CN112018192A - A grid line structure, screen plate, solar cell and traceability method - Google Patents

A grid line structure, screen plate, solar cell and traceability methodDownload PDFInfo

- Publication number

- CN112018192A CN112018192ACN201910451306.1ACN201910451306ACN112018192ACN 112018192 ACN112018192 ACN 112018192ACN 201910451306 ACN201910451306 ACN 201910451306ACN 112018192 ACN112018192 ACN 112018192A

- Authority

- CN

- China

- Prior art keywords

- mark

- line

- marking

- pattern

- gate line

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 238000000034methodMethods0.000titleclaimsabstractdescription27

- 238000007639printingMethods0.000claimsdescription45

- 239000003550markerSubstances0.000claimsdescription14

- 230000008569processEffects0.000abstractdescription11

- 238000007650screen-printingMethods0.000abstractdescription9

- 238000013024troubleshootingMethods0.000abstractdescription5

- 230000005856abnormalityEffects0.000abstractdescription3

- 238000004519manufacturing processMethods0.000description58

- 238000010586diagramMethods0.000description8

- 230000007246mechanismEffects0.000description4

- 239000000565sealantSubstances0.000description3

- 239000002002slurrySubstances0.000description3

- 238000011835investigationMethods0.000description2

- 230000004048modificationEffects0.000description2

- 238000012986modificationMethods0.000description2

- 239000000853adhesiveSubstances0.000description1

- 230000001070adhesive effectEffects0.000description1

- 230000009286beneficial effectEffects0.000description1

- 239000011248coating agentSubstances0.000description1

- 238000000576coating methodMethods0.000description1

- 238000012790confirmationMethods0.000description1

- 238000001035dryingMethods0.000description1

- 230000005684electric fieldEffects0.000description1

- 239000003292glueSubstances0.000description1

- 230000006872improvementEffects0.000description1

- 239000004816latexSubstances0.000description1

- 229920000126latexPolymers0.000description1

- 230000035515penetrationEffects0.000description1

- 238000002360preparation methodMethods0.000description1

- 239000007787solidSubstances0.000description1

Images

Classifications

- H—ELECTRICITY

- H10—SEMICONDUCTOR DEVICES; ELECTRIC SOLID-STATE DEVICES NOT OTHERWISE PROVIDED FOR

- H10F—INORGANIC SEMICONDUCTOR DEVICES SENSITIVE TO INFRARED RADIATION, LIGHT, ELECTROMAGNETIC RADIATION OF SHORTER WAVELENGTH OR CORPUSCULAR RADIATION

- H10F77/00—Constructional details of devices covered by this subclass

- H10F77/20—Electrodes

- H10F77/206—Electrodes for devices having potential barriers

- H10F77/211—Electrodes for devices having potential barriers for photovoltaic cells

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41F—PRINTING MACHINES OR PRESSES

- B41F15/00—Screen printers

- B41F15/14—Details

- B41F15/34—Screens, Frames; Holders therefor

- B41F15/36—Screens, Frames; Holders therefor flat

- B—PERFORMING OPERATIONS; TRANSPORTING

- B41—PRINTING; LINING MACHINES; TYPEWRITERS; STAMPS

- B41P—INDEXING SCHEME RELATING TO PRINTING, LINING MACHINES, TYPEWRITERS, AND TO STAMPS

- B41P2215/00—Screen printing machines

- B41P2215/10—Screen printing machines characterised by their constructional features

- B41P2215/12—Screens

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E10/00—Energy generation through renewable energy sources

- Y02E10/50—Photovoltaic [PV] energy

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Photovoltaic Devices (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及太阳能电池片技术领域,尤其涉及一种栅线结构、网版、太阳能电池片及追溯方法。The invention relates to the technical field of solar cells, in particular to a grid line structure, a screen plate, a solar cell and a tracing method.

背景技术Background technique

太阳能电池片在生产制备过程中,需要经过丝网印刷工艺在电池片表面印刷形成背电极、背电场及正面栅线。现有的网版中,各线别的网版均一样,无差异,去印刷太阳能电池产品,组件客户端采用的太阳能电池片往往来自不同车间不同产线,在生产过程中很难一一甄别遴选,无法从组件客户端做到丝网工序精确线别追溯;对于处理与丝网印刷工序相关的组件端客诉、产线暗电流/ 低效等排查时,无法精确锁定具体线别,给排查带来困扰。In the production and preparation process of solar cells, it is necessary to print on the surface of the cell through a screen printing process to form a back electrode, a back electric field and a front grid. In the existing screen plates, the screen plates of each line are the same, and there is no difference. When printing solar cell products, the solar cells used by the module client are often from different workshops and different production lines, and it is difficult to distinguish them one by one during the production process. For selection, it is impossible to trace the screen process accurately from the component client; when dealing with component-side customer complaints related to the screen printing process, production line dark current/inefficiency, etc., it is impossible to accurately lock the specific line. Troubleshooting.

发明内容SUMMARY OF THE INVENTION

本发明的第一个目的在于提供一种栅线结构,能够追溯栅线结构对应的线别,便于排查各线别丝网印刷工序的问题。The first object of the present invention is to provide a grid line structure, which can trace the line types corresponding to the grid line structure, and is convenient to troubleshoot the problems in the screen printing process of each line type.

为达此目的,本发明采用以下技术方案:For this purpose, the present invention adopts the following technical solutions:

一种栅线结构,包括纵向间隔设置的多条主栅线、横向间隔设置并垂直于所述主栅线的若干条副栅线,该栅线结构还包括基准结构和标记结构,所述基准结构和所述标记结构均设置于所述主栅线上;或所述基准结构和所述标记结构均设置于所述副栅线上;或所述基准结构和所述标记结构中的一个设置于所述主栅线上、另一个设置于所述副栅线上。A gate line structure, comprising a plurality of main gate lines arranged at intervals in the longitudinal direction, a plurality of auxiliary gate lines arranged at horizontal intervals and perpendicular to the main gate lines, the gate line structure further comprises a reference structure and a mark structure, the reference Both the structure and the marking structure are arranged on the main gate line; or both the reference structure and the marking structure are arranged on the secondary gate line; or one of the reference structure and the marking structure is arranged The other is arranged on the main gate line, and the other is arranged on the auxiliary gate line.

作为优选,所述基准结构和所述标记结构位于同一条所述主栅线上;或所述基准结构和所述标记结构位于不同的所述主栅线上。Preferably, the reference structure and the mark structure are located on the same bus line; or the reference structure and the mark structure are located on different bus lines.

作为优选,所述主栅线沿其长度方向间隔设置有镂空区域和印刷区域,所述基准结构和所述标记结构设置于所述镂空区域或所述印刷区域。Preferably, a hollow area and a printing area are arranged at intervals along the length direction of the busbar, and the reference structure and the marking structure are arranged in the hollow area or the printing area.

作为优选,所述基准结构和所述标记结构中的一个设置于所述镂空区域、另一个设置于所述印刷区域;或Preferably, one of the reference structure and the marking structure is arranged in the hollow area, and the other is arranged in the printing area; or

所述基准结构和所述标记结构均设置于所述镂空区域;或Both the reference structure and the marking structure are arranged in the hollow area; or

所述基准结构和所述标记结构均设置于所述印刷区域。Both the reference structure and the marking structure are disposed in the printing area.

作为优选,所述基准结构和所述标记结构均为至少一组,每组所述基准结构包括至少一个基准点,每组所述标记结构包括至少一个标记点。Preferably, each of the reference structures and the marking structures is at least one group, each group of the reference structures includes at least one reference point, and each group of the marking structures includes at least one marking point.

作为优选,当所述基准结构和所述标记结构的组数相同时,每组所述基准结构中的基准点的个数和每组所述标记结构中的标记点的个数不同。Preferably, when the number of groups of the reference structures and the marking structures is the same, the number of reference points in each group of the reference structures and the number of marking points in each group of the marking structures are different.

作为优选,所述基准结构中的基准点的形状和所述标记结构中的标记点的形状不同。Preferably, the shape of the reference point in the reference structure and the shape of the marker point in the marker structure are different.

作为优选,所述基准点和所述标记点的形状均为圆形、三角形、五角形中的一种。Preferably, the shape of the reference point and the mark point is one of a circle, a triangle and a pentagon.

本发明的第二个目的在于提供一种网版,能够根据其印刷的栅线结构追溯到栅线结构对应的线别,便于排查各线别丝网印刷工序的问题。The second object of the present invention is to provide a screen plate, which can be traced back to the line type corresponding to the grid line structure according to the grid line structure printed thereon, so as to facilitate the investigation of problems in the screen printing process of each line type.

为达此目的,本发明采用以下技术方案:For this purpose, the present invention adopts the following technical solutions:

一种用于印刷如上所述栅线结构的网版,包括:A screen plate for printing the grid line structure as described above, comprising:

与所述主栅线对应的主栅线图形;a busbar pattern corresponding to the busbar;

与所述副栅线对应的副栅线图形;以及an auxiliary gate line pattern corresponding to the auxiliary gate line; and

与所述基准结构和所述标记结构对应的基准结构图形和标记结构图形;a reference structure graph and a marker structure graph corresponding to the reference structure and the marker structure;

所述基准结构图形和所述标记结构图形均设置于所述主栅线图形上;或所述基准结构图形和所述标记结构图形均设置于所述副栅线图形上;或所述基准结构图形和所述标记结构图形中的一个设置于所述主栅线图形上、另一个设置于所述副栅线图形上。Both the reference structure pattern and the mark structure pattern are arranged on the bus line pattern; or both the reference structure pattern and the mark structure pattern are arranged on the sub-gate line pattern; or the reference structure One of the pattern and the mark structure pattern is arranged on the main gate line pattern, and the other is arranged on the sub gate line pattern.

本发明的第三个目的在于提供一种太阳能电池片,能够追溯生产太阳能电池片的线别,便于排查各线别丝网印刷工序的问题。The third object of the present invention is to provide a solar cell, which can trace the line of production of the solar cell, so as to facilitate the troubleshooting of the screen printing process of each line.

为达此目的,本发明采用以下技术方案:For this purpose, the present invention adopts the following technical solutions:

一种包括如上所述栅线结构的太阳能电池片。A solar cell sheet comprising the grid line structure as described above.

本发明的第四个目的在于提供一种追溯方法,能够追溯栅线结构对应的线别,便于排查各线别丝网印刷工序的问题。The fourth object of the present invention is to provide a tracing method, which can trace the line type corresponding to the grid line structure, so as to facilitate the investigation of problems in the screen printing process of each line type.

为达此目的,本发明采用以下技术方案:For this purpose, the present invention adopts the following technical solutions:

一种用于如上所述太阳能电池片的追溯方法,通过所述太阳能电池片的所述栅线结构的所述标记结构相对所述基准结构的位置来追溯该栅线结构对应的线别。A traceability method for the above-mentioned solar cell sheet, traces the line classification corresponding to the gridline structure through the position of the marking structure of the gridline structure of the solar cell sheet relative to the reference structure.

作为优选,所述基准结构设置于所述太阳能电池片的一角,所述标记结构设置于不同于所述基准结构的其他位置。Preferably, the reference structure is arranged at a corner of the solar cell sheet, and the marking structure is arranged at another position different from the reference structure.

作为优选,所述标记结构与所述基准结构在所述太阳能电池片上不对称设置。Preferably, the marking structure and the reference structure are asymmetrically arranged on the solar cell sheet.

本发明的有益效果:Beneficial effects of the present invention:

本发明提供了一种栅线结构、网版、太阳能电池片及追溯方法,栅线结构包括基准结构和标记结构,基准结构和标记结构均设置于主栅线上,或均设置于副栅线上,或基准结构和标记结构中的一个设置于主栅线上和副栅线上,通过设置基准结构和标记结构来标记该栅线结构,能够追溯栅线结构对应的线别,便于排查各线别丝网印刷工序的问题,更加高效、快捷、方便处理组件客户端的异常。The invention provides a grid line structure, a screen plate, a solar cell sheet and a tracing method. The grid line structure includes a reference structure and a mark structure, and the reference structure and the mark structure are both arranged on the main grid line, or both are arranged on the auxiliary grid line or one of the reference structure and the marking structure is arranged on the main gate line and the auxiliary gate line. By setting the reference structure and the marking structure to mark the gate line structure, the line corresponding to the gate line structure can be traced back, which is convenient for checking each The problem of line-specific screen printing process is more efficient, fast and convenient to handle the abnormality of the component client.

附图说明Description of drawings

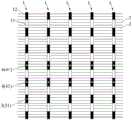

图1是本发明提供的栅线结构的结构示意图;1 is a schematic structural diagram of a gate line structure provided by the present invention;

图2是本发明提供的网版的栅线图形结构的结构示意图;Fig. 2 is the structural representation of the grid pattern structure of the screen plate provided by the present invention;

图3是举例1提供的栅线结构的结构示意图;3 is a schematic structural diagram of the gate line structure provided in Example 1;

图4是举例2提供的栅线结构的结构示意图;4 is a schematic structural diagram of the gate line structure provided in Example 2;

图5是举例3提供的栅线结构的结构示意图;5 is a schematic structural diagram of the gate line structure provided in Example 3;

图6是举例4提供的栅线结构的结构示意图;6 is a schematic structural diagram of the gate line structure provided in Example 4;

图7是举例5提供的栅线结构的结构示意图;7 is a schematic structural diagram of the gate line structure provided in Example 5;

图8是举例6提供的栅线结构的结构示意图;8 is a schematic structural diagram of the gate line structure provided in Example 6;

图9是举例7提供的栅线结构的结构示意图。FIG. 9 is a schematic structural diagram of the gate line structure provided in Example 7. FIG.

图中:In the picture:

1、主栅线;11、镂空区域;12、印刷区域;2、副栅线;3、基准结构;31、基准点;4、标记结构;41、标记点;7、主栅线图形;8、副栅线图形;9、基准结构图形;10、标记结构图形。1. Busbar; 11. Hollow area; 12. Printing area; 2. Secondary grid; 3. Reference structure; 31. Reference point; 4. Marking structure; 41. Marking point; 7. Busbar graphic; 8 , the auxiliary grid line pattern; 9, the reference structure pattern; 10, the mark structure pattern.

具体实施方式Detailed ways

下面详细描述本发明的实施例,实施例的示例在附图中示出,其中自始至终相同或类似的标号表示相同或类似的元件或具有相同或类似功能的元件。下面通过参考附图描述的实施例是示例性的,旨在用于解释本发明,而不能理解为对本发明的限制。Embodiments of the present invention are described in detail below, examples of which are illustrated in the accompanying drawings, wherein the same or similar reference numerals refer to the same or similar elements or elements having the same or similar functions throughout. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention and should not be construed as limiting the present invention.

在本发明的描述中,需要说明的是,术语“中心”、“上”、“下”、“左”、“右”等指示的方位或位置关系为基于附图所示的方位或位置关系,仅是为了便于描述本发明和简化描述,而不是指示或暗示所指的装置或元件必须具有特定的方位、以特定的方位构造和操作,因此不能理解为对本发明的限制。此外,术语“第一”、“第二”仅用于描述目的,而不能理解为指示或暗示相对重要性。其中,术语“第一位置”和“第二位置”为两个不同的位置。In the description of the present invention, it should be noted that the orientation or positional relationship indicated by the terms "center", "upper", "lower", "left", "right", etc. are based on the orientation or positional relationship shown in the accompanying drawings , is only for the convenience of describing the present invention and simplifying the description, rather than indicating or implying that the indicated device or element must have a specific orientation, be constructed and operated in a specific orientation, and therefore should not be construed as a limitation of the present invention. Furthermore, the terms "first" and "second" are used for descriptive purposes only and should not be construed to indicate or imply relative importance. Therein, the terms "first position" and "second position" are two different positions.

除非另有明确的规定和限定,第一特征在第二特征之“上”或之“下”可以包括第一特征和第二特征直接接触,也可以包括第一特征和第二特征不是直接接触而是通过它们之间的另外的特征接触。而且,第一特征在第二特征“之上”、“上方”和“上面”包括第一特征在第二特征正上方和斜上方,或仅仅表示第一特征水平高度高于第二特征。Unless otherwise expressly specified and limited, a first feature "on" or "under" a second feature may include the first feature and the second feature in direct contact, or may include the first feature and the second feature not in direct contact Rather, they are contacted by additional features between them. Also, the first feature being "above", "over" and "above" the second feature includes the first feature being directly above and obliquely above the second feature, or simply means that the first feature is level higher than the second feature.

下面结合附图并通过具体实施方式来进一步说明本发明的技术方案。The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

本发明提供一种太阳能电池片,该太阳能电池片包括栅线结构,如图1所示,该栅线结构包括纵向间隔设置的多条主栅线1、横向间隔设置并垂直于主栅线1的若干条副栅线2。为了能够追溯栅线结构对应的线别,便于排查各线别丝网印刷工序的问题,更加高效、快捷、方便处理组件客户端的异常,该栅线结构还包括基准结构3和标记结构4。The present invention provides a solar cell sheet, the solar cell sheet includes a grid line structure, as shown in FIG. 1 , the grid line structure includes a plurality of main grid lines 1 arranged at intervals in the longitudinal direction, and arranged at horizontal intervals and perpendicular to the main grid lines 1 a number of secondary gate lines 2. In order to be able to trace the lines corresponding to the grid line structure, to facilitate the troubleshooting of the screen printing process of each line, and to handle the abnormality of the component client more efficiently, quickly and conveniently, the grid line structure also includes a

具体地,该基准结构3和标记结构4的设置位置及设置形式,对于实现上述追溯目的是非常关键的。Specifically, the setting position and setting form of the

可选地,该基准结构3和标记结构4可以均设置于主栅线1上;或该基准结构3和标记结构4也可以均设置于副栅线2上;或该基准结构3和标记结构4 中的一个设置于主栅线1上、另一个设置于副栅线2上,此时,可以是基准结构3设置于主栅线1上、标记结构4设置于副栅线2上,也可以是标记结构4 设置于主栅线1上、基准结构3设置于副栅线2上。Optionally, both the

可选地,当基准结构3和标记结构4均位于主栅线1上时,该基准结构3 和标记结构4可以位于同一条主栅线1上;或基准结构3和标记结构4位于不同的主栅线1上。Optionally, when both the

可选地,主栅线1沿其长度方向间隔设置有镂空区域11和印刷区域12,基准结构3和标记结构4设置于镂空区域11或印刷区域12。如基准结构3和标记结构4中的一个设置于镂空区域11、另一个设置于印刷区域12;或基准结构3 和标记结构4均设置于镂空区域11;或基准结构3和标记结构4均设置于印刷区域12。当基准结构3和标记结构4设置于印刷区域12时,可以将其设置为空心结构,当基准结构3和标记结构4设置于镂空区域11时,可以将其设置为实心结构。Optionally, the busbar 1 is provided with a

可选地,基准结构3和标记结构4均为至少一组,每组基准结构3包括至少一个基准点31,每组标记结构4包括至少一个标记点41。Optionally, each of the

作为一种可选方式,当基准结构3和标记结构4的组数相同时,每组基准结构3中的基准点31的个数和每组标记结构4中的标记点41的个数不同。例如,基准结构3为1组,且该组基准结构3包括2个基准点31,标记结构4为 1组,且该组标记机构4包括1个标记点41,这时,就能判断该栅线结构对应来自第一条产线;又如,基准结构3为1组,且该组基准结构3包括2个基准点31,标记结构4为3组,且该组标记机构4包括2个标记点41,这时,就能判断该栅线结构对应来自第三条产线,等等。As an alternative, when the number of groups of the

作为另一种可选方式,基准结构3中的基准点31的形状和标记结构4中的标记点41的形状不同。具体地,基准点31和标记点41的形状均为圆形、三角形、五角形中的一种,例如,基准点31的形状为圆形,标记点41的形状为三角形,等等。As another alternative, the shape of the

通过基准点31和标记点41的个数不同,以及基准点31和标记点41的形状不同,可以很好地区分出基准点31和标记点41,保证判断的准确度。The

进一步地,基准结构3和标记结构4的最大宽度为主栅线1宽度的0.3~0.8 倍。例如,基准结构3和标记结构4的最大宽度为主栅线1宽度的0.3倍、0.4 倍、0.5倍、0.6倍、0.7倍、0.8倍。优选地,基准结构3和标记结构4的最大宽度为主栅线1宽度的0.6倍,在该宽度比值时,基准结构3和标记结构4均能够被有效识别,且不易造成断栅的现象。Further, the maximum width of the

基准点31和标记点41的最大宽度尺寸可以为0.6~1mm,例如为0.6mm、 0.7mm、0.8mm、0.9mm、1mm。上述范围内,基准点31能够被有效识别。The maximum width dimension of the

为了实现上述栅线结构,参照图2,本发明还提供一种用于印刷上述栅线结构的网版,包括栅线图形结构,该栅线图形结构包括与主栅线1对应的主栅线图形7;与副栅线2对应的副栅线图形8;以及与基准结构3和标记结构4对应的基准结构图形9和标记结构图形10。其中,基准结构图形9与上述的基准结构3对应,标记结构图形10与上述的标记结构4对应。也可以理解为,主栅线 1是通过主栅线图形7加工而来,副栅线2是通过副栅线图形8加工而来,基准结构3是通过基准图形结构9加工而来,标记结构4是通过标记图形结构10加工而来。In order to realize the above grid line structure, referring to FIG. 2 , the present invention also provides a screen plate for printing the above grid line structure, including a grid line pattern structure, and the grid line pattern structure includes a bus line corresponding to the bus line 1 A pattern 7 ; a sub gate line pattern 8 corresponding to the

可选地,对应于上述栅线结构的基准结构3和标记结构4,该基准结构图形 9和标记结构图形10可以均设置于主栅线图形7上;或该基准结构图形9和标记结构图形10也可以均设置于副栅线图形8上;或该基准结构图形9和标记结构图形10中的一个设置于主栅线图形7上、另一个设置于副栅线图形8上,此时,可以是基准结构图形9设置于主栅线图形7上、标记结构图形10设置于副栅线图形8上,也可以是标记结构图形10设置于主栅线图形7上、基准结构图形9设置于副栅线图形8上。Optionally, corresponding to the

可选地,当基准结构图形9和标记结构图形10均位于主栅线图形7上时,该基准结构图形9和标记结构图形10可以位于同一条主栅线图形7上;或基准结构图形9和标记结构图形10位于不同的主栅线图形7上。Optionally, when both the

可选地,主栅线图形7沿其长度方向间隔设置有镂空图形区域和印刷图形区域,其中,镂空图形区域和印刷图形区域分别对应主栅线1的印刷区域12和镂空区域11;基准结构图形9和标记结构图形10设置于镂空图形区域或印刷图形区域。如基准结构图形9和标记结构图形10中的一个设置于镂空图形区域、另一个设置于印刷图形区域;或基准结构图形9和标记结构图形10均设置于镂空图形区域;或基准结构图形9和标记结构图形10均设置于印刷图形区域。Optionally, the busbar pattern 7 is provided with a hollow pattern area and a printed pattern area at intervals along its length direction, wherein the hollow pattern area and the printed pattern area correspond to the printed

为实现基准结构图形9和标记结构图形10处的浆料不透过,基准结构图形 9和标记结构图形10处均涂布有封网胶。封网胶为不易被浆料腐蚀且在干结后能够阻止浆料透过的胶,例如乳胶。涂布封网胶的方式简单方便,多个网版可先同批制作好后,在分别对多个网版进行不同位置的涂封网胶,操作简单方便。In order to achieve impermeability of the slurry at the

在其他实施例中,使浆料不透过也可以采用在基准结构图形9和标记结构图形10处粘贴薄膜、或在对网版的图像区域进行显影设计时在基准结构图形9 和标记结构图形10的位置不镂空等方式。上述方式均能在栅线结构的主栅线1 上形成未印刷的空心小点,便于对栅线结构进行识别,从而追溯到生产其的线别,便于排查生产过程中的问题。In other embodiments, to make the paste impermeable, a film can be pasted at the

可选地,基准结构图形9和标记结构图形10均为至少一组,每组基准结构图形9包括至少一个基准点图形,每组标记结构图形10包括至少一个标记点图形。Optionally, each of the

作为一种可选方式,当基准结构图形9和标记结构图形10的组数相同时,每组基准结构图形9中的基准点图形的个数和每组标记结构图形10中的标记点图形的个数不同。例如,基准结构图形9为1组,且该组基准结构图形9包括2 个基准点图形,标记结构图形10为1组,且该组标记机构4包括1个标记点图形,这时,就能判断该网版用于第一条产线;又如,基准结构图形9为1组,且该组基准结构图形9包括2个基准点图形,标记结构图形10为3组,且该组标记机构4包括2个标记点图形,这时,就能判断该网版用于第三条产线,等等。As an alternative, when the number of groups of the

作为另一种可选方式,基准结构图形9中的基准点图形的形状和标记结构图形10中的标记点图形的形状不同。具体地,基准点图形和标记点图形的形状均为圆形、三角形、五角形中的一种,例如,基准点图形的形状为圆形,标记点图形的形状为三角形,等等。As another alternative, the shape of the reference point pattern in the

由此可以看出,本发明的网版的栅线图形结构与本发明的太阳能电池片的栅线结构是一一对应关系。It can be seen from this that there is a one-to-one correspondence between the grid line pattern structure of the screen plate of the present invention and the grid line structure of the solar cell sheet of the present invention.

在上述结构的基础上,本发明提供一种用于太阳能电池片的追溯方法,该追溯方法的目的在于,快速地了解太阳能电池片来自于哪条产线或者哪个生产车间,这样就能很好地确定每条产线生产太阳能电池片的质量。On the basis of the above structure, the present invention provides a traceability method for solar cells, the purpose of which is to quickly know which production line or which production workshop the solar cells come from, so that the Determine the quality of solar cells produced by each production line.

具体地,本发明的追溯方法是通过太阳能电池片的栅线结构的标记结构4 相对基准结构3的位置来追溯该栅线结构对应的线别。Specifically, the tracing method of the present invention is to trace the line classification corresponding to the grid line structure through the position of the marking

更具体地,本发明的追溯方法包括以下步骤:More specifically, the retrospective method of the present invention comprises the following steps:

通过本发明的网版同步印刷主栅线1、副栅线2、标记结构4和基准结构3;The main grid line 1, the

获取基准结构3和标记结构4的信息;Obtain the information of

通过标记结构4相对基准结构3的位置来追溯该栅线结构对应的线别。The line type corresponding to the gate line structure can be traced back by the position of the

通过同步印刷主栅线1、副栅线2、标记结构4和基准结构3,使得在对太阳能电池片依次印刷即可进行标记,省去了在印刷完主栅线1和副栅线2之后再另外设置标记的繁琐步骤,印刷过程简单方便,效率高。By synchronously printing the busbar 1, the

为了很好地辨别基准结构3,在本发明中,基准结构3设置于太阳能电池片的一角,标记结构4设置于不同于基准结构3的其他位置。且标记结构4与基准结构3在太阳能电池片上不对称设置。这时不仅能够快速分辨基准结构3,还能在产品被旋转180°后快速找出基准结构3,避免出现识别混乱或无法识别的问题。In order to distinguish the

此处值得说明的是,太阳能电池片的对称中心线平行于副栅线且与主栅线的中间点相交,因此,标记结构4与基准结构3相对于该对称中心线不对称设置,以便于更好地确认基准结构和标记结构。It is worth noting here that the symmetrical center line of the solar cell is parallel to the secondary grid line and intersects with the middle point of the main grid line. Therefore, the marking

因此,通过这种方式在实际生产中,对每条生产线预设一种基准结构、标记结构及两者的形式,从而便于实际操作中辨认。Therefore, in actual production in this way, each production line is preset with a reference structure, a marking structure, and the form of both, so as to facilitate identification in actual operation.

以下,对于本发明的栅线结构、太阳能电池片及追溯方法,本发明进行举例说明。Hereinafter, the present invention will be exemplified for the grid line structure, the solar cell sheet, and the tracing method of the present invention.

举例1Example 1

如图3所示,在本例中,基准结构3和标记结构4均设置于主栅线1上。基准结构3为1组,基准结构3包括1个基准点31;标记结构4为1组,标记结构包括2个标记点41,其中,基准点31和标记点41的形状相同。该组基准结构的基准点31设置于图1所示的左起第一条主栅线1的左下角的印刷区域12 处;该组标记结构4的2个标记点41紧邻设置于同一印刷区域12中。As shown in FIG. 3 , in this example, both the

若标记结构4的标记点41与基准点31位于同一条主栅线1,且标记点41 位于不同于基准点31的其他印刷区域12处,但标记点41与基准点31不对称设置,则判断该栅线结构来自于第一条产线。If the

若标记结构4的标记点41位于图1左起第二条主栅线1的印刷区域12或镂空区域11处,则判断该栅线结构来自于第二条产线。If the

若标记结构4的标记点41位于图1左起第三条主栅线1的印刷区域12或镂空区域11处,则判断该栅线结构来自于第三条产线。If the

若标记结构4的标记点41位于图1左起第四条主栅线1的印刷区域12或镂空区域11处,则判断该栅线结构来自于第四条产线。If the

若标记结构4的标记点41位于图1左起第五条主栅线1的印刷区域12或镂空区域11处,则判断该栅线结构来自于第五条产线。If the

以此类推,就可以快速的识别每个太阳能电池片的生成产线。By analogy, the production line of each solar cell can be quickly identified.

举例2Example 2

如图4所示,在本例中,基准结构3和标记结构4均设置于主栅线1上。基准结构3为1组,基准结构3包括2个基准点31;标记结构4为1组,标记结构包括1个标记点41。其中,基准点31和标记点41的形状相同。该组基准结构3的基准点31紧邻设置且位于图1所示的左起第一条主栅线1的左下角的印刷区域12处;该组标记结构4的1个标记点41设置于一印刷区域12中。As shown in FIG. 4 , in this example, both the

若标记结构4的标记点41与基准点31位于同一条主栅线1,且标记点41 位于不同于基准点31的其他印刷区域12处,但标记点41与基准点31不对称设置,则判断该栅线结构来自于第一条产线。If the

若标记结构4的标记点41位于图1左起第二条主栅线1的印刷区域12或镂空区域11处,则判断该栅线结构来自于第二条产线。If the

若标记结构4的标记点41位于图1左起第三条主栅线1的印刷区域12或镂空区域11处,则判断该栅线结构来自于第三条产线。If the

若标记结构4的标记点41位于图1左起第四条主栅线1的印刷区域12或镂空区域11处,则判断该栅线结构来自于第四条产线。If the

若标记结构4的标记点41位于图1左起第五条主栅线1的印刷区域12或镂空区域11处,则判断该栅线结构来自于第五条产线。If the

以此类推,就可以快速的识别每个太阳能电池片的生成产线。By analogy, the production line of each solar cell can be quickly identified.

举例3Example 3

如图5所示,在本例中,基准结构3和标记结构4均设置于主栅线1上。基准结构3为2组,每组基准结构3包括1个基准点31;标记结构4为1组,标记结构包括2个标记点41。其中,基准点31和标记点41的形状相同。2组基准结构3分别设置于图1中左起第一条和第二条主栅线1上;1组标记结构4 的2个标记点41设置于同一印刷区域12或同一镂空区域11中。As shown in FIG. 5 , in this example, both the

若标记结构4的标记点41位于图1左起第一条主栅线1上,且标记点41 位于不同于基准点31的其他印刷区域12处,但标记点41与基准点31不对称设置,则判断该栅线结构来自于第一条产线。If the

若标记结构4的标记点41位于图1左起第二条主栅线1的印刷区域12处,且标记点41位于不同于基准点3的其他印刷区域12处,但标记点41与基准点 31不对称设置,则判断该栅线结构来自于第二条产线。If the

若标记结构4的标记点41位于图1左起第三条主栅线1的印刷区域12或镂空区域11处,则判断该栅线结构来自于第三条产线。If the

若标记结构4的标记点41位于图1左起第四条主栅线1的印刷区域12或镂空区域11处,则判断该栅线结构来自于第四条产线。If the

若标记结构4的标记点41位于图1左起第五条主栅线1的印刷区域12或镂空区域11处,则判断该栅线结构来自于第五条产线。If the

以此类推,就可以快速的识别每个太阳能电池片的生成产线。By analogy, the production line of each solar cell can be quickly identified.

举例4Example 4

如图6所示,在本例中,基准结构3和标记结构4均设置于主栅线1上。基准结构3为1组,每组基准结构3包括1个基准点31,该基准点31的形状为三角形;标记结构4为2组,每组标记结构包括1个标记点41,该标记点41的形状为圆形。其中,基准结构3设置于图1中左起第一条主栅线1上;2组标记结构4位于同一条主栅线1上,但2组标记结构4位于不同的区域。As shown in FIG. 6 , in this example, both the

若标记结构4的标记点41位于图1左起第一条主栅线1上,则判断该栅线结构来自于第一条产线。If the

若标记结构4的标记点41位于图1左起第二条主栅线1,则判断该栅线结构来自于第二条产线。If the

若标记结构4的标记点41位于图1左起第三条主栅线1,则判断该栅线结构来自于第三条产线。If the

若标记结构4的标记点41位于图1左起第四条主栅线1,则判断该栅线结构来自于第四条产线。If the

若标记结构4的标记点41位于图1左起第五条主栅线1,则判断该栅线结构来自于第五条产线。If the

以此类推,就可以快速的识别每个太阳能电池片的生成产线。By analogy, the production line of each solar cell can be quickly identified.

举例5Example 5

如图7所示,在本例中,基准结构3和标记结构4均设置于主栅线1上。基准结构3为1组,基准结构3包括2个基准点31;标记结构4为1组,标记结构包括1个标记点41。其中,基准点31设置于主栅线1的印刷区域12处,标记点41设置于主栅线1的镂空区域11处。该组基准结构3的基准点31位于图1所示的左起第一条主栅线1的左下角的印刷区域12处;该组标记结构4的 1个标记点41设置于一镂空区域11中。As shown in FIG. 7 , in this example, both the

若标记结构4的标记点41与基准点31位于同一条主栅线1,则判断该栅线结构来自于第一条产线。If the

若标记结构4的标记点41位于图1左起第二条主栅线1,则判断该栅线结构来自于第二条产线。If the

若标记结构4的标记点41位于图1左起第三条主栅线1,则判断该栅线结构来自于第三条产线。If the

若标记结构4的标记点41位于图1左起第四条主栅线1,则判断该栅线结构来自于第四条产线。If the

若标记结构4的标记点41位于图1左起第五条主栅线1,则判断该栅线结构来自于第五条产线。If the

以此类推,就可以快速的识别每个太阳能电池片的生成产线。By analogy, the production line of each solar cell can be quickly identified.

举例6Example 6

如图8所示,在本例中,基准结构3设置于主栅线1上,标记结构4设置于副栅线2上。基准结构3为1组,基准结构3包括2个基准点31;标记结构 4为1组,标记结构包括1个标记点41。其中,基准点31设置于主栅线1的印刷区域12处,标记点41设置于副栅线2且靠近左边的主栅线1。该组基准结构 3的基准点31位于图1所示的左起第一条主栅线1的左下角的印刷区域12处。As shown in FIG. 8 , in this example, the

若标记结构4的标记点41位于第一条和第二条主栅线1之间,则判断该栅线结构来自于第一条产线。If the

若标记结构4的标记点41位于第二条和第三条主栅线1之间,则判断该栅线结构来自于第二条产线。If the

若标记结构4的标记点41位于第三条和第四条主栅线1之间,则判断该栅线结构来自于第三条产线。If the

若标记结构4的标记点41位于第四条和第五条主栅线1之间,则判断该栅线结构来自于第四条产线。If the

若标记结构4的标记点41位于第五条主栅线1的右侧,则判断该栅线结构来自于第五条产线。If the

以此类推,就可以快速的识别每个太阳能电池片的生成产线。By analogy, the production line of each solar cell can be quickly identified.

举例7Example 7

如图9所示,在本例中,基准结构3和标记结构4均设置于副栅线2上。基准结构3为1组,基准结构3包括2个基准点31;标记结构4为1组,标记结构包括1个标记点41。其中,标记点41设置于副栅线2且靠近左边的主栅线 1。该组基准结构3的基准点31位于图1所示的左起第一条主栅线1的右侧。As shown in FIG. 9 , in this example, both the

若标记结构4的标记点41位于第一条和第二条主栅线1之间,则判断该栅线结构来自于第一条产线。If the

若标记结构4的标记点41位于第二条和第三条主栅线1之间,则判断该栅线结构来自于第二条产线。If the

若标记结构4的标记点41位于第三条和第四条主栅线1之间,则判断该栅线结构来自于第三条产线。If the

若标记结构4的标记点41位于第四条和第五条主栅线1之间,则判断该栅线结构来自于第四条产线。If the

若标记结构4的标记点41位于第五条主栅线1的右侧,则判断该栅线结构来自于第五条产线。If the

以此类推,就可以快速的识别每个太阳能电池片的生成产线。By analogy, the production line of each solar cell can be quickly identified.

本发明的栅线结构,通过每组基准结构3中的基准点31的个数和每组标记结构4中的标记点41的个数不同,以及基准点31和标记点41的形状区别等,能够便于区分基准结构3和标记结构4,避免因栅线结构旋转180°后难以识别或识别错误等情况,保证识别准确。此外,通过增加基准点31个数、标记点41 个数,可以使栅线结构的分类更多,便于对较多线别对应的栅线结构进行标记追踪。In the gate line structure of the present invention, the number of

显然,本发明的上述实施例仅仅是为了清楚说明本发明所作的举例,而并非是对本发明的实施方式的限定。对于所属领域的普通技术人员来说,在上述说明的基础上还可以做出其它不同形式的变化或变动。这里无需也无法对所有的实施方式予以穷举。凡在本发明的精神和原则之内所作的任何修改、等同替换和改进等,均应包含在本发明权利要求的保护范围之内。Obviously, the above-mentioned embodiments of the present invention are only examples for clearly illustrating the present invention, rather than limiting the embodiments of the present invention. For those of ordinary skill in the art, changes or modifications in other different forms can also be made on the basis of the above description. There is no need and cannot be exhaustive of all implementations here. Any modification, equivalent replacement and improvement made within the spirit and principle of the present invention shall be included within the protection scope of the claims of the present invention.

Claims (13)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910451306.1ACN112018192A (en) | 2019-05-28 | 2019-05-28 | A grid line structure, screen plate, solar cell and traceability method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910451306.1ACN112018192A (en) | 2019-05-28 | 2019-05-28 | A grid line structure, screen plate, solar cell and traceability method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN112018192Atrue CN112018192A (en) | 2020-12-01 |

Family

ID=73500640

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910451306.1APendingCN112018192A (en) | 2019-05-28 | 2019-05-28 | A grid line structure, screen plate, solar cell and traceability method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN112018192A (en) |

Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4131879A (en)* | 1976-04-30 | 1978-12-26 | Gretag Aktiengesellschaft | Method and apparatus for determining the relative positions of corresponding points or zones of a sample and an orginal |

| CN102101396A (en)* | 2010-11-19 | 2011-06-22 | 奥特斯维能源(太仓)有限公司 | Method for aligning metal grid line in solar cell metallization process |

| CN103840016A (en)* | 2012-11-27 | 2014-06-04 | 陕西天宏硅材料有限责任公司 | Solar cell with three gate electrode structures |

| CN104417025A (en)* | 2013-08-27 | 2015-03-18 | 茂迪(苏州)新能源有限公司 | Screen printing plate and solar battery manufacturing method |

| CN208077990U (en)* | 2018-03-28 | 2018-11-09 | 通威太阳能(成都)有限公司 | A kind of gradation printing crystal-silicon solar cell front electrode |

| CN109494261A (en)* | 2018-10-19 | 2019-03-19 | 晶澳(扬州)太阳能科技有限公司 | Silica-based solar cell and preparation method, photovoltaic module |

| CN209804672U (en)* | 2019-05-28 | 2019-12-17 | 盐城阿特斯阳光能源科技有限公司 | Grid line structure, screen printing plate and solar cell |

- 2019

- 2019-05-28CNCN201910451306.1Apatent/CN112018192A/enactivePending

Patent Citations (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4131879A (en)* | 1976-04-30 | 1978-12-26 | Gretag Aktiengesellschaft | Method and apparatus for determining the relative positions of corresponding points or zones of a sample and an orginal |

| CN102101396A (en)* | 2010-11-19 | 2011-06-22 | 奥特斯维能源(太仓)有限公司 | Method for aligning metal grid line in solar cell metallization process |

| CN103840016A (en)* | 2012-11-27 | 2014-06-04 | 陕西天宏硅材料有限责任公司 | Solar cell with three gate electrode structures |

| CN104417025A (en)* | 2013-08-27 | 2015-03-18 | 茂迪(苏州)新能源有限公司 | Screen printing plate and solar battery manufacturing method |

| CN208077990U (en)* | 2018-03-28 | 2018-11-09 | 通威太阳能(成都)有限公司 | A kind of gradation printing crystal-silicon solar cell front electrode |

| CN109494261A (en)* | 2018-10-19 | 2019-03-19 | 晶澳(扬州)太阳能科技有限公司 | Silica-based solar cell and preparation method, photovoltaic module |

| CN209804672U (en)* | 2019-05-28 | 2019-12-17 | 盐城阿特斯阳光能源科技有限公司 | Grid line structure, screen printing plate and solar cell |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI503233B (en) | Screen printing method | |

| CN107871679B (en) | A mother board to be cut, a substrate preparation method and a substrate cutting accuracy detection method | |

| US8807026B2 (en) | Method for printing a conductor in two superimposed layers by screen-printing | |

| CN209804672U (en) | Grid line structure, screen printing plate and solar cell | |

| CN204249527U (en) | Screen process press and printing screen plate thereof | |

| CN110459616A (en) | Silicon substrate, solar battery sheet and method for forming same, printing screen | |

| CN111402343A (en) | High-precision calibration plate and calibration method | |

| CN101620039A (en) | Sample positioning template of precision cutting machine table | |

| CN116417367A (en) | Method, device and tool for removing abnormal die of wafer | |

| CN103118482B (en) | There is circuit board and the discrimination method thereof of quality identification mark | |

| CN105091755A (en) | Detection method for secondary printing precision of screen printing machine | |

| CN112018192A (en) | A grid line structure, screen plate, solar cell and traceability method | |

| CN112882340B (en) | Photomask, monitoring wafer and method for monitoring wafer surface cleaning precision | |

| WO2014146369A1 (en) | Color film substrate, manufacturing method therefor, and display panel and display device thereof | |

| CN116379928A (en) | Calibration plate and application thereof | |

| CN206118167U (en) | Prevent slow -witted PCB board | |

| CN112721416B (en) | Electrode chromatography screen plate and electrode contact resistivity testing method | |

| EP3486087A1 (en) | Apparatus for inspecting characters/numbers of negotiable instrument, and method for inspecting characters/numbers of negotiable instrument | |

| CN111315134B (en) | Production process of high-precision photoelectric printed circuit board | |

| CN104460249A (en) | Method for detecting exposure alignment of two sides of inner-layer substrate of circuit board | |

| JPS6151550B2 (en) | ||

| CN106325004A (en) | Energy uniformity detection method of LDI exposure machine | |

| CN209395411U (en) | Photovoltaic cell printing screen | |

| CN207594496U (en) | Screen printing plate | |

| CN209806147U (en) | PCB capable of detecting character printing precision |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| CB02 | Change of applicant information | ||

| CB02 | Change of applicant information | Address after:No.66 Lijiang Road, Yancheng Economic and Technological Development Zone, Suzhou City, Jiangsu Province 224000 Applicant after:YANCHENG ARTES SUNSHINE ENERGY TECHNOLOGY Co.,Ltd. Applicant after:Atlas sunshine Power Group Co.,Ltd. Address before:No.66 Lijiang Road, Yancheng Economic and Technological Development Zone, Suzhou City, Jiangsu Province 224000 Applicant before:YANCHENG ARTES SUNSHINE ENERGY TECHNOLOGY Co.,Ltd. Applicant before:CSI SOLAR POWER GROUP Co.,Ltd. |