CN111880431A - A comprehensive real-time simulation control method and system for joint dispatch of urban drainage system - Google Patents

A comprehensive real-time simulation control method and system for joint dispatch of urban drainage systemDownload PDFInfo

- Publication number

- CN111880431A CN111880431ACN202010563919.7ACN202010563919ACN111880431ACN 111880431 ACN111880431 ACN 111880431ACN 202010563919 ACN202010563919 ACN 202010563919ACN 111880431 ACN111880431 ACN 111880431A

- Authority

- CN

- China

- Prior art keywords

- simulation

- model

- control

- time

- mechanism model

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

Images

Classifications

- G—PHYSICS

- G05—CONTROLLING; REGULATING

- G05B—CONTROL OR REGULATING SYSTEMS IN GENERAL; FUNCTIONAL ELEMENTS OF SUCH SYSTEMS; MONITORING OR TESTING ARRANGEMENTS FOR SUCH SYSTEMS OR ELEMENTS

- G05B17/00—Systems involving the use of models or simulators of said systems

- G05B17/02—Systems involving the use of models or simulators of said systems electric

Landscapes

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Engineering & Computer Science (AREA)

- Automation & Control Theory (AREA)

- Feedback Control In General (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及城市排水系统实时控制领域,特别涉及一种综合性的城市排水系统联合调度实时仿真控制方法及所用系统。The invention relates to the field of real-time control of urban drainage systems, in particular to a comprehensive real-time simulation control method for joint scheduling of urban drainage systems and a system therefor.

背景技术Background technique

排水系统实时控制指根据实时监测数据制定排水系统联合调度的最优运行策略,充分利用现有设施的利用效率,达到预设的运行目标的控制方法。实时控制是未来排水系统的发展趋势。目前城市排水模型领域,对于排水管网、LID设施、泵站、调蓄池、污水厂等设施的模拟研究主要应用美国EPA机构研发的SWMM软件。该软件对各汇水分区在降雨过程中的表现,以及对管道中水的动态流动等有着较好的模拟效果,但是对于排水领域实时控制系统的模拟有着较大不足。The real-time control of the drainage system refers to the control method of formulating the optimal operation strategy of the joint scheduling of the drainage system according to the real-time monitoring data, making full use of the utilization efficiency of the existing facilities, and achieving the preset operation target. Real-time control is the development trend of the future drainage system. At present, in the field of urban drainage model, the SWMM software developed by the US EPA is mainly used in the simulation research of drainage pipe network, LID facilities, pumping station, storage tank, sewage plant and other facilities. The software has a good simulation effect on the performance of each catchment zone in the process of rainfall and the dynamic flow of water in the pipeline, but it has a big deficiency in the simulation of the real-time control system in the drainage field.

目前SWMM软件以及市场上基于SWMM的二次开发软件,只能实现对排水过程的简单逻辑控制,无法实现实时全局多目标最优化控制。同时,由于SWMM等软件的分布式模型计算较为复杂,运算速度慢,不能满足排水系统实时控制的要求(通常需要在5分钟内完成全系统的寻优计算,并反馈控制策略)。因此,对于SWMM模型的优化提升是本专利的重要改进方向。At present, SWMM software and secondary development software based on SWMM in the market can only realize simple logic control of drainage process, but cannot realize real-time global multi-objective optimal control. At the same time, because the distributed model calculation of software such as SWMM is relatively complex and the operation speed is slow, it cannot meet the requirements of real-time control of the drainage system (usually, it is necessary to complete the optimization calculation of the whole system within 5 minutes and feedback the control strategy). Therefore, the optimization and improvement of the SWMM model is an important improvement direction of this patent.

在仿真模拟控制领域,众多商用仿真平台可视化程度高,并且兼容多种编程语言(C/C++,python等等),可以对众多物理过程进行模拟研究。但是这类仿真平台通常并不具有用于模拟城市排水领域的应用模块,目前尚无法直接模拟城市排水系统各水力过程。In the field of simulation simulation control, many commercial simulation platforms have a high degree of visualization and are compatible with a variety of programming languages (C/C++, python, etc.), and can simulate and study many physical processes. However, such simulation platforms usually do not have application modules for simulating the field of urban drainage, and currently it is not possible to directly simulate various hydraulic processes of the urban drainage system.

发明内容SUMMARY OF THE INVENTION

本发明的主要目的是提供一种综合性的城市排水系统联合调度实时仿真控制方法,该方法是一种通用性的排水系统仿真方法,旨在建立一个融合SWMM引擎的算法集成、适用性强、控制策略丰富的仿真平台,从而实现城市厂网河全要素、全时域、多目标的高效实时模拟和优化控制。The main purpose of the present invention is to provide a comprehensive real-time simulation control method for joint scheduling of urban drainage systems, which is a universal simulation method for drainage systems, and aims to establish an algorithm integration that integrates SWMM engine, has strong applicability, A simulation platform with rich control strategies enables efficient real-time simulation and optimal control of all elements, all time domains, and multi-objectives of urban plants, networks, and rivers.

本发明的另一目的是提供上述综合性的城市排水系统联合调度实时仿真控制方法所用的系统。Another object of the present invention is to provide a system for the above-mentioned comprehensive urban drainage system joint dispatch real-time simulation control method.

如上构思,本发明的技术方案是:一种综合性的城市排水系统联合调度实时仿真控制方法,包括以下步骤:As conceived above, the technical solution of the present invention is: a comprehensive real-time simulation control method for joint dispatching of urban drainage systems, comprising the following steps:

步骤1:解析在线机理模型,构建排水系统在线机理模型;Step 1: Analyze the online mechanism model and build the online mechanism model of the drainage system;

步骤2:简化在线机理模型;Step 2: Simplify the online mechanism model;

步骤3:构建离线仿真概化模型;Step 3: Build an offline simulation generalized model;

步骤4:校正模型参数;Step 4: Correct the model parameters;

步骤5:建立设施间逻辑关系;Step 5: Establish the logical relationship between facilities;

步骤6:建立通讯指令关系;Step 6: Establish a communication command relationship;

步骤7:建立降雨过程;Step 7: Establish the rainfall process;

步骤8:建立系统边界条件和控制目标;Step 8: Establish system boundary conditions and control objectives;

步骤9:确定优化控制方法;Step 9: Determine the optimal control method;

步骤10:在线机理模型、简化在线机理模型和离线仿真概化模型耦合;Step 10: Coupling the online mechanism model, the simplified online mechanism model and the offline simulation generalized model;

步骤11:进行联合调度实时仿真模拟;Step 11: perform joint scheduling real-time simulation;

步骤12:数据分析展示。Step 12: Data analysis display.

进一步,所述步骤1包括以下步骤:Further, the

①在线机理模型文件(.inp)的调用和运行;①Invoke and run the online mechanism model file (.inp);

②模拟过程数据和结果数据的整理分析;② Arrangement and analysis of simulation process data and result data;

③将各重要节点的水量、水位和水质信息以时间序列的方式导出,作为边界条件和校正参考用于后续仿真控制步骤。③ Export the water quantity, water level and water quality information of each important node in the form of time series, which are used as boundary conditions and correction references for subsequent simulation control steps.

进一步,所述步骤2简化在线机理模型的方法是:首先对模型设施进行简化,然后对模型进行线性化处理,即利用基于质量守恒的Muskingum模型,使用径流系数R,子段数N,传输时长K和权重系数X对汇水区、管道和河道模型进行定义,将机理模型中复杂的非线性物理关系,转化为包含上述参数的线性关系,最后利用线性拟合的方法,对设施的过程曲线进行线性化处理。Further, the method for simplifying the online mechanism model in the step 2 is: first simplify the model facilities, and then perform linearization processing on the model, that is, using the Muskingum model based on mass conservation, using the runoff coefficient R, the number of subsections N, and the transmission duration K and the weight coefficient X to define the catchment area, pipeline and channel model, convert the complex nonlinear physical relationship in the mechanism model into a linear relationship including the above parameters, and finally use the method of linear fitting to carry out the process curve of the facility. Linearization processing.

进一步,所述步骤3构建离线仿真概化模型的方法是:以在线机理模型设施为基础,构建离线仿真概化模型,包含在线机理模型全部设施种类。Further, the method for constructing an offline simulation generalized model in the step 3 is: building an offline simulation generalized model based on the online mechanism model facility, including all types of facilities of the online mechanism model.

进一步,所述步骤4校正模型参数包括:Further, the step 4 to correct the model parameters includes:

①在线机理模型的参数率定;①The parameter calibration of the online mechanism model;

②简化在线机理模型的参数率定;② simplify the parameter calibration of the online mechanism model;

③离线仿真概化模型中各模块的设定参数校正。③ Correction of the setting parameters of each module in the off-line simulation generalized model.

进一步,所述步骤5建立设施间逻辑关系的方法是:所建模块间的逻辑规则,包括进出水流量关系,最大进/排水能力与流量关系。Further, the method for establishing the logical relationship between the facilities in the

进一步,所述步骤6建立通讯指令关系具体包括:各设施的状态参数上传关系、中央控制器的指令下达关系、局部控制器的指令下达关系、无线信号模拟和外部指令接入模拟。Further, establishing the communication command relationship in step 6 specifically includes: the state parameter upload relationship of each facility, the command issuing relationship of the central controller, the command issuing relationship of the local controller, wireless signal simulation and external command access simulation.

进一步,所述步骤7降雨过程建立具体包括:外部降雨文件的调用、典型雨型数据库调用和给定公式生成降雨。Further, the establishment of the rainfall process in step 7 specifically includes: calling an external rainfall file, calling a database of typical rain patterns, and generating rainfall with a given formula.

进一步,所述步骤8建立系统边界条件和控制目标具体包括:系统的逻辑规则、系统的边界条件和系统的联合控制目标,即包括厂网河系统的溢流,内涝和水质目标。Further, the establishment of system boundary conditions and control objectives in step 8 specifically includes: system logic rules, system boundary conditions and system joint control objectives, that is, including overflow, waterlogging and water quality objectives of the plant, network, and river system.

进一步,所述步骤9确定的优化控制方法具体包括:Further, the optimized control method determined in step 9 specifically includes:

①基于优化算法的控制规则及参数确定:选定受控设施、选定监测位置及所需监测的运行时间、水质、水位和流量信息、选定优化算法及调整算法的默认参数,根据监测信息,结合系统联合控制目标,选定的优化算法将在模拟仿真过程中实时计算出受控位置的最优控制值;利用PID控制方法控制设施平稳达到控制值;① Determination of control rules and parameters based on optimization algorithms: selected facilities to be controlled, selected monitoring locations and required monitoring running time, water quality, water level and flow information, selected optimization algorithms and default parameters of adjustment algorithms, based on monitoring information , combined with the joint control objective of the system, the selected optimization algorithm will calculate the optimal control value of the controlled position in real time during the simulation process; use the PID control method to control the facility to achieve the control value smoothly;

②基于规则控制法或模糊逻辑法的控制规则及参数确定:选定受控设施、选定监测位置及所需监测的运行时间、水质、水位和流量信息,自动生成监测信息和控制指令的响应关系,调整响应关系作为控制依据,模拟控制时利用实时监测值和控制依据得到设施控制值,利用PID控制方法控制设施平稳达到控制值;②Determination of control rules and parameters based on rule control method or fuzzy logic method: selected facilities to be controlled, selected monitoring locations and required monitoring operation time, water quality, water level and flow information, and automatically generate monitoring information and response to control commands Adjust the response relationship as the control basis, use the real-time monitoring value and control basis to obtain the facility control value during simulation control, and use the PID control method to control the facility to achieve the control value smoothly;

前述两种优化方法均可基于系统各位置的运行时间、深度、水头、入流、出流、积水、水质、工作状态信息,实现对堰、闸门、孔口、阀门、分(截)流井、泵站等设施的控制;两种优化控制方法均可以结合PID控制,实现控制值得精准平稳实现。The above two optimization methods can be based on the operating time, depth, water head, inflow, outflow, accumulated water, water quality, and working status information of each position of the system to realize the weir, gate, orifice, valve, branch (intercept) flow well. , pumping station and other facilities; both of the two optimal control methods can be combined with PID control to achieve accurate and stable control.

进一步,所述步骤10在线机理模型、简化在线机理模型和离线仿真概化模型耦合具体包括:Further, the coupling of the online mechanism model, the simplified online mechanism model and the offline simulation generalized model in step 10 specifically includes:

①利用在线机理模型模拟厂网河系统的实时运行状态,将各重要节点的水量、水位和水质信息以时间序列的方式输出至简化在线机理模型;①Using the online mechanism model to simulate the real-time operation state of the plant, network and river system, and output the water volume, water level and water quality information of each important node to the simplified online mechanism model in a time series manner;

②简化在线机理模型根据输入的状态数据,模拟未来时间段内的系统运行情况,将各重要节点的水量、水位和水质信息以时间序列的方式输出离线仿真概化模型;②Simplified online mechanism model According to the input state data, the system operation in the future time period is simulated, and the water volume, water level and water quality information of each important node are output to the offline simulation generalized model in the form of time series;

③离线仿真概化模型依据选定的控制目标和优化方法,根据输入数据,对模拟时间段内的厂网河系统运行进行优化调控,计算出系统最优运行状态下的控制策略;③The offline simulation generalized model optimizes and controls the operation of the plant, network and river system in the simulation time period according to the selected control objective and optimization method, and according to the input data, and calculates the control strategy under the optimal operation state of the system;

④将计算出的控制策略传回在线机理模型,在最优控制策略下进行模拟,得到实时优化控制效果,完成一个时间步长下的仿真控制。④ Send the calculated control strategy back to the online mechanism model, simulate under the optimal control strategy, obtain the real-time optimal control effect, and complete the simulation control under one time step.

进一步,所述步骤11联合调度实时仿真模拟具体包括:自定义时间步长下的联合调度实时仿真和所选定的控制目标和方法下的联合调度实时仿真。Further, the joint scheduling real-time simulation in step 11 specifically includes: joint scheduling real-time simulation under a user-defined time step and joint scheduling real-time simulation under the selected control objective and method.

进一步,所述步骤12数据分析展示具体包括:Further, the step 12 data analysis display specifically includes:

①各节点的数据记录和调用;①Data recording and calling of each node;

②通用性指标的计算;②Calculation of generality indicators;

③自定义公式计算;③ Calculate by custom formula;

④常见数据图表生成。④Generation of common data charts.

所述综合性的城市排水系统联合调度实时仿真控制方法所用系统,包括在线机理模型模块、在线机理模型简化模块、设施编辑和管理模块、模型参数校正模块、目标优化控制模块和模拟和结果展示模块;The system used in the comprehensive urban drainage system joint dispatch real-time simulation control method includes an online mechanism model module, an online mechanism model simplification module, a facility editing and management module, a model parameter correction module, an objective optimization control module, and a simulation and result display module. ;

进一步,①所述在线机理模型模块包括:用于在线机理模型文件(.inp)的系统调用的调用模块、用于在线机理模型文件(.inp)的系统运行的运行模块、模拟过程数据和结果数据的整理分析的数据处理模块和将各重要节点的水量、水位和水质信息以时间序列的方式导出的数据导出模块;Further, 1. the on-line mechanism model module includes: a call module for the system call of the on-line mechanism model file (.inp), an operation module for the system operation of the on-line mechanism model file (.inp), simulation process data and results The data processing module for data sorting and analysis and the data export module for exporting the water volume, water level and water quality information of each important node in a time series manner;

②所述在线机理模型简化模块的功能包括:②The functions of the online mechanism model simplification module include:

A.依据在线机理模型简化方法,将在线机理模型内设施合并、删除或简化;A. According to the online mechanism model simplification method, merge, delete or simplify the facilities in the online mechanism model;

B.修改汇水区、管道和河道模型参数,生成符合线性化要求的模型;B. Modify the model parameters of the catchment area, pipeline and channel to generate a model that meets the linearization requirements;

C.修改闸门、孔口设施的模型参数,生成符合过程曲线线性化要求的模型;C. Modify the model parameters of the gate and orifice facilities to generate a model that meets the linearization requirements of the process curve;

③所述设施编辑和管理模块的功能包括:③ The functions of the facility editing and management module include:

A.离线仿真概化模型的构建,包括管道、LID设施、井、孔口闸阀、蓄水设施、泵、污水处理厂、河道的添加和属性编辑;A. Construction of a generalized model for offline simulation, including the addition and attribute editing of pipelines, LID facilities, wells, orifice gate valves, water storage facilities, pumps, sewage treatment plants, and river channels;

B.设施间逻辑关系建立,包括模块间的逻辑规则、进出水流量关系、最大进/排水能力与流量关系;B. Establishment of logical relationship between facilities, including logical rules between modules, relationship between incoming and outgoing water flow, maximum intake/drainage capacity and flow relationship;

C.通讯指令关系建立,包括各设施的状态参数上传关系、中央控制器/局部控制器的指令下达关系、无线信号模拟、外部指令接入模拟;C. Establishment of communication command relationship, including the status parameter upload relationship of each facility, the command delivery relationship of the central controller/local controller, wireless signal simulation, and external command access simulation;

D.降雨过程建立,包括外部降雨文件的调用、典型雨型数据库调用、给定公式生成降雨。D. Establishment of rainfall process, including calling of external rainfall files, calling of typical rain type database, and generating rainfall with a given formula.

④所述模型参数校正模块的功能包括:在线机理模型的参数率定、简化在线机理模型的参数率定和离线仿真概化模型中各模块的设定参数校正;④ The functions of the model parameter correction module include: parameter calibration of the online mechanism model, parameter calibration of the simplified online mechanism model, and parameter calibration of each module in the offline simulation generalized model;

⑤所述目标优化控制模块的功能包括:⑤ The functions of the target optimization control module include:

A.系统的逻辑规则和边界条件建立;A. The logic rules and boundary conditions of the system are established;

B.系统的联合控制目标建立;B. The establishment of joint control objectives of the system;

C.采用基于优化算法的控制规则及参数确定:选定受控设施;选定监测位置及所需监测的运行时间、水质、水位和流量等信息;选定优化算法及调整算法的默认参数;根据监测信息,结合系统联合控制目标,选定的优化算法将在模拟仿真过程中实时计算出受控位置的最优控制值;利用PID控制方法控制设施平稳达到控制值;或采用基于规则控制法或模糊逻辑法的控制规则及参数确定:选定受控设施;选定监测位置及所需监测的运行时间、水质、水位和流量等信息;自动生成监测信息和控制指令的响应关系;调整响应关系作为控制依据;模拟控制时利用实时监测值和控制依据得到设施控制值;利用PID控制方法控制设施平稳达到控制值;C. Determine the control rules and parameters based on the optimization algorithm: select the controlled facility; select the monitoring location and the required monitoring information such as running time, water quality, water level and flow; select the optimization algorithm and adjust the default parameters of the algorithm; According to the monitoring information, combined with the joint control objectives of the system, the selected optimization algorithm will calculate the optimal control value of the controlled position in real time during the simulation process; use the PID control method to control the facility to achieve the control value smoothly; or use the rule-based control method Or fuzzy logic method control rules and parameter determination: select the controlled facility; select the monitoring location and the required monitoring information such as running time, water quality, water level and flow; automatically generate the response relationship between monitoring information and control instructions; adjust the response The relationship is used as the control basis; in the simulation control, the real-time monitoring value and the control basis are used to obtain the facility control value; the PID control method is used to control the facility to achieve the control value smoothly;

⑥所述模拟和结果展示模块的功能包括:⑥ The functions of the simulation and result display module include:

A.在线机理模型、简化在线机理模型和离线模型耦合;A. Online mechanism model, simplified online mechanism model and offline model coupling;

B.自定义时间步长下的联合调度实时仿真;B. Joint scheduling real-time simulation under custom time step;

C.所选定的控制目标和方法下的联合调度实时仿真;C. Joint scheduling real-time simulation under the selected control objective and method;

D.各节点的数据记录和调用;D. Data recording and calling of each node;

E.通用性指标的计算;E. Calculation of generality indicators;

F.自定义公式计算;F. Custom formula calculation;

G.常见数据图表生成。G. Common data chart generation.

本发明具有如下的优点和积极效果:(1)本发明采用线性化的方法对机理模型进行简化,可以显著提升模型运算速度,实现高效可靠的系统状态预测模拟。(2)本发明在不改变传统机理模型主要逻辑结构的基础上,构建离线仿真概化模型,将在系统模拟结果输出至仿真模型进行模拟,利用优化算法可快速得出优化控制策略,计算出的优化控制策略结果又可以反馈给在线机理模型模拟/验证优化控制策略效果,这种方式解决了传统的机理模型由于运算速率慢且无法实现动态条件下全局多目标最优化控制的问题。(3)本发明的在线机理模型、简化在线机理模型和离线仿真概化模型耦合后,仍具备较快的计算速率,如设定每5分钟完成一次控制时,模型的运算和控制策略寻优可以在3分钟之内完成。(4)本发明集成多种优化算法,可以在根据不同的控制目标选定合适的优化方法,实现最优控制规则的计算,并将优化控制策略传达至执行器。The present invention has the following advantages and positive effects: (1) The present invention adopts the linearization method to simplify the mechanism model, which can significantly improve the model operation speed and realize efficient and reliable system state prediction and simulation. (2) The present invention builds an off-line simulation generalized model without changing the main logic structure of the traditional mechanism model, outputs the in-system simulation results to the simulation model for simulation, and uses an optimization algorithm to quickly obtain an optimal control strategy, and calculates The results of the optimal control strategy can be fed back to the online mechanism model to simulate/verify the effect of the optimal control strategy, which solves the problem that the traditional mechanism model cannot achieve global multi-objective optimal control under dynamic conditions due to its slow operation rate. (3) After the online mechanism model, simplified online mechanism model and offline simulation generalized model of the present invention are coupled, they still have a relatively fast calculation rate. Can be done in 3 minutes. (4) The present invention integrates multiple optimization algorithms, and can select an appropriate optimization method according to different control objectives, realize the calculation of the optimal control rule, and transmit the optimal control strategy to the actuator.

附图说明Description of drawings

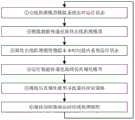

图1是在线机理模型调用模块图;Fig. 1 is the call module diagram of the online mechanism model;

图2是系统离线仿真模型示意图;Fig. 2 is a schematic diagram of an off-line simulation model of the system;

图3是污水厂离线仿真模型示意图;Figure 3 is a schematic diagram of an offline simulation model of a sewage treatment plant;

图4是模型参数校正图模块;Fig. 4 is a model parameter correction map module;

图5是在线机理模型、简化在线机理模型和离线仿真模型耦合流程图;Fig. 5 is the coupling flow chart of the online mechanism model, the simplified online mechanism model and the offline simulation model;

图6是本发明实例流程图。FIG. 6 is a flow chart of an example of the present invention.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention.

如图所示:本发明提出了一种综合性的城市排水系统联合调度实时仿真控制方法,包括如下步骤:As shown in the figure: the present invention proposes a comprehensive real-time simulation control method for joint scheduling of urban drainage systems, including the following steps:

步骤1:解析在线机理模型,构建排水系统在线机理模型;Step 1: Analyze the online mechanism model and build the online mechanism model of the drainage system;

步骤2:在线机理模型简化;Step 2: Simplify the online mechanism model;

步骤3:离线仿真概化模型构建;Step 3: Offline simulation generalized model construction;

步骤4:模型参数校正;Step 4: Model parameter correction;

步骤5:设施间逻辑关系建立;Step 5: Establish the logical relationship between facilities;

步骤6:通讯指令关系建立;Step 6: Establish a communication command relationship;

步骤7:降雨过程建立;Step 7: The rainfall process is established;

步骤8:系统边界条件和控制目标建立;Step 8: Establish system boundary conditions and control objectives;

步骤9:优化控制方法确定;Step 9: Determine the optimal control method;

步骤10:在线机理模型、简化在线机理模型和离线仿真概化模型耦合;Step 10: Coupling the online mechanism model, the simplified online mechanism model and the offline simulation generalized model;

步骤11:联合调度实时仿真模拟;Step 11: Joint scheduling real-time simulation;

步骤12:数据分析展示。Step 12: Data analysis display.

参照图1,在线机理模型文件解析,包括:Referring to Figure 1, the online mechanism model file analysis, including:

①在线机理模型文件(.inp)的调用和运行;①Invoke and run the online mechanism model file (.inp);

②模拟过程数据和结果数据的整理分析;② Arrangement and analysis of simulation process data and result data;

③将各重要节点的水量、水位和水质信息以时间序列的方式导出,作为边界条件和校正参考用于后续仿真控制步骤。③ Export the water quantity, water level and water quality information of each important node in the form of time series, which are used as boundary conditions and correction references for subsequent simulation control steps.

所述在线机理模型简化,包括:The online mechanism model is simplified, including:

①模型设施的概化:将厂网河系统模型进行适度简化,保留关键节点、管道和设施等,将其余部分合理地合并、简化或删除;①Generalization of model facilities: moderately simplify the plant, network and river system model, retain key nodes, pipelines and facilities, and reasonably merge, simplify or delete the rest;

②模型的线性化处理,利用基于质量守恒的Muskingum模型等方式,使用径流系数R,子段数N,传输时长K和权重系数X对汇水区、管道和河道模型进行定义,将机理模型中复杂的非线性物理关系,如降雨-径流关系和进水量-出水量关系,转化为包含上述参数的线性关系;利用线性拟合的方法,对闸门、孔口等设施的过程曲线进行线性化处理。上述方法在不明显损失模拟结果精度的情况下,大幅提高运算速度和效率,满足实时控制对模型运算速度的需要。② Linearization of the model, using Muskingum model based on mass conservation, etc., using the runoff coefficient R, the number of subsections N, the transmission time K and the weight coefficient X to define the catchment area, pipeline and river model, and the complex mechanism model is defined. The nonlinear physical relationship, such as rainfall-runoff relationship and inflow-outflow relationship, is converted into a linear relationship including the above parameters; the process curves of gates, orifices and other facilities are linearized by using the method of linear fitting. The above method can greatly improve the operation speed and efficiency without obviously losing the accuracy of the simulation result, and meet the needs of the real-time control for the model operation speed.

参照图2和图3,所述离线仿真概化模型构建,包括以在线机理模型设施为基础,构建离线仿真概化模型,包含在线机理模型全部设施种类。Referring to FIG. 2 and FIG. 3 , the construction of the offline simulation generalized model includes building an offline simulation generalized model based on the online mechanism model facility, including all types of facilities of the online mechanism model.

参照图4,所述模型参数校正包括:Referring to Figure 4, the model parameter correction includes:

①在线机理模型的参数率定;①The parameter calibration of the online mechanism model;

②简化在线机理模型的参数率定;② simplify the parameter calibration of the online mechanism model;

③离线仿真概化模型中各模块的设定参数校正。③ Correction of the setting parameters of each module in the off-line simulation generalized model.

所述设施间逻辑关系建立包括:所建模块间的逻辑规则,包括进出水流量关系,最大进/排水能力与流量关系等。The establishment of the logical relationship between the facilities includes: logical rules between the built modules, including the relationship between the inflow and outflow water flow, the maximum inflow/drainage capacity and the flow relationship, and the like.

所述通讯指令关系建立包括:The establishment of the communication instruction relationship includes:

①各设施的状态参数上传关系;①The uploading relationship of the status parameters of each facility;

②中央控制器的指令下达关系;②The relationship between the order of the central controller;

③局部控制器的指令下达模块;③The instruction issuing module of the local controller;

④无线信号模拟;④ Wireless signal simulation;

⑤外部指令接入模拟。⑤ External command access simulation.

所述降雨过程建立包括:The rainfall process establishment includes:

①外部降雨文件的调用;① Calling of external rainfall files;

②典型雨型数据库调用;②Typical rain database call;

③给定公式生成降雨。③ Given the formula to generate rainfall.

所述系统边界条件和控制目标建立包括:The establishment of the system boundary conditions and control objectives includes:

①系统的逻辑规则;①The logic rules of the system;

②系统的边界条件;②The boundary conditions of the system;

③系统的联合控制目标,主要包括厂网河系统的溢流,内涝和水质目标。③ The joint control objectives of the system mainly include the overflow, waterlogging and water quality objectives of the plant, network and river system.

所述优化控制方法确定包括:The determination of the optimal control method includes:

①基于优化算法(遗传算法、种群动力学算法、线性求解器法等)的控制规则及参数确定:选定受控设施;选定监测位置及所需监测的运行时间、水质、水位和流量等信息;选定优化算法及调整算法的默认参数;根据监测信息,结合系统联合控制目标,选定的优化算法将在模拟仿真过程中实时计算出受控位置的最优控制值;利用PID控制方法控制设施平稳达到控制值;① Determination of control rules and parameters based on optimization algorithms (genetic algorithm, population dynamics algorithm, linear solver method, etc.): select the controlled facility; select the monitoring location and the running time, water quality, water level and flow rate required for monitoring, etc. information; select the optimization algorithm and the default parameters of the adjustment algorithm; according to the monitoring information, combined with the joint control objective of the system, the selected optimization algorithm will calculate the optimal control value of the controlled position in real time during the simulation process; use the PID control method The control facility reaches the control value smoothly;

②基于规则控制法或模糊逻辑法的控制规则及参数确定:选定受控设施;选定监测位置及所需监测的运行时间、水质、水位和流量等信息;自动生成监测信息和控制指令的响应关系;调整响应关系作为控制依据;模拟控制时利用实时监测值和控制依据得到设施控制值;利用PID控制方法控制设施平稳达到控制值;②Determination of control rules and parameters based on rule control method or fuzzy logic method: select the controlled facility; select the monitoring location and the required monitoring information such as running time, water quality, water level and flow; automatically generate monitoring information and control instructions Response relationship; adjust response relationship as control basis; use real-time monitoring value and control basis to obtain facility control value during simulation control; use PID control method to control facility to achieve control value smoothly;

前述两种优化方法均可基于系统各位置的运行时间、深度、水头、入流、出流、积水、水质、工作状态(开度、工作流量等)信息,实现对堰、闸门、孔口、阀门、分(截)流井、泵站等设施的控制;两种优化控制方法均可以结合PID控制,实现控制值得精准平稳实现。The above two optimization methods can be based on the operating time, depth, water head, inflow, outflow, accumulated water, water quality, working status (opening, working flow, etc.) Control of valves, split (intercept) flow wells, pumping stations and other facilities; both of the two optimal control methods can be combined with PID control to achieve accurate and stable control.

参照图5所述在线机理模型、简化在线机理模型和离线仿真概化模型耦合包括:Referring to Fig. 5, the coupling of the online mechanism model, the simplified online mechanism model and the offline simulation generalized model includes:

①利用在线机理模型模拟厂网河系统的实时运行状态,将各重要节点的水量、水位和水质信息以时间序列的方式输出至简化在线机理模型;①Using the online mechanism model to simulate the real-time operation state of the plant, network and river system, and output the water volume, water level and water quality information of each important node to the simplified online mechanism model in a time series manner;

②简化在线机理模型根据输入的状态数据,模拟未来时间段内的系统运行情况,将各重要节点的水量、水位和水质信息以时间序列的方式输出离线仿真概化模型;②Simplified online mechanism model According to the input state data, the system operation in the future time period is simulated, and the water volume, water level and water quality information of each important node are output to the offline simulation generalized model in the form of time series;

③离线仿真概化模型依据选定的控制目标和优化方法,根据输入数据,对模拟时间段内的厂网河系统运行进行优化调控,计算出系统最优运行状态下的控制策略;③The offline simulation generalized model optimizes and controls the operation of the plant, network and river system in the simulation time period according to the selected control objective and optimization method, and according to the input data, and calculates the control strategy under the optimal operation state of the system;

④将计算出的控制策略传回在线机理模型,在最优控制策略下进行模拟,得到实时优化控制效果,完成一个时间步长下的仿真控制。④ Send the calculated control strategy back to the online mechanism model, simulate under the optimal control strategy, obtain the real-time optimal control effect, and complete the simulation control under one time step.

所述联合调度实时仿真模拟包括:The joint scheduling real-time simulation simulation includes:

①自定义时间步长下的联合调度实时仿真;①Real-time simulation of joint scheduling under custom time step;

②所选定的控制目标和方法下的联合调度实时仿真。② Real-time simulation of joint scheduling under the selected control objective and method.

所述数据分析展示包括:The data analysis presentation includes:

①各节点的数据记录和调用;①Data recording and calling of each node;

②通用性指标的计算;②Calculation of generality indicators;

③自定义公式计算;③ Calculate by custom formula;

④常见数据图表生成。④Generation of common data charts.

参照图6,本发明提出了一种综合性的城市排水系统联合调度实时仿真控制方法的所用系统,该系统包括在线机理模型模块、在线机理模型简化模块、设施编辑和管理模块、模型参数校正模块、目标优化控制模块和模拟和结果展示模块。Referring to FIG. 6 , the present invention proposes a system for a comprehensive real-time simulation control method for joint dispatching of urban drainage systems. The system includes an online mechanism model module, an online mechanism model simplification module, a facility editing and management module, and a model parameter correction module. , target optimization control module and simulation and result display module.

所述系统实施过程包括:The system implementation process includes:

S10:构建排水系统在线机理模块;S10: Build the online mechanism module of the drainage system;

S20:在线机理模型简化模块;S20: online mechanism model simplification module;

S30:构建离线仿真概化模块;S30: Build an offline simulation generalization module;

S40:校正模型参数;S40: Correction model parameters;

S50:建立设施间逻辑关系;S50: Establish a logical relationship between facilities;

S60:建立通讯指令关系;S60: establish a communication command relationship;

S70:建立降雨过程;S70: establish a rainfall process;

S80:建立系统边界条件和控制目标;S80: Establish system boundary conditions and control objectives;

S90:选择优化控制方法;S90: select the optimal control method;

S100:在线机理模型、简化在线机理模型和离线仿真模型耦合;S100: Coupling of online mechanism model, simplified online mechanism model and offline simulation model;

S110:进行联合调度实时仿真模拟;S110: perform a real-time simulation simulation of joint scheduling;

S120:数据分析展示。S120: Data analysis display.

1、S10:构建排水系统在线机理模块,该模块用于模拟排水系统的实时运行状态,为仿真控制提供边界条件和校正参考。在本实例中,使用在线机理模型模块,完整导入现有的SWMM模型文件。1. S10: Build the online mechanism module of the drainage system, which is used to simulate the real-time operating state of the drainage system and provide boundary conditions and correction references for simulation control. In this example, an existing SWMM model file is fully imported using the online mechanism model module.

2、S20:在线机理模型简化模块,该模块用于模拟未来时间段内排水系统的运行状态。在本实例中,使用机理模型简化模块,将机理模型简化,得到线性化的模型文件,过程包括:将在线机理模型模块内设施合并、删除或简化;修改汇水区、管道和河道模型参数,生成符合线性化要求的模型;修改闸门、孔口等设施的模型参数,生成符合过程曲线线性化要求的模型。2. S20: the online mechanism model simplification module, which is used to simulate the operation state of the drainage system in the future time period. In this example, the mechanism model simplification module is used to simplify the mechanism model to obtain a linearized model file. The process includes: merging, deleting or simplifying the facilities in the online mechanism model module; Generate a model that meets the linearization requirements; modify the model parameters of gates, orifices and other facilities to generate a model that meets the linearization requirements of the process curve.

3、S30:构建离线仿真概化模块,该模块用于制定优化控制策略。在本实例中,使用设施编辑和管理模块构建离线仿真概化模型:离线仿真概化模型包括管道模块,LID模块,井模块,孔口闸阀模块,蓄水模块,泵模块,污水处理厂模块,河道模块以及通信控制模块。其中,管道模块模拟管网系统中的雨水管道,污水管道,合流管道,其它连通管道,以及具有一定调蓄能力管道;LID模块模拟系统中LID设施,包括雨水花园,渗透性植草沟,生态旱溪,下沉式绿地等常见LID设施类型;井模块模拟分流井,截流井,检查井等常见设施;孔口闸阀模块包括常见的孔口,各式闸门,各式阀门等;蓄水模块模拟调蓄池,调蓄管道等调蓄设施;泵模块模拟各式水泵及泵站前池水位;污水处理厂模块模拟污水处理厂的处理能力,分级结构以及处理效果;河道模块模拟河道水位、水量和水质;通信控制模块设定系统各设施间的数据和指令的传递规则。3. S30: Build an offline simulation generalization module, which is used to formulate an optimal control strategy. In this example, an offline simulation generalized model is constructed using the facility editing and management module: the offline simulation generalized model includes a pipeline module, a LID module, a well module, an orifice gate valve module, a water storage module, a pump module, a sewage treatment plant module, Channel module and communication control module. Among them, the pipeline module simulates rainwater pipelines, sewage pipelines, confluence pipelines, other connecting pipelines, and pipelines with certain storage capacity in the pipe network system; the LID module simulates the LID facilities in the system, including rain gardens, permeable grass ditch, ecological drought Common LID facility types such as creeks and sunken green spaces; the well module simulates common facilities such as diversion wells, interception wells, and inspection wells; the orifice gate valve module includes common orifices, various gates, and various valves; the water storage module simulates Adjustment and storage facilities such as adjustment and storage tanks, adjustment and storage pipelines; the pump module simulates the water level of various pumps and the front pool of the pumping station; the sewage treatment plant module simulates the treatment capacity, grading structure and treatment effect of the sewage treatment plant; the river module simulates the water level and water volume of the river and water quality; the communication control module sets the transmission rules of data and instructions between the various facilities of the system.

4、S40:校正模型参数。在本实例中,使用模型参数校正模块调整模型参数:使用实地监测数据,进行在线机理模型参数和简化在线机理模型参数率定,以及离线仿真概化模型的参数校正。通过参数调整,使模型能够真实准确地反应实际运行情况。4. S40: Correct the model parameters. In this example, model parameters are adjusted using the model parameter correction module: using field monitoring data, online mechanism model parameters and simplified online mechanism model parameter calibration, and offline simulation generalized model parameter correction. Through parameter adjustment, the model can truly and accurately reflect the actual operating conditions.

5、S50:建立设施间逻辑关系。在本实例中,使用设施编辑和管理模块建立设施间逻辑关系。5. S50: Establish a logical relationship between facilities. In this example, the facility editing and management module is used to establish logical relationships between facilities.

6、S60:建立通讯指令关系。在本实例中,使用设施编辑和管理模块建立通讯指令关系,设置中央控制器和局部控制器,监测设备所记录的运行数据上传至中央控制器和局部控制器;中央控制器和局部控制器将运行指令下达至各受控设施。6. S60: establish a communication command relationship. In this example, use the facility editing and management module to establish the communication command relationship, set up the central controller and the local controller, and upload the operation data recorded by the monitoring equipment to the central controller and the local controller; the central controller and the local controller will Operation instructions are issued to each controlled facility.

7、S70:建立降雨过程。在本实例中,使用设施编辑和管理模块建立降雨过程,数据来源于当地的实际降雨数据。7. S70: establish a rainfall process. In this example, a rainfall process is established using the Facility Editing and Management module, and the data is derived from local actual rainfall data.

8、S80:建立系统边界条件和控制目标。在本实例中,使用目标优化模块建立系统边界条件和控制目标:系统边界条件为系统最大污水处理能力;控制目标为多重目标函数,包括削减合流制溢流量、削减内涝量和充分利用污水厂的处理能力;通过对不同控制目标进行权重分配再加和,构成多重目标函数。8. S80: Establish system boundary conditions and control objectives. In this example, the objective optimization module is used to establish the system boundary conditions and control objectives: the system boundary conditions are the maximum sewage treatment capacity of the system; the control objectives are multiple objective functions, including reducing the combined overflow and waterlogging, and making full use of the sewage treatment plant's capacity. Processing capacity; multiple objective functions are formed by weight distribution and summation of different control objectives.

9、S90:选择优化控制方法。在本实例中,使用目标优化模块选取规则控制法作为仿真运行的控制方法,之后切换多种优化算法,用以比较不同的控制方法对系统运行的影响。9. S90: select the optimal control method. In this example, the objective optimization module is used to select the rule control method as the control method for the simulation operation, and then multiple optimization algorithms are switched to compare the influence of different control methods on the system operation.

10、S100:简化在线机理模型和离线模型耦合。在本实例中,使用模拟和结果展示模块中的模型耦合功能,将简化在线机理模型、在线机理模型和离线仿真概化模型耦合。10. S100: Simplify the coupling between the online mechanism model and the offline model. In this example, the online mechanism model, online mechanism model and offline simulation generalized model coupling will be simplified using the model coupling function in the simulation and results presentation module.

11、S110:进行实时联调联控仿真模拟。在本实例中,使用模拟和结果展示模块:将模拟时间步长设为5分钟;在线机理模型对系统实时模拟运行结果作为输入数据传递至简化在线机理模型;简化在线机理模型对未来降雨的模拟运行结果作为输入数据传递至概化仿真模型;概化仿真模型通过优化控制方法,不断试算,最终计算出满足设定控制目标的最优控制策略;将最优控制策略传递至在线机理模型,在线机理模型运行最优控制策略,模拟控制效果。11. S110: perform real-time joint debugging and joint control simulation. In this example, the simulation and result display module is used: the simulation time step is set to 5 minutes; the online mechanism model transmits the real-time simulation operation results of the system as input data to the simplified online mechanism model; the simplified online mechanism model simulates future rainfall The operation results are transmitted to the generalized simulation model as input data; the generalized simulation model continuously tries and calculates by optimizing the control method, and finally calculates the optimal control strategy that satisfies the set control objectives; the optimal control strategy is transmitted to the online mechanism model, The online mechanism model runs the optimal control strategy and simulates the control effect.

12、S120:数据分析展示。在本实例中,使用模拟和结果展示模块的结果展示功能,将仿真模拟结果通过数据图像进行展示。12. S120: Data analysis display. In this example, the result display function of the simulation and result display module is used to display the simulation results through data images.

以上所述实施例仅表达了本申请的一种实施方式,其描述较为具体和详细,但并不能因此而理解为对本申请专利范围的限制。应当指出的是,对于本领域的普通技术人员来说,在不脱离本申请构思的前提下,还可以做出若干变形和改进,这些都属于本申请的保护范围。因此,本申请专利的保护范围应以所附权利要求为准。The above-mentioned embodiment only expresses an embodiment of the present application, and its description is relatively specific and detailed, but it should not be construed as a limitation on the scope of the patent of the present application. It should be pointed out that for those skilled in the art, without departing from the concept of the present application, several modifications and improvements can be made, which all belong to the protection scope of the present application. Therefore, the scope of protection of the patent of the present application shall be subject to the appended claims.

Claims (15)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010563919.7ACN111880431B (en) | 2020-06-19 | 2020-06-19 | Comprehensive urban drainage system joint scheduling real-time simulation control method and system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010563919.7ACN111880431B (en) | 2020-06-19 | 2020-06-19 | Comprehensive urban drainage system joint scheduling real-time simulation control method and system |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111880431Atrue CN111880431A (en) | 2020-11-03 |

| CN111880431B CN111880431B (en) | 2025-09-19 |

Family

ID=73157941

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010563919.7AActiveCN111880431B (en) | 2020-06-19 | 2020-06-19 | Comprehensive urban drainage system joint scheduling real-time simulation control method and system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111880431B (en) |

Cited By (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112950096A (en)* | 2021-04-27 | 2021-06-11 | 中国电建集团成都勘测设计研究院有限公司 | Integrated classification intelligent scheduling method for network and river |

| CN112989538A (en)* | 2021-03-30 | 2021-06-18 | 清华大学 | Control method and control device for urban drainage system |

| CN113406940A (en)* | 2021-07-28 | 2021-09-17 | 金盛 | Intelligent drainage grading real-time control method based on model predictive control |

| CN113722913A (en)* | 2021-08-31 | 2021-11-30 | 广州市市政工程设计研究总院有限公司 | Simulation and scheduling method, system, device and storage medium of drainage system |

| CN113835357A (en)* | 2021-07-23 | 2021-12-24 | 中国市政工程华北设计研究总院有限公司 | Method for dynamically coupling water quantity and water quality with drainage pipe network mechanism model |

| CN119047724A (en)* | 2024-07-09 | 2024-11-29 | 三峡环境科技有限公司 | Scheduling decision method and system suitable for integrated management of plant, network and river |

Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103399990A (en)* | 2013-07-18 | 2013-11-20 | 北京工业大学 | Method of constructing fine discrete road grid in urban drainage simulation system |

| CN103886151A (en)* | 2014-03-27 | 2014-06-25 | 北京工业大学 | Method for establishing simplified hydraulic model of urban downward-concave overpass area under different rainstorm situations |

| CN104977855A (en)* | 2015-07-07 | 2015-10-14 | 南京南瑞集团公司 | Emulated data simulation method for reservoir operation automatic system |

| CN110276145A (en)* | 2019-06-26 | 2019-09-24 | 天津神州海创科技有限公司 | Sewerage system simulation modeling and dispatching method |

| CN110570126A (en)* | 2019-09-11 | 2019-12-13 | 福州大学 | A real-time scheduling method for rainwater storage facilities based on real-time weather information |

| WO2020117221A1 (en)* | 2018-12-05 | 2020-06-11 | Siemens Aktiengesellschaft | Improved factory scheduling system and method |

- 2020

- 2020-06-19CNCN202010563919.7Apatent/CN111880431B/enactiveActive

Patent Citations (6)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN103399990A (en)* | 2013-07-18 | 2013-11-20 | 北京工业大学 | Method of constructing fine discrete road grid in urban drainage simulation system |

| CN103886151A (en)* | 2014-03-27 | 2014-06-25 | 北京工业大学 | Method for establishing simplified hydraulic model of urban downward-concave overpass area under different rainstorm situations |

| CN104977855A (en)* | 2015-07-07 | 2015-10-14 | 南京南瑞集团公司 | Emulated data simulation method for reservoir operation automatic system |

| WO2020117221A1 (en)* | 2018-12-05 | 2020-06-11 | Siemens Aktiengesellschaft | Improved factory scheduling system and method |

| CN110276145A (en)* | 2019-06-26 | 2019-09-24 | 天津神州海创科技有限公司 | Sewerage system simulation modeling and dispatching method |

| CN110570126A (en)* | 2019-09-11 | 2019-12-13 | 福州大学 | A real-time scheduling method for rainwater storage facilities based on real-time weather information |

Non-Patent Citations (3)

| Title |

|---|

| 王静;李娜;程晓陶;: "城市洪涝仿真模型的改进与应用", 水利学报, no. 12, 15 December 2010 (2010-12-15)* |

| 罗贤伟;: "基于水力模型的智慧排水工程设计与应用", 净水技术, no. 10, 25 October 2020 (2020-10-25)* |

| 顾立忠;: "一种天然河道水面线概化计算方法", 广东水利水电, no. 07, 20 July 2018 (2018-07-20)* |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112989538A (en)* | 2021-03-30 | 2021-06-18 | 清华大学 | Control method and control device for urban drainage system |

| CN112950096A (en)* | 2021-04-27 | 2021-06-11 | 中国电建集团成都勘测设计研究院有限公司 | Integrated classification intelligent scheduling method for network and river |

| CN112950096B (en)* | 2021-04-27 | 2022-06-07 | 中国电建集团成都勘测设计研究院有限公司 | An intelligent dispatching method for integrated classification of plants, networks and rivers |

| CN113835357A (en)* | 2021-07-23 | 2021-12-24 | 中国市政工程华北设计研究总院有限公司 | Method for dynamically coupling water quantity and water quality with drainage pipe network mechanism model |

| CN113835357B (en)* | 2021-07-23 | 2023-12-22 | 中国市政工程华北设计研究总院有限公司 | Method for dynamically coupling water quantity and water quality with drainage pipe network mechanism model |

| CN113406940A (en)* | 2021-07-28 | 2021-09-17 | 金盛 | Intelligent drainage grading real-time control method based on model predictive control |

| CN113406940B (en)* | 2021-07-28 | 2024-05-17 | 金盛 | A real-time control method for intelligent drainage classification based on model predictive control |

| CN113722913A (en)* | 2021-08-31 | 2021-11-30 | 广州市市政工程设计研究总院有限公司 | Simulation and scheduling method, system, device and storage medium of drainage system |

| CN119047724A (en)* | 2024-07-09 | 2024-11-29 | 三峡环境科技有限公司 | Scheduling decision method and system suitable for integrated management of plant, network and river |

| CN119047724B (en)* | 2024-07-09 | 2025-04-01 | 三峡环境科技有限公司 | A dispatching decision method and system suitable for integrated management of plant, network and river |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111880431B (en) | 2025-09-19 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111880431A (en) | A comprehensive real-time simulation control method and system for joint dispatch of urban drainage system | |

| CN110570126B (en) | A real-time scheduling method for rainwater storage facilities based on real-time meteorological information | |

| CN110705171A (en) | A method for water environment management of tide-sensing river network based on MIKE model | |

| WO2021259009A1 (en) | Operation scheduling method and apparatus for deep sewage drainage tunnel, and computer device | |

| CN110555239B (en) | River surge sluice optimization scheduling method based on drainage pipe network model | |

| CN113050430B (en) | Drainage system control method based on robust reinforcement learning | |

| CN112799310A (en) | Method for urban drainage system simulation control mixed model based on mechanism model, concept model and data model of C language | |

| CN101692273A (en) | Modeling method of on-line hydraulic model of municipal drainage pipe network | |

| CN106202618A (en) | A kind of Project Scheduling and the method for numerical simulation of tidal river network pollutant defeated shifting PROCESS COUPLING | |

| CN112596386A (en) | Matlab-based urban drainage system simulation control mixed model with mechanism model, concept model and data model | |

| CN117314062B (en) | Multi-stage gate combined multi-target optimized water distribution scheduling method | |

| CN112101818B (en) | A flood optimization dispatching method for sponge cities with complex hydraulic connections | |

| CN114358664B (en) | Flood dispatch and water resources guarantee methods under changing environment and flood-drought abrupt change | |

| CN115907429B (en) | PSO algorithm-based combined overflow optimization control method and device | |

| CN116523269B (en) | Model predictive control-based river network dynamic intelligent regulation and control method | |

| CN118131825B (en) | Water level control method and device for throttle valve | |

| Ranjbar et al. | Framework for a digital twin of the Canal of Calais | |

| CN112632865B (en) | A control method of optimal flow velocity in inland water system | |

| CN113190945A (en) | Urban drainage pipe network optimization method based on online agent model assisted evolution algorithm | |

| CN113763204A (en) | Evaluation method of water environment improvement effect of river network water diversion project in plain area under multi-objective optimization | |

| CN117929671A (en) | Watershed water environment prediction and early warning method, system and computer equipment | |

| CN119784116B (en) | Reservoir group delivery flow prediction method considering climate change and manual regulation | |

| CN113743032A (en) | Method for determining optimal running water circulation scheme of urban river network based on MIKE 11 | |

| CN118151686A (en) | Multi-channel water level automatic control method and device | |

| CN113406940B (en) | A real-time control method for intelligent drainage classification based on model predictive control |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |