CN112048090A - Water-absorbing, antibacterial and degradable fresh water fish preservative film and preparation method thereof - Google Patents

Water-absorbing, antibacterial and degradable fresh water fish preservative film and preparation method thereofDownload PDFInfo

- Publication number

- CN112048090A CN112048090ACN202010971833.8ACN202010971833ACN112048090ACN 112048090 ACN112048090 ACN 112048090ACN 202010971833 ACN202010971833 ACN 202010971833ACN 112048090 ACN112048090 ACN 112048090A

- Authority

- CN

- China

- Prior art keywords

- aqueous suspension

- water

- microcrystalline cellulose

- polyglutamic acid

- absorbing

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J5/00—Manufacture of articles or shaped materials containing macromolecular substances

- C08J5/18—Manufacture of films or sheets

- B—PERFORMING OPERATIONS; TRANSPORTING

- B65—CONVEYING; PACKING; STORING; HANDLING THIN OR FILAMENTARY MATERIAL

- B65D—CONTAINERS FOR STORAGE OR TRANSPORT OF ARTICLES OR MATERIALS, e.g. BAGS, BARRELS, BOTTLES, BOXES, CANS, CARTONS, CRATES, DRUMS, JARS, TANKS, HOPPERS, FORWARDING CONTAINERS; ACCESSORIES, CLOSURES, OR FITTINGS THEREFOR; PACKAGING ELEMENTS; PACKAGES

- B65D65/00—Wrappers or flexible covers; Packaging materials of special type or form

- B65D65/38—Packaging materials of special type or form

- B65D65/46—Applications of disintegrable, dissolvable or edible materials

- B65D65/466—Bio- or photodegradable packaging materials

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2301/00—Characterised by the use of cellulose, modified cellulose or cellulose derivatives

- C08J2301/04—Oxycellulose; Hydrocellulose

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2425/00—Characterised by the use of homopolymers or copolymers of compounds having one or more unsaturated aliphatic radicals, each having only one carbon-to-carbon double bond, and at least one being terminated by an aromatic carbocyclic ring; Derivatives of such polymers

- C08J2425/02—Homopolymers or copolymers of hydrocarbons

- C08J2425/04—Homopolymers or copolymers of styrene

- C08J2425/06—Polystyrene

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08J—WORKING-UP; GENERAL PROCESSES OF COMPOUNDING; AFTER-TREATMENT NOT COVERED BY SUBCLASSES C08B, C08C, C08F, C08G or C08H

- C08J2477/00—Characterised by the use of polyamides obtained by reactions forming a carboxylic amide link in the main chain; Derivatives of such polymers

- C08J2477/04—Polyamides derived from alpha-amino carboxylic acids

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/04—Oxygen-containing compounds

- C08K5/05—Alcohols; Metal alcoholates

- C08K5/053—Polyhydroxylic alcohols

- C—CHEMISTRY; METALLURGY

- C08—ORGANIC MACROMOLECULAR COMPOUNDS; THEIR PREPARATION OR CHEMICAL WORKING-UP; COMPOSITIONS BASED THEREON

- C08K—Use of inorganic or non-macromolecular organic substances as compounding ingredients

- C08K5/00—Use of organic ingredients

- C08K5/04—Oxygen-containing compounds

- C08K5/15—Heterocyclic compounds having oxygen in the ring

- C08K5/151—Heterocyclic compounds having oxygen in the ring having one oxygen atom in the ring

- C08K5/1545—Six-membered rings

Landscapes

- Engineering & Computer Science (AREA)

- Chemical & Material Sciences (AREA)

- Manufacturing & Machinery (AREA)

- Medicinal Chemistry (AREA)

- Health & Medical Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Materials Engineering (AREA)

- Polymers & Plastics (AREA)

- Organic Chemistry (AREA)

- Life Sciences & Earth Sciences (AREA)

- Biodiversity & Conservation Biology (AREA)

- Mechanical Engineering (AREA)

- Food Preservation Except Freezing, Refrigeration, And Drying (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明属于水产品保鲜技术及领域,具体是一种吸水抑菌可降解的淡水鱼保鲜膜及其制备方法。The invention belongs to the fresh-keeping technology and field of aquatic products, in particular to a fresh-water fish fresh-keeping film capable of absorbing water, inhibiting bacteria and degrading, and a preparation method thereof.

背景技术Background technique

淡水鱼在捕获后和加工过程中易导致鱼肉蛋白分解使鱼肉产生不良的气味而改变鱼肉原有的风味,同时引起鱼体腐败的微生物种类繁多,淡水鱼在贮藏过程中易受腐败菌、内源酶以及化学作用的侵染而失鲜变质。新鲜处理的鱼肉在贮藏和运输过程中也难免有汁液流出现象,这些流出的汁液不仅影响鱼肉产品的外貌感官,而且也可能造成二次污染,严重影响鱼肉的商业价值。冷藏结合防腐剂保鲜是一种控制食物腐败的传统方法,但由于防腐剂的残留,人食用后会对机体造成损害,多种因素造成的食品腐败,对经济和人体健康造成严重危害。Freshwater fish can easily lead to the decomposition of fish meat protein after catching and during processing, resulting in bad odor of fish meat and changing the original flavor of fish meat. At the same time, there are many kinds of microorganisms that cause fish body spoilage. The original enzyme and chemical action of the infection and loss of freshness and deterioration. Freshly processed fish will inevitably have juice outflow during storage and transportation. The outflow of juice not only affects the appearance of fish products, but also may cause secondary pollution, which seriously affects the commercial value of fish. Refrigeration combined with preservatives is a traditional method to control food spoilage. However, due to the residues of preservatives, people will damage the body after eating, and food spoilage caused by various factors will cause serious harm to the economy and human health.

因此,如何保持淡水鱼肉良好的食用品质并且改善鱼肉产品外观,对淡水鱼保鲜加工行业具有重要意义。目前市面上大部分使用的传统PE(聚乙烯)保鲜膜,虽然能隔绝空气,减少空气中的杂菌对产品的污染等基本功能,但也只能使新鲜鱼肉再持续延长保存2~3天,保质期短;传统PE保鲜膜可降解性差,长期积压留存会对环境和人类健康造成巨大隐患;并且传统PE保鲜膜吸水性差,不能吸收肉质品比较常见的血水渗出问题,对肉制品的质量和经济环保影响较大。为此,我们提出一种吸水抑菌可降解的保鲜膜在淡水鱼保鲜中应用,来弥补传统保鲜膜性能的不足,着重增加保鲜膜在吸收肉制品血水渗出的应用范围。Therefore, how to maintain the good edible quality of freshwater fish and improve the appearance of fish products is of great significance to the freshwater fish preservation and processing industry. At present, most of the traditional PE (polyethylene) fresh-keeping film used on the market has basic functions such as isolating the air and reducing the pollution of the products by the bacteria in the air, but it can only prolong the preservation of fresh fish for another 2 to 3 days. , the shelf life is short; the traditional PE plastic wrap is poorly degradable, and the long-term backlog will cause huge hidden dangers to the environment and human health; and the traditional PE plastic wrap has poor water absorption and cannot absorb the more common blood and water leakage problems of meat products, which has a negative impact on the quality of meat products. and economic and environmental protection. To this end, we propose a water-absorbing, bacteriostatic and degradable plastic wrap for freshwater fish preservation to make up for the lack of performance of traditional plastic wrap, focusing on increasing the application range of plastic wrap in absorbing blood and water exudation from meat products.

发明内容SUMMARY OF THE INVENTION

发明目的:本发明所要解决的技术问题是针对传统PE保鲜膜在肉制品保鲜中的常见问题,提供一种吸水抑菌可降解的淡水鱼保鲜膜及其制备方法,以解决淡水鱼肉制品在加工、储藏及运输过程中发生血水外渗影响外观和染菌腐败的两大关键难题。Purpose of the invention: The technical problem to be solved by the present invention is to provide a water-absorbing, bacteriostatic and degradable freshwater fish fresh-keeping film and a preparation method thereof for the common problems of traditional PE fresh-keeping film in the preservation of meat products, so as to solve the problem of processing freshwater fish meat products. , the two key problems of blood and water extravasation during storage and transportation, which affect the appearance and bacteria corruption.

为了解决上述技术问题,本发明采取的技术方案如下:In order to solve the above-mentioned technical problems, the technical scheme adopted by the present invention is as follows:

一种吸水抑菌可降解的淡水鱼保鲜膜,包括:A water-absorbing, bacteriostatic and degradable fresh-water fish fresh-keeping film, comprising:

微晶纤维素(MCC)水悬浮液,Aqueous suspension of microcrystalline cellulose (MCC),

γ-聚谷氨酸(γ-PGA)水悬浮液,γ-Polyglutamic acid (γ-PGA) aqueous suspension,

ε-聚赖氨酸(ε-PL),以及ε-Polylysine (ε-PL), and

增塑剂;plasticizer;

其中,所述微晶纤维素(MCC)水悬浮液和γ-聚谷氨酸(γ-PGA)水悬浮液的质量比为2:1;Wherein, the mass ratio of the microcrystalline cellulose (MCC) aqueous suspension and the γ-polyglutamic acid (γ-PGA) aqueous suspension is 2:1;

所述ε-聚赖氨酸(ε-PL)添加量为微晶纤维素水悬浮液和γ-聚谷氨酸水悬浮液总质量的1~5wt%;The added amount of the ε-polylysine (ε-PL) is 1-5 wt% of the total mass of the microcrystalline cellulose aqueous suspension and the γ-polyglutamic acid aqueous suspension;

所述增塑剂添加量为微晶纤维素水悬浮液和γ-聚谷氨酸水悬浮液总质量的1~2wt%。The added amount of the plasticizer is 1-2 wt% of the total mass of the microcrystalline cellulose aqueous suspension and the γ-polyglutamic acid aqueous suspension.

微晶纤维素(MCC)是由β-1,4葡萄糖苷键联接的直链式多糖,通常是由天然纤维素经物理或化学处理而得到的白色粉末状物质,是一种纯净的纤维素解聚产物,具有较大的比表面积和较低的聚合度,平均聚合度可达其聚合度的极限,其吸水性很强,在水介质中经剪切应力作用后,能生成凝胶,作为保鲜膜的成膜基质。Microcrystalline cellulose (MCC) is a straight-chain polysaccharide linked by β-1,4 glucosidic bonds. It is usually a white powdery substance obtained by physical or chemical treatment of natural cellulose. It is a pure cellulose. The depolymerization product has a large specific surface area and a low degree of polymerization. The average degree of polymerization can reach the limit of its degree of polymerization. It has strong water absorption and can form gel after shear stress in an aqueous medium. As a film-forming substrate for cling film.

γ-PGA侧链上大量羧基负电荷的排斥作用,使得分子链的空间伸展很大,即使在较低的浓度下,分子间也具有强烈的相互作用,γ-PGA是分子量达百万级别的氨基酸均聚物,具有高吸水性能、生物安全性和抗盐性,而冷鲜鱼肉中浸出血液成分属于复杂的电解质溶液,影响薄膜吸附的主要因素是NaCl,因此γ-PGA可作为一种优良的高抗盐性吸水剂。The repulsion of a large number of carboxyl negative charges on the side chain of γ-PGA makes the spatial extension of the molecular chain very large. Even at a low concentration, there is a strong interaction between molecules. γ-PGA has a molecular weight of one million. Amino acid homopolymer has high water absorption, biosafety and salt resistance, while the blood components leached from chilled fish are complex electrolyte solutions, and the main factor affecting the adsorption of the film is NaCl, so γ-PGA can be used as an excellent high salt resistance water absorbent.

ε-PL对革兰氏阳性菌、革兰氏阴性菌、酵母菌、霉菌等都有较好的抑制作用,具备广谱抑菌性,可作为优良的抗菌剂。ε-PL has a good inhibitory effect on Gram-positive bacteria, Gram-negative bacteria, yeast, mold, etc. It has broad-spectrum bacteriostatic properties and can be used as an excellent antibacterial agent.

增塑剂的添加可改善膜的性能,降低膜的内聚力,增加聚合物链的灵活性和抗折能力。The addition of plasticizers can improve the properties of the film, reduce the cohesion of the film, and increase the flexibility and flexural resistance of the polymer chain.

优选地,所述微晶纤维素水悬浮液的浓度为6~10wt%。Preferably, the concentration of the microcrystalline cellulose aqueous suspension is 6-10 wt%.

优选地,所述γ-聚谷氨酸水悬浮液的浓度为5~15wt%,其中,γ-聚谷氨酸的分子量为50万~100万Da。Preferably, the concentration of the γ-polyglutamic acid aqueous suspension is 5 to 15 wt %, wherein the molecular weight of the γ-polyglutamic acid is 500,000 to 1,000,000 Da.

优选地,所述增塑剂为甘油、木糖醇、山梨醇、乙二醇或聚苯乙烯中的任意一种。优选甘油。Preferably, the plasticizer is any one of glycerol, xylitol, sorbitol, ethylene glycol or polystyrene. Glycerol is preferred.

进一步地,本发明还提供上述吸水抑菌可降解的淡水鱼保鲜膜的制备方法,包括如下步骤:Further, the present invention also provides a preparation method of the above-mentioned water-absorbing, bacteriostatic and degradable freshwater fish fresh-keeping film, comprising the following steps:

(1)分别配置微晶纤维素水悬浮液和γ-聚谷氨酸水悬浮液;(1) Prepare the microcrystalline cellulose aqueous suspension and the γ-polyglutamic acid aqueous suspension respectively;

(2)将步骤(1)配置得到的微晶纤维素水悬浮液和γ-聚谷氨酸水悬浮液混合搅拌,得到微晶纤维素-γ-聚谷氨酸混合液;(2) mixing and stirring the microcrystalline cellulose aqueous suspension and the γ-polyglutamic acid aqueous suspension prepared in step (1) to obtain a microcrystalline cellulose-γ-polyglutamic acid mixed solution;

(3)向步骤(2)得到的微晶纤维素-γ-聚谷氨酸混合液中依次加入ε-聚赖氨酸和增塑剂,均质后于水浴40~60℃下搅拌均匀,自然冷却后脱气,得到膜液;(3) adding ε-polylysine and plasticizer to the microcrystalline cellulose-γ-polyglutamic acid mixture obtained in step (2) in turn, homogenizing and stirring uniformly at 40-60° C. in a water bath, After natural cooling, degassing to obtain membrane liquid;

(4)将步骤(3)得到的膜液均匀倒入模具盘中静置成膜,随后烘干即得。(4) The film liquid obtained in step (3) is evenly poured into the mold tray and left to stand for film formation, followed by drying.

具体地,步骤(2)中,所述混合采用磁力搅拌器在转速为600~1200r/min下搅拌30~60min。Specifically, in step (2), the mixing is performed by using a magnetic stirrer at a rotational speed of 600-1200 r/min for 30-60 min.

步骤(3)中,所述均质采用高速分散机在15000~20000rpm下均质5~10min;所述水浴中搅拌的转速为600-800r/mim,时间为15~30min;所述脱气采用超声脱气,超声脱气的频率为35~45HZ,超声脱气的时间为20~30min。In step (3), the homogenization adopts a high-speed disperser at 15000-20000rpm for 5-10min; the stirring speed in the water bath is 600-800r/mim, and the time is 15-30min; the degassing adopts Ultrasonic degassing, the frequency of ultrasonic degassing is 35~45HZ, and the time of ultrasonic degassing is 20~30min.

步骤(4)中,膜液倒入模具盘中静置成膜时间为18~24h;所述烘干的温度为35~40℃,时间控制在20~24h。In step (4), the film liquid is poured into the mold tray and allowed to stand for 18-24 hours for film-forming time; the drying temperature is 35-40° C., and the time is controlled at 20-24 hours.

本发明进一步提供采用上述吸水抑菌可降解的淡水鱼保鲜膜进行淡水鱼肉保鲜的方法,将鲜活的淡水鱼处死后去除内脏,用去离子水洗净后切片,然后用所述的吸水抑菌可降解的淡水鱼保鲜膜包裹好后放入冰箱中,在4±1℃条件下冷藏。The present invention further provides a method for freshwater fish preservation by adopting the above-mentioned water-absorbing, bacteriostatic and degradable freshwater fish fresh-keeping film. The bacteria-degradable freshwater fish plastic wrap was wrapped and placed in the refrigerator, and refrigerated at 4±1°C.

有益效果:Beneficial effects:

1、本发明以ε-聚赖氨酸、聚谷氨酸、微晶纤维素三个可食用基材,使用微晶纤维素作为成膜基质,聚谷氨酸作为吸水剂,ε-聚赖氨酸作为抗菌剂,开发出集抑菌、水分调控、可降解三位一体功能化保鲜膜材料,其结构为水凝胶三维网状,实现肉品血水的有效吸附,避免染菌;同时水凝胶保湿锁水功效可防止产品过度失水变质。1. The present invention uses ε-polylysine, polyglutamic acid, and microcrystalline cellulose as three edible substrates, uses microcrystalline cellulose as a film-forming substrate, polyglutamic acid as a water-absorbing agent, and ε-polylysine. As an antibacterial agent, amino acid has developed a three-in-one functional cling film material that integrates bacteriostasis, moisture regulation and degradability. Its structure is a three-dimensional network of hydrogel, which can effectively absorb blood and water of meat and avoid contamination. At the same time, hydrogel The moisturizing and water-locking effect can prevent excessive water loss and deterioration of the product.

2、本发明实现了保鲜剂与包装材料相结合的食品活性包装,具有安全无毒、抗菌性强和抗菌谱广等特点。针对淡水鱼特定腐败特点研制的低温+生物的联合保鲜方法,在贮藏过程中能有效吸附鱼肉品血水、抑制微生物生长繁殖、良好的可生物降解性、更好地延长淡水鱼的品质及其应用,解决淡水鱼经传统保鲜方法处理后食用品质差、存有安全隐患和保鲜期短等技术难题。2. The present invention realizes the active food packaging in which the preservative is combined with the packaging material, and has the characteristics of safety, non-toxicity, strong antibacterial property and broad antibacterial spectrum. The low temperature and biological combined preservation method developed for the specific spoilage characteristics of freshwater fish can effectively absorb the blood of fish meat during storage, inhibit the growth and reproduction of microorganisms, have good biodegradability, and better prolong the quality of freshwater fish and its application , to solve the technical problems such as poor edible quality, potential safety hazards and short fresh-keeping period of freshwater fish treated by traditional fresh-keeping methods.

附图说明Description of drawings

下面结合附图和具体实施方式对本发明做更进一步的具体说明,本发明的上述和/或其他方面的优点将会变得更加清楚。The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments, and the advantages of the above-mentioned and/or other aspects of the present invention will become clearer.

图1为实施例3制备得到的保鲜膜外观图。Fig. 1 is the appearance diagram of the fresh-keeping film prepared in Example 3.

图2为实施例5制备得到的保鲜膜外观图。FIG. 2 is the appearance diagram of the fresh-keeping film prepared in Example 5. FIG.

图3为各实验组和对照组保鲜膜贮藏期间淡水鱼肉的挥发性盐基氮值(TVB-N)的变化曲线。Figure 3 is the change curve of the volatile base nitrogen value (TVB-N) of freshwater fish meat during the storage period of each experimental group and the control group.

图4为各实验组和对照组保鲜膜贮藏期间淡水鱼肉的菌落总数(TVC)的变化曲线。Figure 4 is the change curve of the total number of colonies (TVC) of freshwater fish during the storage period of the plastic wrap of each experimental group and the control group.

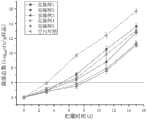

图5为各实验组和对照组保鲜膜的吸附动力曲线。Figure 5 is the adsorption kinetic curve of each experimental group and the control group of plastic wrap.

图6为各实验组和对照组在室内土埋降解试验中的失重率变化曲线。Figure 6 is the weight loss rate change curve of each experimental group and the control group in the indoor soil burial degradation test.

具体实施方式Detailed ways

根据下述实施例,可以更好地理解本发明。The present invention can be better understood from the following examples.

实施例1Example 1

本实施例提供一种淡水鱼保鲜膜,该保鲜膜具体通过以下步骤制得:The present embodiment provides a freshwater fish fresh-keeping film, which is specifically prepared by the following steps:

(1)称取MCC溶于蒸馏水中,制备成浓度为6wt%的MCC水悬浮液(溶解MCC时,在磁力搅拌器的作用下同时将MCC缓慢的加入到蒸馏水中),磁力搅拌30min;(1) take by weighing MCC and be dissolved in distilled water, prepare the MCC water suspension that concentration is 6wt% (when dissolving MCC, under the effect of magnetic stirrer, MCC is slowly added to distilled water simultaneously), magnetic stirring 30min;

称取γ-PGA(分子量为50万Da)溶于蒸馏水中,制备成浓度为5wt%的γ-PGA水悬浮液(溶解γ-PGA时,在磁力搅拌器的作用下同时将γ-PGA缓慢的加入到蒸馏水中),磁力搅拌30min;Weigh γ-PGA (molecular weight of 500,000 Da) and dissolve it in distilled water to prepare a γ-PGA aqueous suspension with a concentration of 5 wt% (when dissolving γ-PGA, under the action of a magnetic stirrer, γ-PGA is slowly mixed. was added to distilled water), magnetic stirring for 30min;

(2)将步骤(1)配置得到的MCC水悬浮液和γ-PGA水悬浮液按照质量比2:1采用磁力搅拌器在转速为600r/min下搅拌30min,得到MCC-γ-PGA混合液;(2) The MCC aqueous suspension and the γ-PGA aqueous suspension prepared in step (1) are stirred for 30 min with a magnetic stirrer according to a mass ratio of 2:1 at a rotational speed of 600 r/min to obtain a MCC-γ-PGA mixed solution ;

(3)向步骤(2)得到的微晶纤维素-γ-聚谷氨酸混合液中依次加入ε-PL(添加量为微晶纤维素-γ-聚谷氨酸混合液质量的1%)和增塑剂(甘油,添加量为微晶纤维素-γ-聚谷氨酸混合液质量的2%),采用高速分散机在15000rpm下均质5min,然后在电热恒温水浴锅内保持60℃,转速为600r/min下搅拌15min,自然冷却后在35HZ下超声脱气20min,得到膜液;(3) adding ε-PL (the addition amount is 1% of the mass of the microcrystalline cellulose-γ-polyglutamic acid mixed solution) into the microcrystalline cellulose-γ-polyglutamic acid mixed solution obtained in step (2) in turn ) and plasticizer (glycerol, the addition amount is 2% of the mass of the microcrystalline cellulose-γ-polyglutamic acid mixture), homogenize at 15,000 rpm with a high-speed disperser for 5 min, and then keep it in an electric heating constant temperature water bath for 60 ℃, stirring at 600r/min for 15min, after natural cooling, ultrasonic degassing at 35HZ for 20min to obtain membrane liquid;

(4)将步骤(3)得到的膜液均匀倒入模具盘中静置18h成膜,随后置于烘箱中在35℃下烘干20h,冷却后得到保鲜膜。(4) The film liquid obtained in step (3) was evenly poured into the mold plate and left to stand for 18 hours to form a film, then placed in an oven to be dried at 35° C. for 20 hours, and a fresh-keeping film was obtained after cooling.

实施例2Example 2

(1)称取MCC溶于蒸馏水中,制备成浓度为8wt%的MCC水悬浮液(溶解MCC时,在磁力搅拌器的作用下同时将MCC缓慢的加入到蒸馏水中),磁力搅拌30min;(1) take by weighing MCC and be dissolved in distilled water, prepare the MCC water suspension that concentration is 8wt% (when dissolving MCC, under the effect of magnetic stirrer, MCC is slowly added to distilled water), magnetic stirring 30min;

称取γ-PGA(分子量为100万Da)溶于蒸馏水中,制备成浓度为15wt%的γ-PGA水悬浮液(溶解γ-PGA时,在磁力搅拌器的作用下同时将γ-PGA缓慢的加入到蒸馏水中),磁力搅拌30min;Weigh γ-PGA (with a molecular weight of 1 million Da) and dissolve it in distilled water to prepare a γ-PGA aqueous suspension with a concentration of 15wt% (when dissolving γ-PGA, under the action of a magnetic stirrer, slowly γ-PGA was added to distilled water), magnetic stirring for 30min;

(2)将步骤(1)配置得到的MCC水悬浮液和γ-PGA水悬浮液按照质量比2:1采用磁力搅拌器在转速为1000r/min下搅拌30min,得到MCC-γ-PGA混合液;(2) The MCC aqueous suspension and the γ-PGA aqueous suspension prepared in step (1) are stirred for 30 min with a magnetic stirrer according to a mass ratio of 2:1 at a rotational speed of 1000 r/min to obtain a MCC-γ-PGA mixed solution ;

(3)向步骤(2)得到的微晶纤维素-γ-聚谷氨酸混合液中依次加入ε-PL(添加量为微晶纤维素-γ-聚谷氨酸混合液质量的5%)和增塑剂(甘油,添加量为微晶纤维素-γ-聚谷氨酸混合液质量的1%),采用高速分散机在18000rpm下均质10min,然后在水浴恒温磁力搅拌器内保持40℃,转速为800r/min下搅拌20min,自然冷却后在40HZ下超声脱气25min,得到膜液;(3) adding ε-PL (the addition amount is 5% of the mass of the microcrystalline cellulose-γ-polyglutamic acid mixed solution) into the microcrystalline cellulose-γ-polyglutamic acid mixed solution obtained in step (2) in turn ) and plasticizer (glycerol, the addition amount is 1% of the mass of the microcrystalline cellulose-γ-polyglutamic acid mixture), homogenize at 18000 rpm with a high-speed disperser for 10 min, and then keep it in a water bath constant temperature

(4)将步骤(3)得到的膜液均匀倒入模具盘中静置24h成膜,随后置于烘箱中在35℃下烘干24h,冷却后得到保鲜膜。(4) The film liquid obtained in step (3) was evenly poured into a mold tray and left to stand for 24 hours to form a film, then placed in an oven to be dried at 35° C. for 24 hours, and a fresh-keeping film was obtained after cooling.

实施例3Example 3

(1)称取MCC溶于蒸馏水中,制备成浓度为10wt%的MCC水悬浮液(溶解MCC时,在磁力搅拌器的作用下同时将MCC缓慢的加入到蒸馏水中),磁力搅拌30min;(1) take by weighing MCC and be dissolved in distilled water, prepare the MCC water suspension that concentration is 10wt% (when dissolving MCC, under the effect of magnetic stirrer, MCC is slowly added to distilled water), magnetic stirring 30min;

称取γ-PGA(分子量为50万Da)溶于蒸馏水中,制备成浓度为10wt%的γ-PGA水悬浮液(溶解γ-PGA时,在磁力搅拌器的作用下同时将γ-PGA缓慢的加入到蒸馏水中),磁力搅拌30min;Weigh γ-PGA (with a molecular weight of 500,000 Da) and dissolve it in distilled water to prepare a γ-PGA aqueous suspension with a concentration of 10 wt% (when dissolving γ-PGA, under the action of a magnetic stirrer, slowly γ-PGA was added to distilled water), magnetic stirring for 30min;

(2)将步骤(1)配置得到的MCC水悬浮液和γ-PGA水悬浮液按照质量比2:1采用磁力搅拌器在转速为1000r/min下搅拌30min,得到MCC-γ-PGA混合液;(2) The MCC aqueous suspension and the γ-PGA aqueous suspension prepared in step (1) are stirred for 30 min with a magnetic stirrer according to a mass ratio of 2:1 at a rotational speed of 1000 r/min to obtain a MCC-γ-PGA mixed solution ;

(3)向步骤(2)得到的微晶纤维素-γ-聚谷氨酸混合液中依次加入ε-PL(添加量为微晶纤维素-γ-聚谷氨酸混合液质量的3%)和增塑剂(甘油,添加量为微晶纤维素-γ-聚谷氨酸混合液质量的1%),采用高速分散机在20000rpm下均质5min,然后在电热恒温水浴锅内保持60℃,转速为800r/min下搅拌30min,自然冷却后在40HZ下超声脱气30min,得到膜液;(3) adding ε-PL (the addition amount is 3% of the mass of the microcrystalline cellulose-γ-polyglutamic acid mixed solution) into the microcrystalline cellulose-γ-polyglutamic acid mixed solution obtained in step (2) in turn ) and plasticizer (glycerol, the addition amount is 1% of the mass of the microcrystalline cellulose-γ-polyglutamic acid mixture), homogenize at 20,000 rpm with a high-speed disperser for 5 min, and then keep it in an electric heating constant temperature water bath for 60 ℃, stirring at 800r/min for 30min, after natural cooling, ultrasonic degassing at 40HZ for 30min to obtain membrane liquid;

(4)将步骤(3)得到的膜液均匀倒入模具盘中静置24h成膜,随后置于烘箱中在35℃下烘干24h,冷却后得到保鲜膜,如图1所示。(4) The film liquid obtained in step (3) was evenly poured into the mold plate and allowed to stand for 24 hours to form a film, then placed in an oven to dry at 35°C for 24 hours, and cooled to obtain a fresh-keeping film, as shown in Figure 1.

实施例4Example 4

(1)称取MCC溶于蒸馏水中,制备成浓度为8wt%的MCC水悬浮液(溶解MCC时,在磁力搅拌器的作用下同时将MCC缓慢的加入到蒸馏水中),磁力搅拌30min;(1) take by weighing MCC and be dissolved in distilled water, prepare the MCC water suspension that concentration is 8wt% (when dissolving MCC, under the effect of magnetic stirrer, MCC is slowly added to distilled water), magnetic stirring 30min;

称取γ-PGA(分子量为80万Da)溶于蒸馏水中,制备成浓度为10wt%的γ-PGA水悬浮液(溶解γ-PGA时,在磁力搅拌器的作用下同时将γ-PGA缓慢的加入到蒸馏水中),磁力搅拌30min;Weigh γ-PGA (molecular weight of 800,000 Da) and dissolve it in distilled water to prepare a γ-PGA aqueous suspension with a concentration of 10 wt% (when dissolving γ-PGA, under the action of a magnetic stirrer, slowly γ-PGA was added to distilled water), magnetic stirring for 30min;

(2)将步骤(1)配置得到的MCC水悬浮液和γ-PGA水悬浮液按照质量比2:1采用磁力搅拌器在转速为1000r/min下搅拌45min,得到MCC-γ-PGA混合液;(2) The MCC aqueous suspension and the γ-PGA aqueous suspension prepared in step (1) are stirred for 45 min with a magnetic stirrer according to a mass ratio of 2:1 at a rotational speed of 1000 r/min to obtain a MCC-γ-PGA mixed solution ;

(3)向步骤(2)得到的微晶纤维素-γ-聚谷氨酸混合液中依次加入ε-PL(添加量为微晶纤维素-γ-聚谷氨酸混合液质量的5%)和增塑剂(甘油,添加量为微晶纤维素-γ-聚谷氨酸混合液质量的1.5%),采用高速分散机在20000rpm下均质8min,然后在电热恒温水浴锅内保持60℃,转速为800r/min下搅拌30min,自然冷却后在40HZ下超声脱气30min,得到膜液;(3) adding ε-PL (the addition amount is 5% of the mass of the microcrystalline cellulose-γ-polyglutamic acid mixed solution) into the microcrystalline cellulose-γ-polyglutamic acid mixed solution obtained in step (2) in turn ) and plasticizer (glycerol, the addition amount is 1.5% of the mass of the microcrystalline cellulose-γ-polyglutamic acid mixed solution), homogenize at 20,000 rpm with a high-speed disperser for 8 min, and then keep it in an electric heating constant temperature water bath for 60 ℃, stirring at 800r/min for 30min, after natural cooling, ultrasonic degassing at 40HZ for 30min to obtain membrane liquid;

(4)将步骤(3)得到的膜液均匀倒入模具盘中静置24h成膜,随后置于烘箱中在38℃下烘干22h,冷却后得到保鲜膜。(4) The film liquid obtained in step (3) was evenly poured into a mold tray and left to stand for 24 hours to form a film, then placed in an oven to be dried at 38° C. for 22 hours, and a fresh-keeping film was obtained after cooling.

实施例5Example 5

(1)称取MCC溶于蒸馏水中,制备成浓度为10wt%的MCC水悬浮液(溶解MCC时,在磁力搅拌器的作用下同时将MCC缓慢的加入到蒸馏水中),磁力搅拌30min;(1) take by weighing MCC and be dissolved in distilled water, prepare the MCC water suspension that concentration is 10wt% (when dissolving MCC, under the effect of magnetic stirrer, MCC is slowly added to distilled water), magnetic stirring 30min;

称取γ-PGA(分子量为50万Da)溶于蒸馏水中,制备成浓度为12wt%的γ-PGA水悬浮液(溶解γ-PGA时,在磁力搅拌器的作用下同时将γ-PGA缓慢的加入到蒸馏水中),磁力搅拌30min;Weigh γ-PGA (with a molecular weight of 500,000 Da) and dissolve it in distilled water to prepare a γ-PGA aqueous suspension with a concentration of 12 wt% (when dissolving γ-PGA, slowly γ-PGA is slowly mixed under the action of a magnetic stirrer. was added to distilled water), magnetic stirring for 30min;

(2)将步骤(1)配置得到的MCC水悬浮液和γ-PGA水悬浮液按照质量比2:1采用磁力搅拌器在转速为1200r/min下搅拌60min,得到MCC-γ-PGA混合液;(2) The MCC aqueous suspension and the γ-PGA aqueous suspension prepared in step (1) were stirred for 60 min with a magnetic stirrer according to a mass ratio of 2:1 at a rotational speed of 1200 r/min to obtain a MCC-γ-PGA mixed solution ;

(3)向步骤(2)得到的微晶纤维素-γ-聚谷氨酸混合液中依次加入ε-PL(添加量为微晶纤维素-γ-聚谷氨酸混合液质量的3%)和增塑剂(甘油,添加量为微晶纤维素-γ-聚谷氨酸混合液质量的2%),采用高速分散机在20000rpm下均质5min,然后在电热恒温水浴锅内保持50℃,转速为700r/min下搅拌30min,自然冷却后在45HZ下超声脱气30min,得到膜液;(3) adding ε-PL (the addition amount is 3% of the mass of the microcrystalline cellulose-γ-polyglutamic acid mixed solution) into the microcrystalline cellulose-γ-polyglutamic acid mixed solution obtained in step (2) in turn ) and plasticizer (glycerol, the addition amount is 2% of the mass of the microcrystalline cellulose-γ-polyglutamic acid mixed solution), homogenize at 20,000 rpm with a high-speed disperser for 5 min, and then keep it in an electric heating constant temperature water bath for 50 ℃, stirring at 700r/min for 30min, after natural cooling, ultrasonic degassing at 45HZ for 30min to obtain membrane liquid;

(4)将步骤(3)得到的膜液均匀倒入模具盘中静置20h成膜,随后置于烘箱中在40℃下烘干24h,冷却后得到保鲜膜,如图2所示。(4) The film liquid obtained in step (3) was evenly poured into the mold plate and left to stand for 20 hours to form a film, then placed in an oven to dry at 40° C. for 24 hours, and after cooling, a fresh-keeping film was obtained, as shown in Figure 2.

表1给出了实施例1~实施例5的参数值。Table 1 shows the parameter values of Examples 1 to 5.

表1不同实施例的参数值Table 1 Parameter values of different embodiments

不同实施例的参数范围为:微晶纤维素浓度6-10wt%;γ-聚谷氨酸浓度5-15wt%;γ-聚谷氨酸分子量50万-100万Da;ε-聚赖氨酸浓度1-5%;增塑剂浓度1-2%;磁力搅拌器转速、搅拌时间分别为600-1200、30-60;高速均质机转速、均质时间分别为15000-20000、5-10min;水浴恒温磁力搅拌器温度、转速、时间分别为40-60℃、600-800r/mim、15-30min;超声脱气频率、时间分别为35-45HZ、20-30min;膜液静置时间18-24h;薄膜烘干温度、时间分别为35-40℃、20-24h。The parameter ranges of different embodiments are: the concentration of microcrystalline cellulose is 6-10wt%; the concentration of γ-polyglutamic acid is 5-15wt%; the molecular weight of γ-polyglutamic acid is 500,000-1 million Da; ε-polylysine Concentration 1-5%; plasticizer concentration 1-2%; magnetic stirrer speed and stirring time are 600-1200, 30-60 respectively; high-speed homogenizer speed and homogenization time are 15000-20000, 5-10min respectively ; The temperature, rotation speed and time of the water bath constant temperature magnetic stirrer are respectively 40-60℃, 600-800r/mim, 15-30min; the frequency and time of ultrasonic degassing are 35-45HZ and 20-30min respectively; the standing time of the membrane liquid is 18 -24h; film drying temperature and time are 35-40°C and 20-24h respectively.

为验证本发明的四种组份(MCC、γ-PGA、ε-PL、甘油)具有协同增效作用,增加两组对比试验MCC+γ-PGA+甘油和MCC+ε-PL+甘油,具体参数如表2所示。In order to verify that the four components of the present invention (MCC, γ-PGA, ε-PL, glycerol) have synergistic effect, two groups of comparative experiments MCC+γ-PGA+glycerol and MCC+ε-PL+glycerol are added, and the specific parameters are as follows. shown in Table 2.

表2对比试验的参数值Table 2 The parameter values of the comparative test

试验1具体操作步骤:The specific operation steps of test 1:

(1)分别配置MCC水悬浮液和γ-PGA水悬浮液,按照质量比2:1采用磁力搅拌器在转速为1000r/min下搅拌30min,将其混合得到MCC-γ-PGA混合液;(1) Dispose MCC water suspension and γ-PGA water suspension respectively, adopt magnetic stirrer to stir 30min under the rotating speed of 1000r/min according to the mass ratio of 2:1, and mix them to obtain MCC-γ-PGA mixed solution;

(2)向步骤(1)得到的MCC-γ-PGA混合液中加入增塑剂甘油(添加量为MCC-γ-PGA混合液质量的1~2%);(2) adding plasticizer glycerin to the MCC-γ-PGA mixed solution obtained in step (1) (the addition amount is 1-2% of the mass of the MCC-γ-PGA mixed solution);

(3)采用高速分散机在20000rpm下均质5min,然后在电热恒温水浴锅内保持60℃,转速为800r/min下搅拌30min,自然冷却后在40HZ下超声脱气30min,得到膜液,将膜液均匀倒入模具盘中静置24h成膜,随后置于烘箱中在35℃下烘干24h,冷却后得到保鲜膜。(3) Homogenize at 20,000 rpm for 5 min with a high-speed disperser, then keep at 60°C in an electric heating constant temperature water bath, stir at a rotational speed of 800 r/min for 30 min, and after natural cooling, ultrasonically degas at 40 Hz for 30 min to obtain a film liquid, The film liquid was evenly poured into the mold plate and left to stand for 24 hours to form a film, and then placed in an oven to be dried at 35° C. for 24 hours, and a fresh-keeping film was obtained after cooling.

与试验1的不同之处在于,试验2混合得到MCC-ε-PL混合液,其余皆相同。The difference from Experiment 1 is that in

将鲜活的淡水鱼处死后去除内脏,用去离子水洗净后切片,然后分别用实施例1~5和对比试验1和实验2制备的吸水抑菌可降解的淡水鱼保鲜膜和普通保鲜膜(PE)包裹好后放入冰箱中,在4±1℃条件下冷藏。After the freshwater fish is put to death, the internal organs are removed, and the slices are cleaned with deionized water, and then the freshwater fish preservative films and the common fresh-keeping fresh-water fish that are prepared by Examples 1 to 5 and Comparative Experiment 1 and

TVB-N(挥发性盐基氮)评价法是判断鱼类鲜度的主要化学指标之一,按照我国水产品鲜度的行业标准规定,淡水鱼一级品的TVB-N值≤13mg/100g,二级品的TVB-N值≤20mg/100g,鱼肉可接受TVB-N值在35~40mg/100g。参考国标GB 5009.44-2003中的半微量定氮法进行鲜度测定,单位以mg/100g样品表示。其具体操作为:称取冷藏一定时间的试样约10.0g,使用均质机匀浆后倒入锥形瓶中,加入100mL水,浸渍30min后过滤,收集滤液于冰箱备用;将盛有10mL硼酸吸收液(20g/L)及5~6滴混合指示液(2g/L的甲基红乙醇指示剂和1g/L的次甲基蓝指示剂等量混合)的锥形瓶置于冷凝管下端,准确吸取5.0mL试样滤液于蒸馏器反应室内,加入5mL氧化镁混悬液(10g/L),迅速盖塞,通入蒸汽进行蒸馏,蒸馏5min即停止,吸收液用0.010mol/L的盐酸标准溶液滴定,直至终点至蓝紫色,同时做试剂空白试验。TVB-N (volatile base nitrogen) evaluation method is one of the main chemical indicators for judging the freshness of fish. According to the industry standards for freshness of aquatic products in my country, the TVB-N value of first-class freshwater fish is ≤13mg/100g , the TVB-N value of the secondary product is ≤20mg/100g, and the acceptable TVB-N value of fish meat is 35-40mg/100g. Refer to the semi-micro nitrogen determination method in the national standard GB 5009.44-2003 for freshness determination, and the unit is expressed in mg/100g sample. The specific operation is as follows: weigh about 10.0 g of the sample that has been refrigerated for a certain period of time, use a homogenizer to homogenize it and pour it into a conical flask, add 100 mL of water, soak for 30 min, filter, and collect the filtrate for use in the refrigerator; The conical flask of boric acid absorption solution (20g/L) and 5-6 drops of mixed indicator solution (2g/L methyl red ethanol indicator and 1g/L methine blue indicator mixed in equal amounts) is placed in the condenser tube At the lower end, accurately draw 5.0 mL of the sample filtrate into the reaction chamber of the distiller, add 5 mL of magnesium oxide suspension (10 g/L), quickly cover the stopper, pass in steam for distillation, and stop the distillation after 5 minutes, and use 0.010 mol/L for the absorption liquid. The standard solution of hydrochloric acid is titrated until the end point is blue-violet, and the reagent blank test is done at the same time.

各实施例鱼片(实验组)贮藏期间TVB-N变化如图3所示,保鲜膜(PE)包裹组作为空白对照组。结果显示,新鲜草鱼的TVB-N含量接近6mg/100g,贮藏期间,各组鱼片TVB-N值均显著上升,贮藏前3天空白对照组含量明显高于其余五组样品,这表明各实验组鱼片在冷藏前3天保持良好的新鲜度。之后对照组和实验组的TVB-N值均迅速上升,但各组实施例在贮藏末期的TVB-N值分别较对照组要小很多。The changes of TVB-N during the storage period of the fish fillets (experimental group) of each embodiment are shown in Fig. 3, and the wrapping film (PE) group was used as the blank control group. The results showed that the TVB-N content of fresh grass carp was close to 6mg/100g. During the storage period, the TVB-N value of fish fillets in each group increased significantly, and the content of the blank control group was significantly higher than that of the other five groups of samples 3 days before storage. Group fillets maintain good freshness for 3 days before refrigeration. After that, the TVB-N values of the control group and the experimental group both increased rapidly, but the TVB-N values of the examples in each group at the end of storage were much lower than those of the control group.

以TVB-N值≤13mg/100g作为鱼肉腐败的临界值,各组不同条件下的鱼片贮藏货架期,如表3所示。Taking TVB-N value ≤13mg/100g as the critical value of fish meat spoilage, the shelf life of fish fillets under different conditions in each group is shown in Table 3.

表3不同实施例在TVB-N评估中的鱼片货架期Table 3 Shelf life of fillets in TVB-N evaluation for different embodiments

其中,实施例1、2、3、4、5分别与空白对照PE组相比较,分别延长了淡水鱼货架期5.5天、7天、11天、6天、8天,实施例3表现出相对更为显著的保鲜效果,可见该种吸水抑菌可降解的保鲜膜可延长淡水鱼肉6~11天。对比试验1、2与空白对照PE组比较,分别延长了淡水鱼货架期2天、1.5天。将MCC+γ-PGA+ε-PL+甘油四种组份和MCC+γ-PGA+甘油,以及MCC+ε-PL+甘油三种组份作比较,MCC+γ-PGA+ε-PL+甘油四种配方具有更显著的保鲜效果。Wherein, compared with the blank control PE group, Examples 1, 2, 3, 4, and 5 prolong the shelf life of freshwater fish by 5.5 days, 7 days, 11 days, 6 days, and 8 days, respectively. More significant fresh-keeping effect, it can be seen that this kind of water-absorbing, bacteriostatic and degradable fresh-keeping film can prolong freshwater fish meat for 6 to 11 days. Compared with the blank control PE group, the

微生物活动是引起鱼肉腐败的重要原因,在各种标准中,菌落总数是评价鱼肉腐败变质的硬性指标。一般情况下,新鲜鱼肉的菌落总数(TVC)在2~4log10cfu/g之间,当TVC增长到6~7log10cfu/g时,鱼肉处于腐败初期,我国先前无公害水产品安全标准的最大TVC允许值为6log10cfu/g。微生物评价淡水鱼肉的方法为:将鱼肉样品切碎后称取10g置于无菌均质袋中,加入90mL 0.9%的无菌生理盐水,均质4min,吸取1mL均匀混液进行10倍梯度稀释(10-1、10-2、10-3......10-10),分别吸取不同浓度的稀释液对微生物进行均匀涂布培养,后计算菌落数,所有操作在无菌条件下进行,微生物计数单位为1og1o cfu/g。Microbial activity is an important cause of fish meat spoilage. Among various standards, the total number of bacterial colonies is a hard indicator for evaluating fish meat spoilage. Under normal circumstances, the total number of bacterial colonies (TVC) of fresh fish meat is between 2 and 4log10cfu/g. When the TVC increases to 6 to 7log10cfu/g, the fish meat is in the early stage of corruption. The maximum allowable TVC value of my country's previous pollution-free aquatic product safety standards is 6log10cfu/g. The method for microbial evaluation of freshwater fish is as follows: after the fish sample is chopped, weigh 10 g and place it in a sterile homogenizing bag, add 90 mL of 0.9% sterile saline, homogenize for 4 min, and draw 1 mL of the uniform mixture for 10-fold gradient dilution (10-1 ,10-2 ,10-3...... , the microbial count unit is 1og1o cfu/g.

各组实施例鱼片贮藏期间TVC变化如图4所示,保鲜膜(PE)包裹组作为空白对照组。随着贮藏时间的延长,空白对照组TVC持续增加,相比之下各组实施例TVC在贮藏前3天无明显变化,之后再持续增加,各组实施例在贮藏末期的TVC值分别较对照组明显要小很多。Figure 4 shows the changes in TVC of the fish fillets in each group of examples during storage, and the plastic wrap (PE)-wrapped group was used as a blank control group. With the prolongation of storage time, the TVC of the blank control group continued to increase. In contrast, the TVC of the examples in each group had no significant change in the first 3 days of storage, and then continued to increase. The TVC values of the examples in each group at the end of storage were higher than those of the control The group was significantly smaller.

以TVC≤6.0log10cfu/g作为鱼肉腐败的临界值,各组不同条件下的鱼片贮藏货架期,如表4所示。Taking TVC≤6.0log10 cfu/g as the critical value of fish meat spoilage, the shelf life of fish fillets under different conditions in each group is shown in Table 4.

表4不同实施例在TVC评估中的鱼片货架期Table 4 Shelf life of fillets in TVC evaluation for different embodiments

其中,实施例1、2、3、4、5分别与空白对照PE组相比较,分别延长了淡水鱼货架期1.7天、3天、5天、2天、4天,实施例3表现出相对更为显著的保鲜效果,可见该种吸水抑菌可降解的保鲜膜可延长淡水鱼肉2~5天。对比1、2与空白对照PE组比较,分别延长了淡水鱼货架期0.5天。表明MCC+γ-PGA+ε-PL+甘油四种组份相比MCC+ε-PL+甘油,以及MCC+γ-PGA+甘油具有更显著的保鲜效果。Wherein, compared with the blank control PE group, Examples 1, 2, 3, 4, and 5 prolong the shelf life of freshwater fish by 1.7 days, 3 days, 5 days, 2 days, and 4 days, respectively. More significant fresh-keeping effect, it can be seen that this kind of water-absorbing, bacteriostatic and degradable fresh-keeping film can prolong freshwater fish meat for 2 to 5 days. Compared with the blank control PE group, the shelf life of freshwater fish was prolonged by 0.5 days in

由此可见,这种吸水抑菌可降解的保鲜膜包裹淡水鱼肉有助于抑制鱼肉中微生物的生长,且实施例3的抑菌效果优于其它实施例组。TVB-N和TVC是水产品货架期评价的经典方法之一,其中TVC评价所得到的各组鱼片货架期延长效果较短,而TVB-N评价所得到的各组鱼片货架期延长效果较长。实施例1和4处理对淡水鱼肉保鲜的货架期延长效果无显著差异。It can be seen that this water-absorbing, bacteriostatic and degradable preservative film wraps freshwater fish meat to help inhibit the growth of microorganisms in the fish meat, and the bacteriostatic effect of Example 3 is better than that of other example groups. TVB-N and TVC are one of the classic methods for evaluating the shelf life of aquatic products. Among them, the shelf life extension effect of each group of fish fillets obtained by TVC evaluation is short, while the shelf life extension effect of each group of fish fillets obtained by TVB-N evaluation is short. longer. There was no significant difference between the treatments of Examples 1 and 4 on the shelf-life extension effect of freshwater fish preservation.

本发明使用γ-PGA作为吸水剂,制备淡水鱼肉浸出液汁的保鲜吸附薄膜,而冷鲜肉中浸出血液成分属于复杂的电解质溶液,影响吸附的主要因素是NaCl,因此该吸水剂的抗盐性是一个重要的考察指标,国际上通常采用生理盐水模拟血液和模拟尿液作为吸水剂抗盐性的测试液。本试验采用模拟血液(质量分数)为:去离子水88.14%,甘油10.00%,NaCl 1.00%,Na2CO30.40%,CMC(羧甲基纤维素)0.46%。具体操作步骤为:称取0.1g保鲜膜样品放入滤袋中,再将滤袋放入烧杯中,加入足量的模拟血液,使保鲜膜充分吸水溶胀,在4℃中每隔一定时间取出,通过滤袋将多余的模拟血液滤出,直至30min内无液滴滴出,收集并测量滤出的液体量,测其吸附倍率,观察吸附倍率与时间的关系曲线,即为该保鲜膜的吸附动力曲线。In the present invention, γ-PGA is used as a water absorbing agent to prepare a fresh-keeping adsorption film for freshwater fish meat leaching juice, while the leached blood component in chilled meat belongs to a complex electrolyte solution, and the main factor affecting the adsorption is NaCl, so the salt resistance of the water absorbing agent is It is an important indicator for investigation. In the world, normal saline is usually used to simulate blood and simulated urine as the test solution for the salt resistance of absorbents. The simulated blood (mass fraction) used in this test is: deionized water 88.14%, glycerol 10.00%, NaCl 1.00%, Na2 CO3 0.40%, CMC (carboxymethyl cellulose) 0.46%. The specific operation steps are as follows: Weigh 0.1g of the plastic wrap sample and put it into the filter bag, then put the filter bag into the beaker, add a sufficient amount of simulated blood to make the plastic wrap fully absorb water and swell, and take it out at regular intervals at 4°C , filter out the excess simulated blood through the filter bag until no droplets drip out within 30min, collect and measure the amount of filtered liquid, measure its adsorption rate, and observe the relationship between adsorption rate and time, which is the Adsorption kinetic curve.

吸附倍率(g/g)=(加入测试液体质量-滤出测试液体质量)/保鲜膜的绝干质量Adsorption ratio (g/g) = (weight of test liquid added - quality of test liquid filtered out) / absolute dry mass of plastic wrap

各组实施例制备获得的保鲜膜的吸附动力曲线如图5所示,保鲜膜(PE)组作为空白对照组。随着吸附时间的延长,该保鲜膜在前40min内吸附倍率增长迅速,实施例3对模拟血液的吸附率增加最大,达到136g/g左右,实施例1对模拟血液的吸附率增加最小,达到90g/g左右。其中,5组实施例分别与空白对照PE组相比较,实施例3制备的保鲜膜对模拟血液的吸附效果最好,达到163g/g。随着时间的延长,吸附倍率增长趋势较平缓,达到饱和。对比试验1和2对模拟血液的吸附效果最高达到95g/g和89g/g。由于淡水鱼肉中汁液浸出的速率非常缓慢,所以γ-PGA作为制备保鲜膜吸附芯材其吸附速率完全可以有效吸附淡水鱼肉的渗出血水。The adsorption kinetic curves of the fresh-keeping films prepared in the examples of each group are shown in Figure 5, and the fresh-keeping film (PE) group was used as a blank control group. With the extension of the adsorption time, the adsorption rate of the fresh-keeping film increased rapidly in the first 40 minutes. The adsorption rate of Example 3 to simulated blood increased the most, reaching about 136 g/g. About 90g/g. Among them, the five groups of examples were compared with the blank control PE group, and the cling film prepared in Example 3 had the best adsorption effect on simulated blood, reaching 163 g/g. With the prolongation of time, the growth trend of the adsorption rate was gentle and reached saturation. The adsorption effect on simulated blood of

以样品的失重率作为各组实施例制备薄膜的降解性研究参考,选择室内情况下对其降解性进行测试。室内条件设定为恒温恒湿箱,试验条件为湿度(60±2)%、温度(30±1)℃,选用10cm×10cm的正方形样品薄膜,将其埋在土壤中,定期取出,将样品放置容器中,用蒸馏水去除可能影响试验结果的残留土壤及残叶,待完全清洗干净,用滤纸擦拭干,将其放置于玻璃板上在65℃烘箱中烘干至恒重(W1),试验初期样品烘干至恒重的质量为W0。The weight loss rate of the samples was used as a reference for the degradability research of the films prepared in each group of examples, and the degradability was tested in indoor conditions. The indoor conditions are set to a constant temperature and humidity chamber, and the test conditions are humidity (60±2)%, temperature (30±1) °C, and a 10cm×10cm square sample film is selected, buried in the soil, and taken out regularly. Put it in a container, use distilled water to remove the residual soil and leaves that may affect the test results, and after it is completely cleaned, wipe it dry with filter paper, place it on a glass plate and dry it in a 65°C oven to constant weight (W1 ), At the beginning of the test, the mass of the sample dried to constant weight is W0 .

薄膜的失重率计算公式如下:The formula for calculating the weight loss rate of the film is as follows:

失重率I(%)=(W0-W1)/W0×100%,平行处理3次取平均值,即为所求失重率。在室内土埋降解试验中各组实施例制备获得的保鲜膜的失重率变化如图6所示,保鲜膜(PE)组作为空白对照组。随着对五组实施例制备获得的保鲜膜土埋时间的延长,失重率呈现先增长较快后稳步增长的趋势,且实施例3制备获得的保鲜膜重量变化相比最大,失重率高达87%,至降解试验末期即第60天,保鲜膜已经大部分降解完全,五组实施例在35天以后失重率的变化趋于平缓,可见该保鲜膜的生物降解性较好。对比试验的失重率最高达到43%和45%。The weight loss rate I (%)=(W0 -W1 )/W0 ×100%, and the average value of three parallel treatments is taken as the weight loss rate. In the indoor soil burial degradation test, the weight loss rate changes of the fresh-keeping films prepared by the examples of each group are shown in Figure 6, and the fresh-keeping film (PE) group was used as the blank control group. With the prolongation of the soil burial time of the fresh-keeping films prepared in the five groups of examples, the weight loss rate showed a trend of increasing rapidly at first and then steadily increasing, and the weight of the fresh-keeping films prepared in Example 3 changed the most, and the weight loss rate was as high as 87%. %, by the end of the degradation test, that is, on the 60th day, most of the plastic wrap had been completely degraded, and the weight loss rate of the five groups of examples tended to be flat after 35 days, indicating that the plastic wrap had better biodegradability. The weight loss rate of the comparison test was up to 43% and 45%.

综合上述评价,本发明制备的保鲜膜在淡水鱼肉保鲜上作用突出,相比现有的PE保鲜膜具有显著的进步。其中,本发明实施例3制备的保鲜膜对淡水鱼肉保鲜作用最为突出,能延长淡水鱼肉货架期约5~11天,对模拟血液的吸附倍率达到163g/g,可以有效吸附淡水鱼肉的渗出血水,在室内土埋降解试验中的保鲜膜失重率最高达到87%,可达到大部分降解完全。Based on the above evaluation, the fresh-keeping film prepared by the present invention has a prominent effect on fresh-water fish preservation, and has a significant improvement compared with the existing PE fresh-keeping film. Among them, the fresh-keeping film prepared in Example 3 of the present invention has the most outstanding effect on freshwater fish meat preservation, can prolong the shelf life of freshwater fish meat by about 5 to 11 days, the adsorption rate of simulated blood reaches 163 g/g, and can effectively absorb the exudation of freshwater fish meat. Blood water, the weight loss rate of the plastic wrap in the indoor soil burial degradation test is up to 87%, and most of it can be completely degraded.

本发明提供了一种吸水抑菌可降解的淡水鱼保鲜膜及其制备方法的思路及方法,具体实现该技术方案的方法和途径很多,以上所述仅是本发明的优选实施方式,应当指出,对于本技术领域的普通技术人员来说,在不脱离本发明原理的前提下,还可以做出若干改进和润饰,这些改进和润饰也应视为本发明的保护范围。本实施例中未明确的各组成部分均可用现有技术加以实现。The present invention provides a water-absorbing, bacteriostatic and degradable freshwater fish fresh-keeping film and a method for preparing the same. There are many specific methods and approaches to realize the technical solution. The above are only the preferred embodiments of the present invention, and it should be pointed out that For those skilled in the art, without departing from the principle of the present invention, several improvements and modifications can also be made, and these improvements and modifications should also be regarded as the protection scope of the present invention. All components not specified in this embodiment can be implemented by existing technologies.

Claims (9)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010971833.8ACN112048090B (en) | 2020-09-16 | 2020-09-16 | Water-absorbing antibacterial degradable fresh-water fish preservative film and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010971833.8ACN112048090B (en) | 2020-09-16 | 2020-09-16 | Water-absorbing antibacterial degradable fresh-water fish preservative film and preparation method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN112048090Atrue CN112048090A (en) | 2020-12-08 |

| CN112048090B CN112048090B (en) | 2023-10-03 |

Family

ID=73604338

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010971833.8AActiveCN112048090B (en) | 2020-09-16 | 2020-09-16 | Water-absorbing antibacterial degradable fresh-water fish preservative film and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112048090B (en) |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112772709A (en)* | 2021-01-06 | 2021-05-11 | 南京工业大学 | Preservative film antibacterial spray and preparation method and application thereof |

| CN113402897A (en)* | 2021-07-06 | 2021-09-17 | 茶纤之维(福建)环保科技有限公司 | High-content tea fiber and plant starch modified composite material, preparation method and application |

| CN113583438A (en)* | 2021-08-06 | 2021-11-02 | 海南金海浆纸业有限公司 | Biodegradable alkali lignin composite material, preparation method and application thereof |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104544472A (en)* | 2014-12-26 | 2015-04-29 | 山东省药学科学院 | Shrimp preservative containing pulullan polysaccharide |

| CN105504357A (en)* | 2016-01-21 | 2016-04-20 | 天津科技大学 | Antibacterial-type nanofiber-based preservative film and preparation method thereof |

| CN105968405A (en)* | 2016-05-30 | 2016-09-28 | 天津工业大学 | Antimicrobial moisturizing degradable porous gel preservative film and preparation method and application thereof |

| US20170014543A1 (en)* | 2013-12-11 | 2017-01-19 | Nanjing Tech University | HYDROGEL BASED ON γ-POLYGLUTAMIC ACID AND ε-POLYLYSINE CROSSLINKED POLYMER, AND PREPARATION METHOD THEREFOR |

| CN107047749A (en)* | 2017-06-08 | 2017-08-18 | 合肥慧明瀚生态农业科技有限公司 | A kind of environmental protection fruit and vegetable fresh-keeping agent and preparation method thereof |

- 2020

- 2020-09-16CNCN202010971833.8Apatent/CN112048090B/enactiveActive

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20170014543A1 (en)* | 2013-12-11 | 2017-01-19 | Nanjing Tech University | HYDROGEL BASED ON γ-POLYGLUTAMIC ACID AND ε-POLYLYSINE CROSSLINKED POLYMER, AND PREPARATION METHOD THEREFOR |

| CN104544472A (en)* | 2014-12-26 | 2015-04-29 | 山东省药学科学院 | Shrimp preservative containing pulullan polysaccharide |

| CN105504357A (en)* | 2016-01-21 | 2016-04-20 | 天津科技大学 | Antibacterial-type nanofiber-based preservative film and preparation method thereof |

| CN105968405A (en)* | 2016-05-30 | 2016-09-28 | 天津工业大学 | Antimicrobial moisturizing degradable porous gel preservative film and preparation method and application thereof |

| CN107047749A (en)* | 2017-06-08 | 2017-08-18 | 合肥慧明瀚生态农业科技有限公司 | A kind of environmental protection fruit and vegetable fresh-keeping agent and preparation method thereof |

Cited By (3)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112772709A (en)* | 2021-01-06 | 2021-05-11 | 南京工业大学 | Preservative film antibacterial spray and preparation method and application thereof |

| CN113402897A (en)* | 2021-07-06 | 2021-09-17 | 茶纤之维(福建)环保科技有限公司 | High-content tea fiber and plant starch modified composite material, preparation method and application |

| CN113583438A (en)* | 2021-08-06 | 2021-11-02 | 海南金海浆纸业有限公司 | Biodegradable alkali lignin composite material, preparation method and application thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| CN112048090B (en) | 2023-10-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN112048090B (en) | Water-absorbing antibacterial degradable fresh-water fish preservative film and preparation method thereof | |

| CN100401921C (en) | Natural film-forming preservative for crystal meat | |

| CN111269515B (en) | Degradable film with antibacterial function and preparation method thereof | |

| CN106883465B (en) | Preparation method of chitosan composite preservative film | |

| CN103053670A (en) | Composited sodium alga acid antibacterial film and application thereof in preservation of livestock meat carcass | |

| CN103570958B (en) | Edible chitosan-collagen antibacterial film and preparation method thereof | |

| CN104489854A (en) | Lagerstroemia speciosa preservative | |

| CN110818956A (en) | Chitosan-nano titanium dioxide composite membrane and preparation method thereof | |

| CN111925541B (en) | Antibacterial and fresh-keeping composite freeze-thaw edible film for cold fresh meat and preparation method thereof | |

| CN102977414B (en) | Edible composite preservative film applied to preservation of fresh pork in supermarket | |

| CN112831074A (en) | A kind of preparation method and application of natural ionic liquid fresh-keeping film | |

| Wang et al. | Preservation effect of meat product by natural antioxidant tea polyphenol | |

| CN111607018A (en) | A kind of preparation method of thymol-embedded intelligent antibacterial fresh-keeping film | |

| CN113755968A (en) | A kind of polysaccharide nanofilm and preparation method thereof | |

| Li et al. | Study on film forming characteristic of ε-polylysine grafted chitosan through TEMPO oxidation system and its preservation effects for pork fillet | |

| CN110272628A (en) | Cold fresh meat active nano preservative film of anti-corrosion, anti-oxidant multiple-effect type and preparation method thereof | |

| CN107474501B (en) | A kind of degradable food preservation film and preparation method thereof | |

| CN102369974B (en) | Method for retaining freshness of mutton through membrane coating | |

| CN117941792A (en) | Composite antibacterial edible film solution loaded with essential oil nanoemulsion and preparation method and application thereof | |

| CN110862582A (en) | Hydrophobic organic/inorganic composite preservative film for meat products | |

| CN105475469A (en) | Preparation method and use of local flavor antimicrobial microemulsion | |

| CN105860110A (en) | Preparation method for antibacterial preservative film used for fresh silver carp fillet | |

| CN113388135B (en) | Preparation of PVA/tapioca starch/LAE active composite film and application of PVA/tapioca starch/LAE active composite film in food packaging bacteriostasis | |

| CN115868532A (en) | Kiwi fruit fresh-keeping storage method | |

| CN115433394A (en) | A kind of instant sea cucumber and preparation method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |