CN111598366A - Real-time drilling auxiliary decision-making method and system - Google Patents

Real-time drilling auxiliary decision-making method and systemDownload PDFInfo

- Publication number

- CN111598366A CN111598366ACN201910126789.8ACN201910126789ACN111598366ACN 111598366 ACN111598366 ACN 111598366ACN 201910126789 ACN201910126789 ACN 201910126789ACN 111598366 ACN111598366 ACN 111598366A

- Authority

- CN

- China

- Prior art keywords

- drilling

- parameter

- risk

- adjustment

- cloud server

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q10/00—Administration; Management

- G06Q10/06—Resources, workflows, human or project management; Enterprise or organisation planning; Enterprise or organisation modelling

- G06Q10/063—Operations research, analysis or management

- G06Q10/0635—Risk analysis of enterprise or organisation activities

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06Q—INFORMATION AND COMMUNICATION TECHNOLOGY [ICT] SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES; SYSTEMS OR METHODS SPECIALLY ADAPTED FOR ADMINISTRATIVE, COMMERCIAL, FINANCIAL, MANAGERIAL OR SUPERVISORY PURPOSES, NOT OTHERWISE PROVIDED FOR

- G06Q50/00—Information and communication technology [ICT] specially adapted for implementation of business processes of specific business sectors, e.g. utilities or tourism

- G06Q50/02—Agriculture; Fishing; Forestry; Mining

- H—ELECTRICITY

- H04—ELECTRIC COMMUNICATION TECHNIQUE

- H04L—TRANSMISSION OF DIGITAL INFORMATION, e.g. TELEGRAPHIC COMMUNICATION

- H04L67/00—Network arrangements or protocols for supporting network services or applications

- H04L67/01—Protocols

Landscapes

- Business, Economics & Management (AREA)

- Engineering & Computer Science (AREA)

- Human Resources & Organizations (AREA)

- Economics (AREA)

- Strategic Management (AREA)

- Tourism & Hospitality (AREA)

- Theoretical Computer Science (AREA)

- General Physics & Mathematics (AREA)

- General Business, Economics & Management (AREA)

- Entrepreneurship & Innovation (AREA)

- Physics & Mathematics (AREA)

- Marketing (AREA)

- Educational Administration (AREA)

- Life Sciences & Earth Sciences (AREA)

- Operations Research (AREA)

- Game Theory and Decision Science (AREA)

- Development Economics (AREA)

- Signal Processing (AREA)

- Computer Networks & Wireless Communication (AREA)

- Quality & Reliability (AREA)

- Agronomy & Crop Science (AREA)

- Animal Husbandry (AREA)

- Marine Sciences & Fisheries (AREA)

- Mining & Mineral Resources (AREA)

- Health & Medical Sciences (AREA)

- General Health & Medical Sciences (AREA)

- Primary Health Care (AREA)

- Operation Control Of Excavators (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及油气勘探开发技术领域,具体地说,涉及一种实时钻井辅助决策方法及系统。The invention relates to the technical field of oil and gas exploration and development, in particular to a real-time drilling assistant decision-making method and system.

背景技术Background technique

随着勘探开发的不断深入,油气勘探开发难度越来越高,地质状况日益复杂,储层埋深增加,钻井工程面临的复杂风险情况越来越多,这样也就导致处理钻井风险和事故所需的成本越来越高,因此实现安全高效钻井是钻井行业的首要目标。With the deepening of exploration and development, the difficulty of oil and gas exploration and development is getting higher and higher, the geological conditions are becoming more and more complex, the reservoir depth is increasing, and the drilling engineering is facing more and more complex risks. The cost of drilling is getting higher and higher, so the realization of safe and efficient drilling is the primary goal of the drilling industry.

目前,与钻井效率和钻井风险直接相关的地层压力、井筒压力、摩阻扭矩等关键参数在钻井过程中无法应用传感器直接测量,只能应用传统计算方法基于钻井现场其他传感器数据进行计算。由于计算过程中涉及到大量数据交互及迭代计算,钻井现场工控机性能无法满足计算需求,也就无法实时计算获得这些关键参数变化趋势提供给钻井人员进行决策。因此,钻井现场施工及风险发生后的参数调控主要依靠现场司钻、钻井队长等少数人员以往的钻井经验,对于人员依赖性过强,难免在决策过程中出现失误。At present, key parameters such as formation pressure, wellbore pressure, and friction torque, which are directly related to drilling efficiency and drilling risk, cannot be directly measured by sensors during the drilling process. Since a large amount of data interaction and iterative calculation are involved in the calculation process, the performance of the IPC at the drilling site cannot meet the calculation requirements, so it is impossible to calculate and obtain the change trend of these key parameters in real time and provide it to the drilling personnel for decision-making. Therefore, the drilling site construction and parameter adjustment after risk occurrence mainly rely on the drilling experience of a few personnel such as the driller and the drilling team leader.

目前专利和文献中所提供的技术和方法主要分为两种。一种是应用灰色关联、决策树等方法基于钻井现场传感器数据变化进行风险征兆识别,另一种则是通过对井筒压力或摩阻扭矩中的某一关键参数的计算对单一风险进行识别。总体而言,目前的方法和技术均集中于钻井风险的识别预测,但是却无法为现场人员提供高效钻进和风险防控所需的调参备选方案,无法直接帮助钻井人员进行决策。The technologies and methods currently provided in patents and literature are mainly divided into two categories. One is to use grey correlation, decision tree and other methods to identify risk symptoms based on changes in drilling site sensor data, and the other is to identify a single risk by calculating a key parameter in wellbore pressure or friction torque. In general, the current methods and technologies focus on the identification and prediction of drilling risks, but they cannot provide field personnel with the parameters adjustment options required for efficient drilling and risk prevention and control, and cannot directly help drillers make decisions.

发明内容SUMMARY OF THE INVENTION

为解决上述问题,本发明提供了一种实时钻井辅助决策方法,所述方法包括:In order to solve the above problems, the present invention provides a real-time drilling assistant decision-making method, the method includes:

步骤一、在钻井端获取待分析钻井的实测数据,并将所述实测数据传输至云端服务器;Step 1: Obtain the measured data of the well to be analyzed at the drilling end, and transmit the measured data to the cloud server;

步骤二、利用云端服务器根据所述实测数据实时计算影响钻井效率和风险的关键参数在井内分布数据和/或变化情况数据;Step 2, using the cloud server to calculate the key parameters affecting drilling efficiency and risk in real time according to the measured data in the well distribution data and/or variation data;

步骤三、利用云端服务器根据所述关键参数在井内分布数据和/或变化情况数据确定当前现场施工参数条件下的钻井风险状态;Step 3, using the cloud server to determine the drilling risk state under the current site construction parameter conditions according to the key parameters in the well distribution data and/or change situation data;

步骤四、利用云端服务器根据当前现场施工参数条件下的钻井风险状态的不同,采用不同的风险识别分析模型确定不同的调参方案集,并将所述调参方案集发送至所述钻井端。Step 4: Using the cloud server to determine different sets of parameter adjustment schemes by using different risk identification and analysis models according to different drilling risk states under the current site construction parameters, and sending the set of parameter adjustment schemes to the drilling end.

根据本发明的一个实施例,所述影响钻井效率和风险的关键参数包括以下所列项中的任一项或几项:According to an embodiment of the present invention, the key parameters affecting drilling efficiency and risk include any one or more of the following items:

地层压力、井筒压力、井眼清洁度、摩阻、扭矩和机械钻速。Formation pressure, wellbore pressure, wellbore cleanliness, friction, torque and ROP.

根据本发明的一个实施例,在所述步骤四中,According to an embodiment of the present invention, in the fourth step,

如果当前现场施工参数条件下的钻进风险状态为正常状态,则采用提速调参分析模型根据所述关键参数确定提速调参方案集;If the drilling risk state under the current on-site construction parameter conditions is a normal state, the speed-up and parameter-adjustment analysis model is used to determine the speed-up and parameter-adjustment scheme set according to the key parameters;

如果当前现场施工参数条件下的钻进风险状态为风险状态,则采用风控调参分析模型根据所述关键参数确定风控调参方案集。If the drilling risk state under the current on-site construction parameter conditions is the risk state, the risk control parameter adjustment analysis model is used to determine the risk control parameter adjustment scheme set according to the key parameters.

根据本发明的一个实施例,确定提速调参方案集的步骤包括:According to an embodiment of the present invention, the step of determining the speed-increasing parameter adjustment scheme set includes:

步骤a、利用调参方案生成模型生成第一预设数量的初始提速调参方案,得到初始提速调参方案集;Step a, generating a first preset number of initial speed-up and parameter-adjustment schemes by using the parameter-adjustment scheme generation model to obtain an initial speed-up and parameter adjustment scheme set;

步骤b、基于所述初始提速调参方案集中的各个初始提速调参方案中调整后的参数,重新执行所述步骤三,确定各个初始提速调参方案下的钻井风险状态;Step b. Based on the adjusted parameters in each of the initial speed-up and parameter-adjustment schemes in the set of initial speed-up and parameter-adjustment schemes, re-execute the step 3 to determine the drilling risk state under each initial speed-up and parameter adjustment scheme;

步骤c、根据所述各个初始提速调参方案下的钻井风险状态确定所述提速调参方案集。Step c: Determine the speed-up and parameter-adjustment scheme set according to the drilling risk status under each of the initial speed-up and parameter-adjustment schemes.

根据本发明的一个实施例,在所述步骤c中,提取钻井风险状态为正常状态的初始提速调参方案,并利用所提取的初始提速调参方案形成所述提速调整方案集。According to an embodiment of the present invention, in the step c, an initial speed-up and parameter adjustment scheme whose drilling risk state is a normal state is extracted, and the speed-up adjustment scheme set is formed by using the extracted initial speed-up and parameter adjustment scheme.

根据本发明的一个实施例,确定风控调参方案集的步骤包括:According to an embodiment of the present invention, the step of determining the risk control parameter adjustment scheme set includes:

步骤d、利用调参方案生成模型生成第二预设数量的风控调参方案,得到初始风控调参方案集;Step d, generating a second preset number of risk control parameter adjustment schemes by using the parameter adjustment scheme generation model to obtain an initial set of risk control and parameter adjustment schemes;

步骤e、基于所述初始风控调参方案集中的各个初始风控调参方案中调整后的参数,重新执行所述步骤三,确定各个初始风控调参方案下的钻井风险状态;Step e, based on the adjusted parameters in each initial risk control parameter adjustment scheme in the initial risk control parameter adjustment scheme set, re-execute the step 3 to determine the drilling risk state under each initial risk control parameter adjustment scheme;

步骤f、根据所述各个初始风控调参方案下的钻井风险状态确定所述风控调参方案集。Step f: Determine the set of risk control and parameter adjustment schemes according to the drilling risk status under each of the initial risk control and parameter adjustment schemes.

本发明还提供了一种实时钻井辅助决策系统,所述系统包括:The present invention also provides a real-time drilling assistant decision-making system, the system includes:

实测数据获取装置,其设置在钻井端,用于获取待分析钻井的实测数据;an actual measured data acquisition device, which is arranged at the drilling end and is used to acquire the measured data of the well to be analyzed;

云端服务器,其与所述实测数据获取装置通信连接,用于接收所述实测数据获取装置上传的实测数据,根据所述实测数据实时计算影响钻井效率和风险的关键参数在井内分布数据和/或变化情况数据,并根据所述关键参数在井内分布数据和/或变化情况数据确定当前现场施工参数条件下的钻井风险状态,进而根据当前现场施工参数条件下的钻井风险状态的不同,采用不同的风险识别分析模型确定不同的调参方案集。A cloud server, connected in communication with the measured data acquisition device, for receiving the measured data uploaded by the measured data acquisition device, and according to the measured data to calculate in real time the key parameters affecting drilling efficiency and risk in the well distribution data and/or Change situation data, and determine the drilling risk state under the current site construction parameter conditions according to the key parameters in the well distribution data and/or change situation data, and then use different drilling risk states under the current site construction parameter conditions. The risk identification analysis model determines different sets of parameter adjustment schemes.

根据本发明的一个实施例,所述系统还包括:According to an embodiment of the present invention, the system further includes:

人机交互装置,其设置在所述钻井端并与所述云端服务器通信连接,用于接收所述云端服务器发送来的调参方案集并输出给用户。A human-computer interaction device, which is arranged on the drilling end and communicates with the cloud server, is used for receiving the parameter adjustment scheme set sent by the cloud server and outputting it to the user.

根据本发明的一个实施例,如果当前现场施工参数条件下的钻进风险状态为正常状态,所述云端服务器则配置为采用提速调参分析模型根据所述关键参数确定提速调参方案集;According to an embodiment of the present invention, if the drilling risk state under the current on-site construction parameters is a normal state, the cloud server is configured to use a speed-up and parameter-adjustment analysis model to determine a speed-up and parameter-adjustment scheme set according to the key parameters;

如果当前现场施工参数条件下的钻进风险状态为风险状态,所述云端服务器则配置为采用风控调参分析模型根据所述关键参数确定风控调参方案集。If the drilling risk state under the current on-site construction parameter condition is a risk state, the cloud server is configured to use a risk control parameter adjustment analysis model to determine a risk control parameter adjustment scheme set according to the key parameters.

根据本发明的一个实施例,所述云端服务器配置为根据如下步骤确定所述提速调参方案集:According to an embodiment of the present invention, the cloud server is configured to determine the speed-up and parameter adjustment scheme set according to the following steps:

利用调参方案生成模型生成第一预设数量的初始提速调参方案,得到初始提速调参方案集;Use the parameter tuning scheme generation model to generate a first preset number of initial speed-up and parameter-tuning schemes, and obtain an initial speed-up and parameter tuning scheme set;

基于所述初始提速调参方案集中的各个初始提速调参方案中调整后的参数,重新执行所述步骤三,确定各个初始提速调参方案下的钻井风险状态;Based on the adjusted parameters in each of the initial speed-up and parameter-adjustment schemes in the set of initial speed-up and parameter-adjustment schemes, the step 3 is re-executed to determine the drilling risk status under each initial speed-up and parameter adjustment scheme;

根据所述各个初始提速调参方案下的钻井风险状态确定所述提速调参方案集。The speed-up and parameter-adjustment scheme set is determined according to the drilling risk state under each of the initial speed-up and parameter-adjustment schemes.

目前的方法和技术均集中于钻井风险的识别预测,但是却无法为现场人员提供高效钻进和风险防控所需的调参备选方案,无法直接帮助钻井人员进行决策的问题。本发明所提供的实时钻井辅助决策方法提供了一种新的技术思路,其基于云计算技术通过应用其分布式计算与并行计算的高效性,实时计算分析与钻井效率和风险直接相关的关键参数,实时生成备选的提速/风控调参方案反馈传输至钻井现场,从而辅助钻井人员结合实际情况进行实时钻井决策,实现安全高效钻井。The current methods and technologies focus on the identification and prediction of drilling risks, but they cannot provide field personnel with options for parameter adjustment required for efficient drilling and risk prevention and control, and cannot directly help drillers make decisions. The real-time drilling assistant decision-making method provided by the present invention provides a new technical idea. Based on cloud computing technology, by applying the high efficiency of distributed computing and parallel computing, it can calculate and analyze key parameters directly related to drilling efficiency and risk in real time. , and generate alternative speed-up/wind-control parameter adjustment schemes in real time and transmit them to the drilling site, so as to assist the drillers to make real-time drilling decisions based on the actual situation and achieve safe and efficient drilling.

本发明的其它特征和优点将在随后的说明书中阐述,并且,部分地从说明书中变得显而易见,或者通过实施本发明而了解。本发明的目的和其他优点可通过在说明书、权利要求书以及附图中所特别指出的结构来实现和获得。Other features and advantages of the present invention will be set forth in the description which follows, and in part will be apparent from the description, or may be learned by practice of the invention. The objectives and other advantages of the invention may be realized and attained by the structure particularly pointed out in the description, claims and drawings.

附图说明Description of drawings

为了更清楚地说明本发明实施例或现有技术中的技术方案,下面将对实施例或现有技术描述中所需要的附图做简单的介绍:In order to more clearly illustrate the embodiments of the present invention or the technical solutions in the prior art, the accompanying drawings required in the description of the embodiments or the prior art will be briefly introduced below:

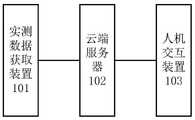

图1是根据本发明一个实施例的实时钻井辅助决策系统的结构示意图;1 is a schematic structural diagram of a real-time drilling assistant decision-making system according to an embodiment of the present invention;

图2是根据本发明一个实施例的实时钻井辅助决策方法的实现流程示意图;Fig. 2 is a schematic diagram of the implementation flow of a real-time drilling assistant decision-making method according to an embodiment of the present invention;

图3是根据本发明一个实施例的实时钻井辅助决策系统的分布示意图;3 is a schematic diagram of the distribution of a real-time drilling assistant decision-making system according to an embodiment of the present invention;

图4是根据本发明一个实施例的确定提速调参方案集的实现流程示意图。FIG. 4 is a schematic diagram of an implementation flow of determining a set of speed-up and parameter-adjustment schemes according to an embodiment of the present invention.

具体实施方式Detailed ways

以下将结合附图及实施例来详细说明本发明的实施方式,借此对本发明如何应用技术手段来解决技术问题,并达成技术效果的实现过程能充分理解并据以实施。需要说明的是,只要不构成冲突,本发明中的各个实施例以及各实施例中的各个特征可以相互结合,所形成的技术方案均在本发明的保护范围之内。The embodiments of the present invention will be described in detail below with reference to the accompanying drawings and examples, so as to fully understand and implement the implementation process of how the present invention applies technical means to solve technical problems and achieve technical effects. It should be noted that, as long as there is no conflict, each embodiment of the present invention and each feature of each embodiment can be combined with each other, and the formed technical solutions all fall within the protection scope of the present invention.

同时,在以下说明中,出于解释的目的而阐述了许多具体细节,以提供对本发明实施例的彻底理解。然而,对本领域的技术人员来说显而易见的是,本发明可以不用这里的具体细节或者所描述的特定方式来实施。Meanwhile, in the following description, for the purposes of explanation, numerous specific details are set forth in order to provide a thorough understanding of the embodiments of the present invention. It will be apparent, however, to those skilled in the art that the present invention may be practiced without the specific details or in the specific manner described herein.

另外,在附图的流程图示出的步骤可以在诸如一组计算机可执行指令的计算机系统中执行,并且,虽然在流程图中示出了逻辑顺序,但是在某些情况下,可以以不同于此处的顺序执行所示出或描述的步骤。Additionally, the steps shown in the flowcharts of the figures may be performed in a computer system, such as a set of computer-executable instructions, and, although shown in a logical order in the flowcharts, in some cases, may be executed differently The steps shown or described are performed in the order shown herein.

申请号为CN201610197209.0的专利文件公开了一种钻井风险预测方法。该方法首先会在原始数据获取步骤中获取待分析钻井的实测数据,其中实测数据包含多个影响参数的原始数据。随后,该方法会在特征向量确定步骤中对实测数据进行处理,从而得到实测数据的特征向量。在关联度系数确定步骤中,该方法会根据实测数据的特征向量和预设钻井风险判断矩阵,分别计算实测数据的特征向量的各个元素与各个故障类型的关联度系数。最后,在风险预测步骤中,该方法则会根据关联度系数计算实测数据与各个故障类型的关联度,并根据关联度判断待分析钻井是否存在风险。The patent document with the application number CN201610197209.0 discloses a drilling risk prediction method. The method first acquires the measured data of the well to be analyzed in the original data acquisition step, wherein the measured data includes the original data of multiple influencing parameters. Subsequently, the method will process the measured data in the feature vector determination step, so as to obtain the feature vector of the measured data. In the step of determining the correlation coefficient, the method calculates the correlation coefficient between each element of the eigenvector of the measured data and each fault type according to the eigenvectors of the measured data and the preset drilling risk judgment matrix. Finally, in the risk prediction step, the method calculates the correlation between the measured data and each fault type according to the correlation coefficient, and judges whether there is a risk in the well to be analyzed according to the correlation.

上述方法基于关联度来对钻进是否存在风险进行分析预测,但无法为现场工程人员提供风险控制所需的具体调参方案,也无法提供无风险状态下的高效钻进方案。The above method analyzes and predicts whether drilling risks exist based on the correlation degree, but cannot provide the specific parameter adjustment plan required for risk control for field engineers, nor can it provide an efficient drilling plan in a risk-free state.

申请号为CN201410005736.8的专利文件公开了一种钻井参数与效率实时优化方法。该方法在实施过程中,首先会进行钻井取芯,利用所建立的岩石强度模型,根据钻井液密度、性质及地层孔隙压力,判断为哪一种钻井方式。如果为气体钻井则可以直接使用单轴抗压强度,否则计算井底围压条件下岩石强度,利用录井资料计算钻头机械比能,并将计算得到的钻头机械比能与井底围压下岩石强度作对比。The patent document with the application number CN201410005736.8 discloses a real-time optimization method for drilling parameters and efficiency. During the implementation of the method, firstly, drilling and coring will be performed, and the established rock strength model will be used to determine which drilling method is used according to the density, properties and formation pore pressure of the drilling fluid. If it is gas drilling, the uniaxial compressive strength can be used directly; otherwise, the rock strength under the condition of bottom hole confining pressure is calculated, and the mechanical specific energy of the drill bit is calculated by using the logging data, and the calculated mechanical specific energy of the drill bit is compared with the bottom hole confining pressure. Rock strength for comparison.

上述方法只能对钻压和转速两个工程参数进行优化,并基于参数的临界失效点判断钻井事故,其适应的风险范围有限且无法针对风险情况给出优化调参方案。The above method can only optimize the two engineering parameters of WOB and rotational speed, and judge drilling accidents based on the critical failure point of the parameters. The scope of adaptability is limited and the optimal parameter adjustment scheme cannot be given according to the risk situation.

针对现有技术中所存在的问题,本发明提供了一种新的实时钻井辅助决策方法及系统,该方法以及系统通过应用云计算技术,在后方云服务平台对直接影响钻井效率和风险的关键参数进行高效实时同步计算,随后再基于风险识别规则通过并行计算形成多种调参备选方案,以帮助现场人员进行钻井施工决策。Aiming at the problems existing in the prior art, the present invention provides a new real-time drilling assistant decision-making method and system. By applying cloud computing technology, the method and system provide the key factors that directly affect drilling efficiency and risks in the rear cloud service platform. The parameters are efficiently and synchronously calculated in real time, and then a variety of parameter adjustment options are formed through parallel calculation based on risk identification rules to help field personnel make drilling construction decisions.

图1示出了本实施例所提供的实时钻井辅助决策系统的结构示意图,图2示出了本实施例所提供的实时钻井辅助决策方法的实现流程示意图。以下结合图1和图2来对该系统的结构、工作原理以及工作过程作进一步的阐述。FIG. 1 shows a schematic structural diagram of the real-time drilling assistant decision-making system provided by this embodiment, and FIG. 2 shows a schematic flowchart of the implementation of the real-time drilling assistant decision-making method provided by this embodiment. The structure, working principle and working process of the system will be further described below with reference to FIG. 1 and FIG. 2 .

如图1所示,本实施例所提供的实时钻井辅助决策系统优选地包括:实测数据获取装置101、云端服务器102以及人机交互装置103。其中,实测数据获取装置101设置在钻井端,其能够在步骤S201中获取待分析钻井的实测数据,并在步骤S202中将获取到的实测数据传输至与之通信连接的云端服务器102。As shown in FIG. 1 , the real-time drilling assistant decision-making system provided in this embodiment preferably includes: an actual measurement

具体地,如图3所示,本实施例中,实测数据获取装置101可以集成在现场工控机中,由于现场工控机与现场传感器连接,因此施工过程中,现场工控机也就可以接收现场传感器所传输来的相关信号。现场工控机根据实际需要对传感器所传输来的信号进行数据采集,也就可以得到上述实测数据。Specifically, as shown in FIG. 3 , in this embodiment, the measured

例如,实测数据获取装置101所获取到的传感器数据可以包括:扭矩数据、总池体积数据、流量数据、钩载数据、钻具裸眼静止时间、钻压、机械比能值和井下循环当量密度等。当然,在本发明的其他实施例中,根据实际需要,实测数据获取装置101所获取到的传感器数据既可以仅包含以上所列项中的某一项或某几项,也可以包含其他未列出的合理项,抑或是以上所列项中的某一项或某几项与其他未列出的合理项的组合,本发明不限于此。For example, the sensor data acquired by the measured

此外,本实施例中,根据实际需要,实测数据获取装置101所获取的实测数据除了传感器数据外,还以包含诸如钻具组合数据、钻井液流变性数据等静态数据。In addition, in this embodiment, according to actual needs, the measured data acquired by the measured

云端服务器102与实测数据获取装置101通信连接,以接收实测数据获取装置101上传的实测数据。具体地,本实施例中,实测数据获取装置101与云端服务器102优选地通过卫星无线网络进行数据通信。The

当然,在本发明的其他实施例中,实测数据获取装置101与云端服务器102之间的数据通信方式还可以采用其他合理方式。例如,在本发明的一个实施例中,实测数据获取装置101还采用移动通信网络(例如3G网络或是4G网络)或互联网来与云端服务器102进行数据通信。Of course, in other embodiments of the present invention, the data communication mode between the measured

本实施例中,云端服务器102在接收到实测数据获取装置101所传输来的实测数据后,能够在步骤S203中根据上述实测数据实时计算影响钻井效率和风险的关键参数在井内分布数据和/或变化情况数据,并在步骤S204中根据计算得到的关键参数在井内分布数据和/或变化情况数据确定当前现场施工参数条件下的钻井风险状态。在得到当前现场施工参数条件下的钻井风险状态后,云端服务器102则会在步骤S205中根据当前现场施工参数条件下的钻井风险状态的不同,采用不同的风险识别分析模型确定不同的调参方案集。In this embodiment, after receiving the measured data transmitted by the measured

具体地,本实施例中,当前现场施工参数条件下的钻进风险状态优选地包括正常状态和风险状态。其中,正常状态表示按照当前现场施工参数继续进行钻进施工不会发生钻井风险,而风险状态则表示按照当前现场施工参数继续进行钻进施工会发生钻井风险。Specifically, in this embodiment, the drilling risk state under the current site construction parameter conditions preferably includes a normal state and a risk state. Among them, the normal state indicates that the drilling operation will not occur according to the current on-site construction parameters, and the risk state indicates that the drilling risk will occur if the drilling and construction continue to be carried out according to the current on-site construction parameters.

本实施例中,云端服务器102所计算得到的影响钻井效率和风险的关键参数优选地包括:地层压力、井筒压力、井眼清洁度、摩阻、扭矩和机械钻速。当然,在本发明的其他实施例中,根据实际需要,云端服务器102所计算得到的影响钻井效率和风险的关键参数既可以仅包含以上所列项中的某一项或某几项,也可以包含其他未列出的合理项,本发明并不对此进行限定。In this embodiment, the key parameters that affect drilling efficiency and risk calculated by the

云端服务器102优选地利用自身部署的实时计算程序来根据实测数据获取装置101所传输来的实测数据实时计算影响钻井效率和风险的关键参数在井内分布数据和/或变化情况数据,并利用自身部署的风险识别程序来根据计算得到的关键参数在井内分布数据和/或变化情况数据确定当前现场施工参数条件下的钻井风险状态。The

需要指出的是,云端服务器102确定钻井风险状态时所使用到的关键参数计算方法以及风险识别规则可以是现有技术中所使用的成熟技术,故在此不再对云端服务器102确定钻进风险状态的具体原理以及过程进行赘述。It should be pointed out that the key parameter calculation methods and risk identification rules used by the

本实施例所提供的实时钻井辅助决策系统利用云端服务器的高效计算效率来实现关键参数计算过程中涉及的大量数据交互及迭代计算量,其能够有效弥补现有技术由于单台计算机计算效率过低无法满足实时性需求的问题。The real-time drilling assistant decision-making system provided in this embodiment utilizes the high computing efficiency of the cloud server to realize a large amount of data interaction and iterative computing involved in the calculation of key parameters, which can effectively compensate for the low computing efficiency of a single computer in the prior art. Unable to meet real-time requirements.

本实施例中,如果当前现场施工参数条件下的钻进风险状态为正常状态,云端服务器102则配置为采用提速调参分析模型根据计算得到的关键参数确定提速调参方案集。而如果当前现场施工参数条件下的钻进风险状态为风险状态,云端服务器102则配置为采用风控调参分析模型根据计算得到的关键参数确定风控调参方案集。In this embodiment, if the drilling risk state under the current on-site construction parameter conditions is normal, the

图4示出了本实施例中确定提速调参方案集的实现流程示意图。FIG. 4 shows a schematic diagram of an implementation flow of determining a set of speed-increasing and parameter-adjusting schemes in this embodiment.

如图4所示,本实施例中,云端服务器102优选地会在步骤S401中利用调参方案生成模型生成第一预设数量的初始提速调参方案,从而得到初始提速调参方案集。随后,云端服务器102会在步骤S402中基于步骤S401中所生成的初始提速调参方案集中的各个初始提速调参方案中调整后的参数,重新执行所述步骤S203和步骤S204,从而重新确定各个初始提速调参方案下的钻井风险状态。最后,云端服务器102会在步骤S403中根据步骤S402中所确定出的各个初始提速调参方案下的钻井风险状态来确定所述提速调参方案集。As shown in FIG. 4 , in this embodiment, the

具体地,在步骤S403中,云端服务器102优选地会提取钻井风险状态为正常状态的初始提速调参方案,并利用所提取的初始提速调参方案来形成所述提速调整方案集。Specifically, in step S403, the

例如,如果按照当前施工参数仍可正常钻进(当前现场施工参数条件下的钻进风险状态为正常状态),云端服务器102则会调用云计算服务器自身所配备的并行计算服务,并利用通过调参方案生成程序生成N个调参方案(即初始提速调参方案集)。在得到并行1-N个参数调整方案后,云端服务器102中配备的并行计算服务仍将调用实时计算程序,从而基于每个初始提速调参方案调整相应的参数项。基于调整后的参数项,云端服务器102会重新对井筒压力、机械钻速等关键参数进行计算分析。For example, if drilling can still be performed normally according to the current construction parameters (the drilling risk state under the current site construction parameters is a normal state), the

云端服务器102会分别确定重新得到的各个初始提速调参方案所对应钻井风险状态,并提取钻井风险状态为正常状态的初始提速调参方案,这样也就可以得到所需要的提速调参方案集。此时,提速调参方案集中所包含的提速调参方案的数量可以指1至N的特定值。本实施例中,提速调参方案优选地包括:调整钻井参数项、调整值以及调整后井筒压力等各项关键参数的分布与变化情况。The

云端服务器102在确定风控调参方案集时,其优选地会首先利用调参方案生成模型生成第二预设数量的风控提速调参方案,从而得到初始风控调参方案集。随后,云端服务器102会基于所得到的初始风控调参方案集中的各个初始风控调参方案中调整后的参数,重新确定各个初始风控调参方案下的钻井风险状态。然后,云端服务器102则会根据各个初始风控调参方案下的钻井风险状态确定所述提速调参方案集。When the

本实施例中,云端服务器102确定风控调参方案集的实现原理以及实现过程与其确定提速调参方案集的内容类似,故在此不再对该部分内容进行赘述。In this embodiment, the implementation principle and implementation process of the

人机交互装置103同样设置在钻井端,其与云端服务器102通信连接。云端服务器102会在步骤S206中将自身所生成的调参方案集传输至人机交互装置103,从而由人机交互装置103在步骤S207中将接收到的调参方案集输出给用户。这样钻井现场人员也就可以根据实际情况来对钻井施工进行决策。The human-computer interaction device 103 is also arranged at the drilling end, and is connected to the

需要指出的是,在本发明的其他实施例中,根据实际需要,实施钻井辅助决策系统还可以不配置人机交互装置,本发明不限于此。It should be noted that, in other embodiments of the present invention, according to actual needs, the drilling assistant decision-making system may not be configured with a human-computer interaction device, and the present invention is not limited thereto.

为了验证本实施例所提供的实时钻井辅助决策方法以及系统的可用性和可靠性,将该方法在西北油田托普台区块某井钻井作业中进行了试验应用,同时,该井的钻井队是首次在该区块进行钻井作业,钻井人员对区块各类情况掌握的经验较少。In order to verify the availability and reliability of the real-time drilling assistant decision-making method and the system provided in this embodiment, the method is tested and applied in the drilling operation of a well in the Toptai block of the Northwest Oilfield. At the same time, the drilling team of the well is It is the first time for drilling operations in this block, and the drillers have little experience in various situations in the block.

在实施过程中,在后方信息中心搭建了云计算服务平台(即云端服务器),应用现有的服务器构建形成了分布式计算与并行计算能力,并在此基础上部署井筒压力等关键参数的实时计算程序、风险识别程序以及调参方案生成程序。During the implementation process, a cloud computing service platform (ie cloud server) was built in the rear information center, and the distributed computing and parallel computing capabilities were formed by applying the existing server construction. On this basis, real-time monitoring of key parameters such as wellbore pressure was deployed. Calculation program, risk identification program and parameter adjustment program generation program.

在该井钻井作业中,实时采集了现场传感器数据及钻井液参数等部分静态数据,并由现场安装部署的卫星网络传输至数据库内。随后经由数据服务与数据接口将所得到的实测数据发送至云计算服务平台。During the drilling operation of this well, some static data such as on-site sensor data and drilling fluid parameters were collected in real time, and transmitted to the database by the satellite network installed and deployed on site. Then the obtained measured data is sent to the cloud computing service platform via the data service and data interface.

实测数据进入云计算服务平台后,云计算服务器平台会调用实时计算程序,以基于云计算服务平台高效计算能力来实时计算井筒压力、摩阻、扭矩等关键参数在井内分布与变化情况。计算结果经风险识别程序判别后,云计算服务器平台会根据具体钻井状态调用调参方案生成程序形成N个备选调参方案。云计算服务平台会基于自身的并行计算能力,对N个备选调参方案同时进行实时计算与分析,最终形成N个提速或风控调参方案,并将方案传输至井场工控机,从而给现场人员提供直观的调参项、调参值及关键参数变化趋势,进而辅助现场人员结合实际情况进行钻井决策。After the measured data enters the cloud computing service platform, the cloud computing server platform will call the real-time computing program to calculate the distribution and changes of key parameters such as wellbore pressure, frictional resistance, and torque in the well in real time based on the efficient computing capability of the cloud computing service platform. After the calculation results are judged by the risk identification program, the cloud computing server platform will call the parameter adjustment plan generation program according to the specific drilling status to form N alternative parameter adjustment plans. Based on its own parallel computing capability, the cloud computing service platform will simultaneously perform real-time calculation and analysis on N alternative parameter adjustment schemes, and finally form N speed-up or risk control parameter adjustment schemes, and transmit the schemes to the wellsite industrial computer, thereby Provide on-site personnel with intuitive parameter adjustment items, parameter adjustment values and change trends of key parameters, and then assist on-site personnel to make drilling decisions based on actual conditions.

在该井钻井作业完成后,通过统计发现虽然钻井队缺少托普台区块钻井经验,但通过应用本方法,该井未出现钻井风险(周边邻井钻井风险统计结果为1.7次/井),钻井时间127天(周边邻井钻井时间统计结果为146天/井),钻井效率显著提升,证明该技术方法应用效果良好,起到了实时辅助决策的作用。After the drilling operation of this well was completed, it was found through statistics that although the drilling team lacked drilling experience in the Toptai block, by applying this method, there was no drilling risk in this well (the statistical result of drilling risk of adjacent adjacent wells was 1.7 times/well). The drilling time was 127 days (the statistical result of the drilling time of adjacent adjacent wells was 146 days/well), and the drilling efficiency was significantly improved, which proved that the application of this technology method was effective and played a role in real-time decision-making.

目前的方法和技术均集中于钻井风险的识别预测,但是却无法为现场人员提供高效钻进和风险防控所需的调参备选方案,无法直接帮助钻井人员进行决策的问题。本发明所提供的实时钻井辅助决策方法提供了一种新的技术思路,其基于云计算技术通过应用其分布式计算与并行计算的高效性,实时计算分析与钻井效率和风险直接相关的关键参数,实时生成备选的提速/风控调参方案反馈传输至钻井现场,从而辅助钻井人员结合实际情况进行实时钻井决策,实现安全高效钻井。The current methods and technologies focus on the identification and prediction of drilling risks, but they cannot provide field personnel with options for parameter adjustment required for efficient drilling and risk prevention and control, and cannot directly help drillers make decisions. The real-time drilling assistant decision-making method provided by the present invention provides a new technical idea. Based on cloud computing technology, by applying the high efficiency of distributed computing and parallel computing, it can calculate and analyze key parameters directly related to drilling efficiency and risk in real time. , and generate alternative speed-up/wind-control parameter adjustment schemes in real time and transmit them to the drilling site, so as to assist the drillers to make real-time drilling decisions based on the actual situation and achieve safe and efficient drilling.

应该理解的是,本发明所公开的实施例不限于这里所公开的特定结构或处理步骤,而应当延伸到相关领域的普通技术人员所理解的这些特征的等同替代。还应当理解的是,在此使用的术语仅用于描述特定实施例的目的,而并不意味着限制。It is to be understood that the disclosed embodiments of the present invention are not limited to the specific structures or process steps disclosed herein, but should extend to equivalents of these features as understood by those of ordinary skill in the relevant art. It is also to be understood that the terminology used herein is for the purpose of describing particular embodiments only and is not meant to be limiting.

说明书中提到的“一个实施例”或“实施例”意指结合实施例描述的特定特征、结构或特性包括在本发明的至少一个实施例中。因此,说明书通篇各个地方出现的短语“一个实施例”或“实施例”并不一定均指同一个实施例。Reference in the specification to "one embodiment" or "an embodiment" means that a particular feature, structure, or characteristic described in connection with the embodiment is included in at least one embodiment of the present invention. Thus, appearances of the phrases "one embodiment" or "an embodiment" in various places throughout the specification are not necessarily all referring to the same embodiment.

虽然上述示例用于说明本发明在一个或多个应用中的原理,但对于本领域的技术人员来说,在不背离本发明的原理和思想的情况下,明显可以在形式上、用法及实施的细节上作各种修改而不用付出创造性劳动。因此,本发明由所附的权利要求书来限定。While the above examples serve to illustrate the principles of the invention in one or more applications, it will be apparent to those skilled in the art that the invention can be made in form, usage, and implementation without departing from the principles and spirit of the invention. Various modifications can be made to the details without creative labor. Accordingly, the invention is defined by the appended claims.

Claims (10)

Translated fromChinesePriority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910126789.8ACN111598366A (en) | 2019-02-20 | 2019-02-20 | Real-time drilling auxiliary decision-making method and system |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN201910126789.8ACN111598366A (en) | 2019-02-20 | 2019-02-20 | Real-time drilling auxiliary decision-making method and system |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111598366Atrue CN111598366A (en) | 2020-08-28 |

Family

ID=72188597

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN201910126789.8APendingCN111598366A (en) | 2019-02-20 | 2019-02-20 | Real-time drilling auxiliary decision-making method and system |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111598366A (en) |

Cited By (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN113010132A (en)* | 2021-03-24 | 2021-06-22 | 成都维泰油气能源技术有限公司 | Auxiliary system and method for intelligent well control |

| CN114169652A (en)* | 2020-09-10 | 2022-03-11 | 中国石油化工股份有限公司 | Cloud edge coordination system and method for intelligent drilling |

| CN115713293A (en)* | 2021-08-19 | 2023-02-24 | 中国石油化工股份有限公司 | Drilling construction guidance system and method based on cloud technology |

| CN115841247A (en)* | 2022-09-30 | 2023-03-24 | 中国石油天然气集团有限公司 | Digital drilling risk monitoring method and device |

Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TW200601114A (en)* | 2004-03-17 | 2006-01-01 | Schlumberger Technology Corp | Method and apparatus and program storage device adapted for automatic qualitative and quantitative risk assessment based on technical wellbore design and earth properties |

| CA2634976A1 (en)* | 2007-06-15 | 2008-12-15 | Baoyou Zhang | A guide rail plate for top drive of a drilling system |

| CA2894507A1 (en)* | 2012-12-20 | 2014-06-26 | Schlumberger Canada Limited | Well construction management and decision support system |

| CN104806226A (en)* | 2015-04-30 | 2015-07-29 | 北京四利通控制技术股份有限公司 | Intelligent drilling expert system |

| CN106150485A (en)* | 2015-04-08 | 2016-11-23 | 中国石油化工股份有限公司 | A kind of drilling well leakage prognoses system based on numeral rock mass |

- 2019

- 2019-02-20CNCN201910126789.8Apatent/CN111598366A/enactivePending

Patent Citations (5)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| TW200601114A (en)* | 2004-03-17 | 2006-01-01 | Schlumberger Technology Corp | Method and apparatus and program storage device adapted for automatic qualitative and quantitative risk assessment based on technical wellbore design and earth properties |

| CA2634976A1 (en)* | 2007-06-15 | 2008-12-15 | Baoyou Zhang | A guide rail plate for top drive of a drilling system |

| CA2894507A1 (en)* | 2012-12-20 | 2014-06-26 | Schlumberger Canada Limited | Well construction management and decision support system |

| CN106150485A (en)* | 2015-04-08 | 2016-11-23 | 中国石油化工股份有限公司 | A kind of drilling well leakage prognoses system based on numeral rock mass |

| CN104806226A (en)* | 2015-04-30 | 2015-07-29 | 北京四利通控制技术股份有限公司 | Intelligent drilling expert system |

Cited By (7)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN114169652A (en)* | 2020-09-10 | 2022-03-11 | 中国石油化工股份有限公司 | Cloud edge coordination system and method for intelligent drilling |

| CN114169652B (en)* | 2020-09-10 | 2025-09-05 | 中国石油化工股份有限公司 | A cloud-edge collaborative system and method for intelligent drilling |

| CN113010132A (en)* | 2021-03-24 | 2021-06-22 | 成都维泰油气能源技术有限公司 | Auxiliary system and method for intelligent well control |

| US11756275B2 (en) | 2021-03-24 | 2023-09-12 | Vertechs Oil & Gas Technology Co., Ltd. | Auxiliary system and method for intelligent well control |

| CN115713293A (en)* | 2021-08-19 | 2023-02-24 | 中国石油化工股份有限公司 | Drilling construction guidance system and method based on cloud technology |

| CN115841247A (en)* | 2022-09-30 | 2023-03-24 | 中国石油天然气集团有限公司 | Digital drilling risk monitoring method and device |

| CN115841247B (en)* | 2022-09-30 | 2025-01-28 | 中国石油天然气集团有限公司 | Digital drilling risk monitoring method and device |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CA3086044C (en) | System and method for optimizing tubular running operations using real-time measurements and modelling | |

| CN111598366A (en) | Real-time drilling auxiliary decision-making method and system | |

| US7861800B2 (en) | Combining belief networks to generate expected outcomes | |

| RU2633006C1 (en) | Automation of drilling with use of optimal control based on stochastic theory | |

| US7610251B2 (en) | Well control systems and associated methods | |

| CN103046918B (en) | Method and system for optimizing drilling parameters | |

| US20090198478A1 (en) | Oilfield emulator | |

| CN104145079A (en) | Determining optimal parameters for a downhole operation | |

| US10920561B2 (en) | Drilling assessment system | |

| NO344286B1 (en) | Well modeling related to the extraction of hydrocarbons from subterranean formations | |

| US11111771B2 (en) | Methods of drilling a wellbore within a subsurface region and drilling control systems that perform the methods | |

| US20150169798A1 (en) | Methods and systems for gas lift rate management | |

| CN114818451B (en) | A mechanical drilling speed prediction method, device, storage medium and equipment | |

| CN118119760A (en) | Hybrid neural network for well anomaly detection | |

| CN113129157B (en) | A real-time early warning method for downhole stuck drill failures in long water sections of shale gas | |

| US10077639B2 (en) | Methods and systems for non-physical attribute management in reservoir simulation | |

| CN111625916B (en) | Wellbore stability value calculation method and system | |

| CN118095045A (en) | A method, system, storage medium and device for analyzing vibration of a torsional drill string | |

| US12404763B2 (en) | Wireless hydrogen subsurface sensing framework for reservoir optimization | |

| CN112443311A (en) | Method for converting wet weight of returned rock debris of drilling well into underground volume | |

| CN110806859A (en) | Modular drilling data monitoring and design system based on machine learning | |

| US11237295B1 (en) | Method for intelligent automatic rock fragments depth determination while drilling | |

| NO20250302A1 (en) | Event detection using hydraulic simulations | |

| Denney | Practical Approach To Achieve Accuracy in Sanding Prediction |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20200828 |