CN112058227A - Preparation method and application of blue algae modified biochar with high adsorption efficiency - Google Patents

Preparation method and application of blue algae modified biochar with high adsorption efficiencyDownload PDFInfo

- Publication number

- CN112058227A CN112058227ACN202010900048.3ACN202010900048ACN112058227ACN 112058227 ACN112058227 ACN 112058227ACN 202010900048 ACN202010900048 ACN 202010900048ACN 112058227 ACN112058227 ACN 112058227A

- Authority

- CN

- China

- Prior art keywords

- carbon material

- biochar

- drying

- adsorption efficiency

- high adsorption

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000001179sorption measurementMethods0.000titleclaimsabstractdescription48

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription12

- 241000195493CryptophytaSpecies0.000titleclaimsdescription9

- 239000003575carbonaceous materialSubstances0.000claimsabstractdescription61

- 241000192700CyanobacteriaSpecies0.000claimsabstractdescription32

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterChemical compoundOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsabstractdescription21

- 238000001035dryingMethods0.000claimsabstractdescription19

- 238000000034methodMethods0.000claimsabstractdescription18

- 238000003763carbonizationMethods0.000claimsabstractdescription16

- 239000008367deionised waterSubstances0.000claimsabstractdescription10

- 229910021641deionized waterInorganic materials0.000claimsabstractdescription10

- 239000000203mixtureSubstances0.000claimsabstractdescription10

- 239000006228supernatantSubstances0.000claimsabstractdescription7

- 238000001816coolingMethods0.000claimsabstractdescription6

- 239000002957persistent organic pollutantSubstances0.000claimsabstractdescription6

- 239000002689soilSubstances0.000claimsabstractdescription6

- 238000005067remediationMethods0.000claimsabstractdescription5

- 239000007787solidSubstances0.000claimsabstractdescription4

- 230000007935neutral effectEffects0.000claimsabstractdescription3

- 238000012805post-processingMethods0.000claimsabstract2

- IJGRMHOSHXDMSA-UHFFFAOYSA-NAtomic nitrogenChemical compoundN#NIJGRMHOSHXDMSA-UHFFFAOYSA-N0.000claimsdescription20

- 238000010438heat treatmentMethods0.000claimsdescription12

- 229910052757nitrogenInorganic materials0.000claimsdescription10

- 238000004108freeze dryingMethods0.000claimsdescription3

- 238000010000carbonizingMethods0.000claims2

- 239000003610charcoalSubstances0.000claims1

- 238000002156mixingMethods0.000claims1

- 238000007873sievingMethods0.000claims1

- 238000005406washingMethods0.000claims1

- 230000000694effectsEffects0.000abstractdescription8

- 230000014759maintenance of locationEffects0.000abstractdescription2

- 238000010298pulverizing processMethods0.000abstractdescription2

- NIQCNGHVCWTJSM-UHFFFAOYSA-NDimethyl phthalateChemical compoundCOC(=O)C1=CC=CC=C1C(=O)OCNIQCNGHVCWTJSM-UHFFFAOYSA-N0.000description36

- 150000001721carbonChemical class0.000description18

- FBSAITBEAPNWJG-UHFFFAOYSA-Ndimethyl phthalateNatural productsCC(=O)OC1=CC=CC=C1OC(C)=OFBSAITBEAPNWJG-UHFFFAOYSA-N0.000description18

- 229960001826dimethylphthalateDrugs0.000description18

- BTJIUGUIPKRLHP-UHFFFAOYSA-N4-nitrophenolChemical compoundOC1=CC=C([N+]([O-])=O)C=C1BTJIUGUIPKRLHP-UHFFFAOYSA-N0.000description17

- 239000000463materialSubstances0.000description16

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical group[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000description15

- 239000011148porous materialSubstances0.000description13

- 229910052799carbonInorganic materials0.000description11

- 125000000524functional groupChemical group0.000description10

- 239000004810polytetrafluoroethyleneSubstances0.000description8

- 229920001343polytetrafluoroethylenePolymers0.000description8

- 238000000197pyrolysisMethods0.000description8

- 238000002441X-ray diffractionMethods0.000description7

- 239000003344environmental pollutantSubstances0.000description7

- 231100000719pollutantToxicity0.000description7

- 238000010586diagramMethods0.000description6

- 230000010355oscillationEffects0.000description5

- 230000035484reaction timeEffects0.000description5

- UXVMQQNJUSDDNG-UHFFFAOYSA-LCalcium chlorideChemical compound[Cl-].[Cl-].[Ca+2]UXVMQQNJUSDDNG-UHFFFAOYSA-L0.000description4

- 239000001110calcium chlorideSubstances0.000description4

- 229910001628calcium chlorideInorganic materials0.000description4

- 235000011148calcium chlorideNutrition0.000description4

- 238000006243chemical reactionMethods0.000description4

- 239000011521glassSubstances0.000description4

- 238000004811liquid chromatographyMethods0.000description4

- 239000012528membraneSubstances0.000description4

- 238000002474experimental methodMethods0.000description3

- 239000002028BiomassSubstances0.000description2

- GRYLNZFGIOXLOG-UHFFFAOYSA-NNitric acidChemical compoundO[N+]([O-])=OGRYLNZFGIOXLOG-UHFFFAOYSA-N0.000description2

- 239000003463adsorbentSubstances0.000description2

- 230000008901benefitEffects0.000description2

- 238000009264compostingMethods0.000description2

- 230000007613environmental effectEffects0.000description2

- 229910001385heavy metalInorganic materials0.000description2

- 229910017604nitric acidInorganic materials0.000description2

- 239000005416organic matterSubstances0.000description2

- 238000004064recyclingMethods0.000description2

- 238000003900soil pollutionMethods0.000description2

- 238000003911water pollutionMethods0.000description2

- 206010021143HypoxiaDiseases0.000description1

- 239000002253acidSubstances0.000description1

- 239000006227byproductSubstances0.000description1

- 230000015556catabolic processEffects0.000description1

- 238000005260corrosionMethods0.000description1

- 230000007797corrosionEffects0.000description1

- 238000000354decomposition reactionMethods0.000description1

- 238000006731degradation reactionMethods0.000description1

- 238000011161developmentMethods0.000description1

- 235000013399edible fruitsNutrition0.000description1

- 238000005516engineering processMethods0.000description1

- 230000002708enhancing effectEffects0.000description1

- 238000000855fermentationMethods0.000description1

- 239000013505freshwaterSubstances0.000description1

- 230000001146hypoxic effectEffects0.000description1

- 239000011261inert gasSubstances0.000description1

- 230000002503metabolic effectEffects0.000description1

- 244000005700microbiomeSpecies0.000description1

- 238000013508migrationMethods0.000description1

- 230000005012migrationEffects0.000description1

- 238000012986modificationMethods0.000description1

- 230000004048modificationEffects0.000description1

- 235000015097nutrientsNutrition0.000description1

- 230000020477pH reductionEffects0.000description1

- 230000029553photosynthesisEffects0.000description1

- 238000010672photosynthesisMethods0.000description1

- 241000512250phototrophic bacteriumSpecies0.000description1

- 238000010248power generationMethods0.000description1

- 230000008569processEffects0.000description1

- 239000010453quartzSubstances0.000description1

- 239000002994raw materialSubstances0.000description1

- 238000011160researchMethods0.000description1

- 239000010865sewageSubstances0.000description1

- VYPSYNLAJGMNEJ-UHFFFAOYSA-Nsilicon dioxideInorganic materialsO=[Si]=OVYPSYNLAJGMNEJ-UHFFFAOYSA-N0.000description1

- 239000003516soil conditionerSubstances0.000description1

- 239000000126substanceSubstances0.000description1

- 239000003053toxinSubstances0.000description1

- 231100000765toxinToxicity0.000description1

- 108700012359toxinsProteins0.000description1

- 230000009466transformationEffects0.000description1

- 239000002699waste materialSubstances0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B01—PHYSICAL OR CHEMICAL PROCESSES OR APPARATUS IN GENERAL

- B01J—CHEMICAL OR PHYSICAL PROCESSES, e.g. CATALYSIS OR COLLOID CHEMISTRY; THEIR RELEVANT APPARATUS

- B01J20/00—Solid sorbent compositions or filter aid compositions; Sorbents for chromatography; Processes for preparing, regenerating or reactivating thereof

- B01J20/02—Solid sorbent compositions or filter aid compositions; Sorbents for chromatography; Processes for preparing, regenerating or reactivating thereof comprising inorganic material

- B01J20/20—Solid sorbent compositions or filter aid compositions; Sorbents for chromatography; Processes for preparing, regenerating or reactivating thereof comprising inorganic material comprising free carbon; comprising carbon obtained by carbonising processes

- B—PERFORMING OPERATIONS; TRANSPORTING

- B09—DISPOSAL OF SOLID WASTE; RECLAMATION OF CONTAMINATED SOIL

- B09C—RECLAMATION OF CONTAMINATED SOIL

- B09C1/00—Reclamation of contaminated soil

- C—CHEMISTRY; METALLURGY

- C02—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F—TREATMENT OF WATER, WASTE WATER, SEWAGE, OR SLUDGE

- C02F1/00—Treatment of water, waste water, or sewage

- C02F1/28—Treatment of water, waste water, or sewage by sorption

- C02F1/283—Treatment of water, waste water, or sewage by sorption using coal, charred products, or inorganic mixtures containing them

Landscapes

- Chemical & Material Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Engineering & Computer Science (AREA)

- Environmental & Geological Engineering (AREA)

- Organic Chemistry (AREA)

- Hydrology & Water Resources (AREA)

- Water Supply & Treatment (AREA)

- Inorganic Chemistry (AREA)

- Analytical Chemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Soil Sciences (AREA)

- Carbon And Carbon Compounds (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种高吸附效能蓝藻改性生物炭的制备方法与应用,属于水处理或土壤修复技术领域。The invention relates to a preparation method and application of cyanobacterial modified biochar with high adsorption efficiency, and belongs to the technical field of water treatment or soil remediation.

背景技术Background technique

蓝藻是存在于许多生态系统中的一种光营养细菌,也是光合作用的关键参与者。但蓝藻一旦生长和扩张太快,就会破坏淡水资源并产生毒素。蓝藻资源化利用是蓝藻处置工作的最后环节,也是避免蓝藻二次污染的有效途径,资料显示:太湖蓝藻2017年打捞量达到250万t,为历史之最,2018年随着国家对湖泊富营养化的治理和气候条件影响,蓝藻打捞量为186万t。目前,国内蓝藻处置方式包括堆肥、厌氧发酵产沼气、沤肥还田以及输送热电厂与其它材料混合进行焚烧发电,但处置效能仍存在资源化技术不成熟,利用水平总体不高的局面。Cyanobacteria are a type of phototrophic bacteria found in many ecosystems and key players in photosynthesis. But once cyanobacteria grow and expand too quickly, they can destroy freshwater resources and produce toxins. The utilization of cyanobacteria resources is the last link in the disposal of cyanobacteria, and it is also an effective way to avoid secondary pollution of cyanobacteria. The data shows that the salvage of cyanobacteria in Taihu Lake reached 2.5 million tons in 2017, the highest in history. Due to the influence of chemical governance and climatic conditions, the salvage volume of cyanobacteria was 1.86 million tons. At present, domestic cyanobacteria disposal methods include composting, anaerobic fermentation to produce biogas, composting and returning to fields, and conveying thermal power plants to mix with other materials for incineration and power generation.

生物炭是生物质在惰性气体保护条件下,高温热解而成的多孔炭材料,它具有比表面积大,表面官能团丰富的特点,对有机污染物及重金属均具有较好的吸附作用。目前有关生物炭的研究大多以农田废弃物、树枝木屑或果壳为原料,经过高温热解制备相应的炭材料,而采用藻类作为生物质原料相对于上述几种常用材料而言,具有相同的优点,同时还能够解决藻类二次污染问题,缓解藻类再利用压力。Biochar is a porous carbon material obtained by pyrolysis of biomass at high temperature under the protection of inert gas. It has the characteristics of large specific surface area and rich surface functional groups, and has a good adsorption effect on organic pollutants and heavy metals. At present, most of the research on biochar uses farmland waste, tree chips or fruit shells as raw materials, and the corresponding carbon materials are prepared by high temperature pyrolysis. At the same time, it can also solve the problem of secondary pollution of algae and relieve the pressure of algae reuse.

因此,将藻类通过改性制备高吸附性能的生物炭材料,使炭结构发生改变,从而具有更大的比表面积和更加丰富的表面官能团,提升对环境中有机污染物的吸附效能,为解决藻类资源化提供了新的途径,也为缓解水体和土壤污染开拓了新的方法,具有良好的经济效益、环境效益和社会效益。Therefore, algae are modified to prepare biochar materials with high adsorption performance, so that the carbon structure is changed, so that it has a larger specific surface area and more abundant surface functional groups, and improves the adsorption efficiency of organic pollutants in the environment. In order to solve the problem of algae Recycling provides a new way, and also opens up a new method for alleviating water and soil pollution, with good economic, environmental and social benefits.

发明内容SUMMARY OF THE INVENTION

针对上述现存的技术问题,本发明提供一种高吸附效能蓝藻改性生物炭的制备方法与应用,以实现开拓蓝藻资源化途径,并解决现有土壤修复技术不完善的问题。In view of the above existing technical problems, the present invention provides a preparation method and application of cyanobacterial modified biochar with high adsorption efficiency, so as to realize the development of cyanobacterial resources and solve the problem of imperfection of the existing soil remediation technology.

为实现上述目的,本发明提供一种高吸附效能蓝藻改性生物炭的制备方法,包括如下具体步骤:In order to achieve the above purpose, the present invention provides a preparation method of cyanobacterial modified biochar with high adsorption efficiency, comprising the following specific steps:

S1、一次炭化:将蓝藻干燥、粉碎后,在惰性氛围下进行炭化,温度由室温升至300℃,并保持1-2h,冷却后得初炭材料。S1. Primary carbonization: After drying and pulverizing the blue-green algae, carbonization is carried out in an inert atmosphere, the temperature is raised from room temperature to 300 ° C, and maintained for 1-2 hours, and the initial carbon material is obtained after cooling.

进一步,所述的干燥是冷冻干燥或置于80-105℃烘箱内烘干。Further, the drying is freeze drying or drying in an oven at 80-105°C.

进一步,所述炭化的升温速率为5℃/min,氮气流量为50-100mL/min。Further, the heating rate of the carbonization is 5°C/min, and the nitrogen flow rate is 50-100 mL/min.

S2、二次炭化:将初炭材料粉碎,与KOH按质量比1:2-3混合,加入去离子水,使KOH浓度在20-40%;将所得混合物干燥后,在惰性氛围下进行炭化,温度由室温升至700℃,并保持1-3h,冷却后得粗炭材料。S2. Secondary carbonization: pulverize the primary carbon material, mix it with KOH in a mass ratio of 1:2-3, add deionized water to make the KOH concentration 20-40%; after drying the obtained mixture, carbonize in an inert atmosphere , the temperature was raised from room temperature to 700 ℃, and kept for 1-3h, and the crude carbon material was obtained after cooling.

上述技术方案中,碱化处理使得炭材料进一步扩孔,炭内部孔隙率及比表面积增大。并且经进一步的高温加热,对炭表面官能团进行了活化,增加了炭材料内部的活性点位,在获得更大的比表面积及孔隙率的同时,加强了对污染物的吸附固持作用。In the above technical solution, the alkalization treatment further expands the pores of the carbon material, and increases the internal porosity and specific surface area of the carbon. And after further high-temperature heating, the functional groups on the carbon surface are activated, which increases the active sites inside the carbon material, and enhances the adsorption and retention of pollutants while obtaining a larger specific surface area and porosity.

进一步,所述的粉碎是利用破碎机破碎,再过100目筛。Further, the crushing is to use a crusher to crush, and then pass through a 100-mesh sieve.

进一步,所述的干燥是置于80-90℃烘箱内烘干。Further, the drying is placed in an oven at 80-90° C. for drying.

进一步,所述炭化的升温速率为5℃/min,氮气流量为50-100mL/min。Further, the heating rate of the carbonization is 5°C/min, and the nitrogen flow rate is 50-100 mL/min.

S3、后处理:向粗炭材料中加入20-40%的HNO3或HCl,置于摇床震荡,再去除上清液,将所得固体水洗至中性后干燥,得改性蓝藻生物炭。S3. Post-treatment: add 20-40% HNO3 or HCl to the crude carbon material, place it on a shaker to shake, remove the supernatant, wash the obtained solid with water to neutrality and then dry to obtain modified cyanobacterial biochar.

上述技术方案中,向粗炭材料中加入酸溶液使得炭材料改性,进一步增加了炭材料表面官能团的种类及活性,有利于加强炭材料对污染物的吸附作用。In the above technical scheme, adding an acid solution to the crude carbon material modifies the carbon material, further increases the types and activities of the surface functional groups of the carbon material, and is conducive to enhancing the adsorption of the carbon material to pollutants.

进一步,所述摇床的条件是温度为25℃,速度为150r/min,震荡时间为2-3h。Further, the conditions of the shaking table are that the temperature is 25° C., the speed is 150 r/min, and the shaking time is 2-3 h.

进一步,所述的干燥是置于80-105℃烘箱内烘干。Further, the drying is placed in an oven at 80-105°C.

利用上述技术方案制备的蓝藻改性生物炭是生物质在无氧或低氧状态下热解后残余的富碳固体副产物。由于其碳含量高且孔隙结构发达,抗腐蚀性好,可保持水分、养分,吸附有机物、重金属等污染物,具有优良的孔隙结构及吸附分解性能,是一种理想的土壤改良剂和吸附剂。The cyanobacteria-modified biochar prepared by the above technical scheme is the residual carbon-rich solid by-product after the biomass is pyrolyzed in an anaerobic or hypoxic state. Due to its high carbon content, developed pore structure, and good corrosion resistance, it can retain water, nutrients, and adsorb pollutants such as organic matter and heavy metals. It has excellent pore structure and adsorption and decomposition performance. It is an ideal soil conditioner and adsorbent. .

并且,本发明还提供一种上述方法制备而得的高吸附效能蓝藻改性生物炭在水处理和土壤修复中的应用。In addition, the present invention also provides an application of the cyanobacterial modified biochar with high adsorption efficiency prepared by the above method in water treatment and soil remediation.

进一步的,该蓝藻改性生物炭对有机污染物具有吸附固持作用。Further, the cyanobacteria-modified biochar has an adsorption and immobilization effect on organic pollutants.

上述技术方案中,通过蓝藻制备的高效能炭吸附材料具有微孔结构,且比表面积大,能够吸附污染物于炭结构内,并起到固定污染物的作用,为后续微生物对该类污染物的降解提供足够的代谢时间,最终使污水或土壤得到有效修复,解决水和土壤污染的问题。In the above technical solution, the high-efficiency carbon adsorption material prepared by cyanobacteria has a microporous structure and a large specific surface area, which can adsorb pollutants in the carbon structure and play the role of fixing pollutants, so that subsequent microorganisms can prevent such pollutants. The degradation of the water provides sufficient metabolic time, and finally the sewage or soil can be effectively repaired, and the problem of water and soil pollution can be solved.

综上,本发明以蓝藻资源化为目的,通过改性制得蓝藻改性生物炭,为具有高比表面积和丰富表面官能团的炭吸附材料,能够有效解决蓝藻二次污染问题,由于蓝藻的丰富和易获取性,充分利用蓝藻制备活性炭,能够实现资源的充分利用。并且,蓝藻改性生物炭相比现有炭吸附材料,大大提高了对有机污染物的吸附效能,降低了污染物在环境介质中的迁移转化风险,具有良好的应用前景。To sum up, the present invention aims at recycling cyanobacteria, and obtains cyanobacterial modified biochar through modification, which is a carbon adsorption material with high specific surface area and rich surface functional groups, which can effectively solve the problem of secondary pollution of cyanobacteria. And easy to obtain, make full use of cyanobacteria to prepare activated carbon, can achieve full utilization of resources. Moreover, compared with the existing carbon adsorption materials, the cyanobacteria-modified biochar greatly improves the adsorption efficiency of organic pollutants, reduces the risk of migration and transformation of pollutants in environmental media, and has good application prospects.

相比现有技术,本发明优势在于碱化后在惰性条件下热解,炭材料孔径得到显著提升,同时热解后进一步酸化,连续碱化热解酸化后,使炭材料特性相比于目前所报道材料具有更大的比表面积及孔隙率。Compared with the prior art, the present invention has the advantage that the carbon material is pyrolyzed under inert conditions after alkalization, the pore size of the carbon material is significantly improved, and at the same time, it is further acidified after pyrolysis, and after continuous alkalization, pyrolysis and acidification, the characteristics of the carbon material are compared with the current ones. The reported material has larger specific surface area and porosity.

附图说明Description of drawings

图1a为实施例1中蓝藻改性生物炭的反应时间对吸附邻苯二甲酸二甲酯(DMP)的影响关系图;Figure 1a is a graph showing the effect of the reaction time of the cyanobacteria-modified biochar on the adsorption of dimethyl phthalate (DMP) in Example 1;

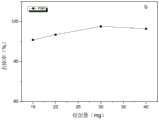

图1b为实施例1中蓝藻改性生物炭的投加量对吸附邻苯二甲酸二甲酯(DMP)的影响关系图;Figure 1b is a graph showing the influence of the dosage of cyanobacteria-modified biochar on the adsorption of dimethyl phthalate (DMP) in Example 1;

图2a为实施例3中蓝藻改性生物炭的反应时间对吸附对硝基苯酚(PNP)的影响关系图;Figure 2a is a graph showing the effect of reaction time of cyanobacteria-modified biochar on adsorption of p-nitrophenol (PNP) in Example 3;

图2b为实施例3中蓝藻改性生物炭的投加量对吸附对硝基苯酚(PNP)的影响关系图;。Figure 2b is a graph showing the effect of the dosage of cyanobacterial modified biochar on the adsorption of p-nitrophenol (PNP) in Example 3;

图3a为实施例1中蓝藻700℃条件下热解,未经改性炭材料扫描电镜(SEM)图;Figure 3a is a scanning electron microscope (SEM) image of the unmodified carbon material after pyrolysis of cyanobacteria at 700°C in Example 1;

图3b为实施例1中蓝藻改性炭材料扫描电镜(SEM)图;Figure 3b is a scanning electron microscope (SEM) image of the cyanobacterial modified carbon material in Example 1;

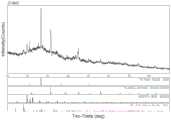

图4a为实施例1中蓝藻700℃条件下热解,未经改性炭材料X射线衍射(XRD)图;Figure 4a is the X-ray diffraction (XRD) pattern of the unmodified carbon material under the condition of pyrolysis of cyanobacteria in Example 1 at 700°C;

图4b为实施例1中蓝藻改性炭材料X射线衍射(XRD)图。FIG. 4b is an X-ray diffraction (XRD) pattern of the cyanobacterial modified carbon material in Example 1. FIG.

具体实施方式Detailed ways

下面结合附图对本发明作进一步说明。The present invention will be further described below in conjunction with the accompanying drawings.

下面结合实施例和附图对本发明作进一步说明。对于本领域技术人员而言,显然本发明不限于下述示范性实施例的细节,而且在不背离本发明的精神或基本特征的情况下,能够以其他的具体形式实现本发明。因此,无论从哪一点来看,均应将实施例看作是示范性的,而且是非限制性的,本发明的范围由所附权利要求而不是下述说明限定,因此旨在将落在权利要求的等同要件的含义和范围内的所有变化囊括在本发明内。The present invention will be further described below with reference to the embodiments and accompanying drawings. It will be apparent to those skilled in the art that the present invention is not limited to the details of the exemplary embodiments described below, but that the present invention may be embodied in other specific forms without departing from the spirit or essential characteristics of the invention. Therefore, the embodiments are to be regarded in all respects as illustrative and not restrictive, the scope of the invention being defined by the appended claims rather than the following description, and it is therefore intended that the All changes that come within the meaning and range of the claimed equivalents are encompassed within the invention.

实施例1:1-1、改性蓝藻生物炭的制备,具体步骤如下:Embodiment 1: 1-1. Preparation of modified cyanobacterial biochar, the specific steps are as follows:

1-1-1、收集由打捞站打捞上来的蓝藻,先置于105℃烘箱内烘干,然后经粉碎机粉碎,再放入石英舟内置于管式炉中,并在氮气保护条件下进行炭化处理。要求升温速率为5℃/min,氮气流量为50mL/min,加热温度先从室温升至300℃,保持1h后冷却至室温,所得炭材料标记为ZC300。1-1-1. Collect the blue-green algae salvaged from the salvage station, dry them in a 105°C oven, pulverize them with a pulverizer, and then put them into a quartz boat and put them in a tube furnace, and carry out the process under nitrogen protection. Carbonized treatment. The heating rate is required to be 5 °C/min, the nitrogen flow rate is 50 mL/min, the heating temperature is first raised from room temperature to 300 °C, maintained for 1 h, and then cooled to room temperature, and the obtained carbon material is marked as ZC300.

1-1-2、先将炭材料ZC300进一步经粉碎机粉碎,并过100目筛。然后将筛下物与KOH按照质量比1:2混合,并加入去离子水使KOH浓度在20%。接着将混合物置于80℃烘箱烘干,再置于管式炉中,并在氮气保护条件下进行炭化处理。加热温度先从室温升至700℃,升温条件为升温速率5℃/min,且氮气流量50mL/min,保持2h后冷却至室温,所得炭材料标记为KOH-ZC700。1-1-2. First, the carbon material ZC300 is further pulverized by a pulverizer and passed through a 100-mesh sieve. Then the undersize was mixed with KOH in a mass ratio of 1:2, and deionized water was added to make the KOH concentration at 20%. Then, the mixture was dried in an oven at 80° C., and then placed in a tube furnace, and carbonized under nitrogen protection. The heating temperature was first increased from room temperature to 700 °C, the heating condition was a heating rate of 5 °C/min, and a nitrogen flow rate of 50 mL/min, kept for 2 h, and then cooled to room temperature. The obtained carbon material was marked as KOH-ZC700.

1-1-3、向炭材料KOH-ZC700中加入20%的HNO3,先摇床震荡3h,摇床条件为温度25℃,速度150r/min,然后去除上清液,并用大量去离子水冲洗炭材料至中性,再置于烘箱内并在80℃条件下烘干,所得炭材料标记为GXC700,即为改性蓝藻生物炭。1-1-3. Add 20% HNO3 to the carbon material KOH-ZC700, shake it for 3 hours first, shake the temperature at 25°C and speed at 150r/min, then remove the supernatant and rinse with plenty of deionized water. The carbon material was neutralized, and then placed in an oven and dried at 80 °C, and the obtained carbon material was marked as GXC700, which was modified cyanobacterial biochar.

对改性蓝藻生物炭进行研究,如图3a所示为蓝藻700℃条件下热解,未经改性炭材料扫描电镜(SEM)图,图3b为蓝藻改性炭材料扫描电镜(SEM)图。如图4a为蓝藻700℃条件下热解,未经改性炭材料X射线衍射(XRD)图,图4b为蓝藻改性炭材料X射线衍射(XRD)图。可见蓝藻改性炭材料孔径得到显著提升,是具有高比表面积和丰富表面官能团的炭吸附材料。The modified cyanobacterial biochar was studied. Figure 3a shows the cyanobacteria pyrolysis at 700 °C, the scanning electron microscope (SEM) image of the unmodified carbon material, and Figure 3b is the scanning electron microscope (SEM) image of the cyanobacterial modified carbon material. . Figure 4a is the X-ray diffraction (XRD) pattern of the unmodified carbon material after pyrolysis of cyanobacteria at 700°C, and Figure 4b is the X-ray diffraction (XRD) pattern of the cyanobacteria modified carbon material. It can be seen that the pore size of the cyanobacterial modified carbon material has been significantly improved, and it is a carbon adsorption material with high specific surface area and abundant surface functional groups.

1-2、验证改性蓝藻生物炭对邻苯二甲酸二甲酯(DMP)的吸附效能,具体步骤如下:1-2. To verify the adsorption performance of modified cyanobacterial biochar on dimethyl phthalate (DMP), the specific steps are as follows:

1-2-1、称取改性蓝藻生物炭15mg,置于40ml带有PTFE材质玻璃离心管中,向管中加入30ml浓度为50mg/L的DMP溶液,溶液CaCl2浓度保持在0.1mol/L,在恒温振荡器内震荡120min,振荡器内温度设置为25℃,震荡速度为150r/min。1-2-1. Weigh 15mg of modified cyanobacterial biochar, put it in a 40ml glass centrifuge tube with PTFE material, add 30ml of DMP solution with a concentration of 50mg/L to the tube, and keep the CaCl2 concentration of the solution at 0.1mol/L , oscillate in a constant temperature oscillator for 120 min, the temperature in the oscillator is set to 25°C, and the oscillation speed is 150 r/min.

1-2-2、吸附结束后用0.45μmPTFE滤膜过滤,再用液相色谱检测反应后溶液中DMP浓度,通过计算得出该改性蓝藻生物炭对DMP的去除率为95.8%。1-2-2. After adsorption, filter with 0.45μm PTFE filter membrane, and then use liquid chromatography to detect the DMP concentration in the solution after the reaction. The removal rate of DMP by the modified cyanobacterial biochar is calculated to be 95.8%.

1-2-3、另设定不同反应时间,即恒温振荡时间分别设为60min、180min和240min,按照上述实验步骤和操作方法,待吸附结束后测定溶液中的DMP浓度,计算得出各组对应的DMP去除率分别为85.6%、97.2%和97.3%,结果如图1a所示。1-2-3. Separately set different reaction times, that is, the constant temperature oscillation time is set to 60min, 180min and 240min respectively. According to the above experimental steps and operation methods, after the adsorption is over, measure the DMP concentration in the solution, and calculate each group. The corresponding DMP removal rates were 85.6%, 97.2% and 97.3%, respectively, and the results are shown in Figure 1a.

1-2-4、另设定不同的投加量,即称取改性蓝藻生物炭的质量分别为20mg、30mg、40mg,按照上述方法步骤进行实验,待吸附结束后测定溶液中的DMP浓度,计算得出各组对应的DMP去除率分别为97.2%、99.4%、99.8%,结果如图1b所示。1-2-4. Separately set different dosages, namely, weigh the quality of modified cyanobacterial biochar as 20mg, 30mg and 40mg respectively, carry out the experiment according to the above method and steps, and measure the DMP concentration in the solution after the adsorption is over. , the DMP removal rates corresponding to each group were calculated to be 97.2%, 99.4%, and 99.8%, respectively, and the results are shown in Figure 1b.

由此可见,改性蓝藻生物炭的投加量为30mg、反应时间为180min的情况下为吸附最佳条件。It can be seen that the optimum conditions for adsorption are when the dosage of modified cyanobacterial biochar is 30 mg and the reaction time is 180 min.

实施例2:Example 2:

2-1、改性蓝藻生物炭的制备,具体步骤如下:2-1. Preparation of modified cyanobacterial biochar, the specific steps are as follows:

2-1-1、将收集的蓝藻置于冷冻干燥机冻干后,经粉碎机粉碎后过100目筛,放入管式炉炭化,升温速率为5℃/min,氮气流量为0.5L/min,温度由室温升至300℃,保持2h后,冷却至室温,所得炭材料标记为ZC300。2-1-1. Put the collected blue-green algae in a freeze-drying machine to freeze-dry, pass through a 100-mesh sieve after being pulverized by a pulverizer, and put them into a tube furnace for carbonization. The heating rate is 5°C/min, and the nitrogen flow rate is 0.5L/ min, the temperature was raised from room temperature to 300 °C, kept for 2 h, and then cooled to room temperature, and the obtained carbon material was marked as ZC300.

2-1-2、先将炭材料ZC300按照质量比1:3加入KOH混合均匀,加去离子水使KOH浓度在30%。将混合物置于80℃烘箱烘干,再置于管式炉中炭化,升温至700℃,保持3h,冷却至室温,所得炭材料标记为KOH-ZC700。2-1-2. First, add the carbon material ZC300 into KOH according to the mass ratio of 1:3 and mix evenly, then add deionized water to make the KOH concentration at 30%. The mixture was dried in an oven at 80 °C, then carbonized in a tube furnace, heated to 700 °C, kept for 3 h, and cooled to room temperature. The obtained carbon material was marked as KOH-ZC700.

2-1-3、将40%的HCl加入到上述冷却后的炭材料中,摇床震荡2h,摇床条件为温度30℃,速度200r/min。静置后去除上清液,将炭材料用大量去离子水冲洗至中性,再置于90℃烘箱内烘干,即为改性蓝藻生物炭。2-1-3. Add 40% HCl to the above-mentioned cooled carbon material, shake on a shaking table for 2 hours, and shake the shaking table at a temperature of 30° C. and a speed of 200 r/min. After standing, remove the supernatant, rinse the carbon material with a large amount of deionized water to neutrality, and then place it in an oven at 90 °C to dry, which is the modified cyanobacterial biochar.

上述制备方法制得的未经改性炭材料和改性蓝藻生物炭的扫描电镜(SEM)图及X射线衍射(XRD)图,如实施例1所示,均可见蓝藻改性炭材料孔径得到显著提升,是具有高比表面积和丰富表面官能团的炭吸附材料。The scanning electron microscope (SEM) diagram and X-ray diffraction (XRD) diagram of the unmodified carbon material and modified cyanobacterial biochar obtained by the above preparation method, as shown in Example 1, all show that the cyanobacterial modified carbon material has a pore size obtained. Significantly improved, it is a carbon adsorption material with high specific surface area and abundant surface functional groups.

2-2、验证改性蓝藻生物炭对邻苯二甲酸二甲酯(DMP)的吸附效能,具体步骤如下:2-2. To verify the adsorption performance of modified cyanobacterial biochar on dimethyl phthalate (DMP), the specific steps are as follows:

2-2-1、称取改性蓝藻生物炭15mg,置于40ml带有PTFE材质玻璃离心管中,加入30ml浓度为50mg/L的DMP溶液,溶液CaCl2浓度保持在0.1mol/L,在恒温振荡器内震荡120min,温度25℃,震荡速度150r/min。2-2-1. Weigh 15mg of modified cyanobacterial biochar, put it in a 40ml glass centrifuge tube with PTFE material, add 30ml of DMP solution with a concentration of 50mg/L, and keep the CaCl2 concentration of the solution at 0.1mol/L. Shake in the oscillator for 120min, the temperature is 25℃, and the shaking speed is 150r/min.

2-2-2、吸附结束后用0.45μmPTFE滤膜过滤,再用液相色谱检测反应后溶液中的DMP浓度,通过计算得出该改性蓝藻生物炭对DMP的去除率为95.4%。2-2-2. After adsorption, filter with 0.45μm PTFE filter membrane, and then use liquid chromatography to detect the DMP concentration in the solution after the reaction. It is calculated that the removal rate of DMP by the modified cyanobacterial biochar is 95.4%.

实施例3:Example 3:

3-1、改性蓝藻生物炭的制备,具体步骤如下:3-1. Preparation of modified cyanobacterial biochar, the specific steps are as follows:

3-1-1、将蓝藻收集后置于105℃烘箱内烘干,再用破碎机破碎后放入管式炉进行炭化处理,升温速率为5℃/min,氮气流量为80mL/min,加热温度从室温升至300℃,并保持1.5h,所得炭材料标记为ZC300。3-1-1. Collect the blue-green algae and place them in a 105°C oven to dry, then crush them with a crusher and put them into a tube furnace for carbonization treatment. The heating rate is 5°C/min, and the nitrogen flow rate is 80mL/min. The temperature was increased from room temperature to 300 °C and maintained for 1.5 h, and the obtained carbon material was marked as ZC300.

3-1-2、将冷却后的ZC300粉碎后过100目筛,按照质量比1:2.5加入KOH混合均匀,加去离子水使KOH浓度在30%,置于90℃烘箱烘干,再置于管式炉中炭化,升温至700℃,保持2.5h,冷却至室温,所得炭材料标记为KOH-ZC700。3-1-2. Pulverize the cooled ZC300 and pass it through a 100-mesh sieve, add KOH according to the mass ratio of 1:2.5 and mix evenly, add deionized water to make the

3-1-3、将30%的HNO3加入到上述冷却后的KOH-ZC700中,摇床震荡2.5h,摇床条件为温度27℃,转速180r/min。静置然后去除上清液,将炭材料用大量去离子水冲洗至中性,置于烘箱内并在85℃条件下烘干,即为改性蓝藻生物炭。3-1-3. Add 30% HNO3 to the above cooled KOH-ZC700, shake the shaker for 2.5h, and shake the shaker at a temperature of 27°C and a rotational speed of 180r/min. After standing, remove the supernatant, rinse the carbon material with a large amount of deionized water to neutrality, place it in an oven and dry it at 85°C, which is the modified cyanobacterial biochar.

上述制备方法制得的未经改性炭材料和改性蓝藻生物炭的扫描电镜(SEM)图及X射线衍射(XRD)图,如实施例1所示,均可见蓝藻改性炭材料孔径得到显著提升,是具有高比表面积和丰富表面官能团的炭吸附材料。The scanning electron microscope (SEM) diagram and X-ray diffraction (XRD) diagram of the unmodified carbon material and modified cyanobacterial biochar obtained by the above preparation method, as shown in Example 1, all show that the cyanobacterial modified carbon material has a pore size obtained. Significantly improved, it is a carbon adsorption material with high specific surface area and abundant surface functional groups.

3-2、通过实验验证炭材料对硝基苯酚(PNP)的吸附效能,具体步骤如下:3-2. The adsorption efficiency of the carbon material p-nitrophenol (PNP) is verified by experiments, and the specific steps are as follows:

3-2-1称取改性蓝藻生物炭15mg,置于40ml带有PTFE材质玻璃离心管中,加入30ml浓度为50mg/L的PNP溶液,溶液CaCl2浓度保持在0.1mol/L,在恒温振荡器内震荡120min,振荡器内温度设置为25℃,震荡速度150r/min。3-2-1 Weigh 15mg of modified cyanobacterial biochar, put it in a 40ml glass centrifuge tube with PTFE material, add 30ml of PNP solution with a concentration of 50mg/L, the solution CaCl2 concentration is kept at 0.1mol/L, shake at constant temperature The oscillator was oscillated for 120 min, the temperature in the oscillator was set to 25 °C, and the oscillation speed was 150 r/min.

3-2-2、吸附后用0.45μmPTFE滤膜过滤,用液相色谱检测反应后溶液中PNP浓度,通过计算,得出该改性蓝藻生物炭对PNP的去除率为95.4%。3-2-2. Filter with 0.45 μm PTFE filter membrane after adsorption, and detect the PNP concentration in the solution after the reaction by liquid chromatography. Through calculation, it is concluded that the removal rate of PNP by the modified cyanobacterial biochar is 95.4%.

3-2-3、另设定不同反应时间,即恒温振荡时间分别设为60min、180min和240min,按照上述实验步骤和操作方法,待吸附结束后测定溶液中的PNP浓度,计算得出各组对应的PNP去除率分别为80.5%、98.8%和98.2%,结果如图1a所示。3-2-3. Separately set different reaction times, that is, the constant temperature oscillation time is set to 60min, 180min and 240min respectively. According to the above-mentioned experimental steps and operation methods, the PNP concentration in the solution is measured after the adsorption is completed, and each group is calculated. The corresponding PNP removal rates were 80.5%, 98.8% and 98.2%, respectively, and the results are shown in Figure 1a.

3-2-4、另设定不同的投加量,即称取改性蓝藻生物炭的质量分别为20mg、30mg、40mg,按照上述方法步骤进行实验,待吸附结束后测定溶液中的PNP浓度,计算得出各组对应的PNP去除率分别为96.7%、98.8%、98.2%,结果如图1b所示。3-2-4. Set different dosages, namely, take the weights of the modified cyanobacterial biochar as 20mg, 30mg and 40mg respectively, carry out the experiment according to the above method and steps, and measure the PNP concentration in the solution after the adsorption is over. , the corresponding PNP removal rates for each group were calculated to be 96.7%, 98.8%, and 98.2%, respectively, and the results are shown in Figure 1b.

实施例4:Example 4:

4-1、制备改性蓝藻生物炭,具体步骤如下:4-1. To prepare modified cyanobacterial biochar, the specific steps are as follows:

4-1-1、蓝藻收集后冷冻干燥,再用破碎机破碎后放入管式炉炭化处理,室温升至300℃,保持2h,所得炭材料标记为ZC300。4-1-1. The cyanobacteria were collected and freeze-dried, then crushed with a crusher, and then put into a tube furnace for carbonization treatment. The room temperature was raised to 300 ° C and kept for 2 hours. The obtained carbon material was marked as ZC300.

4-1-2、将冷却后的ZC300通过粉碎机粉碎后过100目筛,加入KOH混合均匀,加去离子水使KOH浓度在35%,置于90℃烘箱烘干,再置于管式炉中炭化,升温至700℃,保持1.5h,冷却至室温,所得炭材料标记为KOH-ZC700。4-1-2. Pulverize the cooled ZC300 through a pulverizer and pass it through a 100-mesh sieve, add KOH and mix evenly, add deionized water to make the

4-1-3、将35%的HCl加入到上述冷却后的KOH-ZC700中,摇床震荡2h,摇床条件为28℃,190r/min,去除上清液,将炭材料用大量去离子水冲洗至中性,置于烘箱内并在75105℃条件下烘干,即为改性蓝藻生物炭。4-1-3. Add 35% HCl to the above cooled KOH-ZC700, shake on a shaker for 2 hours, shake at 28°C, 190r/min, remove the supernatant, and deionize the carbon material with a large amount of Rinse with water until neutral, place it in an oven and dry at 75105°C, that is, modified cyanobacterial biochar.

上述制备方法制得的未经改性炭材料和改性蓝藻生物炭的扫描电镜(SEM)图及X射线衍射(XRD)图,如实施例1所示,均可见蓝藻改性炭材料孔径得到显著提升,是具有高比表面积和丰富表面官能团的炭吸附材料。The scanning electron microscope (SEM) diagram and X-ray diffraction (XRD) diagram of the unmodified carbon material and modified cyanobacterial biochar obtained by the above preparation method, as shown in Example 1, all show that the cyanobacterial modified carbon material has a pore size obtained. Significantly improved, it is a carbon adsorption material with high specific surface area and abundant surface functional groups.

4-2、验证炭材料对PNP的吸附效能,具体步骤如下:4-2. To verify the adsorption efficiency of carbon materials on PNP, the specific steps are as follows:

4-2-1称取改性蓝藻生物炭15mg,置于40ml带有PTFE材质玻璃离心管中,加入30ml浓度为50mg/L的PNP溶液,溶液CaCl2浓度保持在0.1mol/L,在恒温振荡器内震荡120min,振荡器内温度设置为25℃,震荡速度150r/min。4-2-1 Weigh 15mg of modified cyanobacterial biochar, put it in a 40ml glass centrifuge tube with PTFE material, add 30ml of PNP solution with a concentration of 50mg/L, the solution CaCl2 concentration is kept at 0.1mol/L, shake at constant temperature The oscillator was oscillated for 120 min, the temperature in the oscillator was set to 25 °C, and the oscillation speed was 150 r/min.

4-2-2、吸附后用0.45μmPTFE滤膜过滤,用液相色谱检测反应后溶液中PNP浓度,通过计算,得出该改性蓝藻生物炭对PNP的去除率为94.5%。4-2-2. Filter with 0.45 μm PTFE filter membrane after adsorption, and detect the PNP concentration in the solution after the reaction by liquid chromatography. Through calculation, it is concluded that the removal rate of PNP by the modified cyanobacterial biochar is 94.5%.

此外,将实施例1-4所得的未改性炭材料和改性蓝藻生物炭进行研究,测试各组的比表面积及孔容积,并取平均值得到下表1,可知改性蓝藻生物炭材料特性相比于目前所报道材料具有更大的比表面积及孔隙率。In addition, the unmodified carbon materials and modified cyanobacteria biochar obtained in Examples 1-4 were studied, the specific surface area and pore volume of each group were tested, and the average value was obtained to obtain the following table 1. It can be seen that the modified cyanobacterial biochar material Compared with the currently reported materials, it has a larger specific surface area and porosity.

表1:实施例制备样品的平均比表面积及孔容积Table 1: Average specific surface area and pore volume of the samples prepared in the examples

综上可知,本发明改性蓝藻生物炭具有发达的孔隙结构和丰富的表面官能团,对有机物具有较好的去除效果,是一种理想的吸附剂。本发明的推广使用不仅可节约资源,而且有利于保护生态环境,最终达到治理污染、降低治污成本的目的。In conclusion, the modified cyanobacterial biochar of the present invention has a developed pore structure and abundant surface functional groups, has a good removal effect on organic matter, and is an ideal adsorbent. The popularization and use of the present invention can not only save resources, but also help to protect the ecological environment, and finally achieve the purpose of controlling pollution and reducing the cost of pollution control.

此外,应当理解,虽然本说明书按照实施方式加以描述,但并非每个实施方式仅包含一个独立的技术方案,说明书的这种叙述方式仅仅是为清楚起见,本领域技术人员应当将说明书作为一个整体,各实施例中的技术方案也可以经适当组合,形成本领域技术人员可以理解的其他实施方式。In addition, it should be understood that although this specification is described in terms of embodiments, not each embodiment only includes an independent technical solution, and this description in the specification is only for the sake of clarity, and those skilled in the art should take the specification as a whole , the technical solutions in each embodiment can also be appropriately combined to form other implementations that can be understood by those skilled in the art.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010900048.3ACN112058227A (en) | 2020-08-31 | 2020-08-31 | Preparation method and application of blue algae modified biochar with high adsorption efficiency |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010900048.3ACN112058227A (en) | 2020-08-31 | 2020-08-31 | Preparation method and application of blue algae modified biochar with high adsorption efficiency |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112058227Atrue CN112058227A (en) | 2020-12-11 |

Family

ID=73665300

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010900048.3APendingCN112058227A (en) | 2020-08-31 | 2020-08-31 | Preparation method and application of blue algae modified biochar with high adsorption efficiency |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112058227A (en) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113244883A (en)* | 2021-01-23 | 2021-08-13 | 中国环境科学研究院 | Preparation method and application of blue algae modified charcoal-loaded nano zero-valent iron material |

| CN114247426A (en)* | 2021-12-10 | 2022-03-29 | 有研资源环境技术研究院(北京)有限公司 | Biochar-loaded natural iron-containing mineral magnetic adsorbent and preparation method and application thereof |

| CN114477698A (en)* | 2022-02-11 | 2022-05-13 | 江南大学 | Application of ferric chloride mediated cyanobacteria-based biochar in removing zero-valent mercury in flue gas |

| CN114477691A (en)* | 2022-02-16 | 2022-05-13 | 江南大学 | Method for preparing functional blue algae biochar and applying functional blue algae biochar to strengthening anaerobic digestion |

| CN114560542A (en)* | 2022-02-28 | 2022-05-31 | 安徽工业大学 | A method for preparing in-situ iron-loaded biochar based on thermal cracking of algae-containing flocs by magnetic coagulation and its application |

| CN114797766A (en)* | 2022-03-14 | 2022-07-29 | 南京工业大学 | Porous biochar and preparation method and application thereof |

| CN114917870A (en)* | 2022-05-20 | 2022-08-19 | 江南大学 | Aluminum salt modified blue algae biochar and preparation method and application thereof |

| CN115350688A (en)* | 2022-05-12 | 2022-11-18 | 浙江科技学院 | Method for preparing biochar from blue algae |

| CN115477302A (en)* | 2022-09-29 | 2022-12-16 | 江西科技师范大学 | A kind of biochar and its preparation method and application |

| CN116474748A (en)* | 2023-05-12 | 2023-07-25 | 南昌航空大学 | Modified biochar and application thereof in cadmium and arsenic polluted soil |

| CN116673001A (en)* | 2023-05-04 | 2023-09-01 | 江南大学 | Blue algae biochar based on sodium silicate modification and application thereof in restoring soil Cd pollution and reducing greenhouse gas emission |

| CN118619414A (en)* | 2024-07-17 | 2024-09-10 | 重庆工商大学 | Application of microalgae carbon as particle electrode in flow electrode capacitive desalination |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103130297A (en)* | 2013-03-21 | 2013-06-05 | 中国环境科学研究院 | Method for treating mercury-containing wastewater by using modified blue-green algae |

| US20190022624A1 (en)* | 2016-02-23 | 2019-01-24 | Sony Corporation | Solidified porous carbon material and method of manufacturing the same |

| CN110272085A (en)* | 2019-07-30 | 2019-09-24 | 江南大学 | A kind of modified cyanobacteria biology carbon composite and the application in processing electroplating wastewater |

| CN110465262A (en)* | 2018-05-10 | 2019-11-19 | 天津大学(青岛)海洋工程研究院有限公司 | The method for removing heavy metal cadmium in water removal using the modified Enteromorpha charcoal of potassium hydroxide |

| CN110562977A (en)* | 2019-09-29 | 2019-12-13 | 上海应用技术大学 | Preparation method of biomass charcoal material with high specific surface area and toluene adsorption effect |

- 2020

- 2020-08-31CNCN202010900048.3Apatent/CN112058227A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103130297A (en)* | 2013-03-21 | 2013-06-05 | 中国环境科学研究院 | Method for treating mercury-containing wastewater by using modified blue-green algae |

| US20190022624A1 (en)* | 2016-02-23 | 2019-01-24 | Sony Corporation | Solidified porous carbon material and method of manufacturing the same |

| CN110465262A (en)* | 2018-05-10 | 2019-11-19 | 天津大学(青岛)海洋工程研究院有限公司 | The method for removing heavy metal cadmium in water removal using the modified Enteromorpha charcoal of potassium hydroxide |

| CN110272085A (en)* | 2019-07-30 | 2019-09-24 | 江南大学 | A kind of modified cyanobacteria biology carbon composite and the application in processing electroplating wastewater |

| CN110562977A (en)* | 2019-09-29 | 2019-12-13 | 上海应用技术大学 | Preparation method of biomass charcoal material with high specific surface area and toluene adsorption effect |

Non-Patent Citations (3)

| Title |

|---|

| ZHONGWEI TIAN ET AL.: "The direct carbonization of algae biomass to hierarchical porous carbons and CO2 adsorption properties", 《MATERIALS LETTERS》* |

| 薛智勇等: "《农业固体废物处理与处置》", 30 November 2016, 河南科学技术出版社* |

| 赵洁等: "酸碱改性对生物炭吸附Cr(Ⅵ)性能的影响", 《环境工程》* |

Cited By (15)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113244883A (en)* | 2021-01-23 | 2021-08-13 | 中国环境科学研究院 | Preparation method and application of blue algae modified charcoal-loaded nano zero-valent iron material |

| CN114247426A (en)* | 2021-12-10 | 2022-03-29 | 有研资源环境技术研究院(北京)有限公司 | Biochar-loaded natural iron-containing mineral magnetic adsorbent and preparation method and application thereof |

| CN114247426B (en)* | 2021-12-10 | 2024-02-20 | 有研资源环境技术研究院(北京)有限公司 | Biochar-loaded natural iron-containing mineral magnetic adsorbent and preparation method and application thereof |

| CN114477698B (en)* | 2022-02-11 | 2023-01-03 | 江南大学 | Application of ferric chloride mediated cyanobacteria-based biochar in removing zero-valent mercury in flue gas |

| CN114477698A (en)* | 2022-02-11 | 2022-05-13 | 江南大学 | Application of ferric chloride mediated cyanobacteria-based biochar in removing zero-valent mercury in flue gas |

| CN114477691A (en)* | 2022-02-16 | 2022-05-13 | 江南大学 | Method for preparing functional blue algae biochar and applying functional blue algae biochar to strengthening anaerobic digestion |

| CN114560542B (en)* | 2022-02-28 | 2023-03-14 | 安徽工业大学 | Method for preparing in-situ iron-loaded biochar based on thermal cracking of magnetic coagulation algae-containing flocs and application of method |

| CN114560542A (en)* | 2022-02-28 | 2022-05-31 | 安徽工业大学 | A method for preparing in-situ iron-loaded biochar based on thermal cracking of algae-containing flocs by magnetic coagulation and its application |

| CN114797766A (en)* | 2022-03-14 | 2022-07-29 | 南京工业大学 | Porous biochar and preparation method and application thereof |

| CN115350688A (en)* | 2022-05-12 | 2022-11-18 | 浙江科技学院 | Method for preparing biochar from blue algae |

| CN114917870A (en)* | 2022-05-20 | 2022-08-19 | 江南大学 | Aluminum salt modified blue algae biochar and preparation method and application thereof |

| CN115477302A (en)* | 2022-09-29 | 2022-12-16 | 江西科技师范大学 | A kind of biochar and its preparation method and application |

| CN116673001A (en)* | 2023-05-04 | 2023-09-01 | 江南大学 | Blue algae biochar based on sodium silicate modification and application thereof in restoring soil Cd pollution and reducing greenhouse gas emission |

| CN116474748A (en)* | 2023-05-12 | 2023-07-25 | 南昌航空大学 | Modified biochar and application thereof in cadmium and arsenic polluted soil |

| CN118619414A (en)* | 2024-07-17 | 2024-09-10 | 重庆工商大学 | Application of microalgae carbon as particle electrode in flow electrode capacitive desalination |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN112058227A (en) | Preparation method and application of blue algae modified biochar with high adsorption efficiency | |

| CN108927109B (en) | A kind of phosphogypsum modified biochar method and its application | |

| CN103316632B (en) | A kind of method of giantreed charcoal, preparation method and strengthening ammonia nitrogen absorption | |

| CN110142024A (en) | A method for preparing nitrogen-doped porous biochar from waste biomass and its application | |

| CN111468078B (en) | Reed stalk biochar composite material and its application in remediation of cadmium-contaminated soil | |

| CN113244883A (en) | Preparation method and application of blue algae modified charcoal-loaded nano zero-valent iron material | |

| US11235305B2 (en) | Malic acid and KMnO4-based combined and modified cow dung biogas residue hydrochar preparation method | |

| CN109621929B (en) | Regeneration method and application of waste activated carbon | |

| CN106008106A (en) | Sludge-based charcoal loessal soil conditioner and preparation method thereof | |

| CN104138745A (en) | Preparation method of biological carbon adsorbent for repairing organic pollution | |

| WO2021212672A1 (en) | Special pig manure charcoal modified by amino grafting, preparation method, and use thereof in farmland water-removing and nitrogen recycling | |

| CN114917874A (en) | Ferric salt modified blue algae biochar and preparation method and application thereof | |

| CN103657602B (en) | The purposes of biological adsorption agent, preparation method and removal methylene blue in waste dyestuff thereof | |

| CN107963628B (en) | Preparation of walnut shell activated carbon and method for adsorbing and recovering eluent in phenanthrene-polluted soil eluent by using walnut shell activated carbon | |

| CN110170300A (en) | A kind of preparation method of chicken feather modified honeycomb shape active carbon with high specific surface area adsorbent material | |

| CN115920840A (en) | Sludge-based activated carbon adsorbent and preparation method and application thereof | |

| CN106903151A (en) | The method that Composting repairing polluted soil is realized using stalk | |

| CN109928390A (en) | Heteroatom-modified distiller's grain-based activated carbon and preparation method thereof | |

| CN119215854A (en) | A method for preparing nano biochar using waste straw in two stages and its application | |

| CN104692380A (en) | Preparation method of Ageratina-adenophora-base high-specific-area activated carbon | |

| CN102924189B (en) | Method for recovering carbon-based ammonium bicarbonate in refuse landfill | |

| CN111495349A (en) | Modified biomass charcoal catalyst based on activated sludge and preparation method thereof | |

| CN113321255A (en) | Preparation method and application of manganese oxide-biochar composite solar interface evaporation material | |

| CN118580862A (en) | Preparation method and application of a soil heavy metal passivator for inhibiting microplastic activation | |

| CN105688806A (en) | Method for preparing mesoporous carbon from municipal sewage plant sludge in thermal activation mode and sludge-based mesoporous carbon material |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20201211 | |

| RJ01 | Rejection of invention patent application after publication |