CN111993883A - Distributed electric drive all-terrain vehicle - Google Patents

Distributed electric drive all-terrain vehicleDownload PDFInfo

- Publication number

- CN111993883A CN111993883ACN202010959379.4ACN202010959379ACN111993883ACN 111993883 ACN111993883 ACN 111993883ACN 202010959379 ACN202010959379 ACN 202010959379ACN 111993883 ACN111993883 ACN 111993883A

- Authority

- CN

- China

- Prior art keywords

- vehicle body

- wheel

- vehicle

- distributed

- wheel motor

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000725suspensionSubstances0.000claimsdescription13

- 239000006096absorbing agentSubstances0.000claimsdescription8

- 230000035939shockEffects0.000claimsdescription8

- 238000011084recoveryMethods0.000claimsdescription5

- 230000001154acute effectEffects0.000claimsdescription2

- 230000005540biological transmissionEffects0.000abstractdescription11

- 230000009347mechanical transmissionEffects0.000abstractdescription5

- 239000000243solutionSubstances0.000description9

- 238000009434installationMethods0.000description5

- 230000009286beneficial effectEffects0.000description4

- 230000009471actionEffects0.000description2

- 230000008901benefitEffects0.000description2

- 238000010586diagramMethods0.000description2

- 230000000694effectsEffects0.000description2

- 230000007613environmental effectEffects0.000description2

- 230000000670limiting effectEffects0.000description2

- 238000000034methodMethods0.000description2

- 230000004048modificationEffects0.000description2

- 238000012986modificationMethods0.000description2

- 238000005381potential energyMethods0.000description2

- 238000006467substitution reactionMethods0.000description2

- 229910000831SteelInorganic materials0.000description1

- 230000004075alterationEffects0.000description1

- 239000003637basic solutionSubstances0.000description1

- 238000005452bendingMethods0.000description1

- 238000010276constructionMethods0.000description1

- 238000005265energy consumptionMethods0.000description1

- 230000010354integrationEffects0.000description1

- 238000004519manufacturing processMethods0.000description1

- 238000005065miningMethods0.000description1

- 239000003208petroleumSubstances0.000description1

- 239000010959steelSubstances0.000description1

- 238000003860storageMethods0.000description1

- 230000001360synchronised effectEffects0.000description1

- 238000003466weldingMethods0.000description1

Images

Classifications

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K7/00—Disposition of motor in, or adjacent to, traction wheel

- B60K7/0007—Disposition of motor in, or adjacent to, traction wheel the motor being electric

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G13/00—Resilient suspensions characterised by arrangement, location or type of vibration dampers

- B60G13/02—Resilient suspensions characterised by arrangement, location or type of vibration dampers having dampers dissipating energy, e.g. frictionally

- B60G13/04—Resilient suspensions characterised by arrangement, location or type of vibration dampers having dampers dissipating energy, e.g. frictionally mechanically, e.g. having frictionally-engaging springs as damping elements

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60G—VEHICLE SUSPENSION ARRANGEMENTS

- B60G3/00—Resilient suspensions for a single wheel

- B60G3/18—Resilient suspensions for a single wheel with two or more pivoted arms, e.g. parallelogram

- B60G3/20—Resilient suspensions for a single wheel with two or more pivoted arms, e.g. parallelogram all arms being rigid

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K1/00—Arrangement or mounting of electrical propulsion units

- B60K1/04—Arrangement or mounting of electrical propulsion units of the electric storage means for propulsion

- B—PERFORMING OPERATIONS; TRANSPORTING

- B62—LAND VEHICLES FOR TRAVELLING OTHERWISE THAN ON RAILS

- B62D—MOTOR VEHICLES; TRAILERS

- B62D23/00—Combined superstructure and frame, i.e. monocoque constructions

- B62D23/005—Combined superstructure and frame, i.e. monocoque constructions with integrated chassis in the whole shell, e.g. meshwork, tubes, or the like

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K7/00—Disposition of motor in, or adjacent to, traction wheel

- B60K2007/0038—Disposition of motor in, or adjacent to, traction wheel the motor moving together with the wheel axle

- B—PERFORMING OPERATIONS; TRANSPORTING

- B60—VEHICLES IN GENERAL

- B60K—ARRANGEMENT OR MOUNTING OF PROPULSION UNITS OR OF TRANSMISSIONS IN VEHICLES; ARRANGEMENT OR MOUNTING OF PLURAL DIVERSE PRIME-MOVERS IN VEHICLES; AUXILIARY DRIVES FOR VEHICLES; INSTRUMENTATION OR DASHBOARDS FOR VEHICLES; ARRANGEMENTS IN CONNECTION WITH COOLING, AIR INTAKE, GAS EXHAUST OR FUEL SUPPLY OF PROPULSION UNITS IN VEHICLES

- B60K7/00—Disposition of motor in, or adjacent to, traction wheel

- B60K2007/0092—Disposition of motor in, or adjacent to, traction wheel the motor axle being coaxial to the wheel axle

Landscapes

- Engineering & Computer Science (AREA)

- Mechanical Engineering (AREA)

- Chemical & Material Sciences (AREA)

- Combustion & Propulsion (AREA)

- Transportation (AREA)

- Arrangement Or Mounting Of Propulsion Units For Vehicles (AREA)

- Electric Propulsion And Braking For Vehicles (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本申请涉及全地形车技术领域,更具体地说,涉及一种分布式电驱动全地形车。The present application relates to the technical field of all-terrain vehicles, and more particularly, to a distributed electric drive all-terrain vehicle.

背景技术Background technique

全地形车(UTV)是一种通过性、灵活性都要超过SUV的车辆。其最初设计目的是为了快速通过复杂的地形,在普通车辆无法行驶的路面上快速通勤。后来,UTV逐渐从交通工具演变成了一种娱乐项目、一项极限运动。除了用于运动竞技、休闲娱乐外,它在农林牧业、石油、电力、工地、矿山、抢险、勘探、狩猎、消防、军事等众多领域,都能发挥十分重要的作用。All-terrain vehicle (UTV) is a vehicle that surpasses SUVs in terms of passability and flexibility. It was originally designed to quickly traverse difficult terrain and commute quickly on surfaces that ordinary vehicles cannot. Later, UTV gradually evolved from a means of transportation to an entertainment project and an extreme sport. In addition to being used for sports competition, leisure and entertainment, it can play a very important role in many fields such as agriculture, forestry and animal husbandry, petroleum, electric power, construction sites, mining, emergency rescue, exploration, hunting, fire protection, and military affairs.

全地形车(UTV)能够在坡度较大、坑洼颠簸的复杂路面上行驶,但是由于其行驶的环境和路面及其复杂,因此,全地形车对驱动结构的要求极其严苛,传统的全地形车是通过发动机驱动,在将动力传输给变速箱,通过变速箱对动力切换,再将合适的动力通过分动箱和传动轴等机械传动结构传输至车轮,进而带动车体行进,但是,这样机械传动形式极大的增加了驱动结构的复杂性,驱动部件较多,在复杂的环境中行驶容易对零部件造成损伤,增大了全地形车的不稳定性。All-terrain vehicles (UTVs) can drive on complex roads with steep slopes, potholes and bumps. However, due to the complex driving environment and road surface, UTVs have extremely strict requirements on the driving structure. The terrain vehicle is driven by the engine, transmits the power to the gearbox, switches the power through the gearbox, and then transmits the appropriate power to the wheels through the mechanical transmission structure such as the transfer case and the transmission shaft, and then drives the car body to travel, but, This mechanical transmission form greatly increases the complexity of the driving structure, and there are many driving components. Driving in a complex environment will easily cause damage to the components and increase the instability of the all-terrain vehicle.

因此,如何解决现有的全地形车采用机械式动力传输,驱动结构复杂,容易造成损坏的问题,是本领域技术人员所要解决的关键技术问题。Therefore, how to solve the problem that the existing all-terrain vehicle adopts mechanical power transmission, the drive structure is complex, and the damage is easily caused is a key technical problem to be solved by those skilled in the art.

发明内容SUMMARY OF THE INVENTION

为至少在一定程度上克服相关技术中存在的问题,本申请的目的在于提供一种分布式电驱动全地形车,其能够解决现有的全地形车采用机械式动力传输,驱动结构复杂,容易造成损坏的问题。本申请提供的诸多技术方案中的优选技术方案所能产生的诸多技术效果详见下文阐述。In order to overcome the problems existing in the related art at least to a certain extent, the purpose of the present application is to provide a distributed electric drive all-terrain vehicle, which can solve the problem that the existing all-terrain vehicle adopts mechanical power transmission, and the driving structure is complex and easy. cause damage. The technical effects that can be produced by the preferred technical solutions among the technical solutions provided in this application are described in detail below.

本申请提供了一种分布式电驱动全地形车,包括有车体、用于带动所述车体行进的车轮、用于驱动所述车轮转动的供电组件和控制组件,所述车轮设置有多个、并均匀分布在所述车体的下方,所述车轮包括有轮毂电机和套设在所述轮毂电机外的轮胎,所述轮毂电机的定子部分与所述车体连接、转子部分与所述轮胎连接,各个所述轮毂电机之间相互独立、并通过控制组件与所述供电组件电连接。The present application provides a distributed electric drive all-terrain vehicle, comprising a vehicle body, a wheel for driving the vehicle body, a power supply assembly and a control assembly for driving the wheel to rotate, and the wheel is provided with multiple and evenly distributed under the vehicle body, the wheel includes an in-wheel motor and a tire sleeved outside the in-wheel motor, the stator part of the in-wheel motor is connected with the vehicle body, and the rotor part is connected with the wheel. The tires are connected, each of the in-wheel motors is independent of each other, and is electrically connected to the power supply assembly through a control assembly.

优选地,所述车体通过多连杆独立悬架结构与所述轮毂电机的定子连接固定,所述多连杆独立悬架结构包括有铰接在所述轮毂电机和所述车体之间的连接杆和减震器,所述连接杆和所述减震器之间构成夹角、并在所述车体和所述轮毂电机之间围成锐角三角形。Preferably, the vehicle body is connected and fixed with the stator of the in-wheel motor through a multi-link independent suspension structure, and the multi-link independent suspension structure includes a multi-link independent suspension structure that is hinged between the in-wheel motor and the vehicle body. The connecting rod and the shock absorber form an included angle between the connecting rod and the shock absorber, and form an acute triangle between the vehicle body and the in-wheel motor.

优选地,所述连接杆设置有多个、且并排设置在所述车体和所述轮毂电机之间。Preferably, a plurality of the connecting rods are provided and are arranged side by side between the vehicle body and the in-wheel motor.

优选地,所述车体包括有车身骨架和包覆在所述车身骨架外的车身覆盖件,所述车身骨架与所述轮毂电机的定子部分连接固定。Preferably, the vehicle body includes a vehicle body frame and a vehicle body cover wrapped outside the vehicle body frame, and the vehicle body frame is connected and fixed with the stator part of the in-wheel motor.

优选地,所述车身骨架设置为承载式车身框架结构。Preferably, the body frame is provided as a load-bearing body frame structure.

优选地,所述车体包括移动平台和位于所述移动平台上的各种功能组件,所述移动平台与所述轮毂电机的定子部分连接固定。Preferably, the vehicle body includes a mobile platform and various functional components located on the mobile platform, and the mobile platform is connected and fixed with the stator part of the in-wheel motor.

优选地,多个所述车轮呈矩形阵列分布。Preferably, a plurality of said wheels are distributed in a rectangular array.

优选地,所述轮毂电机设置有动力回收模块。Preferably, the in-wheel motor is provided with a power recovery module.

优选地,所述车体设置有驾驶室和位于所述驾驶室的后方的货箱。Preferably, the vehicle body is provided with a cab and a cargo box behind the cab.

优选地,所述供电组件设置为电池组。Preferably, the power supply assembly is configured as a battery pack.

本申请提供的技术方案可以包括以下有益效果:The technical solution provided by this application can include the following beneficial effects:

各个轮毂电机之间相互独立、并通过控制组件与供电组件电连接,具体地,各个轮毂电机均通过一条线路与供电组件电连接,在控制组件的作用下,可以直接对各个轮毂电机进行单独驱动,以使得每个车轮都构成一个独立的驱动单元,而且在控制组件的控制作用下,可以根据实际情况中的复杂路况,对各个轮毂电机的驱动力进行单独实时控制,有利于提升环境适应性。如此设置,采用分布式轮毂电机驱动系统,无变速箱、无分动箱、无传动轴、无半轴,即无机械传递动力和扭矩,驱动结构简单且稳固,零部件较少不易损伤;整车车轮的动力由供电组件通过控制组件向各个车轮中的轮毂电机提供电能,通过轮毂电机直接驱动车轮转动,并带动车体行驶,有利于在多种复杂环境行驶。Each in-wheel motor is independent of each other and is electrically connected to the power supply assembly through the control assembly. Specifically, each in-wheel motor is electrically connected to the power supply assembly through a line. Under the action of the control assembly, each in-wheel motor can be directly driven independently. , so that each wheel constitutes an independent drive unit, and under the control of the control component, the driving force of each in-wheel motor can be independently controlled in real time according to the complex road conditions in the actual situation, which is conducive to improving environmental adaptability . In this way, the distributed in-wheel motor drive system is adopted, no gearbox, no transfer case, no transmission shaft, no half shaft, that is, no mechanical transmission of power and torque, the drive structure is simple and stable, and the parts are few and not easy to damage; The power of the vehicle wheels is provided by the power supply components to the in-wheel motors in each wheel through the control components, and the in-wheel motors directly drive the wheels to rotate and drive the vehicle body to travel, which is conducive to driving in a variety of complex environments.

应当理解的是,以上的一般描述和后文的细节描述仅是示例性和解释性的,并不能限制本申请。It is to be understood that both the foregoing general description and the following detailed description are exemplary and explanatory only and are not limiting of the present application.

附图说明Description of drawings

此处的附图被并入说明书中并构成本说明书的一部分,示出了符合本申请的实施例,并与说明书一起用于解释本申请的原理。The accompanying drawings, which are incorporated in and constitute a part of this specification, illustrate embodiments consistent with the application and together with the description serve to explain the principles of the application.

为了更清楚地说明本发明实施例或现有技术中的技术方案,下面将对实施例或现有技术描述中所需要使用的附图作简单地介绍,显而易见地,下面描述中的附图仅仅是本发明的一些实施例,对于本领域普通技术人员来讲,在不付出创造性劳动的前提下,还可以根据这些附图获得其他的附图。In order to explain the embodiments of the present invention or the technical solutions in the prior art more clearly, the following briefly introduces the accompanying drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description are only These are some embodiments of the present invention. For those of ordinary skill in the art, other drawings can also be obtained according to these drawings without creative efforts.

图1是根据一些示例性实施例示出的本分布式电驱动全地形车的侧视图;FIG. 1 is a side view of the present distributed electric drive all-terrain vehicle according to some exemplary embodiments;

图2是根据一些示例性实施例示出的本分布式电驱动全地形车的主视图;FIG. 2 is a front view of the present distributed electric drive all-terrain vehicle according to some exemplary embodiments;

图3是根据一些示例性实施例示出的分布式电驱动全地形车的驱动结构示意图;3 is a schematic diagram of a driving structure of a distributed electric drive all-terrain vehicle according to some exemplary embodiments;

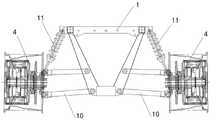

图4是根据一些示例性实施例示出的多连杆独立悬架结构示意图。FIG. 4 is a schematic structural diagram of a multi-link independent suspension according to some exemplary embodiments.

图中:1、车身骨架;2、车身覆盖件;3、车轮;4、轮毂电机;5、轮胎;6、供电组件;7、控制组件;8、驾驶室;9、货箱;10、连接杆;11、减震器;12、整车控制器;13、电机控制器;In the figure: 1. Body frame; 2. Body cover; 3. Wheel; 4. In-wheel motor; 5. Tire; 6. Power supply assembly; 7. Control assembly; 8. Cab; 9. Cargo box; 10. Connection rod; 11, shock absorber; 12, vehicle controller; 13, motor controller;

具体实施方式Detailed ways

这里将详细地对示例性实施例进行说明,其示例表示在附图中。下面的描述涉及附图时,除非另有表示,不同附图中的相同数字表示相同或相似的要素。以下示例性实施例中所描述的实施方式并不代表与本申请相一致的所有实施方式。相反,它们仅是与本申请的一些方面相一致的装置或方法的例子。Exemplary embodiments will be described in detail herein, examples of which are illustrated in the accompanying drawings. Where the following description refers to the drawings, the same numerals in different drawings refer to the same or similar elements unless otherwise indicated. The implementations described in the illustrative examples below are not intended to represent all implementations consistent with this application. Rather, they are merely examples of devices or methods consistent with some aspects of the present application.

为使本发明的目的、技术方案和优点更加清楚,下面将对本发明的技术方案进行详细的描述。显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有做出创造性劳动的前提下所得到的所有其它实施方式,都属于本发明所保护的范围。In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions of the present invention will be described in detail below. Obviously, the described embodiments are only some, but not all, embodiments of the present invention. Based on the embodiments of the present invention, all other implementations obtained by those of ordinary skill in the art without creative work fall within the protection scope of the present invention.

以下,参照附图对实施例进行说明。此外,下面所示的实施例不对权利要求所记载的发明内容起任何限定作用。另外,下面实施例所表示的构成的全部内容不限于作为权利要求所记载的发明的解决方案所必需的。Hereinafter, the embodiment will be described with reference to the drawings. In addition, the embodiments shown below do not have any limiting effect on the content of the invention described in the claims. In addition, the whole content of the structure shown in the following embodiment is not limited to what is necessary for the solution of the invention described in the claim.

参考图1-图4,本具体实施方式提供了一种分布式电驱动全地形车,包括有车体、车轮3、供电组件6和控制组件7,其中,车轮3用于带动车体行进,具体地,车轮3设置有多个、且均匀地分布在车体的下方;供电组件6设置在车体内部,用于提供车体行进的动力,具体地,供电组件6用于驱动车轮3相对于车体转动,以使得车轮3带动着车体行进。Referring to FIGS. 1-4 , this specific embodiment provides a distributed electric drive all-terrain vehicle, including a vehicle body,

车轮3包括有轮毂电机4和轮胎5,轮胎5套设在轮毂电机4外,以保证车体行进的稳定。轮毂电机4是将车子的动力系统、传动系统、刹车系统集成到一起而设计出来的电机,轮毂电机4的工作原理是永磁同步电机,轮边电机、轮毂电机4是指电机安装在车辆的位置不同的电机而言,轮毂电机4的优点是:省略大量传动部件,让车辆结构更简单,可实现多种复杂的驱动方式。由于轮毂电机4具备单个车轮3独立驱动的特性,因此无论是前驱、后驱还是四驱形式,它都可以比较轻松地实现。The

具体地,轮毂电机4具有转子部分和定子部分,其中,定子部分与车体连接,以保持定子部分相对于车体相对固定,转子部分与轮胎5连接,以保持转子部分相对于轮胎5相对固定,通电时定子部分和转子部分相对转动,进而带动轮胎5相对于车体转动,以实现车体的行进。Specifically, the in-

而且,各个轮毂电机4之间相互独立、并通过控制组件7与供电组件6电连接,具体地,各个轮毂电机4均通过一条线路与供电组件6电连接,在控制组件7的作用下,可以直接对各个轮毂电机4进行单独驱动,以使得每个车轮3都构成一个独立的驱动单元,而且在控制组件7的控制作用下,可以根据实际情况中的复杂路况,对各个轮毂电机4的驱动力进行单独实时控制,有利于提升环境适应性。Moreover, each in-

需要说明的是,控制组件7可以包括对车体行进状况进行控制的整车控制器12和对轮毂电机4的电能输送情况进行控制的电机控制器13,电机控制器13连接在供电组件6和各个轮毂电机4之间,用于控制供电组件6和各个轮毂电机4之间的电能传输情况,进而控制各个轮毂电机4的驱动力,有利于节约电能。It should be noted that, the

如此设置,采用分布式轮毂电机4驱动系统,无变速箱、无分动箱、无传动轴、无半轴,即无机械传递动力和扭矩,驱动结构简单且稳固,零部件较少不易损伤;整车车轮3的动力由供电组件6通过控制组件7向各个车轮3中的轮毂电机4提供电能,通过轮毂电机4直接驱动车轮3转动,并带动车体行驶,有利于在多种复杂环境行驶。In this way, the distributed in-

本实施例中,车体通过多连杆独立悬架结构与轮毂电机4的定子连接固定,顾名思义,多连杆式悬架就是指由三根或三根以上连接拉杆构成,并且能提供多个方向的控制力,使轮胎5具有更加可靠的行驶轨迹的悬架结构。多连杆式悬挂不仅可以保证拥有一定的舒适性,而且由于连杆较多,可以使车轮3和地面尽最大可能保持垂直,尽最大可能减小车身的倾斜,最大可能维持轮胎5的贴地性,且具有较佳的舒适性能和操控稳定性。In this embodiment, the vehicle body is connected and fixed to the stator of the in-

其中,多连杆独立悬架结构包括有铰接在轮毂电机4和车体之间的连接杆10和减震器11,连接杆10的第一端铰接在车体的第一位置、第二端铰接在轮毂电机4的定子部分,减震器11的第一端铰接在车体的第二位置、第二端铰接在连接杆10的第二端,连接杆10和减震器11之间构成夹角、并在车体和轮毂电机4之间围成锐角三角形,这样,有利于提升车体的稳固性。Among them, the multi-link independent suspension structure includes a connecting

具体地,连接杆10设置有多个、且并排设置在车体和轮毂电机4之间,这里,连接杆10可以设置有两个、三个或者五个,进一步加强车体行进的稳固性。Specifically, there are a plurality of connecting

一些实施例中,车体包括有车身骨架1和车身覆盖件2,其中,车身骨架1可以通过多连杆独立悬架结构与轮毂电机4的定子部分连接固定,进而构成车体的骨架部分,保证车轮3安装的稳固性;车身覆盖件2包裹在车身骨架1的外侧,可以防护车身骨架1免被风雨侵袭。In some embodiments, the vehicle body includes a

其中,车身骨架1设置为承载式车身框架结构,所谓承载式车身框架结构是指底架、顶盖骨架、前围骨架、后围骨架、侧围骨架合为一体,采用各种截面的异形钢管拼焊而成的一个整体承载结构,该整体结构承受全部载荷,在局部区域,如悬架安装区域、动力总成安装区域和转向系统安装区域等,为了提高局部强度、安装定位精度、生产工艺性,可采用加焊板、筋、箱状构件或槽型构件。这样,整车质量轻,整体弯曲和扭转刚度好,易于批量生产。Among them, the

另一些实施例中,车体包括移动平台和位于移动平台上的各种功能组件,其中,移动平台与轮毂电机4的定子部分连接固定,用于承载各个功能部件,有利于实现多个功能部件的搬运,以及实现多个功能部件的运用和改装。In other embodiments, the vehicle body includes a mobile platform and various functional components located on the mobile platform, wherein the mobile platform is connected and fixed to the stator part of the in-

其中,多个车轮3呈矩形阵列分布,这里,车轮3可以设置为2×8、4×4、6×6、8×8的排布形式,进而有利于提升车体的驱动性能。The plurality of

一些优选方案中,轮毂电机4设置有动力回收模块,通过动力回收模块可以将车体的势能和制动能转化成电能,合理利用资源,减少耗能。In some preferred solutions, the in-

为了方便人员驾驶和货物运输,车体设置有驾驶室8和货箱9,货箱9位于驾驶室8的后方,驾驶室8可以由车身覆盖件2包裹而成。In order to facilitate the driving of personnel and the transportation of goods, the vehicle body is provided with a

具体地,供电组件6设置为电池组,该电池组可充电,且储电量较大,可以满足标准车辆行进所需的电能。Specifically, the power supply component 6 is configured as a battery pack, which is rechargeable and has a large storage capacity, which can meet the electrical energy required for standard vehicle travel.

下面结合上述实施例对本分布式电驱动全地形车进行具体说明。The present distributed electric drive all-terrain vehicle will be specifically described below with reference to the above embodiments.

轮毂电机4分布式布置形式;多连杆式独立悬架系统;轮毂电机4直驱形式;无机械系统传动动力和大扭矩特征;整车可多种分布置式驱动形式,比如4×4、6×6、8×8……;根据不同道路,轮毂电机4可实现最节约能量方式驱动;整车具备越野性能;可作为移动动力平台,实现多种功能添加改装;轮毂电机4具有能量回收功能,车辆电机势能回收功能;本机结构简单,零件少,不需要变速箱,可以实现自动调节速度。In-

需要说明的是,本文所表述的“第一”“第二”等词语,不是对具体顺序的限制,仅仅只是用于区分各个部件或功能。所阐述的“水平”“竖直”“上”“下”“左”“右”是在该分布式电驱动全地形车处于如图1摆放状态时之所指。It should be noted that words such as "first" and "second" expressed in this document do not limit the specific order, but are only used to distinguish each component or function. The described "horizontal", "vertical", "up", "down", "left" and "right" refer to when the distributed electric drive all-terrain vehicle is placed in the state shown in FIG. 1 .

以上所述,仅为本发明的具体实施方式,但本发明的保护范围并不局限于此,任何熟悉本技术领域的技术人员在本发明揭露的技术范围内,可轻易想到变化或替换,都应涵盖在本发明的保护范围之内。因此,本发明的保护范围应以所述权利要求的保护范围为准。The above are only specific embodiments of the present invention, but the protection scope of the present invention is not limited to this. Any person skilled in the art can easily think of changes or substitutions within the technical scope disclosed by the present invention. should be included within the protection scope of the present invention. Therefore, the protection scope of the present invention should be based on the protection scope of the claims.

可以理解的是,上述各实施例中相同或相似部分可以相互参考,在一些实施例中未详细说明的内容可以参见其他实施例中相同或相似的内容。本申请提供的多个方案包含本身的基本方案,相互独立,并不互相制约,但是其也可以在不冲突的情况下相互结合,达到多个效果共同实现。It can be understood that, the same or similar parts in the above embodiments may refer to each other, and the content not described in detail in some embodiments may refer to the same or similar content in other embodiments. The multiple solutions provided in this application include their own basic solutions, which are independent of each other and do not restrict each other, but they can also be combined with each other without conflict to achieve multiple effects.

尽管上面已经示出和描述了本申请的实施例,但可以理解的是,上述实施例是示例性的,不能理解为对本申请的限制,本领域的普通技术人员在本申请的范围内可以对上述实施例进行变化、修改、替换和变型。Although the embodiments of the present application have been shown and described above, it should be understood that the above embodiments are exemplary and should not be construed as limitations on the present application. Variations, modifications, substitutions and alterations are made to the above-described embodiments.

Claims (10)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010959379.4ACN111993883A (en) | 2020-09-14 | 2020-09-14 | Distributed electric drive all-terrain vehicle |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010959379.4ACN111993883A (en) | 2020-09-14 | 2020-09-14 | Distributed electric drive all-terrain vehicle |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111993883Atrue CN111993883A (en) | 2020-11-27 |

Family

ID=73469735

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010959379.4APendingCN111993883A (en) | 2020-09-14 | 2020-09-14 | Distributed electric drive all-terrain vehicle |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111993883A (en) |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2025118491A1 (en)* | 2023-12-04 | 2025-06-12 | 浙江春风动力股份有限公司 | Motorcycle |

Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050052080A1 (en)* | 2002-07-31 | 2005-03-10 | Maslov Boris A. | Adaptive electric car |

| CN102700399A (en)* | 2012-05-31 | 2012-10-03 | 杭州电子科技大学 | Wheel hub motor driven electric automobile |

| CN103370221A (en)* | 2011-02-11 | 2013-10-23 | 北极星工业有限公司 | Side by side all terrain vehicle |

| CN104608825A (en)* | 2015-01-04 | 2015-05-13 | 陈建生 | Wheel type all-terrain vehicle |

| CN110386193A (en)* | 2019-06-25 | 2019-10-29 | 北京大成高科机器人技术有限公司 | All-terrain vehicle chassis |

| CN210391424U (en)* | 2019-05-31 | 2020-04-24 | 赛格威科技有限公司 | All-terrain vehicle |

| CN210652656U (en)* | 2019-10-16 | 2020-06-02 | 洛阳合能电气有限公司 | Vehicle chassis and vehicle |

| CN212289495U (en)* | 2020-09-14 | 2021-01-05 | 洛阳优特威车业有限公司 | Distributed electrically driven all-terrain vehicle |

- 2020

- 2020-09-14CNCN202010959379.4Apatent/CN111993883A/enactivePending

Patent Citations (8)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US20050052080A1 (en)* | 2002-07-31 | 2005-03-10 | Maslov Boris A. | Adaptive electric car |

| CN103370221A (en)* | 2011-02-11 | 2013-10-23 | 北极星工业有限公司 | Side by side all terrain vehicle |

| CN102700399A (en)* | 2012-05-31 | 2012-10-03 | 杭州电子科技大学 | Wheel hub motor driven electric automobile |

| CN104608825A (en)* | 2015-01-04 | 2015-05-13 | 陈建生 | Wheel type all-terrain vehicle |

| CN210391424U (en)* | 2019-05-31 | 2020-04-24 | 赛格威科技有限公司 | All-terrain vehicle |

| CN110386193A (en)* | 2019-06-25 | 2019-10-29 | 北京大成高科机器人技术有限公司 | All-terrain vehicle chassis |

| CN210652656U (en)* | 2019-10-16 | 2020-06-02 | 洛阳合能电气有限公司 | Vehicle chassis and vehicle |

| CN212289495U (en)* | 2020-09-14 | 2021-01-05 | 洛阳优特威车业有限公司 | Distributed electrically driven all-terrain vehicle |

Cited By (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| WO2025118491A1 (en)* | 2023-12-04 | 2025-06-12 | 浙江春风动力股份有限公司 | Motorcycle |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| US12043110B2 (en) | Electric drive axle in a vehicle | |

| CN108058755B (en) | Double-triangular suspension wheel leg type all-terrain mobile robot | |

| US3477538A (en) | Electric propulsion motor vehicle | |

| US20160185207A1 (en) | Electric-drive all-terrain utility vehicle | |

| CN213565396U (en) | Unmanned vehicle driven independently | |

| CN105799491A (en) | New energy automobile double-motor drive axle | |

| CN108128370A (en) | The unmanned chassis of full landform and method of work based on the driving of 8 × 8 type distributions | |

| CN108163094B (en) | Mountain cross-country robot vehicle chassis | |

| CN112319207A (en) | Hybrid Distributed Drive Electric Tractor | |

| CN201736810U (en) | Vehicle chassis and engineering vehicle comprising same | |

| CN111993883A (en) | Distributed electric drive all-terrain vehicle | |

| CN103818493A (en) | All-terrain surface adaptive relief vehicle | |

| CN212289495U (en) | Distributed electrically driven all-terrain vehicle | |

| CN110341498A (en) | Distributed time-sharing four-wheel drive electric vehicle chassis configuration of in-wheel motor, four-wheel drive electric vehicle and control method | |

| CN107054501A (en) | A kind of adaptive dolly of unmanned complex road surface based on parallel institution | |

| CN201070977Y (en) | Electric car | |

| CN207344569U (en) | Chassis structure and the robot for including it | |

| CN102826150B (en) | Combined vehicle with tiltable vehicle body | |

| CN205439980U (en) | Mining explosion -proof lithium ion battery rubber tyer transport vechicle | |

| WO2017213551A1 (en) | Platform of multifunctional vehicle | |

| CN214112266U (en) | Hybrid power distributed driving electric tractor | |

| CN108688726A (en) | A kind of novel modularized pure electric logistics chassis | |

| CN103318264B (en) | Simplify mini electric vehicle development platform | |

| CN203637595U (en) | Electric all terrain vehicle | |

| RU168885U1 (en) | MULTIFUNCTIONAL VEHICLE PLATFORM |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |