CN111939118B - Pharmacosome for treating hyperthyroidism in response to GSH concentration and preparation method - Google Patents

Pharmacosome for treating hyperthyroidism in response to GSH concentration and preparation methodDownload PDFInfo

- Publication number

- CN111939118B CN111939118BCN202010877049.0ACN202010877049ACN111939118BCN 111939118 BCN111939118 BCN 111939118BCN 202010877049 ACN202010877049 ACN 202010877049ACN 111939118 BCN111939118 BCN 111939118B

- Authority

- CN

- China

- Prior art keywords

- methimazole

- drug

- mmi

- gsh

- acrylic acid

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription23

- 206010020850HyperthyroidismDiseases0.000titleclaimsabstractdescription12

- 230000004044responseEffects0.000titledescription2

- 239000003814drugSubstances0.000claimsabstractdescription93

- 229940079593drugDrugs0.000claimsabstractdescription92

- PMRYVIKBURPHAH-UHFFFAOYSA-NmethimazoleChemical compoundCN1C=CNC1=SPMRYVIKBURPHAH-UHFFFAOYSA-N0.000claimsdescription93

- 229960002178thiamazoleDrugs0.000claimsdescription86

- 239000000243solutionSubstances0.000claimsdescription38

- OKKJLVBELUTLKV-UHFFFAOYSA-NMethanolChemical compoundOCOKKJLVBELUTLKV-UHFFFAOYSA-N0.000claimsdescription36

- 238000006243chemical reactionMethods0.000claimsdescription36

- SMZOUWXMTYCWNB-UHFFFAOYSA-N2-(2-methoxy-5-methylphenyl)ethanamineChemical compoundCOC1=CC=C(C)C=C1CCNSMZOUWXMTYCWNB-UHFFFAOYSA-N0.000claimsdescription34

- NIXOWILDQLNWCW-UHFFFAOYSA-N2-Propenoic acidNatural productsOC(=O)C=CNIXOWILDQLNWCW-UHFFFAOYSA-N0.000claimsdescription27

- IJGRMHOSHXDMSA-UHFFFAOYSA-NAtomic nitrogenChemical compoundN#NIJGRMHOSHXDMSA-UHFFFAOYSA-N0.000claimsdescription24

- 238000003756stirringMethods0.000claimsdescription20

- 239000007788liquidSubstances0.000claimsdescription17

- WQDUMFSSJAZKTM-UHFFFAOYSA-NSodium methoxideChemical compound[Na+].[O-]CWQDUMFSSJAZKTM-UHFFFAOYSA-N0.000claimsdescription14

- 239000006228supernatantSubstances0.000claimsdescription14

- UORVCLMRJXCDCP-UHFFFAOYSA-Npropynoic acidChemical compoundOC(=O)C#CUORVCLMRJXCDCP-UHFFFAOYSA-N0.000claimsdescription13

- 229910052757nitrogenInorganic materials0.000claimsdescription12

- 239000013612plasmidSubstances0.000claimsdescription11

- 229940088679drug related substanceDrugs0.000claimsdescription10

- 210000002706plastidAnatomy0.000claimsdescription10

- 239000008186active pharmaceutical agentSubstances0.000claimsdescription9

- PBOSTUDLECTMNL-UHFFFAOYSA-Nlauryl acrylateChemical compoundCCCCCCCCCCCCOC(=O)C=CPBOSTUDLECTMNL-UHFFFAOYSA-N0.000claimsdescription9

- 239000002674ointmentSubstances0.000claimsdescription9

- AXTGDCSMTYGJND-UHFFFAOYSA-N1-dodecylazepan-2-oneChemical groupCCCCCCCCCCCCN1CCCCCC1=OAXTGDCSMTYGJND-UHFFFAOYSA-N0.000claimsdescription7

- LQZZUXJYWNFBMV-UHFFFAOYSA-Ndodecan-1-olChemical compoundCCCCCCCCCCCCOLQZZUXJYWNFBMV-UHFFFAOYSA-N0.000claimsdescription7

- 239000007787solidSubstances0.000claimsdescription7

- 238000000034methodMethods0.000claimsdescription6

- 239000003961penetration enhancing agentSubstances0.000claimsdescription6

- 125000006539C12 alkyl groupChemical group[H]C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])C([H])([H])*0.000claimsdescription4

- PEDCQBHIVMGVHV-UHFFFAOYSA-NGlycerineChemical compoundOCC(O)COPEDCQBHIVMGVHV-UHFFFAOYSA-N0.000claimsdescription4

- DGAQECJNVWCQMB-PUAWFVPOSA-MIlexoside XXIXChemical compoundC[C@@H]1CC[C@@]2(CC[C@@]3(C(=CC[C@H]4[C@]3(CC[C@@H]5[C@@]4(CC[C@@H](C5(C)C)OS(=O)(=O)[O-])C)C)[C@@H]2[C@]1(C)O)C)C(=O)O[C@H]6[C@@H]([C@H]([C@@H]([C@H](O6)CO)O)O)O.[Na+]DGAQECJNVWCQMB-PUAWFVPOSA-M0.000claimsdescription2

- 239000004166LanolinSubstances0.000claimsdescription2

- 125000003178carboxy groupChemical group[H]OC(*)=O0.000claimsdescription2

- 238000004945emulsificationMethods0.000claimsdescription2

- 235000011187glycerolNutrition0.000claimsdescription2

- 229940039717lanolinDrugs0.000claimsdescription2

- 235000019388lanolinNutrition0.000claimsdescription2

- 239000011259mixed solutionSubstances0.000claimsdescription2

- 239000000047productSubstances0.000claimsdescription2

- 229910052708sodiumInorganic materials0.000claimsdescription2

- 239000011734sodiumSubstances0.000claimsdescription2

- RWSXRVCMGQZWBV-WDSKDSINSA-NglutathioneChemical compoundOC(=O)[C@@H](N)CCC(=O)N[C@@H](CS)C(=O)NCC(O)=ORWSXRVCMGQZWBV-WDSKDSINSA-N0.000abstractdescription110

- 229960003180glutathioneDrugs0.000abstractdescription55

- 238000013271transdermal drug deliveryMethods0.000abstractdescription7

- 108010024636GlutathioneProteins0.000abstractdescription5

- 230000000638stimulationEffects0.000abstractdescription5

- 238000003379elimination reactionMethods0.000abstractdescription3

- 230000004043responsivenessEffects0.000abstract2

- 230000001186cumulative effectEffects0.000description32

- -11-methyl-1H-imidazol-2-ylChemical group0.000description16

- 229910052799carbonInorganic materials0.000description15

- 210000001685thyroid glandAnatomy0.000description15

- OKTJSMMVPCPJKN-UHFFFAOYSA-NCarbonChemical compound[C]OKTJSMMVPCPJKN-UHFFFAOYSA-N0.000description14

- RAXXELZNTBOGNW-UHFFFAOYSA-NimidazoleNatural productsC1=CNC=N1RAXXELZNTBOGNW-UHFFFAOYSA-N0.000description12

- 229910021642ultra pure waterInorganic materials0.000description12

- 239000012498ultrapure waterSubstances0.000description12

- 239000001257hydrogenSubstances0.000description10

- 229910052739hydrogenInorganic materials0.000description10

- 230000001965increasing effectEffects0.000description10

- 125000000446sulfanediyl groupChemical group*S*0.000description10

- 238000004108freeze dryingMethods0.000description9

- 238000005406washingMethods0.000description9

- UFHFLCQGNIYNRP-UHFFFAOYSA-NHydrogenChemical compound[H][H]UFHFLCQGNIYNRP-UHFFFAOYSA-N0.000description8

- 230000000694effectsEffects0.000description8

- 230000003902lesionEffects0.000description8

- 230000035515penetrationEffects0.000description8

- 238000001228spectrumMethods0.000description8

- IAZDPXIOMUYVGZ-UHFFFAOYSA-NDimethylsulphoxideChemical compoundCS(C)=OIAZDPXIOMUYVGZ-UHFFFAOYSA-N0.000description6

- LFQSCWFLJHTTHZ-UHFFFAOYSA-NEthanolChemical compoundCCOLFQSCWFLJHTTHZ-UHFFFAOYSA-N0.000description6

- 230000015572biosynthetic processEffects0.000description6

- 230000003834intracellular effectEffects0.000description6

- 230000035699permeabilityEffects0.000description6

- 239000007853buffer solutionSubstances0.000description5

- 230000004048modificationEffects0.000description5

- 238000012986modificationMethods0.000description5

- 238000010992refluxMethods0.000description5

- 239000000126substanceSubstances0.000description5

- XLYOFNOQVPJJNP-UHFFFAOYSA-NwaterSubstancesOXLYOFNOQVPJJNP-UHFFFAOYSA-N0.000description5

- IAZDPXIOMUYVGZ-WFGJKAKNSA-NDimethyl sulfoxideChemical compound[2H]C([2H])([2H])S(=O)C([2H])([2H])[2H]IAZDPXIOMUYVGZ-WFGJKAKNSA-N0.000description4

- 238000005481NMR spectroscopyMethods0.000description4

- KBPLFHHGFOOTCA-UHFFFAOYSA-Ncaprylic alcoholNatural productsCCCCCCCCOKBPLFHHGFOOTCA-UHFFFAOYSA-N0.000description4

- 150000001875compoundsChemical class0.000description4

- 239000012065filter cakeSubstances0.000description4

- 239000002609mediumSubstances0.000description4

- GLDOVTGHNKAZLK-UHFFFAOYSA-Noctadecan-1-olChemical compoundCCCCCCCCCCCCCCCCCCOGLDOVTGHNKAZLK-UHFFFAOYSA-N0.000description4

- NIXOWILDQLNWCW-UHFFFAOYSA-MAcrylateChemical compound[O-]C(=O)C=CNIXOWILDQLNWCW-UHFFFAOYSA-M0.000description3

- 206010067484Adverse reactionDiseases0.000description3

- YMWUJEATGCHHMB-UHFFFAOYSA-NDichloromethaneChemical compoundClCClYMWUJEATGCHHMB-UHFFFAOYSA-N0.000description3

- SNRUBQQJIBEYMU-UHFFFAOYSA-NDodecaneNatural productsCCCCCCCCCCCCSNRUBQQJIBEYMU-UHFFFAOYSA-N0.000description3

- 238000006845Michael addition reactionMethods0.000description3

- 238000010521absorption reactionMethods0.000description3

- 238000009825accumulationMethods0.000description3

- 230000006838adverse reactionEffects0.000description3

- 238000005119centrifugationMethods0.000description3

- 230000006378damageEffects0.000description3

- 238000012377drug deliveryMethods0.000description3

- 238000005886esterification reactionMethods0.000description3

- 150000002191fatty alcoholsChemical class0.000description3

- 230000002209hydrophobic effectEffects0.000description3

- 125000002496methyl groupChemical group[H]C([H])([H])*0.000description3

- 238000005192partitionMethods0.000description3

- 230000001225therapeutic effectEffects0.000description3

- 125000003396thiol groupChemical group[H]S*0.000description3

- 210000001519tissueAnatomy0.000description3

- 231100000331toxicToxicity0.000description3

- 230000002588toxic effectEffects0.000description3

- 23800000164413C nuclear magnetic resonance spectroscopyMethods0.000description2

- 2380000051601H NMR spectroscopyMethods0.000description2

- XUIIKFGFIJCVMT-GFCCVEGCSA-ND-thyroxineChemical compoundIC1=CC(C[C@@H](N)C(O)=O)=CC(I)=C1OC1=CC(I)=C(O)C(I)=C1XUIIKFGFIJCVMT-GFCCVEGCSA-N0.000description2

- 208000030453Drug-Related Side Effects and Adverse reactionDiseases0.000description2

- 239000005977EthyleneSubstances0.000description2

- 210000004027cellAnatomy0.000description2

- 238000013270controlled releaseMethods0.000description2

- 239000003623enhancerSubstances0.000description2

- 230000002255enzymatic effectEffects0.000description2

- IRHTZOCLLONTOC-UHFFFAOYSA-Nhexacosan-1-olChemical compoundCCCCCCCCCCCCCCCCCCCCCCCCCCOIRHTZOCLLONTOC-UHFFFAOYSA-N0.000description2

- 238000004128high performance liquid chromatographyMethods0.000description2

- 125000004435hydrogen atomChemical group[H]*0.000description2

- 150000002460imidazolesChemical class0.000description2

- 230000006872improvementEffects0.000description2

- 238000000338in vitroMethods0.000description2

- 238000001727in vivoMethods0.000description2

- 230000007774longtermEffects0.000description2

- 231100000053low toxicityToxicity0.000description2

- 239000012528membraneSubstances0.000description2

- TVMXDCGIABBOFY-UHFFFAOYSA-Nn-OctanolNatural productsCCCCCCCCTVMXDCGIABBOFY-UHFFFAOYSA-N0.000description2

- 239000000843powderSubstances0.000description2

- 230000008569processEffects0.000description2

- 238000003786synthesis reactionMethods0.000description2

- 229940034208thyroxineDrugs0.000description2

- XUIIKFGFIJCVMT-UHFFFAOYSA-Nthyroxine-binding globulinNatural productsIC1=CC(CC([NH3+])C([O-])=O)=CC(I)=C1OC1=CC(I)=C(O)C(I)=C1XUIIKFGFIJCVMT-UHFFFAOYSA-N0.000description2

- ZCYVEMRRCGMTRW-UHFFFAOYSA-N7553-56-2Chemical compound[I]ZCYVEMRRCGMTRW-UHFFFAOYSA-N0.000description1

- 208000007788Acute Liver FailureDiseases0.000description1

- 206010000804Acute hepatic failureDiseases0.000description1

- 208000032467Aplastic anaemiaDiseases0.000description1

- PRGBHLOZRUPJTA-UHFFFAOYSA-NCCCCCCCCCCCC[C]=CChemical compoundCCCCCCCCCCCC[C]=CPRGBHLOZRUPJTA-UHFFFAOYSA-N0.000description1

- TXNCCOBLYSKFGZ-UHFFFAOYSA-NC[C]CCCCCCCCCCCCChemical compoundC[C]CCCCCCCCCCCCTXNCCOBLYSKFGZ-UHFFFAOYSA-N0.000description1

- JIGUQPWFLRLWPJ-UHFFFAOYSA-NEthyl acrylateChemical compoundCCOC(=O)C=CJIGUQPWFLRLWPJ-UHFFFAOYSA-N0.000description1

- 206010020751HypersensitivityDiseases0.000description1

- OUYCCCASQSFEME-QMMMGPOBSA-NL-tyrosineChemical compoundOC(=O)[C@@H](N)CC1=CC=C(O)C=C1OUYCCCASQSFEME-QMMMGPOBSA-N0.000description1

- 206010067125Liver injuryDiseases0.000description1

- 206010029164Nephrotic syndromeDiseases0.000description1

- 102000003992PeroxidasesHuman genes0.000description1

- 238000003917TEM imageMethods0.000description1

- 208000024799Thyroid diseaseDiseases0.000description1

- AUYYCJSJGJYCDS-LBPRGKRZSA-NThyrolarChemical compoundIC1=CC(C[C@H](N)C(O)=O)=CC(I)=C1OC1=CC=C(O)C(I)=C1AUYYCJSJGJYCDS-LBPRGKRZSA-N0.000description1

- 230000009471actionEffects0.000description1

- 239000013543active substanceSubstances0.000description1

- 231100000836acute liver failureToxicity0.000description1

- 238000007259addition reactionMethods0.000description1

- 125000000217alkyl groupChemical group0.000description1

- 239000003200antithyroid agentSubstances0.000description1

- 229940043671antithyroid preparationsDrugs0.000description1

- 208000006673asthmaDiseases0.000description1

- 230000008901benefitEffects0.000description1

- 230000005540biological transmissionEffects0.000description1

- 239000008280bloodSubstances0.000description1

- 210000004369bloodAnatomy0.000description1

- 239000002775capsuleSubstances0.000description1

- 239000011203carbon fibre reinforced carbonSubstances0.000description1

- 150000001735carboxylic acidsChemical class0.000description1

- 210000000170cell membraneAnatomy0.000description1

- 230000008859changeEffects0.000description1

- 230000008878couplingEffects0.000description1

- 238000010168coupling processMethods0.000description1

- 238000005859coupling reactionMethods0.000description1

- 230000001419dependent effectEffects0.000description1

- 238000000502dialysisMethods0.000description1

- 239000002552dosage formSubstances0.000description1

- 238000001647drug administrationMethods0.000description1

- 238000005516engineering processMethods0.000description1

- 230000002708enhancing effectEffects0.000description1

- 230000032050esterificationEffects0.000description1

- 150000002148estersChemical class0.000description1

- 239000012737fresh mediumSubstances0.000description1

- 210000000777hematopoietic systemAnatomy0.000description1

- 231100000234hepatic damageToxicity0.000description1

- 229940088597hormoneDrugs0.000description1

- 239000005556hormoneSubstances0.000description1

- XMBWDFGMSWQBCA-UHFFFAOYSA-Nhydrogen iodideChemical compoundIXMBWDFGMSWQBCA-UHFFFAOYSA-N0.000description1

- 208000030603inherited susceptibility to asthmaDiseases0.000description1

- 230000002401inhibitory effectEffects0.000description1

- 229910052740iodineInorganic materials0.000description1

- 239000011630iodineSubstances0.000description1

- 208000032839leukemiaDiseases0.000description1

- 239000002502liposomeSubstances0.000description1

- 230000008818liver damageEffects0.000description1

- 230000010534mechanism of actionEffects0.000description1

- 230000008384membrane barrierEffects0.000description1

- GLVAUDGFNGKCSF-UHFFFAOYSA-NmercaptopurineChemical classS=C1NC=NC2=C1NC=N2GLVAUDGFNGKCSF-UHFFFAOYSA-N0.000description1

- 238000001000micrographMethods0.000description1

- GOQYKNQRPGWPLP-UHFFFAOYSA-Nn-heptadecyl alcoholNatural productsCCCCCCCCCCCCCCCCCOGOQYKNQRPGWPLP-UHFFFAOYSA-N0.000description1

- 239000002547new drugSubstances0.000description1

- 231100000956nontoxicityToxicity0.000description1

- ANISOHQJBAQUQP-UHFFFAOYSA-Noctyl prop-2-enoateChemical compoundCCCCCCCCOC(=O)C=CANISOHQJBAQUQP-UHFFFAOYSA-N0.000description1

- 239000007935oral tabletSubstances0.000description1

- 230000003647oxidationEffects0.000description1

- 238000007254oxidation reactionMethods0.000description1

- 239000002245particleSubstances0.000description1

- PNJWIWWMYCMZRO-UHFFFAOYSA-Npent‐4‐en‐2‐oneNatural productsCC(=O)CC=CPNJWIWWMYCMZRO-UHFFFAOYSA-N0.000description1

- 108040007629peroxidase activity proteinsProteins0.000description1

- 230000000144pharmacologic effectEffects0.000description1

- 230000001737promoting effectEffects0.000description1

- 230000008685targetingEffects0.000description1

- 208000021510thyroid gland diseaseDiseases0.000description1

- OUYCCCASQSFEME-UHFFFAOYSA-NtyrosineNatural productsOC(=O)C(N)CC1=CC=C(O)C=C1OUYCCCASQSFEME-UHFFFAOYSA-N0.000description1

- 229920002554vinyl polymerPolymers0.000description1

Images

Classifications

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0002—Galenical forms characterised by the drug release technique; Application systems commanded by energy

- A61K9/0004—Osmotic delivery systems; Sustained release driven by osmosis, thermal energy or gas

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K31/00—Medicinal preparations containing organic active ingredients

- A61K31/33—Heterocyclic compounds

- A61K31/395—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins

- A61K31/41—Heterocyclic compounds having nitrogen as a ring hetero atom, e.g. guanethidine or rifamycins having five-membered rings with two or more ring hetero atoms, at least one of which being nitrogen, e.g. tetrazole

- A61K31/4164—1,3-Diazoles

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/44—Oils, fats or waxes according to two or more groups of A61K47/02-A61K47/42; Natural or modified natural oils, fats or waxes, e.g. castor oil, polyethoxylated castor oil, montan wax, lignite, shellac, rosin, beeswax or lanolin

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/50—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates

- A61K47/51—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent

- A61K47/54—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the non-active ingredient being a modifying agent the modifying agent being an organic compound

- A61K47/541—Organic ions forming an ion pair complex with the pharmacologically or therapeutically active agent

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K47/00—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient

- A61K47/50—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates

- A61K47/69—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the conjugate being characterised by physical or galenical forms, e.g. emulsion, particle, inclusion complex, stent or kit

- A61K47/6905—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the conjugate being characterised by physical or galenical forms, e.g. emulsion, particle, inclusion complex, stent or kit the form being a colloid or an emulsion

- A61K47/6911—Medicinal preparations characterised by the non-active ingredients used, e.g. carriers or inert additives; Targeting or modifying agents chemically bound to the active ingredient the non-active ingredient being chemically bound to the active ingredient, e.g. polymer-drug conjugates the conjugate being characterised by physical or galenical forms, e.g. emulsion, particle, inclusion complex, stent or kit the form being a colloid or an emulsion the form being a liposome

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/0012—Galenical forms characterised by the site of application

- A61K9/0014—Skin, i.e. galenical aspects of topical compositions

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61K—PREPARATIONS FOR MEDICAL, DENTAL OR TOILETRY PURPOSES

- A61K9/00—Medicinal preparations characterised by special physical form

- A61K9/06—Ointments; Bases therefor; Other semi-solid forms, e.g. creams, sticks, gels

- A—HUMAN NECESSITIES

- A61—MEDICAL OR VETERINARY SCIENCE; HYGIENE

- A61P—SPECIFIC THERAPEUTIC ACTIVITY OF CHEMICAL COMPOUNDS OR MEDICINAL PREPARATIONS

- A61P5/00—Drugs for disorders of the endocrine system

- A61P5/14—Drugs for disorders of the endocrine system of the thyroid hormones, e.g. T3, T4

- A61P5/16—Drugs for disorders of the endocrine system of the thyroid hormones, e.g. T3, T4 for decreasing, blocking or antagonising the activity of the thyroid hormones

Landscapes

- Health & Medical Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Medicinal Chemistry (AREA)

- Pharmacology & Pharmacy (AREA)

- Life Sciences & Earth Sciences (AREA)

- Animal Behavior & Ethology (AREA)

- General Health & Medical Sciences (AREA)

- Public Health (AREA)

- Veterinary Medicine (AREA)

- Epidemiology (AREA)

- Bioinformatics & Cheminformatics (AREA)

- Engineering & Computer Science (AREA)

- Dermatology (AREA)

- Diabetes (AREA)

- Endocrinology (AREA)

- Chemical Kinetics & Catalysis (AREA)

- General Chemical & Material Sciences (AREA)

- Nuclear Medicine, Radiotherapy & Molecular Imaging (AREA)

- Organic Chemistry (AREA)

- Oil, Petroleum & Natural Gas (AREA)

- Dispersion Chemistry (AREA)

- Pharmaceuticals Containing Other Organic And Inorganic Compounds (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及甲硫咪唑药质体,特别是涉及一种GSH浓度响应性甲硫咪唑药质体及其制备方法。The invention relates to a methimazole drug plastid, in particular to a GSH concentration-responsive methimazole drug plastid and a preparation method thereof.

背景技术Background technique

甲硫咪唑(Methimazole,MMI)为咪唑类抗甲状腺药物,其作用机制是抑制甲状腺内过氧化物酶,阻碍吸聚到甲状腺内碘化物的氧化及酪氨酸的偶联,进而阻碍甲状腺素(T4)和三碘甲状腺原氨酸(T3)的合成。MMI不影响碘的吸收以及已合成激素的释放,研究表明,MMI口服吸收后在甲状腺内聚集,只有进入甲状腺才能发挥抑制甲状腺素合成的治疗效果,作用强弱取决于甲状腺内的局部药物浓度。由于MMI具有较强的亲水性,难以穿过甲状腺泡膜,致使其口服用药在甲状腺内聚集浓度不高,降低了药物的治疗效果,而单纯的增加剂量又会导致严重的副作用。甲硫咪唑常见的不良反应(ADR)有药物性肝损害、过敏反应、嗅觉系统损害、造血系统损害;罕见的ADR包括肾病综合征与支气管哮喘、诱发白血病和药物性再生障碍性贫血,救治不及时可致严重后果。且甲亢保守治疗的疗程为6个月~2年,同时目前上市剂型主要为口服片剂和胶囊剂。由于甲硫咪唑生物半衰期短,药物口服剂量大,服用次数频繁,可能导致严重后果,目前已有甲硫咪唑致急性肝衰竭死亡的报道。因此,有必要开发新的给药系统,例如经皮给药系统,可以增加甲状腺病灶部位的药物浓度,达到降低药物的不良反应,增加长期用药的顺应性,为患者提供更优的用药选择。Methimazole (MMI) is an imidazole antithyroid drug, its mechanism of action is to inhibit the peroxidase in the thyroid, hinder the oxidation of iodide absorbed into the thyroid and the coupling of tyrosine, and then hinder the thyroxine ( T4) and triiodothyronine (T3) synthesis. MMI does not affect the absorption of iodine and the release of synthesized hormones. Studies have shown that MMI accumulates in the thyroid after oral absorption. Only when it enters the thyroid can it exert its therapeutic effect of inhibiting thyroxine synthesis. The strength of the effect depends on the local drug concentration in the thyroid. Due to the strong hydrophilicity of MMI, it is difficult to pass through the thyroid bubble membrane, resulting in a low concentration of oral administration in the thyroid gland, which reduces the therapeutic effect of the drug, and simply increasing the dose will cause serious side effects. Common adverse reactions (ADRs) of methimazole include drug-induced liver damage, allergic reactions, olfactory system damage, and hematopoietic system damage; rare ADRs include nephrotic syndrome and bronchial asthma, induced leukemia, and drug-induced aplastic anemia. Serious consequences can occur in time. And the course of conservative treatment for hyperthyroidism is 6 months to 2 years, and the currently marketed dosage forms are mainly oral tablets and capsules. Due to the short biological half-life of methimazole, the large oral dose and frequent administration may lead to serious consequences, there have been reports of death from acute liver failure caused by methimazole. Therefore, it is necessary to develop a new drug delivery system, such as a transdermal drug delivery system, which can increase the drug concentration at the thyroid lesion, reduce adverse drug reactions, increase long-term drug compliance, and provide patients with better drug options.

采用经皮给药系统,虽然能改变药物的用药途径,提高药物的靶向性;但经皮给药要求药物具备较好穿越生物质膜屏障的能力。由于MMI是一个亲水性很强的药物,因此有必要采用药质体(pharmacosomes)原理对其进行疏水改性,构成两亲性药质体,提高其渗透性。药质体是一类在体外无活性或活性较小,在体内经酶或非酶作用,释放出活性物质而产生药理作用的化合物。药质体设计必须考虑一个关键因素是与药物化学连接的载体应当在体内生物相容性好、无毒或低毒。脂肪醇(甲醇除外)具有毒性低,与羧酸形成的酯具有良好的疏水性,成为我们药质体设计的首选。Although the transdermal drug delivery system can change the drug administration route and improve the targeting of the drug, the transdermal drug delivery requires the drug to have a better ability to cross the biological membrane barrier. Since MMI is a highly hydrophilic drug, it is necessary to use the principle of pharmacosomes to hydrophobically modify it to form amphiphilic pharmacosomes and improve its permeability. Pharmacosomes are a class of compounds that are inactive or less active in vitro and release active substances through enzymatic or non-enzymatic action in vivo to produce pharmacological effects. A key factor that must be considered in drug plasmid design is that the carrier chemically linked to the drug should have good biocompatibility, non-toxicity or low toxicity in vivo. Fatty alcohols (except methanol) have low toxicity, and the esters formed with carboxylic acids have good hydrophobicity, so they become the first choice for our pharmacosome design.

药质体设计必须考虑的另外一个关键因素是释药开关在药质体到达靶部位后要能快速打开释放出原药。在我们先前的研究中发现,含有巯基的巯嘌呤能通过迈克尔加成反应形成药质体。这种药质体在胞外介质中由于谷胱甘肽(GSH)浓度低(2-20μM)几乎不释放原药;而一旦进入细胞却能响应胞内谷胱甘肽(GSH)浓度(0.5mM-10mM)刺激通过迈克尔消去反应实现原药释放。考虑到MMI结构中含有一个巯基,我们先选择丙炔酸(PA)与MMI进行迈克尔加成反应,制得3-[(1-甲基-1H-咪唑-2-基)硫代]-2-丙烯酸,然后与疏水性的脂肪醇进行酯化反应制得两亲性GSH刺激响应的2-疏基-1-甲基咪唑药质体。该药质体能通过经皮给药作用于甲状腺位点,并响应胞内GSH刺激释放MMI,可达到降低药物毒副作用的目的。Another key factor that must be considered in the design of the drug plasmid is that the drug release switch should be able to quickly open and release the original drug after the drug plasmid reaches the target site. In our previous study, we found that mercaptopurines containing sulfhydryl groups can form pharmacosomes through Michael addition reaction. This drug plastid hardly releases the original drug due to the low concentration of glutathione (GSH) in the extracellular medium; once it enters the cell, it can respond to the concentration of intracellular glutathione (GSH) (0.5 mM-10mM) to stimulate the release of the original drug through the Michael elimination reaction. Considering that there is a mercapto group in the MMI structure, we first select propiolic acid (PA) to carry out Michael addition reaction with MMI to obtain 3-[(1-methyl-1H-imidazol-2-yl)thio]-2 -Acrylic acid, and then carry out esterification reaction with hydrophobic fatty alcohol to prepare the 2-mercapto-1-methylimidazole drug substance that responds to the stimulation of amphiphilic GSH. The drug substance can act on the thyroid site through transdermal administration, and release MMI in response to the stimulation of intracellular GSH, so as to achieve the purpose of reducing the toxic and side effects of the drug.

发明内容Contents of the invention

本发明所要解决的技术问题是:为了解决现有技术中存在的问题,本发明拟通过迈克尔加成反应将甲硫咪唑与丙炔酸发生加成反应,随后通过酯化作用与疏水化合物二~六十醇连接构建一个胞内GSH刺激响应的两亲性药质体;该药质体可以制成经皮给药系统,用于甲状腺病变部位的经皮给药。由于疏水改性和病变部位的经皮靶向施药,药物在病变部位的渗透性增强,在甲状腺内聚集浓度提高,继而其疗效增强,降低了毒副作用。该响应性甲硫咪唑药质体可用于甲状腺病的治疗。The technical problem to be solved by the present invention is: in order to solve the existing problems in the prior art, the present invention intends to add methimazole and propiolic acid through Michael addition reaction, and then react with hydrophobic compound two to two through esterification. An intracellular GSH stimulation-responsive amphiphilic pharmacosome is constructed by linking hexacosyl alcohol; the pharmacosome can be made into a transdermal drug delivery system for transdermal administration of thyroid lesions. Due to the hydrophobic modification and percutaneous targeted drug delivery to the lesion, the permeability of the drug in the lesion is enhanced, and the accumulation concentration in the thyroid is increased, thereby enhancing its curative effect and reducing toxic and side effects. The responsive methimazole drug body can be used for the treatment of thyroid disease.

本发明解决上述技术问题所采用的方案是:The solution adopted by the present invention to solve the problems of the technologies described above is:

一种GSH浓度响应性治疗甲状腺功能亢进的甲硫咪唑药质体,其具有如下通式所示结构:A GSH concentration-responsive treatment of hyperthyroidism methimazole drug plasmid, which has the structure shown in the following general formula:

其中R为C2-30的烷基,药质体的分子量为212~1024。Wherein R is a C2-30 alkyl group, and the molecular weight of the pharmacosome is 212-1024.

优选地,所述R为C12的烷基。Preferably, the R is a C12 alkyl group.

本发明的另一目的是提供一种GSH浓度响应性治疗甲状腺功能亢进的甲硫咪唑药质体的制备方法,包括如下步骤:Another object of the present invention is to provide a method for preparing a GSH concentration-responsive treatment of methimazole drug plasmids for hyperthyroidism, comprising the steps of:

(1)甲硫咪唑丙烯酸的制备(1) Preparation of methimazole acrylic acid

将甲硫咪唑加入甲醇中,再加入甲醇钠,搅拌至甲硫咪唑完全溶解,加入丙炔酸,其中,甲硫咪唑与丙炔酸的摩尔比为(0.1~10):1,甲醇与甲醇钠的摩尔比为(1~100):1;将所得混合液在10℃~100℃、氮气保护条件下回流反应1h~200h;反应结束后,用旋转蒸发仪将反应液在1~80℃下旋蒸10-120min,得浓稠白色液体;将所得浓稠白色液体冻干10-120小时后得白色片状固体甲硫咪唑丙烯酸;Add methimazole to methanol, then add sodium methoxide, stir until methimazole is completely dissolved, add propiolic acid, wherein the molar ratio of methimazole to propiolic acid is (0.1-10):1, methanol to methanol The molar ratio of sodium is (1-100): 1; the obtained mixed solution is refluxed at 10°C-100°C under nitrogen protection conditions for 1h-200h; Rotary steam for 10-120 minutes to obtain a thick white liquid; freeze-dry the obtained thick white liquid for 10-120 hours to obtain white flaky solid methimazole acrylic acid;

(2)甲硫咪唑丙烯酸二~三十酯的制备(2) Preparation of 20-300 methimazole acrylate

按照甲硫咪唑丙烯酸:EDC:NSH=1:(0.7~6):(0.6~15)的摩尔比活化羧基稳定中间体,得到甲硫咪唑丙烯酸溶液;将所得甲硫咪唑丙烯酸溶液按照甲硫咪唑丙烯酸:二~三十醇=(0.1~100):1的摩尔比投料,在10℃~100℃下反应1~200h;反应结束后,将反应溶液放入1~100℃超纯水超声洗涤1-120min,在转速为1000-10000r/min的条件下离心1-30min,取上清液再溶于1~100℃超纯水中离心,取上清液,如此反复1-10次,最后将上清液冷冻干燥10-120小时,即得目标药质体产物甲硫咪唑丙烯酸二~三十酯。According to the molar ratio of methimazole acrylic acid: EDC: NSH = 1: (0.7 ~ 6): (0.6 ~ 15), the carboxyl stable intermediate is activated to obtain the methimazole acrylic acid solution; Acrylic acid: tertiary to triacyl alcohol = (0.1 to 100): 1 molar ratio, react at 10°C to 100°C for 1 to 200 hours; after the reaction, put the reaction solution into ultrapure water at 1 to 100°C for ultrasonic washing 1-120min, centrifuge for 1-30min at the speed of 1000-10000r/min, take the supernatant and then dissolve it in ultra-pure water at 1-100℃ and centrifuge, take the supernatant, repeat this for 1-10 times, and finally The supernatant is freeze-dried for 10-120 hours to obtain the target drug substance product methimazole 20-300 acrylate.

本发明的另一目的是提供一种GSH浓度响应性治疗甲状腺功能亢进的甲硫咪唑经皮给药药膏,所述药膏中含有上述的药质体。Another object of the present invention is to provide a GSH concentration-responsive ointment for transdermal administration of methimazole for the treatment of hyperthyroidism, which contains the above drug substance.

优选地,所述药膏由上述药质体与羊毛脂和甘油用乳化法制得。Preferably, the ointment is prepared by the emulsification method of the above drug plastid, lanolin and glycerin.

优选地,所述药膏中含有促渗剂。Preferably, the ointment contains a penetration enhancer.

优选地,所述促渗剂为氮酮。Preferably, the penetration enhancer is azone.

本发明提供的上述GSH响应性控释药质体的制备方法,其制备的GSH响应性控释药质体的用途是:改善甲硫咪唑的渗透性,可通过甲状腺病变部位经皮给药,药物在甲状腺内聚集浓度会大大提高,并降低对正常组织的毒副作用。The preparation method of the above-mentioned GSH-responsive controlled-release drug plastid provided by the present invention, the purpose of the prepared GSH-responsive controlled-release drug plastid is: to improve the permeability of methimazole, which can be transdermally administered through thyroid lesions, The accumulation concentration of drugs in the thyroid will be greatly increased, and the toxic side effects on normal tissues will be reduced.

本发明拟将MMI与丙炔酸进行巯基加成反应先形成MMISCH=COOH化合物,然后通过酯化反应与脂肪醇连接合成出GSH响应的MMI药质体;然后制成经皮给药系统,用于甲亢局部治疗,具有如下优点:The present invention intends to carry out sulfhydryl addition reaction between MMI and propiolic acid to form MMISCH=COOH compound firstly, and then link with fatty alcohol through esterification reaction to synthesize GSH-responsive MMI drug substance; then make transdermal drug delivery system, use For local treatment of hyperthyroidism, it has the following advantages:

(1)该药物通过疏水改性,获得的药质体会大大增强对甲状腺部位细胞膜及泡膜的渗透性;(1) The drug is hydrophobically modified, and the obtained drug substances will greatly enhance the permeability of the cell membrane and vesicular membrane of the thyroid;

(2)获得的药质体能响应细胞内谷胱甘肽浓度刺激,通过Michael消去反应,实现药物的智能释放。(2) The obtained pharmacosome can respond to the stimulation of intracellular glutathione concentration, and realize the intelligent release of drugs through Michael elimination reaction.

(3)该药物可作为经皮给药系统,增加甲状腺病灶部位的药物局部浓度,延长药物在病灶组织的作用时间,从而提升药物的治疗效果,由于给药系统直接作用于病灶部位,有望减小对正常组织的损伤、降低药物的不良反应;另外,该系统有望提高长期用药的顺应性,提升药物的使用安全性,为患者提供更优的用药选择。(3) The drug can be used as a transdermal drug delivery system to increase the local concentration of the drug in the thyroid lesion and prolong the action time of the drug in the lesion tissue, thereby improving the therapeutic effect of the drug. Since the drug delivery system directly acts on the lesion, it is expected to reduce the concentration of the drug. Small damage to normal tissues and reduced adverse drug reactions; in addition, the system is expected to improve long-term drug compliance, improve drug use safety, and provide patients with better drug options.

附图说明Description of drawings

图1本发明实施例3制备的MMI-AA和MMI-AA-OLa的核磁H谱,其中图a为MMI-AA,图b为MMI-AA-OLa;The NMR H spectrum of MMI-AA and MMI-AA-OLa prepared in the embodiment of the

图2本发明实施例3制备的MMI-AA和MMI-AA-OLa的核磁C谱,其中图a为MMI-AA,图b为MMI-AA-OLa;The NMR C spectrum of MMI-AA and MMI-AA-OLa prepared by the embodiment of the

图3本发明实施例3制备的MMI-AA-OLa的质谱图;The mass spectrogram of the MMI-AA-OLa that Fig. 3 embodiment of the

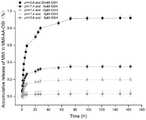

图4~8是本发明实施例1~5制备的甲硫咪唑药质体在不同内环境的药物释放曲线;Figures 4 to 8 are drug release curves of methimazole drug plasmids prepared in Examples 1 to 5 of the present invention in different internal environments;

图9本发明实施例3制备的MMI-AA-OLa的透射电镜图,其中左右图中标尺分别代表1μm、200nm;9 is a transmission electron microscope image of MMI-AA-OLa prepared in Example 3 of the present invention, wherein the scales in the left and right figures represent 1 μm and 200 nm, respectively;

图10本发明实施例制备的MMI-AA-OLa在不同类型促渗剂的药物累积透皮释放百分含量(%)。Fig. 10 is the cumulative transdermal drug release percentage (%) of MMI-AA-OLa prepared in the embodiment of the present invention in different types of penetration enhancers.

具体实施方式Detailed ways

为更好的理解本发明,下面的实施例是对本发明的进一步说明,但本发明的内容不仅仅局限于下面的实施例。For a better understanding of the present invention, the following examples are further descriptions of the present invention, but the content of the present invention is not limited to the following examples.

实施例1:Example 1:

(1)3-[(1-甲基-1H-咪唑-2-基)硫代]-2-丙烯酸(甲硫咪唑丙烯酸,MMI-AA)的制备(1) Preparation of 3-[(1-methyl-1H-imidazol-2-yl)thio]-2-acrylic acid (methimazole acrylic acid, MMI-AA)

将甲硫咪唑(10mmol)溶解于甲醇(1mol)中,在搅拌状态下将甲醇钠(10mmol)加入其中至甲硫咪唑完全溶解,再将丙炔酸(100mmol)加入其中。反应温度:10℃,氮气保护,回流状态下反应200小时。反应结束后,用旋转蒸发仪将反应液在32℃下旋蒸10min后,得浓稠白色液体;将浓稠白色液体冷冻干燥10小时,冻干后即得MMI-AA(白色片状固体)。Methimazole (10mmol) was dissolved in methanol (1mol), sodium methoxide (10mmol) was added thereto under stirring until the methimazole was completely dissolved, and then propiolic acid (100mmol) was added therein. Reaction temperature: 10°C, under nitrogen protection, and react under reflux for 200 hours. After the reaction, use a rotary evaporator to rotate the reaction solution at 32°C for 10 minutes to obtain a thick white liquid; freeze-dry the thick white liquid for 10 hours, and obtain MMI-AA (white flake solid) after lyophilization .

(2)3-[(1-甲基-1H-咪唑-2-基)硫代]-2-丙烯酸-乙酯(甲硫咪唑丙烯酸乙酯,MMI-AA-OEt)的制备(2) Preparation of 3-[(1-methyl-1H-imidazol-2-yl)thio]-2-propenoic acid-ethyl ester (methimazole ethyl acrylate, MMI-AA-OEt)

将所得甲硫咪唑丙烯酸(1mmol)与EDC(6mmol)溶解于DMF(129mmol),搅拌状态下活化20min,20min后加入NHS(15mmol)搅拌状态下稳定1小时。将乙醇(10mmol)溶解于DMF(129mmol),最后将处理好的甲硫咪唑丙烯酸溶液,加入到乙醇溶液中,不断搅拌,反应温度10℃,氮气保护,反应1小时。反应结束后,将反应溶液放入4℃超纯水超声洗涤,超声洗涤1min后,在转速为1000r/min的条件下离心30min,取上清液再溶于4℃超纯水离心,取上清液,如此反复5次,最后将上清液冷冻干燥10小时,冻干后即得MMI-AA-OEt(米黄色液体)。The obtained methimazole acrylic acid (1 mmol) and EDC (6 mmol) were dissolved in DMF (129 mmol), activated under stirring for 20 min, and NHS (15 mmol) was added after 20 min to stabilize under stirring for 1 hour. Dissolve ethanol (10mmol) in DMF (129mmol), and finally add the treated methimazole acrylic acid solution into the ethanol solution, stirring continuously, at a reaction temperature of 10°C, under nitrogen protection, and react for 1 hour. After the reaction, put the reaction solution into 4°C ultrapure water for ultrasonic washing, after ultrasonic washing for 1 min, centrifuge at 1000r/min for 30 min, take the supernatant and redissolve it in 4°C ultrapure water for centrifugation, take the upper The supernatant was repeated five times, and finally the supernatant was freeze-dried for 10 hours to obtain MMI-AA-OEt (beige liquid).

实施例2:Example 2:

(1)3-[(1-甲基-1H-咪唑-2-基)硫代]-2-丙烯酸(甲硫咪唑丙烯酸,MMI-AA)的制备(1) Preparation of 3-[(1-methyl-1H-imidazol-2-yl)thio]-2-acrylic acid (methimazole acrylic acid, MMI-AA)

将甲硫咪唑(10mmol)溶解于甲醇(0.8mol)中,在搅拌状态下将甲醇钠(10mmol)加入其中至甲硫咪唑完全溶解,再将丙炔酸(10mmol)加入其中。反应温度:20℃,氮气保护,回流状态下反应150小时。反应结束后,用旋转蒸发仪将反应液在32℃下旋蒸20min后,得浓稠白色液体;将浓稠白色液体冷冻干燥30小时,冻干后即得MMI-AA(白色片状固体)。Methimazole (10 mmol) was dissolved in methanol (0.8 mol), sodium methoxide (10 mmol) was added thereto under stirring until the methimazole was completely dissolved, and then propiolic acid (10 mmol) was added therein. Reaction temperature: 20°C, under nitrogen protection, under reflux for 150 hours. After the reaction, use a rotary evaporator to rotate the reaction solution at 32°C for 20 minutes to obtain a thick white liquid; freeze-dry the thick white liquid for 30 hours, and obtain MMI-AA (white flake solid) after lyophilization .

(2)3-[(1-甲基-1H-咪唑-2-基)硫代]-2-丙烯酸-正辛酯(甲硫咪唑丙烯酸正辛酯,MMI-AA-OCa)的制备(2) Preparation of 3-[(1-methyl-1H-imidazol-2-yl)thio]-2-acrylic acid-n-octyl ester (methimazole n-octyl acrylate, MMI-AA-OCa)

将所得甲硫咪唑丙烯酸(10mmol)与EDC(10mmol)溶解于DMF(129mmol),搅拌状态下活化20min,20min后加入NHS(10mmol)搅拌状态下稳定1小时。将正辛醇(10mmol)溶解于DMF(129mmol),最后将处理好的甲硫咪唑丙烯酸溶液,加入到正辛醇溶液中,不断搅拌,反应温度20℃,氮气保护,反应100小时。反应结束后,将反应溶液放入4℃超纯水超声洗涤,超声洗涤10min后,在转速为2000r/min的条件下离心20min,取上清液再溶于4℃超纯水离心,取上清液,如此反复5次,最后将上清液冷冻干燥20小时,冻干后即得MMI-AA-OCa(赭黄色液体)。The obtained methimazole acrylic acid (10mmol) and EDC (10mmol) were dissolved in DMF (129mmol), activated under stirring for 20min, and NHS (10mmol) was added after 20min to stabilize under stirring for 1 hour. Dissolve n-octanol (10mmol) in DMF (129mmol), and finally add the treated methimazole acrylic acid solution into the n-octanol solution, stirring constantly, at a reaction temperature of 20°C, under nitrogen protection, and react for 100 hours. After the reaction, put the reaction solution into 4°C ultrapure water for ultrasonic washing, after ultrasonic washing for 10 minutes, centrifuge at 2000r/min for 20min, take the supernatant and redissolve it in 4°C ultrapure water for centrifugation, take the upper The supernatant was repeated five times, and finally the supernatant was freeze-dried for 20 hours to obtain MMI-AA-OCa (ochre-yellow liquid).

实施例3:Example 3:

(1)3-[(1-甲基-1H-咪唑-2-基)硫代]-2-丙烯酸(甲硫咪唑丙烯酸,MMI-AA)的制备(1) Preparation of 3-[(1-methyl-1H-imidazol-2-yl)thio]-2-acrylic acid (methimazole acrylic acid, MMI-AA)

将甲硫咪唑(30mmol)溶解于甲醇(0.5mol)中,在搅拌状态下将甲醇钠(10mmol)加入其中至甲硫咪唑完全溶解,再将丙炔酸(10mmol)加入其中。反应温度:50℃,氮气保护,回流状态下反应100小时。反应结束后,用旋转蒸发仪将反应液在32℃下旋蒸60min后,得浓稠白色液体;将浓稠白色液体冷冻干燥50小时,冻干后即得MMI-AA(白色片状固体)。Methimazole (30mmol) was dissolved in methanol (0.5mol), sodium methoxide (10mmol) was added thereto under stirring until the methimazole was completely dissolved, and then propiolic acid (10mmol) was added therein. Reaction temperature: 50°C, under nitrogen protection, and react under reflux for 100 hours. After the reaction, use a rotary evaporator to evaporate the reaction solution at 32°C for 60 minutes to obtain a thick white liquid; freeze-dry the thick white liquid for 50 hours, and obtain MMI-AA (white flake solid) after lyophilization .

(2)3-[(1-甲基-1H-咪唑-2-基)硫代]-2-丙烯酸-十二酯(甲硫咪唑丙烯酸十二酯,MMI-AA-OLa)的制备(2) Preparation of 3-[(1-methyl-1H-imidazol-2-yl)thio]-2-acrylic acid-dodecyl (methimazole acrylate dodecyl, MMI-AA-OLa)

将甲硫咪唑丙烯酸(9mmol)与EDC(27mmol)溶解于DMF(260mmol),搅拌状态下活化20min,20min后加入NHS(45mmol)搅拌状态下稳定1小时。将十二醇(0.3mmol)溶解于DMF(260mmol),最后将处理好的甲硫咪唑丙烯酸溶液,加入到十二醇溶液中,不断搅拌,反应温度30℃,氮气保护,反应50小时。反应结束后,将反应溶液放入4℃超纯水超声洗涤,超声洗涤60min后,在转速为5000r/min的条件下离心15min,取上清液再溶于4℃超纯水离心,取上清液,如此反复5次,最后将上清液冷冻干燥60小时,冻干后即得MMI-AA-OLa(米黄色液体)。Dissolve methimazole acrylic acid (9mmol) and EDC (27mmol) in DMF (260mmol) and activate for 20min with stirring. After 20min, add NHS (45mmol) and stabilize for 1 hour with stirring. Dissolve dodecyl alcohol (0.3mmol) in DMF (260mmol), and finally add the treated methimazole acrylic acid solution into the dodecanol solution, stirring continuously, at a reaction temperature of 30°C, under nitrogen protection, and react for 50 hours. After the reaction, put the reaction solution into 4°C ultrapure water for ultrasonic washing, after ultrasonic washing for 60 minutes, centrifuge at a speed of 5000r/min for 15 minutes, take the supernatant and redissolve it in 4°C ultrapure water for centrifugation, and take the The supernatant was repeated five times in this way, and finally the supernatant was freeze-dried for 60 hours to obtain MMI-AA-OLa (beige liquid) after freeze-drying.

实施例4:Example 4:

(1)3-[(1-甲基-1H-咪唑-2-基)硫代]-2-丙烯酸(甲硫咪唑丙烯酸,MMI-AA)的制备(1) Preparation of 3-[(1-methyl-1H-imidazol-2-yl)thio]-2-acrylic acid (methimazole acrylic acid, MMI-AA)

将甲硫咪唑(15mmol)溶解于甲醇(0.3mol)中,在搅拌状态下将甲醇钠(10mmol)加入其中至甲硫咪唑完全溶解,再将丙炔酸(3mmol)加入其中。反应温度:80℃,氮气保护,回流状态下反应30小时。反应结束后,用旋转蒸发仪将反应液在32℃下旋蒸80min后,得浓稠白色液体;将浓稠白色液体冷冻干燥100小时,冻干后即得MMI-AA(白色片状固体)。Methimazole (15mmol) was dissolved in methanol (0.3mol), sodium methoxide (10mmol) was added thereto under stirring until the methimazole was completely dissolved, and then propiolic acid (3mmol) was added therein. Reaction temperature: 80° C., under nitrogen protection, and react under reflux for 30 hours. After the reaction, use a rotary evaporator to rotate the reaction solution at 32°C for 80 minutes to obtain a thick white liquid; freeze-dry the thick white liquid for 100 hours, and obtain MMI-AA (white flake solid) after lyophilization .

(2)3-[(1-甲基-1H-咪唑-2-基)硫代]-2-丙烯酸-十八酯(甲硫咪唑丙烯酸十八酯,MMI-AA-OSt)的制备(2) Preparation of 3-[(1-methyl-1H-imidazol-2-yl)thio]-2-acrylic acid-octadecyl (methimazole acrylate octadecyl, MMI-AA-OSt)

将甲硫咪唑丙烯酸(2.7mmol)与EDC(13.5mmol)溶解于DMF(129mmol),搅拌状态下活化20min,20min后加入NHS(27mmol)搅拌状态下稳定1小时。将十八醇(0.03mmol)溶解于DMF(129mmol),60℃下搅拌30min直至完全溶解。最后将处理好的甲硫咪唑丙烯酸溶液,加入到十八醇溶液中,不断搅拌,反应温度60℃,氮气保护,反应10小时。反应结束后,将反应溶液放入4℃超纯水超声洗涤80min,过滤,滤饼再溶于4℃超纯水超声洗涤80min,过滤,如此反复5次,最后将滤饼冷冻干燥90小时,冻干后即得MMI-AA-OSt(白色粉末)。Dissolve methimazole acrylic acid (2.7mmol) and EDC (13.5mmol) in DMF (129mmol), activate with stirring for 20min, add NHS (27mmol) after 20min and stabilize for 1 hour under stirring. Octadecanol (0.03mmol) was dissolved in DMF (129mmol), stirred at 60°C for 30min until completely dissolved. Finally, the treated methimazole acrylic acid solution was added into the stearyl alcohol solution, stirred continuously, the reaction temperature was 60° C., and the reaction was carried out under nitrogen protection for 10 hours. After the reaction, put the reaction solution into 4°C ultrapure water for ultrasonic washing for 80 minutes, filter, then dissolve the filter cake in 4°C ultrapure water, ultrasonically wash for 80 minutes, and filter, repeat this process for 5 times, and finally freeze-dry the filter cake for 90 hours. After lyophilization, MMI-AA-OSt (white powder) was obtained.

实施例5:Example 5:

(1)3-[(1-甲基-1H-咪唑-2-基)硫代]-2-丙烯酸(甲硫咪唑丙烯酸,MMI-AA)的制备(1) Preparation of 3-[(1-methyl-1H-imidazol-2-yl)thio]-2-acrylic acid (methimazole acrylic acid, MMI-AA)

将甲硫咪唑(10mmol)溶解于甲醇(0.3mol)中,在搅拌状态下将甲醇钠(0.3mol)加入其中至甲硫咪唑完全溶解,再将丙炔酸(1mmol)加入其中。反应温度:100℃,氮气保护,回流状态下反应1小时。反应结束后,用旋转蒸发仪将反应液在32℃下旋蒸120min后,得浓稠白色液体;将浓稠白色液体冷冻干燥120小时,冻干后即得MMI-AA(白色片状固体)。Methimazole (10 mmol) was dissolved in methanol (0.3 mol), sodium methoxide (0.3 mol) was added thereto under stirring until the methimazole was completely dissolved, and then propiolic acid (1 mmol) was added therein. Reaction temperature: 100° C., under nitrogen protection, and react under reflux for 1 hour. After the reaction, use a rotary evaporator to rotate the reaction solution at 32°C for 120 minutes to obtain a thick white liquid; freeze-dry the thick white liquid for 120 hours, and then obtain MMI-AA (white flaky solid) after lyophilization .

(2)3-[(1-甲基-1H-咪唑-2-基)硫代]-2-丙烯酸-三十酯(甲硫咪唑丙烯酸三十酯,MMI-AA-OTr)的制备(2) Preparation of 3-[(1-methyl-1H-imidazol-2-yl)thio]-2-acrylic acid-tririatyl (methimazole acrylate, MMI-AA-OTr)

将甲硫咪唑丙烯酸(10mmol)与EDC(7mmol)溶解于DMF(129mmol),搅拌状态下活化20min,20min后加入NHS(6mmol)搅拌状态下稳定1小时。将三十醇(0.1mmol)溶解于DMF(129mmol),60℃下搅拌30min直至完全溶解。最后将处理好的甲硫咪唑丙烯酸溶液,加入到三十醇溶液中,不断搅拌,反应温度100℃,氮气保护,反应1小时。反应结束后,将反应溶液放入4℃超纯水超声洗涤120min,过滤,滤饼再溶于4℃超纯水超声洗涤120min,过滤,如此反复5次,最后将滤饼冷冻干燥120小时,冻干后即得MMI-AA-OTr(白色粉末)。Dissolve methimazole acrylic acid (10 mmol) and EDC (7 mmol) in DMF (129 mmol), activate for 20 min under stirring, and add NHS (6 mmol) after 20 min to stabilize under stirring for 1 hour. Triaconol (0.1 mmol) was dissolved in DMF (129 mmol), stirred at 60° C. for 30 min until completely dissolved. Finally, the treated methimazole acrylic acid solution was added into the triacyl alcohol solution, stirred continuously, the reaction temperature was 100° C., and the reaction was carried out under nitrogen protection for 1 hour. After the reaction, put the reaction solution into 4°C ultrapure water for ultrasonic washing for 120 min, filter, then dissolve the filter cake in 4°C ultrapure water, ultrasonically wash for 120 min, and filter, repeat this process for 5 times, and finally freeze-dry the filter cake for 120 hours. After lyophilization, MMI-AA-OTr (white powder) was obtained.

将上述实施例中制备的GSH响应性药质体冷冻干燥后,分别溶于pH为7.4的三组不同GSH浓度(0μM,10μM和5mM)的缓冲溶液中,和pH为5.6的两组不同GSH浓度(0μM,20mM)的缓冲溶液中,用高效液相色谱法(HPLC)测定甲硫咪唑丙烯酸十二酯的累积释药率,研究其体外释药行为。具体如下:After freeze-drying the GSH-responsive drug bodies prepared in the above examples, they were respectively dissolved in buffer solutions with three different GSH concentrations (0 μM, 10 μM and 5 mM) at pH 7.4, and two groups of different GSH concentrations at pH 5.6. Concentration (0μM, 20mM) of the buffer solution, using high performance liquid chromatography (HPLC) to determine the cumulative release rate of methimazole lauryl acrylate, to study its in vitro drug release behavior. details as follows:

取一定量的冷冻干燥后的上述实施例中的甲硫咪唑丙烯酸十二酯溶于适量的二氯甲烷中,待充分溶解后,将溶液平均分成5份封装进截留分子量200的透析袋中。依次将5份溶液浸没入盛有不同释放介质(pH=7.4,0μM GSH,10μM GSH和5mM GSH;pH=5.6,0μMGSH,20mM GSH)的锥形瓶中。在37℃下,将各锥形瓶连同溶液置于恒温旋转震荡器中震荡模拟生物体环境。在预先设定好的时间间隔内,取出5mL释放介质,同时添加5mL新鲜介质以维持漏槽条件。取出的释放介质中的甲硫咪唑的量通过高效液相色谱法来测定,所有的测试一式三份。Take a certain amount of freeze-dried methimazole lauryl acrylate in the above examples and dissolve it in an appropriate amount of dichloromethane. After fully dissolving, divide the solution into 5 parts and pack them into dialysis bags with a molecular weight cut off of 200. The 5 solutions were sequentially submerged into Erlenmeyer flasks containing different release media (pH=7.4, 0 μM GSH, 10 μM GSH and 5 mM GSH; pH=5.6, 0 μM GSH, 20 mM GSH). At 37°C, each Erlenmeyer flask together with the solution was placed in a constant temperature rotary shaker to vibrate to simulate the biological environment. At pre-set intervals, remove 5 mL of release medium while adding 5 mL of fresh medium to maintain sink conditions. The amount of methimazole in the withdrawn release medium was determined by high performance liquid chromatography, and all tests were performed in triplicate.

按甲硫咪唑标准曲线计算药物浓度。采用以下公式计算甲硫咪唑的累积释药率(Re):The drug concentration was calculated according to the standard curve of methimazole. The following formula was used to calculate the cumulative release rate (Re) of methimazole:

Re=Mt/M0Re=Mt/M0

式中:Re表示纳米制剂的累积释药率;Mt表示在时间t时纳米制剂总释药量;M0为纳米制剂总药量。In the formula: Re represents the cumulative drug release rate of the nano-preparation; Mt represents the total drug release of the nano-preparation at time t; M0 is the total drug dosage of the nano-preparation.

尽管这里参考给出的实施方案说明并且描述了本发明的某些方面,但并不是为了将所附的权利要求限定到所显示的细节中。相反,可以预料本领域的技术人员可以对这些细节进行不同的修改,其中这些修改应该还在所要求的主题的精神和范围内,并且是为了相应地解释这些权利要求。While certain aspects of the invention are illustrated and described herein with reference to the illustrated embodiments, it is not intended that the appended claims be limited to the details shown. Rather, it is to be expected that various modifications of these details may be effected by persons skilled in the art, which modifications shall be within the spirit and scope of the claimed subject matter, and that the claims be construed accordingly.

图1本发明制备的甲硫咪唑丙烯酸(MMI-AA)和甲硫咪唑丙烯酸十二酯(MMI-AA-OLa)的核磁H谱。Figure 1 shows the NMR H spectra of methimazole acrylic acid (MMI-AA) and methimazole acrylate lauryl (MMI-AA-OLa) prepared by the present invention.

MMI-AA氢谱:1H NMR(500MHz,D2O),化学位移(δ):咪唑碳碳双键氢:7.45(t,J=5.7Hz,1H),7.42(d,J=2.0Hz,1H),乙烯碳碳双键氢:6.80(d,J=9.2Hz,1H),6.07(d,J=9.3Hz,1H),D2O:4.70(s,3H),咪唑甲基:3.80(s,3H)。综上所述,MMI-AA各个氢信号峰的归属与其分子结构相符,可以证明MMI-AA的结构形成。MMI-AA hydrogen spectrum: 1H NMR (500MHz, D2O), chemical shift (δ): imidazole carbon-carbon double bond hydrogen: 7.45 (t, J = 5.7Hz, 1H), 7.42 (d, J = 2.0Hz, 1H) , ethylene carbon-carbon double bond hydrogen: 6.80 (d, J = 9.2Hz, 1H), 6.07 (d, J = 9.3Hz, 1H), D2O: 4.70 (s, 3H), imidazole methyl: 3.80 (s, 3H ). In summary, the assignment of each hydrogen signal peak of MMI-AA is consistent with its molecular structure, which can prove the structure formation of MMI-AA.

MMI-AA-OLa氢谱:1H NMR(500MHz,DMSO),化学位移(δ):咪唑碳碳双键氢:7.34(s,1H),7.00(t,J=10.3Hz,1H),乙烯碳碳双键氢:7.73(t,J=16.3Hz,1H),6.12(d,J=9.9Hz,1H),咪唑甲基氢:3.56(m,3H),十二酯碳氧单键氢:4.11(dd,J=18.3,11.7Hz,2H),DMSO-d6:3.31(m,17H),2.50(m,15H)。综上所述,MMI-AA-OLa各个氢信号峰的归属与其分子结构相符,可以证明MMI-AA-OLa的结构形成。MMI-AA-OLa hydrogen spectrum: 1H NMR (500MHz, DMSO), chemical shift (δ): imidazole carbon-carbon double bond hydrogen: 7.34 (s, 1H), 7.00 (t, J = 10.3Hz, 1H), vinyl carbon Carbon double bond hydrogen: 7.73 (t, J=16.3Hz, 1H), 6.12 (d, J=9.9Hz, 1H), imidazole methyl hydrogen: 3.56 (m, 3H), dodecyl carbon oxygen single bond hydrogen: 4.11 (dd, J=18.3, 11.7 Hz, 2H), DMSO-d6: 3.31 (m, 17H), 2.50 (m, 15H). In summary, the assignment of each hydrogen signal peak of MMI-AA-OLa is consistent with its molecular structure, which can prove the structure formation of MMI-AA-OLa.

图2本发明制备的甲硫咪唑丙烯酸(MMI-AA)和甲硫咪唑丙烯酸十二酯(MMI-AA-OLa)的核磁C谱。Fig. 2 is the NMR C spectrum of methimazole acrylic acid (MMI-AA) and methimazole acrylate lauryl (MMI-AA-OLa) prepared by the present invention.

MMI-AA碳谱:13C NMR(126MHz,D2O),化学位移(δ):羧基碳:173.42(s),乙烯双键碳:140.70(s),121.31(s),咪唑碳氮双键碳:134.59(s),咪唑碳碳双键碳:125.22(s),123.90(s),咪唑甲基碳:34.97(s)。综上所述,MMI-AA各个碳信号峰的归属与其分子结构相符,可以证明MMI-AA的结构形成。MMI-AA carbon spectrum: 13C NMR (126MHz, D2O), chemical shift (δ): carboxyl carbon: 173.42 (s), ethylene double bond carbon: 140.70 (s), 121.31 (s), imidazole carbon nitrogen double bond carbon: 134.59(s), imidazole carbon-carbon double bond carbon: 125.22(s), 123.90(s), imidazole methyl carbon: 34.97(s). In summary, the assignment of each carbon signal peak of MMI-AA is consistent with its molecular structure, which can prove the structure formation of MMI-AA.

MMI-AA-OLa碳谱:13C NMR(126MHz,DMSO),化学位移(δ):羧基碳:171.26(s),乙烯双键碳:145.89(m),114.76(m),咪唑碳氮双键碳:139.38(m),咪唑碳碳双键碳:129.21(s),124.65(m),咪唑甲基碳:33.02(s)。十二酯碳氧单键碳:61.18(s),DMSO-d6:40.03(m),十二酯亚甲基碳:31.77(s),29.51(dd,J=11.5,6.5Hz),29.18(s),28.50(s),25.98(s),25.78(d,J=12.3Hz),22.57(s),十二酯甲基碳:14.42(s)。综上所述,MMI-AA-OLa各个碳信号峰的归属与其分子结构相符,可以证明MMI-AA-OLa的结构形成。MMI-AA-OLa carbon spectrum: 13C NMR (126MHz, DMSO), chemical shift (δ): carboxyl carbon: 171.26 (s), ethylene double bond carbon: 145.89 (m), 114.76 (m), imidazole carbon nitrogen double bond Carbon: 139.38(m), imidazole carbon-carbon double bond carbon: 129.21(s), 124.65(m), imidazole methyl carbon: 33.02(s). Dodecyl carbon-oxygen single bond carbon: 61.18(s), DMSO-d6: 40.03(m), dodecyl methylene carbon: 31.77(s), 29.51(dd, J=11.5, 6.5Hz), 29.18( s), 28.50(s), 25.98(s), 25.78(d, J=12.3Hz), 22.57(s), lauryl methyl carbon: 14.42(s). In summary, the assignment of each carbon signal peak of MMI-AA-OLa is consistent with its molecular structure, which can prove the structure formation of MMI-AA-OLa.

图3本发明制备的甲硫咪唑丙烯酸十二酯质谱图。Fig. 3 mass spectrogram of methimazole lauryl acrylate prepared by the present invention.

甲硫咪唑丙烯酸十二酯(MMI-AA-OLa)准分子离子峰[M+1]+=353.21781,C19H32O2N2S+。MMI-AA-OLa分子式为:C19H32O2N2S,理论分子量352.21845。分子量误差为1.82ppm<5ppm,表明MMI-AA-OLa实测分子量与理论相符。The quasi-molecular ion peak of methimazole dodecyl acrylate (MMI-AA-OLa) [M+1]+=353.21781, C19H32O2N2S+. The molecular formula of MMI-AA-OLa is: C19H32O2N2S, and the theoretical molecular weight is 352.21845. The molecular weight error is 1.82ppm<5ppm, indicating that the measured molecular weight of MMI-AA-OLa is consistent with the theory.

表1为本发明制备的甲硫咪唑药质体的表观油水分配系数。Table 1 is the apparent oil-water partition coefficient of the methimazole pharmacosome prepared in the present invention.

表1甲硫咪唑药质体表观油水分配系数(n=5)Table 1 Apparent oil-water partition coefficient of methimazole drug substance (n=5)

可见改性后的甲硫咪唑药质体与甲硫咪唑的lgP对比,lgP值均有所增加,lgP值越大,说明该物质越亲油。lgP对于药物在皮肤吸收速度和程度有很大影响,药物最佳lgP为2<lgP<3,该化合物脂溶性和水溶性适中,具有较好生物膜渗透性而发挥疗效。甲硫咪唑丙烯酸十二酯(MMI-AA-OLa)在pH=5.6和7.4的油水分配系数lgP均在2至3之间,提示其有良好的渗透性,但又维持了一定的水溶性,是用于透皮给药的最佳化合物。Compared with the lgP of methimazole after modification, the lgP value of the modified methimazole drug plastid all increases, and the larger the lgP value, the more lipophilic the substance is. IgP has a great influence on the speed and degree of drug absorption in the skin. The optimal IgP of the drug is 2<lgP<3. The compound has moderate fat solubility and water solubility, and has good biomembrane permeability to exert curative effect. The oil-water partition coefficient lgP of methimazole lauryl acrylate (MMI-AA-OLa) at pH=5.6 and 7.4 is all between 2 and 3, suggesting that it has good permeability, but maintains a certain water solubility, It is the best compound for transdermal administration.

图4~8是本发明制备的甲硫咪唑药质体在不同内环境的药物释放曲线。释放介质一份为GSH浓度10μM、pH7.4的PBS缓冲溶液(模拟人体血液环境),一份为GSH浓度5mM、pH7.4的PBS缓冲溶液(模拟正常细胞内环境),另一份为GSH浓度20mM、pH5.6的PBS缓冲溶液(模拟病变细胞内环境)。结果显示,MMI-AA-OEt在0μM的GSH溶液中只有极少量的药物释放,7.5小时和163小时的累积释药率分别为4.85%(pH=7.4),2.39%(pH=5.6)和6.34%(pH=7.4),3.34%(pH=5.6);而在pH=7.4 and 10μM GSH、pH=7.4 and 5mM GSH、pH=5.6 and20mM GSH的溶液中累积释药率明显增大,7.5小时累积释药率分别为15.17%、26.63%和59.88%,163小时累积释药率分别为19.80%、35.46%和93.01%。MMI-AA-OCa在0μM的GSH溶液中只有极少量的药物释放,7.5小时和163小时的累积释药率分别为4.85%(pH=7.4),2.39%(pH=5.6)和6.33%(pH=7.4),3.33%(pH=5.6);而在pH=7.4 and 10μM GSH、pH=7.4 and 5mM GSH、pH=5.6 and 20mM GSH的溶液中累积释药率明显增大,7.5小时累积释药率分别为15.15%、26.61%和59.82%,163小时累积释药率分别为19.78%、35.43%和92.92%。MMI-AA-OLa在0μM的GSH溶液中只有极少量的药物释放,7.5小时和163小时的累积释药率分别为4.81%(pH=7.4),2.37%(pH=5.6)和6.27%(pH=7.4),3.30%(pH=5.6);而在pH=7.4 and 10μM GSH、pH=7.4 and 5mM GSH、pH=5.6 and 20mM GSH的溶液中累积释药率明显增大,7.5小时累积释药率分别为15.02%、26.37%和59.28%,163小时累积释药率分别为19.61%、35.11%和92.10%。MMI-AA-OSt在0μM的GSH溶液中只有极少量的药物释放,7.5小时和163小时的累积释药率分别为4.80%(pH=7.4),2.37%(pH=5.6)和6.27%(pH=7.4),3.30%(pH=5.6);而在pH=7.4 and 10μM GSH、pH=7.4 and 5mM GSH、pH=5.6 and 20mM GSH的溶液中累积释药率明显增大,7.5小时累积释药率分别为15.00%、26.34%和59.22%,163小时累积释药率分别为19.59%、35.08%和92.00%。MMI-AA-OTr在0μM的GSH溶液中只有极少量的药物释放,7.5小时和163小时的累积释药率分别为4.32%(pH=7.4),2.13%(pH=5.6)和5.64%(pH=7.4),2.97%(pH=5.6);而在pH=7.4and 10μM GSH、pH=7.4 and 5mM GSH、pH=5.6 and 20mM GSH的溶液中累积释药率明显增大,7.5小时累积释药率分别为13.50%、23.71%和53.30%,163小时累积释药率分别为17.63%、31.57%和82.79%。MMI-AA-OTr与其他药质体在同等条件下对比,药物累积释放量有明显差异,可能与碳链的立体位阻有关。结果表明GSH响应性药质体在没有GSH环境中具有较好的稳定性,不会造成药物的大量泄漏;而在pH=7.4and10μM GSH、pH=7.4 and5mM GSH和pH=5.6 and 20mM GSH环境中能逐渐释放药物。总体表现出谷胱甘肽浓度依赖型释药方式。Figures 4 to 8 are drug release curves of methimazole drug plasmids prepared in the present invention in different internal environments. One part of the release medium is a PBS buffer solution with a GSH concentration of 10 μM and pH7.4 (simulating the human blood environment), one part is a PBS buffer solution with a GSH concentration of 5 mM and a pH7.4 (simulating a normal intracellular environment), and the other part is GSH PBS buffer solution with a concentration of 20 mM and a pH of 5.6 (to simulate the intracellular environment of diseased cells). The results show that MMI-AA-OEt has only a very small amount of drug release in 0 μM GSH solution, and the cumulative drug release rates of 7.5 hours and 163 hours are 4.85% (pH=7.4), 2.39% (pH=5.6) and 6.34% respectively. % (pH = 7.4), 3.34% (pH = 5.6); while the cumulative drug release rate in the solution of pH = 7.4 and 10μM GSH, pH = 7.4 and 5mM GSH, pH = 5.6 and 20mM GSH increased significantly, and the accumulation of 7.5 hours The drug release rates were 15.17%, 26.63% and 59.88%, and the cumulative drug release rates in 163 hours were 19.80%, 35.46% and 93.01%, respectively. MMI-AA-OCa has only a very small amount of drug release in 0μM GSH solution, and the cumulative release rates of 7.5 hours and 163 hours are 4.85% (pH=7.4), 2.39% (pH=5.6) and 6.33% (pH =7.4), 3.33% (pH=5.6); while in the solutions of pH=7.4 and 10μM GSH, pH=7.4 and 5mM GSH, pH=5.6 and 20mM GSH, the cumulative drug release rate increased significantly, and the cumulative drug release rate was 7.5 hours The drug release rates were 15.15%, 26.61% and 59.82%, respectively, and the cumulative drug release rates in 163 hours were 19.78%, 35.43% and 92.92%. MMI-AA-OLa has only a very small amount of drug release in 0 μ M GSH solution, and the cumulative release rates of 7.5 hours and 163 hours are 4.81% (pH=7.4), 2.37% (pH=5.6) and 6.27% (pH =7.4), 3.30% (pH=5.6); while in the solutions of pH=7.4 and 10μM GSH, pH=7.4 and 5mM GSH, pH=5.6 and 20mM GSH, the cumulative drug release rate increased significantly, and the cumulative drug release rate was 7.5 hours The rates were 15.02%, 26.37% and 59.28%, respectively, and the cumulative drug release rates in 163 hours were 19.61%, 35.11% and 92.10%. MMI-AA-OSt has only a very small amount of drug release in 0μM GSH solution, and the cumulative release rates of 7.5 hours and 163 hours are 4.80% (pH=7.4), 2.37% (pH=5.6) and 6.27% (pH =7.4), 3.30% (pH=5.6); while in the solutions of pH=7.4 and 10μM GSH, pH=7.4 and 5mM GSH, pH=5.6 and 20mM GSH, the cumulative drug release rate increased significantly, and the cumulative drug release rate was 7.5 hours The drug release rates were 15.00%, 26.34% and 59.22%, respectively, and the cumulative drug release rates in 163 hours were 19.59%, 35.08% and 92.00%. MMI-AA-OTr has only a very small amount of drug release in 0μM GSH solution, and the cumulative release rates of 7.5 hours and 163 hours are 4.32% (pH=7.4), 2.13% (pH=5.6) and 5.64% (pH =7.4), 2.97% (pH=5.6); while in the solutions of pH=7.4and 10μM GSH, pH=7.4 and 5mM GSH, pH=5.6 and 20mM GSH, the cumulative drug release rate increased significantly, and the cumulative drug release rate was 7.5 hours The drug release rates were 13.50%, 23.71% and 53.30%, respectively, and the cumulative drug release rates in 163 hours were 17.63%, 31.57% and 82.79%. Comparing MMI-AA-OTr with other drug plastids under the same conditions, the cumulative release of drugs is significantly different, which may be related to the steric hindrance of the carbon chain. The results show that the GSH-responsive drug plasmid has good stability in the environment without GSH, and will not cause a large amount of drug leakage; while in the environment of pH=7.4and10μM GSH, pH=7.4 and5mM GSH and pH=5.6 and 20mM GSH The drug can be released gradually. Overall, it showed a glutathione concentration-dependent release pattern.

图6本发明制备的甲硫咪唑丙烯酸十二酯的透射电镜图。如图可知甲硫咪唑丙烯酸十二酯药质体的结构为空心纳米囊泡,平均粒径为200±3.6nm。Fig. 6 is a transmission electron micrograph of methimazole lauryl acrylate prepared in the present invention. It can be seen from the figure that the structure of the methimazole dodecyl acrylate drug plastid is a hollow nanovesicle with an average particle size of 200±3.6nm.

图7本发明制备的甲硫咪唑丙烯酸十二酯在不同类型促渗剂的药物累积透皮释放百分含量(%)。MMI(0%PE,1.587±0.444)与MMI(2%Azone,1.632±0.384)的24h累积渗透量(%)对比无明显差异,表明2%氮酮的促渗剂不能增强MMI的24h累积渗透量(%)。MMI(0%PE)与MMI-AA-OLa(0%PE)的24h累积渗透量(%)对比,十二醇改性后的MMI药脂质体(27.924±0.741)的24h累积渗透量(%)比MMI(1.587±0.444)增加了26.337%,表明改性后的MMI-AA-OLa的24h累积渗透量(%)显著提高。MMI-AA-OLa(0%PE)与MMI-AA-OLa(2%Azone)的24h累积渗透量(%)对比,含2%Azone(83.804±0.557)的24h累积渗透量(%)是MMI-AA-OLa(0%PE,27.924±0.741)不含促渗剂的3.001倍,表明2%Azone有良好的促进MMI-AA-OLa渗透皮肤的作用。Fig. 7 is the cumulative transdermal drug release percentage (%) of methimazole lauryl acrylate prepared in the present invention in different types of penetration enhancers. There is no significant difference in the 24h cumulative penetration (%) between MMI (0% PE, 1.587±0.444) and MMI (2% Azone, 1.632±0.384), indicating that 2% azone penetration enhancer cannot enhance the 24h cumulative penetration of MMI quantity(%). The 24h cumulative permeation (%) of MMI (0%PE) and MMI-AA-OLa (0%PE) contrast, the 24h cumulative permeation of the MMI drug liposome (27.924 ± 0.741) after dodecyl alcohol modification ( %) increased by 26.337% compared with MMI (1.587±0.444), indicating that the 24h cumulative penetration (%) of the modified MMI-AA-OLa was significantly increased. The 24h cumulative penetration (%) of MMI-AA-OLa (0% PE) and MMI-AA-OLa (2% Azone) is compared, and the 24h cumulative penetration (%) containing 2% Azone (83.804±0.557) is MMI -AA-OLa (0% PE, 27.924±0.741) is 3.001 times that of no penetration enhancer, indicating that 2% Azone has a good effect of promoting the penetration of MMI-AA-OLa into the skin.

以上所述是本发明的优选实施方式而已,当然不能以此来限定本发明之权利范围,应当指出,对于本技术领域的普通技术人员来说,在不脱离本发明原理的前提下,还可以做出若干改进和变动,这些改进和变动也视为本发明的保护范围。The above description is only a preferred embodiment of the present invention, and of course the scope of rights of the present invention cannot be limited by this. It should be pointed out that for those of ordinary skill in the art, they can also Several improvements and changes are made, and these improvements and changes are also regarded as the protection scope of the present invention.

Claims (6)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010877049.0ACN111939118B (en) | 2020-08-27 | 2020-08-27 | Pharmacosome for treating hyperthyroidism in response to GSH concentration and preparation method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010877049.0ACN111939118B (en) | 2020-08-27 | 2020-08-27 | Pharmacosome for treating hyperthyroidism in response to GSH concentration and preparation method |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111939118A CN111939118A (en) | 2020-11-17 |

| CN111939118Btrue CN111939118B (en) | 2023-02-03 |

Family

ID=73366825

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010877049.0AActiveCN111939118B (en) | 2020-08-27 | 2020-08-27 | Pharmacosome for treating hyperthyroidism in response to GSH concentration and preparation method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111939118B (en) |

Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1857261A (en)* | 2006-03-30 | 2006-11-08 | 华中科技大学 | Aquogel type thiamazole plaster preparation |

Family Cites Families (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN104117066B (en)* | 2014-07-16 | 2016-03-02 | 陈凌 | The preparation method of external-applied ointment used for treating thyropathy |

- 2020

- 2020-08-27CNCN202010877049.0Apatent/CN111939118B/enactiveActive

Patent Citations (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN1857261A (en)* | 2006-03-30 | 2006-11-08 | 华中科技大学 | Aquogel type thiamazole plaster preparation |

Non-Patent Citations (2)

| Title |

|---|

| Microwave-promoted regio- and stereoselective vinylation of heterocyclic thiols;Nimmakuri Rajesh et al.;《RSC Advances》;20140106;7834-7837* |

| Synthesis of 3-(1-Methyl-1H-imidazol-2-ylthio)propanoic Acid and (E)-3-(1-Methyl-1H-imidazol-2-ylthio)acrylic Acid;Christopher M. Hattan et al.;《Synth. Commun.》;20120905;第43卷(第1期);1-8* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111939118A (en) | 2020-11-17 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| JP3903061B2 (en) | Nanoparticles containing drug, method for producing the same, and preparation for parenteral administration comprising the nanoparticles | |

| JP3558344B2 (en) | Parenteral drug formulations | |

| Huang et al. | Deep eutectic solvents as active pharmaceutical ingredient delivery systems in the treatment of metabolic related diseases | |

| JPS6191137A (en) | External pharmaceutical composition | |

| TW200936182A (en) | Agent for enhancing anti-tumor effect comprising oxaliplatin liposome preparation, and anti-tumor agent comprising the liposome preparation | |

| CN101522692A (en) | Positively charged water-soluble prodrugs of oxicams and related compounds with fast skin penetration rates | |

| US20130034617A1 (en) | Gallium compositions for the treatment of liver cancer and methods of use | |

| CN111346081A (en) | New use of pharmaceutical composition comprising n-pentanoic acid, indolpropanic acid and sodium n-butyrate | |

| CA2362888C (en) | Use of r-aryl propionic acids for producing medicaments to treat diseases in humans and animals, whereby said diseases can be therapeutically influenced by inhibiting the activation of nf-kb | |

| CN111939118B (en) | Pharmacosome for treating hyperthyroidism in response to GSH concentration and preparation method | |

| CN100345536C (en) | Pharmaceutical composition comprising 5-methyl-2-(2'-chloro-6'-fluoroanilino)phenylacetic acid | |

| KR101074374B1 (en) | Anti-inflammatory analgesic for external use | |

| CN100502850C (en) | Medicinal composition of total capsaicin compounds and β-cyclodextrin or β-cyclodextrin derivatives | |

| CN111265482A (en) | Glycyrrhetinic acid and/or folic acid ligand modified cantharidin solid lipid nanoparticle and preparation method thereof | |

| WO2005070413A1 (en) | Retinoic acid-containing remedy for diabetes | |

| CN113616620B (en) | An Luoti nix albumin nano-particles, preparation method and application thereof and preparation containing same | |

| AU2007262496A1 (en) | Pharmaceutical composition for injectional, particularly targeted local administration | |

| JPH11507326A (en) | Drug substance for selective treatment of tumor tissue | |

| JP2831030B2 (en) | Composition for transdermal administration preparation containing 3'-azido-3'deoxythymidine as active ingredient | |

| JP4807721B2 (en) | Anti-inflammatory analgesic topical | |

| AU2007262493A1 (en) | Pharmaceutical composition for oral administration | |

| CN111991371B (en) | Pharmacosome hydrogel patch for treating hyperthyroidism in response to GSH concentration and preparation method thereof | |

| RU2536425C2 (en) | Pharmaceutical composition containing sildenafil citrate, and method of using it | |

| JP2005145932A (en) | Antiinflammatory analgesic agent for external use | |

| CN104146951B (en) | Dexibuprofen injection and preparation method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |