CN112038648A - A hollow structure transition metal cobalt and nitrogen co-doped carbon oxygen reduction catalyst and its preparation method and application - Google Patents

A hollow structure transition metal cobalt and nitrogen co-doped carbon oxygen reduction catalyst and its preparation method and applicationDownload PDFInfo

- Publication number

- CN112038648A CN112038648ACN202010920140.6ACN202010920140ACN112038648ACN 112038648 ACN112038648 ACN 112038648ACN 202010920140 ACN202010920140 ACN 202010920140ACN 112038648 ACN112038648 ACN 112038648A

- Authority

- CN

- China

- Prior art keywords

- cobalt

- nitrogen

- catalyst

- polystyrene microspheres

- preparation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- IJGRMHOSHXDMSA-UHFFFAOYSA-NAtomic nitrogenChemical compoundN#NIJGRMHOSHXDMSA-UHFFFAOYSA-N0.000titleclaimsabstractdescription56

- 239000003054catalystSubstances0.000titleclaimsabstractdescription48

- 229910017052cobaltInorganic materials0.000titleclaimsabstractdescription43

- 239000010941cobaltSubstances0.000titleclaimsabstractdescription43

- GUTLYIVDDKVIGB-UHFFFAOYSA-Ncobalt atomChemical compound[Co]GUTLYIVDDKVIGB-UHFFFAOYSA-N0.000titleclaimsabstractdescription43

- 229910052757nitrogenInorganic materials0.000titleclaimsabstractdescription28

- 230000009467reductionEffects0.000titleclaimsabstractdescription28

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription25

- 229910052723transition metalInorganic materials0.000titleclaimsabstractdescription21

- 150000003624transition metalsChemical class0.000titleclaimsabstractdescription21

- CSJDCSCTVDEHRN-UHFFFAOYSA-Nmethane;molecular oxygenChemical compoundC.O=OCSJDCSCTVDEHRN-UHFFFAOYSA-N0.000titleclaimsabstractdescription15

- 238000006722reduction reactionMethods0.000claimsabstractdescription34

- QVGXLLKOCUKJST-UHFFFAOYSA-Natomic oxygenChemical compound[O]QVGXLLKOCUKJST-UHFFFAOYSA-N0.000claimsabstractdescription20

- 239000001301oxygenSubstances0.000claimsabstractdescription20

- 229910052760oxygenInorganic materials0.000claimsabstractdescription20

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical compound[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000claimsabstractdescription12

- 229910052799carbonInorganic materials0.000claimsabstractdescription12

- 238000000034methodMethods0.000claimsabstractdescription10

- 239000000446fuelSubstances0.000claimsabstractdescription7

- 239000004005microsphereSubstances0.000claimsdescription60

- 239000004793PolystyreneSubstances0.000claimsdescription30

- 229920002223polystyrenePolymers0.000claimsdescription29

- PPBRXRYQALVLMV-UHFFFAOYSA-NStyreneChemical groupC=CC1=CC=CC=C1PPBRXRYQALVLMV-UHFFFAOYSA-N0.000claimsdescription25

- 229920001467poly(styrenesulfonates)Polymers0.000claimsdescription24

- 239000000243solutionSubstances0.000claimsdescription21

- 239000002243precursorSubstances0.000claimsdescription19

- OKKJLVBELUTLKV-UHFFFAOYSA-NMethanolChemical compoundOCOKKJLVBELUTLKV-UHFFFAOYSA-N0.000claimsdescription18

- 229910052751metalInorganic materials0.000claimsdescription14

- 239000002184metalSubstances0.000claimsdescription14

- 238000003763carbonizationMethods0.000claimsdescription13

- MYRTYDVEIRVNKP-UHFFFAOYSA-N1,2-DivinylbenzeneChemical compoundC=CC1=CC=CC=C1C=CMYRTYDVEIRVNKP-UHFFFAOYSA-N0.000claimsdescription12

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000claimsdescription12

- 239000000839emulsionSubstances0.000claimsdescription12

- 239000000463materialSubstances0.000claimsdescription12

- 239000013110organic ligandSubstances0.000claimsdescription12

- RAXXELZNTBOGNW-UHFFFAOYSA-NimidazoleNatural productsC1=CNC=N1RAXXELZNTBOGNW-UHFFFAOYSA-N0.000claimsdescription10

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterChemical compoundOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000claimsdescription10

- HEMHJVSKTPXQMS-UHFFFAOYSA-MSodium hydroxideChemical compound[OH-].[Na+]HEMHJVSKTPXQMS-UHFFFAOYSA-M0.000claimsdescription9

- 238000006243chemical reactionMethods0.000claimsdescription9

- 238000000197pyrolysisMethods0.000claimsdescription9

- 238000003756stirringMethods0.000claimsdescription9

- QAOWNCQODCNURD-UHFFFAOYSA-Nsulfuric acidSubstancesOS(O)(=O)=OQAOWNCQODCNURD-UHFFFAOYSA-N0.000claimsdescription9

- 229910021536ZeoliteInorganic materials0.000claimsdescription8

- 239000003960organic solventSubstances0.000claimsdescription8

- 239000010457zeoliteSubstances0.000claimsdescription8

- LXBGSDVWAMZHDD-UHFFFAOYSA-N2-methyl-1h-imidazoleChemical compoundCC1=NC=CN1LXBGSDVWAMZHDD-UHFFFAOYSA-N0.000claimsdescription7

- 239000008367deionised waterSubstances0.000claimsdescription7

- 229910021641deionized waterInorganic materials0.000claimsdescription7

- 239000012621metal-organic frameworkSubstances0.000claimsdescription7

- QJGQUHMNIGDVPM-UHFFFAOYSA-Nnitrogen groupChemical group[N]QJGQUHMNIGDVPM-UHFFFAOYSA-N0.000claimsdescription7

- 239000000047productSubstances0.000claimsdescription7

- 230000035484reaction timeEffects0.000claimsdescription7

- 150000003839saltsChemical class0.000claimsdescription7

- XKRFYHLGVUSROY-UHFFFAOYSA-NArgonChemical group[Ar]XKRFYHLGVUSROY-UHFFFAOYSA-N0.000claimsdescription6

- DNIAPMSPPWPWGF-UHFFFAOYSA-NPropylene glycolChemical compoundCC(O)CODNIAPMSPPWPWGF-UHFFFAOYSA-N0.000claimsdescription6

- 150000001875compoundsChemical class0.000claimsdescription6

- 239000000203mixtureSubstances0.000claimsdescription6

- 238000005406washingMethods0.000claimsdescription6

- 239000000178monomerSubstances0.000claimsdescription5

- 238000006277sulfonation reactionMethods0.000claimsdescription5

- 230000008569processEffects0.000claimsdescription4

- FAPWRFPIFSIZLT-UHFFFAOYSA-MSodium chlorideChemical class[Na+].[Cl-]FAPWRFPIFSIZLT-UHFFFAOYSA-M0.000claimsdescription3

- 229910052786argonInorganic materials0.000claimsdescription3

- 239000007795chemical reaction productSubstances0.000claimsdescription3

- 150000001868cobaltChemical class0.000claimsdescription3

- 239000003431cross linking reagentSubstances0.000claimsdescription3

- 230000007935neutral effectEffects0.000claimsdescription3

- USHAGKDGDHPEEY-UHFFFAOYSA-Lpotassium persulfateChemical compound[K+].[K+].[O-]S(=O)(=O)OOS([O-])(=O)=OUSHAGKDGDHPEEY-UHFFFAOYSA-L0.000claimsdescription3

- 239000002244precipitateSubstances0.000claimsdescription3

- NXRIDTLKJCKPOG-UHFFFAOYSA-N1,4-dihydroimidazole-5-thioneChemical compoundS=C1CN=CN1NXRIDTLKJCKPOG-UHFFFAOYSA-N0.000claimsdescription2

- HYZJCKYKOHLVJF-UHFFFAOYSA-N1H-benzimidazoleChemical compoundC1=CC=C2NC=NC2=C1HYZJCKYKOHLVJF-UHFFFAOYSA-N0.000claimsdescription2

- 229940011182cobalt acetateDrugs0.000claimsdescription2

- GVPFVAHMJGGAJG-UHFFFAOYSA-Lcobalt dichlorideChemical compound[Cl-].[Cl-].[Co+2]GVPFVAHMJGGAJG-UHFFFAOYSA-L0.000claimsdescription2

- UFMZWBIQTDUYBN-UHFFFAOYSA-Ncobalt dinitrateChemical compound[Co+2].[O-][N+]([O-])=O.[O-][N+]([O-])=OUFMZWBIQTDUYBN-UHFFFAOYSA-N0.000claimsdescription2

- 229910001981cobalt nitrateInorganic materials0.000claimsdescription2

- 229940044175cobalt sulfateDrugs0.000claimsdescription2

- 229910000361cobalt sulfateInorganic materials0.000claimsdescription2

- KTVIXTQDYHMGHF-UHFFFAOYSA-Lcobalt(2+) sulfateChemical compound[Co+2].[O-]S([O-])(=O)=OKTVIXTQDYHMGHF-UHFFFAOYSA-L0.000claimsdescription2

- QAHREYKOYSIQPH-UHFFFAOYSA-Lcobalt(II) acetateChemical compound[Co+2].CC([O-])=O.CC([O-])=OQAHREYKOYSIQPH-UHFFFAOYSA-L0.000claimsdescription2

- 239000006185dispersionSubstances0.000claimsdescription2

- 239000012467final productSubstances0.000claimsdescription2

- 239000012266salt solutionSubstances0.000claimsdescription2

- 238000001035dryingMethods0.000claims2

- -1zeolite imidazole esterChemical class0.000claims2

- 238000010438heat treatmentMethods0.000claims1

- 239000003446ligandSubstances0.000claims1

- 238000002156mixingMethods0.000claims1

- 238000004321preservationMethods0.000claims1

- 238000000967suction filtrationMethods0.000claims1

- 230000003197catalytic effectEffects0.000abstractdescription9

- BASFCYQUMIYNBI-UHFFFAOYSA-NplatinumChemical compound[Pt]BASFCYQUMIYNBI-UHFFFAOYSA-N0.000abstractdescription7

- 239000003575carbonaceous materialSubstances0.000description8

- JBFYUZGYRGXSFL-UHFFFAOYSA-NimidazolideChemical compoundC1=C[N-]C=N1JBFYUZGYRGXSFL-UHFFFAOYSA-N0.000description7

- HNPSIPDUKPIQMN-UHFFFAOYSA-Ndioxosilane;oxo(oxoalumanyloxy)alumaneChemical compoundO=[Si]=O.O=[Al]O[Al]=OHNPSIPDUKPIQMN-UHFFFAOYSA-N0.000description6

- 239000011148porous materialSubstances0.000description5

- 150000001869cobalt compoundsChemical class0.000description3

- 229910001429cobalt ionInorganic materials0.000description3

- XLJKHNWPARRRJB-UHFFFAOYSA-Ncobalt(2+)Chemical compound[Co+2]XLJKHNWPARRRJB-UHFFFAOYSA-N0.000description3

- 230000000694effectsEffects0.000description3

- 239000002245particleSubstances0.000description3

- 238000011056performance testMethods0.000description3

- 239000002994raw materialSubstances0.000description3

- 238000012546transferMethods0.000description3

- CURLTUGMZLYLDI-UHFFFAOYSA-NCarbon dioxideChemical compoundO=C=OCURLTUGMZLYLDI-UHFFFAOYSA-N0.000description2

- DHMQDGOQFOQNFH-UHFFFAOYSA-NGlycineChemical compoundNCC(O)=ODHMQDGOQFOQNFH-UHFFFAOYSA-N0.000description2

- RAHZWNYVWXNFOC-UHFFFAOYSA-NSulphur dioxideChemical compoundO=S=ORAHZWNYVWXNFOC-UHFFFAOYSA-N0.000description2

- WYURNTSHIVDZCO-UHFFFAOYSA-NTetrahydrofuranChemical compoundC1CCOC1WYURNTSHIVDZCO-UHFFFAOYSA-N0.000description2

- 230000005540biological transmissionEffects0.000description2

- QGUAJWGNOXCYJF-UHFFFAOYSA-Ncobalt dinitrate hexahydrateChemical compoundO.O.O.O.O.O.[Co+2].[O-][N+]([O-])=O.[O-][N+]([O-])=OQGUAJWGNOXCYJF-UHFFFAOYSA-N0.000description2

- 239000011258core-shell materialSubstances0.000description2

- 230000009881electrostatic interactionEffects0.000description2

- 239000007789gasSubstances0.000description2

- 230000004048modificationEffects0.000description2

- 238000012986modificationMethods0.000description2

- 239000002086nanomaterialSubstances0.000description2

- 239000010970precious metalSubstances0.000description2

- 238000006467substitution reactionMethods0.000description2

- 125000000542sulfonic acid groupChemical group0.000description2

- BAERPNBPLZWCES-UHFFFAOYSA-N(2-hydroxy-1-phosphonoethyl)phosphonic acidChemical compoundOCC(P(O)(O)=O)P(O)(O)=OBAERPNBPLZWCES-UHFFFAOYSA-N0.000description1

- 229920001661ChitosanPolymers0.000description1

- 239000004471GlycineSubstances0.000description1

- 239000002253acidSubstances0.000description1

- 239000007864aqueous solutionSubstances0.000description1

- YDVGDXLABZAVCP-UHFFFAOYSA-NazanylidynecobaltChemical compound[N].[Co]YDVGDXLABZAVCP-UHFFFAOYSA-N0.000description1

- 230000009286beneficial effectEffects0.000description1

- 230000015572biosynthetic processEffects0.000description1

- 238000001354calcinationMethods0.000description1

- 239000001569carbon dioxideSubstances0.000description1

- 229910002092carbon dioxideInorganic materials0.000description1

- 239000007833carbon precursorSubstances0.000description1

- 239000003795chemical substances by applicationSubstances0.000description1

- 239000012921cobalt-based metal-organic frameworkSubstances0.000description1

- 239000002131composite materialSubstances0.000description1

- 239000013078crystalSubstances0.000description1

- 238000003411electrode reactionMethods0.000description1

- 230000032050esterificationEffects0.000description1

- 238000005886esterification reactionMethods0.000description1

- 238000005087graphitizationMethods0.000description1

- 239000002149hierarchical poreSubstances0.000description1

- 238000011065in-situ storageMethods0.000description1

- 230000003993interactionEffects0.000description1

- 239000013082iron-based metal-organic frameworkSubstances0.000description1

- 238000001000micrographMethods0.000description1

- 230000000877morphologic effectEffects0.000description1

- 229910000510noble metalInorganic materials0.000description1

- 229910052697platinumInorganic materials0.000description1

- 230000010287polarizationEffects0.000description1

- 229920000642polymerPolymers0.000description1

- 238000010248power generationMethods0.000description1

- 230000001737promoting effectEffects0.000description1

- 239000000376reactantSubstances0.000description1

- BDHFUVZGWQCTTF-UHFFFAOYSA-MsulfonateChemical compound[O-]S(=O)=OBDHFUVZGWQCTTF-UHFFFAOYSA-M0.000description1

- YLQBMQCUIZJEEH-UHFFFAOYSA-NtetrahydrofuranNatural productsC=1C=COC=1YLQBMQCUIZJEEH-UHFFFAOYSA-N0.000description1

- 229910021642ultra pure waterInorganic materials0.000description1

- 239000012498ultrapure waterSubstances0.000description1

- 238000001291vacuum dryingMethods0.000description1

Images

Classifications

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/86—Inert electrodes with catalytic activity, e.g. for fuel cells

- H01M4/90—Selection of catalytic material

- H01M4/9075—Catalytic material supported on carriers, e.g. powder carriers

- H01M4/9083—Catalytic material supported on carriers, e.g. powder carriers on carbon or graphite

- B—PERFORMING OPERATIONS; TRANSPORTING

- B82—NANOTECHNOLOGY

- B82Y—SPECIFIC USES OR APPLICATIONS OF NANOSTRUCTURES; MEASUREMENT OR ANALYSIS OF NANOSTRUCTURES; MANUFACTURE OR TREATMENT OF NANOSTRUCTURES

- B82Y40/00—Manufacture or treatment of nanostructures

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/86—Inert electrodes with catalytic activity, e.g. for fuel cells

- H01M4/8605—Porous electrodes

- H01M4/861—Porous electrodes with a gradient in the porosity

- H—ELECTRICITY

- H01—ELECTRIC ELEMENTS

- H01M—PROCESSES OR MEANS, e.g. BATTERIES, FOR THE DIRECT CONVERSION OF CHEMICAL ENERGY INTO ELECTRICAL ENERGY

- H01M4/00—Electrodes

- H01M4/86—Inert electrodes with catalytic activity, e.g. for fuel cells

- H01M4/90—Selection of catalytic material

- H01M4/9041—Metals or alloys

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/30—Hydrogen technology

- Y02E60/50—Fuel cells

Landscapes

- Chemical & Material Sciences (AREA)

- Engineering & Computer Science (AREA)

- General Chemical & Material Sciences (AREA)

- Electrochemistry (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Nanotechnology (AREA)

- Materials Engineering (AREA)

- General Physics & Mathematics (AREA)

- Crystallography & Structural Chemistry (AREA)

- Manufacturing & Machinery (AREA)

- Physics & Mathematics (AREA)

- Condensed Matter Physics & Semiconductors (AREA)

- Catalysts (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于催化剂制备技术领域,具体涉及一种中空结构过渡金属钴、氮共掺杂炭氧还原催化剂及其制备方法和应用,用于燃料电池的阴极氧气还原反应。The invention belongs to the technical field of catalyst preparation, and in particular relates to a hollow structure transition metal cobalt and nitrogen co-doped carbon oxygen reduction catalyst, a preparation method and an application thereof, which are used for the cathode oxygen reduction reaction of a fuel cell.

背景技术Background technique

燃料电池是一种发电装置,产物为环保无污染的水,没有二氧化碳、二氧化硫等气体的排放,因此受到研究人员广泛关注。然而,燃料电池电极反应需要贵金属铂作为催化剂,其成本高,资源稀缺,严重制约了燃料电池大规模商业化。因此,开发催化活性高,价格低廉的非贵金属氧还原催化剂有重要意义。A fuel cell is a power generation device that produces environmentally friendly and pollution-free water without the emission of carbon dioxide, sulfur dioxide and other gases, so it has received extensive attention from researchers. However, the electrode reaction of fuel cells requires noble metal platinum as a catalyst, and its high cost and scarcity of resources severely restrict the large-scale commercialization of fuel cells. Therefore, it is of great significance to develop non-precious metal oxygen reduction catalysts with high catalytic activity and low price.

在诸多非贵金属氧还原催化剂中,过渡金属 (TM,典型的如Fe或Co)、氮共掺杂炭材料(TM-N-C)因其具有较为优异的氧还原催化活性受到了较多关注。该类催化剂一般是由过渡金属源、氮和炭前驱体的混合物经过高温处理制备得到。如中国专利申请CN201910836903使用不同粒径的聚苯乙烯微球作为模板,其公开了一种钴和氮掺杂三维有序多孔碳催化剂的制备方法及用途,该方法先合成了不同粒径的PS球并将其制作成模板,将模板浸渍于含六水合硝酸钴和2-甲基咪唑的甲醇溶液中,模板上原位生长ZIF-67,使用四氢呋喃洗去模板,离心得到有序多孔ZIF-67前驱体,碳化处理后即得钴和氮掺杂三维有序多孔碳催化剂。所制备的催化剂为结构规则、颗粒分明的三维碳材料,具有有序孔道、高比表面积、较高的活性、较高稳定性等优点。该方法,对于合成孔隙可控、高的比表面积以及良好的耐久性的氧还原电催化材料提供了很大的可能性。所用原料皆易得且价格低廉,具有工业应用前景。Among many non-precious metal oxygen reduction catalysts, transition metals (TM, typically Fe or Co) and nitrogen co-doped carbon materials (TM-N-C) have attracted more attention due to their excellent catalytic activity for oxygen reduction. Such catalysts are generally prepared by high temperature treatment of a mixture of transition metal sources, nitrogen and carbon precursors. For example, Chinese patent application CN201910836903 uses polystyrene microspheres with different particle sizes as templates, which discloses a preparation method and application of a cobalt and nitrogen-doped three-dimensional ordered porous carbon catalyst. This method firstly synthesizes PS with different particle sizes. The spheres were fabricated into templates, the templates were immersed in methanol solution containing cobalt nitrate hexahydrate and 2-methylimidazole, ZIF-67 was grown in situ on the templates, the templates were washed off with tetrahydrofuran, and centrifuged to obtain ordered porous ZIF- 67 precursor, the cobalt and nitrogen doped three-dimensional ordered porous carbon catalyst is obtained after carbonization. The prepared catalyst is a three-dimensional carbon material with regular structure and distinct particles, and has the advantages of ordered pores, high specific surface area, high activity, high stability, and the like. This method provides a great possibility to synthesize oxygen reduction electrocatalytic materials with controllable pores, high specific surface area and good durability. The raw materials used are readily available and inexpensive, and have industrial application prospects.

近年来,金属有机骨架材料(MOFs)因具有比表面积高、孔结构可调、结构组成多样化等特点,成为制备TM-N-C的理想前驱体。如中国专利申请CN202010087294制备了孔碳材料包覆钴化物的核-壳纳米结构材料,具体公开了一种Co基MOFs-杂原子掺杂多孔碳的氧还原催化剂及其制法,包括以下配方原料:Fe基MOFs、羟基乙叉二膦酸、壳聚糖、甘氨酸、酯化催化剂、复合碱催化剂、缩合剂。该一种Co基MOFs-杂原子掺杂多孔碳的氧还原催化剂及其制法,N/P的共掺杂使碳材料形成了丰富的孔道和大量的介孔结构,有利于活性位点的形成以及氧还原反应的介质传输,孔碳材料包覆钴化物的核-壳纳米结构具有更丰富的形貌结构,使催化剂拥有更好的传质性能,并且纳米结构的Co基MOFs煅烧后形成的钴化物均匀地负载到多孔碳材料的孔道中,钴化物改善了碳材料的石墨化程度,增加了碳材料的导电性,促进了氧还原反应的正向进行。In recent years, metal-organic frameworks (MOFs) have become ideal precursors for the preparation of TM-N-C due to their high specific surface area, tunable pore structure, and diverse structural compositions. For example, Chinese patent application CN202010087294 prepares a core-shell nanostructure material coated with cobalt by porous carbon material, and specifically discloses a Co-based MOFs-heteroatom-doped porous carbon oxygen reduction catalyst and its preparation method, including the following formula materials : Fe-based MOFs, hydroxyethylidene diphosphonic acid, chitosan, glycine, esterification catalyst, composite base catalyst, condensing agent. This is a Co-based MOFs-heteroatom-doped porous carbon oxygen reduction catalyst and its preparation method. The co-doping of N/P makes the carbon material form abundant pores and a large number of mesoporous structures, which is beneficial to the active site. Formation and medium transport of the oxygen reduction reaction, the core-shell nanostructure of the porous carbon material-coated cobalt compound has a richer morphological structure, which makes the catalyst have better mass transfer performance, and the nanostructured Co-based MOFs are formed after calcination. The cobalt compound is uniformly loaded into the pores of the porous carbon material, and the cobalt compound improves the graphitization degree of the carbon material, increases the electrical conductivity of the carbon material, and promotes the positive progress of the oxygen reduction reaction.

然而,MOFs材料热解过程存在结构易坍塌的问题,会导致活性位不能充分暴露,影响催化活性发挥。因此,该类催化剂仍需进一步提高活性位点利用率、强化传质,进而提高氧还原催化活性。However, there is a problem that the structure of MOFs is easily collapsed during the pyrolysis process, which will lead to insufficient exposure of active sites and affect the catalytic activity. Therefore, this type of catalyst still needs to further improve the utilization rate of active sites and enhance the mass transfer, thereby improving the catalytic activity of oxygen reduction.

发明内容SUMMARY OF THE INVENTION

为了解决现有技术中存在的上述问题,本发明提供一种中空结构过渡金属钴、氮共掺杂炭氧还原催化剂及其制备方法和应用,以磺化聚苯乙烯微球为模板,利用微球表面的磺酸基团与金属钴离子之间的静电作用在模板表面生长沸石咪唑酯骨架化合物材料,然后通过在惰性气氛下热解碳化制备得到具有中空结构的过渡金属钴、氮共掺杂炭微球。上述结构可大大提高催化剂的比表面积,进而促进活性位点利用率的提升。本发明制备的过渡金属钴、氮共掺杂炭氧还原催化剂可高效催化氧还原反应,表现出优于商业化Pt/C的氧还原催化活性和电化学稳定性。该制备方法简单可控,且原料储量丰富、成本较低。In order to solve the above-mentioned problems existing in the prior art, the present invention provides a hollow structure transition metal cobalt and nitrogen co-doped carbon-oxygen reduction catalyst and its preparation method and application. The electrostatic interaction between the sulfonic acid groups on the spherical surface and the metal cobalt ions grows the zeolite imidazolate framework compound material on the template surface, and then prepares the transition metal cobalt and nitrogen co-doping with a hollow structure by pyrolysis carbonization in an inert atmosphere carbon microspheres. The above structure can greatly increase the specific surface area of the catalyst, thereby promoting the utilization of active sites. The transition metal cobalt and nitrogen co-doped carbon-oxygen reduction catalyst prepared by the invention can efficiently catalyze the oxygen reduction reaction, and shows oxygen reduction catalytic activity and electrochemical stability superior to commercial Pt/C. The preparation method is simple and controllable, and has abundant raw material reserves and low cost.

本发明采用如下的技术方案:一种中空结构过渡金属钴、氮共掺杂炭氧还原催化剂,其前驱体以磺化聚苯乙烯微球作为模板,金属钴源和含氮有机配体在聚苯乙烯微球表面进行自组装得到。The present invention adopts the following technical scheme: a hollow structure transition metal cobalt and nitrogen co-doped carbon-oxygen reduction catalyst, the precursor of which uses sulfonated polystyrene microspheres as a template, and the metal cobalt source and nitrogen-containing organic ligands are in the polymer The surface of styrene microspheres is self-assembled.

其中,在反应体系中,聚苯乙烯微球表面引入了磺化基团,所述的过渡金属钴、氮共掺杂炭催化剂以磺化聚苯乙烯微球为模板,利用微球表面的磺酸基团与金属钴离子之间的静电作用在模板表面生长沸石咪唑酯金属有机骨架材料。Among them, in the reaction system, sulfonated groups are introduced on the surface of polystyrene microspheres, and the transition metal cobalt and nitrogen co-doped carbon catalyst uses sulfonated polystyrene The electrostatic interaction between acid groups and metal cobalt ions grows zeolitic imidazolate metal organic framework materials on the template surface.

在本发明的优选的实施方式中,所述的过渡金属钴、氮共掺杂炭氧还原催化剂通过在惰性气氛下热解碳化制备得到。In a preferred embodiment of the present invention, the transition metal cobalt and nitrogen co-doped carbon-oxygen reduction catalyst is prepared by pyrolytic carbonization in an inert atmosphere.

在本发明的优选的实施方式中,所述的含氮有机配体为2-甲基咪唑、苯并咪唑、咪唑、2-咪唑啉硫酮中的一种或几种;所述的金属钴源为钴的可溶性盐;更优选的,所述的金属钴源为硝酸钴、氯化钴、硫酸钴、乙酸钴中的一种或几种。In a preferred embodiment of the present invention, the nitrogen-containing organic ligand is one or more of 2-methylimidazole, benzimidazole, imidazole, and 2-imidazoline thione; the metal cobalt The source is a soluble salt of cobalt; more preferably, the metal cobalt source is one or more of cobalt nitrate, cobalt chloride, cobalt sulfate, and cobalt acetate.

本申请还保护上述中空结构过渡金属钴、氮共掺杂炭氧还原催化剂的制备方法,反应体系中,磺化聚苯乙烯微球作为模板,金属钴源和含氮有机配体在聚苯乙烯微球表面进行自组装形成前驱体通过在惰性气氛下热解碳化制备得到。The present application also protects the preparation method of the above hollow structure transition metal cobalt and nitrogen co-doped carbon oxygen reduction catalyst. In the reaction system, sulfonated polystyrene microspheres are used as a template, and the metal cobalt source and nitrogen-containing organic ligand are in polystyrene The surface of the microspheres is self-assembled to form the precursor, which is prepared by pyrolytic carbonization in an inert atmosphere.

在本发明的优选的实施方式中,所述的制备方法为将模板磺化聚苯乙烯微球在有机溶剂中充分分散,然后加入过渡金属钴的可溶性盐溶液,在搅拌的同时将含氮配体的有机溶液缓慢倒入磺化聚苯乙烯微球乳液,使其反应得到模板表面生长有沸石咪唑酯骨架化合物材料的微球。In a preferred embodiment of the present invention, the preparation method is to fully disperse the template sulfonated polystyrene microspheres in an organic solvent, then add a soluble salt solution of transition metal cobalt, and mix nitrogen-containing compounds while stirring. The organic solution of the compound is slowly poured into the sulfonated polystyrene microsphere emulsion, and it is reacted to obtain microspheres with zeolite imidazolate framework compound materials grown on the surface of the template.

在本发明的优选的实施方式中,所述的制备方法包括如下步骤:In a preferred embodiment of the present invention, the preparation method comprises the following steps:

(1)聚苯乙烯微球的制备:将苯乙烯单体、二乙烯基苯单体进行洗涤后,再用去离子水将苯乙烯洗涤至中性;将水和交联剂搅拌均匀后加入苯乙烯,惰性气氛下加热反应1-2h后,加入溶有过硫酸钾的去离子水溶液继续反应;向上述的反应产物中加入饱和NaCl溶液,析出物抽滤干燥得到聚苯乙烯微球;(1) Preparation of polystyrene microspheres: after washing the styrene monomer and divinylbenzene monomer, the styrene is washed with deionized water to neutrality; the water and the cross-linking agent are stirred evenly and then added Styrene, heated and reacted under an inert atmosphere for 1-2 hours, then added a deionized aqueous solution dissolved in potassium persulfate to continue the reaction; added a saturated NaCl solution to the above reaction product, and the precipitate was filtered and dried to obtain polystyrene microspheres;

(2)磺化聚苯乙烯微球乳液的制备:将模板聚苯乙烯微球和浓硫酸混合搅拌,反应后的产物经离心分离、乙醇洗涤后干燥,制备得到磺化聚苯乙烯微球,取磺化聚苯乙烯微球溶于有机溶剂中分散均匀得到磺化聚苯乙烯微球乳液;(2) Preparation of sulfonated polystyrene microsphere emulsion: the template polystyrene microspheres and concentrated sulfuric acid are mixed and stirred, and the reacted product is centrifuged, washed with ethanol and then dried to prepare sulfonated polystyrene microspheres, Dissolve the sulfonated polystyrene microspheres in an organic solvent and disperse them uniformly to obtain a sulfonated polystyrene microsphere emulsion;

(3)前驱体的制备:将钴的可溶性盐、有机配体分别溶于有机溶剂中,在搅拌条件下制备得到表面生长沸石咪唑酯金属有机骨架材料的聚苯乙烯微球;(3) Preparation of precursor: the soluble cobalt salt and the organic ligand are respectively dissolved in the organic solvent, and the polystyrene microspheres with the surface-grown zeolite imidazolate metal-organic framework material are prepared under stirring conditions;

(4)热解碳化过程:将上述(3)制备得到的前驱体在惰性气氛氛围下,以1-10 ℃ min-1的速率升温至600-900 ℃,保温1-3 h,得到过渡金属钴、氮共掺杂炭催化剂。(4) Pyrolytic carbonization process: the precursor prepared in the above (3) is heated to 600-900 ℃ at a rate of 1-10 ℃ min-1 in an inert atmosphere, and kept for 1-3 h to obtain the transition metal Cobalt and nitrogen co-doped carbon catalysts.

在本发明的优选的实施方式中,步骤(1)中,所述的洗涤为采用质量分数为10%的氢氧化钠溶液洗涤苯乙烯单体、二乙烯基苯单体,再用去离子水将苯乙烯洗涤至中性;最终产物的形貌为均匀大小、分散良好的微球形状,直径在500 nm左右。In a preferred embodiment of the present invention, in step (1), the washing is to use sodium hydroxide solution with a mass fraction of 10% to wash styrene monomer and divinylbenzene monomer, and then use deionized water The styrene was washed until neutral; the morphology of the final product was the shape of microspheres with uniform size and good dispersion, with a diameter of about 500 nm.

在本发明的优选的实施方式中,步骤(2)中,所述的有机溶剂为甲醇、乙醇、丙二醇中的一种或几种;磺化温度为30-50 ℃,反应时间为8-10 h,磺化溶液为98%的浓硫酸溶液,聚苯乙烯微球与浓硫酸的质量比为0.01-0.02。In a preferred embodiment of the present invention, in step (2), the organic solvent is one or more of methanol, ethanol and propylene glycol; the sulfonation temperature is 30-50 °C, and the reaction time is 8-10 h, the sulfonation solution is 98% concentrated sulfuric acid solution, and the mass ratio of polystyrene microspheres to concentrated sulfuric acid is 0.01-0.02.

在本发明的优选的实施方式中,步骤(3)中,先将钴溶液倒入(2)中所述聚苯乙烯微球乳液中,然后缓慢将含有机配体的溶液倒入聚苯乙烯微球乳液中;所述钴的可溶性盐与有机配体摩尔比为0.05-0.25,反应时间为2-22 h;钴盐与聚苯乙烯微球的质量比为1.5-2.5。In a preferred embodiment of the present invention, in step (3), the cobalt solution is first poured into the polystyrene microsphere emulsion in (2), and then the solution containing the organic ligand is slowly poured into the polystyrene In the microsphere emulsion; the molar ratio of the cobalt soluble salt to the organic ligand is 0.05-0.25, the reaction time is 2-22 h; the mass ratio of the cobalt salt to the polystyrene microsphere is 1.5-2.5.

在本发明的优选的实施方式中,步骤(4)中,所述的惰性气氛为氩气或氮气,保温时间为2-3 h。In a preferred embodiment of the present invention, in step (4), the inert atmosphere is argon or nitrogen, and the holding time is 2-3 h.

本发明还保护所述的钴、氮共掺杂炭氧还原催化剂用于碱性燃料电池的阴极氧还原反应。The present invention also protects that the cobalt and nitrogen co-doped carbon oxygen reduction catalyst is used in the cathode oxygen reduction reaction of an alkaline fuel cell.

与现有技术相比,本发明具有以下优点:Compared with the prior art, the present invention has the following advantages:

(1)本发明制备过程简单可控,且原料储量丰富、成本低廉。(1) The preparation process of the present invention is simple and controllable, and the raw material reserves are abundant and the cost is low.

(2)本发明采用浓硫酸对模板聚苯乙烯微球进行磺化,在聚苯乙烯微球表面引入磺酸基团以提高微球表面带负电性,增强了金属钴离子与微球之间的静电作用,从而确保了沸石咪唑酯金属有机骨架材料在微球表面的均匀生长,且经高温热解碳化去除模板后,制备的具有中空结构的催化剂可较好继承聚苯乙烯模板的微球结构。(2) The present invention uses concentrated sulfuric acid to sulfonate the template polystyrene microspheres, and introduces sulfonic acid groups on the surface of the polystyrene microspheres to improve the negative charge on the surface of the microspheres, and enhance the interaction between the metal cobalt ions and the microspheres. The electrostatic effect of the zeolite imidazolate metal-organic framework material on the surface of the microspheres is guaranteed to be uniform, and after the template is removed by high-temperature pyrolysis and carbonization, the prepared catalyst with a hollow structure can better inherit the polystyrene template of the microspheres. structure.

(3)本发明制备的钴、氮共掺杂炭氧还原催化剂去除模板后具有中空结构,比表面积大,具有微孔/介孔的分级孔结构,可有效促进活性位的暴露与反应物的传质,氧还原催化活性优于商业化Pt/C。(3) The cobalt and nitrogen co-doped carbon-oxygen reduction catalyst prepared by the present invention has a hollow structure after removing the template, a large specific surface area, and a hierarchical pore structure of micropores/mesopores, which can effectively promote the exposure of active sites and the release of reactants. Mass transfer, oxygen reduction catalytic activity is better than commercial Pt/C.

附图说明Description of drawings

下面结合附图做进一步的说明:Further description is made below in conjunction with the accompanying drawings:

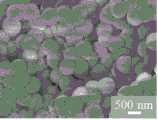

图1是实施例1中经过磺化处理后的聚苯乙烯微球的扫描电镜图;Fig. 1 is the scanning electron microscope picture of the polystyrene microsphere after sulfonation treatment in embodiment 1;

图2是实施例1中表面生长有沸石咪唑酯骨架化合物材料的磺化聚苯乙烯微球的扫描电镜图;Fig. 2 is the scanning electron microscope picture of the sulfonated polystyrene microspheres with the zeolite imidazolate framework compound material growing on the surface in embodiment 1;

图3是实施例1中过渡金属钴、氮共掺杂炭的透射电镜图;3 is a transmission electron microscope image of transition metal cobalt and nitrogen co-doped carbon in Example 1;

图4是实施例1中不同反应时间制备的钴、氮共掺杂炭和商业20% Pt/C的极化曲线图。FIG. 4 is a graph of polarization curves of cobalt, nitrogen co-doped carbon and commercial 20% Pt/C prepared at different reaction times in Example 1. FIG.

具体实施方式Detailed ways

下面结合附图与实施例进一步阐明本发明。应理解的是,这些实施例仅用于说明本发明,而不用于限制本发明的范围。The present invention is further illustrated below in conjunction with the accompanying drawings and embodiments. It should be understood that these examples are only used to illustrate the present invention and not to limit the scope of the present invention.

实施例1:Example 1:

以表面生长有沸石咪唑酯骨架化合物材料(ZIF-67)的磺化聚苯乙烯微球为前驱体,通过高温热解碳化制备钴、氮共掺杂炭氧还原催化剂,包括如下步骤:Using sulfonated polystyrene microspheres with zeolite imidazolate framework compound materials (ZIF-67) grown on the surface as precursors, cobalt and nitrogen co-doped carbon-oxygen reduction catalysts are prepared by high-temperature pyrolysis carbonization, including the following steps:

采用质量分数为10%的氢氧化钠溶液洗涤苯乙烯单体、二乙烯基苯单体,再用去离子水将苯乙烯洗涤至中性;将0.7 g交联剂二乙烯基苯溶于120 mL超纯水中,搅拌均匀后加入14g苯乙烯,在惰性气氛下加热反应1 h,将0.03 g过硫酸钾溶解在10 mL去离子水中,加入到反应体系中,继续反应10 h;向上述的反应产物中加入饱和NaCl溶液,析出物抽滤干燥得到聚苯乙烯微球。将1.70 g 聚苯乙烯微球模板和60 mL浓硫酸混合到烧杯中,搅拌或超声均匀分散聚苯乙烯微球。然后在40 ℃恒温下搅拌9 h, 反应后的产物经离心分离, 弃去未反应的浓硫酸,将上层产物反复用超过量乙醇洗涤分离,重复3~5次,产物在真空干燥箱干燥。Use 10% sodium hydroxide solution to wash styrene monomer and divinylbenzene monomer, and then use deionized water to wash styrene to neutrality; dissolve 0.7 g of crosslinking agent divinylbenzene in 120 mL of ultrapure water, stir evenly, add 14 g of styrene, heat and react under an inert atmosphere for 1 h, dissolve 0.03 g of potassium persulfate in 10 mL of deionized water, add it to the reaction system, and continue the reaction for 10 h; Saturated NaCl solution was added to the reaction product, and the precipitate was filtered and dried to obtain polystyrene microspheres. Mix 1.70 g of the polystyrene microsphere template and 60 mL of concentrated sulfuric acid into a beaker, and stir or sonicate to uniformly disperse the polystyrene microspheres. Then the mixture was stirred at a constant temperature of 40 °C for 9 h, the reacted product was centrifuged, the unreacted concentrated sulfuric acid was discarded, and the upper product was repeatedly washed and separated with excess ethanol for 3 to 5 times, and the product was dried in a vacuum drying oven.

称量90 mg 磺化聚苯乙烯微球溶于60 mL甲醇中超声至分散均匀,称量174 mg六水合硝酸钴溶于10 mL甲醇,称量492 mg 2-甲基咪唑溶于10 mL甲醇中(金属盐与2-甲基咪唑摩尔比为1:10),超声至溶解,将钴溶液倒入聚苯乙烯微球乳液中,利用磁子搅拌,再将2-甲基咪唑溶液缓慢倒入磺化聚苯乙烯微球乳液中,继续在室温下分别搅拌反应14 h。将得到的溶液抽滤、烘干即可。取适量前驱体放置在管式炉中,抽真空排除空气,再通入氩气保护,以5 ℃ min-1的速率进行升温至700 ℃,升温后保温2 h,由此制备得到过渡金属钴、氮共掺杂炭催化剂,将其研磨后装入样品瓶。Weigh 90 mg of sulfonated polystyrene microspheres and dissolve in 60 mL of methanol and sonicate until uniformly dispersed, weigh 174 mg of cobalt nitrate hexahydrate and dissolve in 10 mL of methanol, and weigh 492 mg of 2-methylimidazole and dissolve in 10 mL of methanol medium (the molar ratio of metal salt and 2-methylimidazole is 1:10), sonicated until dissolved, poured the cobalt solution into the polystyrene microsphere emulsion, stirred with a magnet, and then slowly poured the 2-methylimidazole solution into the sulfonated polystyrene microsphere emulsion, and continued to stir the reaction for 14 h at room temperature. The obtained solution is filtered and dried. Take an appropriate amount of the precursor and place it in a tube furnace, evacuate the air to remove the air, and then protect it with argon gas. The temperature is increased to 700 °C at a rate of 5 °C min-1 , and the temperature is maintained for 2 h. The transition metal cobalt is thus prepared. , Nitrogen co-doped carbon catalyst, grind it and put it into a sample bottle.

对本实施例得到的前驱体进行了扫描电镜分析和透射电镜分析,所制备的磺化聚苯乙烯呈球形,直径约为500 nm(图1),生长ZIF-67晶体后,仍保有磺化聚苯乙烯模板微球形貌(图2)。通过热解碳化的制备钴、氮共掺杂炭催化剂继承了前驱体的球形形貌(图3)。氧还原性能测试(图4)表明该催化剂具有优于商业20% Pt/C的电催化活性。Scanning electron microscope analysis and transmission electron microscope analysis were carried out on the precursor obtained in this example. The prepared sulfonated polystyrene was spherical with a diameter of about 500 nm (Fig. 1). After growing ZIF-67 crystals, the sulfonated polystyrene still remained. Styrene template microsphere morphology (Figure 2). The cobalt-nitrogen co-doped carbon catalyst prepared by pyrolytic carbonization inherited the spherical morphology of the precursor (Fig. 3). The oxygen reduction performance test (Fig. 4) showed that the catalyst has electrocatalytic activity superior to that of commercial 20% Pt/C.

实施例2Example 2

操作条件如同实施例1,不同之处在于,在前驱体制备过程中,反应时间提高至18 h。热解碳化制备的催化剂氧还原性能测试(图4)表明该催化剂仍表现出优异的氧还原催化活性。The operating conditions were the same as in Example 1, except that during the preparation of the precursor, the reaction time was increased to 18 h. The oxygen reduction performance test of the catalyst prepared by pyrolysis carbonization (Fig. 4) shows that the catalyst still exhibits excellent oxygen reduction catalytic activity.

实施例3Example 3

操作条件如同实施例1,不同之处在于,在前驱体制备过程中,反应时间提高至22 h。热解碳化制备的催化剂氧还原性能测试(图4)表明该催化剂仍表现出优异的氧还原催化活性。The operating conditions were the same as in Example 1, except that during the preparation of the precursor, the reaction time was increased to 22 h. The oxygen reduction performance test of the catalyst prepared by pyrolysis carbonization (Fig. 4) shows that the catalyst still exhibits excellent oxygen reduction catalytic activity.

实施例4Example 4

操作条件如同实施例1,不同之处在于,在前驱体制备过程中,金属盐与2-甲基咪唑摩尔比为1:20,制备的金属钴、氮共掺杂炭催化剂仍较好保有前驱体的微球形貌。The operating conditions are the same as those in Example 1, except that in the process of preparing the precursor, the molar ratio of metal salt to 2-methylimidazole is 1:20, and the prepared metal cobalt and nitrogen co-doped carbon catalyst still better retains the precursor The microsphere morphology of the body.

以上已对本发明的较佳实施例进行了具体说明,但本发明并不限于所述实施例,熟悉本领域的技术人员在不违背本发明精神的前提下还可作出种种的等同的变型或替换,这些等同的变型或替换均包含在本申请权利要求所限定的范围内。The preferred embodiments of the present invention have been specifically described above, but the present invention is not limited to the embodiments. Those skilled in the art can make various equivalent modifications or substitutions without departing from the spirit of the present invention. , these equivalent modifications or substitutions are all included within the scope defined by the claims of the present application.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010920140.6ACN112038648B (en) | 2020-09-04 | 2020-09-04 | A hollow structure transition metal cobalt and nitrogen co-doped carbon oxygen reduction catalyst and its preparation method and application |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010920140.6ACN112038648B (en) | 2020-09-04 | 2020-09-04 | A hollow structure transition metal cobalt and nitrogen co-doped carbon oxygen reduction catalyst and its preparation method and application |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN112038648Atrue CN112038648A (en) | 2020-12-04 |

| CN112038648B CN112038648B (en) | 2022-07-26 |

Family

ID=73590530

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010920140.6AActiveCN112038648B (en) | 2020-09-04 | 2020-09-04 | A hollow structure transition metal cobalt and nitrogen co-doped carbon oxygen reduction catalyst and its preparation method and application |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112038648B (en) |

Cited By (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112509823A (en)* | 2020-12-22 | 2021-03-16 | 上海第二工业大学 | Hollow carbon microsphere supercapacitor electrode material and solvent-free preparation method thereof |

| CN112820886A (en)* | 2020-12-29 | 2021-05-18 | 北京化工大学 | A three-dimensional hierarchical porous non-metallic carbon-based material and its preparation method and application |

| CN113422082A (en)* | 2021-07-06 | 2021-09-21 | 中国科学技术大学 | Nitrogen-doped carbon five-membered ring structure-containing graphene-like carbon material electrocatalyst and preparation method and application thereof |

| CN113908874A (en)* | 2021-09-30 | 2022-01-11 | 华中科技大学 | Nitrogen-rich porous composite carbon material, and preparation method and application thereof |

| CN114188557A (en)* | 2021-10-29 | 2022-03-15 | 陕西师范大学 | Preparation method and application of mesoporous transition metal-nitrogen-carbon catalyst |

| CN114497576A (en)* | 2022-01-19 | 2022-05-13 | 佛山仙湖实验室 | Low-cost ordered porous oxygen reduction catalyst and preparation method thereof |

| CN114656337A (en)* | 2022-04-22 | 2022-06-24 | 陕西科技大学 | A method for preparing 2-methoxy-4-methylphenol from biomass-based vanillin |

| CN114849710A (en)* | 2022-04-22 | 2022-08-05 | 陕西科技大学 | Method for synthesizing amine chemicals by reducing amine with biomass-based furan derivative |

| CN114914460A (en)* | 2022-05-17 | 2022-08-16 | 深圳大学 | Bifunctional catalytic material and preparation method and application thereof |

| CN115124020A (en)* | 2022-06-22 | 2022-09-30 | 江南大学 | A boron-nitrogen co-doped carbon material with hierarchical pores and its preparation method and application |

| CN115910623A (en)* | 2022-10-09 | 2023-04-04 | 黑龙江东方学院 | A kind of cobalt nanoparticle/nitrogen-doped carbon porous sphere-in-sphere composite material and its preparation method and application |

| CN120622555A (en)* | 2025-08-13 | 2025-09-12 | 赣南师范大学 | Cobalt-molybdenum nitride/cobalt-modified nitrogen-doped hollow carbon microspheres and their preparation and application |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101805361A (en)* | 2010-03-19 | 2010-08-18 | 上海师范大学 | Double-shell hollow spherical organic metal framework material and preparation method thereof |

| US20150232340A1 (en)* | 2013-11-01 | 2015-08-20 | The Board Of Trustees Of The Leland Stanford Junior University | Microporous/Mesoporous Carbon |

| CN105214727A (en)* | 2014-06-24 | 2016-01-06 | 中国石油天然气集团公司 | A kind of polystyrene-based CuBTC composite catalyst of dumb-bell shape and preparation method |

| US20160248099A1 (en)* | 2013-10-01 | 2016-08-25 | Imperial Innovations Limited | Oxygen reduction catalysts |

| WO2016175879A1 (en)* | 2015-04-30 | 2016-11-03 | The Board Of Trustees Of The Leland Stanford Junior University | Microporous/mesoporous carbon |

| CN108940198A (en)* | 2018-07-19 | 2018-12-07 | 深圳市环球绿地新材料有限公司 | Spherical activated charcoal, the preparation method and use of carried metal ferro element |

| US20200099040A1 (en)* | 2017-08-31 | 2020-03-26 | Lg Chem, Ltd. | Method for preparing hollow structure |

| CN110961162A (en)* | 2019-12-09 | 2020-04-07 | 北京化工大学 | Catalyst carrier, precious metal catalyst, and preparation method and application thereof |

- 2020

- 2020-09-04CNCN202010920140.6Apatent/CN112038648B/enactiveActive

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN101805361A (en)* | 2010-03-19 | 2010-08-18 | 上海师范大学 | Double-shell hollow spherical organic metal framework material and preparation method thereof |

| US20160248099A1 (en)* | 2013-10-01 | 2016-08-25 | Imperial Innovations Limited | Oxygen reduction catalysts |

| US20150232340A1 (en)* | 2013-11-01 | 2015-08-20 | The Board Of Trustees Of The Leland Stanford Junior University | Microporous/Mesoporous Carbon |

| CN105214727A (en)* | 2014-06-24 | 2016-01-06 | 中国石油天然气集团公司 | A kind of polystyrene-based CuBTC composite catalyst of dumb-bell shape and preparation method |

| WO2016175879A1 (en)* | 2015-04-30 | 2016-11-03 | The Board Of Trustees Of The Leland Stanford Junior University | Microporous/mesoporous carbon |

| US20200099040A1 (en)* | 2017-08-31 | 2020-03-26 | Lg Chem, Ltd. | Method for preparing hollow structure |

| CN108940198A (en)* | 2018-07-19 | 2018-12-07 | 深圳市环球绿地新材料有限公司 | Spherical activated charcoal, the preparation method and use of carried metal ferro element |

| CN110961162A (en)* | 2019-12-09 | 2020-04-07 | 北京化工大学 | Catalyst carrier, precious metal catalyst, and preparation method and application thereof |

Non-Patent Citations (1)

| Title |

|---|

| XIAODONG CHEN等: "Rational design of hollow N/Co-doped carbon spheres from bimetal-ZIFs for high-efficiency electrocatalysis", 《CHEMICAL ENGINEERING JOURNAL》* |

Cited By (16)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112509823A (en)* | 2020-12-22 | 2021-03-16 | 上海第二工业大学 | Hollow carbon microsphere supercapacitor electrode material and solvent-free preparation method thereof |

| CN112820886B (en)* | 2020-12-29 | 2023-05-26 | 北京化工大学 | Three-dimensional hierarchical porous nonmetal carbon-based material, and preparation method and application thereof |

| CN112820886A (en)* | 2020-12-29 | 2021-05-18 | 北京化工大学 | A three-dimensional hierarchical porous non-metallic carbon-based material and its preparation method and application |

| CN113422082A (en)* | 2021-07-06 | 2021-09-21 | 中国科学技术大学 | Nitrogen-doped carbon five-membered ring structure-containing graphene-like carbon material electrocatalyst and preparation method and application thereof |

| CN113908874A (en)* | 2021-09-30 | 2022-01-11 | 华中科技大学 | Nitrogen-rich porous composite carbon material, and preparation method and application thereof |

| CN114188557A (en)* | 2021-10-29 | 2022-03-15 | 陕西师范大学 | Preparation method and application of mesoporous transition metal-nitrogen-carbon catalyst |

| CN114497576A (en)* | 2022-01-19 | 2022-05-13 | 佛山仙湖实验室 | Low-cost ordered porous oxygen reduction catalyst and preparation method thereof |

| CN114497576B (en)* | 2022-01-19 | 2024-05-14 | 佛山仙湖实验室 | Low-cost ordered porous oxygen reduction catalyst and preparation method thereof |

| CN114656337A (en)* | 2022-04-22 | 2022-06-24 | 陕西科技大学 | A method for preparing 2-methoxy-4-methylphenol from biomass-based vanillin |

| CN114849710A (en)* | 2022-04-22 | 2022-08-05 | 陕西科技大学 | Method for synthesizing amine chemicals by reducing amine with biomass-based furan derivative |

| CN114914460A (en)* | 2022-05-17 | 2022-08-16 | 深圳大学 | Bifunctional catalytic material and preparation method and application thereof |

| CN114914460B (en)* | 2022-05-17 | 2023-09-01 | 深圳大学 | Dual-function catalytic material and preparation method and application thereof |

| CN115124020A (en)* | 2022-06-22 | 2022-09-30 | 江南大学 | A boron-nitrogen co-doped carbon material with hierarchical pores and its preparation method and application |

| CN115910623A (en)* | 2022-10-09 | 2023-04-04 | 黑龙江东方学院 | A kind of cobalt nanoparticle/nitrogen-doped carbon porous sphere-in-sphere composite material and its preparation method and application |

| CN115910623B (en)* | 2022-10-09 | 2023-10-27 | 黑龙江东方学院 | Cobalt nanoparticle/nitrogen-doped carbon porous sphere middle sphere composite material and preparation method and application thereof |

| CN120622555A (en)* | 2025-08-13 | 2025-09-12 | 赣南师范大学 | Cobalt-molybdenum nitride/cobalt-modified nitrogen-doped hollow carbon microspheres and their preparation and application |

Also Published As

| Publication number | Publication date |

|---|---|

| CN112038648B (en) | 2022-07-26 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN112038648B (en) | A hollow structure transition metal cobalt and nitrogen co-doped carbon oxygen reduction catalyst and its preparation method and application | |

| CN109638295B (en) | Preparation method of oxygen reduction catalyst based on metal organic framework compound | |

| CN107522867B (en) | Preparation method of hollow carbon nanospheres with MOFs growing in internal confinement | |

| CN107175125B (en) | A kind of activation method of MOFs-based oxygen reduction electrocatalyst | |

| CN106410229B (en) | Preparation method and application of a supported carbon-based fuel cell anode catalyst | |

| CN106694018A (en) | Cobalt-nitrogen co-doped carbon oxygen reduction catalyst with gradient pore structure, and preparation method and application thereof | |

| CN107481827A (en) | Preparation method of hollow magnetic carbon nanospheres with internal confinement growth MOFs | |

| CN110961162B (en) | Catalyst carrier, precious metal catalyst, and preparation method and application thereof | |

| CN110182859A (en) | Using the compound ZIF-67 of ZIF-8 as the preparation of the ternary composite metal oxide of template and application | |

| CN115259137B (en) | A two-dimensional mesoporous carbon nanosheet and its preparation method and application | |

| CN110690468B (en) | Preparation and application of single-atom platinum catalysts based on platinum-coordinated cyclodextrin inclusion complexes | |

| CN113856722B (en) | High-loading metal monoatomic catalyst and preparation method and application thereof | |

| CN116454295A (en) | Preparation method of nitrogen-rich porous carbon coated iron nanoparticle for oxygen reduction reaction | |

| CN114843538A (en) | A kind of non-precious metal catalyst based on carbon quantum dots and preparation method thereof | |

| CN113097504A (en) | Hierarchical pore ZIFs electrocatalyst and preparation method thereof | |

| CN111530486A (en) | Novel nitrogen-doped carbon-loaded copper-doped cobalt phosphide double-layer hollow nanoparticle composite array material and preparation method thereof | |

| CN109179379B (en) | Carbon material with nano-network structure and carbon nanotube core @ functional amorphous carbon shell unit, and preparation method and application thereof | |

| CN115518690B (en) | A Cu7S4-MOF composite material and its preparation method and application | |

| CN110137518B (en) | A kind of self-supported Fe-N-C oxygen reduction catalyst and preparation method thereof | |

| CN106699550A (en) | Preparation method of nano Cu-CuBTC type metal organic framework material | |

| CN112480421B (en) | A method for the synthesis of solvent-induced sea urchin-like MOFs | |

| CN111682215B (en) | A kind of preparation method of nitrogen-doped egg-yolk phenolic resin-based derivative carbon sphere | |

| CN111822054A (en) | A kind of nanoporous material anode catalyst and preparation method thereof | |

| CN115155554B (en) | Nanometer hollow mesoporous carbon sphere supported platinum nanoparticle catalyst and preparation method thereof | |

| CN106111141A (en) | A kind of three-dimensional titanium dioxide graphene composite material and preparation method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |