CN112054466A - De-service lithium battery-based ice melting device and method - Google Patents

De-service lithium battery-based ice melting device and methodDownload PDFInfo

- Publication number

- CN112054466A CN112054466ACN202010891754.6ACN202010891754ACN112054466ACN 112054466 ACN112054466 ACN 112054466ACN 202010891754 ACN202010891754 ACN 202010891754ACN 112054466 ACN112054466 ACN 112054466A

- Authority

- CN

- China

- Prior art keywords

- ice

- melting

- wire

- lithium battery

- temperature

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000002844meltingMethods0.000titleclaimsabstractdescription182

- 230000008018meltingEffects0.000titleclaimsabstractdescription137

- WHXSMMKQMYFTQS-UHFFFAOYSA-NLithiumChemical compound[Li]WHXSMMKQMYFTQS-UHFFFAOYSA-N0.000titleclaimsabstractdescription87

- 229910052744lithiumInorganic materials0.000titleclaimsabstractdescription87

- 238000000034methodMethods0.000titleclaimsabstractdescription28

- 239000004020conductorSubstances0.000claimsdescription19

- 238000004364calculation methodMethods0.000claimsdescription11

- 230000005855radiationEffects0.000claimsdescription10

- XAGFODPZIPBFFR-UHFFFAOYSA-NaluminiumChemical compound[Al]XAGFODPZIPBFFR-UHFFFAOYSA-N0.000claimsdescription7

- 229910052782aluminiumInorganic materials0.000claimsdescription7

- 239000011248coating agentSubstances0.000claimsdescription5

- 238000000576coating methodMethods0.000claimsdescription5

- 238000010438heat treatmentMethods0.000claimsdescription5

- 229910000831SteelInorganic materials0.000claimsdescription4

- 239000010959steelSubstances0.000claimsdescription4

- RYGMFSIKBFXOCR-UHFFFAOYSA-NCopperChemical compound[Cu]RYGMFSIKBFXOCR-UHFFFAOYSA-N0.000claimsdescription3

- 229910052802copperInorganic materials0.000claimsdescription3

- 239000010949copperSubstances0.000claimsdescription3

- 230000005540biological transmissionEffects0.000abstractdescription16

- 230000008569processEffects0.000description9

- 238000010586diagramMethods0.000description8

- 230000008859changeEffects0.000description6

- 238000004146energy storageMethods0.000description5

- 238000010309melting processMethods0.000description5

- 239000000243solutionSubstances0.000description5

- 230000007423decreaseEffects0.000description4

- 230000000694effectsEffects0.000description4

- 238000005516engineering processMethods0.000description3

- 230000036541healthEffects0.000description3

- 238000006243chemical reactionMethods0.000description2

- 238000013461designMethods0.000description2

- 238000012938design processMethods0.000description2

- 238000011161developmentMethods0.000description2

- 230000018109developmental processEffects0.000description2

- 238000009434installationMethods0.000description2

- 238000012423maintenanceMethods0.000description2

- 238000012986modificationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 125000006850spacer groupChemical group0.000description2

- 238000012360testing methodMethods0.000description2

- 238000009834vaporizationMethods0.000description2

- 230000008016vaporizationEffects0.000description2

- 230000032683agingEffects0.000description1

- 238000004458analytical methodMethods0.000description1

- 230000002238attenuated effectEffects0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000015556catabolic processEffects0.000description1

- 150000001868cobaltChemical class0.000description1

- 238000010276constructionMethods0.000description1

- 238000006731degradation reactionMethods0.000description1

- 230000002500effect on skinEffects0.000description1

- 238000009429electrical wiringMethods0.000description1

- 239000007772electrode materialSubstances0.000description1

- 239000003792electrolyteSubstances0.000description1

- 230000008030eliminationEffects0.000description1

- 238000003379elimination reactionMethods0.000description1

- 238000001704evaporationMethods0.000description1

- 230000008020evaporationEffects0.000description1

- 230000003862health statusEffects0.000description1

- 238000002347injectionMethods0.000description1

- 239000007924injectionSubstances0.000description1

- 238000009413insulationMethods0.000description1

- 230000016507interphaseEffects0.000description1

- 238000002955isolationMethods0.000description1

- 230000007774longtermEffects0.000description1

- 150000002696manganeseChemical class0.000description1

- 238000012544monitoring processMethods0.000description1

- 239000007773negative electrode materialSubstances0.000description1

- 150000002815nickelChemical class0.000description1

- 239000002245particleSubstances0.000description1

- 230000010287polarizationEffects0.000description1

- 239000007774positive electrode materialSubstances0.000description1

- 238000012545processingMethods0.000description1

- 230000006798recombinationEffects0.000description1

- 238000005215recombinationMethods0.000description1

- 238000004064recyclingMethods0.000description1

- 238000004088simulationMethods0.000description1

- 239000007784solid electrolyteSubstances0.000description1

- 238000012546transferMethods0.000description1

- 230000001052transient effectEffects0.000description1

- 230000007704transitionEffects0.000description1

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description1

Images

Classifications

- H—ELECTRICITY

- H02—GENERATION; CONVERSION OR DISTRIBUTION OF ELECTRIC POWER

- H02G—INSTALLATION OF ELECTRIC CABLES OR LINES, OR OF COMBINED OPTICAL AND ELECTRIC CABLES OR LINES

- H02G7/00—Overhead installations of electric lines or cables

- H02G7/16—Devices for removing snow or ice from lines or cables

Landscapes

- Charge And Discharge Circuits For Batteries Or The Like (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种基于退役锂电池的融冰装置及方法,属于电网架空线路维护技术领域。The invention relates to an ice melting device and method based on a retired lithium battery, and belongs to the technical field of power grid overhead line maintenance.

背景技术Background technique

近些年工业活动高速发展加剧极端气候变化,2008年初,我国南方地区遭受了严重冰雪灾害,输电线路覆冰故障对救灾工作和人民群众生活都产生了严重的影响。我国幅员辽阔,冬、春两季东北地区及南方山林地区夜间气温极低、空气湿度大容易造成输电线路覆冰。冬季低温环境下,电网导线覆冰后使输电线路重量、弧垂增加,可能导致断线、倒塔和架空线舞动等事故;导线的绝缘子在覆冰后绝缘强度下降,易导致闪络事故发生;若不及时利用融冰装置融冰,在环境温度升高时冰层脱落滑动易造成架空线外层磨损、钢芯移动等问题。随着我国电气化铁路建设及超、特高压远距离输电高速发展,现代电网若因覆冰引起电网故障,将导致长时间停电,从而对交通运输、国民经济造成重大损失。In recent years, the rapid development of industrial activities has exacerbated extreme climate change. In early 2008, the southern region of my country suffered from severe ice and snow disasters. The ice-covered failure of transmission lines had a serious impact on disaster relief work and people's lives. my country has a vast territory. In winter and spring, the nighttime temperatures in the Northeast and the southern mountain forests are extremely low, and the air humidity is high, which may easily cause transmission lines to be covered with ice. Under the low temperature environment in winter, the weight and sag of the transmission line will increase after the power grid wire is covered with ice, which may lead to accidents such as disconnection, tower collapse and overhead line galloping. ; If the ice melting device is not used to melt the ice in time, the ice layer will fall off and slide when the ambient temperature rises, which will easily cause problems such as wear of the outer layer of the overhead line and movement of the steel core. With the construction of electrified railways and the rapid development of ultra-high voltage long-distance power transmission in China, if the modern power grid fails due to icing, it will lead to long-term power outages, which will cause heavy losses to transportation and the national economy.

根据现有的融冰技术水平来看,交流短路融冰法与直流电源融冰法是面向大型电网较为可靠的两种方法。交流短路融冰模式需将变压器低压侧接入融冰电路,在现场实际操作时需拆除母线PT柜、避雷器,同时在应对不同距离覆冰线路时,需另外施加变频设备,电路较为复杂。交流融冰法在应对220kV以上的交流线路和直流输电线路融冰时,效果不明显,对系统冲击较大,可能引起电网运行不稳定。According to the current level of ice melting technology, the AC short-circuit ice melting method and the DC power ice melting method are two more reliable methods for large-scale power grids. In the AC short-circuit ice-melting mode, the low-voltage side of the transformer needs to be connected to the ice-melting circuit. During the actual operation on site, the busbar PT cabinet and arrester need to be removed. At the same time, when dealing with ice-covered lines at different distances, additional frequency conversion equipment needs to be applied, and the circuit is more complicated. When the AC ice melting method is used to deal with the ice melting of AC lines and DC transmission lines above 220kV, the effect is not obvious, and the impact on the system is relatively large, which may cause unstable operation of the power grid.

目前利用直流电流对架空线路融冰时,需依托VSC设备,在母线上对交流电先整流再升压以提供注入电压。此融冰方案设备投资大,不仅需要对系统进行无功补偿,而且需要消除VSC等装置工作过程中产生的谐波。At present, when using DC current to melt ice on overhead lines, it is necessary to rely on VSC equipment to rectify the AC current on the busbar and then boost it to provide the injection voltage. The equipment investment of this ice melting solution is large, which not only needs to perform reactive power compensation for the system, but also needs to eliminate the harmonics generated during the operation of the VSC and other devices.

110kV及以上系统的电气主接线采用双母线接线方式,以提高用户的供电可靠性,并配置旁路母线,用于在出线断路器发生故障进行检修时,以旁路断路器代替出线断路器,经由旁路母线为负荷供电。传统VSC融冰设备为实现不停电融冰,对覆冰段进行融冰操作,将旁路兼母联断路器闭合,利用旁路母线保证系统正常供电,通过刀闸操作实现不停电融冰。The main electrical wiring of 110kV and above systems adopts double-bus connection to improve the reliability of power supply for users, and a bypass bus is configured to replace the outgoing circuit breaker with a bypass circuit breaker when the outgoing circuit breaker fails for maintenance. The load is supplied via the bypass bus. In order to realize non-stop ice melting, traditional VSC ice melting equipment performs ice melting operation on the icing section, closes the bypass and bus tie breaker, uses the bypass bus to ensure the normal power supply of the system, and realizes non-stop ice melting through knife switch operation.

当采用直流融冰模式时,在母线出口处加装整流装置,将220kV交流电整流为符合线路要求的直流电,来进行热力融冰。对覆冰实现不停电融冰操作,将母联隔离开关三相分闸,旁路母线保证系统正常供电,通过刀闸操作实现不停电融冰。现有不停电直流融冰方案有以下缺点:(1)需要在变电所母线出口处加装VSC整流设备,设备价格昂贵并且维护困难;(2)整流设备工作时,其中使用了大量电力电子器件,会产生大量谐波,影响供电质量;(3)具体操作时,需进行频繁的刀闸操作When the DC ice melting mode is adopted, a rectifier device is installed at the bus outlet to rectify the 220kV alternating current into a direct current that meets the line requirements for thermal ice melting. To realize non-stop ice melting operation for icing, the three-phase disconnection switch of the bus tie is opened, and the bypass busbar ensures the normal power supply of the system, and the non-stop ice melting is realized through the operation of the knife switch. The existing uninterrupted DC ice melting solution has the following disadvantages: (1) VSC rectifier equipment needs to be installed at the busbar outlet of the substation, which is expensive and difficult to maintain; (2) When the rectifier equipment works, a large amount of power electronics is used. The device will generate a lot of harmonics and affect the power supply quality; (3) During the specific operation, frequent knife switch operations are required.

新能源电动汽车中的锂电池储能容量衰减到初始容量80%以下时,新能源汽车电动机效率和续航里程明显下降,面临更换淘汰,但是锂电池储能容量仍有很大的利用价值。现有针对退役锂电池梯次利用主要应用在规模集成储能方面,需要施加复杂的BMS系统,对锂电池进行状态监测;很少将退役锂电池应用在高压线路及输电线路融冰方面。When the energy storage capacity of lithium batteries in new energy electric vehicles decays to less than 80% of the initial capacity, the motor efficiency and cruising range of new energy vehicles will drop significantly, and they will face replacement and elimination. However, the energy storage capacity of lithium batteries still has great utilization value. The existing cascade utilization of retired lithium batteries is mainly used in large-scale integrated energy storage, and a complex BMS system needs to be applied to monitor the status of lithium batteries; retired lithium batteries are rarely used in high-voltage lines and transmission lines.

发明内容SUMMARY OF THE INVENTION

针对以上方法存在的不足,本发明提出了一种基于退役锂电池的融冰装置及方法,其能够将退役锂电池梯次利用与直流融冰技术相结合,在规定时间内完成融冰工作,极大地节约融冰成本。In view of the shortcomings of the above methods, the present invention proposes an ice melting device and method based on decommissioned lithium batteries, which can combine the cascade utilization of decommissioned lithium batteries with the DC ice melting technology, and complete the ice melting work within a specified time. Great savings in ice melting costs.

本发明解决其技术问题采取的技术方案是:The technical scheme adopted by the present invention to solve its technical problems is:

一方面,本发明实施例提供的一种基于退役锂电池的融冰装置,包括退役锂电池、分裂导线、短路棒和温控开关,通过分裂导线的两条子导线将退役锂电池、短路棒和待融冰线路构成直流融冰回路,所述温控开关设置在退役锂电池正极一端的直流融冰回路中。On the one hand, an ice melting device based on a decommissioned lithium battery provided by an embodiment of the present invention includes a decommissioned lithium battery, a split wire, a shorting bar and a temperature control switch, and the decommissioned lithium battery, the shorting bar and the The ice melting circuit to be melted constitutes a DC ice melting circuit, and the temperature control switch is arranged in the DC ice melting circuit at the positive end of the decommissioned lithium battery.

作为本实施例一种可能的实现方式,所述待融冰线路的两端分别串联一个短路棒后与分裂导线的两条子导线连接。As a possible implementation manner of this embodiment, two ends of the line to be melted ice are respectively connected in series with a shorting bar and then connected to the two sub-conductors of the split lead.

作为本实施例一种可能的实现方式,所述短路棒采用紫铜材质短路棒。As a possible implementation manner of this embodiment, the shorting bar is made of red copper.

作为本实施例一种可能的实现方式,所述分裂导线的两条子导线长度相同。As a possible implementation manner of this embodiment, the lengths of the two sub-conductors of the split wire are the same.

另一方面,本发明实施例提供的一种基于退役锂电池的融冰方法,包括以下步骤:On the other hand, an ice melting method based on a retired lithium battery provided by an embodiment of the present invention includes the following steps:

通过分裂导线的两条子导线将退役锂电池、2个短路棒和待融冰线路构成直流融冰回路,在直流融冰回路中设置温控开关;The decommissioned lithium battery, two shorting bars and the line to be melted ice form a DC ice melting circuit through the two sub-wires of the split wire, and a temperature control switch is set in the DC ice melting circuit;

计算融冰电流,闭合温控开关对覆冰线路进行热力融冰,冰层脱落后断开温控开关;Calculate the ice melting current, close the temperature control switch to thermally melt the ice coating line, and disconnect the temperature control switch after the ice layer falls off;

计算保线电流,且气温低于保线电流工作设定温度时自动闭合温控开关。Calculate the line protection current, and automatically close the temperature control switch when the air temperature is lower than the set temperature of the line protection current.

作为本实施例一种可能的实现方式,将短路棒设置在待融冰线路的两端且与分裂导线的两条子导线连接,分裂导线的两条子导线长度相同。As a possible implementation manner of this embodiment, the shorting bars are arranged at both ends of the line to be melted and connected to two sub-conductors of the split conductor, and the two sub-conductors of the split conductor have the same length.

作为本实施例一种可能的实现方式,所述温控开关设置在退役锂电池正极一端的直流融冰回路中。As a possible implementation manner of this embodiment, the temperature control switch is arranged in the DC ice melting circuit at the positive end of the retired lithium battery.

作为本实施例一种可能的实现方式,所述融冰电流的计算公式为:As a possible implementation manner of this embodiment, the calculation formula of the ice melting current is:

其中,ρice为冰的密度,取0.9g/cm3;r为架空线半径,l为导线内芯到冰层外部的距离,(l-r)为覆冰冰筒的厚度(mm);RT0为等效冰层传导热阻(℃·cm/W),RT1为对流及辐射等效热阻(℃·cm/W);ΔT为加热后的导线温度与环境温度差,Tmax为线路融冰时最高温度;ε为导线热阻膨胀系数,LGJ-300/40型取(19.6×10-6/℃);R0为0℃时单位长度架空线电阻(Ω/m)。Among them, ρice is the density of ice, which is taken as 0.9g/cm3 ; r is the radius of the overhead wire, l is the distance from the inner core of the wire to the outside of the ice layer, (lr) is the thickness of the ice-covered ice cylinder (mm); RT0 is Equivalent ice conduction thermal resistance (℃·cm/W), RT1 is the equivalent thermal resistance of convection and radiation (℃·cm/W); ΔT is the difference between the temperature of the wire after heating and the ambient temperature, and Tmax is the melting point of the line. The maximum temperature when ice is present; ε is the thermal resistance expansion coefficient of the wire, which is taken from the LGJ-300/40 type (19.6×10-6 /°C); R0 is the overhead wire resistance per unit length at 0°C (Ω/m).

作为本实施例一种可能的实现方式,所述对覆冰线路进行热力融冰时间的计算公式为:As a possible implementation manner of this embodiment, the calculation formula of the thermal ice-melting time for the ice-covered line is:

其中,ρice为冰的密度,取0.9g/cm3;r为架空线半径,l为导线内芯到冰层外部的距离,(l-r)为覆冰冰筒的厚度(mm);RT0为等效冰层传导热阻(℃·cm/W),RT1为对流及辐射等效热阻(℃·cm/W);ΔT为加热后的导线温度与环境温度差,Tmax为线路融冰时最高温度;ε为导线热阻膨胀系数,LGJ-300/40型取(19.6×10-6/℃);R0为0℃时单位长度架空线电阻(Ω/m)。Among them, ρice is the density of ice, which is taken as 0.9g/cm3 ; r is the radius of the overhead wire, l is the distance from the inner core of the wire to the outside of the ice layer, (lr) is the thickness of the ice-covered ice cylinder (mm); RT0 is Equivalent ice conduction thermal resistance (℃·cm/W), RT1 is the equivalent thermal resistance of convection and radiation (℃·cm/W); ΔT is the difference between the temperature of the wire after heating and the ambient temperature, and Tmax is the melting point of the line. The maximum temperature when ice is present; ε is the thermal resistance expansion coefficient of the wire, which is taken from the LGJ-300/40 type (19.6×10-6 /°C); R0 is the overhead wire resistance per unit length at 0°C (Ω/m).

作为本实施例一种可能的实现方式,所述保线电流的计算公式为:As a possible implementation manner of this embodiment, the calculation formula of the line protection current is:

式中,ΔT′为环境温度与0℃的温差;K为冰的熔化热(单位质量冰在融化时需要吸收的热量),K=3.35×10-5J/kg;ct为钢芯铝绞线的比热容;ρt为钢芯铝绞线密度;tp为保线电流工作时间。In the formula, ΔT' is the temperature difference between the ambient temperature and 0°C; K is the melting heat of ice (the heat that a unit mass of ice needs to absorb when melting), K=3.35×10-5 J/kg; ct is the steel core aluminum The specific heat capacity of the stranded wire; ρt is the density of the steel-cored aluminum stranded wire; tp is the working time of the wire protection current.

本发明实施例的技术方案可以具有的有益效果如下:The beneficial effects that the technical solutions of the embodiments of the present invention can have are as follows:

本发明根据退役锂电池低成本特点,在考虑退役锂电池低温环境下输出效率基础上,将退役电池梯次利用重组为直流电源;确定与实际工况相适应的短距离间隔设置的方案,以保障融冰装置融冰效率。According to the low-cost characteristics of the retired lithium battery, the invention reorganizes the retired battery into a DC power supply in cascade on the basis of considering the output efficiency of the retired lithium battery under the low temperature environment; Ice melting device melting efficiency.

针对退役锂电池梯次利用,本发明将退役锂电池二次利用于高压输电线路融冰工作中,不仅能够在规定时间内完成融冰工作,而且可以极大地节约融冰成本。当高压输电线路采用分裂导线形式时,可利用短路间隔棒构成融冰回路进行融冰工作,且直流融冰电流不会流出该回路。在设计直流融冰参数时,考虑研究退役锂电池低温输出特性的基础上及电池衰退的因素的影响,改进融冰参数计算公式;根据不停电融冰接线模式,进行融冰电流观测及架空线环境温度场模拟试验,证明设计的融冰电源效率符合设计要求。本发明利用退役锂电池作为融冰电源,可以解决锂电池大量退役后梯次利用问题,实现退役锂电池在电网中的二次利用。For the cascade utilization of the retired lithium battery, the present invention utilizes the retired lithium battery twice in the ice melting work of the high-voltage transmission line, which can not only complete the ice melting work within a specified time, but also greatly save the ice melting cost. When the high-voltage transmission line adopts the form of split conductors, a short-circuit spacer can be used to form an ice-melting circuit for ice-melting work, and the DC ice-melting current will not flow out of the circuit. When designing the DC ice-melting parameters, considering the low-temperature output characteristics of decommissioned lithium batteries and the influence of factors of battery degradation, the calculation formula of the ice-melting parameters is improved; The simulation test of the ambient temperature field proves that the designed efficiency of the ice-melting power supply meets the design requirements. The invention utilizes the retired lithium battery as the ice melting power source, can solve the problem of cascade utilization after a large number of lithium batteries are retired, and realize the secondary utilization of the retired lithium battery in the power grid.

附图说明:Description of drawings:

图1是根据一示例性实施例示出的一种基于退役锂电池的融冰装置示意图图;FIG. 1 is a schematic diagram of an ice melting device based on a retired lithium battery according to an exemplary embodiment;

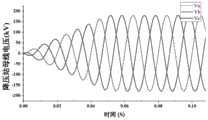

图2是一种融冰过程中三相电流波形示意图;Fig. 2 is a kind of schematic diagram of three-phase current waveform in the process of melting ice;

图3是一种融冰过程升压站母线电压示意图;Figure 3 is a schematic diagram of the bus voltage of a booster station in a melting ice process;

图4是一种融冰过程降压站母线电压示意图;Figure 4 is a schematic diagram of the busbar voltage of a step-down station during the ice melting process;

图5是一种融冰过程中架空线路温度分布图;Fig. 5 is a kind of temperature distribution diagram of overhead line in the process of melting ice;

图6是一种退役锂电池低温环境下开路电压随时间变化示意图;Fig. 6 is a schematic diagram of the change of open circuit voltage with time in a low temperature environment of a retired lithium battery;

图7是一种退役锂电池低温环境下SOH变化示意图。Figure 7 is a schematic diagram of SOH changes in a decommissioned lithium battery in a low temperature environment.

具体实施方式Detailed ways

下面结合附图与实施例对本发明做进一步说明:Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

为能清楚说明本方案的技术特点,下面通过具体实施方式,并结合其附图,对本发明进行详细阐述。下文的公开提供了许多不同的实施例或例子用来实现本发明的不同结构。为了简化本发明的公开,下文中对特定例子的部件和设置进行描述。此外,本发明可以在不同例子中重复参考数字和/或字母。这种重复是为了简化和清楚的目的,其本身不指示所讨论各种实施例和/或设置之间的关系。应当注意,在附图中所图示的部件不一定按比例绘制。本发明省略了对公知组件和处理技术及工艺的描述以避免不必要地限制本发明。In order to clearly illustrate the technical features of the solution, the present invention will be described in detail below through specific embodiments and in conjunction with the accompanying drawings. The following disclosure provides many different embodiments or examples for implementing different structures of the invention. In order to simplify the disclosure of the present invention, the components and arrangements of specific examples are described below. Furthermore, the present invention may repeat reference numerals and/or letters in different instances. This repetition is for the purpose of simplicity and clarity and does not in itself indicate a relationship between the various embodiments and/or arrangements discussed. It should be noted that the components illustrated in the figures are not necessarily drawn to scale. Descriptions of well-known components and processing techniques and processes are omitted from the present invention to avoid unnecessarily limiting the present invention.

图1是根据一示例性实施例示出的一种基于退役锂电池的融冰装置示意图图。如图2所示,本发明实施例提供的一种基于退役锂电池的融冰装置,包括退役锂电池、分裂导线、短路棒和温控开关,通过分裂导线的两条子导线将退役锂电池、短路棒和待融冰线路构成直流融冰回路,所述温控开关设置在退役锂电池正极一端的直流融冰回路中。FIG. 1 is a schematic diagram of an ice melting device based on a retired lithium battery according to an exemplary embodiment. As shown in FIG. 2 , an ice melting device based on a retired lithium battery provided by an embodiment of the present invention includes a retired lithium battery, a split wire, a shorting bar, and a temperature control switch. The shorting bar and the line to be melted constitute a DC ice melting circuit, and the temperature control switch is arranged in the DC ice melting circuit at the positive end of the decommissioned lithium battery.

针对新能源汽车中锂电池大量退役,难以实现有效的梯次利用,本发明将退役锂电池二次利用与直流融冰技术相结合,应用于高压架空线路融冰工作中。针对南方地区、东北地区及山林地区易发生输电线路覆冰现象,考虑直流融冰装置成本和电池储能单元输出功率、容量,结合新能源汽车中大量锂电池退役可进行梯次利用,提出了一种利用退役锂电池储能的融冰装置。Aiming at the large number of retired lithium batteries in new energy vehicles, it is difficult to achieve effective cascade utilization, the invention combines the secondary utilization of retired lithium batteries with the DC ice melting technology, and is applied to the ice melting work of high-voltage overhead lines. In view of the transmission line icing phenomenon that is prone to occur in the southern region, the northeastern region and the mountain forest region, considering the cost of the DC ice melting device and the output power and capacity of the battery energy storage unit, combined with the retirement of a large number of lithium batteries in new energy vehicles, it can be used for cascade utilization. An ice melting device that utilizes decommissioned lithium batteries for energy storage.

本发明基于退役锂电池二次利用的直流融冰电源的设计过程如下。The design process of the DC ice melting power source based on the secondary utilization of the retired lithium battery in the present invention is as follows.

1、融冰参数计算:1. Calculation of melting ice parameters:

(1)融冰电流(1) Ice melting current

根据国家电网《输电线路电流融冰技术导则》,采用直流融冰电源工作模式下要以“融、抗结合”为原则,融冰设备需要具备两种功能,即提供保线电流和融冰电流。在计算融冰电流时,环境温度选取应该按当地平均最低气温考虑。架空线热辐射范围内的环境或线路温度持续高于0℃时,线路覆冰将被融化而脱冰。为提升融冰效率,按技术导则规定,设定最大融冰电流,避免温度过高造成钢芯铝绞线膨胀形变,产生永久性损坏,因此计算时应考虑架空线温度限制(70~90℃)和架空线路热膨胀系数。利用能量守恒定律,考虑热辐射损失、导线黑度(导线对外热辐射)及架空线路热膨胀系数,可以得到融冰电流的计算公式,如式(1)所示。According to the "Technical Guidelines for Current Ice Melting of Transmission Lines" of the State Grid, the principle of "melting and anti-combination" should be adopted in the working mode of DC ice melting power supply. current. When calculating the melting ice current, the selection of ambient temperature should be considered according to the local average minimum air temperature. When the ambient or line temperature within the thermal radiation range of the overhead line is continuously higher than 0°C, the line icing will be melted and de-iced. In order to improve the ice melting efficiency, according to the technical guidelines, the maximum ice melting current is set to avoid the expansion and deformation of the steel-cored aluminum stranded wire caused by excessive temperature, resulting in permanent damage. Therefore, the temperature limit of the overhead line (70 ~ 90 °C) and the thermal expansion coefficient of overhead lines. Using the law of conservation of energy, considering the heat radiation loss, the blackness of the wire (the external heat radiation of the wire) and the thermal expansion coefficient of the overhead line, the calculation formula of the ice melting current can be obtained, as shown in formula (1).

其中,ρice为冰的密度,取0.9g/cm3;r为架空线半径,l为导线内芯到冰层外部的距离,(l-r)为覆冰冰筒的厚度(mm);RT0为等效冰层传导热阻(℃·cm/W),RT1为对流及辐射等效热阻(℃·cm/W);ΔT为加热后的导线温度与环境温度差,Tmax为线路融冰时最高温度;ε为导线热阻膨胀系数,LGJ-300/40型取(19.6×10-6/℃)。R0为0℃时单位长度架空线电阻(Ω/m)。Among them, ρice is the density of ice, which is taken as 0.9g/cm3 ; r is the radius of the overhead wire, l is the distance from the inner core of the wire to the outside of the ice layer, (lr) is the thickness of the ice-covered ice cylinder (mm); RT0 is Equivalent ice conduction thermal resistance (℃·cm/W), RT1 is the equivalent thermal resistance of convection and radiation (℃·cm/W); ΔT is the difference between the temperature of the wire after heating and the ambient temperature, and Tmax is the melting point of the line. The maximum temperature when ice is present; ε is the thermal resistance expansion coefficient of the wire, which is taken from the LGJ-300/40 type (19.6×10-6 /℃). R0 is the overhead wire resistance per unit length (Ω/m) at 0°C.

(2)融冰时间:(2) Melting time:

融冰时间计算公式能够充分体现架空线路融冰的两个过程:一是架空线路温升至0℃,到达临界融冰点;二是架空线路持续加热,覆冰层开始吸热融化。输电线路融冰过程是一个变参数暂态温度场问题,温度随空间和时间变化的关系复杂,将传统融冰细化为线路温升和焦耳热辐射融冰这两个阶段,可以得到考虑等效冰层传导、架空线对外热辐射损失下的融冰时间计算公式(2)。The calculation formula of ice melting time can fully reflect the two processes of ice melting of the overhead line: one is that the temperature of the overhead line rises to 0°C and reaches the critical melting point; The ice melting process of transmission lines is a transient temperature field problem with variable parameters. The relationship between temperature changes with space and time is complex. The traditional ice melting is refined into two stages: line temperature rise and Joule heat radiation ice melting, which can be considered, etc. Calculation formula (2) of ice melting time under effective ice layer conduction and external heat radiation loss from overhead lines.

(3)保线电流:(3) Line protection current:

直流融冰设备需具备“融、抗结合”功能,抵抗冰雪灾害天气,提供保线电流为保护线路在极端天气下不发生覆冰现象的最小电流,保线电流通过导线产生热量与需消耗热量平衡,计算公式(3)所示。保线温度一般设计为0℃以上(一般取2℃)。The DC ice melting equipment needs to have the function of "melting and anti-combination" to resist the weather of ice and snow disaster, and to provide the line protection current as the minimum current to protect the line from icing in extreme weather. The line protection current generates heat and consumes heat through the wire. balance, as shown in formula (3). The wire protection temperature is generally designed to be above 0°C (generally 2°C).

式中,ΔT′为环境温度与0℃的温差;K为冰的熔化热(单位质量冰在融化时需要吸收的热量),K=3.35×10-5J/kg;ct为钢芯铝绞线的比热容;ρt为钢芯铝绞线密度;tp为保线电流工作时间。In the formula, ΔT' is the temperature difference between the ambient temperature and 0°C; K is the melting heat of ice (the heat that a unit mass of ice needs to absorb when melting), K=3.35×10-5 J/kg; ct is the steel core aluminum The specific heat capacity of the stranded wire; ρt is the density of the steel-cored aluminum stranded wire; tp is the working time of the wire protection current.

2、融冰电源设计:2. Design of ice melting power supply:

无论是交流融冰,还是直流融冰模式,当融冰线路过长时,融冰时所需电压过高、变压器容量过大。采用退役锂电池的直流融冰电源,价格低廉、经济,适用于短距离、多间隔融冰模式。Whether it is AC ice melting or DC ice melting mode, when the ice melting line is too long, the voltage required for ice melting is too high and the transformer capacity is too large. The DC ice-melting power supply using retired lithium batteries is inexpensive and economical, and is suitable for short-distance, multi-interval ice-melting mode.

结合融冰段地理环境及历史气象数据,考虑退役锂电池容量特性(退役时容量为初始容量80%),考虑随使用时间增长和融冰时进行的倍率放电会加速锂电池内部极化反应和容量衰减,因此在设定融冰电源容量时应留有一定裕度。根据表1参考LGJ-300/40型号导线融冰时间、融冰电流幅值及对应架空线长度下融冰电源容量。本发明以5km二分裂覆冰架空线路(0.09211Ω/km)、融冰电源输出1kA直流为例,考虑锂电池容量衰退,设定20%容量裕度,退役锂电池直流融冰电源容量约为1.15MW。Combined with the geographical environment and historical meteorological data of the melting ice section, considering the capacity characteristics of the retired lithium battery (the capacity at the time of retirement is 80% of the initial capacity), considering that the rate discharge with the increase of use time and the melting ice will accelerate the internal polarization reaction of the lithium battery and The capacity decays, so a certain margin should be reserved when setting the capacity of the ice melting power supply. Refer to Table 1 for reference to LGJ-300/40 type wire ice melting time, ice melting current amplitude and ice melting power supply capacity corresponding to the length of the overhead line. The invention takes 5km two-split ice-covered overhead line (0.09211Ω/km) and the ice melting power output 1kA DC as an example. Considering the capacity decline of lithium battery, a 20% capacity margin is set, and the capacity of the retired lithium battery DC ice melting power supply is about 1.15MW.

表1 LGJ-300/40型架空线融冰参数Table 1 Ice melting parameters of LGJ-300/40 overhead line

以18650型号电池为例,退役锂电池重组为1.2WM融冰电源。因为不同品牌新能源汽车中采用的18650型三元锂电池标准容量各不相同,平均容量约为3000mAh,平均质量约为40~50g;考虑锂电池退役条件为初始容量的75~80%,按衰减到SOH=75%计算,需要12500节18650电池,按照电池衰减设置20%裕量,设计36组电池组、每350节为一组;直流融冰电源中退役锂电池质量约为1600kg。电池组交叉紧密排列方式,单个锂电池组尺寸为10×(180×70×51mm),电池所占体积为0.237762m3,考虑到保护所用的隔离开关及电池管理系统(Battery Management System,BMS)所占空间,组成电源大小约为0.3m3。Taking the 18650 battery as an example, the retired lithium battery is reorganized into a 1.2WM ice melting power supply. Because the standard capacity of the 18650 ternary lithium battery used in different brands of new energy vehicles is different, the average capacity is about 3000mAh, and the average mass is about 40-50g; considering that the lithium battery retirement condition is 75-80% of the initial capacity, according to Attenuated to SOH=75%, 12,500 18650 batteries are needed, and a 20% margin is set according to the battery attenuation, and 36 battery packs are designed, each with 350 cells as a group; the quality of retired lithium batteries in the DC ice melting power supply is about 1600kg. The battery packs are closely arranged in a crisscross pattern. The size of a single lithium battery pack is 10×(180×70×51mm), and the volume occupied by the battery is 0.237762m3. Considering the isolation switch and battery management system (BMS) used for protection Occupy space, the size of the power supply is about 0.3m3.

保证融冰时间在国网融冰技术准则要求范围内,不能以提高融冰效率为目的而设置过高的融冰电流,否则会引起线路电压抬高和绝缘破坏问题。如图2所示,为融冰过程中三相电流波形,可以看出直流电源接入进行保线、融冰工作时,三相电流维持稳定,融冰相电流出现明显跃迁,能够达到融冰要求。Ensure that the ice-melting time is within the requirements of the State Grid's ice-melting technical guidelines. Do not set an excessively high ice-melting current for the purpose of improving the ice-melting efficiency, otherwise it will cause the line voltage to rise and insulation damage. As shown in Figure 2, it is the three-phase current waveform during the ice-melting process. It can be seen that when the DC power supply is connected for line protection and ice-melting work, the three-phase current remains stable, and the ice-melting phase current has obvious transitions, which can achieve ice-melting. Require.

为了进一步观测融冰电源对其中一相线路进行融冰操作时,融冰电流对其他两相电压稳定性的影响,需对升压站母线上电压波形进行观测;用户端的电压不能出现太大的偏移,否则会影响用户的电压质量,因此也需要对降压站母线上的电压波形进行观测。如图3、图4所示升压站侧、降压站侧高压母线上三相电压波形,融冰电源接入对变电站侧和用户侧影响都可以忽略,利用PSCAD仿真软件搭建快速傅里叶变换(fast fourier transform,FFT)谐波观测模块,监测三相电压畸变率,可以发现单相总谐波畸变率小于0.328%,几乎可以忽略不计。In order to further observe the influence of the ice-melting current on the voltage stability of the other two phases when the ice-melting power supply performs ice-melting operation on one of the lines, it is necessary to observe the voltage waveform on the bus of the booster station; the voltage at the user end should not be too large. Offset, otherwise it will affect the voltage quality of the user, so it is also necessary to observe the voltage waveform on the bus of the step-down station. As shown in Figure 3 and Figure 4, the three-phase voltage waveforms on the high-voltage bus on the booster station side and the step-down station side can be ignored. Transform (fast fourier transform, FFT) harmonic observation module, monitoring the three-phase voltage distortion rate, it can be found that the single-phase total harmonic distortion rate is less than 0.328%, almost negligible.

在-10℃低温环境、架空线覆冰10mm冰筒条件下,利用COMSOL软件仿真对应型号数据的架空线融冰过程,得到架空线温度场变化。理想条件下,融冰电源工作时,架空线路温度变化,当融冰电流达到988.54A时,如图5所示,覆冰接触层最高温度达到66.58℃,架空线内部温度为82.86℃,且架空线工作在合理温度限制内。Under the condition of -10℃ low temperature and 10mm ice cylinder covered by overhead line, the ice melting process of the overhead line corresponding to the model data is simulated by COMSOL software, and the temperature field change of the overhead line is obtained. Under ideal conditions, when the ice-melting power supply is working, the temperature of the overhead line changes. When the ice-melting current reaches 988.54A, as shown in Figure 5, the maximum temperature of the ice-covered contact layer reaches 66.58°C, the internal temperature of the overhead line is 82.86°C, and the overhead Lines operate within reasonable temperature limits.

基于退役锂电池二次利用的直流融冰电源的设计过程需要注意事项如下。The design process of the DC ice melting power supply based on the secondary utilization of retired lithium batteries needs to be noted as follows.

1、考虑导线热膨胀系数:1. Consider the thermal expansion coefficient of the wire:

覆冰层融化过程中经历了:导线温升→冰筒融化(液化)→汽化潜热→融冰完成的过程。导线在汽化潜热过程中,额外吸收架空线放出的热能,使冰筒内壁融化形成的水蒸发,忽略蒸发过程所吸收的能量时,会导致选取融冰电流过小,不能在额定时间内完成融冰工作,降低融冰电源效率。因此,计算融冰电流时,在考虑导线热膨胀系数的同时,应将传导RT0、RT1温差范围设定为最大值,还应考虑当地低温环境下风速的影响,为直流电源容量的选取留出一定裕度,如公式(4)、公式(5)所示。During the melting process of the ice-covered layer, it has experienced the process of wire temperature rise → ice cylinder melting (liquefaction) → latent heat of vaporization → completion of ice melting. In the process of latent heat of vaporization, the wire will additionally absorb the heat energy released by the overhead line, so that the water formed by the melting of the inner wall of the ice cylinder evaporates. If the energy absorbed in the evaporation process is ignored, the selected melting current will be too small to complete the melting within the rated time. Ice work, reducing ice melting power efficiency. Therefore, when calculating the ice-melting current, while considering the thermal expansion coefficient of the wire, the temperature difference range of RT0 and RT1 should be set to the maximum value, and the influence of the wind speed in the local low temperature environment should also be considered, which is reserved for the selection of DC power supply capacity. A certain margin is obtained, as shown in formula (4) and formula (5).

Vwind为融冰时同期风速,m/s;λ为覆冰导热系数,雨凇取0.0227,雾凇取0.0012。δ为导线黑度(分裂导线辐射率系数),一般新导线取0.22~0.43,旧导线取0.9。Vwind is the wind speed in the same period when the ice is melting, m/s; λ is the thermal conductivity of ice coating, which is 0.0227 for rain and 0.0012 for rime. δ is the blackness of the wire (split wire emissivity coefficient), generally the new wire is 0.22 to 0.43, and the old wire is 0.9.

2、考虑退役锂电池低温输出特性:2. Consider the low temperature output characteristics of retired lithium batteries:

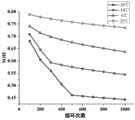

新能源汽车普遍采用三元锂电池,本发明以18650型三元锂电池(镍盐、钴盐、锰盐比例为6:2:2)为例,标称电压为3.7V,充电截止的浮充电压为3.9~4.2V,最低输出为2.5V。结合美国航天局的NASA PCoE研究中心提供的退役锂电池数据,利用COMSOL物理仿真软件拟合随机电池使用数据集(randomized battery usage data set,RBUD)中乘用汽车退役的三元锂电池;并通过改变退役三元锂电池在不同荷电状态(state of charge,SOC)下的正、负电极材料颗粒粒径、固体电解质膜(solid electrolyte interphase,SEI)厚度、电极材料孔率及电解质体积分数,来模拟退役电池老化程度。改变退役锂电池工作环境温度,分别设定-20℃、-10℃、0℃及25℃,对比低温环境下1000次充放电循环的电压降落,如图6所示。New energy vehicles generally use ternary lithium batteries. The present invention takes 18650 ternary lithium batteries (the ratio of nickel salt, cobalt salt, and manganese salt is 6:2:2) as an example. The charging voltage is 3.9~4.2V, and the minimum output is 2.5V. Combined with the retired lithium battery data provided by the NASA PCoE Research Center of NASA, the COMSOL physical simulation software is used to fit the ternary lithium batteries retired from passenger cars in the randomized battery usage data set (RBUD); Change the positive and negative electrode material particle size, solid electrolyte interphase (SEI) thickness, electrode material porosity and electrolyte volume fraction of decommissioned ternary lithium batteries under different state of charge (SOC), to simulate the aging of retired batteries. Change the working environment temperature of the retired lithium battery and set -20℃, -10℃, 0℃ and 25℃ respectively, and compare the voltage drop of 1000 charge-discharge cycles in a low temperature environment, as shown in Figure 6.

四种环境温度下,模拟退役三元锂电池在充放电循环过程中,开路电压(opencircuit voltage,OCV)下降情况和健康状态(stage of health,SOH)衰减,由表2数据可知,开路电压减小到2.5V(锂电池截止电压)时,标准工况温度25℃下,电池放电时间约为2800s。相对理想温度下;1C标准放电倍率下,模拟季低温-20℃环境,放电时间为2048s,相对标准工况减小27.84%;-10℃条件下,放电至截止电压时间为25℃条件下的94.01%。Under the four ambient temperatures, the open circuit voltage (OCV) drop and the stage of health (SOH) decay during the charge-discharge cycle of the decommissioned ternary lithium battery are simulated. From the data in Table 2, the open circuit voltage decreases. When the voltage is as small as 2.5V (cut-off voltage of lithium battery), the battery discharge time is about 2800s under the standard operating temperature of 25℃. Under the relative ideal temperature; under the standard discharge rate of 1C, simulating the low temperature -20℃ environment in the season, the discharge time is 2048s, which is 27.84% less than the standard working condition; under the condition of -10℃, the discharge to cut-off voltage time is under the condition of 25℃. 94.01%.

表2退役锂电池开路电压降落Table 2 Decommissioned Lithium Battery Open Circuit Voltage Drop

在直流融冰模式下,退役锂电池重组形成的直流电源需要在规定时间内输出较大的电流进行快速融冰,(LGJ-300/40)型导线融冰电流范围为(700~1200A),同时应分析退役锂电池在不同环境温度、高倍率放电条件下的SOH变化;对比标准环境下温度(25℃),验证退役锂电池健康状态是否能达到直流融冰电源的工作要求,模拟新能源汽车使用至初始容量80%退役后三元锂电池以4C充放电循环。In the DC ice melting mode, the DC power supply formed by the recombination of the retired lithium battery needs to output a large current within a specified time to quickly melt the ice. At the same time, the SOH change of the retired lithium battery under different ambient temperatures and high-rate discharge conditions should be analyzed; compared with the temperature in the standard environment (25 °C), it is verified whether the health status of the retired lithium battery can meet the working requirements of the DC ice melting power supply, and simulate new energy. The ternary lithium battery is charged and discharged at 4C after the car is used to 80% of the initial capacity after decommissioning.

在COMSOL仿真软件中,模拟退役锂电池低温环境下SOH变化。由图7分析可知:In COMSOL simulation software, the SOH changes in the low temperature environment of decommissioned lithium batteries are simulated. It can be seen from the analysis of Figure 7 that:

(1)0℃下初始SOH接近75%,健康状态下降较为缓和。(1) The initial SOH is close to 75% at 0°C, and the decline of the health state is relatively mild.

(2)-10℃环境下,将近300次充放电循环后,SOH衰减至全新状态下的58.37%。(2) At -10°C, after nearly 300 charge-discharge cycles, the SOH decays to 58.37% of the new state.

(3)当环境气温下降至-20℃时,退役锂电池在500次循环内,健康状态下降明显,衰减至初始SOH的46.07%。(3) When the ambient temperature drops to -20 °C, the health state of the retired lithium battery decreases significantly within 500 cycles, and decays to 46.07% of the initial SOH.

但因为融冰电源使用次数较少,只需应对极端雾凇、雨凇出现的低温天气,因此该试验下的新能源乘用车退役锂电池符合直流电源工作要求。However, because the ice-melting power supply is used less frequently, it only needs to deal with the low temperature weather caused by extreme rime and rain. Therefore, the retired lithium battery of the new energy passenger vehicle under this test meets the working requirements of the DC power supply.

3、利用短路间隔棒对分裂导线进行融冰:3. Use the short-circuit spacer to melt the split wire:

现有直流融冰电源多采用移动电源车的形式,融冰时需要将移动式电源车(或应急电源车)行驶至融冰线路下方,对于空气湿度大、夜间气温低的山林地区,移动式直流电源车难以到达。此外,移动式电源车需搭配成套固定的直流电压源换流器(voltage sourceconverter,VSC)或是6/12脉动整流器,成本过高,无法实现良好的经济效益。The existing DC ice-melting power supply is mostly in the form of a mobile power supply vehicle. When melting ice, the mobile power supply vehicle (or emergency power supply vehicle) needs to be driven below the ice-melting line. DC power carts are hard to reach. In addition, the mobile power supply vehicle needs to be equipped with a complete set of fixed DC voltage source converter (VSC) or 6/12-pulse rectifier, which is expensive and cannot achieve good economic benefits.

目前高压输电网为降低集肤效应、抑制电晕放电及减少线路电抗,架空线路多采用分裂导线形式。针对采用分裂导线形式的架空线路,根据经典传输线理论中分裂导线各相子导线电位相等的原理,将直流融冰电源、分裂导线的两条子导线和短路棒构成直流融冰回路,利用直流融冰电流和线路负荷电流共同对融冰段内的覆冰线路加热,从而达到融冰的效果,且在工作过程中不需对覆冰线路进行阻抗匹配和负荷转移。At present, in order to reduce the skin effect, suppress the corona discharge and reduce the line reactance in the high-voltage transmission network, the overhead lines are mostly in the form of split conductors. For overhead lines in the form of split conductors, according to the principle that the potentials of the sub-conductors of each phase of the split conductor are equal in the classical transmission line theory, the DC ice-melting power supply, the two sub-conductors of the split conductor and the short-circuit bar form a DC ice-melting circuit. The current and the line load current jointly heat the ice-covered line in the ice-melting section, so as to achieve the effect of ice-melting, and there is no need to perform impedance matching and load transfer on the ice-covered line during the working process.

本发明以lGJ-300/40二分裂导线为例,设计融冰电源方案原理如图1所示。将两根良导体制成的短路棒(主要起引渡直流电流的作用),安装在需要融冰段的两端。每相线路所对应的两根子导线之间等电位,因此可将其看成等势面,直流融冰电源在非工作状态时,则使其正、负电极分别与两根子导线相连。以对二分裂架空线路C相融冰为例,直流电流自融冰电源流入输电线路,流经短路棒,将需要融冰的线路串联起来,构成融冰回路,直流电流在“融冰电源-线路-短路棒”回路内流动,电流的热效应使得覆冰线路温度升高,从而达到融冰目的。The present invention takes the lGJ-300/40 two-split wire as an example, and the principle of designing the ice-melting power supply scheme is shown in FIG. 1 . Two short-circuit bars made of good conductors (mainly used for extradition of DC current) are installed at both ends of the ice-melting section. There is equipotential between the two sub-conductors corresponding to each phase line, so it can be regarded as an equipotential surface. When the DC ice melting power supply is not working, its positive and negative electrodes are connected to the two sub-conductors respectively. Taking the ice melting of phase C of the two-split overhead line as an example, the DC current flows into the transmission line from the ice melting power supply, flows through the short-circuit bar, and connects the lines that need to be melted to form an ice melting circuit. The line-shorting bar" circuit flows, and the thermal effect of the current increases the temperature of the ice-covered line, thereby achieving the purpose of melting ice.

如图1所示,融冰装置主要包括退役锂电池、短路棒和温控开关。As shown in Figure 1, the ice melting device mainly includes decommissioned lithium batteries, shorting bars and temperature-controlled switches.

①退役锂电池:输出直流电,提供融冰电流和保线电流。①Retired lithium battery: output DC power, provide ice melting current and line protection current.

②温控开关:需要进行融冰操作时闭合温控开关,并且当气温低于设定温度(列如-10℃,此温度需根据当地电网发生线路覆冰现象时环境温度数据进行设置)冬季发生雾凇、雨凇现象时,自动闭合开关提供保线电流。②Temperature control switch: close the temperature control switch when the ice melting operation is required, and when the air temperature is lower than the set temperature (for example, -10℃, this temperature needs to be set according to the ambient temperature data when the line ice coating occurs in the local power grid) in winter In the event of rime and rain, the switch is automatically closed to provide line protection current.

③短路棒1、2:采用紫铜材质短路棒,最小电阻为0.0172Ω/m,最大外径为150mm,耐受温度满足融冰时的温度限制要求,约为100℃,超过融冰时架空线路最高温度。架设在覆冰线路起、始两端,保证直流融冰电流不流出回路。③ Shorting bars 1 and 2: shorting bars made of red copper, the minimum resistance is 0.0172Ω/m, the maximum outer diameter is 150mm, and the withstand temperature meets the temperature limit requirements during ice melting, about 100 °C, exceeding the overhead line when ice melting maximum temperature. It is erected at the beginning and beginning of the icing line to ensure that the DC ice melting current does not flow out of the circuit.

利用本发明进行融冰的具体操作步骤为:The concrete operation steps that utilize the present invention to melt ice are:

①融冰电源,固定方式可以选为220kV杆塔安装,用短距离电缆或电缆接头进行连接,并在电源接线上安装温控开关。①The ice melting power supply can be fixed by 220kV tower installation, connected with short-distance cables or cable joints, and a temperature control switch is installed on the power supply wiring.

②假设覆冰段距离长度为l(km),将短路棒1、2安装(安装方式需人工操作进行安装)在二分裂架空线上,保证电源正、负极接入两处并联等长度(长度为l)的架空线路。②Assuming that the length of the ice-covered section is l(km), install the shorting bars 1 and 2 (the installation method requires manual operation) on the two-split overhead line, and ensure that the positive and negative poles of the power supply are connected in parallel at the same length (length). For the overhead line of l).

③闭合温控开关,使融冰电源输出公式(1)计算的融冰电流,对覆冰线路进行热力融冰,冰层脱落后断开温控开关③Close the temperature control switch, so that the ice melting power supply outputs the ice melting current calculated by formula (1), and the ice coating circuit is thermally melted, and the temperature control switch is turned off after the ice layer falls off.

④温控开关在冬季易发生覆冰的时段,并且气温低于保线电流工作设定温度时自动闭合,输出公式(3)计算的保线电流,保证线路不发生覆冰④The temperature control switch will automatically close when the temperature is lower than the set temperature of the line protection current in winter, and the line protection current calculated by the formula (3) will be output to ensure that the line will not be covered with ice.

⑤融冰工作结束后,由工作人员断开拆除电源接线和短路棒本发明将退役锂电池梯次利用于直流融冰工作中,提升退役电池回收利用率、拓宽退役电池利用途径。对于锂电池“二次寿命”而言,能效比虽然不再满足电动汽车运行经济条件,但在输电网、配电网中二次利用时,其剩余容量、开路电压、能量密度条件仍满足电网运行要求。⑤ After the ice-melting work is completed, the staff disconnects and removes the power supply wiring and the short-circuit bar. The present invention utilizes the retired lithium battery in the DC ice-melting work step by step, improves the recycling rate of the retired battery, and broadens the utilization of the retired battery. For the "secondary life" of lithium batteries, although the energy efficiency ratio no longer meets the economic conditions for electric vehicle operation, its residual capacity, open circuit voltage, and energy density still meet the grid conditions for secondary utilization in transmission and distribution networks. run requirements.

最后应当说明的是:以上实施例仅用以说明本发明的技术方案而非对其限制,尽管参照上述实施例对本发明进行了详细的说明,所属领域的普通技术人员应当理解:依然可以对本发明的具体实施方式进行修改或者等同替换,而未脱离本发明精神和范围的任何修改或者等同替换,其均应涵盖在本发明的权利要求保护范围之内。Finally, it should be noted that the above embodiments are only used to illustrate the technical solutions of the present invention rather than to limit them. Although the present invention has been described in detail with reference to the above embodiments, those of ordinary skill in the art should understand that: the present invention can still be Modifications or equivalent replacements are made to the specific embodiments of the present invention, and any modifications or equivalent replacements that do not depart from the spirit and scope of the present invention shall be included within the protection scope of the claims of the present invention.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010891754.6ACN112054466A (en) | 2020-08-28 | 2020-08-28 | De-service lithium battery-based ice melting device and method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010891754.6ACN112054466A (en) | 2020-08-28 | 2020-08-28 | De-service lithium battery-based ice melting device and method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112054466Atrue CN112054466A (en) | 2020-12-08 |

Family

ID=73607641

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010891754.6APendingCN112054466A (en) | 2020-08-28 | 2020-08-28 | De-service lithium battery-based ice melting device and method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112054466A (en) |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101272041A (en)* | 2008-04-14 | 2008-09-24 | 朱发国 | Wire-protecting and de-icing method of unit type high tension power line |

| US20090250449A1 (en)* | 2008-04-02 | 2009-10-08 | The Trustees Of Dartmouth College | System And Method For Deicing Of Power Line Cables |

| CN105406433A (en)* | 2016-01-23 | 2016-03-16 | 国网福建省电力有限公司 | Optimal power and capacity selection method of mobile battery energy storage DC-based deicing system |

| CN105826889A (en)* | 2015-01-08 | 2016-08-03 | 罗日成 | Transmission line charged segmented DC ice melting method |

| CN106786298A (en)* | 2016-11-16 | 2017-05-31 | 国网山东省电力公司荣成市供电公司 | A kind of self-heating deicing system of high-tension transmission lines |

| CN108832539A (en)* | 2018-07-27 | 2018-11-16 | 贵州电网有限责任公司 | A kind of online de-icing method using the energy storage device optimization transmission line of electricity method of operation |

| CN109449854A (en)* | 2018-12-06 | 2019-03-08 | 四川大学 | Station lossless three-phase current divider and design and control method for anti-icing ice-melt |

- 2020

- 2020-08-28CNCN202010891754.6Apatent/CN112054466A/enactivePending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20090250449A1 (en)* | 2008-04-02 | 2009-10-08 | The Trustees Of Dartmouth College | System And Method For Deicing Of Power Line Cables |

| CN101272041A (en)* | 2008-04-14 | 2008-09-24 | 朱发国 | Wire-protecting and de-icing method of unit type high tension power line |

| CN105826889A (en)* | 2015-01-08 | 2016-08-03 | 罗日成 | Transmission line charged segmented DC ice melting method |

| CN105406433A (en)* | 2016-01-23 | 2016-03-16 | 国网福建省电力有限公司 | Optimal power and capacity selection method of mobile battery energy storage DC-based deicing system |

| CN106786298A (en)* | 2016-11-16 | 2017-05-31 | 国网山东省电力公司荣成市供电公司 | A kind of self-heating deicing system of high-tension transmission lines |

| CN108832539A (en)* | 2018-07-27 | 2018-11-16 | 贵州电网有限责任公司 | A kind of online de-icing method using the energy storage device optimization transmission line of electricity method of operation |

| CN109449854A (en)* | 2018-12-06 | 2019-03-08 | 四川大学 | Station lossless three-phase current divider and design and control method for anti-icing ice-melt |

Non-Patent Citations (3)

| Title |

|---|

| 刘坚: ""电动汽车退役电池储能应用潜力及成本分析"", 《储能科学与技术》* |

| 敬华兵,年晓红: ""输电线路柔性直流融冰技术"", 《高电压技术》* |

| 王朗珠,杨绍远,郑连清: ""500kV变电站的直流融冰技术研究"", 《华北电力大学学报》* |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN102055214B (en) | An electric vehicle power supply system | |

| CN103915808B (en) | DC ice melting device based on voltage source type current converter and control method thereof | |

| CA3024347C (en) | Traction power supply system for high speed train and its on-board power storage and discharge system | |

| CN102510039B (en) | Multifunctional direct-current ice melting automatic conversion circuit and conversion method thereof | |

| CN105406433B (en) | The power of mobile battery energy storage direct current ice melting system and capacity optimum option method | |

| CN102255274B (en) | Direct-current ice melting method for overhead ground wire and composite optical fiber ground wire | |

| CN101882774B (en) | Direct-current ice melting device without special rectifier transformer and protection method thereof | |

| CN106253314A (en) | Communication base station ferric phosphate lithium cell echelon utilizes charge-discharge system and control method | |

| CN201893567U (en) | Electric energy supply system for electric automobile | |

| CN203813384U (en) | DC ice melting device based on voltage source type current converter | |

| CN103117595B (en) | Distributed direct current independent power supply system | |

| Han et al. | A review on development practice of smart grid technology in China | |

| CN107472037B (en) | A traction power supply system for high-speed trains and its on-board storage and discharge system | |

| CN103219766A (en) | Non floating charge lithium battery type DC (direct current) power system used for station | |

| CN202094584U (en) | Ice melting system for overhead contact line of electrified railway | |

| CN204145012U (en) | The complete charging device in a kind of ground for super capacitor energy-storage type tramcar | |

| CN203326621U (en) | Non floating charge lithium battery type DC (direct current) power system used for station | |

| CN203119615U (en) | Distributed direct-current independent power supply system | |

| Latyshev et al. | Charging stations for electric cars using hybrid energy storage systems | |

| CN112054466A (en) | De-service lithium battery-based ice melting device and method | |

| CN103117596B (en) | Distributed direct-current power supply system for substation | |

| CN103326299B (en) | Starting method of overhead ground wire and composite optical fiber ground wire direct-current ice melting system | |

| CN203119617U (en) | Distributed direct-current independent power supply system for transformer substation | |

| CN111130046B (en) | Ice melting loop of electrified railway overhead contact system and control method thereof | |

| CN209948688U (en) | Distribution station energy storage cabinet |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20201208 | |

| RJ01 | Rejection of invention patent application after publication |