CN112060924A - Low-temperature control method of extended range vehicle - Google Patents

Low-temperature control method of extended range vehicleDownload PDFInfo

- Publication number

- CN112060924A CN112060924ACN202010917762.3ACN202010917762ACN112060924ACN 112060924 ACN112060924 ACN 112060924ACN 202010917762 ACN202010917762 ACN 202010917762ACN 112060924 ACN112060924 ACN 112060924A

- Authority

- CN

- China

- Prior art keywords

- battery

- vehicle

- threshold

- temperature

- control method

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L15/00—Methods, circuits, or devices for controlling the traction-motor speed of electrically-propelled vehicles

- B60L15/20—Methods, circuits, or devices for controlling the traction-motor speed of electrically-propelled vehicles for control of the vehicle or its driving motor to achieve a desired performance, e.g. speed, torque, programmed variation of speed

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L58/00—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles

- B60L58/10—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries

- B60L58/12—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries responding to state of charge [SoC]

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60L—PROPULSION OF ELECTRICALLY-PROPELLED VEHICLES; SUPPLYING ELECTRIC POWER FOR AUXILIARY EQUIPMENT OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRODYNAMIC BRAKE SYSTEMS FOR VEHICLES IN GENERAL; MAGNETIC SUSPENSION OR LEVITATION FOR VEHICLES; MONITORING OPERATING VARIABLES OF ELECTRICALLY-PROPELLED VEHICLES; ELECTRIC SAFETY DEVICES FOR ELECTRICALLY-PROPELLED VEHICLES

- B60L58/00—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles

- B60L58/10—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries

- B60L58/24—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries for controlling the temperature of batteries

- B60L58/27—Methods or circuit arrangements for monitoring or controlling batteries or fuel cells, specially adapted for electric vehicles for monitoring or controlling batteries for controlling the temperature of batteries by heating

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/70—Energy storage systems for electromobility, e.g. batteries

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02T—CLIMATE CHANGE MITIGATION TECHNOLOGIES RELATED TO TRANSPORTATION

- Y02T10/00—Road transport of goods or passengers

- Y02T10/60—Other road transportation technologies with climate change mitigation effect

- Y02T10/72—Electric energy management in electromobility

Landscapes

- Engineering & Computer Science (AREA)

- Power Engineering (AREA)

- Transportation (AREA)

- Mechanical Engineering (AREA)

- Life Sciences & Earth Sciences (AREA)

- Sustainable Development (AREA)

- Sustainable Energy (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于车辆控制领域,特别是涉及一种增程式车辆的低温控制方法。The invention belongs to the field of vehicle control, in particular to a low-temperature control method for a range-extended vehicle.

背景技术Background technique

目前大部分PHEV整车控制策略为根据电池SOC控制增程器启停,未将电池温度作为启动增程器的变量,在SOC较高但是电池温度较低的情况下,由于纯电行驶(增程器不参与工作),锂离子动力电池的性能容易受到环境温度的影响,一般会通过电热的方式加热,包括PTC热敏电阻和其他电热方式(如电热丝)来进行直接加热,以防止电池低温劣化。但是这种加热方式电池加热效果较慢,低温环境下表现为性能下降与寿命衰退,为插电式混合动力轻卡在高纬度的北方寒冷地区的发展和推广造成了很大阻碍。At present, most PHEV vehicle control strategies are to control the start and stop of the range extender according to the battery SOC, and the battery temperature is not used as a variable to start the range extender. The performance of the lithium-ion power battery is easily affected by the ambient temperature, and it is generally heated by electric heating, including PTC thermistor and other electric heating methods (such as heating wires) for direct heating to prevent the battery Low temperature deterioration. However, the heating effect of this heating method is slow, and the performance declines and the lifespan declines in a low temperature environment.

PHEV在零下温度环境中将遭受严重的纯电行驶里程损失,并且由于电池低温衰减而增加了PHEV的运行成本。因此,需要对PHEV的低温性能进行研究,并制定加热策略,以提高PHEV的性能。PHEVs will suffer severe pure electric mileage loss in sub-zero temperature environments, and the operating costs of PHEVs will increase due to low-temperature battery decay. Therefore, it is necessary to study the low temperature performance of PHEVs and develop heating strategies to improve the performance of PHEVs.

发明内容SUMMARY OF THE INVENTION

本发明的一个目的是提供一种增程式车辆的低温控制方法,能够有效保护低温下的电池。An object of the present invention is to provide a low-temperature control method for an extended-range vehicle, which can effectively protect the battery at low temperature.

