CN111520617B - A device and method for monitoring the cracking of the mortar protective layer of prestressed steel cylinder concrete pipe based on piezoelectric sensing technology - Google Patents

A device and method for monitoring the cracking of the mortar protective layer of prestressed steel cylinder concrete pipe based on piezoelectric sensing technologyDownload PDFInfo

- Publication number

- CN111520617B CN111520617BCN202010113744.XACN202010113744ACN111520617BCN 111520617 BCN111520617 BCN 111520617BCN 202010113744 ACN202010113744 ACN 202010113744ACN 111520617 BCN111520617 BCN 111520617B

- Authority

- CN

- China

- Prior art keywords

- piezoelectric ceramic

- zirconate titanate

- lead zirconate

- protective layer

- pccp

- Prior art date

- Legal status (The legal status is an assumption and is not a legal conclusion. Google has not performed a legal analysis and makes no representation as to the accuracy of the status listed.)

- Active

Links

Images

Classifications

- F—MECHANICAL ENGINEERING; LIGHTING; HEATING; WEAPONS; BLASTING

- F17—STORING OR DISTRIBUTING GASES OR LIQUIDS

- F17D—PIPE-LINE SYSTEMS; PIPE-LINES

- F17D5/00—Protection or supervision of installations

- F17D5/02—Preventing, monitoring, or locating loss

- F17D5/06—Preventing, monitoring, or locating loss using electric or acoustic means

Landscapes

- Engineering & Computer Science (AREA)

- Physics & Mathematics (AREA)

- Acoustics & Sound (AREA)

- Mechanical Engineering (AREA)

- General Engineering & Computer Science (AREA)

- Investigating Or Analyzing Materials By The Use Of Ultrasonic Waves (AREA)

Abstract

Description

Translated fromChinese技术领域technical field

本发明涉及一种基于压电传感技术的裂缝监测装置及方法。The invention relates to a crack monitoring device and method based on piezoelectric sensing technology.

背景技术Background technique

PCCP管是我国近十几年来在引进和消化吸收国外先进技术和关键设备基础之上研究发展起来的第一代预应力混凝土压力管,目前在南水北调等国家战略输水工程之中大量采用,具有很强的工程应用背景。而砂浆保护层位于PCCP结构的最外层,承担了抗渗、抗碳化、抗硫酸盐、抗氯离子侵袭等任务,保证了内部的预应力钢丝和钢筒免受水和其他腐蚀介质的侵蚀,从而保障PCCP管的结构安全性和使用寿命。因此,PCCP管砂浆保护层对PCCP结构的使用和维护有着十分重要的意义。而目前针对工程材料损伤开裂的无损监测研究主要集中在混凝土和钢结构上,针对砂浆还缺乏有效可行的方法和深入研究。基于以上几点,开发一种成本低廉,且可以试用于PCCP管实际工作运行状态的砂浆保护层开裂监测方法及装置就显得十分重要。PCCP pipe is the first generation of prestressed concrete pressure pipe developed on the basis of introducing and absorbing foreign advanced technology and key equipment in my country in the past ten years. It is currently widely used in national strategic water transfer projects such as South-to-North Water Transfer Project. Strong background in engineering applications. The mortar protection layer is located at the outermost layer of the PCCP structure, which undertakes the tasks of impermeability, anti-carbonization, anti-sulfate, anti-chlorine ion attack, etc., and ensures that the internal prestressed steel wire and steel cylinder are protected from water and other corrosive media. , so as to ensure the structural safety and service life of the PCCP pipe. Therefore, the PCCP pipe mortar protective layer is of great significance to the use and maintenance of the PCCP structure. At present, the non-destructive monitoring research on damage and cracking of engineering materials mainly focuses on concrete and steel structures, and there is still a lack of effective and feasible methods and in-depth research on mortar. Based on the above points, it is very important to develop a method and device for monitoring the cracking of the mortar protective layer that is low in cost and can be used in the actual working state of the PCCP pipe.

发明内容Contents of the invention

本发明的目的是提供一种基于压电传感技术的预应力钢筒混凝土管(PCCP)砂浆保护层开裂监测的装置及方法。The object of the present invention is to provide a device and method for monitoring the cracking of the mortar cover of prestressed steel cylinder concrete pipe (PCCP) based on piezoelectric sensing technology.

为实现本发明目的而采用的技术方案是这样的,一种基于压电传感技术的预应力钢筒混凝土管(PCCP)砂浆保护层开裂监测的装置,括示波器、数据分析系统、动态数据采集系统和预埋在PCCP监测段内的锆钛酸铅系压电陶瓷片。The technical scheme adopted for realizing the object of the present invention is such, a kind of device based on the cracking monitoring of the prestressed steel cylinder concrete pipe (PCCP) mortar cover of piezoelectric sensing technology, including oscilloscope, data analysis system, dynamic data acquisition The system and the lead zirconate titanate piezoelectric ceramic sheet embedded in the PCCP monitoring section.

所述PCCP监测段为两端敞口且内部中空的管段,PCCP监测段包括内管芯混凝土、外管芯混凝土和砂浆保护层,内管芯混凝土为管壁的最内层,内管芯混凝土的外表面套设有钢筒,钢筒的外表面包裹有外管芯混凝土,外管芯混凝土上缠绕有预应力钢丝,砂浆保护层将外管芯混凝土和预应力钢丝包裹。The PCCP monitoring section is a pipe section with open ends and a hollow interior. The PCCP monitoring section includes an inner pipe core concrete, an outer pipe core concrete and a mortar protection layer. The inner pipe core concrete is the innermost layer of the pipe wall, and the inner pipe core concrete A steel cylinder is sheathed on the outer surface of the steel cylinder, and the outer surface of the steel cylinder is wrapped with the concrete of the outer tube core, and the prestressed steel wire is wound on the concrete of the outer tube core, and the mortar protective layer wraps the concrete of the outer tube core and the prestressed steel wire.

若干所述锆钛酸铅系压电陶瓷片预埋在PCCP监测段的砂浆保护层内,每三个锆钛酸铅系压电陶瓷片分布在砂浆保护层的同一横截面上,这三个锆钛酸铅系压电陶瓷片沿砂浆保护层的周向等间距布置,这三个锆钛酸铅系压电陶瓷片组成一个压电陶瓷片组,若干压电陶瓷片组沿砂浆保护层的轴向等间距布置。Several lead zirconate titanate piezoelectric ceramic sheets are pre-embedded in the mortar protective layer of the PCCP monitoring section, and every three lead zirconate titanate piezoelectric ceramic sheets are distributed on the same cross section of the mortar protective layer. Lead zirconate titanate piezoelectric ceramic sheets are arranged at equal intervals along the circumference of the mortar protective layer. These three lead zirconate titanate piezoelectric ceramic sheets form a piezoelectric ceramic sheet group, and several piezoelectric ceramic sheet groups are arranged along the mortar protective layer. The axial equidistant arrangement.

所述示波器与一个锆钛酸铅系压电陶瓷片连接,该锆钛酸铅系压电陶瓷片作为信号发射端。所述动态数据采集系统与信号发射端相邻的锆钛酸铅系压电陶瓷片连接,该锆钛酸铅系压电陶瓷片作为信号接收端。所述示波器通过正弦信号激发所连接的锆钛酸铅系压电陶瓷片振动,锆钛酸铅系压电陶瓷片产生振动并生成应力波,信号接收端的锆钛酸铅系压电陶瓷片因应力波产生电信号,动态数据采集系统接收该电信号,并将电信号传送至数据分析系统进行数据储存和分析处理。The oscilloscope is connected with a lead zirconate titanate piezoelectric ceramic sheet, and the lead zirconate titanate piezoelectric ceramic sheet is used as a signal transmitting end. The dynamic data acquisition system is connected to the lead zirconate titanate piezoelectric ceramic sheet adjacent to the signal transmitting end, and the lead zirconate titanate piezoelectric ceramic sheet is used as the signal receiving end. The oscilloscope excites the connected lead zirconate titanate piezoelectric ceramic sheet to vibrate through a sinusoidal signal, the lead zirconate titanate piezoelectric ceramic sheet vibrates and generates stress waves, and the lead zirconate titanate piezoelectric ceramic sheet at the signal receiving end The stress wave generates electrical signals, and the dynamic data acquisition system receives the electrical signals and transmits the electrical signals to the data analysis system for data storage, analysis and processing.

进一步,所述锆钛酸铅系压电陶瓷片上设置有正负极接线头,正负极接线头伸出PCCP监测段的砂浆保护层。Further, the lead zirconate titanate-based piezoelectric ceramic sheet is provided with positive and negative terminals, and the positive and negative terminals protrude from the mortar protection layer of the PCCP monitoring section.

所述示波器与锆钛酸铅系压电陶瓷片上的正负极接线头连接,动态数据采集系统与锆钛酸铅系压电陶瓷片上的正负极接线头连接。The oscilloscope is connected with the positive and negative terminals on the lead zirconate titanate piezoelectric ceramic sheet, and the dynamic data acquisition system is connected with the positive and negative terminal terminals on the lead zirconate titanate piezoelectric ceramic sheet.

进一步,所述锆钛酸铅系压电陶瓷片距离砂浆保护层的外表面1~2mm。Further, the lead zirconate titanate piezoelectric ceramic sheet is 1-2 mm away from the outer surface of the mortar protection layer.

一种基于压电传感技术的预应力钢筒混凝土管(PCCP)砂浆保护层开裂监测的方法,基于上述的装置,包括以下步骤:A method for monitoring the cracking of the prestressed steel cylinder concrete pipe (PCCP) mortar cover based on piezoelectric sensing technology, based on the above-mentioned device, comprising the following steps:

1)浇筑两个所述PCCP监测段的内管芯混凝土和外管芯混凝土,并在每个外管芯混凝土的表面缠绕预应力钢丝。1) Pouring the inner pipe core concrete and the outer pipe core concrete of the two PCCP monitoring sections, and winding prestressed steel wires on the surface of each outer pipe core concrete.

2)在每个所述外管芯混凝土的外表面插上若干定位钢板,定位钢板伸出外管芯混凝土的长度与砂浆保护层的厚度一致。其中,每三个定位钢板分布在外管芯混凝土的同一横截面上,这三个定位钢板沿外管芯混凝土的周向等间距布置,这三个定位钢板组成一个定位钢板组,若干定位钢板组沿外管芯混凝土的轴向等间距布置。每个所述定位钢板上连接有锆钛酸铅系压电陶瓷片。2) A number of positioning steel plates are inserted on the outer surface of each outer tube core concrete, and the length of the positioning steel plates protruding from the outer tube core concrete is consistent with the thickness of the mortar protective layer. Among them, every three positioning steel plates are distributed on the same cross section of the outer tube core concrete, and the three positioning steel plates are arranged at equal intervals along the circumference of the outer tube core concrete. These three positioning steel plates form a positioning steel plate group, and several positioning steel plate groups Arranged at equal intervals along the axial direction of the outer pipe core concrete. Each of the positioning steel plates is connected with a lead zirconate titanate piezoelectric ceramic sheet.

3)浇筑两个所述PCCP监测段的砂浆保护层,确保每个锆钛酸铅系压电陶瓷片的正负极接线头露出砂浆保护层。其中,所述锆钛酸铅系压电陶瓷片距离砂浆保护层的外表面1~2mm。3) Pouring the mortar protection layer of the two PCCP monitoring sections, ensuring that the positive and negative terminals of each lead zirconate titanate piezoelectric ceramic sheet are exposed to the mortar protection layer. Wherein, the lead zirconate titanate piezoelectric ceramic sheet is 1-2 mm away from the outer surface of the mortar protection layer.

4)将钢片沿一个所述PCCP监测段的横截面方向插入该PCCP监测段的砂浆保护层。4) Insert the steel sheet into the mortar protective layer of the PCCP monitoring section along the cross-sectional direction of the PCCP monitoring section.

5)在所述砂浆保护层终凝前,拔出钢片,砂浆保护层上形成裂缝,从而制作出完好的PCCP监测段和设置有裂缝的PCCP监测段。5) Before the final setting of the mortar protective layer, the steel sheet is pulled out, and cracks are formed on the mortar protective layer, thereby making a complete PCCP monitoring section and a PCCP monitoring section with cracks.

6)对完好的所述PCCP监测段进行监测,沿该PCCP监测段的轴向,将相邻两个锆钛酸铅系压电陶瓷片的正负极接线头分别连接到示波器和动态数据采集系统上,每个锆钛酸铅系压电陶瓷片所在位置收集到动态数据采集系统内。所述示波器激发所连接的锆钛酸铅系压电陶瓷片振动,锆钛酸铅系压电陶瓷片因振动生成应力波,另一个锆钛酸铅系压电陶瓷片因应力波产生电信号Ⅰ,动态数据采集系统接收到电信号Ⅰ,并将电信号Ⅰ传送至数据分析系统进行数据储存和分析处理。6) Monitor the intact PCCP monitoring section, and connect the positive and negative terminals of two adjacent lead zirconate titanate piezoelectric ceramic sheets to the oscilloscope and dynamic data acquisition respectively along the axial direction of the PCCP monitoring section. In the system, the location of each lead zirconate titanate piezoelectric ceramic sheet is collected into the dynamic data acquisition system. The oscilloscope excites the connected lead zirconate titanate piezoelectric ceramic sheet to vibrate, the lead zirconate titanate piezoelectric ceramic sheet generates a stress wave due to the vibration, and the other lead zirconate titanate piezoelectric ceramic sheet generates an electrical signal due to the stress wave Ⅰ. The dynamic data acquisition system receives the electrical signal Ⅰ and transmits the electrical signal Ⅰ to the data analysis system for data storage, analysis and processing.

7)对设置有所述裂缝的PCCP监测段进行监测,裂缝两侧的锆钛酸铅系压电陶瓷片的正负极接线头分别连接到示波器和动态数据采集系统上,每个锆钛酸铅系压电陶瓷片所在位置收集到动态数据采集系统内。所述示波器激发所连接的锆钛酸铅系压电陶瓷片振动,锆钛酸铅系压电陶瓷片因振动生成应力波,另一个锆钛酸铅系压电陶瓷片因应力波产生电信号Ⅱ,动态数据采集系统接收到电信号Ⅱ,并将电信号Ⅱ传送至数据分析系统进行数据储存和分析处理。7) Monitor the PCCP monitoring section provided with the crack. The positive and negative terminals of the lead zirconate titanate piezoelectric ceramic sheets on both sides of the crack are respectively connected to an oscilloscope and a dynamic data acquisition system. Each zirconate titanate The location of the lead piezoelectric ceramic sheet is collected in the dynamic data acquisition system. The oscilloscope excites the connected lead zirconate titanate piezoelectric ceramic sheet to vibrate, the lead zirconate titanate piezoelectric ceramic sheet generates a stress wave due to the vibration, and the other lead zirconate titanate piezoelectric ceramic sheet generates an electrical signal due to the stress wave II, the dynamic data acquisition system receives the electrical signal II, and transmits the electrical signal II to the data analysis system for data storage, analysis and processing.

8)所述数据分析系统分析出两个PCCP监测段对应位置上的电信号Ⅰ和电信号Ⅱ的幅值、波形和能量,电信号Ⅱ的幅值较电信号Ⅰ的幅值下降15%以上时,即判断该位置处的砂浆保护层产生裂缝,从而统计出裂缝的存在、位置及数量。8) The data analysis system analyzes the amplitude, waveform and energy of the electrical signal I and the electrical signal II at the corresponding positions of the two PCCP monitoring sections, and the amplitude of the electrical signal II is lower than the amplitude of the electrical signal I by more than 15% When , it is judged that the mortar protective layer at this position has cracks, so as to count the existence, position and number of cracks.

进一步,步骤6)和7)均在所述PCCP监测段输水或停水的状态下实施。Further, both steps 6) and 7) are implemented in the state of water delivery or water stop in the PCCP monitoring section.

本发明的有益效果在于:The beneficial effects of the present invention are:

1.通过对比应力波信号在损伤前后的变化,可以监测裂缝的出现;1. By comparing the changes of stress wave signals before and after damage, the appearance of cracks can be monitored;

2.本发明装置材料体积小,成本低,可操作性强;2. The material of the device of the present invention is small in size, low in cost and strong in operability;

3.本发明不仅可以监测裂缝的产生,也可以对裂缝的开展形式进行判断;当裂缝延伸至砂浆层内部时,可以使用体波作为信号波来提高监测灵敏度。3. The present invention can not only monitor the generation of cracks, but also judge the development form of cracks; when the cracks extend to the inside of the mortar layer, the body wave can be used as the signal wave to improve the monitoring sensitivity.

附图说明Description of drawings

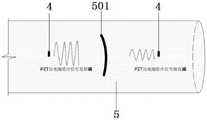

图1为本发明的监测装置示意图;Fig. 1 is the schematic diagram of monitoring device of the present invention;

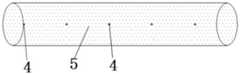

图2为本发明的砂浆保护层监测远离图;Fig. 2 is that the mortar protection layer of the present invention monitors away from figure;

图3为无裂缝砂浆保护层与带缝砂浆保护层应力波接收端信号幅值对比图;Fig. 3 is a comparison diagram of the signal amplitude of the stress wave receiving end of the mortar protective layer without cracks and the mortar protective layer with cracks;

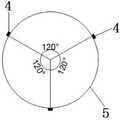

图4为锆钛酸铅系压电陶瓷片沿砂浆保护层轴向的分布图;Fig. 4 is the distribution diagram of the lead zirconate titanate series piezoelectric ceramic sheet along the axial direction of the mortar protective layer;

图5为锆钛酸铅系压电陶瓷片沿砂浆保护层周向的分布图。Fig. 5 is a distribution diagram of the lead zirconate titanate series piezoelectric ceramic sheets along the circumferential direction of the mortar protective layer.

图中:示波器1、数据分析系统2、动态数据采集系统3、锆钛酸铅系压电陶瓷片4、PCCP监测段5和裂缝501。In the figure:

具体实施方式detailed description

下面结合实施例对本发明作进一步说明,但不应该理解为本发明上述主题范围仅限于下述实施例。在不脱离本发明上述技术思想的情况下,根据本领域普通技术知识和惯用手段,做出各种替换和变更,均应包括在本发明的保护范围内。The present invention will be further described below in conjunction with the examples, but it should not be understood that the scope of the subject of the present invention is limited to the following examples. Without departing from the above-mentioned technical ideas of the present invention, various replacements and changes made according to common technical knowledge and conventional means in this field shall be included in the protection scope of the present invention.

实施例1:Example 1:

本实施例公开了一种基于压电传感技术的预应力钢筒混凝土管(PCCP)砂浆保护层开裂监测的装置,包括示波器1、数据分析系统2、动态数据采集系统3和预埋在PCCP监测段5内的锆钛酸铅系压电陶瓷片4。This embodiment discloses a device for monitoring the cracking of the mortar cover of prestressed steel cylinder concrete pipe (PCCP) based on piezoelectric sensing technology, including an

所述锆钛酸铅系压电陶瓷片4的简称为PZT,数据分析系统2为笔记本工作站。The abbreviation of the lead zirconate titanate piezoelectric

所述PCCP监测段5为两端敞口且内部中空的管段,PCCP监测段5包括内管芯混凝土、外管芯混凝土和砂浆保护层,内管芯混凝土为管壁的最内层,内管芯混凝土的外表面套设有钢筒,钢筒的外表面包裹有外管芯混凝土,外管芯混凝土上缠绕有预应力钢丝,砂浆保护层将外管芯混凝土和预应力钢丝包裹。The

若干所述锆钛酸铅系压电陶瓷片4预埋在PCCP监测段5的砂浆保护层内,锆钛酸铅系压电陶瓷片4距离砂浆保护层的外表面1~2mm。所述锆钛酸铅系压电陶瓷片4上设置有正负极接线头,正负极接线头伸出PCCP监测段5的砂浆保护层,便于后续示波器1和动态数据采集系统3的连接。A plurality of the lead zirconate titanate piezoelectric

参见图5,砂浆保护层的同一横截面上分布有三个锆钛酸铅系压电陶瓷片4,这三个锆钛酸铅系压电陶瓷片4沿砂浆保护层的周向等间距布置,这三个锆钛酸铅系压电陶瓷片4组成一个压电陶瓷片组。参见图4,若干所述压电陶瓷片组沿砂浆保护层的轴向等间距布置,相邻两个压电陶瓷片组之间的最佳间距应该在监测前通过设置不同间距的试验来确定。Referring to Fig. 5, three lead zirconate titanate piezoelectric

参见图1或2,所述示波器1与一个锆钛酸铅系压电陶瓷片4连接,该锆钛酸铅系压电陶瓷片4作为信号发射端。所述动态数据采集系统3与信号发射端相邻的锆钛酸铅系压电陶瓷片4连接,该锆钛酸铅系压电陶瓷片4作为信号接收端,信号发射端和信号接收端的位置信息导入动态数据采集系统3内。所述示波器1通过正弦信号激发所连接的锆钛酸铅系压电陶瓷片4振动,锆钛酸铅系压电陶瓷片4产生振动并生成应力波,信号接收端的锆钛酸铅系压电陶瓷片4因应力波产生电信号,动态数据采集系统3接收该电信号,并将电信号传送至数据分析系统2进行数据储存和分析处理。Referring to Fig. 1 or 2, the

本实施例的监测装置以所述锆钛酸铅系压电陶瓷片4作为传感器埋入在砂浆保护层的内部,用于发射信号及信号的接收。该信号以机械体波的形式在砂浆内进行传播。参见图2,发射端的所述锆钛酸铅系压电陶瓷片4被激发振动产生应力波之后在砂浆内部进行传播,当传播至裂缝501处时,由于散射、绕射、反射等原因会造成应力波产生能量损失,当其最终传播至接收端的锆钛酸铅系压电陶瓷片4时,将会引起振动产生电信号。参见图3,通过对比完好砂浆情况下和砂浆开裂情况下的电信号的幅值、波形、能量等物理量确定砂浆开裂的存在、位置及数量。In the monitoring device of this embodiment, the lead zirconate titanate piezoelectric

实施例2:Example 2:

本实施例公开了一种基于压电传感技术的预应力钢筒混凝土管(PCCP)砂浆保护层开裂监测的方法,基于实施例1所述的装置,包括以下步骤:This embodiment discloses a method for crack monitoring of prestressed steel cylinder concrete pipe (PCCP) mortar cover layer based on piezoelectric sensing technology, based on the device described in

1)浇筑两个所述PCCP监测段5的内管芯混凝土和外管芯混凝土,并在每个外管芯混凝土的表面缠绕预应力钢丝。其中,一个所述PCCP监测段5作为无裂缝试件,另一个用于制作带缝试件,PCCP监测段5的长度为1m。1) Pouring the inner pipe core concrete and the outer pipe core concrete of the two

2)在每个所述外管芯混凝土的外表面插上六个定位钢板,定位钢板伸出外管芯混凝土的长度与砂浆保护层的厚度一致。其中,每三个定位钢板分布在外管芯混凝土的同一横截面上,这三个定位钢板沿外管芯混凝土的周向等间距布置,这三个定位钢板组成一个定位钢板组,两个定位钢板组沿外管芯混凝土的轴向间隔布置,两个定位钢板组分别靠近PCCP监测段5的两端,每个定位钢板组距离PCCP监测段5端部10cm。沿所述外管芯混凝土的轴向,两个相邻的定位钢板的连线记为直线L,直线L与该PCCP监测段5的轴线平行,每个定位钢板上连接有锆钛酸铅系压电陶瓷片4。2) Six positioning steel plates are inserted on the outer surface of each outer tube core concrete, and the length of the positioning steel plates protruding from the outer tube core concrete is consistent with the thickness of the mortar protective layer. Among them, every three positioning steel plates are distributed on the same cross section of the outer tube core concrete, and the three positioning steel plates are arranged at equal intervals along the circumference of the outer tube core concrete. These three positioning steel plates form a positioning steel plate group, and the two positioning steel plates The groups are arranged at intervals along the axial direction of the outer pipe core concrete, and two positioning steel groups are respectively close to the two ends of the

3)浇筑两个所述PCCP监测段5的砂浆保护层,确保每个锆钛酸铅系压电陶瓷片4的正负极接线头露出砂浆保护层,锆钛酸铅系压电陶瓷片4距离砂浆保护层的外表面1~2mm。3) Pour the mortar protective layer of the two

4)制作所述裂缝501,将钢片沿一个PCCP监测段5的横截面方向插入该PCCP监测段5的砂浆保护层,钢片厚0.5mm、高30mm、长200mm,钢片与直线L垂直且位于直线L的中点上。4) Make the

5)在所述砂浆保护层终凝前,拔出钢片,砂浆保护层上形成裂缝501,从而制作出完好的PCCP监测段5和设置有裂缝501的PCCP监测段5。5) Before the final setting of the mortar protective layer, the steel sheet is pulled out, and cracks 501 are formed on the mortar protective layer, thereby making a complete

6)可在输水或停水的状态下,对完好的所述PCCP监测段5进行监测,将直线L上的两个锆钛酸铅系压电陶瓷片4的正负极接线头分别连接到示波器1和动态数据采集系统3上,每个锆钛酸铅系压电陶瓷片4所在位置收集到动态数据采集系统3内。所述示波器1激发所连接的锆钛酸铅系压电陶瓷片4振动,锆钛酸铅系压电陶瓷片4因振动生成应力波,另一个锆钛酸铅系压电陶瓷片4因应力波产生电信号Ⅰ,动态数据采集系统3接收到电信号Ⅰ,并将电信号Ⅰ传送至数据分析系统2进行数据储存和分析处理。6) In the state of water delivery or water stoppage, the intact

7)可在输水或停水的状态下,对设置有所述裂缝501的PCCP监测段5进行监测,裂缝501两侧的锆钛酸铅系压电陶瓷片4的正负极接线头分别连接到示波器1和动态数据采集系统3上,每个锆钛酸铅系压电陶瓷片4所在位置收集到动态数据采集系统3内。所述示波器1激发所连接的锆钛酸铅系压电陶瓷片4振动,锆钛酸铅系压电陶瓷片4因振动生成应力波,另一个锆钛酸铅系压电陶瓷片4因应力波产生电信号Ⅱ,动态数据采集系统3接收到电信号Ⅱ,并将电信号Ⅱ传送至数据分析系统2进行数据储存和分析处理。7) The

8)所述数据分析系统2分析出两个PCCP监测段5各个对应位置上的电信号Ⅰ和电信号Ⅱ的幅值、波形和能量,电信号Ⅱ的幅值较电信号Ⅰ的幅值下降15%以上时,即判断该位置处的砂浆保护层产生裂缝,从而统计出裂缝501的存在、位置及数量。8) The

参见图2,所述示波器1与锆钛酸铅系压电陶瓷片4连接的一端作为信号发射端,示波器1向锆钛酸铅系压电陶瓷片4激发特定频率的正弦信号,该特定频率为通过多次试验得到的最佳监测频率,本实施例中,该特定频率为10kHz。所述动态数据采集系统3与锆钛酸铅系压电陶瓷片4连接的一端作为信号接收端,动态数据采集系统3将接收到的信号进行储存和分析处理。Referring to FIG. 2, the end of the

参见图3,可以看出,相较无裂缝的所述砂浆保护层,带缝的砂浆保护层应力波接收端信号幅值下降明显,证明了本实施例的监测方法的有效性。Referring to FIG. 3 , it can be seen that compared with the mortar protection layer without cracks, the signal amplitude of the stress wave receiving end of the mortar protection layer with cracks drops significantly, which proves the effectiveness of the monitoring method of this embodiment.

实施例3:Example 3:

本实施例公开了一种基于压电传感技术的预应力钢筒混凝土管(PCCP)砂浆保护层开裂监测的装置,包括示波器1、数据分析系统2、动态数据采集系统3和预埋在PCCP监测段5内的锆钛酸铅系压电陶瓷片4。This embodiment discloses a device for monitoring the cracking of the mortar cover of prestressed steel cylinder concrete pipe (PCCP) based on piezoelectric sensing technology, including an

所述PCCP监测段5为两端敞口且内部中空的管段,PCCP监测段5包括内管芯混凝土、外管芯混凝土和砂浆保护层,内管芯混凝土为管壁的最内层,内管芯混凝土的外表面套设有钢筒,钢筒的外表面包裹有外管芯混凝土,外管芯混凝土上缠绕有预应力钢丝,砂浆保护层将外管芯混凝土和预应力钢丝包裹。The

若干所述锆钛酸铅系压电陶瓷片4预埋在PCCP监测段5的砂浆保护层内,每三个锆钛酸铅系压电陶瓷片4分布在砂浆保护层的同一横截面上,参见图5,这三个锆钛酸铅系压电陶瓷片4沿砂浆保护层的周向等间距布置,这三个锆钛酸铅系压电陶瓷片4组成一个压电陶瓷片组,参见图4,若干压电陶瓷片组沿砂浆保护层的轴向等间距布置。Several of the lead zirconate titanate piezoelectric

参见图1或2,所述示波器1与一个锆钛酸铅系压电陶瓷片4连接,该锆钛酸铅系压电陶瓷片4作为信号发射端。所述动态数据采集系统3与信号发射端相邻的锆钛酸铅系压电陶瓷片4连接,该锆钛酸铅系压电陶瓷片4作为信号接收端。所述示波器1通过正弦信号激发所连接的锆钛酸铅系压电陶瓷片4振动,锆钛酸铅系压电陶瓷片4产生振动并生成应力波,信号接收端的锆钛酸铅系压电陶瓷片4因应力波产生电信号,动态数据采集系统3接收该电信号,并将电信号传送至数据分析系统2进行数据储存和分析处理。所述数据分析系统2对比分析应力波在砂浆保护层传递过程中的损耗,显示出这两个锆钛酸铅系压电陶瓷片4之间的砂浆保护层的开裂情况。Referring to Fig. 1 or 2, the

实施例4:Example 4:

本实施例主要结构同实施例3,进一步,所述锆钛酸铅系压电陶瓷片4上设置有正负极接线头,正负极接线头伸出PCCP监测段5的砂浆保护层。The main structure of this embodiment is the same as that of

参见图1,所述示波器1与锆钛酸铅系压电陶瓷片4上的正负极接线头连接,动态数据采集系统3与锆钛酸铅系压电陶瓷片4上的正负极接线头连接。Referring to Fig. 1, the

实施例5:Example 5:

本实施例主要结构同实施例4,进一步,所述锆钛酸铅系压电陶瓷片4距离砂浆保护层的外表面1~2mm。The main structure of this embodiment is the same as that of

Claims (3)

Priority Applications (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010113744.XACN111520617B (en) | 2020-02-24 | 2020-02-24 | A device and method for monitoring the cracking of the mortar protective layer of prestressed steel cylinder concrete pipe based on piezoelectric sensing technology |

Applications Claiming Priority (1)

| Application Number | Priority Date | Filing Date | Title |

|---|---|---|---|

| CN202010113744.XACN111520617B (en) | 2020-02-24 | 2020-02-24 | A device and method for monitoring the cracking of the mortar protective layer of prestressed steel cylinder concrete pipe based on piezoelectric sensing technology |

Publications (2)

| Publication Number | Publication Date |

|---|---|

| CN111520617A CN111520617A (en) | 2020-08-11 |

| CN111520617Btrue CN111520617B (en) | 2022-12-09 |

Family

ID=71901456

Family Applications (1)

| Application Number | Title | Priority Date | Filing Date |

|---|---|---|---|

| CN202010113744.XAActiveCN111520617B (en) | 2020-02-24 | 2020-02-24 | A device and method for monitoring the cracking of the mortar protective layer of prestressed steel cylinder concrete pipe based on piezoelectric sensing technology |

Country Status (1)

| Country | Link |

|---|---|

| CN (1) | CN111520617B (en) |

Families Citing this family (1)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| CN111521642B (en)* | 2020-02-24 | 2024-11-15 | 重庆大学 | Device and method for detecting fracture of prestressed steel wire of prestressed concrete cylinder pipe |

Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5883311A (en)* | 1996-06-21 | 1999-03-16 | General Electric Company | Methods and apparatus for detection of crack initiation |

| WO2002062206A2 (en)* | 2001-02-08 | 2002-08-15 | University Of South Carolina | In-situ structural health monitoring, diagnostics and prognostics system utilizing thin piezoelectric sensors |

| KR20020088959A (en)* | 2001-05-22 | 2002-11-29 | 지오콘머테리얼 주식회사 | Method of construction for repairing crack and coming-off of concrete structures using ultra-fine particles suspension or polymer ceramics hybrid suspension grouts |

| JP2003065944A (en)* | 2001-08-27 | 2003-03-05 | Sumitomo Metal Ind Ltd | Method for detecting abnormalities in transport pipes, method for monitoring safety of transport conditions, and abnormality detecting device |

| US6637268B1 (en)* | 2002-05-20 | 2003-10-28 | Kohji Toda | Vibration displacement sensing system |

| JP2005337818A (en)* | 2004-05-25 | 2005-12-08 | Japan Fine Ceramics Center | Damage sensor, manufacturing method thereof, and strain detection method |

| CN105911100A (en)* | 2016-06-15 | 2016-08-31 | 大连理工大学 | Piezoelectric ceramic annular sensor for tubular concrete structure health monitoring |

| CN106932485A (en)* | 2017-02-23 | 2017-07-07 | 长沙理工大学 | Prestressed tendon corrosion depth monitoring method based on piezoelectric intelligent aggregate |

| CN207197581U (en)* | 2017-09-29 | 2018-04-06 | 长安大学 | A kind of health monitoring systems of prefabricated assembling type reinforced sleeve connector |

| CN108360743A (en)* | 2018-05-09 | 2018-08-03 | 长沙理工大学 | Built-in H-shaped steel prestressed concrete beam and preparation method thereof, and beam slippage monitoring device and method |

| CN207945496U (en)* | 2018-03-14 | 2018-10-09 | 齐海铭 | A kind of Prestressed concrete cylinder pipe road long distance wireless safety monitoring assembly |

| CN110702509A (en)* | 2019-09-23 | 2020-01-17 | 重庆大学 | Cement-based material continuous loading device for durability test |

Family Cites Families (10)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| SE518997C2 (en)* | 2001-04-02 | 2002-12-17 | Impressonic Ab | Method and apparatus for detecting damage in materials or articles |

| CN101216443B (en)* | 2008-01-02 | 2010-09-15 | 沈阳建筑大学 | A Piezoelectric Smart Aggregate for Health Monitoring of Civil Engineering Structures |

| CN103472095B (en)* | 2013-09-10 | 2015-04-08 | 河海大学 | Device and method for monitoring strength of hydraulic concrete based on piezoelectric ceramic smart module |

| CN103645210B (en)* | 2013-11-22 | 2016-08-17 | 中建二局第一建筑工程有限公司 | Concrete filled steel tubular member quality fluctuation method based on piezoelectric monitoring construction |

| CN103852492B (en)* | 2014-03-24 | 2016-05-04 | 长沙理工大学 | Pumping of prostressed duct density monitoring method based on piezoelectric ceramics |

| CN106168604A (en)* | 2016-08-04 | 2016-11-30 | 上海交通大学 | The monitoring method of a kind of concrete slab interlayer straight joint and device |

| CN207599164U (en)* | 2017-11-08 | 2018-07-10 | 温振刚 | A kind of prestress steel cylinder concrete pressure pipeline of FRP external protections |

| CN108332846B (en)* | 2018-01-03 | 2020-04-24 | 东南大学 | Embedded ultrasonic sensor in cement concrete structure |

| CN108956752A (en)* | 2018-05-22 | 2018-12-07 | 中国水利水电科学研究院 | PCCP pipeline compressor wire number of breaks detection system and method |

| CN109465173B (en)* | 2018-10-23 | 2020-04-24 | 武汉大学 | Rock mass structure shear wave transducer based on piezoelectric ceramic micro-displacement actuator and preparation method |

- 2020

- 2020-02-24CNCN202010113744.XApatent/CN111520617B/enactiveActive

Patent Citations (12)

| Publication number | Priority date | Publication date | Assignee | Title |

|---|---|---|---|---|

| US5883311A (en)* | 1996-06-21 | 1999-03-16 | General Electric Company | Methods and apparatus for detection of crack initiation |

| WO2002062206A2 (en)* | 2001-02-08 | 2002-08-15 | University Of South Carolina | In-situ structural health monitoring, diagnostics and prognostics system utilizing thin piezoelectric sensors |

| KR20020088959A (en)* | 2001-05-22 | 2002-11-29 | 지오콘머테리얼 주식회사 | Method of construction for repairing crack and coming-off of concrete structures using ultra-fine particles suspension or polymer ceramics hybrid suspension grouts |

| JP2003065944A (en)* | 2001-08-27 | 2003-03-05 | Sumitomo Metal Ind Ltd | Method for detecting abnormalities in transport pipes, method for monitoring safety of transport conditions, and abnormality detecting device |

| US6637268B1 (en)* | 2002-05-20 | 2003-10-28 | Kohji Toda | Vibration displacement sensing system |

| JP2005337818A (en)* | 2004-05-25 | 2005-12-08 | Japan Fine Ceramics Center | Damage sensor, manufacturing method thereof, and strain detection method |

| CN105911100A (en)* | 2016-06-15 | 2016-08-31 | 大连理工大学 | Piezoelectric ceramic annular sensor for tubular concrete structure health monitoring |

| CN106932485A (en)* | 2017-02-23 | 2017-07-07 | 长沙理工大学 | Prestressed tendon corrosion depth monitoring method based on piezoelectric intelligent aggregate |

| CN207197581U (en)* | 2017-09-29 | 2018-04-06 | 长安大学 | A kind of health monitoring systems of prefabricated assembling type reinforced sleeve connector |

| CN207945496U (en)* | 2018-03-14 | 2018-10-09 | 齐海铭 | A kind of Prestressed concrete cylinder pipe road long distance wireless safety monitoring assembly |

| CN108360743A (en)* | 2018-05-09 | 2018-08-03 | 长沙理工大学 | Built-in H-shaped steel prestressed concrete beam and preparation method thereof, and beam slippage monitoring device and method |

| CN110702509A (en)* | 2019-09-23 | 2020-01-17 | 重庆大学 | Cement-based material continuous loading device for durability test |

Non-Patent Citations (2)

| Title |

|---|

| 基于压电陶瓷的混凝土裂缝损伤监测;赵晓燕等;《压电与声光》;20090615(第03期);1-5* |

| 超大口径预存裂缝的预应力钢筒混凝土管结构分析与试验研究;胡少伟等;《水利学报》;20100715(第07期);全文* |

Also Published As

| Publication number | Publication date |

|---|---|

| CN111520617A (en) | 2020-08-11 |

Similar Documents

| Publication | Publication Date | Title |

|---|---|---|

| CN103852492B (en) | Pumping of prostressed duct density monitoring method based on piezoelectric ceramics | |

| CN110455914B (en) | Grouting sleeve internal grouting state detection method based on built-in piezoelectric ceramic element | |

| CN102384803B (en) | Electromagnetic interference preventing embedded type multifunctional piezoelectric intelligent aggregate of concrete structure | |

| Tang et al. | Guided wave‐based cable damage detection using wave energy transmission and reflection | |

| CN106770653B (en) | Stacked piezoelectric intelligent aggregate for concrete structure health monitoring | |

| CN111520617B (en) | A device and method for monitoring the cracking of the mortar protective layer of prestressed steel cylinder concrete pipe based on piezoelectric sensing technology | |

| CN206035991U (en) | A intelligent bolt device for $monitoring bolted connection developments atress situation | |

| CN101140266A (en) | Device for detecting defects in magnetically permeable components based on magnetostrictive torsional waves | |

| CN108387611B (en) | Annular sensor for monitoring corrosion of steel bars and preparation method thereof | |

| WO2020207076A1 (en) | Explosion-proof electromagnetic ultrasonic oil and gas pipeline corrosion thinning on-line detection system and method | |

| CN109406631B (en) | Parallel steel wire pulling sling detection device and method | |

| CN204731207U (en) | A kind of ultrasonic guided wave transducer and mould thereof being applicable to power station line construction monitoring | |

| CN118465078B (en) | Novel pre-stressed steel cylinder concrete pipe with pre-embedded acoustic emission sensor and distributed optical fibers and manufacturing and broken wire monitoring method | |

| Wang et al. | Experimental study on identifying the number of wire breaks in prestressed concrete cylinder pipe based on piezoelectric sensing technology | |

| US20140253110A1 (en) | Magnetostrictive Sensor Having Crimped Magnetostrictive Strip for High Temperature Operation | |

| CN103990592A (en) | Flexible comb-shaped wave guiding transducer suitable for curved plate tubing part detecting | |

| CN114551027A (en) | A Halbeck-type magnetizer and bridge cable defect detection device | |

| CN111521642B (en) | Device and method for detecting fracture of prestressed steel wire of prestressed concrete cylinder pipe | |

| CN106286550A (en) | A kind of intelligent nut device for monitoring bolt connection state | |

| CN212364181U (en) | On-line monitoring and detecting system for medium and low frequency electromagnetic eddy current | |

| CN212255015U (en) | A kind of extravasation electric accelerated steel corrosion test device | |

| CN201184875Y (en) | Apparatus for detecting magnetic conduction component defect base on magnetic deformation torsion wave | |

| CN113311234B (en) | Reinforcing bar corrosion sensing device | |

| CN206035999U (en) | A intelligent nut device for $monitoring bolted connection situation | |

| CN215088602U (en) | Transducer and testing device thereof |

Legal Events

| Date | Code | Title | Description |

|---|---|---|---|

| PB01 | Publication | ||

| PB01 | Publication | ||

| SE01 | Entry into force of request for substantive examination | ||

| SE01 | Entry into force of request for substantive examination | ||

| GR01 | Patent grant | ||

| GR01 | Patent grant | ||

| EE01 | Entry into force of recordation of patent licensing contract | Application publication date:20200811 Assignee:CHONGQING ANTE PIPE INDUSTRY Co.,Ltd. Assignor:Chongqing University Contract record no.:X2024980045244 Denomination of invention:A device and method for monitoring cracking of mortar protective layer of prestressed steel cylinder concrete pipe based on piezoelectric sensing technology Granted publication date:20221209 License type:Common License Record date:20250328 | |

| EE01 | Entry into force of recordation of patent licensing contract |