CN111523540A - Deep learning-based metal surface defect detection method - Google Patents

Deep learning-based metal surface defect detection methodDownload PDFInfo

- Publication number

- CN111523540A CN111523540ACN202010306489.0ACN202010306489ACN111523540ACN 111523540 ACN111523540 ACN 111523540ACN 202010306489 ACN202010306489 ACN 202010306489ACN 111523540 ACN111523540 ACN 111523540A

- Authority

- CN

- China

- Prior art keywords

- deep learning

- metal surface

- feature

- data set

- inputting

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Pending

Links

Images

Classifications

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T7/00—Image analysis

- G06T7/0002—Inspection of images, e.g. flaw detection

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06F—ELECTRIC DIGITAL DATA PROCESSING

- G06F18/00—Pattern recognition

- G06F18/20—Analysing

- G06F18/21—Design or setup of recognition systems or techniques; Extraction of features in feature space; Blind source separation

- G06F18/214—Generating training patterns; Bootstrap methods, e.g. bagging or boosting

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06N—COMPUTING ARRANGEMENTS BASED ON SPECIFIC COMPUTATIONAL MODELS

- G06N3/00—Computing arrangements based on biological models

- G06N3/02—Neural networks

- G06N3/04—Architecture, e.g. interconnection topology

- G06N3/045—Combinations of networks

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06V—IMAGE OR VIDEO RECOGNITION OR UNDERSTANDING

- G06V10/00—Arrangements for image or video recognition or understanding

- G06V10/20—Image preprocessing

- G06V10/25—Determination of region of interest [ROI] or a volume of interest [VOI]

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06V—IMAGE OR VIDEO RECOGNITION OR UNDERSTANDING

- G06V10/00—Arrangements for image or video recognition or understanding

- G06V10/40—Extraction of image or video features

- G06V10/44—Local feature extraction by analysis of parts of the pattern, e.g. by detecting edges, contours, loops, corners, strokes or intersections; Connectivity analysis, e.g. of connected components

- G—PHYSICS

- G06—COMPUTING OR CALCULATING; COUNTING

- G06T—IMAGE DATA PROCESSING OR GENERATION, IN GENERAL

- G06T2207/00—Indexing scheme for image analysis or image enhancement

- G06T2207/20—Special algorithmic details

- G06T2207/20016—Hierarchical, coarse-to-fine, multiscale or multiresolution image processing; Pyramid transform

Landscapes

- Engineering & Computer Science (AREA)

- Theoretical Computer Science (AREA)

- Physics & Mathematics (AREA)

- General Physics & Mathematics (AREA)

- Computer Vision & Pattern Recognition (AREA)

- Data Mining & Analysis (AREA)

- Multimedia (AREA)

- Life Sciences & Earth Sciences (AREA)

- Artificial Intelligence (AREA)

- Evolutionary Computation (AREA)

- General Engineering & Computer Science (AREA)

- Computing Systems (AREA)

- Bioinformatics & Cheminformatics (AREA)

- General Health & Medical Sciences (AREA)

- Computational Linguistics (AREA)

- Mathematical Physics (AREA)

- Software Systems (AREA)

- Biophysics (AREA)

- Molecular Biology (AREA)

- Bioinformatics & Computational Biology (AREA)

- Biomedical Technology (AREA)

- Evolutionary Biology (AREA)

- Health & Medical Sciences (AREA)

- Quality & Reliability (AREA)

- Investigating Materials By The Use Of Optical Means Adapted For Particular Applications (AREA)

- Image Analysis (AREA)

- Image Processing (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及金属表面缺陷检测技术领域,特别涉及一种基于深度学习的金 属表面缺陷检测方法。The invention relates to the technical field of metal surface defect detection, in particular to a deep learning-based metal surface defect detection method.

背景技术Background technique

目前,产品表面质量检测已得到广泛关注,因此检测技术获得迅速发展, 尤其是以深度学习为基础的检测算法,取得了许多优秀成果。以深度学习为基 础的检测算法在产品表面质量控制方面比人工检测效率更高,也可以降低检测 员的工作量,降低企业生产成本,缺陷检测精度和定位更加准确,提高生产效 率,推动制造业自动化,智能化发展,推动智慧工厂的建设。另外,在科学研 究方面,深度学习属于新领域,理论成果和实践相结合,使得研究成果落地, 在实际应用中,寻求更好的改进,也能更好的促进相关算法的深入发展,开展 深度学习理论成果结合实践应用研究,对于深度学习的而发展具有很重要的研究意义。At present, the detection of product surface quality has received extensive attention, so the detection technology has developed rapidly, especially the detection algorithm based on deep learning, which has achieved many excellent results. The inspection algorithm based on deep learning is more efficient than manual inspection in product surface quality control, and can also reduce the workload of inspectors, reduce the production cost of enterprises, make defect detection accuracy and positioning more accurate, improve production efficiency, and promote manufacturing. Automation and intelligent development promote the construction of smart factories. In addition, in terms of scientific research, deep learning belongs to a new field. The combination of theoretical results and practice enables the implementation of research results. In practical applications, seeking better improvements can also better promote the in-depth development of related algorithms. The combination of theoretical learning results and practical application research has important research significance for the development of deep learning.

发明内容SUMMARY OF THE INVENTION

本发明提供了一种基于深度学习的金属表面缺陷检测方法,其目的是为了 解决机器视觉受环境因素影响较大的问题。The present invention provides a metal surface defect detection method based on deep learning, the purpose of which is to solve the problem that machine vision is greatly affected by environmental factors.

为了达到上述目的,本发明的实施例提供了一种基于深度学习的金属表面 缺陷检测方法,包括:In order to achieve the above object, an embodiment of the present invention provides a deep learning-based metal surface defect detection method, comprising:

步骤1,根据金属缺陷零件大小确定相机和光源型号,搭建好光源和相机 的取图环境,进行图像采集;Step 1: Determine the model of the camera and the light source according to the size of the metal defect parts, build the image capturing environment of the light source and the camera, and perform image acquisition;

步骤2,对采集的图像进行数据集标注和数据集增强,并输入到混合特征 金字塔网络结构中,进行特征提取;Step 2, carry out dataset labeling and dataset enhancement on the collected images, and input them into the hybrid feature pyramid network structure for feature extraction;

步骤3,将得到的每一层的特征图输入到RPN网络中,进行候选区域选 取;Step 3, the obtained feature map of each layer is input into the RPN network, and the candidate region is selected;

步骤4,结合得到的每一层的特征图和候选区域进入ROIAlign,将感兴 趣区域映射到特征图上,并且划分成固定大小,进行池化操作;Step 4, combine the obtained feature map and candidate region of each layer into ROIAlign, map the region of interest to the feature map, and divide it into a fixed size for pooling operation;

步骤5,将ROI Align池化得到的输出输入到卷积层,得到卷积层的输出, 将卷积层的输出输入到全连接层进行分类和回归。Step 5: Input the output obtained by ROI Align pooling to the convolutional layer to obtain the output of the convolutional layer, and input the output of the convolutional layer to the fully connected layer for classification and regression.

其中,所述步骤2具体包括:Wherein, the step 2 specifically includes:

数据集标注采用Labelimg工具在线处理,数据集增强采用旋转,伪造缺 陷图像和放缩,随机明暗度。The labeling of the dataset is processed online by the Labelimg tool, and the dataset is enhanced by rotation, fake defect images and scaling, and random shades.

其中,所述步骤2还包括:Wherein, the step 2 further includes:

在基础的混合特征金字塔网络之上,融合得到的特征图。On top of the basic hybrid feature pyramid network, the resulting feature maps are fused.

其中,所述步骤3具体包括:Wherein, the step 3 specifically includes:

通过使用3x3的卷积得到16x16个256维特征向量,通过使用两次1x1 的卷积得到一个18x16x16的特征图和一个36x16x16的特征图,最终得到 16x16x9个结果,每个结果中有四个坐标和两个分数,再通过已设定好的 Anchors的大小,处理之后得到候选框。By using 3x3 convolution to get 16x16 256-dimensional feature vectors, by using two 1x1 convolutions to get a 18x16x16 feature map and a 36x16x16 feature map, and finally get 16x16x9 results, each of which has four coordinates and Two scores, and then through the set size of Anchors, the candidate frame is obtained after processing.

其中,所述步骤4具体包括:Wherein, the step 4 specifically includes:

将特征representation整合,输出为一个值。Integrate the feature representation and output it as a value.

其中,所述步骤5具体包括:Wherein, the step 5 specifically includes:

将卷积层得到的局部特征通过权值矩阵组成完整的图,再进行分类。The local features obtained by the convolution layer are formed into a complete graph through the weight matrix, and then classified.

本发明的上述方案有如下的有益效果:The above-mentioned scheme of the present invention has the following beneficial effects:

本发明的上述实施例所述的基于深度学习的金属表面缺陷检测方法,实现 自动对生产线输入图像进行检测和缺陷识别定位,特征自动提取,消除手工特 征提取带来的负影响,克服了机器视觉中受环境因素影响较大的缺点,混合特 征金字塔网络结构针对较小目标以及多尺度问题有更好的表现。The deep learning-based metal surface defect detection method described in the above-mentioned embodiments of the present invention realizes automatic detection of the input image of the production line, defect identification and positioning, automatic feature extraction, eliminates the negative influence caused by manual feature extraction, and overcomes machine vision. Due to the disadvantage that it is greatly affected by environmental factors, the hybrid feature pyramid network structure has better performance for smaller targets and multi-scale problems.

附图说明Description of drawings

图1为本发明的流程图;Fig. 1 is the flow chart of the present invention;

图2为本发明的深度学习模型示意图;2 is a schematic diagram of a deep learning model of the present invention;

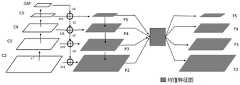

图3为本发明的混合特征金字塔网络的架构图;Fig. 3 is the architecture diagram of the hybrid feature pyramid network of the present invention;

图4为本发明的表现效果平均准确率图(1);Fig. 4 is the performance effect average accuracy rate figure (1) of the present invention;

图5为本发明的表现效果平均准确率图(2)。FIG. 5 is a graph (2) of the average accuracy rate of the performance effect of the present invention.

具体实施方式Detailed ways

为使本发明要解决的技术问题、技术方案和优点更加清楚,下面将结合附 图及具体实施例进行详细描述。In order to make the technical problems, technical solutions and advantages to be solved by the present invention more clear, the following will be described in detail with reference to the accompanying drawings and specific embodiments.

本发明针对现有的机器视觉受环境因素影响较大的问题,提供了一种基于 深度学习的金属表面缺陷检测方法。Aiming at the problem that the existing machine vision is greatly affected by environmental factors, the present invention provides a metal surface defect detection method based on deep learning.

如图1至图5所示,本发明的实施例提供了一种基于深度学习的金属表面 缺陷检测方法,包括:步骤1,根据金属缺陷零件大小确定相机和光源型号, 搭建好光源和相机的取图环境,进行图像采集;步骤2,对采集的图像进行数 据集标注和数据集增强,并输入到混合特征金字塔网络结构中,进行特征提取; 步骤3,将得到的每一层的特征图输入到RPN网络中,进行候选区域选取; 步骤4,结合得到的每一层的特征图和候选区域进入ROIAlign,将感兴趣区 域映射到特征图上,并且划分成固定大小,进行池化操作;步骤5,将ROIAlign 池化得到的输出输入到卷积层,得到卷积层的输出,将卷积层的输出输入到全连接层进行分类和回归。As shown in FIG. 1 to FIG. 5 , an embodiment of the present invention provides a method for detecting metal surface defects based on deep learning, including: Step 1. Determine the model of the camera and the light source according to the size of the metal defect part, and build the light source and the camera. Take the image environment, and perform image acquisition; Step 2, perform dataset annotation and dataset enhancement on the collected images, and input them into the hybrid feature pyramid network structure for feature extraction; Step 3, obtain the feature map of each layer Input into the RPN network to select the candidate region; Step 4, combine the obtained feature map and candidate region of each layer into ROIAlign, map the region of interest to the feature map, and divide it into fixed sizes for pooling operation; Step 5: Input the output obtained by ROIAlign pooling to the convolutional layer to obtain the output of the convolutional layer, and input the output of the convolutional layer to the fully connected layer for classification and regression.

本发明的上述实施例所述的基于深度学习的金属表面缺陷检测方法,以佛 山铝型材生产线为研究,发现目前生产线以人工检测为主,但人工检测的效率 低,评估标准难以准确量化,没有实现全面自动化生产,现场收集大量缺陷图 片,进行数据集分析后,所述基于深度学习的金属表面缺陷检测方法选择深度 学习模型为出发点。相对于纺织物的瑕疵检测或者光学组件的检测,在金属表 面缺陷的检测中,金属表面与光滑表面(例如和光学组件)相比,金属表面的 照片可能容易出现一些如照明不均匀,强反射和背景噪声以及污渍等问题,因 此使用机器视觉的方法检测难度很大。另外,由于生产环境的限制,产品表面 容易出现污染物,这是不可避免的,还有灰尘和纤维等外物的影响。综上,对 于金属表面缺陷的检测,深度学习模型在金属表面缺陷检测上有更好的优势。The deep learning-based metal surface defect detection method described in the above-mentioned embodiments of the present invention is based on the Foshan aluminum profile production line. Fully automated production is realized, a large number of defect pictures are collected on site, and after data set analysis is performed, the deep learning model is selected as the starting point for the deep learning-based metal surface defect detection method. Compared to defect detection of textiles or detection of optical components, in the detection of metal surface defects, the metal surface may be prone to some problems such as uneven lighting, strong reflections, compared with smooth surfaces (eg, and optical components). and background noise and stains, so it is very difficult to use the method of machine vision to detect. In addition, due to the limitations of the production environment, contaminants are prone to appear on the surface of the product, which is unavoidable, as well as the influence of foreign objects such as dust and fibers. In summary, for the detection of metal surface defects, the deep learning model has better advantages in the detection of metal surface defects.

本发明的上述实施例所述的基于深度学习的金属表面缺陷检测方法,大致 分为两部分,第一阶段,数据集采集,图片预处理;第二阶段,输入图片到混 合特征金字塔网络中反复训练优化,得到性能较高的网络模型。The deep learning-based metal surface defect detection method described in the above-mentioned embodiments of the present invention is roughly divided into two parts. The first stage is data set collection and image preprocessing; the second stage, the input image is repeated in the hybrid feature pyramid network Training optimization to obtain a network model with higher performance.

其中,所述步骤2具体包括:数据集标注采用Labelimg工具在线处理, 数据集增强采用旋转,伪造缺陷图像和放缩,随机明暗度。Wherein, the step 2 specifically includes: the labeling of the data set is processed online by the Labelimg tool, the data set is enhanced by rotation, forged defect images and scaling, and random brightness.

其中,所述步骤2还包括:在基础的混合特征金字塔网络之上,融合得到 的特征图。Wherein, the step 2 further includes: on the basic hybrid feature pyramid network, fusing the obtained feature map.

本发明的上述实施例所述的基于深度学习的金属表面缺陷检测方法,在基 础的特征金字塔网络之上,融合得到的特征图的方法是将特征图通过插值或者 最大池化方式裁剪到相同的尺寸,再将相同尺寸的特征图相加取平均值,得到 均值特征图,通过上下采样或者卷积将均值特征图裁剪到之前特征图的尺寸, 通过这种方法可以融合和高层和低层的语义信息,充分使用浅层的信息,更好 的检测小目标。In the method for detecting metal surface defects based on deep learning described in the above-mentioned embodiments of the present invention, on the basis of the basic feature pyramid network, the method of fusing the obtained feature maps is to cut the feature maps to the same level by interpolation or maximum pooling. Then add the feature maps of the same size and take the average value to obtain the average feature map. The average feature map is clipped to the size of the previous feature map by up-sampling or convolution. This method can integrate the semantics of high-level and low-level information, make full use of shallow information, and better detect small targets.

其中,所述步骤3具体包括:通过使用3x3的卷积得到16x16个256 维特征向量,通过使用两次1x1的卷积得到一个18x16x16的特征图和一个 36x16x16的特征图,最终得到16x16x9个结果,每个结果中有四个坐标 和两个分数,再通过已设定好的Anchors的大小,处理之后得到候选框。The step 3 specifically includes: obtaining 16x16 256-dimensional feature vectors by using 3x3 convolution, obtaining a 18x16x16 feature map and a 36x16x16 feature map by using two 1x1 convolutions, and finally obtaining 16x16x9 results, There are four coordinates and two scores in each result, and then through the set size of Anchors, the candidate frame is obtained after processing.

其中,所述步骤4具体包括:将特征representation整合,输出为一个值。Wherein, the step 4 specifically includes: integrating the feature representation and outputting it as a value.

其中,所述步骤5具体包括:将卷积层得到的局部特征通过权值矩阵组成 完整的图,再进行分类。Wherein, the step 5 specifically includes: forming a complete graph of the local features obtained by the convolution layer through the weight matrix, and then classifying.

本发明的上述实施例所述的基于深度学习的金属表面缺陷检测方法,需要 对深度学习模型进行训练,在训练过程中,不断优化深度学习模型,如使用 soft-NMS替换掉NMS,通过k-means聚类算法分析训练集中真实框的分布, 获得数据集的anchors尺寸,采用可行变卷积代替最后的卷积层,可以很好地 适应几何形变,提取特征的位置更加准确,反复训练调整参数设置,直到满足 生产线的鲁棒性和准确率要求。The deep learning-based metal surface defect detection method described in the above-mentioned embodiment of the present invention needs to train the deep learning model. During the training process, the deep learning model is continuously optimized. The means clustering algorithm analyzes the distribution of the real boxes in the training set, obtains the anchors size of the data set, and uses a feasible variable convolution to replace the final convolution layer, which can well adapt to geometric deformation, and the position of the extracted features is more accurate. Repeated training to adjust the parameters settings until the robustness and accuracy requirements of the production line are met.

本发明的上述实施例所述的基于深度学习的金属表面缺陷检测方法,具体 实施步骤如下:采集图片,各类缺陷图片共计300张,总共3000张图片,为 提高检测结果的正确性,采用数据增广的方式使得每类缺陷图片数量达到 3000张。对于特征提取部分的训练,缺陷图片和正常图片联合进行训练。使 用的主干网络都在ImageNet上进行了预训练,对于改进的混合特征金字塔网 络结构加入之后,学习率从0.001开始,批量大小为16,为了进行评估,检测 器在具有CUDA9和CUDNN7的单个Titan X GPU上运行,批处理大小为1。 训练过程中,深度学习模型优化的地方:K-means聚类的方法代替固定的anchor 大小,提升了大概1个百分点,尺寸大小变化了,比例不变。使用ROI Align 代替ROI Pooling,ROI Align是一种区域特征聚集方式,很好地解决ROI Pooling操作中两次量化造成的区域不匹配的问题,实验显示,在检测任务中 将ROI Pooling替换为ROI Align可以提升检测模型的准确性。原本Resent-101 结构的最后一个block改成了可形变卷积,原因是在可形变卷积的实现中,需 要基于前面的特征来学习一个偏移,前面的特征得足够强才能保证这个偏移不 会乱学,因此改动了最后一个block,所述基于深度学习的金属表面缺陷检测 方法的总体流程如图1所示,所述基于深度学习的金属表面缺陷检测方法的表 现效果如图4,图4中擦花,漏底,桔皮以及脏点这几类缺陷上提高比较明显, 平均准确率达到86.31%。The method for detecting metal surface defects based on deep learning described in the above embodiments of the present invention, the specific implementation steps are as follows: collecting pictures, a total of 300 pictures of various types of defects, a total of 3000 pictures, in order to improve the correctness of the detection results, use data The augmented method makes the number of each type of defect pictures reach 3000. For the training of the feature extraction part, the defective pictures and the normal pictures are jointly trained. The backbone networks used are all pre-trained on ImageNet. After the improved hybrid feature pyramid network structure is added, the learning rate starts from 0.001 and the batch size is 16. For evaluation, the detector is run on a single Titan X with CUDA9 and CUDNN7. Run on GPU with batch size 1. During the training process, the optimization of the deep learning model: the K-means clustering method replaces the fixed anchor size, which is increased by about 1%, the size changes, and the proportion remains unchanged. Use ROI Align instead of ROI Pooling. ROI Align is a regional feature aggregation method, which can well solve the problem of regional mismatch caused by two quantizations in the ROI Pooling operation. Experiments show that ROI Pooling is replaced in the detection task. ROI Align The accuracy of the detection model can be improved. The last block of the original Resent-101 structure was changed to deformable convolution. The reason is that in the implementation of deformable convolution, an offset needs to be learned based on the previous features, and the previous features must be strong enough to ensure this offset. I won't mess with learning, so I changed the last block. The overall process of the deep learning-based metal surface defect detection method is shown in Figure 1, and the performance of the deep learning-based metal surface defect detection method is shown in Figure 4. In Figure 4, the defects such as scratches, leaks, orange peels and dirty spots are significantly improved, and the average accuracy rate reaches 86.31%.

不断通过改进优化所述基于深度学习的金属表面缺陷检测方法,使得最终 所述基于深度学习的金属表面缺陷检测方法的整体平均准确率不断提升,在数 据集部分,数据集增强部分引入了伪造缺陷图像的方法,分析缺陷图像的阈值 分布,通过添加小方块或者随机形状的图形,消除方法对特征周围环境的依赖; 在数据集感情部分,尝试过通过混合两张图像的方式,考虑到过多的干扰,对 最终的检测结果并不友好,因此放弃了这一种方式,同时在训练的过程中,使 用soft-NMS来代替NMS。如图5是所述基于深度学习的金属表面缺陷检测方 法在数据集上的最终表现,整体表现良好,图5中杂色,角位漏底和起坑三种缺陷的平均准确率可以到达100%的效果,整体平均准确率提高到了88.91%, 提升2个百分点左右。Through continuous improvement and optimization of the deep learning-based metal surface defect detection method, the overall average accuracy of the deep learning-based metal surface defect detection method is continuously improved. In the data set part, the data set enhancement part introduces forgery defects The image method analyzes the threshold distribution of the defect image, and eliminates the dependence of the method on the surrounding environment of the feature by adding small squares or random shapes. The interference is not friendly to the final detection result, so this method is abandoned, and in the process of training, soft-NMS is used instead of NMS. Figure 5 is the final performance of the deep learning-based metal surface defect detection method on the data set, and the overall performance is good. % effect, the overall average accuracy rate increased to 88.91%, an increase of about 2 percentage points.

本发明的上述实施例所述的基于深度学习的金属表面缺陷检测方法,实现 自动对生产线输入图像进行检测和缺陷识别定位,特征自动提取,消除手工特 征提取带来的负影响,克服了机器视觉中受环境因素影响较大的缺点,混合特 征金字塔网络结构针对较小目标以及多尺度问题有更好的表现。The deep learning-based metal surface defect detection method described in the above-mentioned embodiments of the present invention realizes automatic detection of the input image of the production line, defect identification and positioning, automatic feature extraction, eliminates the negative influence caused by manual feature extraction, and overcomes machine vision. Due to the disadvantage that it is greatly affected by environmental factors, the hybrid feature pyramid network structure has better performance for smaller targets and multi-scale problems.

以上所述是本发明的优选实施方式,应当指出,对于本技术领域的普通技 术人员来说,在不脱离本发明所述原理的前提下,还可以作出若干改进和润饰, 这些改进和润饰也应视为本发明的保护范围。The above are the preferred embodiments of the present invention. It should be pointed out that for those skilled in the art, without departing from the principles of the present invention, several improvements and modifications can be made. It should be regarded as the protection scope of the present invention.

Claims (6)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010306489.0ACN111523540A (en) | 2020-04-17 | 2020-04-17 | Deep learning-based metal surface defect detection method |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010306489.0ACN111523540A (en) | 2020-04-17 | 2020-04-17 | Deep learning-based metal surface defect detection method |

Publications (1)

| Publication Number | Publication Date |

|---|---|

| CN111523540Atrue CN111523540A (en) | 2020-08-11 |

Family

ID=71904421

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010306489.0APendingCN111523540A (en) | 2020-04-17 | 2020-04-17 | Deep learning-based metal surface defect detection method |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111523540A (en) |

Cited By (9)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112184619A (en)* | 2020-08-25 | 2021-01-05 | 华北电力大学(保定) | Metal part surface defect detection method based on deep learning |

| CN112508090A (en)* | 2020-12-04 | 2021-03-16 | 重庆大学 | External package defect detection method |

| CN113012153A (en)* | 2021-04-30 | 2021-06-22 | 武汉纺织大学 | Aluminum profile flaw detection method |

| CN113239786A (en)* | 2021-05-11 | 2021-08-10 | 重庆市地理信息和遥感应用中心 | Remote sensing image country villa identification method based on reinforcement learning and feature transformation |

| CN113658108A (en)* | 2021-07-22 | 2021-11-16 | 西南财经大学 | Glass defect detection method based on deep learning |

| CN114723668A (en)* | 2022-03-09 | 2022-07-08 | 三门三友科技股份有限公司 | A method and system for quality detection of cathode copper based on area scan camera |

| WO2022160170A1 (en)* | 2021-01-28 | 2022-08-04 | 东莞职业技术学院 | Method and apparatus for detecting metal surface defects |

| CN114863094A (en)* | 2022-05-31 | 2022-08-05 | 征图新视(江苏)科技股份有限公司 | Industrial image region-of-interest segmentation algorithm based on double-branch network |

| CN114972246A (en)* | 2022-05-24 | 2022-08-30 | 河海大学 | A deep learning-based surface defect detection method for die-cutting products |

Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110443791A (en)* | 2019-08-02 | 2019-11-12 | 西安工程大学 | A kind of workpiece inspection method and its detection device based on deep learning network |

| CN110782183A (en)* | 2019-11-07 | 2020-02-11 | 山东浪潮人工智能研究院有限公司 | A method of aluminum defect detection based on Faster R-CNN |

| CN110853015A (en)* | 2019-11-12 | 2020-02-28 | 中国计量大学 | Aluminum profile defect detection method based on improved Faster-RCNN |

| CN110929685A (en)* | 2019-12-10 | 2020-03-27 | 电子科技大学 | Pedestrian detection network structure based on mixed feature pyramid and mixed expansion convolution |

- 2020

- 2020-04-17CNCN202010306489.0Apatent/CN111523540A/enactivePending

Patent Citations (4)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN110443791A (en)* | 2019-08-02 | 2019-11-12 | 西安工程大学 | A kind of workpiece inspection method and its detection device based on deep learning network |

| CN110782183A (en)* | 2019-11-07 | 2020-02-11 | 山东浪潮人工智能研究院有限公司 | A method of aluminum defect detection based on Faster R-CNN |

| CN110853015A (en)* | 2019-11-12 | 2020-02-28 | 中国计量大学 | Aluminum profile defect detection method based on improved Faster-RCNN |

| CN110929685A (en)* | 2019-12-10 | 2020-03-27 | 电子科技大学 | Pedestrian detection network structure based on mixed feature pyramid and mixed expansion convolution |

Non-Patent Citations (1)

| Title |

|---|

| 双锴: "《计算机视觉》", 31 January 2020, 北京邮电大学出版社* |

Cited By (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN112184619A (en)* | 2020-08-25 | 2021-01-05 | 华北电力大学(保定) | Metal part surface defect detection method based on deep learning |

| CN112508090A (en)* | 2020-12-04 | 2021-03-16 | 重庆大学 | External package defect detection method |

| WO2022160170A1 (en)* | 2021-01-28 | 2022-08-04 | 东莞职业技术学院 | Method and apparatus for detecting metal surface defects |

| CN113012153A (en)* | 2021-04-30 | 2021-06-22 | 武汉纺织大学 | Aluminum profile flaw detection method |

| CN113239786A (en)* | 2021-05-11 | 2021-08-10 | 重庆市地理信息和遥感应用中心 | Remote sensing image country villa identification method based on reinforcement learning and feature transformation |

| CN113658108A (en)* | 2021-07-22 | 2021-11-16 | 西南财经大学 | Glass defect detection method based on deep learning |

| CN114723668A (en)* | 2022-03-09 | 2022-07-08 | 三门三友科技股份有限公司 | A method and system for quality detection of cathode copper based on area scan camera |

| WO2023168984A1 (en)* | 2022-03-09 | 2023-09-14 | 三门三友科技股份有限公司 | Area-array camera-based quality inspection method and system for cathode copper |

| CN114972246A (en)* | 2022-05-24 | 2022-08-30 | 河海大学 | A deep learning-based surface defect detection method for die-cutting products |

| CN114863094A (en)* | 2022-05-31 | 2022-08-05 | 征图新视(江苏)科技股份有限公司 | Industrial image region-of-interest segmentation algorithm based on double-branch network |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN111523540A (en) | Deep learning-based metal surface defect detection method | |

| CN108765402B (en) | Non-woven fabric defect detection and classification method | |

| CN113393426B (en) | Steel rolling plate surface defect detection method | |

| CN114663346A (en) | Strip steel surface defect detection method based on improved YOLOv5 network | |

| CN111292305A (en) | Improved YOLO-V3 metal processing surface defect detection method | |

| CN113240623B (en) | Pavement disease detection method and device | |

| WO2022236876A1 (en) | Cellophane defect recognition method, system and apparatus, and storage medium | |

| CN110458807A (en) | A Machine Vision Detection System for Railway Track Defects | |

| CN106875381A (en) | A kind of phone housing defect inspection method based on deep learning | |

| CN105894036A (en) | Image feature template matching method being applied to detection of mobile phone screen defects | |

| CN105809121A (en) | Multi-characteristic synergic traffic sign detection and identification method | |

| CN113177924A (en) | Industrial production line product flaw detection method | |

| CN112102224B (en) | A cloth defect recognition method based on deep convolutional neural network | |

| CN110473201A (en) | A kind of automatic testing method and device of disc surface defect | |

| CN108416774A (en) | A Fabric Type Recognition Method Based on Fine-grained Neural Network | |

| CN118392891A (en) | Chip packaging defect detection method and system based on machine vision | |

| CN112419237B (en) | A method for surface defect detection of automobile clutch master cylinder groove based on deep learning | |

| CN114926407A (en) | Steel surface defect detection system based on deep learning | |

| CN118967672A (en) | Industrial defect detection method, system, device and storage medium | |

| CN113221881B (en) | A multi-level smartphone screen defect detection method | |

| CN114486916A (en) | Defect detection method of mobile phone glass cover based on machine vision | |

| CN119715554B (en) | Electric tricycle body spraying defect detection method and system based on machine vision | |

| CN115082776A (en) | Electric energy meter automatic detection system and method based on image recognition | |

| CN112102253A (en) | Non-woven fabric surface defect automatic detection method and system based on machine vision | |

| CN111667465A (en) | Metal hand basin defect detection method based on far infrared image |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| RJ01 | Rejection of invention patent application after publication | ||

| RJ01 | Rejection of invention patent application after publication | Application publication date:20200811 |