本发明的另一个目的是要节约预热成本。Another object of the present invention is to save on preheating costs.

特别地,本发明提供了一种增程式车辆的低温控制方法,包括:In particular, the present invention provides a low temperature control method for an extended-range vehicle, comprising:

采集车辆的电池的温度、电池的荷电状态和整车需求功率;Collect the temperature of the battery of the vehicle, the state of charge of the battery and the required power of the vehicle;

当所述电池的温度小于第一阈值且大于等于第二阈值且所述电池的荷电状态无法满足所述整车需求功率时,控制增程器启动并按所述整车需求功率输出功率、所述车辆以预设车速行驶且禁止能量回收,其中,所述第一阈值用于表示能够满足车辆正常行驶的温度值,所述第二阈值用于表示所述电池完全失去充放电能力的温度值,所述预设车速根据所述电池的可放电功率确定;When the temperature of the battery is less than the first threshold and greater than or equal to the second threshold and the state of charge of the battery cannot meet the required power of the entire vehicle, the range extender is controlled to start and output power according to the required power of the entire vehicle, The vehicle travels at a preset speed and energy recovery is prohibited, wherein the first threshold value is used to represent a temperature value that can meet the normal driving of the vehicle, and the second threshold value is used to represent a temperature value at which the battery completely loses charge and discharge capability value, the preset vehicle speed is determined according to the dischargeable power of the battery;

采集增程器发动机的水温;Collect the water temperature of the range extender engine;

当所述增程器发动机的水温大于暖机温度阈值时,控制所述增程器发动机的热管理系统为所述电池加热。When the water temperature of the range extender engine is greater than the warm-up temperature threshold, the thermal management system of the range extender engine is controlled to heat the battery.

可选地,所述电池的荷电状态无法满足所述整车需求功率包括:Optionally, the state of charge of the battery cannot meet the power demand of the entire vehicle includes:

所述电池的SOC小于等于电量阈值,且所述整车需求功率持续大于等于功率阈值第一预设时间。The SOC of the battery is less than or equal to a power threshold, and the required power of the entire vehicle continues to be greater than or equal to the power threshold for a first preset time.

可选地,控制所述增程器发动机的热管理系统为所述电池加热的步骤,包括:Optionally, the step of controlling the thermal management system of the range extender engine to heat the battery includes:

控制所述热管理系统中的水泵以预设转速运转、所述热管理系统中的暖风散热器处的鼓风机以预设风量为所述电池包送风,以控制送风温度。The water pump in the thermal management system is controlled to run at a preset rotational speed, and the blower at the warm air radiator in the thermal management system supplies air to the battery pack at a preset air volume, so as to control the air supply temperature.

可选地,低温控制方法还包括:Optionally, the low temperature control method further includes:

在所述电池的温度小于第一阈值时,控制加热器加热所述电池。When the temperature of the battery is less than the first threshold, the heater is controlled to heat the battery.

可选地,低温控制方法还包括:Optionally, the low temperature control method further includes:

当所述电池的温度小于第一阈值且大于等于第二阈值、所述电池的荷电状态小于等于电量阈值,并且所述整车需求功率持续小于功率阈值第二预设时间时,控制所述增程器持续处于怠速状态第三预设时间后关闭、所述车辆以蠕行车速行驶且禁止能量回收。When the temperature of the battery is less than a first threshold and greater than or equal to a second threshold, the state of charge of the battery is less than or equal to a power threshold, and the vehicle demand power is continuously less than a power threshold for a second preset time, control the The range extender is turned off after being in the idle state for a third preset time, the vehicle is traveling at a creep speed and energy recovery is disabled.

可选地,低温控制方法还包括:Optionally, the low temperature control method further includes:

当所述电池的温度小于第一阈值且大于等于第二阈值、所述电池的荷电状态大于电量阈值时,控制所述增程器不启动、所述车辆以所述蠕行车速行驶并禁止能量回收。When the temperature of the battery is less than the first threshold and greater than or equal to the second threshold, and the state of charge of the battery is greater than the threshold, the range extender is controlled to not start, the vehicle runs at the creeping speed, and is prohibited Energy recovery.

可选地,当所述车辆以所述蠕行车速行驶时,点亮用于指示所述车辆蠕行的乌龟灯。Optionally, when the vehicle travels at the creeping speed, a turtle light for indicating the creeping of the vehicle is turned on.

可选地,低温控制方法还包括:当所述电池的温度大于等于第一阈值时,控制所述车辆正常行驶。Optionally, the low temperature control method further includes: when the temperature of the battery is greater than or equal to a first threshold, controlling the vehicle to drive normally.

可选地,低温控制方法还包括:当所述电池的温度小于第二阈值时,控制车辆停车。Optionally, the low temperature control method further includes: when the temperature of the battery is lower than a second threshold, controlling the vehicle to stop.

本发明的低温控制方法在电池处于低温(小于第一阈值A0且大于等于第二阈值A1)状态且电池的电量无法满足整车需求功率时启动增程器,并将增程器发动机作为热源为电池预热,这样既可以节约预热系统成本,又能在不增加整车质量的同时达到预热电池组的目的。The low temperature control method of the present invention starts the range extender when the battery is in a low temperature state (less than the first threshold A0 and greater than or equal to the second threshold A1) and the battery power cannot meet the required power of the whole vehicle, and uses the range extender engine as the heat source: The battery is preheated, which can not only save the cost of the preheating system, but also achieve the purpose of preheating the battery pack without increasing the quality of the whole vehicle.

进一步地,在电池处于低温情况下启动增程器,可以尽量少地让低温的电池参与驱动工作,尽量多的利用增程器驱动整车行驶,从而保护电池,避免造成电池大幅度的老化衰退。另外,还可以提高整车在极限工况下的行驶适应性,改善客户驾驶体验。Further, starting the range extender when the battery is at a low temperature can let the low-temperature battery participate in the driving work as little as possible, and use the range extender to drive the whole vehicle as much as possible, so as to protect the battery and avoid causing the battery to be greatly deteriorated due to aging. . In addition, it can also improve the driving adaptability of the whole vehicle under extreme working conditions and improve the customer's driving experience.

根据下文结合附图对本发明具体实施例的详细描述,本领域技术人员将会更加明了本发明的上述以及其他目的、优点和特征。The above and other objects, advantages and features of the present invention will be more apparent to those skilled in the art from the following detailed description of the specific embodiments of the present invention in conjunction with the accompanying drawings.

附图说明Description of drawings

后文将参照附图以示例性而非限制性的方式详细描述本发明的一些具体实施例。附图中相同的附图标记标示了相同或类似的部件或部分。本领域技术人员应该理解,这些附图未必是按比例绘制的。附图中:Hereinafter, some specific embodiments of the present invention will be described in detail by way of example and not limitation with reference to the accompanying drawings. The same reference numbers in the figures designate the same or similar parts or parts. It will be understood by those skilled in the art that the drawings are not necessarily to scale. In the attached picture:

图1是根据本发明一个实施例的增程式车辆的低温控制方法的流程图;FIG. 1 is a flowchart of a low temperature control method for an extended-range vehicle according to an embodiment of the present invention;

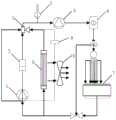

图2是根据本发明一个实施例的增程式车辆的低温控制方法所应用的热管理系统框架图;2 is a frame diagram of a thermal management system applied to a low temperature control method for an extended-range vehicle according to an embodiment of the present invention;

图3是根据本发明另一个实施例的增程式车辆的低温控制方法的流程图。FIG. 3 is a flowchart of a low temperature control method for an extended-range vehicle according to another embodiment of the present invention.

具体实施方式Detailed ways

图1是根据本发明一个实施例的增程式车辆的低温控制方法的流程图。如图1所示,一个实施例中,本发明的增程式车辆的低温控制方法,包括:FIG. 1 is a flowchart of a low temperature control method for an extended-range vehicle according to an embodiment of the present invention. As shown in FIG. 1, in one embodiment, the low temperature control method of the extended-range vehicle of the present invention includes:

步骤S10:采集车辆的电池的温度Ai、电池的荷电状态和整车需求功率。这里电池的温度Ai可以是电池组中各个电池的平均温度或最低温度。Step S10: Collect the temperature Ai of the battery of the vehicle, the state of charge of the battery, and the required power of the entire vehicle. Here, the temperature Ai of the battery may be the average temperature or the minimum temperature of each battery in the battery pack.

步骤S20:当电池的温度Ai小于第一阈值A0且大于等于第二阈值A1且电池的荷电状态无法满足整车需求功率时,控制增程器启动并按整车需求功率输出功率、车辆以预设车速行驶且禁止能量回收。其中,第一阈值A0用于表示能够满足车辆正常行驶的温度值,可选地,第一阈值A0为0℃。第二阈值A1用于表示电池完全失去充放电能力的温度值,可选地,第二阈值A1为-15℃。预设车速根据电池的可放电功率确定。Step S20: when the temperature Ai of the battery is less than the first threshold A0 and greater than or equal to the second threshold A1, and the state of charge of the battery cannot meet the power required by the entire vehicle, control the range extender to start and output power according to the required power of the entire vehicle, and the Driving at the preset speed and recuperation disabled. Wherein, the first threshold A0 is used to indicate a temperature value that can satisfy the normal running of the vehicle, and optionally, the first threshold A0 is 0°C. The second threshold A1 is used to represent the temperature value at which the battery completely loses the charging and discharging capability. Optionally, the second threshold A1 is -15°C. The preset vehicle speed is determined according to the dischargeable power of the battery.

一个实施例中,电池的荷电状态无法满足整车需求功率包括:In one embodiment, the state of charge of the battery cannot meet the power demand of the entire vehicle includes:

电池的SOC小于等于电量阈值,且整车需求功率持续大于等于功率阈值第一预设时间。这里的电量阈值可以取90%,功率阈值可以取6Kw,第一预设时间为10s。The SOC of the battery is less than or equal to the power threshold, and the vehicle demand power is continuously greater than or equal to the power threshold for the first preset time. The power threshold here can be 90%, the power threshold can be 6Kw, and the first preset time is 10s.

步骤S30:采集增程器发动机的水温。Step S30: Collect the water temperature of the range extender engine.

步骤S40:当增程器发动机的水温大于暖机温度阈值时,控制增程器发动机的热管理系统为电池加热。这里的暖机温度阈值可以取85℃,即当检测到增程器发动机的水温大于85℃时,认为增程器发动机暖机成功,此时利用增程器发动机的热量为电池加热。Step S40: When the water temperature of the range extender engine is greater than the warm-up temperature threshold, control the thermal management system of the range extender engine to heat the battery. The warm-up temperature threshold here can be 85°C, that is, when the water temperature of the range extender engine is detected to be greater than 85°C, it is considered that the range extender engine is successfully warmed up, and the heat of the range extender engine is used to heat the battery.

本实施例的低温控制方法在电池处于低温(小于第一阈值A0且大于等于第二阈值A1)状态且电池的电量无法满足整车需求功率时启动增程器,并将增程器发动机作为热源为电池预热,这样既可以节约预热系统成本,又能在不增加整车质量的同时达到预热电池组的目的。The low temperature control method of this embodiment starts the range extender when the battery is in a low temperature state (less than the first threshold A0 and greater than or equal to the second threshold A1) and the battery power cannot meet the required power of the whole vehicle, and uses the range extender engine as the heat source Preheating the battery can not only save the cost of the preheating system, but also achieve the purpose of preheating the battery pack without increasing the mass of the whole vehicle.

进一步地,在电池处于低温情况下启动增程器,可以尽量少地让低温的电池参与驱动工作,尽量多的利用增程器驱动整车行驶,从而保护电池,避免造成电池大幅度的老化衰退。另外,还可以提高整车在极限工况下的行驶适应性,改善客户驾驶体验。Further, starting the range extender when the battery is at a low temperature can let the low-temperature battery participate in the driving work as little as possible, and use the range extender to drive the whole vehicle as much as possible, so as to protect the battery and avoid causing the battery to be greatly deteriorated due to aging. . In addition, it can also improve the driving adaptability of the whole vehicle under extreme working conditions and improve the customer's driving experience.

图2是根据本发明一个实施例的增程式车辆的低温控制方法所应用的热管理系统框架图。一般地,增程式车辆的增程器发动机和电池包的热管理系统包括如图2进行连接水泵1、增程器发动机2、节温器3、温度传感器4、水泵5、PTC加热器6、电池7、膨胀水箱8、暖风散热器9、鼓风机10以及阀门等部件,通过在增程式发动机2的外循环回路上的暖风散热器9处设置鼓风机10,再设置用于将鼓风机10吹出的风引流至电池7的相应管路,可以将增程器发动机2的热量带到电池7处,为电池7预热。一个实施例中,步骤S40包括:控制热管理系统中的水泵1以预设转速运转、热管理系统中的暖风散热器9处的鼓风机10以预设风量为电池包送风,以控制送风温度,实现送风温度达到设定的目标温度。其中,预设转速可根据需求从水泵的转速与流量对应关系表查得。FIG. 2 is a frame diagram of a thermal management system applied to a low temperature control method for an extended-range vehicle according to an embodiment of the present invention. Generally, the thermal management system of the range extender engine and the battery pack of the range extender vehicle includes a

本低温控制方法提出了利用发动机作为热源,引用暖风散热器9的热风为电池7进行预热的方案,通过搭建预热系统结构,控制鼓风机10和水泵1实现预热电池组的目的。This low-temperature control method proposes a scheme of using the engine as a heat source and citing the hot air of the warm air radiator 9 to preheat the battery 7. By building a preheating system structure, the blower 10 and the

图3是根据本发明另一个实施例的增程式车辆的低温控制方法的流程图。如图3所示,另一个实施例中,低温控制方法还包括:FIG. 3 is a flowchart of a low temperature control method for an extended-range vehicle according to another embodiment of the present invention. As shown in Figure 3, in another embodiment, the low temperature control method further includes:

步骤S50:在电池的温度Ai小于第一阈值A0时,控制加热器加热电池。这里的加热器可以是PTC加热器。也就是说,一旦电池温度低于第一阈值A0,表面电池不能满足车辆正常行驶,就对电池进行加热,促使电池迅速达到理想工作状态。Step S50: When the temperature Ai of the battery is lower than the first threshold A0, the heater is controlled to heat the battery. The heater here may be a PTC heater. That is to say, once the battery temperature is lower than the first threshold value A0, and the surface battery cannot meet the normal running of the vehicle, the battery is heated to prompt the battery to quickly reach an ideal working state.

如图3所示,低温控制方法还包括:As shown in Figure 3, the low temperature control method further includes:

步骤S60:当电池的温度Ai小于第一阈值A0且大于等于第二阈值A1、电池的荷电状态小于等于电量阈值,并且整车需求功率持续小于功率阈值第二预设时间时,控制增程器持续处于怠速状态第三预设时间后关闭、车辆以蠕行车速行驶且禁止能量回收。这里的第二预设时间可以标定为20s,第三预设时间可以标定为60s,蠕行车速可以是7km/h。Step S60: When the temperature Ai of the battery is less than the first threshold A0 and greater than or equal to the second threshold A1, the state of charge of the battery is less than or equal to the power threshold, and the vehicle demand power is continuously less than the power threshold for a second preset time, control the range extension After a third preset time of idling, the car is turned off, the vehicle is running at creep speed and energy recovery is disabled. The second preset time here may be calibrated as 20s, the third preset time may be calibrated as 60s, and the creep speed may be 7km/h.

步骤S60中增程器的输出功率为0,可以避免电池过充,从而保护电池。In step S60, the output power of the range extender is 0, which can prevent the battery from being overcharged, thereby protecting the battery.

如图3所示,一个实施例中,低温控制方法还包括:As shown in Figure 3, in one embodiment, the low temperature control method further includes:

步骤S70:当电池的温度Ai小于第一阈值A0且大于等于第二阈值A1、电池的荷电状态大于电量阈值时,控制增程器不启动、车辆以蠕行车速行驶并禁止能量回收。Step S70: When the temperature Ai of the battery is less than the first threshold A0 and greater than or equal to the second threshold A1, and the state of charge of the battery is greater than the power threshold, the range extender is controlled not to start, the vehicle runs at a creeping speed, and energy recovery is prohibited.

步骤S70中控制车辆进入低温纯电模式,利用电池的电量驱动车辆蠕行。In step S70, the vehicle is controlled to enter a low-temperature pure electric mode, and the power of the battery is used to drive the vehicle to creep.

如图3所示,另一个实施例中,当车辆以蠕行车速行驶时,点亮用于指示车辆蠕行的乌龟灯。即步骤S60或步骤S70中还包括点亮乌龟灯的步骤。As shown in FIG. 3 , in another embodiment, when the vehicle is traveling at a creeping speed, the turtle light for indicating the creeping of the vehicle is turned on. That is, step S60 or step S70 further includes the step of lighting the turtle lamp.

一个实施例中,如图3所示,低温控制方法还包括:In one embodiment, as shown in Figure 3, the low temperature control method further includes:

步骤S80:当电池的温度Ai大于等于第一阈值A0时,控制车辆正常行驶。即增程器、电池、电机均按正常行驶模式提供车辆动力。Step S80: When the temperature Ai of the battery is greater than or equal to the first threshold A0, control the vehicle to drive normally. That is, the range extender, battery, and motor all provide vehicle power according to the normal driving mode.

另一个实施例中,如图3所示,低温控制方法还包括:In another embodiment, as shown in Figure 3, the low temperature control method further includes:

步骤S90:当电池的温度Ai小于第二阈值A1时,控制车辆停车。即当电池的温度Ai过低时,车辆进入低温电池保护模式,车辆不能行使,不进入准备状态,从而保护电池。Step S90: When the temperature Ai of the battery is lower than the second threshold A1, the vehicle is controlled to stop. That is, when the temperature Ai of the battery is too low, the vehicle enters the low-temperature battery protection mode, the vehicle cannot run, and does not enter the ready state, thereby protecting the battery.

本低温控制策略,综合考虑环境温度、电池低温充放电特性、SOC、增程器表现和车辆行驶功率需求,评估对电池充放电功率的需求,根据整车需求功率判定增程器是否开启,整车需求功率≥6kW(根据PTC功率设定),增程器开启,整车功率需求下行至低于6kW时,20S(可标定)后增程器先切换至怠速(要求增程器10s之内降至怠速),怠速超过60S(可标定)停止工作。This low-temperature control strategy comprehensively considers the ambient temperature, the low-temperature charge-discharge characteristics of the battery, SOC, the performance of the range extender and the driving power demand of the vehicle, and evaluates the demand for the charging and discharging power of the battery. Vehicle demand power ≥6kW (set according to PTC power), the range extender is turned on, and when the vehicle power demand drops below 6kW, the range extender switches to idle speed after 20s (can be calibrated) (the range extender is required to be within 10s) Drop to idle speed), if the idle speed exceeds 60S (can be calibrated), it will stop working.

至此,本领域技术人员应认识到,虽然本文已详尽示出和描述了本发明的多个示例性实施例,但是,在不脱离本发明精神和范围的情况下,仍可根据本发明公开的内容直接确定或推导出符合本发明原理的许多其他变型或修改。因此,本发明的范围应被理解和认定为覆盖了所有这些其他变型或修改。By now, those skilled in the art will recognize that, although various exemplary embodiments of the present invention have been illustrated and described in detail herein, the present invention may still be implemented in accordance with the present disclosure without departing from the spirit and scope of the present invention. The content directly determines or derives many other variations or modifications consistent with the principles of the invention. Accordingly, the scope of the present invention should be understood and deemed to cover all such other variations or modifications.

Claims (9)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010917762.3ACN112060924A (en) | 2020-09-03 | 2020-09-03 | Low-temperature control method of extended range vehicle |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010917762.3ACN112060924A (en) | 2020-09-03 | 2020-09-03 | Low-temperature control method of extended range vehicle |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112060924Atrue CN112060924A (en) | 2020-12-11 |

Family

ID=73666578

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010917762.3APendingCN112060924A (en) | 2020-09-03 | 2020-09-03 | Low-temperature control method of extended range vehicle |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112060924A (en) |

Cited By (11)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112606736A (en)* | 2021-01-05 | 2021-04-06 | 南昌济铃新能源科技有限责任公司 | Range extender control method and range-extending electric automobile |

| CN112660103A (en)* | 2020-12-31 | 2021-04-16 | 重庆金康赛力斯新能源汽车设计院有限公司 | Vehicle control mode determination method and device and whole vehicle control system |

| CN112677776A (en)* | 2021-01-13 | 2021-04-20 | 天津易众腾动力技术有限公司 | Power safety control method for range-extending system of range-extending electric automobile |

| CN113978444A (en)* | 2021-10-29 | 2022-01-28 | 东风汽车集团股份有限公司 | Control method and system for hybrid vehicle under extremely cold condition |

| CN114407730A (en)* | 2021-12-14 | 2022-04-29 | 岚图汽车科技有限公司 | Low-temperature thermal management system and method for extended-range new energy automobile |

| CN114670712A (en)* | 2022-03-24 | 2022-06-28 | 东风汽车集团股份有限公司 | Temperature control method, vehicle, and storage medium |

| CN114802181A (en)* | 2022-04-12 | 2022-07-29 | 柳州五菱新能源汽车有限公司 | Range extender power generation control method and device for hybrid vehicle and vehicle |

| CN115071456A (en)* | 2022-06-13 | 2022-09-20 | 一汽解放汽车有限公司 | Control method of SOFC (solid oxide Fuel cell) range extending system, SOFC range extending system and vehicle |

| CN116572932A (en)* | 2023-05-29 | 2023-08-11 | 成都赛力斯科技有限公司 | Control method for extended-range electric vehicles under low temperature and low battery discharge power scenarios |

| CN117301954A (en)* | 2023-09-26 | 2023-12-29 | 重庆赛力斯新能源汽车设计院有限公司 | Battery charge state adjusting method and device, electronic equipment and storage medium |

| WO2024244535A1 (en)* | 2023-05-30 | 2024-12-05 | 重庆长安汽车股份有限公司 | Torque distribution method and apparatus, electronic device and storage medium |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105946604A (en)* | 2016-04-28 | 2016-09-21 | 郑州宇通客车股份有限公司 | Method and system for controlling heating of power battery |

| CN107351640A (en)* | 2017-06-30 | 2017-11-17 | 浙江合众新能源汽车有限公司 | A kind of stroke-increasing electric automobile heat management system and control method |

| CN207257354U (en)* | 2017-10-16 | 2018-04-20 | 北京车和家信息技术有限公司 | New energy vehicle |

| CN108248398A (en)* | 2018-01-16 | 2018-07-06 | 浙江吉利新能源商用车有限公司 | A kind of control method and control system of extended-range power cell of vehicle |

| CN111469714A (en)* | 2020-04-24 | 2020-07-31 | 上海元城汽车技术有限公司 | Starting control method, device, equipment and storage medium of extended range electric vehicle |

- 2020

- 2020-09-03CNCN202010917762.3Apatent/CN112060924A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN105946604A (en)* | 2016-04-28 | 2016-09-21 | 郑州宇通客车股份有限公司 | Method and system for controlling heating of power battery |

| CN107351640A (en)* | 2017-06-30 | 2017-11-17 | 浙江合众新能源汽车有限公司 | A kind of stroke-increasing electric automobile heat management system and control method |

| CN207257354U (en)* | 2017-10-16 | 2018-04-20 | 北京车和家信息技术有限公司 | New energy vehicle |

| CN108248398A (en)* | 2018-01-16 | 2018-07-06 | 浙江吉利新能源商用车有限公司 | A kind of control method and control system of extended-range power cell of vehicle |

| CN111469714A (en)* | 2020-04-24 | 2020-07-31 | 上海元城汽车技术有限公司 | Starting control method, device, equipment and storage medium of extended range electric vehicle |

Cited By (17)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112660103A (en)* | 2020-12-31 | 2021-04-16 | 重庆金康赛力斯新能源汽车设计院有限公司 | Vehicle control mode determination method and device and whole vehicle control system |

| CN112606736B (en)* | 2021-01-05 | 2022-07-22 | 南昌智能新能源汽车研究院 | Range extender control method and range-extending electric automobile |

| CN112606736A (en)* | 2021-01-05 | 2021-04-06 | 南昌济铃新能源科技有限责任公司 | Range extender control method and range-extending electric automobile |

| CN112677776A (en)* | 2021-01-13 | 2021-04-20 | 天津易众腾动力技术有限公司 | Power safety control method for range-extending system of range-extending electric automobile |

| CN112677776B (en)* | 2021-01-13 | 2022-08-09 | 天津易众腾动力技术有限公司 | Power safety control method for range-extending system of range-extending electric automobile |

| CN113978444A (en)* | 2021-10-29 | 2022-01-28 | 东风汽车集团股份有限公司 | Control method and system for hybrid vehicle under extremely cold condition |

| CN114407730A (en)* | 2021-12-14 | 2022-04-29 | 岚图汽车科技有限公司 | Low-temperature thermal management system and method for extended-range new energy automobile |

| CN114407730B (en)* | 2021-12-14 | 2024-01-09 | 岚图汽车科技有限公司 | Low-temperature heat management system and method for extended-range new energy automobile |

| CN114670712A (en)* | 2022-03-24 | 2022-06-28 | 东风汽车集团股份有限公司 | Temperature control method, vehicle, and storage medium |

| CN114802181A (en)* | 2022-04-12 | 2022-07-29 | 柳州五菱新能源汽车有限公司 | Range extender power generation control method and device for hybrid vehicle and vehicle |

| CN114802181B (en)* | 2022-04-12 | 2025-08-01 | 柳州五菱新能源汽车有限公司 | Range extender power generation control method and device for hybrid electric vehicle and vehicle |

| CN115071456A (en)* | 2022-06-13 | 2022-09-20 | 一汽解放汽车有限公司 | Control method of SOFC (solid oxide Fuel cell) range extending system, SOFC range extending system and vehicle |

| CN115071456B (en)* | 2022-06-13 | 2024-05-14 | 一汽解放汽车有限公司 | Control method of SOFC (solid oxide Fuel cell) range-extending system, SOFC range-extending system and vehicle |

| CN116572932A (en)* | 2023-05-29 | 2023-08-11 | 成都赛力斯科技有限公司 | Control method for extended-range electric vehicles under low temperature and low battery discharge power scenarios |

| WO2024244535A1 (en)* | 2023-05-30 | 2024-12-05 | 重庆长安汽车股份有限公司 | Torque distribution method and apparatus, electronic device and storage medium |

| CN117301954A (en)* | 2023-09-26 | 2023-12-29 | 重庆赛力斯新能源汽车设计院有限公司 | Battery charge state adjusting method and device, electronic equipment and storage medium |

| CN117301954B (en)* | 2023-09-26 | 2024-07-16 | 重庆赛力斯新能源汽车设计院有限公司 | Battery charge state adjusting method and device, electronic equipment and storage medium |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN112060924A (en) | Low-temperature control method of extended range vehicle | |

| CN112060925B (en) | Whole vehicle control method and system of extended range vehicle | |

| CN108878997A (en) | A kind of electric automobile power battery pre-heating system and its pre-heating mean based on mobile client | |

| JP4508281B2 (en) | Battery control apparatus and storage battery charge / discharge control method | |

| EP3623198B1 (en) | Power battery cooling system and method based on solar sunroof | |

| JP2008049877A (en) | Battery control device | |

| CN109572486A (en) | A kind of power battery for hybrid electric vehicle heat management system and control method | |

| CN115503678B (en) | Hybrid vehicle control method and device, vehicle and computer storage medium | |

| CN104760488B (en) | Motor vehicle driven by mixed power | |

| CN113517454B (en) | Thermal management control method and system for fuel cell power generation system | |

| US11597252B2 (en) | Plug-in electric vehicle and method for heating a passenger cabin | |

| CN103608200A (en) | Vehicle control apparatus | |

| CN115571023B (en) | Battery heating control method, device and vehicle | |

| KR20110131885A (en) | Car seat air conditioning unit | |

| CN211524942U (en) | Temperature adjusting device and hybrid power system | |

| CN111055835B (en) | Idle speed control method and system of hybrid power vehicle | |

| CN117584697A (en) | Energy-saving control method, device, equipment and storage medium for hybrid electric vehicle | |

| KR102598417B1 (en) | Controlling method for heating of hybrid vehicle | |

| KR101906385B1 (en) | Pre heating control apparatus and method of plugin hybrid electric commercial vehicle | |

| KR100957363B1 (en) | Fuel cell preheating and winter indoor heating device for fuel cell hybrid bus and its control method | |

| JP3894180B2 (en) | Hybrid vehicle cooling system | |

| US12005809B2 (en) | Method for the thermal conditioning of traction batteries | |

| CN111102056A (en) | A temperature regulating device, working method and hybrid power system | |

| CN111546866B (en) | A hybrid power system cooling and heating device | |

| CN110509786A (en) | Electric vehicle charging method, charging system, electric vehicle |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| TA01 | Transfer of patent application right | ||

| TA01 | Transfer of patent application right | Effective date of registration:20211202 Address after:Room 612, building 1, 1760 Jiangling Road, Binjiang District, Hangzhou City, Zhejiang Province Applicant after:ZHEJIANG GEELY NEW ENERGY COMMERCIAL VEHICLE GROUP Co.,Ltd. Applicant after:GEELY SICHUAN COMMERCIAL VEHICLE Co.,Ltd. Applicant after:JIANGXI GEELY NEW ENERGY COMMERCIAL VEHICLE Co.,Ltd. Applicant after:Zhejiang remote commercial vehicle R & D Co.,Ltd. Applicant after:ZHEJIANG GEELY HOLDING GROUP Co.,Ltd. Address before:Room 612, building 1, 1760 Jiangling Road, Binjiang District, Hangzhou City, Zhejiang Province Applicant before:ZHEJIANG GEELY NEW ENERGY COMMERCIAL VEHICLE GROUP Co.,Ltd. Applicant before:GEELY SICHUAN COMMERCIAL VEHICLE Co.,Ltd. Applicant before:JIANGXI GEELY NEW ENERGY COMMERCIAL VEHICLE Co.,Ltd. Applicant before:ZHEJIANG GEELY HOLDING GROUP Co.,Ltd. | |

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20201211 |