CN112135044B - Food material purifying machine - Google Patents

Food material purifying machineDownload PDFInfo

- Publication number

- CN112135044B CN112135044BCN202010998876.5ACN202010998876ACN112135044BCN 112135044 BCN112135044 BCN 112135044BCN 202010998876 ACN202010998876 ACN 202010998876ACN 112135044 BCN112135044 BCN 112135044B

- Authority

- CN

- China

- Prior art keywords

- liquid level

- water

- inner barrel

- food

- level detection

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N23/00—Cameras or camera modules comprising electronic image sensors; Control thereof

- H04N23/60—Control of cameras or camera modules

- A—HUMAN NECESSITIES

- A23—FOODS OR FOODSTUFFS; TREATMENT THEREOF, NOT COVERED BY OTHER CLASSES

- A23L—FOODS, FOODSTUFFS OR NON-ALCOHOLIC BEVERAGES, NOT OTHERWISE PROVIDED FOR; PREPARATION OR TREATMENT THEREOF

- A23L5/00—Preparation or treatment of foods or foodstuffs, in general; Food or foodstuffs obtained thereby; Materials therefor

- A23L5/20—Removal of unwanted matter, e.g. deodorisation or detoxification

- A23L5/27—Removal of unwanted matter, e.g. deodorisation or detoxification by chemical treatment, by adsorption or by absorption

- A—HUMAN NECESSITIES

- A47—FURNITURE; DOMESTIC ARTICLES OR APPLIANCES; COFFEE MILLS; SPICE MILLS; SUCTION CLEANERS IN GENERAL

- A47J—KITCHEN EQUIPMENT; COFFEE MILLS; SPICE MILLS; APPARATUS FOR MAKING BEVERAGES

- A47J43/00—Implements for preparing or holding food, not provided for in other groups of this subclass

- A47J43/24—Devices for washing vegetables or the like

- G—PHYSICS

- G01—MEASURING; TESTING

- G01F—MEASURING VOLUME, VOLUME FLOW, MASS FLOW OR LIQUID LEVEL; METERING BY VOLUME

- G01F23/00—Indicating or measuring liquid level or level of fluent solid material, e.g. indicating in terms of volume or indicating by means of an alarm

- G01F23/22—Indicating or measuring liquid level or level of fluent solid material, e.g. indicating in terms of volume or indicating by means of an alarm by measuring physical variables, other than linear dimensions, pressure or weight, dependent on the level to be measured, e.g. by difference of heat transfer of steam or water

- G01F23/26—Indicating or measuring liquid level or level of fluent solid material, e.g. indicating in terms of volume or indicating by means of an alarm by measuring physical variables, other than linear dimensions, pressure or weight, dependent on the level to be measured, e.g. by difference of heat transfer of steam or water by measuring variations of capacity or inductance of capacitors or inductors arising from the presence of liquid or fluent solid material in the electric or electromagnetic fields

- G01F23/263—Indicating or measuring liquid level or level of fluent solid material, e.g. indicating in terms of volume or indicating by means of an alarm by measuring physical variables, other than linear dimensions, pressure or weight, dependent on the level to be measured, e.g. by difference of heat transfer of steam or water by measuring variations of capacity or inductance of capacitors or inductors arising from the presence of liquid or fluent solid material in the electric or electromagnetic fields by measuring variations in capacitance of capacitors

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04B—TRANSMISSION

- H04B11/00—Transmission systems employing sonic, ultrasonic or infrasonic waves

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N23/00—Cameras or camera modules comprising electronic image sensors; Control thereof

- H04N23/80—Camera processing pipelines; Components thereof

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04N—PICTORIAL COMMUNICATION, e.g. TELEVISION

- H04N5/00—Details of television systems

- H04N5/30—Transforming light or analogous information into electric information

- H04N5/33—Transforming infrared radiation

Landscapes

- Engineering & Computer Science (AREA)

- Signal Processing (AREA)

- Multimedia (AREA)

- Physics & Mathematics (AREA)

- Food Science & Technology (AREA)

- Power Engineering (AREA)

- Polymers & Plastics (AREA)

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Nutrition Science (AREA)

- Health & Medical Sciences (AREA)

- Electromagnetism (AREA)

- Thermal Sciences (AREA)

- Fluid Mechanics (AREA)

- General Physics & Mathematics (AREA)

- Computer Networks & Wireless Communication (AREA)

- Mechanical Engineering (AREA)

- Cleaning By Liquid Or Steam (AREA)

- Physical Water Treatments (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及食材净化机领域,特别涉及一种可对食材进行净化的食材净化机。The invention relates to the field of food purifiers, in particular to a food purifier capable of purifying food.

背景技术Background technique

随着人们生活水平的提高,现有技术中出现了在厨房使用的食材净化机,这种食材净化机可以对家庭食用的蔬菜、水果等进行清洁,以保障用户的身体健康。例如中国实用新型专利CN203153499U公开了一种食材清洗机,其中包括臭氧发生器,得到高浓度微泡臭氧的臭氧水,对食材进行杀菌消毒,但是这种食材机没有考虑到臭氧对人体健康的危害,并且单一的消毒方式对食材的清洁能力较低;CN208875365U公开了一种基于超声波、水羟基技术清洗的食材净化机,通过超声波发生器的超声波高频震动工作,去除果蔬表面的淤泥及污物之后,再通过膜电极模块的水羟基技术消毒,杀灭果蔬细菌并分解激素,达到食材杀菌消毒的净化功能,但是这种净化机先启动超声波清洗,后释放羟基,对食材的清洁效果仅停留在两种清洁效果的简单叠加状态,仍然不能达到满意的状态。中国实用新型专利CN210782841U公开了一种用于蔬菜清洗的农药残留去除装置,设置了臭氧发生器、超声波发生器以及金刚石电解装置,其工作时超声波发射高频超声波,同时水依次流过臭氧发生器和金刚石电解装置,金刚石电解装置将臭氧发生器所产生臭氧进行分解产生了羟基,因此三者同时工作,这样的缺点是三种装置缺乏统一的控制,水中的羟基浓度升高后臭氧发生器还在不断产生臭氧,容易造成水中的臭氧浓度过高并散布到空气中,危害人体健康。With the improvement of people's living standards, food purifiers used in the kitchen have appeared in the prior art. This food purifier can clean vegetables, fruits, etc. that are eaten by households, so as to ensure the health of users. For example, Chinese utility model patent CN203153499U discloses a food washing machine, which includes an ozone generator, obtains ozone water with high concentration of microbubble ozone, and sterilizes the food, but this food machine does not consider the harm of ozone to human health. , and a single disinfection method has low cleaning ability for food; CN208875365U discloses a food purifier based on ultrasonic and water hydroxyl technology cleaning, which removes silt and dirt on the surface of fruits and vegetables through ultrasonic high-frequency vibration of an ultrasonic generator. After that, it is sterilized by the water hydroxyl technology of the membrane electrode module to kill fruit and vegetable bacteria and decompose hormones, so as to achieve the purification function of food sterilization and disinfection, but this kind of purifier starts ultrasonic cleaning first, and then releases the hydroxyl group, and the cleaning effect on the food only stays. In the simple superposition state of the two cleaning effects, a satisfactory state is still not achieved. Chinese utility model patent CN210782841U discloses a pesticide residue removal device for vegetable cleaning, which is provided with an ozone generator, an ultrasonic generator and a diamond electrolysis device. During operation, the ultrasonic wave emits high-frequency ultrasonic waves, and at the same time, water flows through the ozone generator in sequence. And the diamond electrolysis device, the diamond electrolysis device decomposes the ozone generated by the ozone generator to produce hydroxyl groups, so the three work at the same time. The continuous generation of ozone can easily cause the ozone concentration in the water to be too high and spread into the air, which is harmful to human health.

另外,臭氧可能对空气造成污染,进而危害人体健康,而过长时间的超声波清洗会损坏食材的品质,因此,如果食材表面残留的污物较多,食材净化机需要较大的清洁功率,而如果食材表面残留的污物较少,或者清洁的效果比较好,那么食材净化机不需要释放较多的臭氧、羟基等物质进行清洁,也不需要长时间进行超声波清洗,以免造成污染或损害食材。而现有的食材净化机都无法评估对食材的清洁效果,也无法根据对食材的清洁效果调整清洁功率,其智能化、自动化的水平较低。In addition, ozone may pollute the air, thereby endangering human health, and ultrasonic cleaning for a long time will damage the quality of the food. Therefore, if there is a lot of dirt remaining on the surface of the food, the food purifier needs a larger cleaning power, and If there is less dirt remaining on the surface of the food, or the cleaning effect is better, the food purifier does not need to release more ozone, hydroxyl and other substances for cleaning, and does not need to perform ultrasonic cleaning for a long time to avoid pollution or damage to the food. . However, the existing food purifiers cannot evaluate the cleaning effect of the food, nor can the cleaning power be adjusted according to the cleaning effect of the food, and the level of intelligence and automation is low.

发明内容SUMMARY OF THE INVENTION

本发明提出一种可以对食材清洁程度进行评估的食材净化机,所述食材净化机包括外壳和内桶,所述内桶设置在外壳之内,用于放置待清洁的食材,所述外壳和内桶之间具有空隙,所述空隙包括底部设备空间和侧部设备空间,所述底部设备空间和侧部设备空间用于安装食材净化机的内部设备。所述内桶底部设置有排水口,所述排水口与排水管连接,用于将内桶中的废水排出,所述排水管上设置有排水阀。所述排水口的一侧设置有超声波发射器,所述超声波发射器的发射端朝向内桶,用于向内桶内部发射超声波。所述排水口的另一侧设置有臭氧水出口和羟基水出口,所述底部设备空间内安装有臭氧水装置和羟基水装置,所述臭氧水装置所生成的臭氧水通过臭氧水出口排放到内桶,所述羟基水装置所生成的羟基水通过羟基水出口排放到内桶。The present invention provides a food purifier that can evaluate the cleanliness of food. The food purifier includes an outer casing and an inner barrel. The inner barrel is arranged in the outer casing and is used for placing the food to be cleaned. The outer casing and the inner barrel are between the outer casing and the inner barrel. There is a gap between them, and the gap includes a bottom equipment space and a side equipment space, and the bottom equipment space and the side equipment space are used for installing the internal equipment of the food purifier. The bottom of the inner barrel is provided with a drain port, the drain port is connected with a drain pipe for discharging waste water in the inner barrel, and a drain valve is arranged on the drain pipe. One side of the water outlet is provided with an ultrasonic transmitter, and the transmitting end of the ultrasonic transmitter faces the inner barrel and is used for emitting ultrasonic waves into the inner barrel. The other side of the water outlet is provided with an ozone water outlet and a hydroxyl water outlet, an ozone water device and a hydroxyl water device are installed in the bottom equipment space, and the ozone water generated by the ozone water device is discharged to the ozone water outlet through the ozone water outlet. In the inner barrel, the hydroxyl water generated by the hydroxyl water device is discharged into the inner barrel through the outlet of the hydroxyl water.

所述侧部设备空间中还设置有进水管,所述进水管上设置有进水阀,所述进水管连接臭氧水装置,在进水阀打开时,外部水源通过进水管进入臭氧水装置,所述臭氧水装置产生臭氧分子,臭氧分子溶解在水中形成臭氧水,并从臭氧水出口排放到内桶中。所述羟基水装置通过羟基水出口与内桶连通,并且所述羟基水装置通过电解设备产生羟基自由基,并将生成的羟基水通过羟基水出口流通到内桶中。The side equipment space is also provided with a water inlet pipe, and a water inlet valve is arranged on the water inlet pipe, and the water inlet pipe is connected to the ozone water device. When the water inlet valve is opened, the external water source enters the ozone water device through the water inlet pipe. The ozone water device generates ozone molecules, the ozone molecules are dissolved in water to form ozone water, and are discharged into the inner barrel from the ozone water outlet. The hydroxy water device is communicated with the inner barrel through the hydroxy water outlet, and the hydroxy water device generates hydroxy radicals through an electrolysis device, and the generated hydroxy water is circulated into the inner barrel through the hydroxy water outlet.

所述内桶内壁上还设置有液位计,所述液位计可采用超声波液位计或压差液位计,所述液位计用于检测内桶内的水位高度,并将液位信号发送给主控板。The inner wall of the inner barrel is also provided with a liquid level gauge. The liquid level gauge can be an ultrasonic level gauge or a differential pressure level gauge. The level gauge is used to detect the water level in the inner barrel and send a liquid level signal to the main control board.

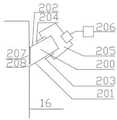

进一步地,本申请所采用的所述液位计采用电容式液位计,所述电容式液位计包括液位检测槽、上极板、下极板、电容检测单元和液位检测单元。所述内桶侧壁的设定高度开设有液位检测槽,所述设定高度由内桶允许的水面高度所决定,所述液位检测槽相对于水平面向上偏转一定角度θ,所述液位检测槽具有上检测面和下检测面,上下检测面的高度可设置为2-3厘米,所述上检测面的上表面设置有上极板,下检测面的下表面设置有下极板,所述上下极板相对设置,并且上下极板之间相互绝缘,并由电容测量单元检测上下极板之间的电容,并将电容值发送给液位检测单元,所述液位检测单元将电容值与预设电容值相比较,所述预设电容值为所述检测槽中没有水时上下极板之间的电容,并根据比较结果生成液位信号发送给主控板。Further, the liquid level gauge used in this application adopts a capacitive liquid level gauge, and the capacitive liquid level gauge includes a liquid level detection tank, an upper pole plate, a lower pole plate, a capacitance detection unit and a liquid level detection unit. The set height of the side wall of the inner barrel is provided with a liquid level detection groove, the set height is determined by the allowable water surface height of the inner barrel, the liquid level detection groove is deflected upward by a certain angle θ relative to the horizontal The slot has an upper detection surface and a lower detection surface, the height of the upper and lower detection surfaces can be set to 2-3 cm, the upper surface of the upper detection surface is provided with an upper pole plate, and the lower surface of the lower detection surface is provided with a lower pole plate, so The upper and lower pole plates are arranged opposite each other, and the upper and lower pole plates are insulated from each other, and the capacitance between the upper and lower pole plates is detected by the capacitance measuring unit, and the capacitance value is sent to the liquid level detection unit, and the liquid level detection unit Compared with the preset capacitance value, the preset capacitance value is the capacitance between the upper and lower plates when there is no water in the detection tank, and a liquid level signal is generated and sent to the main control board according to the comparison result.

进一步地,为了防止内桶中的食材进入检测槽中干扰电容检测单元,所述液位检测槽的槽口上端竖直设置有阻挡板,所述阻挡板与液位检测槽的槽口下端之间具有进液口,进液口的高度可设为0.2-0.5厘米,阻挡板可以防止食材进入液位检测槽造成干扰,而液位检测槽的倾斜设置可以在排水时使得液位检测槽中的水在重力作用下完全排出而不会在液位检测槽中滞留。当进水管向内桶进水时,内桶内部的水面高度不断上升,并从进液口进入液位检测槽中。当液位检测槽中没有水时,上下极板之间的电容为第一电容,液位检测单元将第一电容与预设电容值比较,两者差值在允许范围之内,液位检测单元产生第一液位信号;而液位检测槽进水后,由于自来水的介电常数与空气存在差异,因此会引起上下极板之间的电容产生显著变化,产生第二电容,液位检测单元将第二电容与预设电容值比较,两者差值超过允许范围,液位检测单元产生第二液位信号。而主控板接收到第一液位信号,表示目前内桶中无水或者水位并不满,主控板接收到第二液位信号,表示内桶中的水位已经达到预设水位,应停止进水。Further, in order to prevent the ingredients in the inner barrel from entering the detection tank and interfering with the capacitance detection unit, the upper end of the notch of the liquid level detection tank is vertically provided with a blocking plate, between the blocking plate and the lower end of the notch of the liquid level detection tank. It has a liquid inlet, and the height of the liquid inlet can be set to 0.2-0.5 cm. The blocking plate can prevent the ingredients from entering the liquid level detection tank and cause interference. The water is completely drained by gravity without being stagnant in the level detection tank. When the water inlet pipe enters the inner barrel, the water level inside the inner barrel rises continuously, and enters the liquid level detection tank from the liquid inlet. When there is no water in the liquid level detection tank, the capacitance between the upper and lower plates is the first capacitance, and the liquid level detection unit compares the first capacitance with the preset capacitance value, and the difference between the two is within the allowable range. The unit generates the first liquid level signal; after the liquid level detection tank is filled with water, due to the difference between the dielectric constant of the tap water and the air, the capacitance between the upper and lower plates will change significantly, resulting in a second capacitance, the liquid level detection The unit compares the second capacitance with a preset capacitance value, and the difference between the two exceeds the allowable range, and the liquid level detection unit generates a second liquid level signal. The main control board receives the first liquid level signal, which means that there is no water in the inner bucket or the water level is not full.

所述进水阀、排水阀均为可控电磁阀,并与主控板电气连接,所述主控板可控制进水阀和排水阀的开闭。The water inlet valve and the water discharge valve are both controllable electromagnetic valves, and are electrically connected to the main control board, and the main control board can control the opening and closing of the water inlet valve and the water discharge valve.

食材净化机的外壳上表面包括上盖和控制区,所述上盖可以打开并从内桶中取放食材。所述上盖上设置有显示屏,所述控制区包括控制显示器和控制按键。所述上盖的内侧设置有摄像模组和照明模组,所述摄像模组用于对内桶内的食材进行成像,并将食材图像发送给主控板,所述照明模组用于为摄像模组提供照明光源。所述显示屏、控制按键、控制显示器、照明模组和摄像模组均与主控板电气连接。The upper surface of the shell of the food purifier includes an upper cover and a control area, and the upper cover can be opened to take food from the inner tub. The upper cover is provided with a display screen, and the control area includes a control display and a control button. The inner side of the upper cover is provided with a camera module and a lighting module, the camera module is used to image the food in the inner barrel, and send the image of the food to the main control board, and the lighting module is used for the camera. The module provides the lighting source. The display screen, the control button, the control display, the lighting module and the camera module are all electrically connected with the main control board.

具体地,所述摄像模组为可见光和红外光双模镜头,所述摄像模组包括二向分色镜,以及在二向分色镜上方、沿垂直光轴设置的可见光摄像头,和在二向分色镜侧方、沿水平光轴设置的红外光摄像头,在二向分色镜的两侧还分别设置有蓝光光源和红外光光源,例如采用环形线状光源或环形多点光源的布置方式,所述二向分色镜的下端朝向内桶内部,所述蓝光光源和红外光光源用于向内桶内部投射照明光,分别为可见光摄像头和红外光摄像头提供照明光源。内桶中的食材所反射的照明光经过所述二向分色镜,其中可见光垂直通过所述二向分色镜进入可见光摄像头,红外光经过二向分色镜水平反射后进入红外摄像头。所述可见光摄像头和红外摄像头分别生成食材的可见光图像和红外光图像,并将所述可见光图像和红外光图像发送给主控板,由主控板的图像处理单元对所述可见光图像和红外光图像进行进一步处理。Specifically, the camera module is a dual-mode lens of visible light and infrared light, and the camera module includes a dichroic mirror, and a visible light camera disposed above the dichroic mirror and along the vertical optical axis, and two The infrared camera is arranged to the side of the dichroic mirror and along the horizontal optical axis, and a blue light source and an infrared light source are respectively arranged on both sides of the dichroic mirror, for example, the arrangement of annular linear light source or annular multi-point light source In this way, the lower end of the dichroic mirror faces the inside of the inner barrel, and the blue light source and the infrared light source are used to project illumination light into the inner barrel, respectively providing illumination light sources for the visible light camera and the infrared light camera. The illumination light reflected by the ingredients in the inner barrel passes through the dichroic mirror, wherein the visible light enters the visible light camera vertically through the dichroic mirror, and the infrared light enters the infrared camera after being horizontally reflected by the dichroic mirror. The visible light camera and the infrared camera respectively generate the visible light image and the infrared light image of the food, and send the visible light image and the infrared light image to the main control board, and the visible light image and the infrared light image are processed by the image processing unit of the main control board. image for further processing.

所述底部设备空间或侧部设备空间中设置有主控板,所述主控板上具有控制器,所述主控板用于向进水阀和排水阀发送控制信号,以控制进水阀和排水阀的开闭,并且接收控制按键发送的控制信号,并且在控制显示器上显示相应控制信息,同时向显示屏发送所显示的图像信息,并对摄像模组和光源模组进行控制,并且接收所述摄像模组所发送的图像信号以及液位计所发送的液位信号。The bottom equipment space or the side equipment space is provided with a main control board, the main control board has a controller, and the main control board is used to send control signals to the water inlet valve and the drain valve to control the water inlet valve And the opening and closing of the drain valve, and receive the control signal sent by the control button, and display the corresponding control information on the control display, at the same time send the displayed image information to the display, and control the camera module and the light source module, and The image signal sent by the camera module and the liquid level signal sent by the liquid level gauge are received.

所述底部设备空间或侧部设备空间中还设置有网络模块,所述网络模块可支持无线或有线局域网、公共通信网络或近程通信网络等通信模式,主控板通过网络模块与云端服务器实现数据交互。The bottom equipment space or the side equipment space is also provided with a network module. The network module can support communication modes such as wireless or wired local area network, public communication network or short-range communication network. The main control board is implemented through the network module and the cloud server. Data interaction.

进一步地,本发明提出一种食材净化机的控制方法,其基于上述实施例的食材净化机,并包括顺序执行的以下步骤:Further, the present invention provides a control method for a food purifier, which is based on the food purifier of the above-mentioned embodiment, and includes the following steps executed in sequence:

步骤一:当食材被放入内桶中并且上盖闭合后,主控板控制蓝光光源开启,并控制可见光摄像头获取内桶中食材的第一可见光图像后关闭蓝光光源;Step 1: When the ingredients are put into the inner barrel and the upper cover is closed, the main control board controls the blue light source to turn on, and controls the visible light camera to obtain the first visible light image of the ingredients in the inner barrel, and then turns off the blue light source;

步骤二:主控板控制红外光源开启,并控制红外光摄像头获取内桶中食材的第一红外光图像后关闭红外光光源;Step 2: The main control board controls the infrared light source to turn on, and controls the infrared light camera to obtain the first infrared light image of the ingredients in the inner barrel, and then turns off the infrared light source;

步骤三:主控板根据第一可见光图像和第一红外光图像获得食材的第一叠加图像;具体地,食材例如水果表面的腐败区域、疤痕或虫眼的温度与其他正常区域存在差异,例如这些区域的微生物活动比较活跃,产生大量热量,因此在红外光图像中,这些区域的颜色与其他正常区域存在色差,而在可见的蓝色光照射下,水果表面的泥沙、碎叶等可清洗污迹和腐败区域、疤痕或虫眼等不可清洗的缺陷并没有太大区别,均会在蓝光图像中形成深色斑点,因此主控板的图像处理单元接收到第一可见光图像和第一红外光图像后,将两幅图像经过滤波去噪处理后,通过像素提取或滤波法提取仅包括第一可见光图像中深色斑点的第二可见光图像,这些深色斑点可能是泥沙、碎叶等可清洗污迹,也可能是腐败区域、疤痕或虫眼等不可清洗的缺陷,并同时采用均值滤波法滤除红外光图像中的正常区域的图像,仅保留腐败区域、疤痕或虫眼等不可清洗的缺陷所产生的色差区域的红外光第二图像,由于红外光摄像头和可见光摄像头是同轴的,因此两者获取的图像可以直接叠加,通过将第二可见光图像和第二红外光图像进行叠加,就可以将第一可见光图像中因为腐败区域、疤痕或虫眼等不可清洗的缺陷所形成的深色斑点去除,而仅保留泥沙、碎叶等可清洗污迹所形成的深色斑点,因此可以对食材的清洁状况进行评估。Step 3: The main control board obtains the first superimposed image of the food material according to the first visible light image and the first infrared light image; The microbial activities in the area are relatively active and generate a lot of heat. Therefore, in the infrared light image, the color of these areas is different from other normal areas. Under the visible blue light, the sediment and broken leaves on the fruit surface can be cleaned. There is not much difference between stains and uncleanable defects such as corrupt areas, scars or bug eyes, all of which will form dark spots in the blue light image, so the image processing unit of the main control board receives the first visible light image and the first infrared light image. After filtering and denoising the two images, a second visible light image that only includes dark spots in the first visible light image is extracted by pixel extraction or filtering. These dark spots may be sediment, broken leaves, etc., which can be cleaned Smudges may also be uncleanable defects such as corrupt areas, scars or bug eyes, and at the same time, the average filter method is used to filter out the normal area images in the infrared light image, and only the corrupt areas, scars or bug eyes and other uncleanable defects are retained. The generated second image of infrared light in the chromatic aberration area, since the infrared light camera and the visible light camera are coaxial, the images obtained by the two can be directly superimposed. By superimposing the second visible light image and the second infrared light image, you can Remove the dark spots in the first visible light image due to uncleanable defects such as spoiled areas, scars or bug eyes, and only retain the dark spots formed by washable stains such as sand, broken leaves, etc. cleanliness assessment.

步骤四:主控板控制进水阀开启,同时控制臭氧水装置启动,外部水源通过进水管进入臭氧水装置,臭氧水装置产生臭氧分子并溶解在水中形成臭氧水,所述臭氧水通过臭氧水出口进入到内桶中,同时,液位计发送第一液位信号给主控板;Step 4: The main control board controls the opening of the water inlet valve and at the same time controls the start of the ozone water device. The external water source enters the ozone water device through the water inlet pipe. The ozone water device generates ozone molecules and dissolves in water to form ozone water. The ozone water passes through the ozone water. The outlet enters the inner barrel, and at the same time, the liquid level gauge sends the first liquid level signal to the main control board;

步骤五:当内桶中的液位到达液位检测槽,液位计发送第二液位信号给主控板,主控板控制进水阀关闭,同时关闭臭氧水装置并启动超声波发射器,对内桶内部发射超声波,经过第一超声波清洗时长后关闭超声波发射器。由于超声波在水中产生空化效果,水中的微小气泡发生膨胀并破裂,增大了臭氧的溶解率,并使得臭氧分子加速分解出自由基,污染物与自由基反应而生成无害的水和二氧化碳,并杀灭细菌,大大加强了臭氧的消毒效果,并且超声波可以使得食材表面的泥沙等污迹从食材表面脱落,达到清洗食材表面的目的。Step 5: When the liquid level in the inner barrel reaches the liquid level detection tank, the liquid level gauge sends the second liquid level signal to the main control board, and the main control board controls the water inlet valve to close, and at the same time closes the ozone water device and starts the ultrasonic transmitter. The inner barrel emits ultrasonic waves, and the ultrasonic transmitter is turned off after the first ultrasonic cleaning period. Due to the cavitation effect of ultrasonic waves in water, the tiny bubbles in the water expand and burst, increasing the dissolution rate of ozone and accelerating the decomposition of ozone molecules into free radicals. The pollutants react with free radicals to generate harmless water and carbon dioxide. , and kill bacteria, which greatly strengthens the disinfection effect of ozone, and ultrasonic waves can make the sediment and other stains on the surface of the food fall off from the surface of the food, so as to achieve the purpose of cleaning the surface of the food.

步骤六:主控板开启羟基水装置,所述羟基水装置生成羟基水并扩散到内桶中,主控板控制超声波发射器启动,并经过第二超声波清洗时长后关闭羟基水装置和超声波发射器。在本步骤中,羟基水装置所产生的羟基水对食材表面的污染物进一步反应,并且超声波发射器加速羟基水在内桶中的扩散,使得羟基与污染物充分接触,同时分解水中残留的臭氧,以防止对人体产生危害,并进一步对食材表面的污迹进行清洗。Step 6: The main control board turns on the hydroxyl water device, the hydroxyl water device generates hydroxyl water and diffuses into the inner barrel, the main control board controls the start of the ultrasonic transmitter, and closes the hydroxyl water device and the ultrasonic transmitter after the second ultrasonic cleaning time . In this step, the hydroxyl water produced by the hydroxyl water device further reacts to the pollutants on the surface of the food, and the ultrasonic transmitter accelerates the diffusion of the hydroxyl water in the inner barrel, so that the hydroxyl groups are fully contacted with the pollutants, and at the same time, the residual ozone in the water is decomposed, In order to prevent harm to the human body, and further clean the stains on the surface of the food.

步骤七:主控板开启排水阀,所述内桶中的水通过排水口排出,经过预设时长后排水阀关闭。Step 7: The main control board opens the drain valve, the water in the inner bucket is discharged through the drain port, and the drain valve is closed after a preset time period.

步骤八:主控板控制蓝光光源开启,并控制可见光摄像头获取内桶中食材的第三可见光图像后关闭蓝光光源;Step 8: The main control board controls the blue light source to turn on, and controls the visible light camera to obtain the third visible light image of the ingredients in the inner barrel, and then turns off the blue light source;

步骤九:主控板控制红外光源开启,并控制红外光摄像头获取内桶中食材的第四红外光图像后关闭红外光光源;Step 9: The main control board controls the infrared light source to turn on, and controls the infrared light camera to obtain the fourth infrared light image of the ingredients in the inner barrel, and then turns off the infrared light source;

步骤十:主控板根据第三可见光图像和第三红外光图像获得食材的第二叠加图像;Step ten: the main control board obtains the second superimposed image of the food material according to the third visible light image and the third infrared light image;

步骤十一:主控板通过比较第一叠加图像和第二叠加图像评估食材的净化效果,如果食材净化效果较好,执行步骤十二;如果食材净化效果不足,根据评估结果调整第一超声波清洗时长和/或第二超声波清洗时长,并执行步骤四。例如,如果在第一叠加图像(即清洗之前的图像)中,食材表面可清洗的污迹就比较少,并且通过第二叠加图像(即清洗后的图像)和第一叠加图像的对比,发现食材表面可清洗的污迹也清洗的比较彻底,那么可以停止清洗。而如果在第一叠加图像(即清洗之前的图像)中,食材表面可清洗的污迹比较多,或通过第二叠加图像(即清洗后的图像)和第一叠加图像的对比,发现食材表面可清洗的污迹还残留了一定数量,那么可以适当地延长第一超声波清洗时长和/或第二超声波清洗时长并进行第二次清洗。Step 11: The main control board evaluates the purification effect of the ingredients by comparing the first superimposed image and the second superimposed image. If the purification effect of the ingredients is good, go to

步骤十二:清洁停止,主控板将第一可见光图像和第三可见光图像发送给显示屏,显示屏显示食材清洁前后的对比图像。Step 12: The cleaning stops, the main control board sends the first visible light image and the third visible light image to the display screen, and the display screen displays the comparison images of the ingredients before and after cleaning.

在可替代的实施例中,上述图像处理的部分工作可由云端服务器完成,主控板通过通信模块将可见光图像和红外光图像上传云端服务器,由云端服务器进行处理并得到第一叠加图像和第二叠加图像,并通过所述第一叠加图像和第二叠加图像评估清洁效果,并通过深度学习获得调整后的第一超声波清洗时长和/或第二超声波清洗时长,并将评估结果和调整后的第一超声波清洗时长和/或第二超声波清洗时长发送给主控板。In an alternative embodiment, part of the above image processing can be completed by a cloud server, and the main control board uploads the visible light image and the infrared light image to the cloud server through the communication module, and the cloud server processes and obtains the first superimposed image and the second superimposed image. Superimpose images, and evaluate the cleaning effect through the first superimposed image and the second superimposed image, and obtain the adjusted first ultrasonic cleaning duration and/or second ultrasonic cleaning duration through deep learning, and evaluate the results and the adjusted ultrasonic cleaning duration. The first ultrasonic cleaning duration and/or the second ultrasonic cleaning duration are sent to the main control board.

本发明提出一种食材净化机以及其控制方法,食材机具有的摄像模组为可见光和红外光双模镜头,可分别对内桶内的食材拍摄可见光图像和红外光图像,并通过将两种图像进行处理后获取叠加图像,并根据叠加图像对食材净化程度进行评估,进而调整净化机的净化参数,在保障食材净化效果的同时防止食材品质的降低。同时本发明净化机的液位计设计有倾斜的液位检测槽,检测内桶水位的同时可防止食材对液位检测的干扰。The invention provides a food purifier and a control method thereof. The camera module provided by the food machine is a dual-mode lens of visible light and infrared light, which can respectively take a visible light image and an infrared light image of the food in the inner barrel, and by combining the two images After processing, the superimposed image is obtained, and the degree of purification of the food is evaluated according to the superimposed image, and then the purification parameters of the purifier are adjusted to ensure the purification effect of the food and prevent the reduction of the quality of the food. At the same time, the liquid level gauge of the purifier of the present invention is designed with an inclined liquid level detection tank, which can prevent the interference of the food material on the liquid level detection while detecting the water level of the inner barrel.

附图说明Description of drawings

图1是本发明的食材净化机的外观图;1 is an external view of a food purifier of the present invention;

图2是本发明的食材净化机的侧面剖视图;Fig. 2 is the side sectional view of the food purifier of the present invention;

图3是本发明的食材净化机的内部俯视图;3 is an internal top view of the food purifier of the present invention;

图4是本发明的食材净化机的摄像模组示意图;4 is a schematic diagram of a camera module of the food purifier of the present invention;

图5是本发明的食材净化机的液位计示意图。5 is a schematic diagram of a liquid level gauge of the food purifier of the present invention.

其中,摄像模组1,显示屏2,控制按键3,控制显示器4,臭氧水出口5,排水口6、羟基水出口7,主控板8,臭氧水装置9,羟基水装置10,进水管11,排水阀12,超声波发射器13,进水阀14,外壳15,内桶16,网络模块17,照明模组19-20,上盖18,液位检测槽200,下检测面201,上检测面202,下极板203,上极板204,电容检测单元205,液位检测单元206,阻挡板207,进液口208,二向分色镜300,红外光摄像头301,可见光摄像头302,图像处理单元303,蓝光光源304,红外光光源305,垂直光轴306,水平光轴307。Among them, camera module 1, display screen 2,

具体实施方式Detailed ways

以下结合具体实施例和说明书附图对本发明进行进一步解释。The present invention will be further explained below with reference to specific embodiments and accompanying drawings.

在一个实施例中,参见图2,本发明的食材机包括外壳15和内桶16,所述内桶16设置在外壳15之内,用于放置待清洁的食材。所述外壳15和内桶16之间具有空隙,所述空隙包括底部设备空间和侧部设备空间,所述底部设备空间和侧部设备空间用于安装食材净化机的内部设备。所述内桶16底部设置有排水口6,所述排水口6与排水管连接,用于将内桶16中的废水排出,所述排水管上设置有排水阀12。所述排水口6的一侧设置有超声波发射器13,所述超声波发射器13的发射端朝向内桶16,用于向内桶16内部发射超声波。所述排水口6的另一侧设置有臭氧水出口5和羟基水出口7,所述底部设备空间内安装有臭氧水装置9和羟基水装置10,所述臭氧水装置9所生成的臭氧水通过臭氧水出口5排放到内桶16,所述羟基水装置10所生成的羟基水通过羟基水出口7排放到内桶16。In one embodiment, referring to FIG. 2 , the food maker of the present invention includes an

所述侧部设备空间中还设置有进水管11,所述进水管11上设置有进水阀14,所述进水管11连接臭氧水装置9,在进水阀14打开时,外部水源(例如自来水)通过进水管11进入臭氧水装置9,所述臭氧水装置9产生臭氧分子,臭氧分子溶解在水中形成臭氧水,并从臭氧水出口5排放到内桶16中。所述臭氧水装置9可采用臭氧石产生臭氧分子。所述羟基水装置10通过羟基水出口7与内桶16连通,并且所述羟基水装置10通过电解设备产生羟基自由基,并将生成的羟基水通过羟基水出口7流通到内桶16中。The side equipment space is also provided with a

所述内桶16内壁上还设置有液位计,所述液位计可采用超声波液位计或压差液位计,所述液位计用于检测内桶16内的水位高度,并将液位信号发送给主控板8。The inner wall of the

由于本申请的内桶16内同时存在水和固体食材,而对于固液混合情况下测量液面的高度,现有技术中的液位计容易受到容器中固体物体的干扰(例如超声波传感器所发射的超声波被高出水面的固体食材所反射,无法体现正确的液位),因此不适合本发明中内桶16中液位的检测,在其他实施例中,本申请所采用的所述液位计采用电容式液位计。所述电容式液位计包括液位检测槽200、上极板204、下极板203、电容检测单元205和液位检测单元206(参见图5)。所述内桶16侧壁的设定高度(所述设定高度指的是从内桶16底部的高度)开设有液位检测槽200(参见图2内桶中上部左侧壁位置),所述设定高度由内桶16允许的水面高度所决定,所述液位检测槽200相对于水平面向上偏转一定角度θ,所述液位检测槽200具有上检测面202和下检测面201,上下检测面的高度可设置为2-3厘米,所述上检测面202的上表面设置有上极板204,下检测面201的下表面设置有下极板203,所述上下极板相对设置,并且上下极板之间相互绝缘(例如上下极板与上下检测面之间粘接绝缘层,或液位检测槽200的上下检测面采用塑料或绝缘树脂材料制成),并由电容测量单元检测上下极板之间的电容,并将电容值发送给液位检测单元206,所述液位检测单元206将电容值与预设电容值相比较,所述预设电容值为所述检测槽中没有水时上下极板之间的电容,并根据比较结果生成液位信号发送给主控板8。进一步地,为了防止内桶16中的食材进入检测槽中干扰电容检测单元205,所述液位检测槽200的槽口上端竖直设置有阻挡板207,所述阻挡板207与液位检测槽200的槽口下端之间具有进液口208,进液口208的高度可设为0.2-0.5厘米,阻挡板207可以防止食材进入液位检测槽200造成干扰,而液位检测槽200的倾斜设置可以在排水时使得液位检测槽200中的水在重力作用下完全排出而不会在液位检测槽200中滞留。当进水管11向内桶16进水时,内桶16内部的水面高度不断上升,并从进液口208进入液位检测槽200中。当液位检测槽200中没有水时,上下极板之间的电容为第一电容,液位检测单元206将第一电容与预设电容值比较,两者差值在允许范围之内,液位检测单元206产生第一液位信号;而液位检测槽200进水后,由于自来水的介电常数与空气存在差异,因此会引起上下极板之间的电容产生显著变化,产生第二电容,液位检测单元206将第二电容与预设电容值比较,两者差值超过允许范围,液位检测单元206产生第二液位信号。而主控板8接收到第一液位信号,表示目前内桶16中无水或者水位并不满,主控板8接收到第二液位信号,表示内桶16中的水位已经达到预设水位,应停止进水。Since there are both water and solid food in the

所述进水阀14、排水阀12均为可控电磁阀,并与主控板8电气连接,所述主控板8可控制进水阀14和排水阀12的开闭。The

如图1所示,食材净化机的外壳15上表面包括上盖18和控制区,所述上盖18可以打开并从内桶16中取放食材。所述上盖18上设置有显示屏2,所述控制区包括控制显示器4和控制按键3。所述上盖18的内侧设置有摄像模组1和照明模组19、20,所述摄像模组1用于对内桶16内的食材进行成像,并将食材图像发送给主控板8,所述照明模组19、20用于为摄像模组1提供照明光源。所述显示屏2、控制按键3、控制显示器4、照明模组和摄像模组1均与主控板8电气连接。As shown in FIG. 1 , the upper surface of the

具体地,所述摄像模组1为可见光和红外光双模镜头,参见图4,所述摄像模组1包括二向分色镜300,以及在二向分色镜300上方、沿垂直光轴306设置的可见光摄像头302,和在二向分色镜300侧方、沿水平光轴307设置的红外光摄像头301,在二向分色镜300的两侧还分别设置有蓝光光源304和红外光光源305,例如采用环形线状光源或环形多点光源的布置方式,所述二向分色镜300的下端朝向内桶16内部,所述蓝光光源304和红外光光源305用于向内桶16内部投射照明光,分别为可见光摄像头302和红外光摄像头301提供照明光源。内桶16中的食材所反射的照明光经过所述二向分色镜300,其中可见光垂直通过所述二向分色镜300进入可见光摄像头302,红外光经过二向分色镜300水平反射后进入红外光摄像头301。所述可见光摄像头302和红外光摄像头301分别生成食材的可见光图像和红外光图像,并将所述可见光图像和红外光图像发送给主控板8,由主控板8的图像处理单元303对所述可见光图像和红外光图像进行进一步处理。Specifically, the camera module 1 is a dual-mode lens of visible light and infrared light. Referring to FIG. 4 , the camera module 1 includes a

所述底部设备空间或侧部设备空间中设置有主控板8,所述主控板8上具有控制器,所述主控板8用于向进水阀14和排水阀12发送控制信号,以控制进水阀14和排水阀12的开闭,并且接收控制按键3发送的控制信号,并且在控制显示器4上显示相应控制信息,同时向显示屏2发送所显示的图像信息,并对摄像模组1和光源模,19、20进行控制,并且接收所述摄像模组1所发送的图像信号以及液位计所发送的液位信号。The bottom equipment space or the side equipment space is provided with a main control board 8, the main control board 8 has a controller, and the main control board 8 is used to send control signals to the

所述底部设备空间或侧部设备空间中还设置有网络模块17,所述网络模块17可支持无线或有线局域网、公共通信网络或近程通信网络等通信模式,主控板8通过网络模块17与云端服务器实现数据交互。The bottom equipment space or the side equipment space is also provided with a

由于待净化的食材表面可能存在可清洗污迹,例如泥沙、小虫、腐烂的叶片等,这些污迹可以通过超声波清洗的方式从食材表面清除,但是超声波本身对食材有负面影响,长时间的超声波清洗可能造成食材的损伤,并且加速食材的腐烂或软化,降低食材的品质,目前现有技术中的净化机对食材的净化是依靠预设程序进行的,其净化时长不能随着食材净化程度而调整,并且,食材表面可能有无法清除的固有缺陷,比如水果表面有腐败区、黑点或虫眼,这些缺陷是无法通过清洗的方式进行消除的,如何将可清洗的污迹和这些无法清洗的固有缺陷所区分开来、根据市场的净化程度动态调整食材净化程序的时长,是本发明要解决的技术问题。Since there may be cleanable stains on the surface of the food to be purified, such as sand, small insects, rotten leaves, etc., these stains can be removed from the surface of the food by ultrasonic cleaning, but the ultrasonic itself has a negative impact on the food. Ultrasonic cleaning may cause damage to the ingredients, accelerate the decay or softening of the ingredients, and reduce the quality of the ingredients. The purification machines in the prior art rely on preset programs to purify the ingredients, and the purification time cannot follow the purification of the ingredients. In addition, the surface of the ingredients may have inherent defects that cannot be removed, such as spoiled areas, black spots or insect eyes on the surface of the fruit. These defects cannot be eliminated by cleaning. Distinguishing the inherent defects of cleaning and dynamically adjusting the duration of the food purification procedure according to the purification degree of the market is the technical problem to be solved by the present invention.

进一步地,本发明提出一种食材净化机的控制方法,其基于上述实施例的食材净化机,并包括顺序执行的以下步骤:Further, the present invention provides a control method for a food purifier, which is based on the food purifier of the above-mentioned embodiment, and includes the following steps executed in sequence:

步骤一:当食材被放入内桶16中并且上盖18闭合后,主控板8控制蓝光光源304开启,并控制可见光摄像头302获取内桶16中食材的第一可见光图像后关闭蓝光光源304;Step 1: when the ingredients are put into the

步骤二:主控板8控制红外光源开启,并控制红外光摄像头301获取内桶16中食材的第一红外光图像后关闭红外光光源305;Step 2: The main control board 8 controls the infrared light source to be turned on, and controls the infrared

步骤三:主控板8根据第一可见光图像和第一红外光图像获得食材的第一叠加图像;具体地,食材例如水果表面的腐败区域、疤痕或虫眼的温度与其他正常区域存在差异,例如这些区域的微生物活动比较活跃,产生大量热量,因此在红外光图像中,这些区域的颜色与其他正常区域存在色差,而在可见的蓝色光照射下,水果表面的泥沙、碎叶等可清洗污迹和腐败区域、疤痕或虫眼等不可清洗的缺陷并没有太大区别,均会在蓝光图像中形成深色斑点,因此主控板8的图像处理单元303接收到第一可见光图像和第一红外光图像后,将两幅图像经过滤波去噪处理后,通过像素提取或滤波法提取仅包括第一可见光图像中深色斑点的第二可见光图像,这些深色斑点可能是泥沙、碎叶等可清洗污迹,也可能是腐败区域、疤痕或虫眼等不可清洗的缺陷,并同时采用均值滤波法滤除红外光图像中的正常区域的图像,仅保留腐败区域、疤痕或虫眼等不可清洗的缺陷所产生的色差区域的红外光第二图像,由于红外光摄像头301和可见光摄像头302是同轴的,因此两者获取的图像可以直接叠加,通过将第二可见光图像和第二红外光图像进行叠加,就可以将第一可见光图像中因为腐败区域、疤痕或虫眼等不可清洗的缺陷所形成的深色斑点去除,而仅保留泥沙、碎叶等可清洗污迹所形成的深色斑点,因此可以对食材的清洁状况进行评估。Step 3: The main control board 8 obtains the first superimposed image of the food material according to the first visible light image and the first infrared light image; The microbial activities in these areas are relatively active and generate a lot of heat. Therefore, in the infrared light image, the color of these areas is different from other normal areas. Under the visible blue light, the sediment and broken leaves on the surface of the fruit can be washed. There is not much difference between stains and uncleanable defects such as corrupt areas, scars or bug eyes, all of which will form dark spots in the blue light image. Therefore, the

步骤四:主控板8控制进水阀14开启,同时控制臭氧水装置9启动,外部水源通过进水管11进入臭氧水装置9,臭氧水装置9产生臭氧分子并溶解在水中形成臭氧水,所述臭氧水通过臭氧水出口5进入到内桶16中,同时,液位计发送第一液位信号给主控板8;Step 4: The main control board 8 controls the

步骤五:当内桶16中的液位到达液位检测槽200,液位计发送第二液位信号给主控板8,主控板8控制进水阀14关闭,同时关闭臭氧水装置9并启动超声波发射器13,对内桶16内部发射超声波,经过第一超声波清洗时长后关闭超声波发射器13。由于超声波在水中产生空化效果,水中的微小气泡发生膨胀并破裂,增大了臭氧的溶解率,并使得臭氧分子加速分解出自由基,污染物与自由基反应而生成无害的水和二氧化碳,并杀灭细菌,大大加强了臭氧的消毒效果,并且超声波可以使得食材表面的泥沙等污迹从食材表面脱落,达到清洗食材表面的目的。Step 5: When the liquid level in the

步骤六:主控板8开启羟基水装置10,所述羟基水装置10生成羟基水并扩散到内桶16中,主控板8控制超声波发射器13启动,并经过第二超声波清洗时长后关闭羟基水装置10和超声波发射器13。在本步骤中,羟基水装置10所产生的羟基水对食材表面的污染物进一步反应,并且超声波发射器13加速羟基水在内桶16中的扩散,使得羟基与污染物充分接触,同时分解水中残留的臭氧,以防止对人体产生危害,并进一步对食材表面的污迹进行清洗。Step 6: The main control board 8 turns on the

步骤七:主控板8开启排水阀12,所述内桶16中的水通过排水口6排出,经过预设时长后排水阀12关闭。Step 7: The main control board 8 opens the

步骤八:主控板8控制蓝光光源304开启,并控制可见光摄像头302获取内桶16中食材的第三可见光图像后关闭蓝光光源304;Step 8: The main control board 8 controls the blue

步骤九:主控板8控制红外光源开启,并控制红外光摄像头301获取内桶16中食材的第四红外光图像后关闭红外光光源305;Step 9: The main control board 8 controls the infrared light source to turn on, and controls the infrared

步骤十:主控板8根据第三可见光图像和第三红外光图像获得食材的第二叠加图像;Step ten: the main control board 8 obtains the second superimposed image of the food material according to the third visible light image and the third infrared light image;

步骤十一:主控板8通过比较第一叠加图像和第二叠加图像评估食材的净化效果,如果食材净化效果较好,执行步骤十二;如果食材净化效果不足,根据评估结果调整第一超声波清洗时长和/或第二超声波清洗时长,并执行步骤四。例如,如果在第一叠加图像(即清洗之前的图像)中,食材表面可清洗的污迹就比较少,并且通过第二叠加图像(即清洗后的图像)和第一叠加图像的对比,发现食材表面可清洗的污迹也清洗的比较彻底,那么可以停止清洗。而如果在第一叠加图像(即清洗之前的图像)中,食材表面可清洗的污迹比较多,或通过第二叠加图像(即清洗后的图像)和第一叠加图像的对比,发现食材表面可清洗的污迹还残留了一定数量,那么可以适当地延长第一超声波清洗时长和/或第二超声波清洗时长并进行第二次清洗。Step 11: The main control board 8 evaluates the purification effect of the ingredients by comparing the first superimposed image and the second superimposed image. If the purification effect of the ingredients is good, perform

步骤十二:清洁停止,主控板8将第一可见光图像和第三可见光图像发送给显示屏2,显示屏2显示食材清洁前后的对比图像。Step 12: The cleaning stops, the main control board 8 sends the first visible light image and the third visible light image to the display screen 2, and the display screen 2 displays the comparison images of the ingredients before and after cleaning.

在可替代的实施例中,上述图像处理的部分工作可由云端服务器完成,主控板8通过通信模块将可见光图像和红外光图像上传云端服务器,由云端服务器进行处理并得到第一叠加图像和第二叠加图像,并通过所述第一叠加图像和第二叠加图像评估清洁效果,并通过深度学习获得调整后的第一超声波清洗时长和/或第二超声波清洗时长,并将评估结果和调整后的第一超声波清洗时长和/或第二超声波清洗时长发送给主控板8。In an alternative embodiment, part of the above image processing can be done by a cloud server, and the main control board 8 uploads the visible light image and the infrared light image to the cloud server through the communication module, and the cloud server processes and obtains the first superimposed image and the second image. Two superimposed images, and the cleaning effect is evaluated through the first superimposed image and the second superimposed image, and the adjusted first ultrasonic cleaning duration and/or second ultrasonic cleaning duration are obtained through deep learning, and the evaluation result and the adjusted duration are obtained. The first ultrasonic cleaning duration and/or the second ultrasonic cleaning duration are sent to the main control board 8 .

以上仅为本发明优选的具体实施方式,但本发明的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本发明揭露的技术范围内,可想到变化或替换都应涵盖在本发明的保护范围之内。The above are only the preferred specific embodiments of the present invention, but the protection scope of the present invention is not limited thereto. Any person skilled in the art who is familiar with the technical scope disclosed by the present invention can imagine that changes or replacements should be covered by the present invention. within the scope of protection of the invention.

Claims (1)

Priority Applications (2)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202210311977.XACN114697552A (en) | 2020-09-22 | 2020-09-22 | A kind of control method of food purifier |

| CN202010998876.5ACN112135044B (en) | 2020-09-22 | 2020-09-22 | Food material purifying machine |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010998876.5ACN112135044B (en) | 2020-09-22 | 2020-09-22 | Food material purifying machine |

Related Child Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210311977.XADivisionCN114697552A (en) | 2020-09-22 | 2020-09-22 | A kind of control method of food purifier |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN112135044A CN112135044A (en) | 2020-12-25 |

| CN112135044Btrue CN112135044B (en) | 2022-05-13 |

Family

ID=73843041

Family Applications (2)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010998876.5AActiveCN112135044B (en) | 2020-09-22 | 2020-09-22 | Food material purifying machine |

| CN202210311977.XAPendingCN114697552A (en) | 2020-09-22 | 2020-09-22 | A kind of control method of food purifier |

Family Applications After (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202210311977.XAPendingCN114697552A (en) | 2020-09-22 | 2020-09-22 | A kind of control method of food purifier |

Country Status (1)

| Country | Link |

|---|---|

| CN (2) | CN112135044B (en) |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101053493A (en)* | 2007-05-15 | 2007-10-17 | 王宝根 | Ultrasonic extracting machine with sterilizing function |

| KR20080009864A (en)* | 2006-07-25 | 2008-01-30 | (주)케로트코리아 | Carrot washing and automatic sorting device |

| CN101336809A (en)* | 2008-08-22 | 2009-01-07 | 谭燕 | Food purification apparatus |

| CN103876655A (en)* | 2014-03-27 | 2014-06-25 | 河海大学常州校区 | Kitchen cleaning and disinfecting machine with sound-light and ozone combined and working method thereof |

| CN204788571U (en)* | 2015-07-27 | 2015-11-18 | 温州方圆仪器有限公司 | Water level detector |

| CN208491880U (en)* | 2017-08-17 | 2019-02-15 | 宁波腾威食品机械制造有限公司 | A kind of efficient fruit washing machine |

| CN109998398A (en)* | 2019-05-16 | 2019-07-12 | 山东滨州龙海厨房设备有限公司 | Multi-function article for washing vegetable and its wash vegetables method |

| CN210093323U (en)* | 2019-05-08 | 2020-02-18 | 深圳奥比中光科技有限公司 | Optical zoom imaging device and depth camera |

Family Cites Families (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| DE102008033237A1 (en)* | 2008-07-15 | 2010-01-21 | Henkel Ag & Co. Kgaa | Adapter for coupling a dosing system with a water-carrying pipe |

| TW201106676A (en)* | 2009-08-04 | 2011-02-16 | Pacific Image Electronics Co Ltd | Double-light sources optical scanning device and method of using the same |

| CN204335776U (en)* | 2014-12-08 | 2015-05-20 | 田野创新股份有限公司 | The water lev el control of fruit-vegetable cleaner and silt sundry separating device |

| CN205625710U (en)* | 2016-04-21 | 2016-10-12 | 张艳燕 | Water -saving ultrasonic cleaning dish basin |

| CN107316285A (en)* | 2017-07-05 | 2017-11-03 | 江南大学 | The image interfusion method detected towards apple quality |

| CN109719076A (en)* | 2018-12-28 | 2019-05-07 | 中食净化科技(北京)股份有限公司 | Self-service food materials clearing machine and its purification method for public place |

| CN110672523A (en)* | 2019-11-14 | 2020-01-10 | 厦门华联电子股份有限公司 | Turbidity sensor |

| CN111397693A (en)* | 2020-04-26 | 2020-07-10 | 上海明略人工智能(集团)有限公司 | Electrode type liquid level detection assembly, liquid level switch and dish washing machine |

- 2020

- 2020-09-22CNCN202010998876.5Apatent/CN112135044B/enactiveActive

- 2020-09-22CNCN202210311977.XApatent/CN114697552A/enactivePending

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| KR20080009864A (en)* | 2006-07-25 | 2008-01-30 | (주)케로트코리아 | Carrot washing and automatic sorting device |

| CN101053493A (en)* | 2007-05-15 | 2007-10-17 | 王宝根 | Ultrasonic extracting machine with sterilizing function |

| CN101336809A (en)* | 2008-08-22 | 2009-01-07 | 谭燕 | Food purification apparatus |

| CN103876655A (en)* | 2014-03-27 | 2014-06-25 | 河海大学常州校区 | Kitchen cleaning and disinfecting machine with sound-light and ozone combined and working method thereof |

| CN204788571U (en)* | 2015-07-27 | 2015-11-18 | 温州方圆仪器有限公司 | Water level detector |

| CN208491880U (en)* | 2017-08-17 | 2019-02-15 | 宁波腾威食品机械制造有限公司 | A kind of efficient fruit washing machine |

| CN210093323U (en)* | 2019-05-08 | 2020-02-18 | 深圳奥比中光科技有限公司 | Optical zoom imaging device and depth camera |

| CN109998398A (en)* | 2019-05-16 | 2019-07-12 | 山东滨州龙海厨房设备有限公司 | Multi-function article for washing vegetable and its wash vegetables method |

Also Published As

| Publication number | Publication date |

|---|---|

| CN112135044A (en) | 2020-12-25 |

| CN114697552A (en) | 2022-07-01 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| KR101135697B1 (en) | Water quality measuring equipment based on multiple sensing technology | |

| JP3193045B2 (en) | Contact lens cleaning system | |

| US5683576A (en) | Water ozonation treatment apparatus | |

| CN101702901A (en) | Underwater plasma processing apparatus and system and method for processing ballast water of ship using the same | |

| KR20200001935A (en) | Method for controlling of cleaning and sterilization device | |

| CN209242839U (en) | A kind of Industrial sewage treatment system | |

| CN112135044B (en) | Food material purifying machine | |

| KR20200143865A (en) | Air Cleaning Apparatus Combined with Denture Cleaning Device | |

| CN103657424B (en) | The built-in system cleaning sterilizing device of ultrapure water machine | |

| US20200385285A1 (en) | Sensor system for a system allowing for purification and recycling of water or separation of water | |

| CN113638186A (en) | Washing machine barrel cleaning method and device | |

| CN202036072U (en) | Fruit and vegetable cleaning machine | |

| KR102634007B1 (en) | Safe drinking water supply apparatus and method | |

| CN215925352U (en) | Washing machine barrel cleaning device | |

| TWI675707B (en) | Compound water oxygen cleaning function equipment | |

| US20230227332A1 (en) | Water treatment pitcher | |

| CN207276347U (en) | A kind of novel sewage treatment unit | |

| CN207130063U (en) | One kind is camped sewage-treatment plant | |

| JP2015036133A (en) | Ballast water filtration device and ballast water treatment system | |

| CN202968193U (en) | Household running water sterilization direct drinking machine | |

| CN209367998U (en) | A kind of environment-friendly type city domestic sewage processing equipment | |

| CN206809247U (en) | A kind of chopstick cleaning device | |

| CN210945180U (en) | Sterilizing and disinfecting device for production and processing of barreled drinking water | |

| CN215124084U (en) | A fruit and vegetable washing machine | |

| CN103771591A (en) | Household tap water sterilization direct-drinking machine |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| PE01 | Entry into force of the registration of the contract for pledge of patent right | ||

| PE01 | Entry into force of the registration of the contract for pledge of patent right | Denomination of invention:A food ingredient purifier Effective date of registration:20231115 Granted publication date:20220513 Pledgee:China Construction Bank Corporation Ningbo Branch Pledgor:ZHEJIANG JIUDIAN HEALTH TECHNOLOGY CO.,LTD. Registration number:Y2023980065778 |