CN111876732B - A kind of molybdenum boron nitride/molybdenum sulfide nanocomposite coating and preparation method thereof - Google Patents

A kind of molybdenum boron nitride/molybdenum sulfide nanocomposite coating and preparation method thereofDownload PDFInfo

- Publication number

- CN111876732B CN111876732BCN202010555201.3ACN202010555201ACN111876732BCN 111876732 BCN111876732 BCN 111876732BCN 202010555201 ACN202010555201 ACN 202010555201ACN 111876732 BCN111876732 BCN 111876732B

- Authority

- CN

- China

- Prior art keywords

- molybdenum

- coating

- substrate

- boron nitride

- magnetron sputtering

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

- C23C14/35—Sputtering by application of a magnetic field, e.g. magnetron sputtering

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/0021—Reactive sputtering or evaporation

- C23C14/0036—Reactive sputtering

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/06—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the coating material

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

- C23C14/3407—Cathode assembly for sputtering apparatus, e.g. Target

- C—CHEMISTRY; METALLURGY

- C23—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; CHEMICAL SURFACE TREATMENT; DIFFUSION TREATMENT OF METALLIC MATERIAL; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL; INHIBITING CORROSION OF METALLIC MATERIAL OR INCRUSTATION IN GENERAL

- C23C—COATING METALLIC MATERIAL; COATING MATERIAL WITH METALLIC MATERIAL; SURFACE TREATMENT OF METALLIC MATERIAL BY DIFFUSION INTO THE SURFACE, BY CHEMICAL CONVERSION OR SUBSTITUTION; COATING BY VACUUM EVAPORATION, BY SPUTTERING, BY ION IMPLANTATION OR BY CHEMICAL VAPOUR DEPOSITION, IN GENERAL

- C23C14/00—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material

- C23C14/22—Coating by vacuum evaporation, by sputtering or by ion implantation of the coating forming material characterised by the process of coating

- C23C14/34—Sputtering

- C23C14/3435—Applying energy to the substrate during sputtering

- C23C14/345—Applying energy to the substrate during sputtering using substrate bias

- Y—GENERAL TAGGING OF NEW TECHNOLOGICAL DEVELOPMENTS; GENERAL TAGGING OF CROSS-SECTIONAL TECHNOLOGIES SPANNING OVER SEVERAL SECTIONS OF THE IPC; TECHNICAL SUBJECTS COVERED BY FORMER USPC CROSS-REFERENCE ART COLLECTIONS [XRACs] AND DIGESTS

- Y02—TECHNOLOGIES OR APPLICATIONS FOR MITIGATION OR ADAPTATION AGAINST CLIMATE CHANGE

- Y02E—REDUCTION OF GREENHOUSE GAS [GHG] EMISSIONS, RELATED TO ENERGY GENERATION, TRANSMISSION OR DISTRIBUTION

- Y02E60/00—Enabling technologies; Technologies with a potential or indirect contribution to GHG emissions mitigation

- Y02E60/30—Hydrogen technology

- Y02E60/36—Hydrogen production from non-carbon containing sources, e.g. by water electrolysis

Landscapes

- Chemical & Material Sciences (AREA)

- Chemical Kinetics & Catalysis (AREA)

- Engineering & Computer Science (AREA)

- Materials Engineering (AREA)

- Mechanical Engineering (AREA)

- Metallurgy (AREA)

- Organic Chemistry (AREA)

- Physical Vapour Deposition (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明属于材料表面涂层技术领域,具体涉及一种硼氮化钼/硫化钼纳米复合涂层及其制备方法。The invention belongs to the technical field of material surface coatings, and in particular relates to a molybdenum boron nitride/molybdenum sulfide nanocomposite coating and a preparation method thereof.

背景技术Background technique

随着切削技术的发展,特别是在一些高速切削和等特定加工情况,如深孔加工以及一些复杂的加工环境,切削液无法充分润滑冷却时,对刀具材料的性能要求更高。高速切削条件下或局部不能充分润滑冷却时,由于摩擦产生大量切削热逐渐导致刀具发生粘结磨损而失效,并使工件加工质量下降。这意味着刀具本身需要具有硬度高、耐磨性好、化学性能稳定、耐热耐氧化、摩擦系数低等特点。兼顾耐磨与抗磨特点的低摩擦系数硬质涂层,不仅可以降低工件的摩擦与磨损,减少或替代液体润滑冷却,节约设备投资,还可以避免切削液带来的环境污染,实现清洁化生产,因此是一种高效、清洁的绿色切削刀具,在现代切削加工行业拥有相当广阔的应用前景。With the development of cutting technology, especially in some high-speed cutting and other specific processing situations, such as deep hole processing and some complex processing environments, when the cutting fluid cannot fully lubricate and cool, the performance requirements for tool materials are higher. Under high-speed cutting conditions or local lubrication and cooling are not sufficient, a large amount of cutting heat due to friction will gradually cause the tool to fail due to adhesive wear and reduce the processing quality of the workpiece. This means that the tool itself needs to have the characteristics of high hardness, good wear resistance, stable chemical properties, heat resistance and oxidation resistance, and low friction coefficient. The low friction coefficient hard coating, which takes into account the characteristics of wear resistance and anti-wear, can not only reduce the friction and wear of the workpiece, reduce or replace liquid lubrication and cooling, save equipment investment, but also avoid environmental pollution caused by cutting fluid and realize cleanliness Therefore, it is an efficient and clean green cutting tool, which has a very broad application prospect in the modern cutting processing industry.

金属钼的氮化物具有较高的硬度,而摩擦系数则远低于TiN等其他过渡族金属氮化物。虽然氮化钼涂层高温下摩擦系数较低,但因为容易氧化导致强度硬度降低,耐磨性不足。通过合金化的方法在提高氮化钼涂层抗氧化性和硬度的同时,进一步降低涂层摩擦系数,可拓展其应用领域和使用工况。目前研究Mo-B-S-C-N五元涂层的文献尚未见报道。The nitride of molybdenum metal has high hardness, and the friction coefficient is much lower than that of other transition metal nitrides such as TiN. Although the molybdenum nitride coating has a low friction coefficient at high temperature, it is easy to oxidize, resulting in a decrease in strength and hardness, and insufficient wear resistance. The alloying method improves the oxidation resistance and hardness of the molybdenum nitride coating while further reducing the friction coefficient of the coating, which can expand its application field and working conditions. At present, there is no report on the literature on Mo-B-S-C-N quinary coating.

发明内容Contents of the invention

本发明的目的在于提供一种硼氮化钼/硫化钼纳米复合涂层及其制备方法,通过共溅射的方法制备出Mo-B-S-C-N五元涂层,该涂层兼备耐磨和室温及高温下低摩擦系数的特点。The object of the present invention is to provide a molybdenum boron nitride/molybdenum sulfide nano-composite coating and its preparation method. The Mo-B-S-C-N five-component coating is prepared by co-sputtering. The coating has both wear resistance and room temperature and high temperature. Features a low coefficient of friction.

为达到上述目的,本发明采用的技术方案为:In order to achieve the above object, the technical scheme adopted in the present invention is:

一种硼氮化钼/硫化钼纳米复合涂层的制备方法,包括以下步骤:A preparation method of molybdenum boron nitride/molybdenum sulfide nanocomposite coating, comprising the following steps:

1)将由金属Mo与B4C和MoS2构成的复合靶和基底分别置于磁控溅射设备真空室内的阴极和样品台上;1) The composite target and substrate composed of metal Mo, B4 C and MoS2 are respectively placed on the cathode and the sample stage in the vacuum chamber of the magnetron sputtering equipment;

2)对磁控溅射设备真空室抽真空,然后用氩离子溅射清洗基底表面;2) Vacuumize the vacuum chamber of the magnetron sputtering equipment, and then clean the substrate surface with argon ion sputtering;

3)向磁控溅射设备真空室内通入氩气和氮气,磁控溅射复合靶,并在沉积过程中用氮离子对沉积中的涂层进行辅助轰击,得到硼氮化钼/硫化钼纳米复合涂层。3) Argon and nitrogen are introduced into the vacuum chamber of the magnetron sputtering equipment, the magnetron sputtering composite target is used, and nitrogen ions are used to assist the bombardment of the deposited coating during the deposition process to obtain molybdenum boron nitride/molybdenum sulfide nanocomposite coating.

所述的复合靶中的金属Mo与(B4C和MoS2)的面积比为10:1~7:3,其中B4C和MoS2面积比为5:1~1:5,Mo的纯度为99.99%、B4C和MoS2的纯度为99.9%,复合靶与基底间的距离为80~120mm。The area ratio of metal Mo to (B4 C and MoS2 ) in the composite target is 10:1 to 7:3, wherein the area ratio of B4 C and MoS2 is 5:1 to 1:5, and the area ratio of Mo The purity is 99.99%, the purity of B4 C and MoS2 is 99.9%, and the distance between the composite target and the substrate is 80-120mm.

所述的基底为金属基底或陶瓷基底,其中金属基底为钢、铸铁或硬质合金。The base is a metal base or a ceramic base, wherein the metal base is steel, cast iron or hard alloy.

所述步骤2)中将磁控溅射设备真空室内的真空度抽到≤5×10-4Pa后,基底加负偏压400~800V,利用氩离子溅射清洗基底表面至少10min。In the step 2), after the vacuum degree in the vacuum chamber of the magnetron sputtering equipment is evacuated to ≤5×10-4 Pa, a negative bias voltage of 400-800V is applied to the substrate, and the surface of the substrate is cleaned by argon ion sputtering for at least 10 minutes.

所述步骤3)中通入的氩气和氮气的流量比为1:1~1:10,工作气压为0.1~2Pa。The flow ratio of argon and nitrogen fed in the step 3) is 1:1-1:10, and the working pressure is 0.1-2Pa.

所述步骤3)中磁控溅射的功率为100~300W,时间为120~240min。The power of the magnetron sputtering in the step 3) is 100-300W, and the time is 120-240min.

所述步骤3)中在沉积过程中基底加负偏压40V~120V,利用氮离子和氩离子对沉积中的涂层进行辅助轰击。In the step 3), a negative bias voltage of 40V-120V is applied to the substrate during the deposition process, and nitrogen ions and argon ions are used to assist bombardment of the coating being deposited.

所述步骤3)中在磁控溅射结束后,停止通入氩气和氮气,保持真空状态,至基底温度≤60℃。In the step 3), after the magnetron sputtering is finished, the flow of argon and nitrogen is stopped, and the vacuum state is maintained until the substrate temperature is ≤60°C.

所述的硼氮化钼/硫化钼纳米复合涂层的制备方法制得的硼氮化钼/硫化钼纳米复合涂层,该硼氮化钼/硫化钼纳米复合涂层为Mo-B-S-C-N五元涂层,其中Mo元素的原子百分比为55~40%,N元素的原子百分比为42~24%,B元素的原子百分比为0.5~12%,C元素的原子百分比为2~14%,S元素的原子百分比为0.5~10%。The molybdenum boron nitride/molybdenum sulfide nanocomposite coating prepared by the preparation method of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating is Mo-B-S-C-N five-element Coating, wherein the atomic percentage of Mo element is 55-40%, the atomic percentage of N element is 42-24%, the atomic percentage of B element is 0.5-12%, the atomic percentage of C element is 2-14%, and the atomic percentage of S element is The atomic percentage is 0.5 to 10%.

该硼氮化钼/硫化钼纳米复合涂层的硬度为19~27GPa,常温下的摩擦系数≥0.19,600℃时的摩擦系数≥0.15。The hardness of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating is 19-27GPa, the friction coefficient at normal temperature is ≥0.19, and the friction coefficient at 600°C is ≥0.15.

相对于现有技术,本发明的有益效果为:Compared with the prior art, the beneficial effects of the present invention are:

本发明提供的硼氮化钼/硫化钼纳米复合涂层的制备方法,在氮化钼涂层的基础上,选用了合适的金属Mo与B4C及MoS2复合靶以及相应的溅射工艺参数,采用反应磁控溅射技术阴极溅射金属Mo与B4C和MoS2复合靶,并与真空室中Ar和N2混合气体中的N2气反应,在基底表面形成了获得了B、C、S元素含量适当的Mo-B-S-C-N五元硬质涂层,即硼氮化钼/硫化钼纳米复合涂层,通过调节复合靶中B4C与MoS2靶所占的面积,使得该涂层中B和S的含量容易控制,并且该方法工艺简单,易于实施。The preparation method of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating provided by the present invention, on the basis of the molybdenum nitride coating, selects a suitable composite target of metal Mo and B4 C and MoS2 and the corresponding sputtering process Parameters, using reactive magnetron sputtering technology to cathode sputter metal Mo with B4 C and MoS2 composite target, and react with N2 gas in the mixed gas of Ar and N2 in the vacuum chamber, forming a B on the surface of the substrate Mo-BSCN five-component hard coating with appropriate content of , C, and S elements, that is, molybdenum boron nitride/molybdenum sulfide nanocomposite coating, by adjusting the area occupied by B4 C and MoS2 targets in the composite target, the The content of B and S in the coating is easy to control, and the method is simple in process and easy to implement.

本发明提供的硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元硬质涂层),其中B、C、S、Mo、N元素的原子百分比分别为0.5~12%、2~14%、0.5~10%、55~40%、42~24%。该涂层克服了现有硬质镀层性能摩擦学性能方面的不足,兼备硬度高、耐磨以及室温和高温下低摩擦系数的特点,使其在高速切削或干切削工具上具有良好的推广应用前景。Molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-B-S-C-N five-element hard coating) provided by the present invention, wherein the atomic percentages of B, C, S, Mo, N elements are respectively 0.5~12%, 2~ 14%, 0.5-10%, 55-40%, 42-24%. The coating overcomes the deficiencies in the tribological properties of existing hard coatings, and has the characteristics of high hardness, wear resistance and low friction coefficient at room temperature and high temperature, making it suitable for high-speed cutting or dry cutting tools. prospect.

进一步通过实验发现,本发明制得的硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元硬质涂层)的硬度可以达到27GPa,室温下摩擦系数低至0.19,600℃摩擦系数可低至0.15,并且磨损率不到氮化钼涂层的1/80。It is further found through experiments that the hardness of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-B-S-C-N five-component hard coating) prepared by the present invention can reach 27GPa, and the friction coefficient is as low as 0.19 at room temperature, and the friction coefficient at 600 ° C It can be as low as 0.15, and the wear rate is less than 1/80 of that of molybdenum nitride coating.

附图说明Description of drawings

图1为本发明使用的由金属Mo与B4C和MoS2构成的复合靶的结构示意图;Fig. 1 is the structural representation of the compound target that is made of metal Mo and B4 C and MoS2 used in the present invention;

图2为本发明制得的硼氮化钼/硫化钼纳米复合涂层的XRD图;Fig. 2 is the XRD figure of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating that the present invention makes;

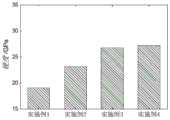

图3为本发明制得的硼氮化钼/硫化钼纳米复合涂层的硬度与B、S含量的关系图;Fig. 3 is the relationship figure of hardness and B, S content of molybdenum boron nitride/molybdenum sulfide nanocomposite coating that the present invention makes;

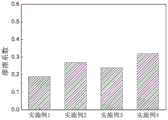

图4为常温下本发明制得的硼氮化钼/硫化钼纳米复合涂层的平均摩擦系数与B、S含量的关系图。Fig. 4 is a graph showing the relationship between the average friction coefficient and the B and S contents of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating prepared by the present invention at room temperature.

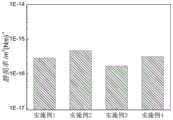

图5为常温下本发明制得的硼氮化钼/硫化钼纳米复合涂层的磨损率与B、S含量的关系图。Fig. 5 is a graph showing the relationship between the wear rate and the B and S contents of the molybdenum boronitride/molybdenum sulfide nanocomposite coating prepared by the present invention at room temperature.

图6为600℃下本发明制得的硼氮化钼/硫化钼纳米复合涂层的平均摩擦系数与B、S含量的关系图。Fig. 6 is a graph showing the relationship between the average friction coefficient and the B and S contents of the molybdenum boronitride/molybdenum sulfide nanocomposite coating prepared at 600°C.

图7为600℃下本发明制得的硼氮化钼/硫化钼纳米复合涂层的磨损率与B、S含量的关系图。Fig. 7 is a graph showing the relationship between the wear rate and the B and S contents of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating prepared by the present invention at 600°C.

具体实施方式Detailed ways

本发明制备硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元涂层),采用钼靶(纯度99.99%)和B4C靶(纯度99.9%)以及MoS2靶(纯度99.9%)制成复合靶,通过直流磁控溅射,沉积在金属、硬质合金或陶瓷的基底上,并在基底负偏压作用下利用氮离子、氩离子辅助轰击得到。制得的硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元涂层)的厚度为1~5μm,硬度为17~27GPa,常温下的摩擦系数最低为0.19,高温下(600℃)的摩擦系数最低为0.15。其中C元素的原子百分比为2~14%,B元素的原子百分比为0.5~12%,S元素的原子百分比为0.5~10%,Mo元素的原子百分比为55~40%,N元素的原子百分比为44~24%。The present invention prepares molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-BSCN five-element coating), using molybdenum target (purity 99.99%), B4 C target (purity 99.9%) and MoS2 target (purity 99.9%) ) to make a composite target, which is deposited on a metal, hard alloy or ceramic substrate by DC magnetron sputtering, and is obtained by assisting bombardment with nitrogen ions and argon ions under the negative bias of the substrate. The prepared molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-BSCN five-component coating) has a thickness of 1-5 μm, a hardness of 17-27 GPa, and a minimum friction coefficient of 0.19 at room temperature. ) has a minimum coefficient of friction of 0.15. Among them, the atomic percentage of C element is 2-14%, the atomic percentage of B element is 0.5-12%, the atomic percentage of S element is 0.5-10%, the atomic percentage of Mo element is 55-40%, and the atomic percentage of N element is 44-24%.

结合不同温度下摩擦系数和耐磨性,得出更优范围为S元素的原子百分比3~6%,B元素的原子百分比4~12%。Combining the friction coefficient and wear resistance at different temperatures, it is obtained that the atomic percentage of S element is 3-6%, and the atomic percentage of B element is 4-12%.

本发明提供的硼氮化钼/硫化钼纳米复合涂层的制备方法的具体步骤为:The specific steps of the preparation method of molybdenum boron nitride/molybdenum sulfide nanocomposite coating provided by the invention are:

1)以金属(钢、铸铁或硬质合金)或陶瓷为基底,去油、去氧化物、热风吹干后固定在真空室中的可旋转工件架上;1) Based on metal (steel, cast iron or hard alloy) or ceramics, it is fixed on the rotatable workpiece frame in the vacuum chamber after degreasing, deoxidizing, hot air drying;

2)将高纯Mo和一定数量的B4C及MoS2靶片组成的复合靶安装在磁控溅射源上;复合靶中的金属Mo与(B4C和MoS2)的面积比为10:1~7:3,其中B4C和MoS2面积比为5:1~1:5,Mo的纯度为99.99%、B4C和MoS2的纯度为99.9%,复合靶与基底间的距离为80~120mm;2) Install a composite target composed of high-purity Mo and a certain amount of B4 C and MoS2 targets on the magnetron sputtering source; the area ratio of metal Mo in the composite target to (B4 C and MoS2 ) is 10:1~7:3, where the area ratio of B4 C and MoS2 is 5:1~1:5, the purity of Mo is 99.99%, the purity of B4 C and MoS2 is 99.9%, the gap between the composite target and the substrate The distance is 80 ~ 120mm;

3)随后将真空室内真空度抽到≤5×10-4Pa,通入流量为20sccm的Ar,当真空室气压为0.3Pa时,预溅射Mo/B4C复合靶5min,预溅射的功率为150W;3) Then, the vacuum degree in the vacuum chamber was evacuated to ≤5×10-4 Pa, and the Ar flow rate was20 sccm. The power is 150W;

4)随后离子源通入6sccm氩气,基底加负偏压400-800V,用辉光放电产生的氩离子溅射清洗基底表面至少10min;4) Then the ion source is fed with 6 sccm argon gas, the substrate is negatively biased at 400-800V, and the surface of the substrate is cleaned by sputtering with argon ions generated by glow discharge for at least 10 minutes;

5)随后通入4~10sccm氩气和4~40sccm氮气,形成混合气氛,氩气与氮气间的流量比为1:1~1:10,工作气压为0.1~2Pa。5) Then, 4-10sccm argon and 4-40sccm nitrogen are introduced to form a mixed atmosphere. The flow ratio between argon and nitrogen is 1:1-1:10, and the working pressure is 0.1-2Pa.

6)真空室内在氩氮混合气氛中,以100~300W的功率溅射Mo/B4C复合靶120~240min,并对基底加40eV~120V负偏压,利用氮离子和氩离子对沉积中的涂层进行辅助轰击,制得硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元硬质涂层)。6) Sputter the Mo/B4 C composite target with a power of 100-300W for 120-240min in the mixed atmosphere of argon and nitrogen in the vacuum chamber, and apply a negative bias voltage of 40eV-120V to the substrate, and use nitrogen ions and argon ions to pair the deposition process The coating was assisted bombarded to prepare a molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-BSCN five-component hard coating).

以下结合附图和实施例详述本发明,但本发明不局限于下述实施例。The present invention is described in detail below in conjunction with accompanying drawing and embodiment, but the present invention is not limited to following embodiment.

实施例1Example 1

1)将图1中钼靶和2块B4C及2块MoS2组成的复合靶作为磁控溅射源,其中B4C与MoS2和Mo的面积比为1:1:8,复合靶与基底的距离为10cm;1) The molybdenum target in Figure 1 and the composite target composed of 2 pieces of B4 C and 2 pieces of MoS2 are used as the magnetron sputtering source, wherein the area ratio of B4 C to MoS2 and Mo is 1:1:8, and the composite The distance between the target and the substrate is 10cm;

2)选用高速钢作为基底材料,将其表面除锈抛光,并分别用丙酮、酒精和去离子水在超声波清洗器中各清洗10min后,用热风吹干并置于真空室内的样品台上;2) Select high-speed steel as the base material, derust and polish its surface, and clean it with acetone, alcohol and deionized water in an ultrasonic cleaner for 10 minutes respectively, then dry it with hot air and place it on the sample stage in the vacuum chamber;

3)真空室内真空度抽到≤5×10-4Pa后,基底加负偏压800V,用辉光放电产生的氩离子溅射清洗基底表面10min;3) After the vacuum degree in the vacuum chamber is evacuated to ≤5×10-4 Pa, apply a negative bias voltage of 800V to the substrate, and clean the surface of the substrate by argon ion sputtering generated by glow discharge for 10 minutes;

4)通入4sccm氩气和20sccm氮气,流量比为1:5,工作气压为0.8Pa,形成混合气氛,采用磁控溅射技术溅射Mo和(B4C及MoS2)复合靶,沉积过程中基底加负偏压100eV,利用氮离子对沉积中的涂层进行辅助轰击,磁控溅射的功率为200W,时间为200min,磁控溅射结束后,停止通入氩气和氮气,保持真空状态,至基底温度≤60℃,制得硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元硬质涂层)。涂层中元素的原子百分含量为48.0Mo-31.0N-5.5B-11.0C-4.5S,涂层的硬度为23.5GPa,厚度为2.0μm,常温摩擦系数为0.19,600℃时的摩擦系数为0.34。4) Introduce 4sccm argon and 20sccm nitrogen, the flow ratio is 1:5, and the working pressure is 0.8Pa to form a mixed atmosphere. Use magnetron sputtering technology to sputter Mo and (B4 C and MoS2 ) composite targets, and deposit During the process, the substrate is applied with a negative bias voltage of 100eV, and nitrogen ions are used to assist in the bombardment of the coating being deposited. The power of magnetron sputtering is 200W, and the time is 200min. Maintain a vacuum state until the substrate temperature is ≤60°C to prepare a molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-BSCN five-component hard coating). The atomic percentage content of the elements in the coating is 48.0Mo-31.0N-5.5B-11.0C-4.5S, the hardness of the coating is 23.5GPa, the thickness is 2.0μm, the friction coefficient at room temperature is 0.19, and the friction coefficient at 600°C is 0.34.

实施例2Example 2

1)将图1中钼靶和2块B4C及1块MoS2组成的复合靶作为磁控溅射源,其中B4C与MoS2和Mo的面积比为2:1:17,复合靶与基底的距离为10cm;1) The molybdenum target in Figure 1 and the composite target composed of 2 pieces of B4 C and 1 piece of MoS2 are used as the magnetron sputtering source, where the area ratio of B4 C to MoS2 and Mo is 2:1:17, and the composite The distance between the target and the substrate is 10cm;

2)选用高速钢作为基底材料,将其表面除锈抛光,并分别用丙酮、酒精和去离子水在超声波清洗器中各清洗10min后,用热风吹干并置于真空室内的样品台上;2) Select high-speed steel as the base material, derust and polish its surface, and clean it with acetone, alcohol and deionized water in an ultrasonic cleaner for 10 minutes respectively, then dry it with hot air and place it on the sample stage in the vacuum chamber;

3)真空室内真空度抽到≤5×10-4Pa后,基底加负偏压800V,用辉光放电产生的氩离子溅射清洗基底表面10min;3) After the vacuum degree in the vacuum chamber is evacuated to ≤5×10-4 Pa, apply a negative bias voltage of 800V to the substrate, and clean the surface of the substrate by argon ion sputtering generated by glow discharge for 10 minutes;

4)通入4sccm氩气和20sccm氮气,流量比为1:5,工作气压为0.8Pa,形成混合气氛,采用磁控溅射技术溅射Mo和(B4C及MoS2)复合靶,沉积过程中基底加负偏压100eV,利用氮离子对沉积中的涂层进行辅助轰击,磁控溅射的功率为190W,时间为180min,磁控溅射结束后,停止通入氩气和氮气,保持真空状态,至基底温度≤60℃,制得硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元硬质涂层)。涂层中元素的原子百分含量为52.0Mo-31.0N-4.5B-9.5C-3.0S,涂层的硬度为23.2GPa,厚度为2.1μm,常温摩擦系数为0.27,600℃时的摩擦系数为0.26。4) Introduce 4sccm argon and 20sccm nitrogen, the flow ratio is 1:5, and the working pressure is 0.8Pa to form a mixed atmosphere. Use magnetron sputtering technology to sputter Mo and (B4 C and MoS2 ) composite targets, and deposit During the process, a negative bias voltage of 100eV was applied to the substrate, and nitrogen ions were used to assist in the bombardment of the coating being deposited. The power of magnetron sputtering was 190W, and the time was 180min. Maintain a vacuum state until the substrate temperature is ≤60°C to prepare a molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-BSCN five-component hard coating). The atomic percentage content of the elements in the coating is 52.0Mo-31.0N-4.5B-9.5C-3.0S, the hardness of the coating is 23.2GPa, the thickness is 2.1μm, the friction coefficient at room temperature is 0.27, and the friction coefficient at 600°C is 0.26.

实施例3Example 3

1)将图1中钼靶和4块B4C及2块MoS2组成的复合靶作为磁控溅射源,其中B4C与MoS2和Mo的面积比为2:1:7,复合靶与基底的距离为10cm;1) The molybdenum target in Figure 1 and the composite target composed of 4 B4 C and 2 MoS2 are used as the magnetron sputtering source, where the area ratio of B4 C to MoS2 and Mo is 2:1:7, and the composite The distance between the target and the substrate is 10cm;

2)选用高速钢作为基底材料,将其表面除锈抛光,并分别用丙酮、酒精和去离子水在超声波清洗器中各清洗10min后,用热风吹干并置于真空室内的样品台上;2) Select high-speed steel as the base material, derust and polish its surface, and clean it with acetone, alcohol and deionized water in an ultrasonic cleaner for 10 minutes respectively, then dry it with hot air and place it on the sample stage in the vacuum chamber;

3)真空室内真空度抽到≤5×10-4Pa后,基底加负偏压800V,用辉光放电产生的氩离子溅射清洗基底表面10min;3) After the vacuum degree in the vacuum chamber is evacuated to ≤5×10-4 Pa, apply a negative bias voltage of 800V to the substrate, and clean the surface of the substrate by argon ion sputtering generated by glow discharge for 10 minutes;

4)通入4sccm氩气和40sccm氮气,流量比为1:10,工作气压为1.2Pa,形成混合气氛,采用磁控溅射技术溅射Mo和B4C复合靶,沉积过程中基底加负偏压100eV,利用氮离子对沉积中的涂层进行辅助轰击,磁控溅射的功率为180W,时间为120min,磁控溅射结束后,停止通入氩气和氮气,保持真空状态,至基底温度≤60℃,制得硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元硬质涂层)。涂层中元素的原子百分含量为42.0Mo-32.0N-9.5B-12.5C-4.0S,涂层的硬度为26.8GPa,厚度为1.5μm,常温摩擦系数为0.24,600℃时的摩擦系数为0.15。4) Introduce 4sccm argon and 40sccm nitrogen, the flow ratio is 1:10, and the working pressure is 1.2Pa to form a mixed atmosphere. The Mo and B4 C composite targets are sputtered by magnetron sputtering technology, and the substrate is negatively charged during the deposition process. The bias voltage is 100eV, and nitrogen ions are used to assist in the bombardment of the coating being deposited. The power of magnetron sputtering is 180W, and the time is 120min. The substrate temperature is less than or equal to 60°C, and a molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-BSCN five-component hard coating) is prepared. The atomic percentage content of the elements in the coating is 42.0Mo-32.0N-9.5B-12.5C-4.0S, the hardness of the coating is 26.8GPa, the thickness is 1.5μm, the friction coefficient at room temperature is 0.24, and the friction coefficient at 600°C is 0.15.

实施例4Example 4

1)将图1中钼靶和5块B4C及1块MoS2组成的复合靶作为磁控溅射源,其中B4C与MoS2和Mo的面积比为5:1:14,复合靶与基底的距离为10cm;1) The composite target composed of molybdenum target, 5 pieces of B4 C and 1 piece of MoS2 in Figure 1 is used as the magnetron sputtering source, where the area ratio of B4 C to MoS2 and Mo is 5:1:14, and the composite The distance between the target and the substrate is 10cm;

2)选用高速钢作为基底材料,将其表面除锈抛光,并分别用丙酮、酒精和去离子水在超声波清洗器中各清洗10min后,用热风吹干并置于真空室内的样品台上;2) Select high-speed steel as the base material, derust and polish its surface, and clean it with acetone, alcohol and deionized water in an ultrasonic cleaner for 10 minutes respectively, then dry it with hot air and place it on the sample stage in the vacuum chamber;

3)真空室内真空度抽到≤5×10-4Pa后,基底加负偏压800V,用辉光放电产生的氩离子溅射清洗基底表面10min;3) After the vacuum degree in the vacuum chamber is evacuated to ≤5×10-4 Pa, apply a negative bias voltage of 800V to the substrate, and clean the surface of the substrate by argon ion sputtering generated by glow discharge for 10 minutes;

4)通入4sccm氩气和40sccm氮气,流量比为1:10,工作气压为1.2Pa,形成混合气氛,采用磁控溅射技术溅射Mo和B4C复合靶,沉积过程中基底加负偏压90eV,利用氮离子对沉积中的涂层进行辅助轰击,磁控溅射的功率为180W,时间为240min,磁控溅射结束后,停止通入氩气和氮气,保持真空状态,至基底温度≤60℃,制得硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元硬质涂层)。涂层中元素的原子百分含量为40.0Mo-33.5N-12.B-14.0C-0.5S,涂层的硬度为27.5GPa,厚度为1.7μm,常温摩擦系数为0.32,600℃时的摩擦系数为0.20。4) Introduce 4sccm argon and 40sccm nitrogen, the flow ratio is 1:10, and the working pressure is 1.2Pa to form a mixed atmosphere. The Mo and B4 C composite targets are sputtered by magnetron sputtering technology, and the substrate is negatively charged during the deposition process. The bias voltage is 90eV, and nitrogen ions are used to assist the bombardment of the coating being deposited. The power of magnetron sputtering is 180W, and the time is 240min. The substrate temperature is less than or equal to 60°C, and a molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-BSCN five-component hard coating) is prepared. The atomic percentage of elements in the coating is 40.0Mo-33.5N-12.B-14.0C-0.5S, the hardness of the coating is 27.5GPa, the thickness is 1.7μm, the friction coefficient at room temperature is 0.32, and the friction at 600℃ The coefficient is 0.20.

实施例5Example 5

1)将钼靶和B4C及MoS2组成的复合靶作为磁控溅射源,其中B4C与MoS2和Mo的面积比为1:1:20,复合靶与基底的距离为8cm;1) The composite target composed of molybdenum target and B4 C and MoS2 is used as the magnetron sputtering source, where the area ratio of B4 C to MoS2 and Mo is 1:1:20, and the distance between the composite target and the substrate is 8cm ;

2)选用硬质合金作为基底材料,将其表面抛光,并分别用丙酮、酒精和去离子水在超声波清洗器中各清洗10min后,用热风吹干并置于真空室内的样品台上;2) Select cemented carbide as the base material, polish its surface, and clean it with acetone, alcohol and deionized water in an ultrasonic cleaner for 10 minutes respectively, then dry it with hot air and place it on the sample stage in the vacuum chamber;

3)真空室内真空度抽到≤5×10-4Pa后,基底加负偏压800V,用辉光放电产生的氩离子溅射清洗基底表面12min;3) After the vacuum degree in the vacuum chamber is evacuated to ≤5×10-4 Pa, apply a negative bias voltage of 800V to the substrate, and clean the surface of the substrate by argon ion sputtering generated by glow discharge for 12 minutes;

4)通入4sccm氩气和4sccm氮气,流量比为1:1,工作气压为0.1Pa,形成混合气氛,采用磁控溅射技术溅射Mo和B4C复合靶,沉积过程中基底加负偏压120eV,利用氮离子对沉积中的涂层进行辅助轰击,磁控溅射的功率为300W,时间为160min,磁控溅射结束后,停止通入氩气和氮气,保持真空状态,至基底温度≤60℃,制得硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元硬质涂层)。4) Introduce 4 sccm argon and 4 sccm nitrogen, the flow ratio is 1:1, and the working pressure is 0.1Pa to form a mixed atmosphere. The magnetron sputtering technology is used to sputter Mo and B4 C composite targets, and the substrate is negatively charged during the deposition process. The bias voltage is 120eV, and nitrogen ions are used to assist the bombardment of the coating being deposited. The power of magnetron sputtering is 300W, and the time is 160min. The substrate temperature is less than or equal to 60°C, and a molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-BSCN five-component hard coating) is prepared.

实施例6Example 6

1)将钼靶和B4C及MoS2组成的复合靶作为磁控溅射源,其中B4C与MoS2和Mo的面积比为1:2:7,复合靶与基底的距离为9cm;1) The composite target composed of molybdenum target and B4 C and MoS2 is used as the magnetron sputtering source, where the area ratio of B4 C to MoS2 and Mo is 1:2:7, and the distance between the composite target and the substrate is 9cm ;

2)选用铸铁作为基底材料,将其表面除锈抛光,并分别用丙酮、酒精和去离子水在超声波清洗器中各清洗10min后,用热风吹干并置于真空室内的样品台上;2) Select cast iron as the base material, derust and polish its surface, and clean it with acetone, alcohol and deionized water in an ultrasonic cleaner for 10 minutes respectively, then dry it with hot air and place it on the sample stage in the vacuum chamber;

3)真空室内真空度抽到≤5×10-4Pa后,基底加负偏压800V,用辉光放电产生的氩离子溅射清洗基底表面15min;3) After the vacuum degree in the vacuum chamber is evacuated to ≤5×10-4 Pa, apply a negative bias voltage of 800V to the substrate, and clean the surface of the substrate by argon ion sputtering generated by glow discharge for 15 minutes;

4)通入8sccm氩气和32sccm氮气,流量比为5:1,工作气压为2Pa,形成混合气氛,采用磁控溅射技术溅射Mo和B4C复合靶,沉积过程中基底加负偏压40eV,利用氮离子对沉积中的涂层进行辅助轰击,磁控溅射的功率为140W,时间为200min,磁控溅射结束后,停止通入氩气和氮气,保持真空状态,至基底温度≤60℃,制得硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元硬质涂层)。4) Introduce 8sccm argon and 32sccm nitrogen, the flow ratio is 5:1, and the working pressure is 2Pa to form a mixed atmosphere. The magnetron sputtering technology is used to sputter Mo and B4 C composite targets, and the substrate is negatively biased during the deposition process. The pressure is 40eV, and nitrogen ions are used to assist the bombardment of the coating being deposited. The power of magnetron sputtering is 140W, and the time is 200min. The temperature is less than or equal to 60°C, and a molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-BSCN five-component hard coating) is prepared.

实施例7Example 7

1)将钼靶和B4C及MoS2组成的复合靶作为磁控溅射源,其中B4C与MoS2和Mo的面积比为1:5:14,复合靶与基底的距离为11cm;1) The composite target composed of molybdenum target and B4 C and MoS2 is used as the magnetron sputtering source, where the area ratio of B4 C to MoS2 and Mo is 1:5:14, and the distance between the composite target and the substrate is 11cm ;

2)选用氧化铝陶瓷作为基底材料,将其表面磨光,并分别用丙酮、酒精和去离子水在超声波清洗器中各清洗10min后,用热风吹干并置于真空室内的样品台上;2) Select alumina ceramics as the base material, polish its surface, and clean it with acetone, alcohol, and deionized water in an ultrasonic cleaner for 10 minutes, then dry it with hot air and place it on the sample stage in the vacuum chamber;

3)真空室内真空度抽到≤5×10-4Pa后,基底加负偏压800V,用辉光放电产生的氩离子溅射清洗基底表面20min;3) After the vacuum degree in the vacuum chamber is evacuated to ≤5×10-4 Pa, apply a negative bias voltage of 800V to the substrate, and clean the surface of the substrate for 20 minutes with argon ion sputtering generated by glow discharge;

4)通入10sccm氩气和30sccm氮气,流量比为3:1,工作气压为1.6Pa,形成混合气氛,采用磁控溅射技术溅射Mo和B4C复合靶,沉积过程中基底加负偏压60eV,利用氮离子对沉积中的涂层进行辅助轰击,磁控溅射的功率为280W,时间为220min,磁控溅射结束后,停止通入氩气和氮气,保持真空状态,至基底温度≤60℃,制得硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元硬质涂层)。4) Introduce 10sccm argon and 30sccm nitrogen, the flow ratio is 3:1, and the working pressure is 1.6Pa to form a mixed atmosphere. The Mo and B4 C composite targets are sputtered by magnetron sputtering technology, and the substrate is negatively charged during the deposition process. The bias voltage is 60eV, and nitrogen ions are used to assist the bombardment of the coating being deposited. The power of magnetron sputtering is 280W, and the time is 220min. The substrate temperature is less than or equal to 60°C, and a molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-BSCN five-component hard coating) is prepared.

实施例8Example 8

1)将钼靶和B4C组成的复合靶作为磁控溅射源,其中B4C与Mo的面积比为1:15,复合靶与基底的距离为12cm;1) A composite target composed of a molybdenum target and B4 C is used as a magnetron sputtering source, wherein the area ratio of B4 C to Mo is 1:15, and the distance between the composite target and the substrate is 12 cm;

2)选用高速钢作为基底材料,将其表面除锈抛光,并分别用丙酮、酒精和去离子水在超声波清洗器中各清洗10min后,用热风吹干并置于真空室内的样品台上;2) Select high-speed steel as the base material, derust and polish its surface, and clean it with acetone, alcohol and deionized water in an ultrasonic cleaner for 10 minutes respectively, then dry it with hot air and place it on the sample stage in the vacuum chamber;

3)真空室内真空度抽到≤5×10-4Pa后,基底加负偏压700V,用辉光放电产生的氩离子溅射清洗基底表面10min;3) After the vacuum degree in the vacuum chamber is evacuated to ≤5×10-4 Pa, apply a negative bias voltage of 700V to the substrate, and clean the surface of the substrate by argon ion sputtering generated by glow discharge for 10 minutes;

4)通入6sccm氩气和12sccm氮气,流量比为1:2,工作气压为0.4Pa,形成混合气氛,采用磁控溅射技术溅射Mo和B4C复合靶,沉积过程中基底加负偏压80eV,利用氮离子对沉积中的涂层进行辅助轰击,磁控溅射的功率为100W,时间为140min,磁控溅射结束后,停止通入氩气和氮气,保持真空状态,至基底温度≤60℃,制得硼氮化钼/硫化钼纳米复合涂层(Mo-B-S-C-N五元硬质涂层)。4) Introduce 6sccm argon and 12sccm nitrogen, the flow ratio is 1:2, and the working pressure is 0.4Pa to form a mixed atmosphere. The Mo and B4 C composite targets are sputtered by magnetron sputtering technology, and the substrate is negatively charged during the deposition process. The bias voltage is 80eV, and nitrogen ions are used to assist the bombardment of the coating being deposited. The power of magnetron sputtering is 100W, and the time is 140min. The substrate temperature is less than or equal to 60°C, and a molybdenum boron nitride/molybdenum sulfide nanocomposite coating (Mo-BSCN five-component hard coating) is prepared.

图2为本发明制得的硼氮化钼/硫化钼纳米复合涂层的XRD图;从图2中可以看出,Mo-B-S-C-N五元硬质涂层主要由MoN相和Mo2N相组成,涂层中还存在少量MoB和MoS2相。Fig. 2 is the XRD figure of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating that the present invention makes; As can be seen from Fig. 2, the Mo-BSCN five-component hard coating is mainly composed of MoN phase and Mo2 N phase , there are also a small amount of MoB andMoS2 phases in the coating.

图3为本发明制得的硼氮化钼/硫化钼纳米复合涂层的硬度与B、S含量的关系图,其中实施例1制得的涂层中B、S元素的原子百分含量分别为5.5%和4.5%,实施例2制得的涂层中B、S元素的原子百分含量分别为4.5%和3.0%,实施例3制得的涂层中B、S元素的原子百分含量分别为9.5%和4.0%,实施例4制得的涂层中B、S元素的原子百分含量分别为12.0%和0.5%。从图3中可以看出,添加B、S元素后形成的硼氮化钼/硫化钼纳米复合涂层的硬度均较高,且B元素含量增加,硼氮化钼/硫化钼纳米复合涂层的硬度增高,而加入S元素会降低涂层硬度。Fig. 3 is the relationship figure of hardness and B, S content of molybdenum boron nitride/molybdenum sulfide nanocomposite coating that the present invention makes, wherein the atomic percentage content of B, S element in the coating that embodiment 1 makes is respectively 5.5% and 4.5%, the atomic percentages of B and S elements are respectively 4.5% and 3.0% in the coating made in embodiment 2, and the atomic percentages of B and S elements in the coating made in embodiment 3 The contents are respectively 9.5% and 4.0%, and the atomic percent contents of B and S elements in the coating prepared in Example 4 are respectively 12.0% and 0.5%. It can be seen from Figure 3 that the hardness of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating formed after adding B and S elements is higher, and the content of B element increases, and the molybdenum boron nitride/molybdenum sulfide nanocomposite coating The hardness of the coating increases, and the addition of S element will reduce the hardness of the coating.

图4为常温下本发明制得的硼氮化钼/硫化钼纳米复合涂层的平均摩擦系数与B、S元素含量的关系图,其中实施例1制得的涂层中B、S元素的原子百分含量分别为5.5%和4.5%,实施例2制得的涂层中B、S元素的原子百分含量分别为4.5%和3.0%,实施例3制得的涂层中B、S元素的原子百分含量分别为9.5%和4.0%,实施例4制得的涂层中B、S元素的原子百分含量分别为12.0%和0.5%。从图4中可以看出,添加B、S元素后形成的硼氮化钼/硫化钼纳米复合涂层的平均摩擦系数低于0.32,且S元素含量增加,硼氮化钼/硫化钼纳米复合涂层的平均摩擦系数降低。Fig. 4 is the relationship figure of the average friction coefficient and B, S element content of the molybdenum boron nitride/molybdenum sulfide nano-composite coating that the present invention makes under normal temperature, wherein the coating of embodiment 1 makes B, the relationship figure of S element Atomic percentages are respectively 5.5% and 4.5%. The atomic percentages of B and S elements in the coating obtained in Example 2 are respectively 4.5% and 3.0%. In the coating obtained in Example 3, B and S The atomic percentages of elements are 9.5% and 4.0%, respectively, and the atomic percentages of B and S elements in the coating prepared in Example 4 are 12.0% and 0.5%, respectively. It can be seen from Figure 4 that the average friction coefficient of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating formed after adding B and S elements is lower than 0.32, and the content of S element increases, the molybdenum boron nitride/molybdenum sulfide nanocomposite The average coefficient of friction of the coating is reduced.

图5为常温下本发明制得的硼氮化钼/硫化钼纳米复合涂层的磨损率与C、B含量的关系图,其中实施例1制得的涂层中B、S元素的原子百分含量分别为5.5%和4.5%,实施例2制得的涂层中B、S元素的原子百分含量分别为4.5%和3.0%,实施例3制得的涂层中B、S元素的原子百分含量分别为9.5%和4.0%,实施例4制得的涂层中B、S元素的原子百分含量分别为12.0%和0.5%。从图5中可以看出,添加B、S元素后形成的硼氮化钼/硫化钼纳米复合涂层的磨损率较低,均在10-16m3(N·m)-1数量级,且随着B、S元素含量的增高,硼氮化钼/硫化钼纳米复合涂层的磨损率降低。Fig. 5 is the relationship figure of wear rate and C, B content of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating that the present invention makes under normal temperature, wherein the atomic hundred of B, S element in the coating that embodiment 1 makes content is respectively 5.5% and 4.5%, the atomic percent content of B, S element is respectively 4.5% and 3.0% in the coating that embodiment 2 makes, and the B, S element in the coating that embodiment 3 makes The atomic percentages are 9.5% and 4.0% respectively, and the atomic percentages of B and S elements in the coating prepared in Example 4 are 12.0% and 0.5% respectively. It can be seen from Figure 5 that the wear rate of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating formed after the addition of B and S elements is low, both on the order of 10-16 m3 (N·m)-1 , and The wear rate of molybdenum boron nitride/molybdenum sulfide nanocomposite coatings decreased with the increase of B and S element content.

图6为600℃下本发明制得的硼氮化钼/硫化钼纳米复合涂层的平均摩擦系数与C、B含量的关系图,其中实施例1制得的涂层中B、S元素的原子百分含量分别为5.5%和4.5%,实施例2制得的涂层中B、S元素的原子百分含量分别为4.5%和3.0%,实施例3制得的涂层中B、S元素的原子百分含量分别为9.5%和4.0%,实施例4制得的涂层中B、S元素的原子百分含量分别为12.0%和0.5%。从图6中可以看出,添加B、S元素后形成的硼氮化钼/硫化钼纳米复合涂层的平均摩擦系数均低于0.4,而添加较多B、S元素后形成的硼氮化钼/硫化钼纳米复合涂层的平均摩擦系数更低,说明高温下适当的C、B含量更有利于降低Mo-B-S-C-N五元硬质涂层的摩擦系数。Figure 6 is a graph showing the relationship between the average coefficient of friction and the content of C and B of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating prepared by the present invention at 600°C, wherein the content of B and S in the coating prepared in Example 1 Atomic percentages are respectively 5.5% and 4.5%. The atomic percentages of B and S elements in the coating obtained in Example 2 are respectively 4.5% and 3.0%. In the coating obtained in Example 3, B and S The atomic percentages of elements are 9.5% and 4.0%, respectively, and the atomic percentages of B and S elements in the coating prepared in Example 4 are 12.0% and 0.5%, respectively. It can be seen from Figure 6 that the average friction coefficient of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating formed after adding B and S elements is lower than 0.4, while the boron nitride nanocomposite coating formed after adding more B and S elements The average friction coefficient of the molybdenum/molybdenum sulfide nanocomposite coating is lower, indicating that the appropriate C and B content at high temperature is more conducive to reducing the friction coefficient of the Mo-B-S-C-N five-component hard coating.

图7为600℃下本发明制得的硼氮化钼/硫化钼纳米复合涂层的磨损率与C、B含量的关系图,其中实施例1制得的涂层中B、S元素的原子百分含量分别为5.5%和4.5%,实施例2制得的涂层中B、S元素的原子百分含量分别为4.5%和3.0%,实施例3制得的涂层中B、S元素的原子百分含量分别为9.5%和4.0%,实施例4制得的涂层中B、S元素的原子百分含量分别为12.0%和0.5%。从图7中可以看出,添加B、S元素后形成的硼氮化钼/硫化钼纳米复合涂层的磨损率比氮化钼有明显降低,但随着B、S元素含量的增加,硼氮化钼/硫化钼纳米复合涂层的磨损率降低,且B、S元素比例适当时磨损率仅为MoN的1/80。Figure 7 is a graph showing the relationship between the wear rate and the C and B contents of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating prepared by the present invention at 600°C, where the atoms of the B and S elements in the coating prepared in Example 1 The percentages are respectively 5.5% and 4.5%. The atomic percentages of B and S elements in the coating obtained in Example 2 are respectively 4.5% and 3.0%. In the coating obtained in Example 3, the B and S elements The atomic percentages of the elements are 9.5% and 4.0%, respectively, and the atomic percentages of B and S elements in the coating prepared in Example 4 are 12.0% and 0.5%, respectively. It can be seen from Figure 7 that the wear rate of the molybdenum boron nitride/molybdenum sulfide nanocomposite coating formed after adding B and S elements is significantly lower than that of molybdenum nitride, but with the increase of B and S elements, the boron The wear rate of molybdenum nitride/molybdenum sulfide nanocomposite coating is reduced, and the wear rate is only 1/80 of that of MoN when the ratio of B and S elements is appropriate.

Claims (8)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010555201.3ACN111876732B (en) | 2020-06-17 | 2020-06-17 | A kind of molybdenum boron nitride/molybdenum sulfide nanocomposite coating and preparation method thereof |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010555201.3ACN111876732B (en) | 2020-06-17 | 2020-06-17 | A kind of molybdenum boron nitride/molybdenum sulfide nanocomposite coating and preparation method thereof |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111876732A CN111876732A (en) | 2020-11-03 |

| CN111876732Btrue CN111876732B (en) | 2023-06-06 |

Family

ID=73156798

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010555201.3AActiveCN111876732B (en) | 2020-06-17 | 2020-06-17 | A kind of molybdenum boron nitride/molybdenum sulfide nanocomposite coating and preparation method thereof |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111876732B (en) |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61120897A (en)* | 1984-11-19 | 1986-06-07 | Nippon Telegr & Teleph Corp <Ntt> | Preparation of solid lubricant film |

| US5135808A (en)* | 1990-09-27 | 1992-08-04 | Diamonex, Incorporated | Abrasion wear resistant coated substrate product |

| CN105441890A (en)* | 2015-12-22 | 2016-03-30 | 西安交通大学 | High-temperature and low-friction-coefficient hard coating layer and preparation method thereof |

| CN105887025A (en)* | 2016-06-15 | 2016-08-24 | 济宁学院 | ZrTiN/MoS2 composite anti-friction and wear-resistant coating tool and its preparation technology |

| CN110735120A (en)* | 2019-10-31 | 2020-01-31 | 江苏科技大学 | NbN/MoSN/MoS2Hard self-lubricating nano-structure composite film and preparation method thereof |

- 2020

- 2020-06-17CNCN202010555201.3Apatent/CN111876732B/enactiveActive

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPS61120897A (en)* | 1984-11-19 | 1986-06-07 | Nippon Telegr & Teleph Corp <Ntt> | Preparation of solid lubricant film |

| US5135808A (en)* | 1990-09-27 | 1992-08-04 | Diamonex, Incorporated | Abrasion wear resistant coated substrate product |

| CN105441890A (en)* | 2015-12-22 | 2016-03-30 | 西安交通大学 | High-temperature and low-friction-coefficient hard coating layer and preparation method thereof |

| CN105887025A (en)* | 2016-06-15 | 2016-08-24 | 济宁学院 | ZrTiN/MoS2 composite anti-friction and wear-resistant coating tool and its preparation technology |

| CN110735120A (en)* | 2019-10-31 | 2020-01-31 | 江苏科技大学 | NbN/MoSN/MoS2Hard self-lubricating nano-structure composite film and preparation method thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111876732A (en) | 2020-11-03 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107130222B (en) | High-power pulsed magnetron sputtering CrAlSiN nanocomposite coating and preparation method thereof | |

| CN101798678B (en) | A Novel Superhard TiB2/c-BN Nano-Multilayer Film Prepared by Magnetron Sputtering Technology | |

| CN109023243B (en) | A kind of super tough, low friction carbon-based tool coating and preparation method thereof | |

| CN109023361B (en) | Gradient coating tool and preparation method thereof | |

| CN108677144B (en) | A kind of method for preparing aluminum-nitrogen co-doped diamond-like carbon composite film | |

| CN111647925A (en) | Micro-arc oxidation antifriction composite coating on aluminum alloy surface and preparation method thereof | |

| CN107916402A (en) | A kind of AlCrTiSiCN coating structures and preparation method thereof | |

| CN111321381B (en) | AlCrNbSiTiBN-based nano composite coating of hard alloy blade and preparation method thereof | |

| CN113981392B (en) | A Ti-Al-C MAX phase coating and low temperature phase preparation method thereof | |

| CN100572597C (en) | FeS/MoS2 nanometer multilayer film and its preparation method | |

| CN110670038A (en) | AlCrN/MoS2 nanocomposite film with self-lubricating and wear-resistant properties and preparation method thereof | |

| CN107354442B (en) | A kind of wear-reducing protective coating with hard and tough substrate surface and preparation method thereof | |

| CN106119798A (en) | The preparation method of anode film linear ion source auxiliary cubic boron nitride coated cutting tool | |

| CN106868450A (en) | A method of preparing AlTiN hard coating by modulating high power pulse magnetron sputtering | |

| CN113201719A (en) | AlCrBN hard coating prepared by modulating high-power pulse magnetron sputtering and preparation method thereof | |

| CN101921983A (en) | A kind of preparation method of W-S-C composite film | |

| CN114921754A (en) | High-thermal-conductivity wear-resistant high-entropy coating for cutting tool and preparation method thereof | |

| CN118441242B (en) | A superhard wear-resistant high entropy coating and its preparation method and application | |

| CN111876732B (en) | A kind of molybdenum boron nitride/molybdenum sulfide nanocomposite coating and preparation method thereof | |

| CN114959558A (en) | Metal-doped molybdenum disulfide high-temperature-resistant composite film and preparation method thereof | |

| CN117867447A (en) | A hard high entropy alloy nitride film material and preparation method thereof | |

| CN106835032A (en) | A kind of B Cr/ta C coated cutting tools and preparation method thereof | |

| CN102534494B (en) | Cutting tool with hard CBN coating | |

| CN114807880B (en) | A kind of nanocrystalline TaWMoCrZr refractory high-entropy alloy coating and preparation method thereof | |

| CN115821205A (en) | High-entropy alloy nitride nano composite structure hard coating with adjustable structural components and preparation method thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| TR01 | Transfer of patent right | Effective date of registration:20250520 Address after:100042 No.1, Building 1, 3rd Floor, Room 303-8, Tianshunzhuang North Road, Shijingshan District, Beijing Patentee after:Beijing Zhongfa Lingtu New Materials Research Institute Co.,Ltd. Country or region after:China Address before:710049 Xianning West Road, Shaanxi, China, No. 28, No. Patentee before:XI'AN JIAOTONG University Country or region before:China | |

| TR01 | Transfer of patent right | ||

| TR01 | Transfer of patent right | Effective date of registration:20250624 Address after:100144 Beijing Shi Jing Shan District Shi Xing Street 30 Hao Yuan 17 Building 9 Floor 907-45 (Cluster Registration) Patentee after:Beijing Lingtu Armor Shield Technology Co.,Ltd. Country or region after:China Address before:100042 No.1, Building 1, 3rd Floor, Room 303-8, Tianshunzhuang North Road, Shijingshan District, Beijing Patentee before:Beijing Zhongfa Lingtu New Materials Research Institute Co.,Ltd. Country or region before:China | |

| TR01 | Transfer of patent right |