CN111624079A - Metallographic sample preparation robot for power plants and chemical plants - Google Patents

Metallographic sample preparation robot for power plants and chemical plantsDownload PDFInfo

- Publication number

- CN111624079A CN111624079ACN202010414479.9ACN202010414479ACN111624079ACN 111624079 ACN111624079 ACN 111624079ACN 202010414479 ACN202010414479 ACN 202010414479ACN 111624079 ACN111624079 ACN 111624079A

- Authority

- CN

- China

- Prior art keywords

- electrolyte

- turntable

- processed

- cleaning liquid

- sample preparation

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

- 239000000126substanceSubstances0.000titleclaimsabstractdescription19

- 238000002360preparation methodMethods0.000titleclaimsabstractdescription15

- 239000003792electrolyteSubstances0.000claimsabstractdescription97

- 238000003860storageMethods0.000claimsabstractdescription77

- 239000000463materialSubstances0.000claimsabstractdescription44

- 238000004140cleaningMethods0.000claimsdescription42

- 239000007788liquidSubstances0.000claimsdescription36

- 238000000034methodMethods0.000claimsdescription9

- 230000005540biological transmissionEffects0.000claimsdescription4

- 238000001514detection methodMethods0.000claimsdescription4

- 238000005259measurementMethods0.000claimsdescription4

- 210000000352storage cellAnatomy0.000claimsdescription4

- 230000005294ferromagnetic effectEffects0.000claims1

- 238000005498polishingMethods0.000abstractdescription4

- 230000009286beneficial effectEffects0.000abstractdescription2

- 238000003754machiningMethods0.000abstract1

- 239000012530fluidSubstances0.000description4

- 230000002411adverseEffects0.000description3

- 230000000694effectsEffects0.000description3

- 238000005868electrolysis reactionMethods0.000description2

- AOFYLCZPMMOVJT-UHFFFAOYSA-N[Fe]([S])([S])[S]Chemical compound[Fe]([S])([S])[S]AOFYLCZPMMOVJT-UHFFFAOYSA-N0.000description1

- 238000005260corrosionMethods0.000description1

- 239000003599detergentSubstances0.000description1

- 238000009826distributionMethods0.000description1

- 239000000284extractSubstances0.000description1

- 238000005088metallographyMethods0.000description1

Images

Classifications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N1/00—Sampling; Preparing specimens for investigation

- G01N1/28—Preparing specimens for investigation including physical details of (bio-)chemical methods covered elsewhere, e.g. G01N33/50, C12Q

- G01N1/32—Polishing; Etching

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N21/00—Investigating or analysing materials by the use of optical means, i.e. using sub-millimetre waves, infrared, visible or ultraviolet light

- G01N21/84—Systems specially adapted for particular applications

- G—PHYSICS

- G01—MEASURING; TESTING

- G01N—INVESTIGATING OR ANALYSING MATERIALS BY DETERMINING THEIR CHEMICAL OR PHYSICAL PROPERTIES

- G01N35/00—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor

- G01N35/0099—Automatic analysis not limited to methods or materials provided for in any single one of groups G01N1/00 - G01N33/00; Handling materials therefor comprising robots or similar manipulators

Landscapes

- Physics & Mathematics (AREA)

- Health & Medical Sciences (AREA)

- Life Sciences & Earth Sciences (AREA)

- Chemical & Material Sciences (AREA)

- Analytical Chemistry (AREA)

- Biochemistry (AREA)

- General Health & Medical Sciences (AREA)

- General Physics & Mathematics (AREA)

- Immunology (AREA)

- Pathology (AREA)

- Engineering & Computer Science (AREA)

- Robotics (AREA)

- Cleaning And De-Greasing Of Metallic Materials By Chemical Methods (AREA)

Abstract

Translated fromChineseDescription

Translated fromChinese技术领域technical field

本发明涉及金相技术领域,尤其涉及一种电厂及化工厂金相制样机器人。The invention relates to the technical field of metallography, in particular to a metallographic sample preparation robot for power plants and chemical plants.

背景技术Background technique

目前,电厂及化工厂中的金相试样的过程中仍需要工作人员亲手完成打磨抛光等加工过程,不仅不同水平的检验人员所制出的试样质量参差不齐,并且在材料进行打磨抛光等加工的过程中常需要使用一些化工药品,然而这些化工药品会对人体产生不良影响。At present, in the process of metallographic samples in power plants and chemical plants, staff still need to complete the processing such as grinding and polishing by themselves. Not only the quality of samples produced by inspectors of different levels is uneven, but also the materials are ground and polished. In the process of other processing, some chemicals are often used, but these chemicals will have adverse effects on the human body.

因此如何完成对材料的打磨抛光的同时,还能避免对人体产生损害,现有技术中仍缺少一种电解制样机器人。Therefore, there is still a lack of an electrolytic sample preparation robot in the prior art as to how to complete the grinding and polishing of the material while avoiding damage to the human body.

发明内容SUMMARY OF THE INVENTION

针对上述产生的问题,本发明的目的在于提供一种电厂及化工厂金相制样机器人,其特征在于,用于待加工材料,包括:In view of the above-mentioned problems, the object of the present invention is to provide a metallographic sample preparation robot for power plants and chemical plants, which is characterized in that it is used for materials to be processed, including:

一定位车;a car;

一机械臂,设置在所述定位车的上方的一侧,并与所述定位车固定连接;a mechanical arm, arranged on the upper side of the positioning vehicle and fixedly connected with the positioning vehicle;

一转盘,通过一转轴与所述机械臂连接,所述转盘中包括:A turntable is connected to the robotic arm through a shaft, and the turntable includes:

多个电解液存储槽,设置在所述转盘中,所述电解液存储槽用于存储电解液,所述电解液用于对所述待加工材料进行电解加工;a plurality of electrolyte storage tanks, arranged in the turntable, the electrolyte storage tanks are used for storing electrolyte, and the electrolyte is used for electrolytic processing of the material to be processed;

一定位装置,所述定位装置设置在所述转盘的下方,用于获取所述机械臂和所述待加工材料的位置信息,并将所述位置信息输出;a positioning device, the positioning device is arranged below the turntable, and is used for acquiring the position information of the robotic arm and the material to be processed, and outputting the position information;

所述定位车带动所述机械臂进行移动,并根据所述定位摄像装置输出的所述位置信息停止移动,所述机械臂移动并根据所述位置信息控制所述转盘转动,所述电解液存储槽中存储的所述电解液对所述待加工材料进行电解加工。The positioning vehicle drives the robotic arm to move, and stops moving according to the position information output by the positioning camera device, the robotic arm moves and controls the turntable to rotate according to the position information, and the electrolyte is stored The electrolyte stored in the tank electrolytically processes the material to be processed.

优选的,还包括:Preferably, it also includes:

一电解液存储池,设置在所述定位车上方的另一侧,用于存储电解液;an electrolyte storage tank, arranged on the other side above the positioning vehicle, for storing electrolyte;

所述电解液存储槽通过第一导管与所述电解液存储池连接,用于从所述电解液存储池中获取所述电解液。The electrolyte storage tank is connected to the electrolyte storage cell through a first conduit, and is used for obtaining the electrolyte from the electrolyte storage cell.

优选的,所述电解液存储池中设置一电解液泵。Preferably, an electrolyte pump is provided in the electrolyte storage tank.

优选的,还包括:Preferably, it also includes:

一清洁液存储池,设置在所述定位车上方的另一侧,用于存储清洁液,所述清洁液用于对电解加工后的所述待加工材料进行清洁;a cleaning liquid storage tank, disposed on the other side above the positioning vehicle, for storing cleaning liquid, and the cleaning liquid is used for cleaning the to-be-processed material after electrolytic processing;

所述转盘中还包括:The turntable also includes:

多个清洁液存储槽,设置在所述转盘中并通过第二导管与所述清洁液存储池连接,用于从所述清洁液存储池中获取所述清洁液。A plurality of cleaning liquid storage tanks are provided in the turntable and connected to the cleaning liquid storage tank through a second conduit for obtaining the cleaning liquid from the cleaning liquid storage tank.

优选的,所述清洁液存储池中设置一清洁液泵。Preferably, a cleaning fluid pump is provided in the cleaning fluid storage tank.

优选的,所述转轴为浮动转轴,所述浮动转轴用于改变所述转盘与所述机械臂之间的夹角;Preferably, the rotating shaft is a floating rotating shaft, and the floating rotating shaft is used to change the angle between the turntable and the mechanical arm;

所述机械臂根据所述位置信息控制所述浮动转轴浮动。The robotic arm controls the floating shaft to float according to the position information.

优选的,所述转盘中还包括:Preferably, the turntable also includes:

一金相显微镜,设置在所述转盘中,用于对所述待加工材料进行测量检测。A metallurgical microscope, arranged in the turntable, is used for measuring and detecting the material to be processed.

优选的,所述金相显微镜中包括:Preferably, the metallographic microscope includes:

一无线传输模块,用于获取所述金相显微镜的测量检测结果并输出。A wireless transmission module for acquiring and outputting the measurement and detection results of the metallographic microscope.

上述技术方案的有益效果是:完成对材料的打磨抛光,避免对人体产生损害。The beneficial effects of the above-mentioned technical solutions are: finishing the grinding and polishing of the material and avoiding damage to the human body.

附图说明Description of drawings

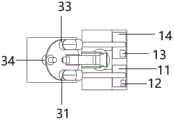

图1是本发明的一种优选实施例的俯视图;Fig. 1 is a top view of a preferred embodiment of the present invention;

图2是本发明的一种优选实施例的仰视图;2 is a bottom view of a preferred embodiment of the present invention;

图3是本发明的一种优选实施例的仰视图。Figure 3 is a bottom view of a preferred embodiment of the present invention.

具体实施方式Detailed ways

下面将结合本发明实施例中的附图,对本发明实施例中的技术方案进行清楚、完整地描述,显然,所描述的实施例仅仅是本发明一部分实施例,而不是全部的实施例。基于本发明中的实施例,本领域普通技术人员在没有作出创造性劳动的前提下所获得的所有其他实施例,都属于本发明保护的范围。The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, but not all of the embodiments. Based on the embodiments of the present invention, all other embodiments obtained by those of ordinary skill in the art without creative work fall within the protection scope of the present invention.

需要说明的是,在不冲突的情况下,本发明中的实施例及实施例中的特征可以相互组合。It should be noted that the embodiments of the present invention and the features of the embodiments may be combined with each other under the condition of no conflict.

下面结合附图和具体实施例对本发明作进一步说明,但不作为本发明的限定。The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but it is not intended to limit the present invention.

一种电厂及化工厂金相制样机器人,如图1-图3所示,用于待加工材料,包括:A metallographic sample preparation robot for power plants and chemical plants, as shown in Figures 1-3, is used for materials to be processed, including:

一定位车1;A

一机械臂2,设置在定位车1的上方的一侧,并与定位车1固定连接;a

一转盘3,通过一转轴与机械臂2连接,转盘3中包括:A

多个电解液存储槽31,设置在转盘3中,电解液存储槽31用于存储电解液,电解液用于对待加工材料进行电解加工;A plurality of

一定位装置32,定位装置32设置在转盘3的下方,用于获取机械臂和待加工材料的位置信息,并将位置信息输出;a

定位车1带动机械臂2进行移动,并根据定位摄像装置输出的位置信息停止移动,机械臂2移动并根据位置信息控制转盘3转动,电解液存储槽31中存储的电解液对待加工材料进行电解加工。The positioning

具体的,考虑到电厂、化工厂、实验室、车间中需要加工的材料过多,摆放分布过程不能完全集中在一个位置处,为实现对不同位置处的待加工材料进行加工,需要扩大机器人的使用区域。由此设置一定位车1,机械臂2设置在定位上的一侧上方,可通过预设程序控制定位车1带动机械臂2移动。Specifically, considering that there are too many materials to be processed in power plants, chemical plants, laboratories, and workshops, the placement and distribution process cannot be completely concentrated in one location. In order to process materials to be processed at different locations, it is necessary to expand the robot. area of use. Thus, a

考虑到待加工材料的规格尺寸可能过小以及在加工过程中只需要加工整个材料中的一部分区域等情况,因此需要提高加工过程中的加工位置的准确性。由此设置一定位装置32,定位装置32可设置在转盘3的下方并与转盘3连接,定位车1带动机械臂2移动过程中,也使转盘3移动,从而实现定位装置32移动。定位装置32在定位车1移动过程中,能够测量当前位置信息也就是机械臂2和装盘的位置信息,以及待加工的材料的位置信息,当机械臂2带动转盘3移动到待加工材料处,可以生成一停止指令控制定位车1停止移动,使机械臂2和转盘3一并停止移动。Considering that the size of the material to be processed may be too small and only a part of the entire material needs to be processed during the processing, it is necessary to improve the accuracy of the processing position during the processing. Therefore, a

考虑到一部分化工药品会对人体产生不良影响,因此设置一电解液存储槽31设置在转盘3中,在定位车1和定位装置32将机械臂2带动转盘3到待加工材料处,机械臂2下移带动电解液存储槽31下降,从而实现电解液存储槽31中的电解液对待加工材料的加工,于此处,常选用三硫化铁作为电解液。Considering that some chemicals will have adverse effects on the human body, an

进一步地,考虑到转盘3中设置多个电解液存储槽31,而定位装置32与需要使用的电解液存储槽31之间具有角度差,因此可对每个电解液存储槽31设置编号,并对应预设每个电解液存储槽31和定位装置32之间的角度差值,在定位装置32发送停止指令后,机械臂2可以根据定位装置32和需要使用的电解液存储槽31之间的角度需要使用的电解液存储槽31之间具有角度差,因此可对每个电解液存储槽31设置编号,并对应预设每个电解液存储槽31和定位装置32之间的角度差值,控制转轴转动,使需要使用电解液存储槽31转动对准待加工材料。Further, considering that a plurality of

进一步地,考虑到电解液存储槽31中存储大量电解液,由此于电解液存储槽31的开口处可设置电解阀,在接收到转轴转动完毕信号后,自动开启电解阀,以实现待加工材料的自动加工。Further, considering that a large amount of electrolyte is stored in the

进一步地,考虑到电解液存储槽31中电解液始终在消耗,为避免出现因电解液不足而无法完成待加工材料的加工,因此于电解液存储槽31上设置一预警部件,用于检测当前的电解液存储槽31中的电解液存储量,若小于预设预警阈值,则可对操作人员发出警示,以及时补充电解液。Further, considering that the electrolyte is always consumed in the

本发明的一种较优实施例中,还包括:In a preferred embodiment of the present invention, it also includes:

一电解液存储池11,设置在定位车1上方的另一侧,用于存储电解液;An

电解液存储槽31通过第一导管与电解液存储池11连接,用于从电解液存储池11中获取电解液。The

具体地,考虑到电解液存储槽31中电解液始终在消耗,由此于定位车1上方的另一侧设置电解液存储池11,电解液存储槽31可从电解液存储池11中获取电解液。Specifically, considering that the electrolyte in the

进一步地,为避免出现电解液存储池11中的电解液不足的情况,于电解液存储池11上设置一容量预警部件,用于检测当前的电解液存储池11中的电解液存储量,若小于预设预警阈值,则可对操作人员发出警示,以及时补充电解液。Further, in order to avoid the situation of insufficient electrolyte in the

进一步地,为避免电解液存储池11中电解液挥发过程会产生不良影响,由此可于电解液存储池11上方设置一电解液存储盖,该电解液存储盖也选用防腐材料制作。Further, in order to avoid adverse effects of the volatilization process of the electrolyte in the

本发明的一种较优实施例中,电解液存储池11中设置一电解液泵12。In a preferred embodiment of the present invention, an

具体的,由于电解液存储槽31设置在电解液存储池11上方,因此设置一电解液泵12,用于实现电解液存储槽31通过第一导管从电解液存储池11中抽取电解液。Specifically, since the

本发明的一种较优实施例中,还包括:In a preferred embodiment of the present invention, it also includes:

一清洁液存储池13,设置在定位车1上方的另一侧,用于存储清洁液,清洁液用于对电解加工后的待加工材料进行清洁;A cleaning

转盘3中还包括:Also included in Turntable 3:

多个清洁液存储槽,设置在转盘3中并通过第二导管与清洁液存储池13连接,用于从清洁液存储池13中获取清洁液。A plurality of cleaning liquid storage tanks are arranged in the

具体的,由于使用电解液对待加工材料进行加工后,电解液会残留在待加工材料表面,因此于转盘3中设置多个清洁液存储槽,可对残留的电解液进行清洁。Specifically, after using the electrolyte to process the material to be processed, the electrolyte will remain on the surface of the material to be processed. Therefore, a plurality of cleaning liquid storage tanks are arranged in the

进一步地,为避免出现清洁液存储池13中的清洁液不足的情况,因此设置在定位车1上方的另一侧上设置清洁液存储池13,清洁液存储槽可从清洁液存储池13获取清洁液。Further, in order to avoid the situation of insufficient cleaning liquid in the cleaning

本发明的一种较优实施例中,清洁液存储池13中设置一清洁液泵14。In a preferred embodiment of the present invention, a cleaning

具体的,由于清洁液存储槽设置在清洁液存储池13上方,因此设置一清洁液泵14,用于实现清洁液存储槽通过第一导管从清洁液存储池13中抽取清洁液。Specifically, since the cleaning liquid storage tank is disposed above the cleaning

本发明的一种较优实施例中,转轴为浮动转轴,浮动转轴用于改变转盘3与机械臂2之间的夹角;In a preferred embodiment of the present invention, the rotating shaft is a floating rotating shaft, and the floating rotating shaft is used to change the angle between the

机械臂2根据位置信息控制浮动转轴浮动。The

具体的,考虑到待加工材料的待加工表面不完全为平滑曲面、在不改变机械臂2的情况下先后对不同高度的待加工材料进行加工,以及对同一个待加工材料的不同高度进行同时加工等,由此,于此处选取浮动转轴实现转盘3与机械臂2之间的连接,在控制电解液存储槽31释放滴落电解液之前,可根据定位装置32获取的位置信息,调节浮动转轴,以实现转盘3与机械臂2之间的夹角改变,提高本装置的灵活性。Specifically, considering that the surface to be processed of the material to be processed is not completely a smooth curved surface, the materials to be processed of different heights are processed successively without changing the

本发明的一种较优实施例中,转盘3中还包括:In a preferred embodiment of the present invention, the

一金相显微镜4,设置在转盘3中,用于对待加工材料进行测量检测。A metallographic microscope 4, which is arranged in the

具体的,为使工作人员能够及时获取待加工材料的加工情况,可以转盘3中设置金相显微镜4,通过金相显微镜4及时获取加工情况。Specifically, in order to enable the staff to obtain the processing status of the material to be processed in time, a metallographic microscope 4 may be arranged in the

本发明的一种较优实施例中,金相显微镜4中包括:In a preferred embodiment of the present invention, the metallographic microscope 4 includes:

一无线传输模块,用于获取金相显微镜4的测量检测结果并输出。A wireless transmission module for acquiring and outputting the measurement and detection results of the metallographic microscope 4 .

具体的,考虑到化学药品对人体影响,因此待加工材料与机器人常与工作人员之间具有一定距离,由此于金相显微镜4上设置无线传输模块,用于将测量检测结果输出至工作人员。Specifically, considering the impact of chemicals on the human body, there is often a certain distance between the material to be processed and the robot and the staff. Therefore, a wireless transmission module is set on the metallographic microscope 4 for outputting the measurement and detection results to the staff. .

以上仅为本发明较佳的实施例,并非因此限制本发明的实施方式及保护范围,对于本领域技术人员而言,应当能够意识到凡运用本发明说明书及图示内容所作出的等同替换和显而易见的变化所得到的方案,均应当包含在本发明的保护范围内。The above are only preferred embodiments of the present invention, and are not intended to limit the embodiments and protection scope of the present invention. For those skilled in the art, they should be aware of the equivalent replacement and Solutions obtained by obvious changes shall all be included in the protection scope of the present invention.

Claims (8)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010414479.9ACN111624079A (en) | 2020-05-15 | 2020-05-15 | Metallographic sample preparation robot for power plants and chemical plants |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010414479.9ACN111624079A (en) | 2020-05-15 | 2020-05-15 | Metallographic sample preparation robot for power plants and chemical plants |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111624079Atrue CN111624079A (en) | 2020-09-04 |

Family

ID=72258917

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010414479.9APendingCN111624079A (en) | 2020-05-15 | 2020-05-15 | Metallographic sample preparation robot for power plants and chemical plants |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111624079A (en) |

Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4661680A (en)* | 1985-06-28 | 1987-04-28 | Westinghouse Electric Corp. | End-of-arm tooling carousel apparatus for use with a robot |

| US6571657B1 (en)* | 1999-04-08 | 2003-06-03 | Applied Materials Inc. | Multiple blade robot adjustment apparatus and associated method |

| CN1664486A (en)* | 2005-02-28 | 2005-09-07 | 中国矿业大学 | High-pressure water jet online cleaning robot technology for power plant condenser |

| CN2779328Y (en)* | 2005-02-28 | 2006-05-10 | 中国矿业大学 | High pressure water jetting online cleaning robot for power plant condenser |

| US20070221495A1 (en)* | 2006-03-23 | 2007-09-27 | Applied Materials, Inc. | Electropolish assisted electrochemical mechanical polishing apparatus |

| JP2011110629A (en)* | 2009-11-24 | 2011-06-09 | Idec Corp | Robot control method and robot control system |

| CN106843213A (en)* | 2017-02-10 | 2017-06-13 | 中国东方电气集团有限公司 | The method that a kind of movement and courses of action based on mobile robot are planned automatically |

| CN206359651U (en)* | 2016-12-16 | 2017-07-28 | 衢州学院 | A kind of EBSD samples electrobrightening equipment |

| CN107765681A (en)* | 2016-08-15 | 2018-03-06 | 深圳市朗驰欣创科技股份有限公司 | A kind of crusing robot and cruising inspection system |

| CN107812748A (en)* | 2017-12-12 | 2018-03-20 | 厦门理工学院 | A kind of sprayer cleaning device and sprayer cleaning mode |

| CN208481273U (en)* | 2018-01-05 | 2019-02-12 | 山东交通学院 | High-altitude cleaning robot with class manual work mode |

| CN209656389U (en)* | 2019-01-22 | 2019-11-19 | 湖南三德科技股份有限公司 | A kind of intelligence sample-preparing system |

| CN110977964A (en)* | 2019-11-26 | 2020-04-10 | 汕头大学 | Intelligent inspection robot for detecting micro-leakage of power plant equipment operation and detection method |

| CN212748486U (en)* | 2020-05-15 | 2021-03-19 | 王韬略 | Metallographic sample preparation robot for power plants and chemical plants |

- 2020

- 2020-05-15CNCN202010414479.9Apatent/CN111624079A/enactivePending

Patent Citations (14)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US4661680A (en)* | 1985-06-28 | 1987-04-28 | Westinghouse Electric Corp. | End-of-arm tooling carousel apparatus for use with a robot |

| US6571657B1 (en)* | 1999-04-08 | 2003-06-03 | Applied Materials Inc. | Multiple blade robot adjustment apparatus and associated method |

| CN1664486A (en)* | 2005-02-28 | 2005-09-07 | 中国矿业大学 | High-pressure water jet online cleaning robot technology for power plant condenser |

| CN2779328Y (en)* | 2005-02-28 | 2006-05-10 | 中国矿业大学 | High pressure water jetting online cleaning robot for power plant condenser |

| US20070221495A1 (en)* | 2006-03-23 | 2007-09-27 | Applied Materials, Inc. | Electropolish assisted electrochemical mechanical polishing apparatus |

| JP2011110629A (en)* | 2009-11-24 | 2011-06-09 | Idec Corp | Robot control method and robot control system |

| CN107765681A (en)* | 2016-08-15 | 2018-03-06 | 深圳市朗驰欣创科技股份有限公司 | A kind of crusing robot and cruising inspection system |

| CN206359651U (en)* | 2016-12-16 | 2017-07-28 | 衢州学院 | A kind of EBSD samples electrobrightening equipment |

| CN106843213A (en)* | 2017-02-10 | 2017-06-13 | 中国东方电气集团有限公司 | The method that a kind of movement and courses of action based on mobile robot are planned automatically |

| CN107812748A (en)* | 2017-12-12 | 2018-03-20 | 厦门理工学院 | A kind of sprayer cleaning device and sprayer cleaning mode |

| CN208481273U (en)* | 2018-01-05 | 2019-02-12 | 山东交通学院 | High-altitude cleaning robot with class manual work mode |

| CN209656389U (en)* | 2019-01-22 | 2019-11-19 | 湖南三德科技股份有限公司 | A kind of intelligence sample-preparing system |

| CN110977964A (en)* | 2019-11-26 | 2020-04-10 | 汕头大学 | Intelligent inspection robot for detecting micro-leakage of power plant equipment operation and detection method |

| CN212748486U (en)* | 2020-05-15 | 2021-03-19 | 王韬略 | Metallographic sample preparation robot for power plants and chemical plants |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| TWI741159B (en) | Surface grinding method and surface grinding device | |

| CN1075422C (en) | Automated wafer lapping system | |

| US6052653A (en) | Spreading resistance profiling system | |

| EP1710048B1 (en) | Polishing pad surface shape measuring instrument, method of using polishing pad surface shape measuring instrument, method of measuring apex angle of cone of polishing pad, method of measuring depth of groove of polishing pad, cmp polisher, and method of manufacturing semiconductor device | |

| EP2865489B1 (en) | Observation and photography apparatus | |

| JP2012501841A (en) | Apparatus for automatic catalyst exchange by multiple working steps in a reactor with a tube bundle consisting of multiple contact tubes | |

| CN103904007B (en) | Cleaning device | |

| JP5806092B2 (en) | Foil roller inspection system | |

| CN108663278A (en) | Hardness-testing device and non-transitory computer-readable medium | |

| EP0905502A2 (en) | A probe apparatus and a method for polishing a probe | |

| CN111624079A (en) | Metallographic sample preparation robot for power plants and chemical plants | |

| CN111152128A (en) | Grinding device for failed wafer | |

| CN210690361U (en) | Automatic test system for metallographic corrosion | |

| TWI754087B (en) | Grinding device | |

| CN212748486U (en) | Metallographic sample preparation robot for power plants and chemical plants | |

| CN207996820U (en) | Automatic loading and unloading system | |

| CN218191184U (en) | Probe cleaning system for wafer test | |

| JP2005294378A (en) | Apparatus and method for polishing double-surface of semiconductor wafer | |

| JP2010120130A (en) | Device, method, and control program for polishing | |

| CN220729810U (en) | Metallographic automatic corrosion device with adjustable corrosion height | |

| CN222134551U (en) | Numerical control small grinding head polishing machine with coordinate detection function | |

| JP2005279782A (en) | Machining method and apparatus | |

| CN117086735A (en) | Polishing equipment and polishing method | |

| CN222087640U (en) | Probe of alternating current fluorescent magnetic powder inspection machine | |

| US6572456B2 (en) | Bathless wafer measurement apparatus and method |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination |