CN111855738A - An experimental device for perspiration cooling of sintered porous dielectric materials - Google Patents

An experimental device for perspiration cooling of sintered porous dielectric materialsDownload PDFInfo

- Publication number

- CN111855738A CN111855738ACN202010735686.4ACN202010735686ACN111855738ACN 111855738 ACN111855738 ACN 111855738ACN 202010735686 ACN202010735686 ACN 202010735686ACN 111855738 ACN111855738 ACN 111855738A

- Authority

- CN

- China

- Prior art keywords

- cooling

- experimental

- pressure

- porous medium

- medium material

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Granted

Links

- 238000001816coolingMethods0.000titleclaimsabstractdescription60

- 239000003989dielectric materialSubstances0.000titleclaimsdescription6

- 239000000463materialSubstances0.000claimsabstractdescription43

- 238000010438heat treatmentMethods0.000claimsabstractdescription31

- 239000002826coolantSubstances0.000claimsabstractdescription27

- 238000012360testing methodMethods0.000claimsabstractdescription24

- 239000010453quartzSubstances0.000claimsabstractdescription13

- VYPSYNLAJGMNEJ-UHFFFAOYSA-Nsilicon dioxideInorganic materialsO=[Si]=OVYPSYNLAJGMNEJ-UHFFFAOYSA-N0.000claimsabstractdescription13

- 230000035900sweatingEffects0.000claimsabstractdescription5

- 239000005083Zinc sulfideSubstances0.000claimsdescription9

- 239000011521glassSubstances0.000claimsdescription9

- 229910052984zinc sulfideInorganic materials0.000claimsdescription9

- DRDVZXDWVBGGMH-UHFFFAOYSA-Nzinc;sulfideChemical compound[S-2].[Zn+2]DRDVZXDWVBGGMH-UHFFFAOYSA-N0.000claimsdescription9

- 238000001802infusionMethods0.000claimsdescription7

- 210000004907glandAnatomy0.000claimsdescription3

- 239000011810insulating materialSubstances0.000claims1

- 238000011160researchMethods0.000abstractdescription6

- 238000000034methodMethods0.000abstractdescription4

- 210000004243sweatAnatomy0.000abstractdescription4

- 238000012546transferMethods0.000abstractdescription4

- 230000008569processEffects0.000abstractdescription3

- 229910001220stainless steelInorganic materials0.000description6

- 239000010935stainless steelSubstances0.000description6

- 238000005516engineering processMethods0.000description5

- 238000011161developmentMethods0.000description4

- 238000010586diagramMethods0.000description3

- 230000004907fluxEffects0.000description3

- 239000012774insulation materialSubstances0.000description3

- 238000010521absorption reactionMethods0.000description2

- 230000009471actionEffects0.000description2

- 230000008859changeEffects0.000description2

- 230000000694effectsEffects0.000description2

- 238000012545processingMethods0.000description2

- 230000009286beneficial effectEffects0.000description1

- 238000009529body temperature measurementMethods0.000description1

- 239000003795chemical substances by applicationSubstances0.000description1

- 238000002474experimental methodMethods0.000description1

- 239000012530fluidSubstances0.000description1

- 238000009413insulationMethods0.000description1

- 238000005259measurementMethods0.000description1

- 230000007246mechanismEffects0.000description1

- 230000035515penetrationEffects0.000description1

- 238000005245sinteringMethods0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N25/00—Investigating or analyzing materials by the use of thermal means

- G01N25/20—Investigating or analyzing materials by the use of thermal means by investigating the development of heat, i.e. calorimetry, e.g. by measuring specific heat, by measuring thermal conductivity

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N19/00—Investigating materials by mechanical methods

Landscapes

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Investigating Or Analyzing Materials Using Thermal Means (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及一种烧结多孔介质材料发汗冷却的实验装置,属于温度、流量可控主动冷却的实验技术领域。The invention relates to an experimental device for perspiration cooling of sintered porous media materials, belonging to the experimental technical field of active cooling with controllable temperature and flow.

背景技术Background technique

航空航天技术的发展体现了一个国家最高的科技水平,随着航天航空技术的发展,飞行器的速度不断提升。高超声速飞行器是指飞行速度超过5倍音速的飞机、导弹、炮弹之类的有翼或无翼飞行器。因其具有快速打击以及突防成功率高的特点,有着巨大的军事战略价值。然而,由于飞行速度极高,气动热流密度和速度的三次方成正比,导致外壳热流密度较大,尤其是前缘承受了极高的热流密度。飞行器的头锥、机翼前缘和进气道唇口前缘等关键部位受热严重,由气动加热效应引起的极端热环境成为制约高超声速飞行器发展的一个重要难题。在这种情况下,发展有效的热防护技术尤为重要。与其他主动冷却技术相比,发汗冷却的效率更高,且需要的冷却剂用量少、冷却后表面的温度分布更均匀。多孔介质材料发汗冷却是指冷却剂在驱动压力作用下透过多孔结构到达热端表面,冷却剂经过多孔介质内部时流动吸热,当到达热端表面后在表面形成一层冷却介质薄膜,将受热结构与高温热流隔开,从而达到较好的冷却效果。The development of aerospace technology reflects the highest level of science and technology in a country. With the development of aerospace technology, the speed of aircraft continues to increase. Hypersonic aircraft refers to winged or wingless aircraft such as aircraft, missiles, and artillery shells that fly at a speed of more than 5 times the speed of sound. Because of its fast strike and high penetration success rate, it has huge military strategic value. However, due to the extremely high flight speed, the aerodynamic heat flux density is proportional to the cube of the speed, resulting in a large shell heat flux density, especially the leading edge is subjected to extremely high heat flux density. The key parts of the aircraft, such as the nose cone, the leading edge of the wing, and the leading edge of the intake lip, are severely heated. The extreme thermal environment caused by the aerodynamic heating effect has become an important problem restricting the development of hypersonic vehicles. In this case, the development of effective thermal protection technology is particularly important. Compared to other active cooling technologies, sweat cooling is more efficient, requires less coolant, and has a more uniform temperature distribution on the cooled surface. Perspiration cooling of porous media materials means that the coolant passes through the porous structure to reach the surface of the hot end under the action of driving pressure. When the coolant passes through the interior of the porous medium, it flows and absorbs heat. The heated structure is isolated from the high temperature heat flow, so as to achieve a better cooling effect.

发明内容SUMMARY OF THE INVENTION

本发明的目的是提供一种烧结多孔介质材料发汗冷却的实验装置,从宏观应用角度涉及多孔介质材料内部流动吸热的冷却问题,为揭示这些过程的物理本质,从发现流体流经多孔介质材料吸热冷却的流动换热特性出发,研究流体在多孔介质材料内部流动、相变和换热机理。The purpose of the present invention is to provide an experimental device for perspiration cooling of sintered porous media materials, which is related to the cooling problem of internal flow and heat absorption of porous media materials from the perspective of macroscopic application. Starting from the flow heat transfer characteristics of endothermic cooling, the mechanism of fluid flow, phase change and heat transfer in porous media materials is studied.

本发明解决其技术问题所采用的技术方案是:一种烧结多孔介质材料发汗冷却的实验装置,它包括加热系统、冷却系统和实验系统,它还包括一个由纳米级保温材料制作的壳体和设置在壳体中的压力罐,在壳体的上部设有一个固定有硫化锌红外玻璃板的上盖,所述加热系统在壳体內设置电阻丝石英加热管;所述压力罐设置在壳体内的底部中间位置,所述冷却系统采用高压输液泵把冷却剂箱中的冷却剂通过管道送入压力罐的冷却腔中,在压力罐的上部设有用压盖固定的多孔介质材料试验件,在冷却腔中设有一个接触多孔介质材料试验件的第一热电偶和一个位于冷却腔中间位置的第二热电偶,在压力罐外设有一个测量冷却腔中压力的压力变送器;所述实验系统用红外热像仪测量多孔介质材料试验件的温度,实验系统的温度和压力通过数据采集系统在计算机上实时储存并显示,实现加热温度控制在100-1000℃、冷却剂流量控制在10-200ml/min。The technical scheme adopted by the present invention to solve the technical problem is as follows: an experimental device for sweating and cooling of sintered porous media materials, which includes a heating system, a cooling system and an experimental system, and also includes a shell made of nano-scale thermal insulation materials and The pressure tank arranged in the shell is provided with an upper cover fixed with a zinc sulfide infrared glass plate on the upper part of the shell, and the heating system is provided with a resistance wire quartz heating tube in the shell; the pressure tank is arranged in the shell In the middle of the bottom of the body, the cooling system uses a high-pressure infusion pump to send the coolant in the coolant tank into the cooling cavity of the pressure tank through a pipeline, and a porous medium material test piece fixed with a gland is arranged on the upper part of the pressure tank. A first thermocouple contacting the test piece of porous medium material and a second thermocouple located in the middle of the cooling chamber are arranged in the cooling chamber, and a pressure transmitter for measuring the pressure in the cooling chamber is arranged outside the pressure tank; The experimental system uses an infrared thermal imager to measure the temperature of the porous medium material test piece. The temperature and pressure of the experimental system are stored and displayed in real time on the computer through the data acquisition system, so that the heating temperature is controlled at 100-1000 °C, and the coolant flow is controlled at 10-200ml/min.

所述电阻丝石英加热管设置在壳体內的上部两侧,与电阻丝石英加热管电连接的功率调节器设置在壳体的外部。The resistance wire quartz heating tube is arranged on both sides of the upper part in the casing, and the power regulator electrically connected with the resistance wire quartz heating tube is arranged outside the casing.

所述实验系统把红外热像仪、硫化锌红外玻璃板和多孔介质材料试验件设置在一直线上,所述压力变送器、第一热电偶和第二热电偶电连接数据采集器,数据采集器电连接计算机。In the experimental system, the infrared thermal imager, the zinc sulfide infrared glass plate and the porous medium material test piece are arranged in a straight line. The pressure transmitter, the first thermocouple and the second thermocouple are electrically connected to the data collector, and the data The collector is electrically connected to the computer.

本发明的有益效果是:这种烧结多孔介质材料发汗冷却的实验装置包括加热系统、冷却系统和实验系统,在壳体中设有压力罐和电阻丝石英加热管,在压力罐的上部设有用压盖固定的多孔介质材料试验件,在冷却腔中设有一个接触多孔介质材料试验件的第一热电偶和一个位于冷却腔中间位置的第二热电偶,在压力罐外设有一个测量冷却腔中压力的压力变送器;实验系统用红外热像仪测量多孔介质材料试验件的温度,实验系统的温度和压力通过数据采集系统在计算机上实时储存并显示,实现加热温度控制在100-1000℃、冷却剂流量控制在10-200ml/min。该实验装置可获得高温场中烧结多孔介质材料的发汗冷却过程,研究不同温度、不同材料、不同冷却剂流量环境下,烧结多孔介质材料的发汗冷却效率,微米级多孔结构内部及表面上热传递规律的实验研究工作,为烧结多孔介质材料发汗冷却的理论研究提供有效的支撑。The beneficial effects of the present invention are as follows: the experimental device for sweating and cooling the sintered porous medium material includes a heating system, a cooling system and an experimental system, a pressure tank and a resistance wire quartz heating tube are arranged in the shell, and an upper part of the pressure tank is provided with a A test piece of porous medium material with a fixed cover, a first thermocouple contacting the test piece of porous medium material and a second thermocouple located in the middle of the cooling cavity are arranged in the cooling chamber, and a measurement cooling device is arranged outside the pressure tank The pressure transmitter of the pressure in the cavity; the experimental system uses an infrared thermal imager to measure the temperature of the porous medium material test piece, and the temperature and pressure of the experimental system are stored and displayed on the computer in real time through the data acquisition system, so that the heating temperature can be controlled within 100- 1000℃, the coolant flow is controlled at 10-200ml/min. This experimental device can obtain the perspiration cooling process of sintered porous media materials in a high temperature field, and study the perspiration cooling efficiency of sintered porous media materials under different temperatures, different materials, and different coolant flow environments, and the heat transfer inside and on the surface of the micron-scale porous structure. The regular experimental research work provides effective support for the theoretical research on sweat cooling of sintered porous media materials.

附图说明Description of drawings

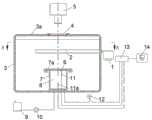

图1是一种烧结多孔介质材料发汗冷却实验系统的示意图。Figure 1 is a schematic diagram of a perspiration cooling experimental system for sintered porous dielectric materials.

图2是图1中的A-A图。FIG. 2 is an A-A diagram in FIG. 1 .

图中:1、功率调节器,2、电阻丝石英加热管,3、壳体,3a、上盖,4、硫化锌红外玻璃板,5、红外热像仪,6、多孔介质材料试验件,7、压力罐,7a、压盖,8、冷却腔,9、冷却剂箱,10、高压输液泵,11、第一热电偶,11a、第二热电偶,12、压力变送器,13、数据采集器,14、计算机。In the picture: 1. Power regulator, 2. Resistance wire quartz heating tube, 3. Housing, 3a, upper cover, 4. Zinc sulfide infrared glass plate, 5. Infrared thermal imager, 6. Porous dielectric material test piece, 7. Pressure tank, 7a, gland, 8, cooling chamber, 9, coolant tank, 10, high pressure infusion pump, 11, first thermocouple, 11a, second thermocouple, 12, pressure transmitter, 13, Data collector, 14. Computer.

具体实施方式Detailed ways

图1、2示出了一种烧结多孔介质材料发汗冷却实验系统的示意图。图中,这种烧结多孔介质材料发汗冷却的实验装置包括加热系统、冷却系统和实验系统,还包括一个由纳米级保温材料制作的壳体3和设置在壳体3中的压力罐7。Figures 1 and 2 show a schematic diagram of a perspiration cooling experimental system for sintered porous media materials. In the figure, the experimental device for sweat cooling of the sintered porous medium material includes a heating system, a cooling system and an experimental system, as well as a

在壳体3的上部设有一个固定有硫化锌红外玻璃板4的上盖3a。加热系统在壳体3內设置电阻丝石英加热管2,电阻丝石英加热管2设置在壳体3內的上部两侧,与电阻丝石英加热管2电连接的功率调节器1设置在壳体3的外部。On the upper part of the

压力罐7设置在壳体3内的底部中间位置,冷却系统采用高压输液泵10把冷却剂箱9中的冷却剂通过管道送入压力罐7的冷却腔8中,在压力罐7的上部设有用压盖7a固定的多孔介质材料试验件6,在冷却腔8中设有一个接触多孔介质材料试验件6的第一热电偶11和一个位于冷却腔8中间位置的第二热电偶11a,在压力罐7外设有一个测量冷却腔8中压力的压力变送器12。The pressure tank 7 is arranged in the middle of the bottom of the

实验系统用红外热像仪5测量多孔介质材料试验件6的温度,实验系统的温度和压力通过数据采集系统13在计算机14上实时储存并显示,实现加热温度控制在100-1000℃、冷却剂流量控制在10-200ml/min。实验系统把红外热像仪5、硫化锌红外玻璃板4和多孔介质材料试验件6设置在一直线上,压力变送器12、第一热电偶11和第二热电偶11a电连接数据采集器13,数据采集器13电连接计算机14。The experimental system uses an infrared

采用上述的技方方案,加热系统包括两套功率调节器和电阻丝石英加热管、纳米级保温材料的壳体用于保温绝热。在多孔介质材料试验件表面安装高精度热电偶测量加热温度,通过功率调节器改变加热装置,最高加热温度可达1000℃,从而实现加热温度的有效控制。Using the above technical solution, the heating system includes two sets of power regulators, resistance wire quartz heating tubes, and a shell of nanoscale thermal insulation material for thermal insulation. A high-precision thermocouple is installed on the surface of the porous medium material test piece to measure the heating temperature, and the heating device is changed by a power regulator.

试验系统的核心部分是不锈钢压力罐,多孔介质材料试验件固定在不锈钢压力罐上,不锈钢压力罐內的冷却腔可以储存冷却剂,当冷却剂填满冷却腔后流进多孔介质材料试验件,在多孔介质材料试验件内部流动吸热实现多孔介质材料发汗冷却。多孔介质材料发汗冷却是指冷却剂在驱动压力作用下透过多孔结构到达热端表面,冷却剂经过多孔介质内部时流动吸热,当到达热端表面后在表面形成一层冷却介质薄膜,将受热结构与高温热流隔开。The core part of the test system is the stainless steel pressure tank. The porous medium material test piece is fixed on the stainless steel pressure tank. The cooling cavity in the stainless steel pressure tank can store the coolant. When the coolant fills the cooling cavity, it flows into the porous medium material test piece. The perspiration cooling of the porous media material is realized by flowing heat absorption inside the porous media material test piece. Perspiration cooling of porous media materials means that the coolant passes through the porous structure to reach the surface of the hot end under the action of driving pressure. When the coolant passes through the interior of the porous medium, it flows and absorbs heat. The heated structure is isolated from the high temperature heat flow.

冷却系统包括冷却剂箱、高压输液泵和耐高温不锈钢管路,高压输液泵经冷却剂管连接冷却剂箱,通过设定高压输液泵的流量,将冷却剂泵入冷却腔中,从而实现冷却剂流量的有效控制。The cooling system includes a coolant tank, a high-pressure infusion pump and a high-temperature-resistant stainless steel pipeline. The high-pressure infusion pump is connected to the coolant tank through the coolant pipe. By setting the flow rate of the high-pressure infusion pump, the coolant is pumped into the cooling chamber to achieve cooling. Effective control of agent flow.

红外测温系统包括一个硫化锌红外玻璃和一个红外热像仪,根据红外热像仪型号选择硫化锌红外玻璃作为可视窗口,红外热像仪固定于烧结多孔介质材料板的正上方,调节好焦距和测温范围。使用过程中无需连接计算机,实验后将红外热像仪内部的SD卡与计算机连接用专业软件进行数据处理。The infrared temperature measurement system includes a zinc sulfide infrared glass and an infrared thermal imager. According to the model of the infrared thermal imager, the zinc sulfide infrared glass is selected as the visible window. Focal length and temperature range. There is no need to connect the computer during use. After the experiment, connect the SD card inside the infrared thermal imager to the computer and use professional software for data processing.

数据采集系统由压力变送器、热电偶、数据采集器及计算机组成,压力变送器与不锈钢压力罐底部引出的管路连接,测量冷却腔内冷却剂的压力,热电偶通过螺栓连接从不锈钢压力罐底部插入测量冷却剂温度。将压力变送器和热电偶与数据采集器连接,数据采集器与计算机相连,计算机安装数据采集器自带软件,以记录压力和温度数据。The data acquisition system consists of a pressure transmitter, a thermocouple, a data collector and a computer. The pressure transmitter is connected to the pipeline drawn from the bottom of the stainless steel pressure tank to measure the pressure of the coolant in the cooling chamber. The thermocouple is connected by bolts from the stainless steel. The bottom insert of the pressure tank measures the coolant temperature. The pressure transmitter and thermocouple are connected with the data collector, the data collector is connected with the computer, and the computer is installed with the software of the data collector to record the pressure and temperature data.

将数据采集器与计算机连接,更改计算机IP地址,用安装在计算机上的数据采集器自带软件设置参数,如数据类型、记录间隔时间和数据范围,将记录的数据保存至计算机中,以供后续图像处理。实验系统的温度和压力通过数据采集系统在计算机上实时储存并显示,可实现加热温度控制在100-1000℃、冷却流量控制在10-200ml/min,从而实现温度和流量可控条件下,烧结多孔介质材料发汗冷却的实验研究工作,可有效地模拟高超声速飞行器的头锥、机翼前缘和进气道唇口前缘等关键部位发汗冷却的过程,同时为多孔介质材料发汗冷却的理论研究提供有效的支撑。Connect the data collector to the computer, change the IP address of the computer, use the data collector's own software installed on the computer to set parameters, such as data type, recording interval time and data range, and save the recorded data to the computer for use. Subsequent image processing. The temperature and pressure of the experimental system are stored and displayed on the computer in real time through the data acquisition system, and the heating temperature can be controlled at 100-1000°C, and the cooling flow can be controlled at 10-200ml/min, so that the sintering can be achieved under controllable temperature and flow conditions. The experimental research work on perspiration cooling of porous media materials can effectively simulate the perspiration and cooling process of key parts such as the nose cone, leading edge of the wing and the leading edge of the air intake lip of a hypersonic vehicle. Research provides effective support.

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010735686.4ACN111855738B (en) | 2020-07-28 | 2020-07-28 | Experimental device for sintered porous medium material sweating and cooling |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010735686.4ACN111855738B (en) | 2020-07-28 | 2020-07-28 | Experimental device for sintered porous medium material sweating and cooling |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111855738Atrue CN111855738A (en) | 2020-10-30 |

| CN111855738B CN111855738B (en) | 2022-05-27 |

Family

ID=72947890

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010735686.4AActiveCN111855738B (en) | 2020-07-28 | 2020-07-28 | Experimental device for sintered porous medium material sweating and cooling |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111855738B (en) |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115901846A (en)* | 2022-11-24 | 2023-04-04 | 中国人民解放军国防科技大学 | Sweating cooling test device and method |

| CN119619221A (en)* | 2024-10-28 | 2025-03-14 | 上海交通大学 | An adjustable sweating cooling effect test system and test method thereof |

Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1026606A (en)* | 1996-07-11 | 1998-01-27 | Rigaku Corp | Method for monitoring de-fatted sintering state for method for unmolding metal powder, and method and device for simulating de-fatted sintering condition for method for unmolding metal powder |

| JP2008275588A (en)* | 2007-03-30 | 2008-11-13 | Horiba Ltd | Combustible gas sensor |

| CN102879423A (en)* | 2012-10-09 | 2013-01-16 | 北京航空航天大学 | Single-side high-temperature testing device of hypersonic aircraft material in 1800-degree aerobic environment |

| CN105352992A (en)* | 2015-10-14 | 2016-02-24 | 华东交通大学 | Method for determining thermal-conduction resistance of metal foam porous medium |

| CN105911094A (en)* | 2016-06-23 | 2016-08-31 | 哈尔滨工业大学 | Micro/nanopore material high-temperature heat transfer measuring device and high-temperature heat transfer experiment method |

| CN106872512A (en)* | 2016-12-29 | 2017-06-20 | 中南大学 | A method for testing rapid solidification behavior and solidification heat flow of metal materials |

| CN207703750U (en)* | 2017-12-26 | 2018-08-07 | 中国航天空气动力技术研究院 | Radiant heating-transpiration-cooling test device |

| CN108931551A (en)* | 2018-05-31 | 2018-12-04 | 重庆大学 | A kind of surface of solids engaging portion contact conductane measuring device |

| CN110455859A (en)* | 2019-09-10 | 2019-11-15 | 山东源瑞试验设备有限公司 | Sweat coolling test macro and test method based on oxy-acetylene platform |

- 2020

- 2020-07-28CNCN202010735686.4Apatent/CN111855738B/enactiveActive

Patent Citations (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| JPH1026606A (en)* | 1996-07-11 | 1998-01-27 | Rigaku Corp | Method for monitoring de-fatted sintering state for method for unmolding metal powder, and method and device for simulating de-fatted sintering condition for method for unmolding metal powder |

| JP2008275588A (en)* | 2007-03-30 | 2008-11-13 | Horiba Ltd | Combustible gas sensor |

| CN102879423A (en)* | 2012-10-09 | 2013-01-16 | 北京航空航天大学 | Single-side high-temperature testing device of hypersonic aircraft material in 1800-degree aerobic environment |

| CN105352992A (en)* | 2015-10-14 | 2016-02-24 | 华东交通大学 | Method for determining thermal-conduction resistance of metal foam porous medium |

| CN105911094A (en)* | 2016-06-23 | 2016-08-31 | 哈尔滨工业大学 | Micro/nanopore material high-temperature heat transfer measuring device and high-temperature heat transfer experiment method |

| CN106872512A (en)* | 2016-12-29 | 2017-06-20 | 中南大学 | A method for testing rapid solidification behavior and solidification heat flow of metal materials |

| CN207703750U (en)* | 2017-12-26 | 2018-08-07 | 中国航天空气动力技术研究院 | Radiant heating-transpiration-cooling test device |

| CN108931551A (en)* | 2018-05-31 | 2018-12-04 | 重庆大学 | A kind of surface of solids engaging portion contact conductane measuring device |

| CN110455859A (en)* | 2019-09-10 | 2019-11-15 | 山东源瑞试验设备有限公司 | Sweat coolling test macro and test method based on oxy-acetylene platform |

Non-Patent Citations (6)

| Title |

|---|

| JUNXIANG SHI: "A Numerical Investigation on the Laminar Boundary Flow Layer with Transpiration Cooling", 《TRANSPORT IN POROUS MEDIA》* |

| 丁亮: "烧结多孔介质材料发汗冷却的研究", 《中国优秀博硕士学位论文全文数据库(博士)》* |

| 吴亚东: "多孔介质相变发汗冷却主动热防护试验研究", 《宇航学报》* |

| 孟松鹤: "多孔C/C材料发汗冷却实验研究", 《固体火箭技术》* |

| 廖致远: "超声速主流平板相变发汗冷却实验研究", 《推进技术》* |

| 王炳章: "《物理世界漫游》", 31 December 2015* |

Cited By (2)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN115901846A (en)* | 2022-11-24 | 2023-04-04 | 中国人民解放军国防科技大学 | Sweating cooling test device and method |

| CN119619221A (en)* | 2024-10-28 | 2025-03-14 | 上海交通大学 | An adjustable sweating cooling effect test system and test method thereof |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111855738B (en) | 2022-05-27 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN107091798B (en) | Simulator is transformed in anxious formula hot and cold alternation coalbed methane reservoir | |

| CN114428102B (en) | Device and test method for measuring high-low temperature heat conduction physical property parameters of anisotropic material | |

| CN107884152A (en) | A kind of experimental provision and method for plane wall jet flow gaseous film control | |

| WO2020019577A1 (en) | Battery thermal runaway experiment apparatus, system, and method thereof | |

| CN111855738B (en) | Experimental device for sintered porous medium material sweating and cooling | |

| CN104748371A (en) | Resistive heater used for engine combustion chamber experiment system | |

| CN111337536B (en) | A droplet flow radiation heat transfer experimental device and method | |

| CN117493744B (en) | A method for determining experimental correlation equations for convective heat transfer of ice crystal particles | |

| CN112067240A (en) | Method for determining surface recovery enthalpy of flat model under arc wind tunnel condition | |

| CN114169077A (en) | Strong-coupling three-dimensional numerical simulation method for hot gas anti-icing of aircraft engine inlet part | |

| CN113567491A (en) | An experimental research device and method for heat transfer characteristics of high temperature heat pipe with adjustable angle | |

| CN114740042B (en) | Thermal conductivity test device and test method for molten salt nanoparticle suspension | |

| CN207585879U (en) | A kind of experimental provision for plane wall jet flow gaseous film control | |

| CN112730510A (en) | Liquid drop radiation heat exchange experimental device and method | |

| CN207148022U (en) | A kind of coal body heat conductivity measuring device | |

| CN206362728U (en) | Rapid temperature change test box with automatic defrosting device | |

| CN217424028U (en) | A device for adjusting pressure and measuring the heat transfer coefficient of water evaporation | |

| Huang et al. | Investigation of supersonic transpiration cooling through sintered metal porous flat plates | |

| CN110068140A (en) | A kind of approximation isothermal wall pipe is interior to heat high-temperature air heater | |

| CN109100392A (en) | Heat sink heating module and composite phase-change heat transfer experiment equipment | |

| CN205374351U (en) | Solid propellant temperature resistant experimental apparatus | |

| CN107843347A (en) | A kind of porous media three dimensional temperature distribution measurement method | |

| Aufdermaur et al. | A wind tunnel investigation on the local heat transfer from a sphere, including the influence of turbulence and roughness | |

| CN117741177A (en) | An airspeed measurement device and method based on heat loss | |

| Tewfik et al. | Heat transfer, recovery factor, and pressure distributions around a circular cylinder, normal to a supersonic rarefied-air stream |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant |