordinary plastic nonel millisecond delay detonator is used, and the average explosive unit consumption is 0.40kg /m3 or so. The freezing situation is that after one or a few days after drilling all the blastholes in the blast area, the phenomenon of freezing will appear in the hole when the powder is charged. Ice, and in severe cases, almost the entire borehole in the blast zone is frozen. The application effect of the present invention is illustrated with this project:

一、爆区钻孔前,装备好所需器材;1. Before drilling in the blast zone, equip the required equipment;

二、钻完一孔后,立即将本装置放进待封闭炮孔(10)内,封闭桶(1)底部到达孔底后,将充气接头(5)与高压充气设备连接,开始匀速充气,待封闭桶(1)膨胀至超出炮孔(10)孔口5-10cm后停止充气,用卡钳夹紧,对折后再次用卡钳夹紧,然后用装有钻孔岩屑的封口砂袋(9)压在炮孔(10)孔口封闭桶(1)上端,即完成炮孔(10)的全封闭处理;2. After drilling a hole, immediately put the device into the blast hole (10) to be sealed, and after the bottom of the closed barrel (1) reaches the bottom of the hole, connect the inflation joint (5) to the high-pressure inflation equipment, and start to inflate at a constant speed. Stop inflating after the closed barrel (1) expands to 5-10cm beyond the blast hole (10), clamp it with calipers, fold it in half and clamp it again with calipers, and then use the sealing sand bag (9 ) is pressed on the upper end of the hole sealing barrel (1) of the blasthole (10), that is, the full sealing treatment of the blasthole (10) is completed;

三、逐个将爆区内钻完的炮孔(10)进行全封闭处理;3. Completely seal the blastholes (10) drilled in the explosion zone one by one;

四、待装药时,移除封口砂袋(9),松开卡钳,气体排出后封闭桶(1)收缩恢复到初始的状态,借助安全绳(7)的辅助作用将其从炮孔(10)中提出,然后进行装药作业。4. When charging, remove the sealing sand bag (9), loosen the caliper, and after the gas is discharged, the closed barrel (1) shrinks back to its original state, and with the help of the safety rope (7), remove it from the blast hole ( 10), and then carry out the charging operation.

应用本发明,上述工程实例中炮孔均没有出现冻冰的情况。With the application of the present invention, there is no freezing situation in the blastholes in the above-mentioned engineering examples.

Claims (2)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011120376.8ACN112197662B (en) | 2020-10-19 | 2020-10-19 | A device for preventing blast holes from freezing |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202011120376.8ACN112197662B (en) | 2020-10-19 | 2020-10-19 | A device for preventing blast holes from freezing |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN112197662A CN112197662A (en) | 2021-01-08 |

| CN112197662Btrue CN112197662B (en) | 2023-01-06 |

Family

ID=74009431

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202011120376.8AActiveCN112197662B (en) | 2020-10-19 | 2020-10-19 | A device for preventing blast holes from freezing |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112197662B (en) |

Families Citing this family (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112179230B (en)* | 2020-10-19 | 2024-09-17 | 辽宁科技学院 | Full-closed device for blast holes |

| CN114739245B (en)* | 2022-04-19 | 2023-06-02 | 辽宁科技大学 | Device for preventing blast hole water from being frozen in alpine region and use method |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04124600A (en)* | 1990-09-14 | 1992-04-24 | Gijutsu Shigen Kaihatsu Kk | Method of blasting |

| CN102435113A (en)* | 2011-12-20 | 2012-05-02 | 鞍钢集团矿业公司 | Radial air-spaced charge device for blasthole blasting |

| CN202648549U (en)* | 2012-06-29 | 2013-01-02 | 广东宏大爆破股份有限公司 | Spacer of blast hole |

| CN106152887A (en)* | 2016-08-12 | 2016-11-23 | 浙江科技学院 | Inflation expanding perforation plugging device certainly for tunnel deep hole blasting |

| CN210718871U (en)* | 2019-09-19 | 2020-06-09 | 中国矿业大学(北京) | An accurate isolation charge device for blasting gas in rich water deep hole in open-pit mine |

| CN112179230A (en)* | 2020-10-19 | 2021-01-05 | 辽宁科技学院 | Device for totally closing blast hole |

| CN213714115U (en)* | 2020-10-19 | 2021-07-16 | 辽宁科技学院 | A device with a fully closed blast hole |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US9243878B2 (en)* | 2011-01-20 | 2016-01-26 | Crinum Ip Pty Ltd | Borehole plug inflation control |

- 2020

- 2020-10-19CNCN202011120376.8Apatent/CN112197662B/enactiveActive

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH04124600A (en)* | 1990-09-14 | 1992-04-24 | Gijutsu Shigen Kaihatsu Kk | Method of blasting |

| CN102435113A (en)* | 2011-12-20 | 2012-05-02 | 鞍钢集团矿业公司 | Radial air-spaced charge device for blasthole blasting |

| CN202648549U (en)* | 2012-06-29 | 2013-01-02 | 广东宏大爆破股份有限公司 | Spacer of blast hole |

| CN106152887A (en)* | 2016-08-12 | 2016-11-23 | 浙江科技学院 | Inflation expanding perforation plugging device certainly for tunnel deep hole blasting |

| CN210718871U (en)* | 2019-09-19 | 2020-06-09 | 中国矿业大学(北京) | An accurate isolation charge device for blasting gas in rich water deep hole in open-pit mine |

| CN112179230A (en)* | 2020-10-19 | 2021-01-05 | 辽宁科技学院 | Device for totally closing blast hole |

| CN213714115U (en)* | 2020-10-19 | 2021-07-16 | 辽宁科技学院 | A device with a fully closed blast hole |

Also Published As

| Publication number | Publication date |

|---|---|

| CN112197662A (en) | 2021-01-08 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN213714115U (en) | A device with a fully closed blast hole | |

| CN106225617B (en) | A kind of rock-burst prevention method based on quick-fried rammer hydrofracturing | |

| CN112179230B (en) | Full-closed device for blast holes | |

| CN103148748B (en) | Pressure-adjustable expansion plastic pipe deep hole blasting control method | |

| CN110118084B (en) | Ultra-deep shaft construction method | |

| CN112378301A (en) | Method for preventing blast hole from freezing | |

| CN112197662B (en) | A device for preventing blast holes from freezing | |

| CN103206903B (en) | Hard roof directional pressure-bearing blasting control method | |

| CN110080763B (en) | Coal seam surrounding rock pressure relief method based on internal injection type static crushing pressure relief mechanism | |

| CN102162372B (en) | Method and system for clearing blockage of ore chute | |

| CN109186389A (en) | A kind of blasthole blocking up method | |

| CN106761852A (en) | Wide area coal petrography deep hole pressure-bearing microexplosion grouting water blocking method under water | |

| CN110630208A (en) | A multi-stage segmented grouting plugging device and sealing method for gas drainage boreholes | |

| CN110500925A (en) | Deep hole blasting charging method for penetrating through molten cavity and molten cavity detection device | |

| CN108547617A (en) | A kind of static(al) broken rock flexible sleeve explosive charge method | |

| CN109186390B (en) | Open-air deep hole blasting water interval-coupled charge blasting method and special water column bag | |

| CN215810502U (en) | Blast hole charging structure for energy-gathered water pressure blasting | |

| CN113739657A (en) | Three-level air plug sealing heat preservation method for preventing blast hole from freezing | |

| CN109989752B (en) | Internal injection type static broken coal bed surrounding rock pressure relief device | |

| CN113983885B (en) | Open-air underground water-filled Kong Daizhuang water-resistant explosive charging device and method | |

| CN215832596U (en) | An inflatable capsule for preventing blast hole freezing | |

| CN202832353U (en) | Straight-buckle fast connection cement head device with large inner diameter | |

| CN109238058A (en) | A kind of method for sealing based on swollen plasticity non-Newtonian fluid material | |

| CN209959248U (en) | An internal injection type static crushing coal seam surrounding rock pressure relief device | |

| CN210802246U (en) | A wedge-shaped blast hole plugging device |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |